PRIMETALS TECHNOLOGIES AND ALFED WELCOME YOU

ALUMINIUMFLAT ROLLED PRODUCTS MARKET –SUPPORTING THE CIRCULAR ECONOMY IN THE UK

WEDNESDAY 6 SEPTEMBER 2023

Restricted © Primetals Technologies 2021-2023. All rights reserved.

Grant Shoebridge Head of Downstream

Health & Safety

Bathrooms

• Toilets are located just outside this room on the righ-hand side

Smoking

• A designated smoking area can be found behind the marquee in the rear carpark

Fire

• There is no fire drill expected

• In the event of the alarm being raised please leave immediately through the main door.

• Please assemble at the fire meeting point at the far side of the carpark.

Restricted © Primetals Technologies2021-2023. All rights reserved. 2 6 September 2023

Welcome

WELCOME TO SHAPETECH

CELEBRATING 50 YEAR OF UK MANUFACTURING

Grant Shoebridge

Primetals Technologies

Restricted © Primetals Technologies2021-2023. All rights reserved. 3 6 September 2023

09.45 –10.00

WELCOME

GRANT SHOEBRIDGE | HEAD OF DOWNSTREAM | PRIMETALS TECHNOLOGIES

10.00 –10.30

UK VEHICLE BATTERY PRODUCTION -WHERE IS THE FOIL COMING FROM?

PAUL WILLIAMS | HEAD OF ALUMINIUM | CRU

10.30 –11.00

EXPECTATIONS FOR THE UK BEVERAGE CAN MARKET (CIRCULAR ECONOMY)

NICK SAUNDERS| SENIOR SALES MANAGER

11.00 –11.15

BREAK

11.15 –11.45

MAXIMISING PRODUCTIVITY: NEW V OLD EQUIPMENT –PANEL DISCUSSION

JAN LUKASZEWSKI | TECHNICAL MANAGER | ALFED

MIKE BRAMMER | DIRECTOR | PRIMETALS TECHNOLOGIES

DAVID PARKIN | HEAD OF PROJECTS AND ENGINEERING| PRIMETALS TECHNOLOGIES

GRANT SHOEBRIDGE | HEAD OF DOWSTREAM | PRIMETALS TECHNOLOGIES

11.45 –12.15

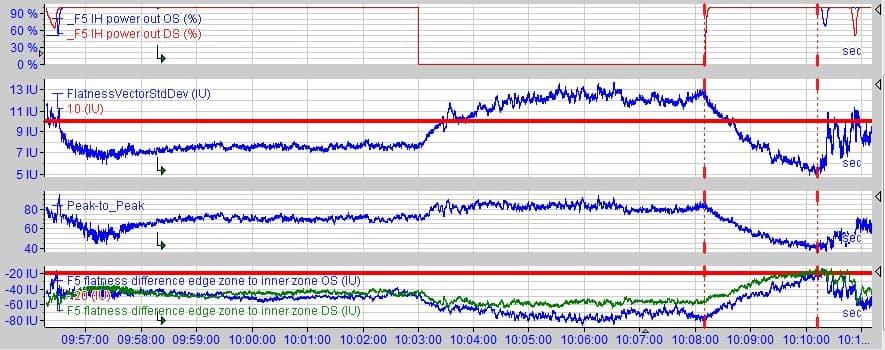

ENSURING PRODUCT QUALITY THROUGH CLASS LEADING FLATNESS & CONTROL

RHYSVERRINDER| PROCESS ENGINEER | PRIMETALS TECHNOLOGIES

12.15 –12.45

WORKSHOP TOUR

12.45 –13.30

LUNCH

Restricted © Primetals Technologies2021-2023. All rights reserved. 6 September 2023 4 Contents

Restricted © Primetals Technologies2021-2023. All rights reserved. Primetals worldwide network 7000 EMPLOYEES TOTAL 55 RESEARCH PARTNERS IN THE INDUSTRY 60 KEY EXPERTS 25 UNIVERSITIESAND SCIENTIFIC PARTNERS 24 COUNTRIES 250 R&D SPECIALISTS 6 CENTERS OF COMPETENCE 6 September 2023 5

UK Locations

SHEFFIELD

PLATE MILLS

STECKEL MILLS

ALUMINIUM ROLLING MILLS

METALLURGICAL SERVICES

CHISWICK

HEAD OFFICE

CHRISTCHURCH (SHAPETECH)

STEEL, ALUMINIUM& NON FERROUS

FLAT & LONG PRODUCT

FILTRATION, SENSORS & SYSTEMS

STOCKTON-ON-TEES

BLAST FURNACE TECHNOLOGIES

SCUNTHORPE

EAF PROJECTS & SERVICES WORKSHOP

Restricted © Primetals Technologies2021-2023. All rights reserved. 6 6 September 2023

