S09 ORME 6 2021 Cyber Security_Layout 1 23/09/2021 07:21 Page 32

Compressors

Proactive maintenance of

compressor systems Rajesh Fotedar, product manager for Oil-free Industrial Compressors at CompAir, discusses why a proactive maintenance model – enabled by the IIoT – can deliver enhanced efficiencies and reduce risks for compressed air systems. ITH INDUSTRY AVERAGES suggesting energy costs account for more than 80% of the total cost of ownership of a compressor, any initiatives that can help companies identify inefficiencies and assist with performance optimisation, leak reduction and practical air management processes should be welcomed. The IIoT is without doubt, the greatest opportunity available today to help businesses work smarter. Data analytics can help operators to understand how efficiently a compressor is running, and whether any improvements can be made. These insights will not only help highlight any potential issues now, but also enable operators to forecast any potential future problems too, based on deteriorating machine performance. Predictive maintenance models based on real-time data can then be established to help reduce energy consumption, improve process efficiencies, and mitigate any potential risks. However, for a proactive maintenance model to realise its full potential, the right information must be provided at the right time. Proactive maintenance requires a proper plan of action and correctly defined interfaces.

Enabling proactive maintenance Along with cloud technology and software advances, sensors form the heart of the IIoT, helping owners and operators to better understand their systems. Developments in the field of sensor technology have resulted in more compact, intelligent, and cost-effective products. Digital networking of these components in a system – which will typically cover a compressor, its filters, and downstream equipment like dryers – can minimise costs while ensuring any issues are tracked and identified quickly. Indeed, digital networking is a key factor when it comes to making savings. Not only does it influence and reduce energy and service costs, but it can also lead to greater reliability around a site’s processes, as well as improved cost control.

32

oilreview.me

Issue 6 2021

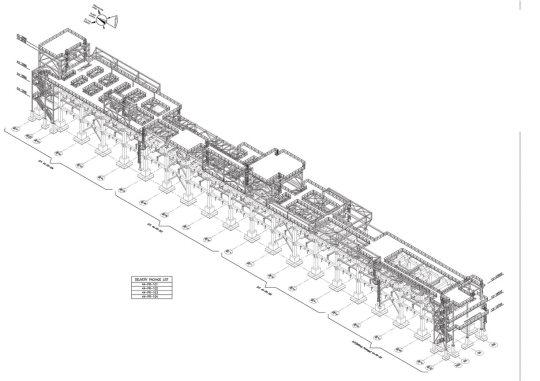

Image Credit: Ingersoll Rand

W

Implementing a proactive maintenance model delivers a range of key benefits.

Proactive maintenance requires a proper plan of action and correctly defined interfaces.” Digital networking provides data relevant to wear, costs, and quality. Once the compressed air component is equipped with sensors and networked via the IIoT, it can share messages with those responsible for maintaining the system. This then provides them with precise information about when maintenance and inspections may need to be performed, or perhaps when a component has reached the end of its service life prematurely. This approach helps ensure

timely intervention, so any problems can be remedied quickly. Operators will typically find that service requirements will mainly be based on two sets of criteria: either detailed information relating to the system itself, covering its functions and historical machine data or environmental factors, which might include weather conditions, room temperature and humidity. These sensors will report the status of the monitored systems in real-time, with defined parameters – such as temperature, speed, and humidity – observed and evaluated over a specific period, to help inform and contribute towards predictive analysis strategies.

Reactive vs. proactive maintenance Let’s consider how a reactive approach to maintenance differs from a proactive strategy. In terms of notifications, for traditional ways of