30 minute read

Oils and Lubes: All the latest on oils and lubes

BACK ON THE ROAD Penrite is supporting Aussies as they hit the road this holiday season

For nearly 100 years, Penrite Oil has been a trusted partner for the Australian automotive trade. Penrite says that thanks to being a 100 percent Australian owned and operated business that produces the highest quality lubricant formulations, it has remained the go-to product for workshops and service centers for engine oils, gear oils, transmission fluids and other lubricants used in the automotive trade for nearly 10 decades, As more Australians than ever will hit the road this Christmas holiday season, Penrite says its Oils and Lubricants will be their trusted partner too, providing the highest levels of protection, performance, and economy for their vehicles. For the workshops and service centers that prepare the vehicles for the great Australian road trip, Penrite says it offers them the peace of mind that comes from knowing they are using products which “were blended right here in Australia that meet the highest of manufacturing and industry Most mechanically minded diesel vehicle owners have tried a variety of fuel additives, often purchased at service stations or automotive supermarkets. And justifiably, there’s always been a lot of scepticism surrounding the use of fuel and oil additives because the sales pitch and advertising on these additives often makes claims that they simply don’t deliver on, leaving the vehicle owners disillusioned about their effectiveness. Yet today, Responsive Engineering says Common Rail Diesels suffer more from fuel quality issues due to their precision, high performance engines, high fuel pressures and high operating temperatures than ever before. Compared to older technology diesel fuel systems, Common Rail Diesels are totally unforgiving when it comes to any type of fuel contamination, explains Responsive Engineering, which explains very small amounts of water or particles will wreck pumps, injectors and throughout the whole fuel system. And, it says, they’re pretty much nonrepairable, so that means all new components. Added to this, CRD engines have been developed to meet the modern emission standards, and diesel fuel sulphur has been reduced for the same reason. But low sulphur fuel happens to compound another problem: lubricity. At a time when pumps standards, including selected products with OEM approvals and/or industry licenses.” Further, Penrite says they are reassured to know they are using products supplied by a company with nearly 100 years of experience – stating that no other Australian lubricant brand has that heritage of longevity and trust. Over the last 10 decades, Penrite has continued to innovate and bring the latest specification products to the market, so it says its customers have the “Right Product for the Right Application.” This doesn’t only apply to engine oils either, says Penrite, which explains that its commitment to providing members of the trade with all of the products they need to complete servicing requirements means they have an extensive range of products, including transmission and gear oils, brake, hydraulic and steering fluids, greases coolants, additives and cleaning fluids. Being Australian made, owned, and operated, and injectors rely even more on diesel fuel for lubrication, it has been actually reduced in the fuel, says Responsive Engineering. Responsive Engineering says a fuel additive that will protect all these parts has never been more important, and states that it has developed and produced here in Australia a fuel additive specifically designed to keep Common Rail Diesels performing like new. The Responsive Diesel Fuel Lubricant and Conditioner lubricates moving parts and provides anti-corrosion protection for diesel fuel pumps, injectors and all fuel system components. This fuel lubricant and conditioner contains a powerful Nano formula that has been specifically designed for diesel engines, with a focus on Common Rail fuel systems which also has an anti-bacterial biocide in the formula to protect the whole fuel system. Responsive Fuel Additive does not contain hygroscopic dispersants which Responsive Engineering says is often found in major brands of fuel lubricants. These dispersants don’t remove water from fuel, instead they just make it less visible and because it is still in the fuel it can flow past filters and water detection units where it causes catastrophic damage in diesel vehicles, warns Responsive Engineering. Penrite says it is employing Australians to keep other Australians in business and employment. As such, by using Penrite lubricants, it says workshops and service centers are contributing to the development of Australia and keeping money in the country to support other Australian businesses and people. As Australians hit the road again and the country gets back on the road to recovery, Penrite says it will “continue to support the automotive trade with products to cover the oldest to the latest technologies with the service and support that only comes from a 100 percent Australian owned and operated business.”

