6 minute read

WORKSHOP: LD MAINTENANCE PT2

LOCKDOWN AIRSOFT MAINTENANCE

FRENCHIE HAS BEEN MAINTAINING KIT FOR LONGER THEN WE DARE MENTION AND CONTINUES HIS NEW SERIES WITH A LOOK AT GBB MAINTENANCE.

As promised, this month I’ll turn my attention to Gas Blowback (GBB) maintenance. Now, there is a real danger that I’m teaching my granny to suck eggs here, as people with GBBs who don’t perform regular maintenance are called “players without guns”!

Some GBBs are pretty tolerant of careless use but the majority aren’t, so ignore this at your peril. I will also confess that I am no wizard when it comes to GBBs - I’ve always been far more comfortable with AEGs and spring guns, however, I have worked on gas guns for decades and it’s always a delight when they respond as I hoped they would! In part this is because I prefer either electric pistols or a shotgun as a secondary – and from that statement you may fairly deduce I prize function over the “boom factor”! I know AEPs (Automatic Electric Pistols) are rightly the butt of many jokes and scathing remarks but they work, and if you invest in a Marui, they work really well. That, however, is a subject for another day.

Back to gas guns. Personally, the greatest appeal of GBBs for me has always been their proximity to the workings of real guns - only the motive power, compressed gas rather than a chemical explosion, really differentiates them. It follows that maintaining them is far closer to maintaining a real firearm than say, an AEG. Fundamentally that comes down to cleaning and lubrication, with a few extra annoyances in the form of seals and nozzles thrown in for good measure.

KEEP IT CLEAN!

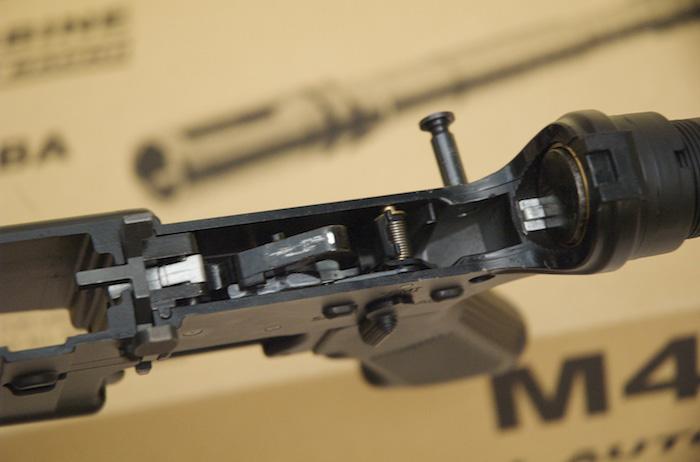

First and foremost therefore, keep your GBB clean. Like real firearms there is a potential for dirt or other foreign bodies to enter the action and stop them working. Bolts and slides have to move and in doing so, they expose the inner workings in a way that electric guns seldom do. Fortunately, most gas guns disassemble in a manner that closely replicates the firearm they are based on, so if you’re unsure, refer either to the user manual or check YouTube - someone has almost certainly posted a video of how to take your particular gun apart.

Let’s be clear what I mean by “disassembly”; in the real world it would be referred to as “field stripping”, the level of disassembly required to perform basic maintenance. On a typical pistol that will involve removing the magazine and the slide

and extracting the barrel and recoil spring(s). That leaves you with all the principle components free for inspection, cleaning and lubrication. Going beyond that is the remit of the tech or the keen. Unless there is a problem, there is seldom a need to strip down the hammer and trigger group, although some pistols do make that relatively easy.

Once apart, clean the components. That may just be a wipe down with a clean J-cloth (dead handy things) or a bit of a work over with an old toothbrush. Remove any bits of forest you may have acquired during your last outing. Don’t forget to clean the barrel.

Inspect the parts for wear or breakages. Generally, wear should be superficial - finish becoming worn due to friction but as steel is little used and light alloys abound, it’s worth making sure that nothing is worn and shiny that shouldn’t be. Clean off existing lubricant from the slide and frame and wipe down the hammer group as far as possible. This is where that toothbrush can come in handy.

KEEP IT MOIST!

We now come to the bit where those who encountered me in a past life might start shouting at their screens – lubrication!

I used to be very dogmatic about this, but age and experience have softened my attitudes somewhat. The one absolute rule is never use mineral-based lubricants. So no “Three-In-One” oil, no “WD40”. That applies to all airsoft guns as mineral-based lubricants can (and often will) damage the seals all guns require for efficient operation. Beyond that, as I said, I’m a lot less strict. Silicon oil and grease are probably your friends here. The oil can be used sparingly around gas nozzles, trigger groups and the grease can be used on slide rails. I used to decry the use of any silicon product from metal-to-metal surfaces but a couple of things changed my mind: I could never find any literature which said that silicon based lubricants couldn’t be used for that purpose and secondly, if you are looking after your guns on a regular basis the lubricant isn’t going to be there for long, as you’ll clean and replace it. It is arguable that even with heavy use, by airsoft standards, silicon grease is more than robust enough to handle the task. You would never use it on the gears in an AEG, but few of us use our gas guns to anything like the extent we cane our electrics.

If you want to use what the suppliers recommend for metal to metal, Abbey’s LT2 grease is ideal, although it is mucky, stringy stuff. They recommend it for all metal to metal contact and far be it from me to argue with them, but meh. I would, however, concur with Abbey where GBB rifles are concerned, as they are moving much larger and heavier chunks of metal around and will benefit from a more robust lubricant between those parts.

Key to all of this is the word “sparingly”. Once you have bought your various lubricants, they should all last you a long time. There is a phenomenon I have encountered occasionally in airsoft which I can best describe as “squaddie lubrication”, which involves putting as much lube on a gun as possible. Oddly this doesn’t really help and I have seen Marui HiCapas reduced to useless lumps as they fail to overcome a surfeit of love. You just need a little! Abbey describes applying LT2 to the slide rails as “polishing”. That’s very good advice.

Magazines, assuming they aren’t leaking, need a little silicon oil applied to the filler port, the release button (the bit struck by the hammer) and the gas router on top of the magazine. If you are stripping your magazine, I would personally use silicon grease on the internal seals to keep them healthy.

Beyond that the usual rules about keeping your guns clean and corrosion free apply, although they are more relevant to gas guns because of the nature of the moving parts. Too little cleaning and too much lubrication generally spells trouble for gas guns as does a lack of maintenance. In the UK, with our unpredictable weather and less than encouraging temperatures, gas guns have their work cut out. A bit of time and care on your part can ensure that they at least have a decent chance of performing as you want them to. AA