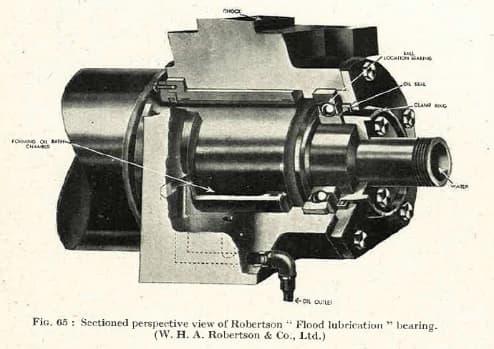

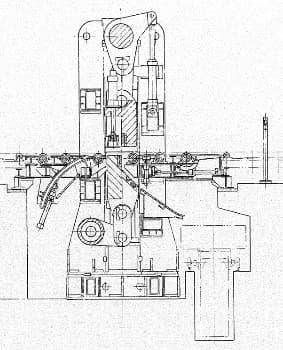

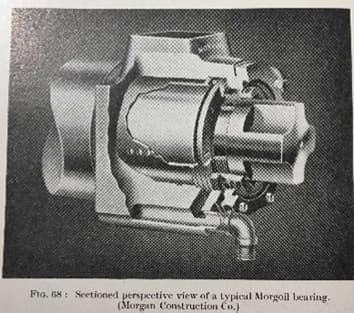

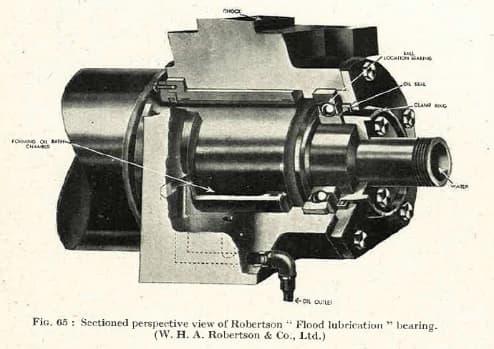

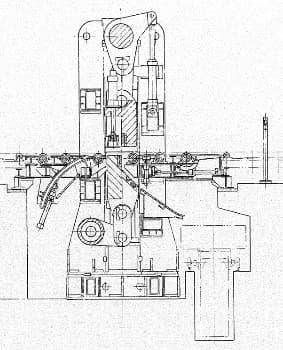

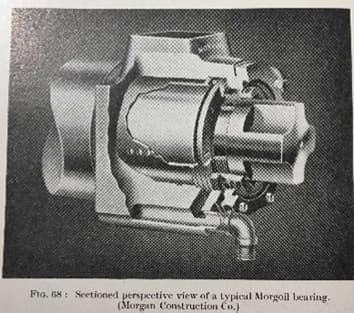

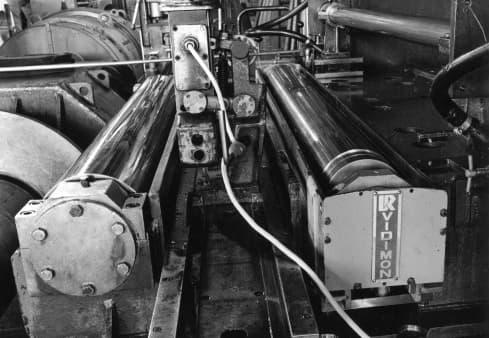

100 Years of Aluminium Innovation

1920s

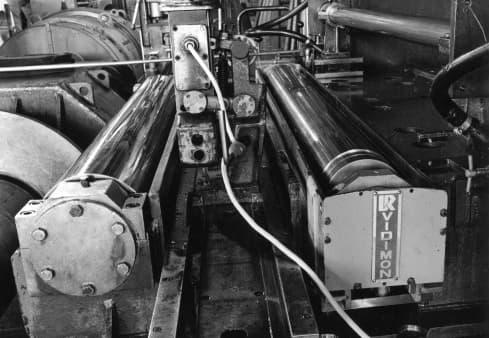

Robertson Flood Bearing

1930s

1960s

1970s

1980s

1st Hydraulic Hot Mill shear

1980s

First Hydraulic Mill

First Taper Rolling Morgoil Bearing

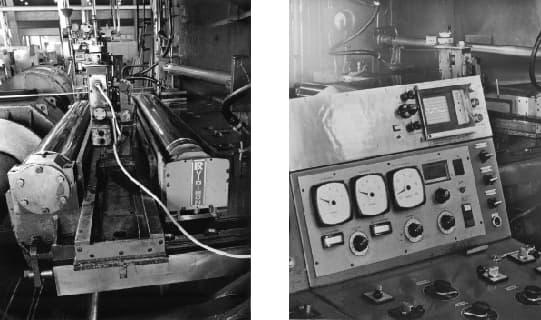

BISRA Hydraulic AGC Pre-Stressed Alu.Cold Mill

Air Bearing Shapemeter Introduced

Pioneers in Flatness Control

1st 2,000 mpmFoil Mill TFX –Strip Heating

1990s Model Based Hot Rolling Scheduling & Profile Control

DynamicShape Roll for Flatness, Thickness & Profile Control

2000s

Hydraulic Edger Smart Crown

ISV Sprays Introduced 1st Split Lubricationand Coolant System

2010s

System 2 Digital Process Control Systems Launched

2020…

UCM 6 Hi Rolling Mill Technology

Restricted © Primetals Technologies2021-2023. All rights reserved. 7 6 September 2023

• While known to the ancient world (Pliny the Elder in the 5th century BC), aluminium only started to be produced industrially in the later half of the nineteenth century.

• Small scale production in the early part of that century using chemical methods resulted in aluminium being a luxury product.

• The Hall-Héroultelectrolysis process from 1886 changed that fundamentally.

• Aluminiumwas seen very much as the metal of the future.

• For example Jules Verne was inspired by aluminiumin his book: From the Earth to the Moon.

• Jules Verne’s novel described the manufacturing of a 20,000-pound aluminiumspace capsule to take men to the moon -the same weight as the Apollo 8 capsule that orbited the moon more than 100 years later.

Restricted © Primetals Technologies2021-2023. All rights reserved. 8 6 September 2023

Aluminium –seen as the metal of the future

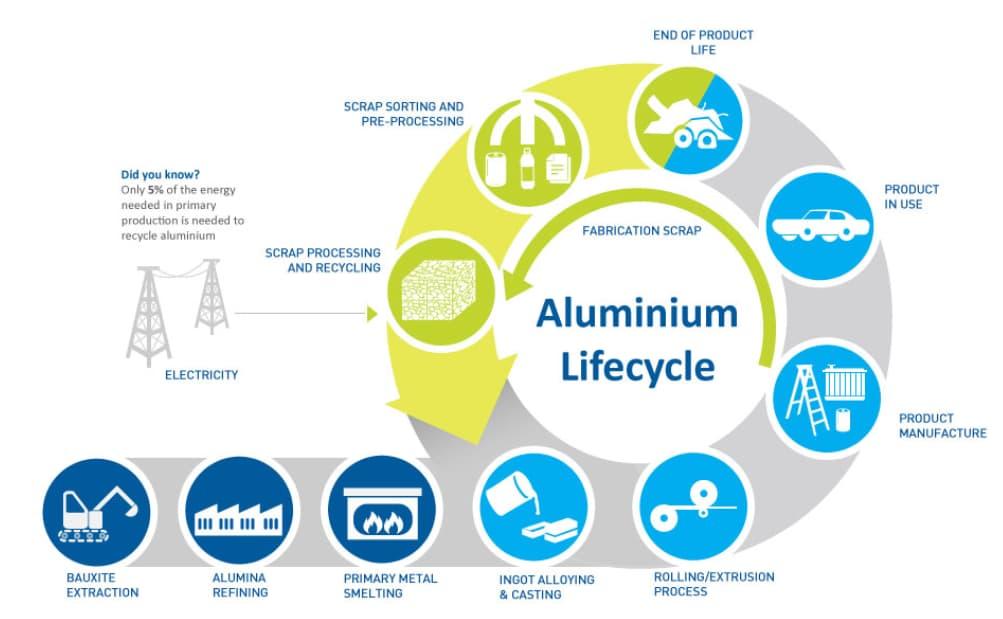

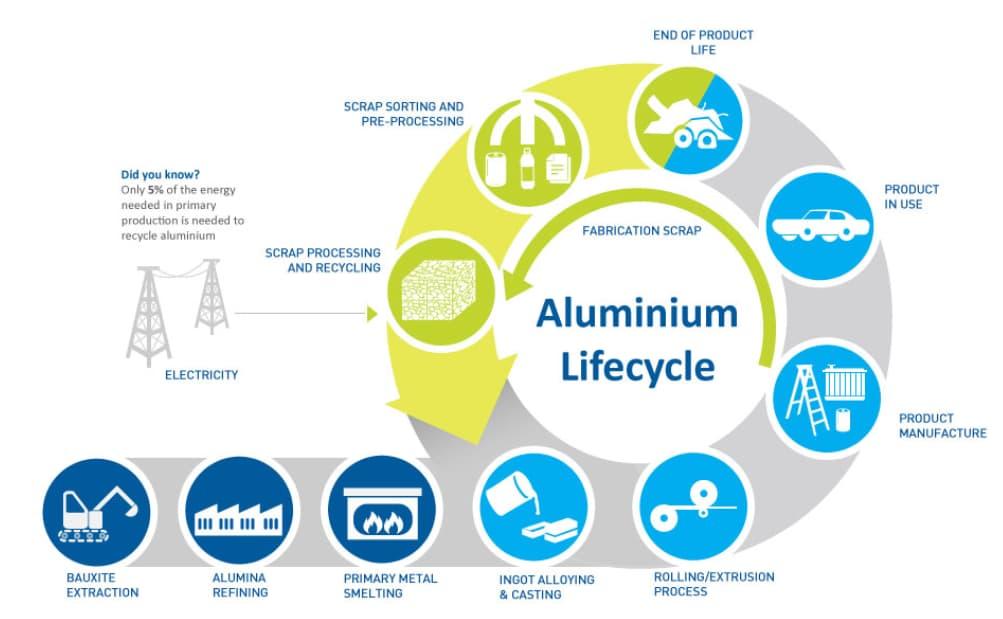

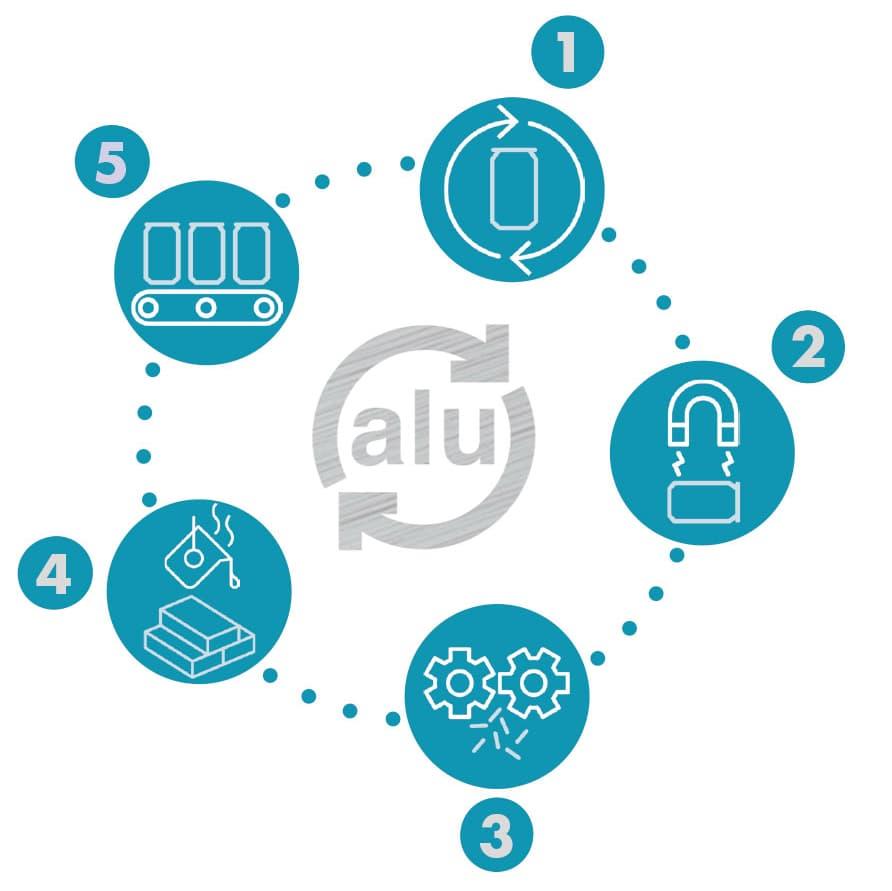

Aluminium Lifecycle

• Aluminiumis third most abundant element in the earth’s crust (8%) –and the most abundant metal.