RESPONSIVE DIESEL FUEL LUBRICANT AND CONDITIONER

Common Rail Diesel vehicles need specifically designed fuel additives

For more information, visit www.penriteoil.com.au

Responsive Fuel Additive can reportedly quieten rattly injectors, reduce emissions, and improve fuel consumption and the overall performance of your vehicle. Because it is a specialised product, it is only available from specialised diesel repairers or direct from the manufacturer – Responsive Engineering. The bottle has been designed to fit into the door pocket so it’s always in the vehicle (not sitting in the garage at home) and the concentrated formula of 150ml will treat up to 2400 litres of fuel. It is available from Responsive Engineering, located at 64 Kembla Street, Fyshwick in the ACT.

For more information, call 02 6280 4334 or visit www.specialisttools.com.au

JLM GDI INJECTOR CLEANER

Engine technology does not stand still, so why should fuel additives?

With Gasoline Direct Injection (GDI) posing new challenges to workshops, JLM Lubricants says it has risen to the challenge to support garages and car owners with its latest fuel additive, formulated solely to address GDI fuel injector problems. While GDI engines boast impressive performance, efficiency and CO2 figures when the car is new, the benefits do not last forever. Tighter tolerances of the mechanical parts and higher soot/particulate production make GDI engines highly sensitive to contamination as they age. The first issue many owners report is either an illuminated engine management light, reduced power, or excessive exhaust emissions that result in a roadworthiness inspection failure. Rectifying the root-cause is not straightforward. As the fuel injectors are exposed to not only heat but also the by-products of the combustion process, contaminations become baked onto the injector tip, blocking its fine holes and altering the spray pattern. Sophisticated engine management will compensate for this injector fouling by adjusting

Burg Design says its not too late

Burg Design says its X-1R products can help you take care of your vehicle to keep it running smoothly for longer, even when it has been neglected. The products have reportedly been tested and proven by independent labs and by a company which supplies NASA. Products include: • X-1R Engine Oil Based Flush – contains controlled-released detergents to dissolve sludge, gum, varnish, grit and other deposits that, even with regular maintenance, slowly build up inside the engine. Usually, you need only pour it into your crankcase and let the engine run for 15 minutes before draining it. • X-1R Engine Treatment – formulated to reduce friction and operating temperatures, thus optimising engine performance. the fuelling automatically, but only to a point. The challenge is not only to address the symptoms and effect a cure but also curtail future build-up. JLM Lubricants says its GDI fuel additive performs all of these tasks. It is suitable for all GDI, FSI, TSI, TFSI, CGI and SIGI engine types, providing excellent nozzle cleanliness while cleaning the inside of the GDI injector. It reduces emissions (PN, NOx and CO2) and is compatible with the Euro 6/ VI+ Exhaust Emissions Std. GCG Turbochargers is the exclusive Australian and NZ distributor of JLM Lubricants. “We are confident that JLM Lubricants GDI Injector cleaner is the finest on the market, but we admit that it cannot resolve all contamination issues in modern engines,” GCG Turbochargers Operations Manager, Paul Franks, said. “Deposits that restrict low tension piston ring movement are best addressed with JLM’s Engine Oil Flush at every service, to restore the resultant lost compression. “While more complete combustion has the • Fuel System Cleaner – cleans the entire fuel delivery system and combustion chamber for an overall more efficient combustion process, with effect most often immediate. • X-1R Automatic Transmission Treatment – works by reducing the transmission’s operating temperatures, resulting in smoother shifting, and longer transmission fluid and gearbox life. As testament to the might of these products, Burg Design offers up the recent customer case of Terry Russ, the owner of a 2003 Subaru Outback H6 3L automatic. Terry had owned the Outback for around 12 years and admitted that the car — which had over 270,000 kilometres clocked on the odometer, additional benefit of reducing inlet deposits, JLM’s GDI Injector Cleaner cannot clean clogged intake manifolds, EGR valves and cylinder head ports. For this, JLM recommends its Air Intake Cleaner both as a cleaner and a preventative measure at service time. “With the new GDI petrol injector cleaner joining forces with JLM’s existing Engine Oil Flush and Air Intake Cleaner products, JLM Lubricants allows workshops to offer the complete GDI decontamination cure to benefit the motorist, their cars and, of course, the environment.”

NEGLECTED YOUR CAR MAINTENANCE?

