5 minute read

ASK RALPH

Plastics: A Primer

BY RALPH YOUNG

Advertisement

The corrugated and paper industries, both domestically and internationally, have rallied to sing our praises and use hard analytical approaches to assert that organic fiber-based packaging solutions are more environmentally friendly than plastic alternatives. One such case was the life cycle analysis of comparing corrugated shipping containers to returnable plastic crates for fresh fruit and produce. On a personal basis, my wine club in California switched from Styrofoam primary bottle protection to molded pulp. Yeah!

In the 1950s, ’60s, and ’70s, there was a Dupont advertising slogan one would often hear on TV or read in the news magazines: “Better Things for Better Living ... Through Chemistry.” They are known for their research and innovation. In those old days, most single-use and, often, returnable or truly recyclable single-use food-grade products came in glass or metal containers. Paperboard for juice and milk cartons and food packaging was just starting to be introduced. Then came plastic food jars.

Single-use plastic has always been an issue, especially in the area of food service. A few countries, states, and cities have even banned plastic straws recently. Check out www.bio-agave.com. They have discovered additional uses for agave beyond liquid tequila.

At the time of this writing, a group called Break Free From Plastic reported research from their collection from 55 countries and found that for three years running, Coca-Cola, PepsiCo, and Nestlé were the top three plastic polluters globally. And 5,000 other brands were also categorized from the waste stream. Plastics do not disintegrate or disappear, but instead break up into microplastics that often get consumed by the tiniest organisms. These toxins bioaccumulate and move their way up the food chain and into our air, food, and water. Now the research is focused on the even smaller nanoparticles. Maybe a Yeti cup is the pollution solution!

Amazon reports that it used about 116 million pounds of plastic packaging in 2019. Oceana disagrees and reports Amazon’s volume is 465 million pounds of plastic waste. Maybe 22 million tons of that end up in our water ecosystems. I wonder what it is in the COVID year, considering those two-ply bubble wrap plastic envelopes. A recycled-pulp bulk liner seems a better substitute.

Recycling rates for plastic are generally around 10%, with No. 1 and 2 rates at nearly 30%. These have sufficient market demand and domestic recycling and reprocessing capacity. Corrugated has been at the 90% level for many years, but it may have been a little lower in 2020, as collections from institutional facilities have fallen and as residential curbside collection has never been stellar.

Europeans are ahead of us on the replacement of plastics with corrugated and paperboard. Mondi, as recently announced in the media, is providing reductions in both plastic and carbon dioxide emissions. Their solution was a paper-based bag that was fully recyclable in existing paper streams and was able to be filled and sealed on existing machines.

Other innovative paper-based packaging options do come along, like the collaborative venture of Fishbone and Atlantic Packaging with a recyclable four- and six-pack can carrier system. And there are compostable paper-based mulches available to replace plastic sheets in farming, which are used to conserve moisture, control weeds, and boost soil temperatures.

So-called biodegradable plastics are not like cellulose-based or fiber-based packaging. They require special industrial facilities and still get comingled with recyclable and compostable materials. At the present time, biodegradable plastics are not the solution. A recent press release said that DuPont and Kemira have partnered to bring about bio-based and inherently biodegradable product lines derived from simple sugars. The process is commercial and will be rolled out shortly. The product will provide strength and barrier properties to fiberbased packaging.

The United States, China, and India appear to be the leading plastic waste generators. Taken collectively, European Union nations would come next. It had been reported at a 2018 Bank of America materials conference that the 10 worst river-to-ocean plastic waste streams come from eight rivers in China and two in Africa. In total, it has been estimated that 8.8 million tons of plastic waste flow from the world’s coastal regions each year. Some estimates report that the total count of micro- and nanoparticles in the oceans’ surfaces is between 12.5 trillion and 125 trillion.

In conclusion, stay informed, and look even more intentionally at replacing plastic with corrugated and paperboard and recyclable coatings. Act before your customers ask. We are here to support you and are always working on your behalf.

Ralph Young is the principal of Alternative Paper Solutions and is AICC’s technical advisor. Contact Ralph directly about technical issues that impact our industry at askralph@aiccbox.org.

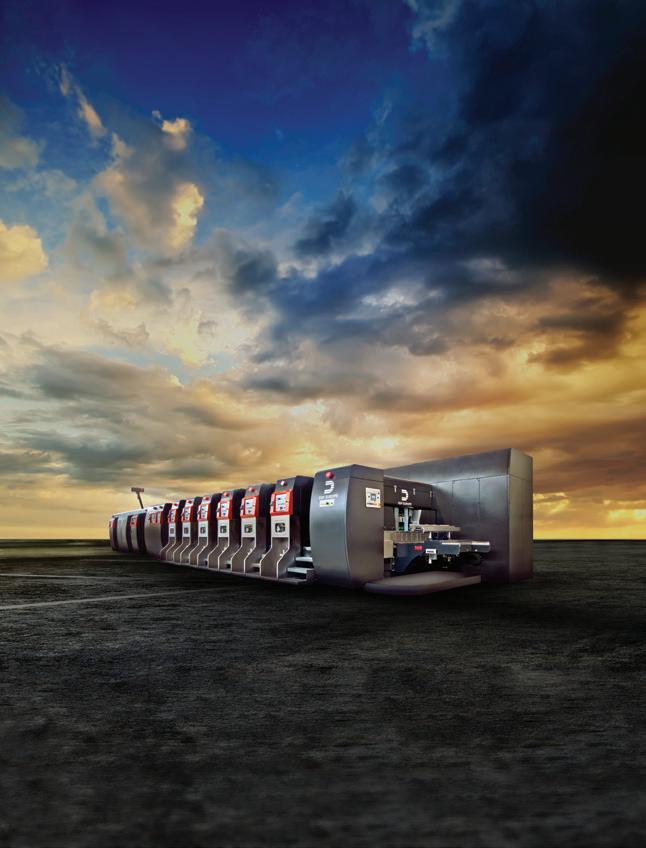

The Measure of Quality.

The Accora Advantages

HARDENED STAINLESS STEEL APPLICATOR ROLL CONSISTENT, CONTROLLED GAP

MIRROR-FINISH 1300 VICKERS RATED CERAMIC DOCTOR ROLL

Clean up your act.

AD Washboarding, warping & delaminating: the dirty laundry of corrugators everywhere. But top-quality, APEX consistently-printable board is within your reach: Accora.

You’re busier than ever. So if you’re getting bent out of shape over warped or washboarded corrugated runs — or if you’re resigned to overgluing as the norm, don’t put off looking at Apex Accora glue sets.

Unlike chrome-plated applicator rolls, Accora’s hardened AST stainless steel rolls never flake or corrode. We take extra quality-control steps in our applicator roll engraving process to ensure equivalent cell volume throughout. Accora doctor rolls feature super-dense, lowporosity ceramic that maximizes resistance to scoring and corrosion.

Accora is certified and approved by all major OEMs. But because we use premium materials and methods on our rolls and journals, Accora exceeds OEM standards for T.I.R. tolerances. We minimize T.I.R. down to 0.0005” for the tightest controlled gap. Results? How about faster speeds and easier clean-up? Longer roll life. Job repeatability. Flatter board and fewer rejections. And potential starch/energy savings.

Discover what the leading box manufacturers already know: Accora makes quality board easier. Request a quote today for your new or refurbished set.