• Bauxite is an ore most commonly found in tropical and subtropical regions.

• Globally approximately 55 to 75 billion Mt of bauxite reserves (US Geo Survey)

• Worldwide smelter production 78 million tonnesper annum (US Geo Survey)

• 4 metric tonnesbauxite = 1 tonneof primary aluminium.

• 4% of global CO2 from aluminiumproduction

• Aluminiumhas a lifecycle, and can be recycled and reused

Melt (separate alu from alumina)

Cast (Primary aluwith Mg, Si, Cu)

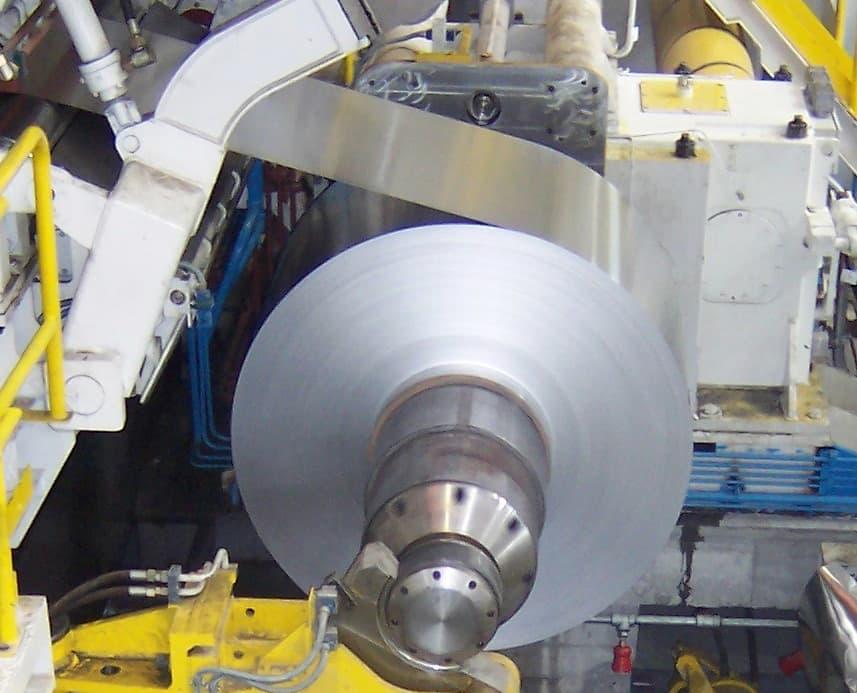

Roll (Alloyed metal rolled to gauge)

Use (Can stock, automotive)

Recycle (End of life, scrap & sort)

Melt (Returned to almost primary form)

Source(s) US Geological Survey, Hulamin

Restricted © Primetals Technologies2021-2023. All rights reserved. 9 6 September 2023

Aluminium sustainability

• All producers are under pressure to become sustainable.

• Many are seekingASI certification on this point.

• The LME is about to start trading a “green” aluminium contract.

• The EU is proposing a “green border”.

• This will drive investment:

-Yield improvement –minimisinglosses. Near net shape rolling, crop optimisation.

-Energy efficiency –hot charging of furnaces, regenerative burners, high efficiency motors, recovery of waste heat etc.

-Recycling –only 5% or so of energy is required for remelt compared to primary production.

Restricted © Primetals Technologies2021-2023. All rights reserved. 10 6 September 2023

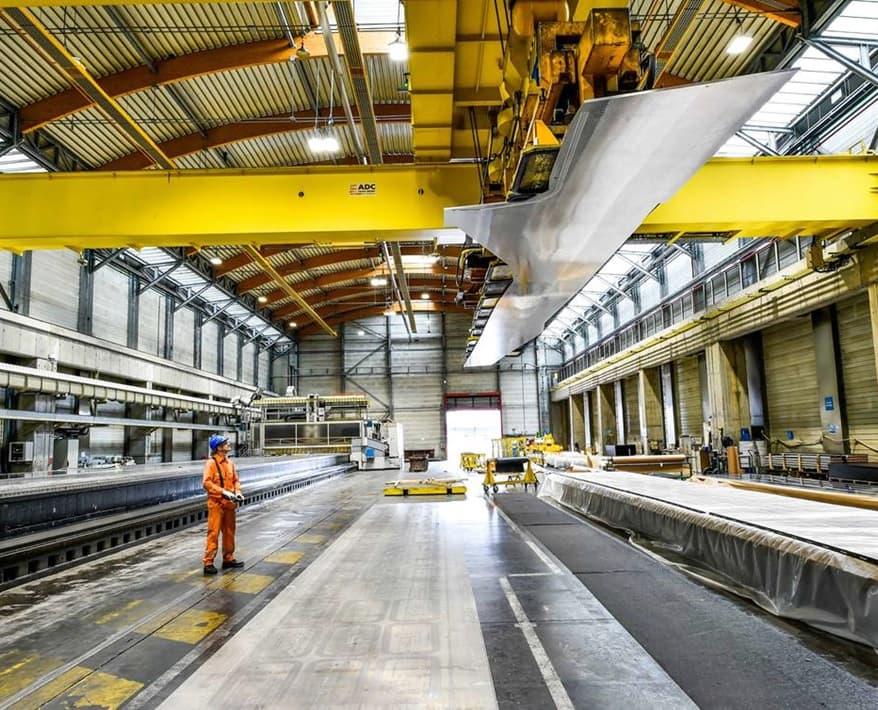

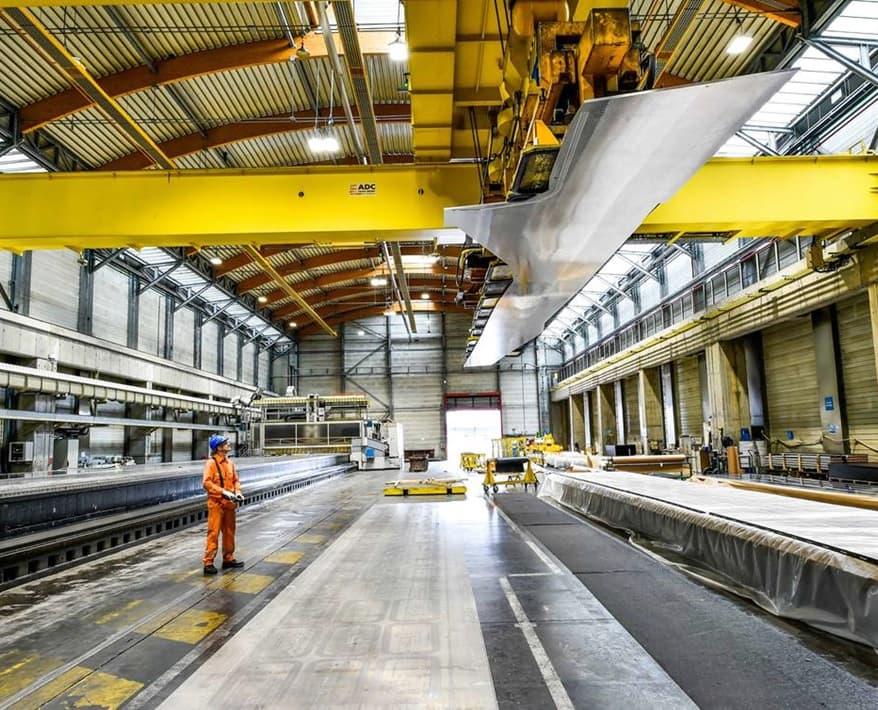

Constellium Issoire -Wingskin

Restricted © Primetals Technologies2021-2023. All rights reserved. 11 6 September 2023