For more information, visit www.gcg.com.au

half of them in town and half on the highway — had not been looked after. Burg Design says that while you could be forgiven for thinking the Outback’s engine would be a goner at that stage, Terry was able to treat his car with the above products for great results. “The oil and filter had probably been changed maybe three times (I had to use a piece of pipe on the sump plug spanner to crack it), and the engine warning light had been on for about five years,” Terry explained. “Over the 200 kilometres since (treatment with X-1R products), it has only gotten better,” Terry said. “My son, who is the normal driver, is seriously impressed. My son is a Chemical Engineer and is also very impressed by the several studies that he has researched on benefits of X-1R . “I am more than happy to recommend the X-1R products for everyday use and will be treating my other vehicles shortly.”

For more information, visit www.x1r.com.au

GULF WESTERN OILS

Made in Australia, exported to the world

Gulf Western Oil says it is a proudly Australian owned manufacturer of lubricants for supply into the Australian and export markets. The company says its lubricants are produced in its ultra-modern, technically advanced production facility in Sydney using only the highest quality components from the world’s leading suppliers of base oils and additive technology; with formulations that are tailor made to meet Australia’s harsh conditions. Gulf Western’s national distributors and retail partners are supported by five company owned and strategically located warehouses and a distributor network allowing for reliable and timely supply throughout Australia. Gulf Western Oil has been manufacturing for more than 30 years, supplying the Australian market and exporting to more than 20 countries around the world. For many years, Gulf Western has supplied product into New Zealand, China, Vietnam, New Guinea, India and throughout the Asia Pacific. During 2020, Gulf Western opened a distribution hub in Asia allowing for further expansion into new locations to grow its distributor footprint into new markets within the Philippines, Myanmar, Korea and Russia. Gulf Western says its technical team works in conjunction with its local and overseas customers and its additive suppliers to ensure that it is at the forefront of new formulation technology that meets the local climatic conditions and specific OEM requirements. Brake hoses and sealing elements can also be For more than three decades, Gulf Western Oil says it has proven to be a reliable supplier of high quality, Australian made and Internationally approved lubricants to the industry. In these uncertain and trying times, Gulf Western says its proven reliability of high quality locally manufactured lubricants with local technical support is more important than ever to ensure reliable operation of your equipment. In addition, Gulf Western has invested in a new virtual tour program that allows complete access to its state-of-the-art manufacturing facility. It says this allows you the opportunity to walk through and see how the production of lubricants happens.

For more information or to take a Virtual Tour, visit

WHY CHANGING BRAKE FLUID IS SO IMPORTANT

ZF Aftermarket experts recommend regular inspections and a yearly fluid change

High-quality brake fluid is crucial in ensuring which can occur with prolonged engagement over continued stopping power, with ZF Services extended gradients, in turn causing the fluid to Australia recommending workshops regularly boil. This can then lead to an evaporative reaction, remind customers to have their brake fluid and the formation of air bubbles. checked, with yearly changes advised. When the brake pedal is pressed again, the Brake fluid plays a vital role in ensuring the bubbles are compressed, but the braking force smooth operation of the braking system, and may be lessened or not transmitted at all, like all lubricants, the oil degrades over time, ultimately leading to brake failure. regardless of mileage. Another common fault found in braking systems Deteriorated brake fluid can impact on the is the ingress of water, with the entry point often operation of the various components in the being the breather hole in the cover of the tank, braking system, which in a worst case scenario which is designed to provide ventilation in the could lead to brake failure. event of fluctuating brake fluid levels. ZF Aftermarket experts have produced the below helpful tips on how to check the condition of brake fluid, quickly and reliably. Armed with this knowledge, ZF says workshops can offer customers a wider range of services, and improve the safety of their cars. However, atmospheric humidity can also enter the system via this ventilation hole. Additionally, water can make its way into the overrun tank through the ventilation hole when the engine bay or vehicle is cleaned.

www.gulfwestern.com.au

Severe overheating can lead to total failure responsible for increased water levels in the brake Hydraulic fluid resides in the lines, tubes fluid, as water can diffuse through these parts, and reservoirs of the brake system in various especially when they age. configurations of disc and drum brakes, transmitting pressure whenever the brake pedal Venting device for reliable repair results is engaged, with additional power provided by On average, brake fluids have a water content brake boosters. level of around 0.05 percent, with the value There are various influences that can greatly affect typically trending upwards over time. the liquid over time, including severe overheating, If the water content level exceeds 3.5 percent, it is strongly recommended that the fluid be changed, as the wet boiling point has been reached. When the three percent mark is exceeded, the boiling point of the fluid drops to between 140 and 180°C. ZF says it offers a range of specialist tools for brake fluid changes, as well as the broad portfolio of TRW brake fluids, which are suitable for most vehicle types. TRW brake fluids reportedly ensure optimal braking behaviour from -50°C to +50°C, with enhanced protection against corrosion, and compatibility with the sensor systems installed in late model cars, such as ESP.

