4 minute read

Clutch Industries - New 4WD Clutch range

NEW 4WD CLUTCH RANGE From Clutch Industries

An OE vehicle comes fitted with a standard clutch and this is suitable for most drivers, but we are not all standard drivers. If an engine is modified, or if the vehicle is under a higher strain than normal (like four-wheel driving or towing heavy loads), Clutch Industries says an upgraded clutch is required. Repco and NAPA Auto Parts stock a wide range of clutch upgrade brands and Clutch Industries says one of the newest and most popular ranges of 4WD clutches is the 4Terrain Heavy Duty clutch system. 4Terrain Heavy Duty is made by Clutch Industries, which has more than 69 years of experience designing and engineering clutch systems for Australian conditions. Clutch Industries says it is in fact the oldest and largest clutch manufacturer in Australia and still Australian owned with an Australian based engineering and R&D team. The company was also an OE supplier for Toyota, Holden, Ford, Nissan and Mitsubishi when these manufacturers were building vehicles in Australia and is now well known for its OE replacement and performance clutch ranges. Clutch Industries says the 4Terrain Heavy Duty product is ideal for applications where the standard clutch is stressed beyond typical daily driving conditions, such as towing, trade/ commercial use or off-road driving. The range is well-known worldwide, thanks to its use in everything from armoured personnel carriers in harsh deserts to rock crawling boulders in Northern America. Further, it says it delivers an increase in torque capacity while also increasing the life of the clutch through improving the following components.