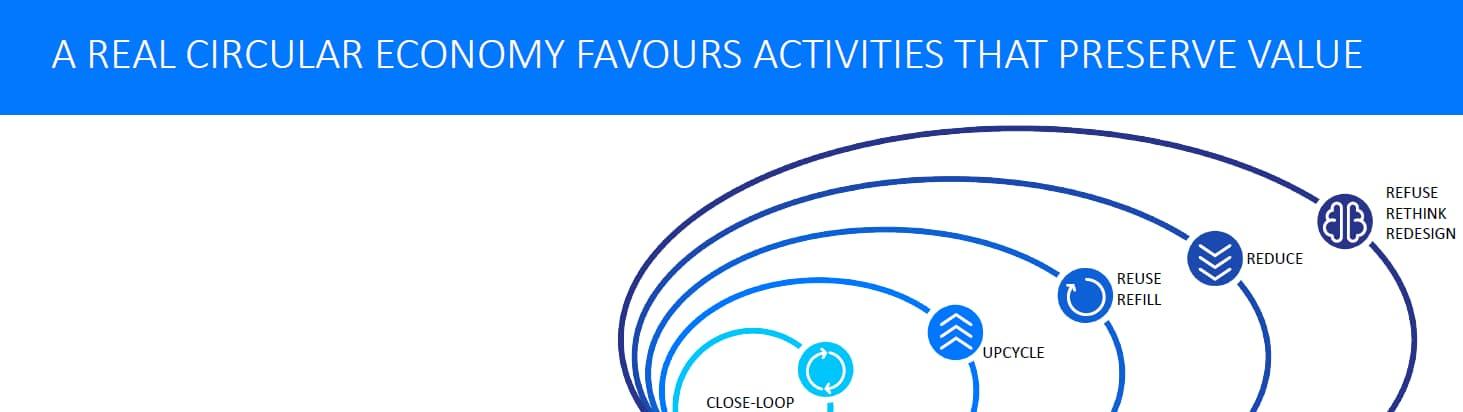

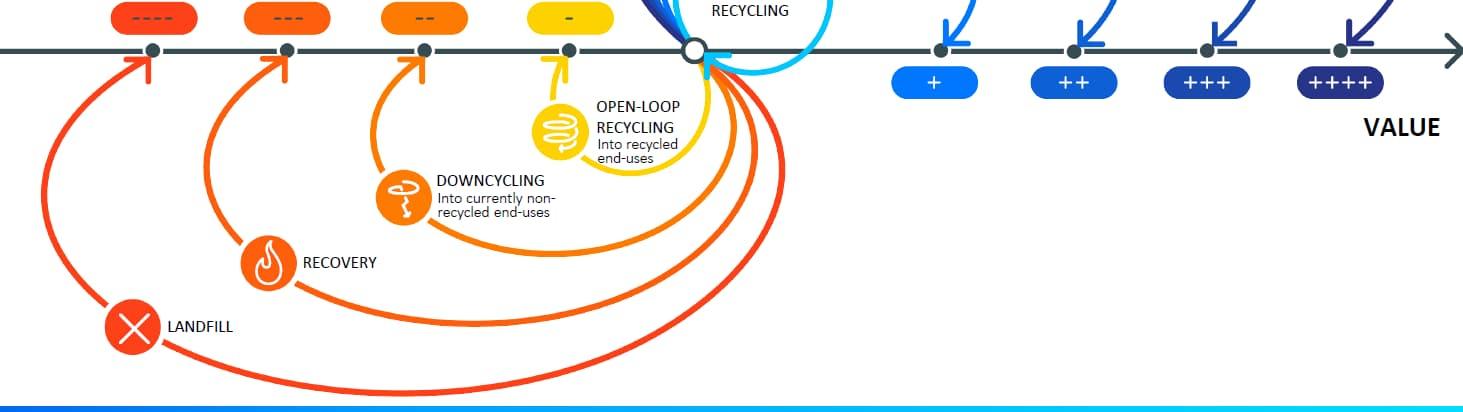

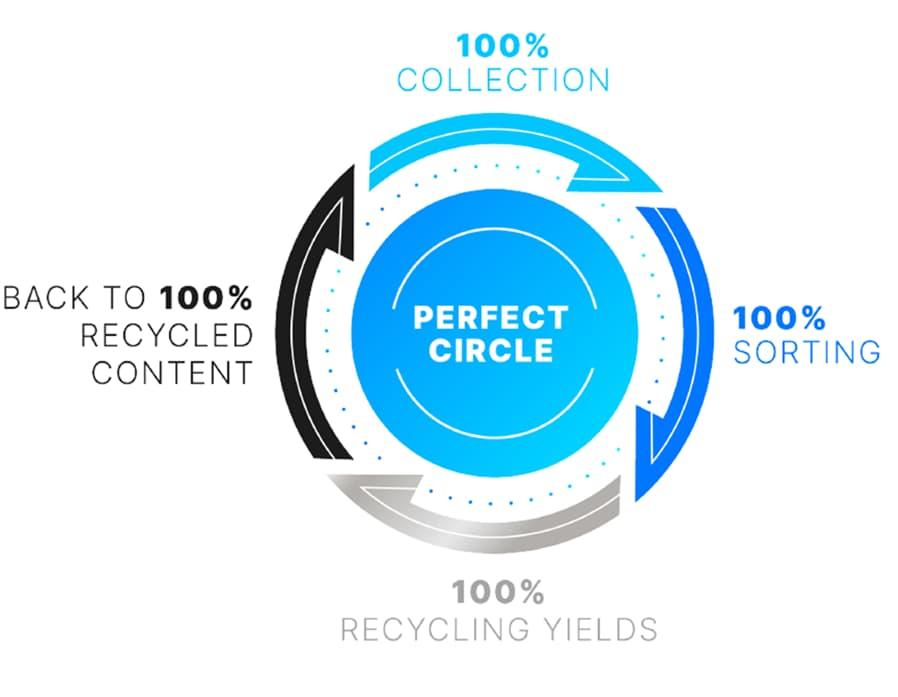

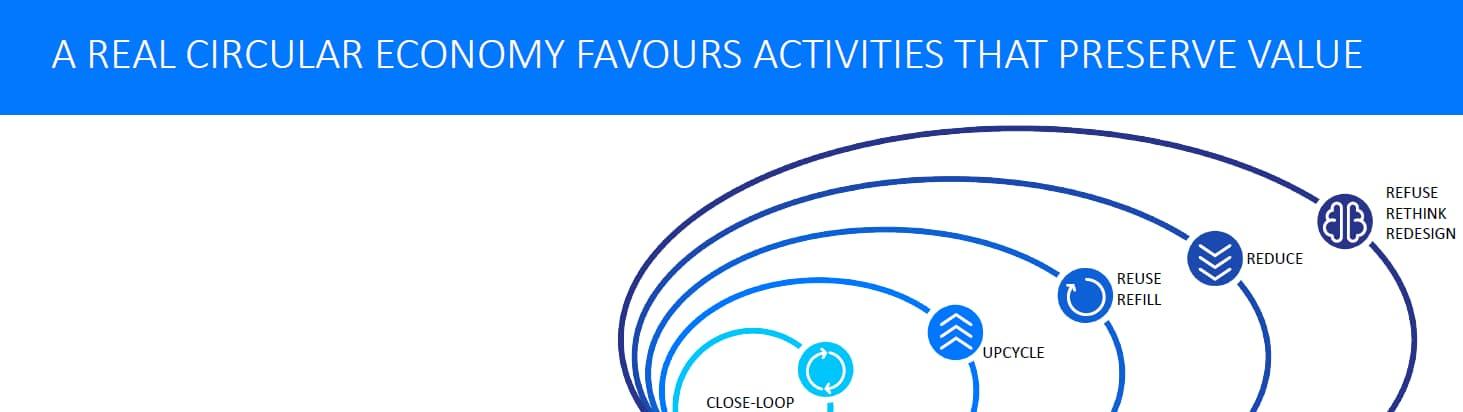

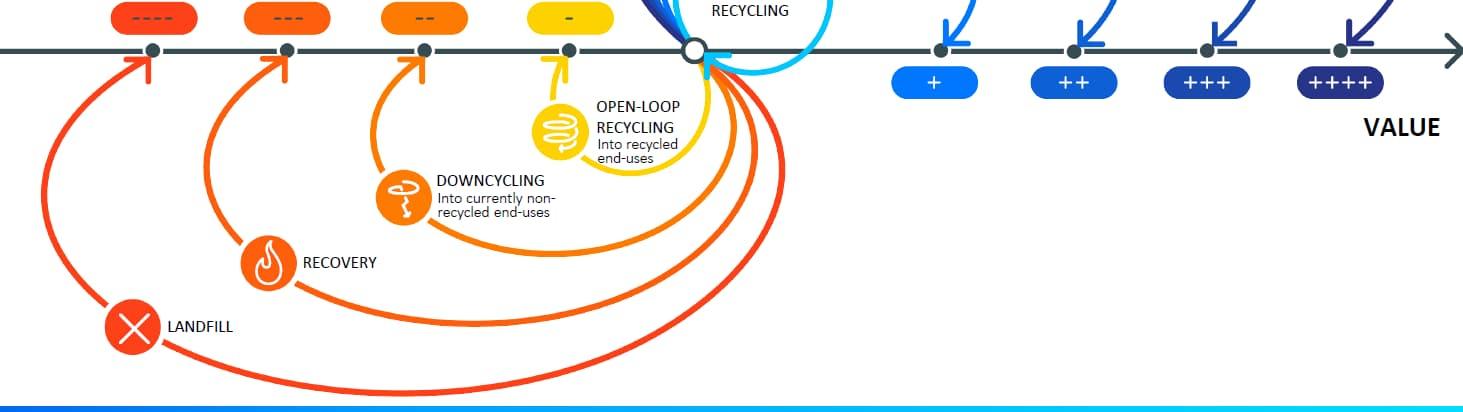

How to create a circular economy (Ball 2021)

Applications for Rolled Products

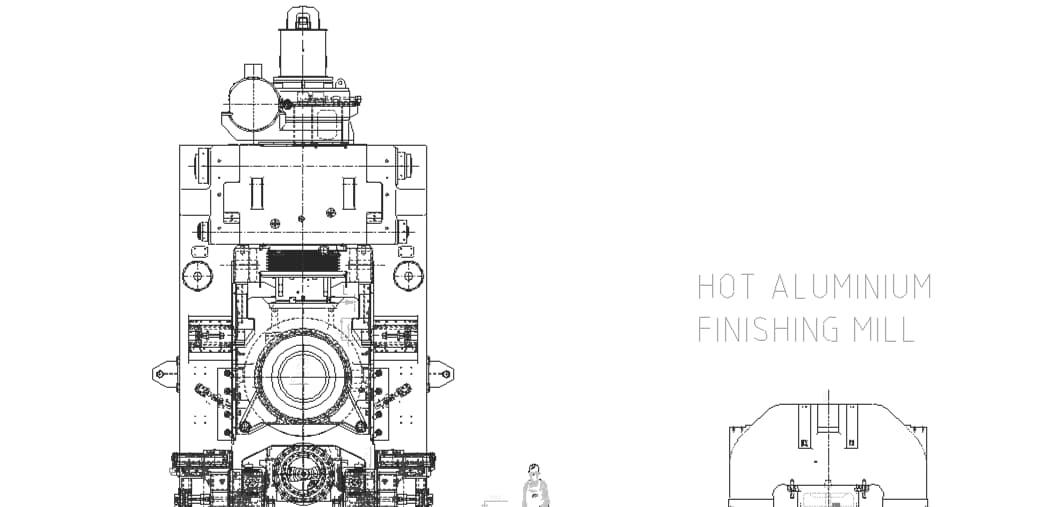

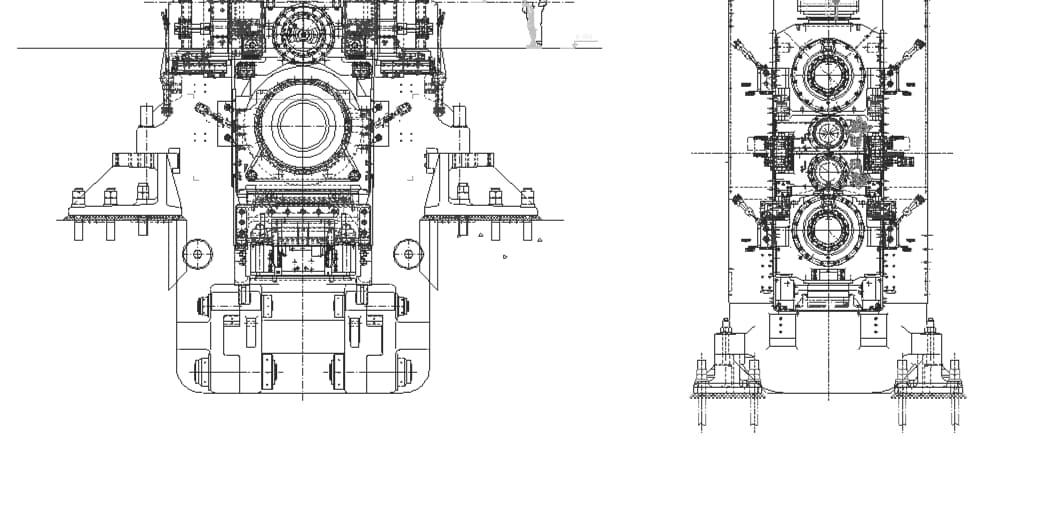

Hot Rolling Mill

Restricted © Primetals Technologies2021-2023. All rights reserved. 12 6 September 2023

Cold Rolling Mill Foil Mill Buildings Automotive Can & can end Aerospace Packaging Ship building Transportation Foil & sheet

Applications for Rolled Products

Foil & Packaging

• £38bn economy in Europe

• UK is the biggest European consumer

• Average UK home uses 144m of foil and 112 foil tray each year

Battery Foil

• Announced UK giggafactories

• Currently foil would need to be imported

• Average Li ion battery cell is 15% aluminum

Beverage Cans

• 12 Bn used in the UK each year (600 per home)

• 40kg waste can per home per year

• Most can stock is imported into the UK

Restricted © Primetals Technologies2021-2023. All rights reserved. 13 6 September 2023

Aluminium Alloys & Typical Uses

Alloying Element AA Properties

None 1xxx Low strength, good formability, weldability & corrosion resistance. High electrical and thermal conductivity.