For more information, visit www.trwaftermarket.com or contact ZF Aftermarket via 02 9679 5555.

PASSIONATE ABOUT YOUR BUSINESS?

Then Liqui Moly says you should choose its products

German oil brand Liqui Moly is well known to mechanics and the brand says it is now looking forward to being even more active across the Australian automotive and workshop scene. Following its entry into the Australian market this month, the local team for Liqui Moly says they are aiming to boost investment in the brand and provide more products which customers and car enthusiasts love and trust. Prior to the launch of Liqui Moly Australia, Liqui Moly products were distributed locally through the company’s exclusive import partner, MotorActive. MotorActive, being a multi-brand importer, distributor and marketer, partnered with Liqui Moly for a number of years to grow selection and establish supply of Liqui Moly in Australia. “However, based on our customer’s feedback we realised that we outgrew this structure and needed to do more ourselves,” Liqui Moly Australia Managing Director, Mark Johnson, said. “Giving workshops exactly what they want and need is our aim, both in terms of accessing our extensive product catalogue and receiving Liqui Moly specific expert-level customer service. IQ Merchandising has a range of licensed branded and generic products imported from Germany that can be used for either on-sale purposes or as a promotional tool for your brand. With the focus in this month’s magazine being on oils and lubes, IQ Merchandising says it is an appropriate time to highlight to you its very popular oil barrel-shaped tins that can be used as either a money box for your loose coins or as a handy desk-top container for pens and markers. It says its German supplier’s retro-inspired designs are proving very popular, not just in the current environment but as demand for nostalgic products in general increases around the world. The money boxes are available off-the-shelf in various licensed designs including HarleyDavidson, BMW, Volkswagen and Moto-Guzzi for $7.00 each. There is also a generic US Oil Co company design. Alternatively, IQ Merchandising says it can get these functional tins made up in your logo and design for $6.00 each plus GST with a minimum quantity run of 1000. This is what prompted our expansion and direct investment in Australia. “We pride ourselves in only selling premium – being able to offer the right oil for practically every car. Our specialty is being able to supply a complete range of oils for late model European vehicles. “We now look forward to soon making many of our 4,000 products locally available. “Along with a wide variety of newly formulated motor oils and additives, we also have a vast range of automotive chemicals, like service products, such as brake cleaner; car care products, polishes; greases, pastes; and underbody protection. “You can continue to order Liqui Moly through our partner network for supply same day. Well known spare parts resellers HSY and Imparts carry a large selection of Liqui Moly products, along with a wide selection of complementary high-quality spares and premium brands. “We also provide advice on oils and additives to workshops which service late model European vehicles, supporting independent workshops with the latest technical and application insights and information. The tins measure 12cm high and 9.5cm in diameter and so are a perfect size “no matter what the use.” The lid is removeable so they can be used over and over again as a money box, or you can take the lid off and use it as an open container. IQ Merchandising says these money boxes are a great way to have your brand constantly in front of your customers, sitting on their desks or in the workshop. It says its supplier manufactures licensed merchandise for leading global brands including Harley-Davidson, Ford, Mercedes-Benz, Goodyear, BMW, Volkswagen, Audi, Vespa, Fiat, Moto Guzzi, Mini and Coca-Cola. It says you can be assured that your branded product would be made to the same exacting standards that these companies demand. IQ Merchandising offers a range of retro-inspired products including not only money boxes but also tin signs, thermometers, clocks, storage tins, mint tins, ceramic and enamel mugs, metal

OIL BARREL-SHAPED MONEY BOXES

IQ Merchandising say these are a great promotional idea at only $6.00 a tin

“Liqui Moly is well known as a family owned business and Germany’s most popular motor oil. Aussies are well known to question and demand quality. “Liqui Moly ensures all markets receive the same Made in Germany product that our home market receives. We do this by developing and producing our entire range in Germany.”

