2 minute read

The Impact of Non-Approved Parts on Flight Safety in Agricultural Aviation

FERNÃO CAPELO

Dr. Rogério Ribeiro Cardozo roger.cardozo@hotmail.com.br

One problem that has a huge impact on operational safety in aviation worldwide is the use of non-approved, noncertified parts or even original factory parts that does not have proper documentation. Such parts are called “Unnaproved Parts”, “Counterfeit Parts”, or “Bogus Parts”, as they do not have traceability. Traceability is the ability to reconstruct the historical past of a part or component from its manufacture to the present day. When a part does not have its documentation, or has the documentation altered, it becomes a “Bogus Part”.

This problem occurs worldwide. The clandestine parts and components market reaches global levels. It is necessary that ag-operators and maintenance managers have the wisdom and firmness to resist enchantments of a more affordable price. In agricultural aviation, these functions are often confused. The pilot may perform maintenance, as well as purchase materials, parts and equipment for operation and if not a licensed mechanic not understand the ramifications of unapproved parts.

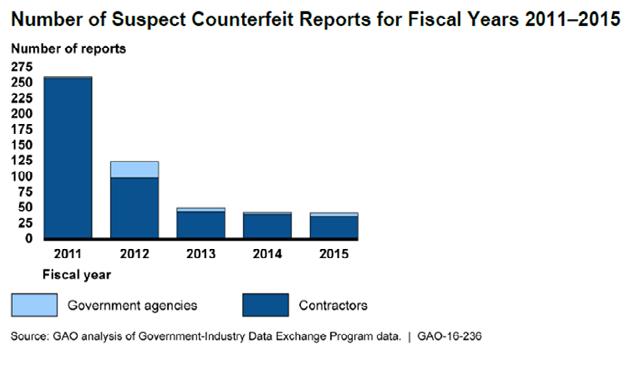

The data chart refers to the number of reports of suspected parts not approved for years between 2011 and 2015 in the USA. Brazil does not have statistical data as accurate as this. Unfortunately, only when an accident occurs is the data collected and entered in the database of the appropriate agencies.

This problem can affect the safety of operations by installing equipment that is not approved or may often not be made of aeronautical-type materials. Once, while taking a CENIPA (Brazilian Air Force Accident Investigation and Prevention Center) course, the class was presented with reports and photographs of bogus parts. It was thought to be a joke. Was not! They were photos taken from accident reports made by highly qualified, accredited personnel.

All equipment installed on an aircraft must have a Supplemental Type Approval Certificate (STC) issued by the product manufacturer and approved by the aircraft or engine manufacturer, or an equivalent document that attests that its installation will not cause any type of interference that impairs the operation of the aircraft. This document accompanies every kit of accessories produced under license from the aircraft manufacturer.

It is worth remembering that all aeronautical material, besides the specific certification, goes through an exhaustive quality control process which enables its use in the most diverse conditions that includes adverse conditions of temperature and pressure above its design and manufacture. What may seem cheap initially when a part or component is offered at practically half the price, can be extremely expensive. The price of an accident is incalculable. It can compromise the existence of a company, not to mention the lives that can be taken away by such an attitude.

Prof. Mestre Rogerio Ribeiro Cardozo is an Aircraft Maintenance Technician, helicopter specialist, business administrator and university professor with a Masters in Environmental Science and Technology. Since 2012, he has been writing in the environmental and sustainability area, having published academic papers and articles involving administration and sustainability, including works about aerospace services oriented by it. In the research area, he developed a new type of plastic totally produced with PVC waste and aeronautical engine oil waste, which earned him a nomination for a Doctorate at the University of São Paulo in the area of building materials development (Architecture and Urbanism). He is also Seripa V Certified Element in the Agricultural Aviation Safety area.