Copper 2xxx Heat treatable, high strength, non-weldable, poor corrosion resistance.

Manganese 3xxx Medium strength, work hardening. Good weldability, formability and corrosion resistance.

Silicon 4xxx Low melting point, work hardening.

Magnesium 5xxx High strength, work hardening. Good weldability, formability and corrosion resistance.

Magnesium +Silicon 6xxx Heat treatable, medium strength, good weldability and corrosion resistance.

Zinc 7xxx Heat treatable. Very high strength, non-weldable, poor corrosion resistance, ballistic deterrent.

Special 8xxx

Applications

Foil, lithographic, food, pharmaceutical, conductors, finstock, reflectors.

Aerospace, structural, machine parts.

Can body, foil, structural, building, bottle caps, cookware.

Heat exchangers, clad alloy, construction.

Can lid, Transportation, structural, pressure vessels, cryogenic, chemical.

Transportation, Marine,Automotive, Aerospace, Structural, architectural, beer barrels.

Aerospace, armoured vehicles, cycle frames, sporting goods.

Foil,Aerospace (Lithium).

Restricted © Primetals Technologies2021-2023. All rights reserved. 14 6 September 2023

THANK YOU

Restricted © Primetals Technologies2021-2023. All rights reserved. 15 6 September 2023

UK VEHICLE BATTERY PRODUCTION -WHERE IS THE FOIL COMING FROM?