For more information, call Liqui Moly Australia on

1300 318 961.

coasters, keyrings and magnets – all of which are available to be manufactured in your company branding.

For more information, call Jim from IQ Merchandising on 0488 068 286 or visit www.iqmerchandising.com.au

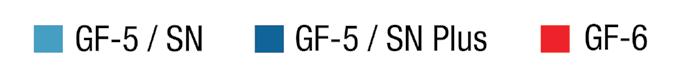

API SP AND ILSAC GF-6

What’s the big deal?

Valvoline says stricter emission and economy regulations around the world have driven leading car manufacturers to introduce newer, more powerful and more efficient engines; Gasoline Direct Injection (GDI) and Turbocharged Gasoline Direct Injection (TGDI). These engines need a higher specification engine oil in order to protect them from “Low Speed PreIgnition” or LSPI. Valvoline explains that in simple terms, LSPI is early combustion in the engine which can lead to catastrophic engine failure. Preventing LSPI requires improvements in engine lubrication chemistry.

It is all about efficiency

In order to meet emission and fuel economy regulations, vehicle manufacturers have made a number of changes to their engine designs. These include downsizing, introducing gasoline direct injection (GDI), turbocharging and gasoline particulate filters (GPF). Most new passenger cars and light commercials from leading vehicle manufacturers come with these new generation engines. The needs of these engines are different and require higherperformance engine oils that aid in fuel economy, provide emission system compatibility, protect against low speed pre-ignition (LSPI) and aid cleanliness by fighting turbocharger deposits.

Protect your vehicle

Vehicle owners have an expectation that the engine oil used will protect their car engine and meet its lubrication requirements. However, Valvoline says it is important to note that older oil specifications such as API SN/ILSAC GF-5 and earlier will not meet all the performance needs of these modern engines. While ILSAC GF-5 addresses fuel economy and deposit control, for these modern engines, LSPI protection is also required. Engine oil needs to deliver on all three of these important performance characteristics. Valvoline explains that LSPI is an abnormal, uncontrolled combustion event that can occur in modern Gasoline Direct Injection (GDI) and Turbo Gasoline Direct Injection (TGDI) engines. At a minimum, LSPI can generate an audible knocking noise noticeable to the driver and prevent the engine from operating at optimum efficiency. More severe LSPI can cause engine hardware failure, including damaged spark plugs, pistons and even catastrophic engine failure, leading to user disruption and high vehicle repair costs. Valvoline says that usage of older generation engine oils (API SN/ILSAC GF-5) in such modern engines can lead to catastrophic engine damage. Industry bodies have recognised this and have launched the ILSAC GF-6, a new specification which is designed specifically to protect modern engines. To demonstrate the difference, a field trial was conducted in two identical cars – both having modern gasoline engines. One car was filled with older generation engine oil and other with ILSAC GF-6 oil. A comparison of their pistons (pictured below) clearly showed the impact the wrong engine oil can have on engine components.

Valvoline says it is ready

Valvoline says its products with ILSAC GF-6 specifications have been available to the market since the first license date in May 2020. In November, Valvoline also upgraded numerous engine oils to API SP to ensure its customers benefit from the latest industry specifications.

