6 minute read

THE ASSOCIATE ADVANTAGE

—Gene Marino, AICC chairman and executive vice president, Akers Packaging Service Group

Advertisement

but at end of the day, you still have the security blanket.”

And of course, suppliers will return the favor. If Welch Packaging’s own corrugator goes down, “it’s nice to know that they could ramp their volume up,” Welch says. “Th ey can help us.”

Ensuring a return on the investment in corrugating capabilities demands that the machinery be steadily occupied. “Th e capital to put in a corrugator is very signifi cant, and if you don’t have the volume to operate that corrugator every day, it can be a very expensive,” says Welch. “You can lose money pretty easily if your trim pool is not good, your waste is high, and you don’t have enough volume to absorb the fi xed costs of the operation.”

Marino agrees that strong vendor relationships remain necessary to fi ll the strategic but inevitable gaps in vertical integration. “Th ere are certain grades we don’t run on our corrugator,” he says. “I still have to make a call to a vendor who will make sheets for me because I choose not to carry diff erent grades or diff erent varieties of paperboard.”

While vertical integration off ers multiple advantages, including independence from suppliers, it also runs complexities upstream or downstream, adds Marino. A box plant that invests in making its own sheets now has responsibilities for buying and storing containerboard and maintaining expensive equipment. A mill, once acquired, demands a constant supply of personnel and feedstock that keep it running almost 24/7, plus strategically planned preventive maintenance breaks in order to reap returns on the costly investment.

Th at’s why it’s important to remember, when contemplating any sort of integration, that “there are some very effi cient and very well-run suppliers out there,” Marino says. “It’s really like anything else. What will be the return on the investment in capital in order to make that move?”

Pandemic Agility

Even as the global economy experienced upheaval from the COVID-19 pandemic, Welch says that the acquisition that led to creation of Green Meadows Paper Co. “could not have come at a better time.”

“All suppliers have struggled the past year,” he says. “Integrating and having more control of our supply was a distinct benefi t for Welch. We have certainly benefi ted from having input or control rather than being at the mercy of the free market.”

But as Marino notes, an economic crisis can exacerbate the existing challenges of integration, depending on the business model. Some in the industry run their own truck fl eets, while others choose to outsource transportation. Even before the pandemic, the driver shortage—worsening now as the last of the baby boomers age into retirement— created roadblocks for both.

It’s a dilemma that Welch and his team manage every day, but one that extensive integration makes manageable. “Having the ability to build redundancy plans and alternative options, that’s where having control is an advantage,” he says. “I’d rather fail myself than get mad at somebody else for holding me up.”

Few companies have been immune to the supply chain and personnel challenges of the current economic climate, Marino says. “We’ve just had to be a little more proactive in how we maintain and turn over inventory stock and work with our suppliers to make sure we’ve got the least amount of interruptions possible,” he says.

In its 50 years, Akers Packaging Service Group has acquired or started 13 paper and packaging businesses—13 sites in six states. Th e size that comes with those acquisitions and that integration has allowed Marino’s Akers Packaging “more responsiveness and more fl exibility because we could rely on other plants for spikes in business,” he says. “It’s the ability to rely on other locations to continue to be responsible and meet customer demand versus the single-site facility that, let’s say, had a COVID outbreak that took half the shift down. Th e size speaks to

our ability to have replicated assets that we can leverage and rely on across our platform.”

Every business in the corrugated realm is adapting to a new normal of people and supply shortages, Marino says. Integration off ers a tool for managing. “Ultimately, if push comes to shove, if I have the board and a vendor tells me they can’t do a job, I have the ability to run it,” he says. “Industrywide, many would tell you that for larger customers, they’ve increased their safety stock so they don’t run out. Th ey can try to be a little more strategic in how to manufacture when that call comes in. You have to take care of best your customers.”

As companies build capabilities through acquisition or joint ventures, the key to successful integration and growth is retaining a strong company culture across sites. In the case of Welch Packaging, it’s a commitment to community and to each other, as Welch saw when the entire enterprise stepped up to help a newer employee who lost his home in a fi re.

New ventures, such as a corrugator purchase, demand the confi dence that “we can sustain something that we bought,” Welch notes, especially to avoid devastating the people who work the site and their families if the initiative fails.

“Th at you have to control supplies is just the reality of this business, but more important to us are the other pieces—the ability to recruit talent, the ability to develop talent, and most importantly, the ability to expand your company culture,” he says. “Th ose are the real things when you think about integration or expansion. If we can do those things, we feel we are on the right path.”

M. Diane McCormick is a Pennsylvania-based freelance writer.

The Measure of Quality.

PATENTED OPENCHANNEL ENGRAVING PROVEN FASTER & EASIER CLEAN-UP COMBINATION SOLID AND SCREEN PRINTING

NEXT-GEN ANILOX ROLLS

CORROSION & SCORE RESISTANCE UPGRADED SOLID, LINE & CMYK PRINTABILITY CUSTOM OR CONVENTIONAL ENGRAVINGS

CONVENTIONAL ANILOX ENGRAVINGS

Apex anilox rolls let you print your best on corrugated.

Don’t let your anilox rolls hold you back from finer screens, stronger solids, & sharper lines. Treat your customers to higher print quality with GTT and UltraCell anilox engravings. Let legendary Apex precision & durability reduce problems & boost your profits.

GTTCORR “L”

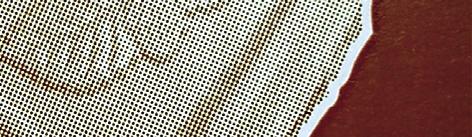

SOLIDS & SCREENS ON ONE INK STATION Full solid and 65 LPI screen with one print plate on white-coated B-flute using GTTCORR

Conventional 250 LPI Anilox Engraving Conventional 360 LPI Anilox Engraving

GTTCORR “L”

ACHIEVE YOUR FINEST DETAIL GTTCORRanilox (far right) helps you print finer screens, stronger solids, and sharper edges.

Get on board with higher print quality & contact us for your next anilox quote.