Restricted © Primetals Technologies2021-2023. All rights reserved. 16 6 September 2023

CRU

Paul Williams

Discussion of rolled products market

Primetals: 50 years’ celebrations

Paul Williams

Head of Aluminium

Elijah Santos

Battery metals analyst, Exawatt (CRU)

Simon Large Analyst, Aluminium

September 2023

CRU Aluminum: Expertise across three continents

CRU International Limited London | Sydney | Tokyo | Beijing | Shanghai | Singapore | Mumbai | New York | Pittsburgh | Sao Paulo | Santiago Registered in England No.940750. Registered office: Charles House, 108

2

Steve Williamson Research Manager Min Wang Senior Analyst

CRU Aluminium Team

Alexey Pavlov Senior Analyst

Tiantian Zheng Senior Analyst

Guillaume Osouf Head of Prices Development

Ross Strachan Lead Analyst, Primary & Recycled Metal

Deborah Idowu Analyst Ravindra Panwar Research Analyst

Matthew Abrams Analyst Simon Large Analyst

Joseph Cherrez Senior Analyst Zaid Aljanabi Principal Analyst

Aluminium sheet & plate consumption in UK and Ireland

Association data indicates market size of 553kt in 2022

Packaging reflects can sheet (inc. food and other applications – but no foil stock)

3

16% 7% 9% 6% 49% 13%

UK and Ireland sheet and plate market is over 550kt, and will grow in coming years

DATA: EA

ABS Other road transport Other transport B&C Packaging Other industrial sectors

Majority of FRP needs are imported

UK imported 467kt of FRPs in 2022

EU is the major supplier of sheet to the UK

• China has become second largest supplier due to increasing share of can sheet demand

• Turkey, Switzerland and Norway are key suppliers of general purpose FRPs

• Saudi Arabia and S. Africa also supply

4

DATA: CRU, S&P Global 0 100 200 300 400 500 600 2018 2019 2020 2021 2022 EU China Turkey Saudi Arabia Other Europe South Africa Others 000s kt

UK imports all its foil needs

UK imported 109kt of foil (all types) in 2022

DATA: CRU, S&P Global. Note: “Other Asia” includes Armenia and excludes Middle East. “Others” is mainly S. Africa

All foil needs met by imports

• Over half of foil supplied by Europe (54%)

• China remains a key supplier, along with Turkey (16% and 14% respectively)

• Rest a variety of sources

• About half comes in as plain foil, other half is converted foils

5

0 20 40 60 80 100 120 2018 2019 2020 2021 2022 EU+EFTA China Turkey USA Other Asia Others 000s kt

UK imports all its can sheet needs

UK can sheet imports as identified by trade data

Identified aluminium can sheet imports totalled 210kt in 2022

DATA: CRU, S&P Global

EU is the major supplier of can sheet to the UK also

• China increasing player and significant increase in imports from China in 2022.

• 33kt of body and 7kt of end from China

• S. Africa supplies can end sheet, but increased body sheet supply in 2022

6

79% 18%

3% EU China S. Africa

Europe can stock demand falters in 2023 H1, longer term trends intact

Can stock consumption

Growth trends for can markets

Can sheet demand weakens in H1

Rollers reported weak market conditions in H1. This reflected weak beverage markets and inventory adjustments.

Crown reported EU down 5% Q2 y/y on weakness in Greece, Italy and Spain.

Can sheet imports for the UK confirms the weak outcome for Q1 here.

Ball reported weaker shipments in Europe but that reflected the divestment of Russian assets. Kettering plant has opened.

Ardagh reported “resilient” results for Europe.

The market should improve in H2, but persistently high core inflation may dampen can demand further in the short-term.

Medium term prospects remain healthier given shifts to aluminium packaging. More can capacity will come on stream: UK (Ball and Crown), Czech Republic (Crown), and in Italy and Spain (Crown). (Hungary in next year or so).

7 Aluminium Beverage Can Sheet | Market Outlook

-5% 0% 5% 10% 15% Germany UK France Spain Other Western Other Eastern Total Europe 2022 2023 CAGR 2024-2031 % Change 0 200 400 600 800 1,000 1,200 1,400 1,600 1,800 Other Western Other Eastern UK Germany Spain Russia France ‘000t

More beverage can body plants for the UK; 9 up from 7, and one other planned

Key:

Ball Corp plants

Crown plants

Ardagh plants

Canpack plants

• Ball: New can plants in Kettering. UK and Pilsen, Czechia coming on stream as planned in 2023

KetteringPeterborough

• Crown also indicate that Peterborough plant coming on stream in 2023 as planned

• Ardagh plant for Belfast looks to be delayed according to the Irish News

8

Strong medium to longer term trends in European beverage can markets

2-3% CAGR volume growth anticipated over coming years for UK; short-term weakness as inflation bites

Millennials

Favouring cans over other materials

Positive market changes

Increases in packaged drinks

Mixers, waters, wine, coffee etc, - more product launches in cans

Positive substitution trends

Recycling legislation

Good story around sustainability; recyclability, DRS schemes positive?

Switch from glass to can in beer

Switch from PET in soft drinks

Can is winning out against glass;

Plastics backlash gives opportunities for cans

New beverages favour cans

All leading to more can lines coming on stream, including in the UK

Source: CRU Aluminium Can Stock Market Outlook

9

World embarks on BEV transition

Light duty vehicle sales per year, split by powertrain type, million

▪ Markets will move at different rates with different drivers

▪ Battery raw material supply threatens BEV growth

▪ BEV targets can be reached but likely with a smaller global vehicle market

BEV % (RHS) 0% 20% 40% 60% 80% 100% 0 20 40 60 80 100 2015 2020 2025 2030 2035 2040

Combustion

Other Electric Battery Electric

Internal

Hybrid Electric

DATA: CRU May 2023. 10

The global vehicle market shifts to xEVs

Global xEV production by type European xEV Production

0 20 40 60 80 BEV PHEV HEV Million units 0 4 8 12 16 Other Europe UK Million units HEV BEV PHEV 11

BEV= battery electric vehicle; PHEV = plug-in electric vehicle; HEV = hybrid electric vehicle

UK vehicle production recovering slowly post pandemic

UK vehicle production unlikely to get back to pre 2019 levels

Vehicle production to grow with transition to NEVs

• But the growth in NEVs and BEVs especially will advance strongly over next 10 years

• JLR:

• Range Rover electric 2024

• Jaguar EV rebranding 2025

• Further expansion of EV range 20252030

• All models with EV availability 2030

12

DATA: CRU, LMCA -40% -30% -20% -10% 0% 10% 20% 0 200 400 600 800 1,000 1,200 1,400 1,600 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 Car production Commercial vehicle production % change

Global battery demand to surge

Global battery demand by powertrain type

TWh

0 1 2 3 4 5 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 2030 2031 2032 2033 HEV PHEV BEV

13

Battery foil a new application of growth for the aluminium industry

• Aluminium foils act as a substrate on which the cathode active material is placed.

• The Aluminium also provides a uniform path for the charges to into the cathode when a complete circuit is formed with the anode.

• Aluminium foil is also consumed as a pouch casing instead of a rigid case (but has a 25% share). As prismatic cells increase the share could fall as it uses rigid casing. However, rigid casings will be aluminium, mostly sheet.

• Intensities can vary greatly depending on chemistry and battery type and power. Gross weight of foil per average battery can range from 0.11 – 0.16 kg/kWh or 7- 13 kg/vehicle

• Sodium ion cells (lower cost new technology but has low range for vehicles) have a higher kg/kWh aluminium foil loading but there are currently no firm plans to mass manufacture this chemistry in the UK

14

Global battery foil demand for xEVs to advance strongly

Global automotive battery Aluminium foil demand

HEV BEV PHEV 15 000's t 0.0 100.0 200.0 300.0 400.0 500.0 600.0 700.0 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 2030 2031 2032 2033 High case Base case

UK gigafactories about to take off and advance battery capacity

10 20 30 40 50 60 70 80 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 2030 2031 2032 2033 UK battery capacity GWh Tata Group Envision AESC: plant 2 Envision AESC: plant 1 AMTE Power Thurso 16

UK aluminium foil demand for BEVs to advance based on giga factory capacity

UK Aluminium foil demand

• Upside risk from any storage capacity coming in or extra auto giga factory capacity

• Downside risk is that the giga factories operate below capacity

• High case would be if there is no downgauging

0 2 4 6 8 10 12 14

High case

000's t

Base case

17

European foil capacity: Dingsheng emerging as a player

18 0 100 200 300 400 500 600 700 800 900 1,000 2022 2023 2024 2025 Constantia Teich Eurofoil Novelis Dingsheng

Speira Symetal Laminazione Sottile

Lotte Aluminium Others 000s kt/y

Amcor

Granges

Who will produce battery foil in Europe?