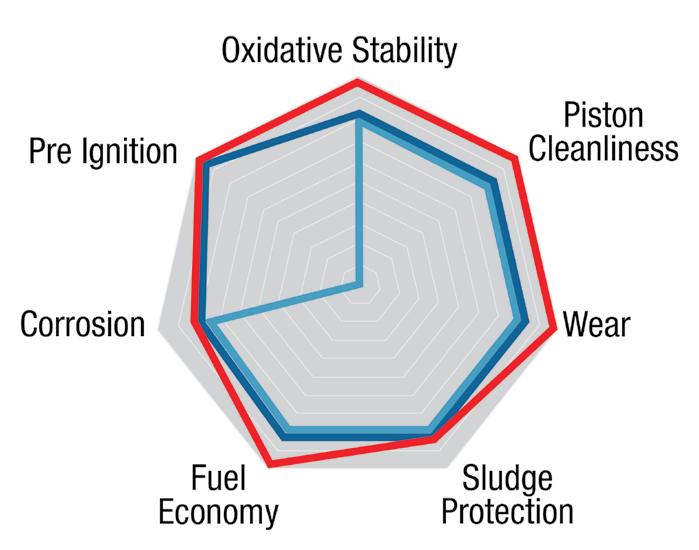

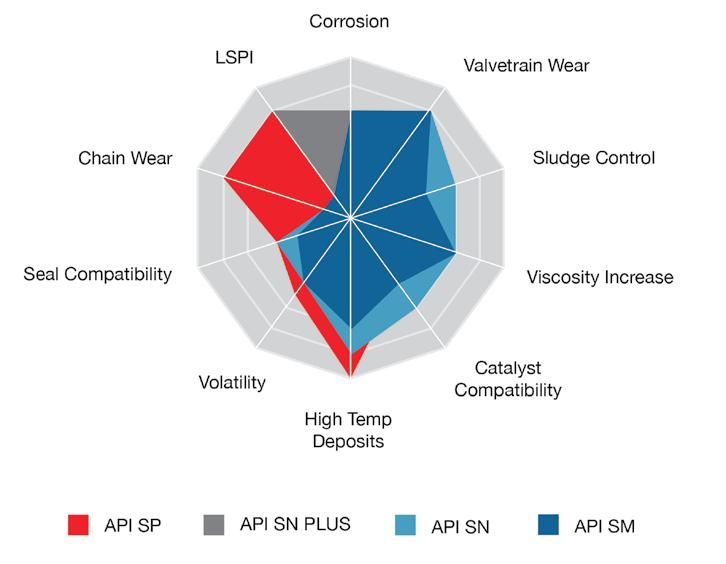

A step-up in quality

Valvoline engine oils with ILSAC GF-6, will see a significant boost in performance characteristics; reformulated to pass stringent engine tests for fuel

Chart One

Chart Two

economy, LSPI, chain wear, sludge and varnish, oxidation and deposits, wear and corrosion limits. Chart one shows the benefits vehicle owners can expect over earlier generation GF-5 oils. Similar to the ILSAC GF-6 changes, Valvoline says its engine oils with API SP will be a significant boost in performance characteristics. These have been reformulated to pass stringent engine tests for LSPI, chain wear, sludge and varnish formation, oxidation and deposits, wear and corrosion limits. Chart two explains the benefits vehicle owners can expect over earlier generation API oils.

For more information on Valvoline engine oils, or to place an order, contact Valvoline Customer Service on 1800 458 237 or its Technical Hotline on 1800 804 658.

UAP: NOT JUST PARTS Unique Auto Parts is the only Australian stockiest for Carlube

In addition to supplying top quality new parts for Mercedes Benz, BMW, Mini, Audi, Volkswagen, Seat, Skoda, Peugeot, Renault, Citroen, Porsche and Volvo, Unique Auto Parts says it is the only Australian stockist of high quality lubricants and fluids from Carlube. While Carlube has recently changed its packaging, Unique Auto Parts says the products are still the same great OEM quality consumables that were introduced to the Australian market by the Unique Auto Parts business. Unique Auto Parts says Carlube oils are not only recommended for all modern vehicles but also have a specific focus on European makes and come with approval from some of the world’s

With Morey Oil products

Morey Oil says its products have been designed to protect against engine wear, carbon build-up and high fuel cost. Untreated vehicles, whether that be in the fuel system or the lubricating oils throughout, can be subject to damage or higher running costs. Morey Oil says servicing these vehicles with a high-quality product like its Heavy Duty Oil Stabilizer will assist with a smoother running and a more efficient vehicle. Morey’s Heavy Duty Oil Stabilizer reportedly reduces friction wear, keeps the oil at its peak performance for longer, reduces oil burn and sludge build up, reduces heat, cleans bearings, rejuvenates seals and reduces noise. It says this is also the case with using Morey’s Upper Cylinder Lubricant (in unleaded vehicles) and Diesel Smoke Killer (in diesel vehicles). It states these fuel conditioners will help with removing the carbon build up in the fuel system, cleaning injectors, lubricating moving parts and maintaining a more efficient fuel burn. leading car manufacturers such as Mercedes Benz, Renault, Volvo and many others. All Carlube oils not only meet the stringent requirements set forth by these car manufacturers, but in many cases surpass them, says Unique Auto Parts, which states they are also formulated for maximum fuel efficiency with added environmental benefits without compromising lubricant durability. Unique Auto Parts stocks a wide range of Carlube Low Ash/Low SAPS oil – fully synthetic and semi synthetic oils that are suitable for a large variety of passenger and commercial vehicles. The team also says it has all bases covered, with products available for all application areas such as engine, transmission, differential, power steering and brake systems. In stock are fuel system products, engine cleaners and windscreen fluid.