High Clamp, Grooved Cover Assembly

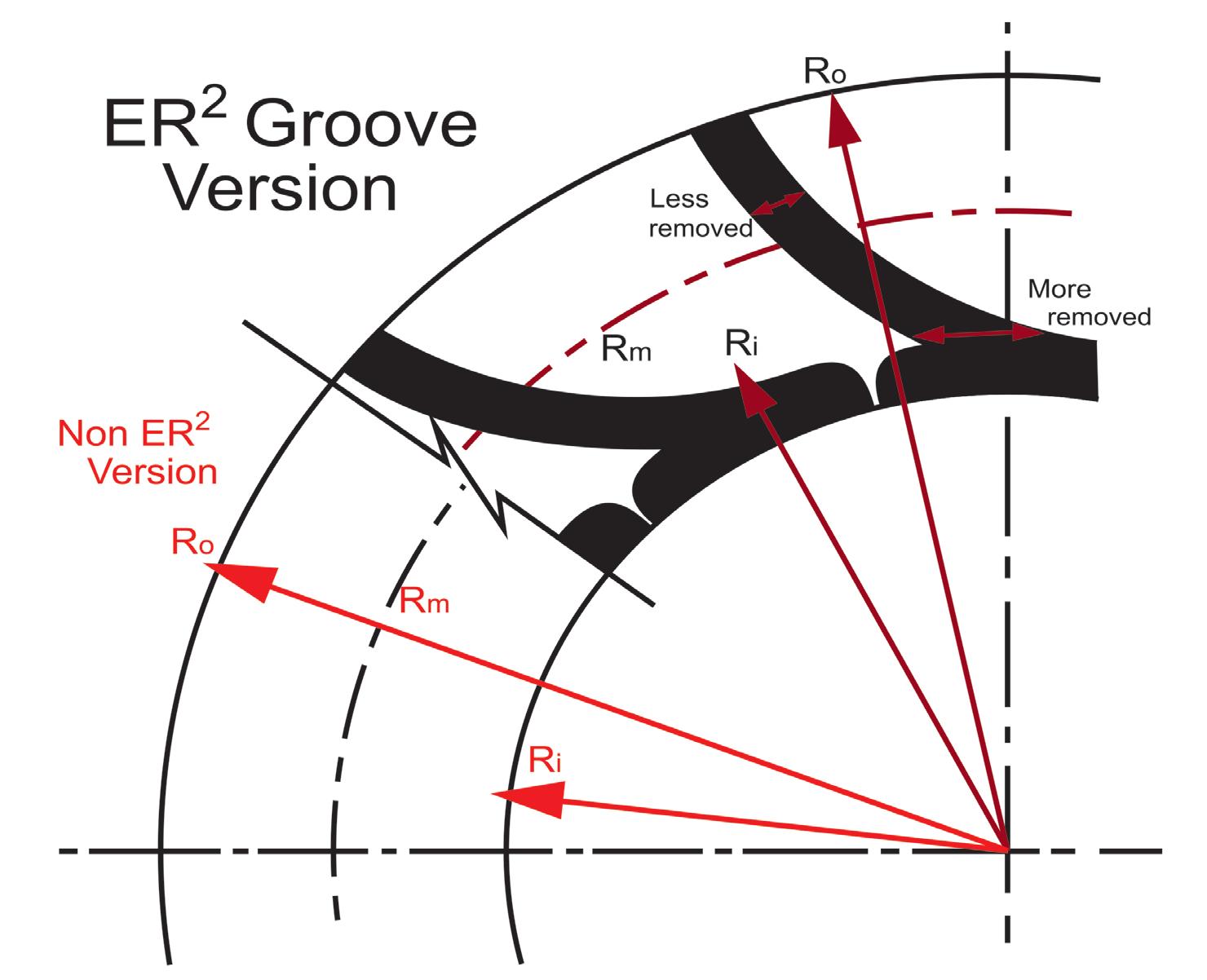

4Terrain Cover Assemblies all feature a high clamp, spheroidal graphite casted (SG Iron) pressure plate along with the Patented ER2 Groove Design, featuring a unique groove pattern which is CNC machined on the friction face of the pressure plate. To begin, the SG Iron pressure plate is said to be 300 percent stronger than regular grey cast iron pressure plate, which Clutch Industries says has the reputation of being known as a “burst proof pressure plate.” This pressure plate material also allows for better heat distribution which draws the heat out of the clutch disc, giving the clutch system a longer life and improved performance. Another feature of the 4Terrain Heavy Duty cover assembly is the higher clamp load, which Clutch Industries says is on average 20 percent more than the OE spec. Clutch Industries says that the amount of clamp load increases on its performance clutch kits is designed to have a minimal effect on pedal feel and to work with the OE hydraulics while increasing the amount of torque capacity. It states that increasing the clamp load by too much not only creates a heavy pedal, but can also reduce the life of the clutch. So then, a balance must be struck between increasing the clamp load to gain torque capacity and retaining drivability and longevity. Further torque capacity gains come from the patented ER2 grooved pressure plate. This groove has been specifically designed to increase the Mean Effective Radius of the pressure plate and assist in heat removal. The increase in the Mean Effective Radius of the cover assembly gives a significant increase in torque capacity which is backed up by dyno testing. By adding the groove to the pressure plate, the inside radius of the friction face has effectively been increased.

The first 8mm of the pressure plate has all but been removed and added to this, there is progressively less material removed as the radius increases. The net effect of this is to move the effective inside radius further out. When comparing the Mean Effective Radius (Rm) of the ER2 version to the non ER2 version, Clutch Industries says you can see the ER2 version is further out. This increases the torque capacity of the clutch as torque is directly related to Rm.

More friction material

The 4T Heavy Duty clutch disc features a 25 percent thicker friction material for longer life and Clutch Industries explains this is backed up by a three-year/50,000Km warranty which it says is the best warranty in the market.

Everything you need to get the job done

A 4Terrain Heavy Duty clutch kit comes with everything you need to do the job including the release bearing or concentric slave cylinder (CSC), spigot bearing and clutch aligning tool. Also, 4T Heavy Duty has a range of replacement flywheel kits to take away the hassle of sending the flywheel off to be machined. Some of Clutch Industries’ most popular 4x4 standard replacement flywheels are for Hiluxes, Pajeros and Landcruisers. Clutch Industries says it is seeing a trend where mechanics are preferring to replace their flywheel instead of grinding. It says this is mostly because of the time saved on the hoist but also due to the fact that replacing with a new flywheel decreases the risk of having issues such as shudder, noise or slipping that can be related to a bad flywheel grind. Clutch Industries says the 4Terrain Heavy Duty Clutch system is built to endure the rugged demands of hard-working vehicles and is a logical choice for anyone who demands relentless reliability.

For more information, visit www.4terrain.com.au or chat to your local Repco or NAPA Auto Parts branch.