European foil mills

Operator Battery foil

Constantia Teich unlikely; focus is packaging foils

Impol Not aware

Eurofoil Possibly

Novelis Unlikely - focus on battery sheet casings

SLIM

Now possible after being acquired by Dingsheng

Amcor no reference to battery foil

Speira Yes - has created a special battery foil HyLectral, Symetal produces automotive heat shields

Carcano Antonio unlikely

Laminazione Sottile produces heat shields

Lotte Aluminium yes

Aludium no

Iberfoil no

Gränges (including Konin)

Alcomet

Yes, looking to develop

Yes, investment announced start of September

Al Invest no

Arconic no

Alupol no

Impexmetal possible as now part of Granges

19

Battery foil projects coming on stream in China

Major battery foil producers in China

North China Aluminium

Chinese rollers increase investment in battery foil projects

The largest battery foil producers in China include Dingsheng New Materials, North China Aluminium, Anhui Zhongji, Nanshan

Aluminium, Henan-base Shenlong Baoding New Material and Xiamen Xiashun.

Jiangyin Xinren Technology added to its existing capacity with 20,000 t/y battery foil, coming on stream as planned in July.

Anhui Zhongji

Dingsheng New Materials

Jiangyin Xinren Technology DATA: CRU

Shenlong Baoding New Material

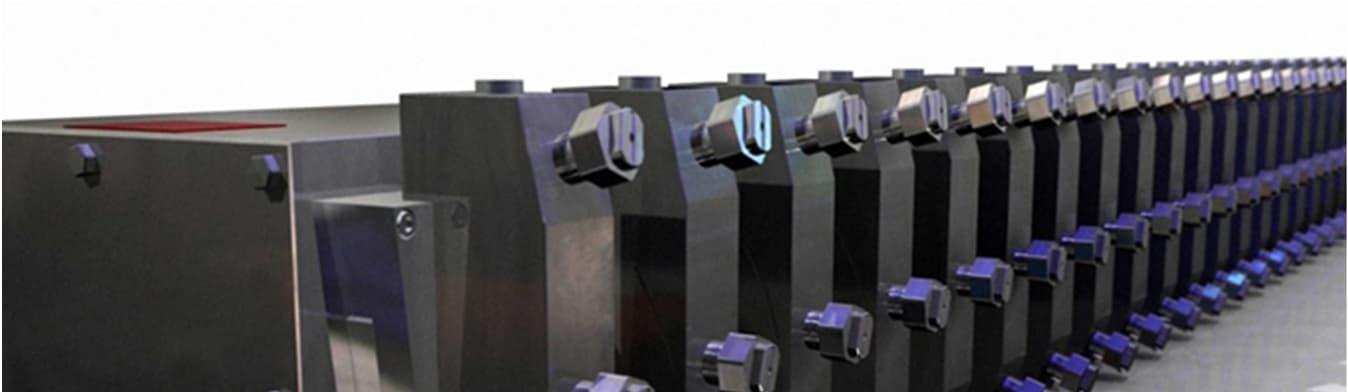

Jiangyin Xinren is investing in a 200,000 t/y battery foil project, 3 foil mills of the new project have been in trials and 8 are being installed. The installation for all 16 foil mills will be completed by the end of this year.

Xiamen Xiashun

Sichuan Wanshun Zhongji is constructing a 130,000 t/y aluminium rolling project, which includes 80,000 t/y battery foil capacity and 50,000 t/y light gauge foil capacity. Some facilities of the projects had been in trials in July 2023. The whole project is expected to come on stream by end of 2023.

20

Dingsheng Hangzhou Five Star Aluminium Rolled Products | Market Outlook | August 2023

Takeaways

Beverage can production will continue to grow in UK, but shortterm weakness.

Demand for battery will grow in UK as gigafactories come on stream and hit capacity. 4 major giga plant projects identified

We think in very long term the advance of solar power will mean huge storage capacity will be needed. This battery foil requirement may eventually swamp auto demand for foil.

21

DATA: CRU

The global vehicle market shifts to BEVs

Batteries also needed for hybrids

0 15 30 45 60 2015 2017 2019 2021 2023 2025 2027 2029 2031 2033 Million units 0 4 8 12 16 2015 2017 2019 2021 2023 2025 2027 2029 2031 2033 Million units

Global BEV production European BEV production 22

EXPECTATIONS FOR THE UK BEVERAGE CAN MARKET (CIRCULAR ECONOMY)

Restricted © Primetals Technologies2021-2023. All rights reserved. 17 6 September 2023

CAN TO COIL TO CAN

EXPECTATIONS OF THE UK BEVERAGE CAN MARKET (CIRCULAR ECONOMY)

Restricted © Primetals Technologies2021-2023. All rights reserved. 18 6 September 2023

• FACTORS DRIVING THE UK CAN MARKET & OPPORTUNITIES FOR UK MANUFACTURE OF ALUMINIUM

• ALUMINIUM RECYCLED CIRCULAR ECONOMY

• PROCESS ROUTE FOR ALUMINUM SHEET PRODUCTION.

• HOT MILL OVERVIEW

• COLD MILL OVERVIEW

• OPPORTUNITIES FOR FOIL MANUFACTURE IN THE UK

• PROCESS ROUTE FOR FOIL MANUFACTURE

• SUMMARY

Restricted © Primetals Technologies2021-2023. All rights reserved. 6 September 2023 19 Contents

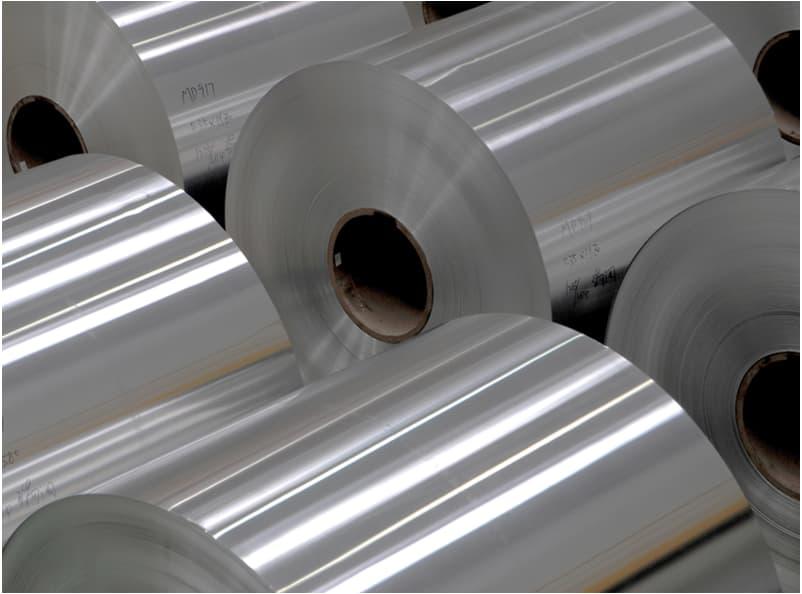

Can Production

• Global trend from plastics to cans increasing the demand for aluminium canned products

• Global push to reduce CO2 emissions.

• Primary aluminium CO2 emissions range from 3-18 tonnes CO2 per tonne

• 90% reduction in CO2 emissions recycled vs primary aluminium

• 60 day can to can is now achievable

• Rolling process is the same from primary or recycled

• UK scrap currently exported for use in flat products

• UK can body, lid and tab currently imported

• Coil transportation estimated at 0.45kg, CO2/mile

• 2 USAprojects started for green can production

• Numerous countries exploring the can circular economy

68% 82%

OF ALL ALUMINIUM PACKAGING SOLD IN THE UK WAS RECYCLED IN 2021. (AN INCREASE OF 3% FROM 2020)

OF ALL ALUMINIUM DRINKS CANS SOLD IN THE UK WERE RECYCLED IN 2021.

