6 minute read

TECH: KEEP IT CLEAN

KEEP IT CLEAN!

OWN A GBB PISTOL OF SOME DESCRIPTION? WE BET YOU DO! ANY SELF-RESPECTING ‘SOFTER OWNS AND USES FREQUENTLY A GBB PISTOL BUT OWNING ANY GBB PISTOL REQUIRES A CERTAIN AMOUNT OF MAINTENANCE, SOMEWHAT MORE THAN AN AEG. IN THIS INSTALMENT OF “TECH”, JIMMY COVERS HOW TO GO ABOUT LOOKING AFTER YOUR PISTOL, WHETHER IT BE OUT OF THE BOX OR HEAVILY USED. ARE YOU SITTING COMFORTABLY? IF SO, HE’LL BEGIN…

It can be a real let down (and sometimes infuriating) having to swap to your secondary only for it to fall flat on its face in your hour of need, letting an opponent get the drop on you and giving you that “long walk” back to the Safe Zone, can’t it? However, much of the time, a pistol failing to do the job is primarily down to lack of maintenance. I’m not about to start pointing fingers but some people might not understand the importance - nor even how to - go about basic pistol maintenance and this month I’ll pass on a few tips for those that don’t know. Some pistols require a little more love than others and one thing you will need to become familiar with is how to strip your pistol.

For basic maintenance you don’t need to be stripping it down to every single component but knowing how to separate the slide from the frame is a must in order for you to clean and lubricate it effectively. Most pistol’s takedown is relatively straightforward, by way of a lever or a frame pin. When it comes to maintenance everybody has their preferred method and likes to use their favoured products, which is absolutely fine as there’s more than one way to peel a potato and there’s a wide variety of products available (each claiming to be “the best”).

When it comes to new pistols, I like to remove the slide and do away with the heavy thick grease commonly used by manufacturers. Grease should not be used on any part of a pistol. No grease? I hear you ask …correct, no grease! While grease is a lubricant, it is thick and heavy and can slow your pistol down, even making it inefficient. A good oil or lubricant is far better to use as it is much lighter and it allows everything to move easier with less effort, making your cycle time quicker and maintaining gas efficiency. So, with an out-of-the-box GBB, I will clean and remove as much grease as possible and lubricate only the places that are needed.

For example, when it comes to any contact points between the slide and the frame, you don’t need a lot of lubricant. With a good oil, a few drops properly placed properly will go far. My choice of oils/lubricants are GHK silicone oil and Maglube oil. Both are very good lubricants and perfect for use on all aspects of your pistol and can be purchased fairly cheaply.

GETTING DOWN TO IT

Here is my process for cleaning and lubricating my pistols:

I start by cleaning any old oil or grease from the slide, inside the rails and around the blowback housing and nozzle using cotton buds, as they can reach the smaller areas and they are inexpensive.

Next, I will inspect my barrel and hop rubber to check for any grime down the barrel and check for wear on the hop rubber. I also look for any signs of lubricant on the hop rubber. Contaminants on your

hop rubber will have adverse effects on accuracy and range.

Using a cleaning rod and small squares of cotton t-shirts which I cut up myself (old t-shirts of course!) I then clean the barrel. It may take three or four goes before your barrel is clean but repeat the process until the wipe comes out clean. For this I use either isopropyl alcohol, or Zippo lighter fluid. The trick here is to clean the grime from the barrel and leave it oil and grime-free, while being mindful at all times of your hop rubber. Try not to push the rod too far as you may damage your rubber. It’s amazing the difference a simple clean of the barrel makes on both range and accuracy.

Once you are happy that your barrel is clean, turn your attention to your mag. Your pistol is nothing without an efficient mag. Using a cotton bud with some oil on, wipe around the release valve (the oil helps to pick up any debris) making sure there is no dirt or dust around the valve, as this could cause problems when the knocker strikes the valve to release gas.

This next step isn’t vital but it’s something I do to be sure the BB can feed up the mag and that the mag follower doesn’t jam. By removing the feed lips on the mag, I then remove the follower and the spring followed by the base plate and, using another cotton bud with some alcohol, I clean the channel from top to bottom, ensuring no contaminants are present. Grit and dirt can get into your mag and jam BBs. Give the spring and the follower a wipe over with some rag or workshop towel. All of these sections should be free of obstructions and contaminants as this can cause feeding issues and any oils will be picked up on your BB and then sent through the barrel.

At this stage we now have three sections of your pistol cleaned and ready for oil but before you do this inspect your pistol, check for any signs of wear, check for any breaks or cracks. If you see any screws or grub screws just give them a check making sure they are tight, along with the gas valves; release and fill and just check they are tight.