Recently Unique Auto Parts has also begun stocking larger quantities, with 20, 60 and 199 litre drums available, providing a convenient and cost-effective option. Oils are also available in one and five litre bottles.

Unique Auto Parts has five conveniently located Morey Oil says with a fuel system running cleaner, there will be less carbon that goes into the DPF filters, prolonging its life. Morey Oil encourages you to keep your customer base happy with a complete service with Morey Oil products, helping reduce the cost of major breakdowns. Morey Oil says its HDOS, UCL and DSK are safe to use in vehicles either new or old, keeping new cars newer for longer and keeping the older vehicles running. For diesel vehicles it states it is safe to use the HDOS, DSK and UCL, with no issues with common rail or DPF units. However, Morey’s Upper Cylinder Lubricant is not suitable for use in vehicles running E85 fuel. Also available is Morey Oil BigFoot Fire Orange Grease for 4WDs. Morey Oil warns that grease contamination can be a very costly expense, that can be prevented. It explains that even if a vehicle has an underbody wash after four-wheel driving, if branches around Melbourne, Brisbane and Perth and the team says each is fully stocked with all these great products. Delivery is available from each branch and freight is dispatched Australia wide daily using “the fastest and most efficient couriers.”

To be connected to your nearest Unique Auto Parts branch, call 1300 864 864 or visit

REDUCE VEHICLE RUNNING COSTS

www.uniqueautoparts.com.au for more information.

contamination has already penetrated the grease, or the grease has been displaced, the damage has already begun. Morey Oil says its BigFoot Fire Orange Grease will prevent this from happening, as thanks to the superior quality lithium complex greases’ very sticky/tacky nature, it will “stay in place” even in the toughest conditions of water, dirt or mud.

For further information, please contact the Morey Oil Head Office on 1800 637 173 or visit www.moreyoil.com.au

COOLDRIVE TO PARTNER WINNING LUBRICANTS

CoolDrive Auto Parts says it continues to stock race-winning lubricants, with the Syntium range from Petronas available through its branches and online. Best known globally for its partnership with the all-conquering Mercedes-AMG Petronas Formula One team, Petronas produces a range of advanced engine and transmission lubricants and coolants used by the team in Grand Prix competition. The 2020 Formula One season saw Petronas Fluid Technology Solutions power the MercedesAMG Petronas Formula One Team into the history books, claiming Formula One’s longest unbroken run as Constructors’ World Champions, thanks to Lewis Hamilton’s season victory. Syntium lubricants all use Petronas’ trademarked CoolTech formulation. The Syntium with CoolTech lubricants are all uniquely formulated utilising the latest in proprietary base stocks and industry additive packages, and engineered with strong oil chains to effectively absorb heat and transfer excessive heat out of critical engine parts to ensure a trouble free drive. Petronas Syntium lubricants carry a wide range of manufacturer approvals including MercedesBenz, BMW, Porsche and the various Volkswagen group brands for passenger car and light commercial applications, and meet or exceed the latest API and ACEA classifications. The Syntium lubricants are suitable for petrol and diesel powered vehicles, ensuring wide coverage of the Australian car market. Petronas engine lubricants are available from CoolDrive in 1 litre, 5 litre, 18 litre, 20 litre and 200 litre containers.

Further information is available at www.cooldrive.com.au or at CoolDrive branches nationally.

Shell says the E-fluids portfolio improves reliability, efficiency and performance for all vehicles with electric powertrains. Shell has expanded its globally available specialised fluids portfolio – Shell E-Fluids – to support battery electric (BEV) as well as fuel cell electric (FCEV) powertrains for commercial light-, medium- and heavy-duty vehicles. Shell says it works with truck and bus manufacturers to co-engineer bespoke fluids that meet the specific needs of their different electric drivetrains for their commercial vehicle models. Shell says this extension to its portfolio builds on the successful launch of the Shell E-Fluids range for passenger vehicles in May 2019. With this expansion to the portfolio, manufacturers of all electric vehicles from passenger and van models to larger trucks and buses can now benefit from the extensive range of specialised Shell E-Fluids and E-Greases. “Once added to the sealed environments of BEV or FCEV commercial vehicles, the fluids need

An essential part of brake servicing

Specially engineered and formulated ceramic brake parts lubricant has become an essential part of brake servicing, avoiding wear on several mechanisms which scientists categorise as adhesive, abrasive, fretting and erosion. In a brake caliper, the brake pads move in their abutment slides not only when the brakes are applied but also when vibrations are transmitted from the road surface and drivetrain. According to leading Brake manufacturer Bendix, some wear is closely associated with corrosion where oxygen from the air reacts with metal to form oxides. This results in oxidisation forming and this is much harder than metal. When this is present the sliding interfaces can be abrasive causing rapid acceleration of the mechanical wear rate. This can be microscopic in the early stages creating roughness on the sliding surfaces, becoming worse over time with wear on the slides increasing until the pads can no longer move freely. Pads that jam in the caliper can lead to a raft of brake problems including shudder, drag, rapid pad wear, noise levels and overheating. Bendix also advises that the noise behaviour of a brake system is a complex interaction between all parts of the braking system, ie: the pads, caliper, to perform at optimum levels over the vehicle’s lifetime; this is why first fill is so important for electric vehicles,” Shell Global Commercial Executive Vice President, Carlos Maurer, said. “We have used Shell gas to liquid (GTL) base oil technology for the Shell E-fluids portfolio because its low viscosity properties allow for higher efficiency in the vehicle’s powertrain. “Our lubricants research laboratories have focused on delivering cutting-edge fluid solutions to meet the specific electric drivetrain challenges of temperature control, oxidation, copper erosion and thermal conductivity.” The Shell E-Fluids range for commercial vehicles consists of e-transmission fluids, e-greases and battery thermal fluids. Shell states that to date, commercial vehicle manufacturers have had to predominantly rely on a range of fluids, which have been developed for internal combustion engines vehicles and do not deliver the necessary ultimate performance and

BRAKE PARTS LUBRICANT

efficiency for electric powered vehicles. rotor and often the suspension components. When several components in the system go into resonant vibration together it can lead into brake noise and a strategy to avoid this is to isolate the pads from the caliper. To overcome these many problems Bendix engineers say that have developed a specially formulated ceramic high performance synthetic lubricant called Ceramasil Brake Parts Lubricant which is available in a handy 255 gram tube with an extended nozzle, ideal for workshops working on a brake job. Whilst any grease will do the job in the short term, this specially formulated lubricant is designed to last the life of the brake job. It is designed to work in a range of temperatures from the coldest winter’s morning to searing temperatures generated under hard working braking conditions and not melt. Tested and proven under the worst undercar conditions where it is exposed to continuous jets of water, clouds of dust and road grime Bendix Ceramasil remains as a constant lubricant. Application of Bendix Ceramasil between the back plate of the pad and the piston and fingers of the caliper is an effective way to isolate the pads and decouple a system resonance. Guide The commercial road transport sector, which delivers goods to shops and consumers’ homes as well as providing public transport, emits eight percent* of global energy related CO2. Shell E-Fluids is one of the ways that Shell says it is partnering with the commercial vehicle sector to help deliver decarbonisation pathways.

For more information, visit www.vivaenergy.com.au

* Eight percent includes trucks and buses: Source: IEA Tracking Transport 2019, IEA Energy Technology Perspectives 2017, IEA Future of Trucks

pins of a sliding caliper require lubrication to operate correctly, allowing the caliper to centre over the rotor and adjust to accommodate wear on the pad. Bendix recommends that with each brake service Ceramasil be applied to the caliper slide pins, the abutment slides of the caliper, between the back plate and the caliper fingers and the caliper bolt.

For more information free call the Bendix Brake Advice Centre on 1800 819 666 or +61 3 5327 0211 from overseas (8am - 5pm Monday to Friday EST), email brakeadvicecentre@bendix.com.au or visit www.bendix.com.au