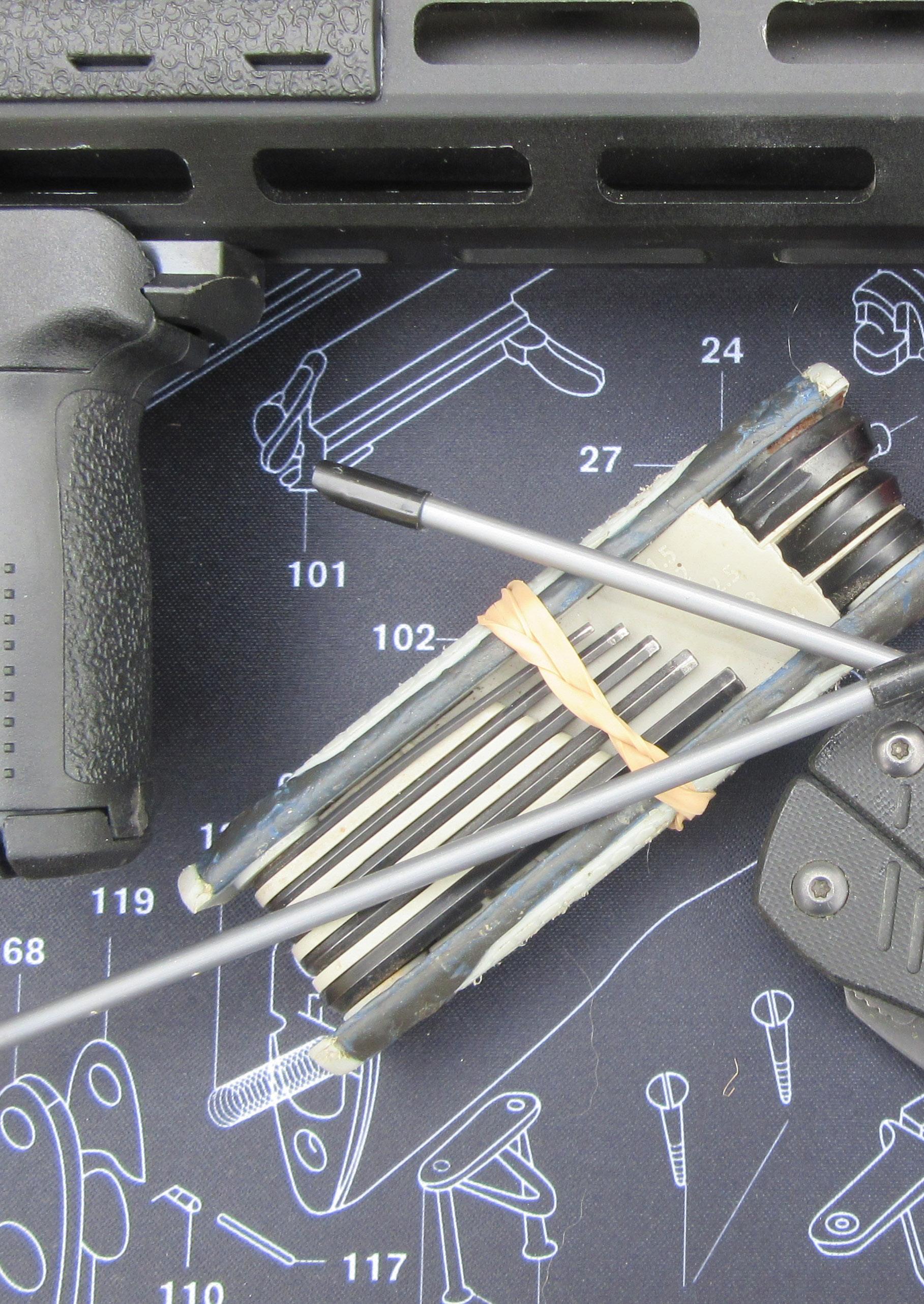

TOOLS FOR THE JOB

If you plan on regularly maintaining your pistol(s) yourself, I highly recommend investing in some valve tools. These make life much easier than trying to do it with ill-fitting screwdrivers.

After the inspection and you are happy with the condition of things, now is the time to get the lube out (ooh matron!) if you have ever seen Evolution’s “there’s always time for lube” …sorry got a bit distracted there!

With the oil we don’t want it dripping out everywhere, we just want to administer enough in the areas needed. So, the railed sections on both the slide and the frame, add a few drops at points you know are contact points. Next add a drop or two on the disconnectors, pull back the hammer if you have a hammer and add two drops to the hammer and sear contact point and (if you can get to it) add two drops to the valve knocker; also draw open your nozzle and add a drop or two onto your piston o-ring. At this point you can replace your slide and by hand, cycle the slide a few times so that the oil becomes evenly distributed.

Next is the mag and the only point on your magazine to add oil is around the release valve; two drops should suffice and one drop on the fill valve.

I mentioned about a hammer. Some pistols aren’t hammer action but, instead, are known as striker- fired; Glocks for example. With the slide removed you can see pretty much all of the action, so look for any point of pivot or component contact and just add a drop in these areas.

I believe this concludes the process of basic pistol maintenance.

Always remember that a well-maintained pistol is a happy pistol! Look after your gear and your gear will look after you. Now get out there and enjoy taking down your opponents! AA