Restricted © Primetals Technologies2021-2023. All rights reserved. 20 6 September 2023

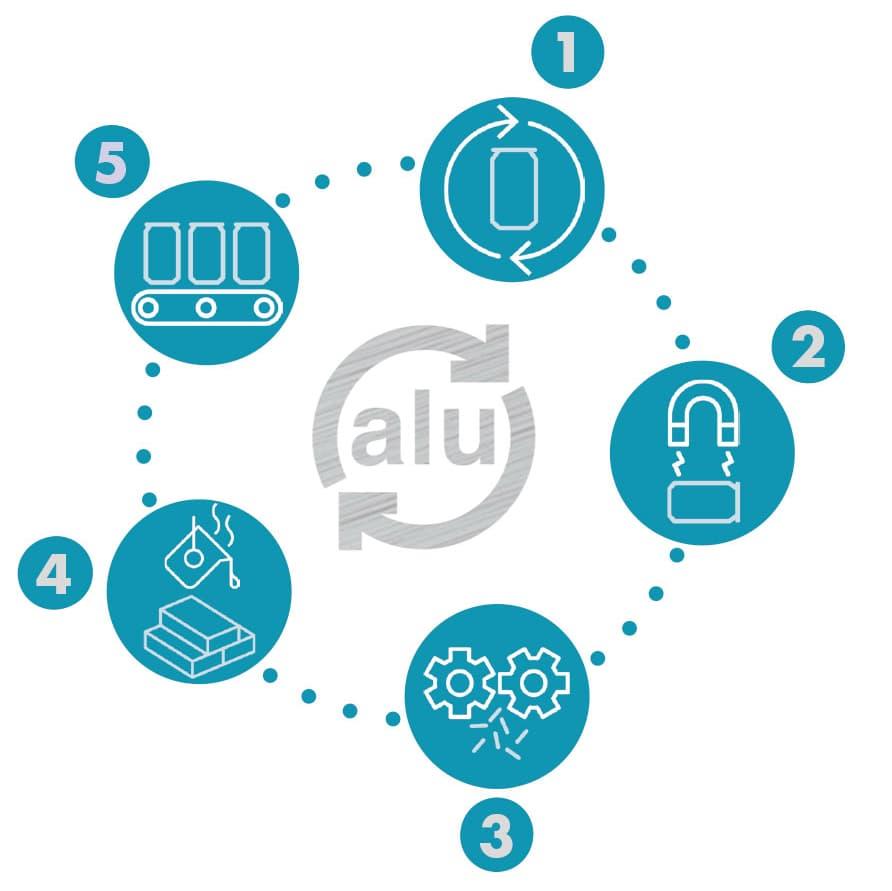

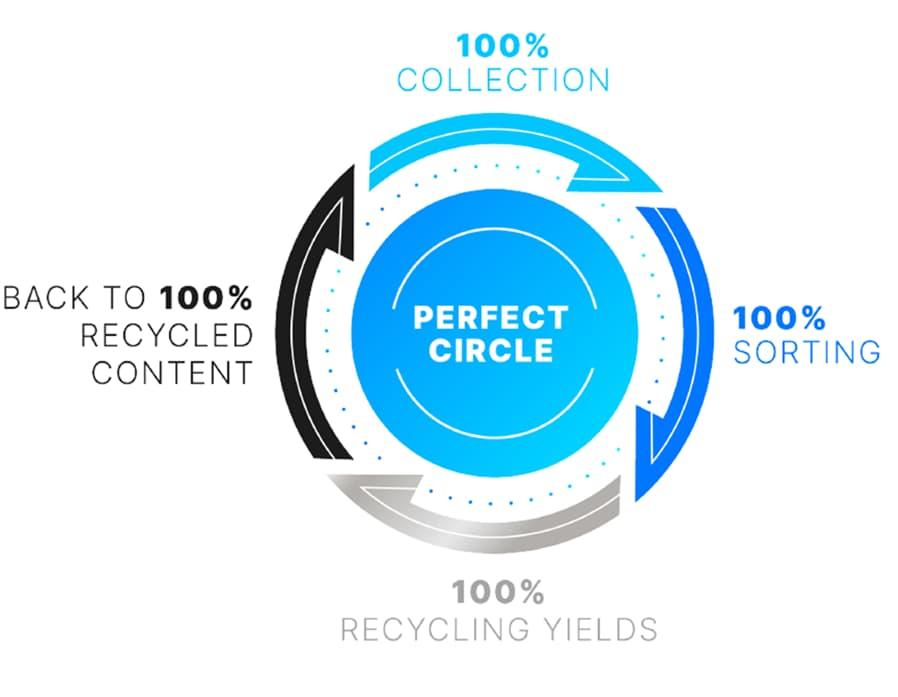

Can to coil to can

Aluminium Recycled Circular Economy (ALUPRO)

Finally, the sheets are converted back into packaging products ready to be filled with your favouritefood or drinks.

The clean, silvery material is then melted in a furnace at over 650oC before being cast into ingots, which are then sent to rolling mills that transform them into sheets of metal suitable for the final application (e.g. foil containers or beverage cans).

Aluminiumis widely collected for recycling in the UK by local authorities because it is very valuable; in fact, aluminiumpackaging is the most valuable material in your recycling bin!

Once collected aluminiumis easily separated from packaging made of other materials using an Eddy Current Separator, which uses an electrical current to ‘throw’ items made of aluminiuminto a different container. These are commonly installed throughout sorting centresin the UK. The separated aluminiumis then sent to a recycling plant.

At the recycling plant, the sorted aluminiumpackaging is shredded into small pieces, before being passed through an oven that burns off any paint or lacquer on the packaging.

Restricted © Primetals Technologies2021-2023. All rights reserved.

Can to coil to can

6 September 2023 21

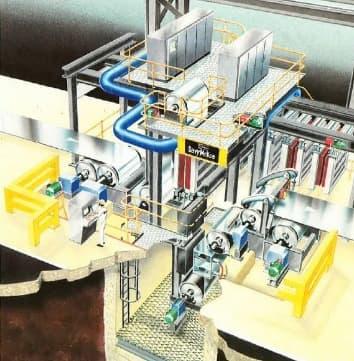

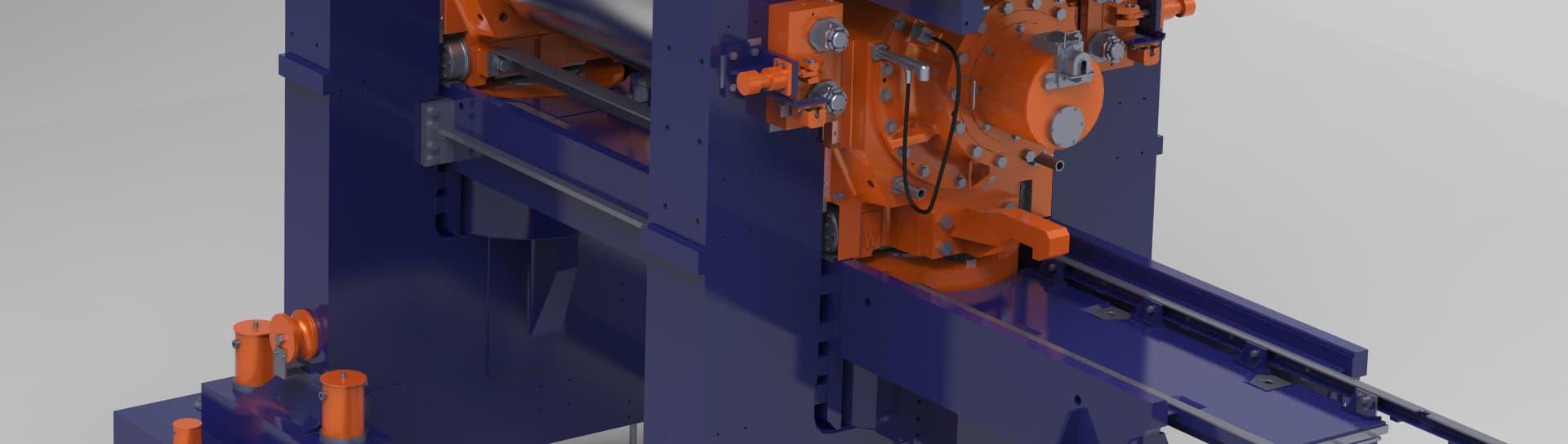

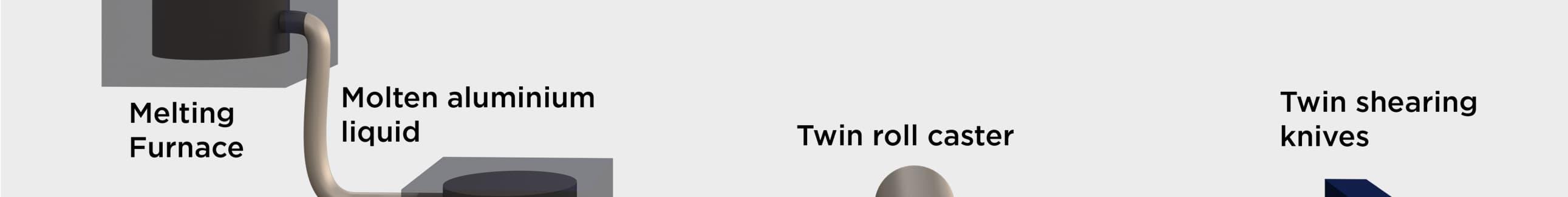

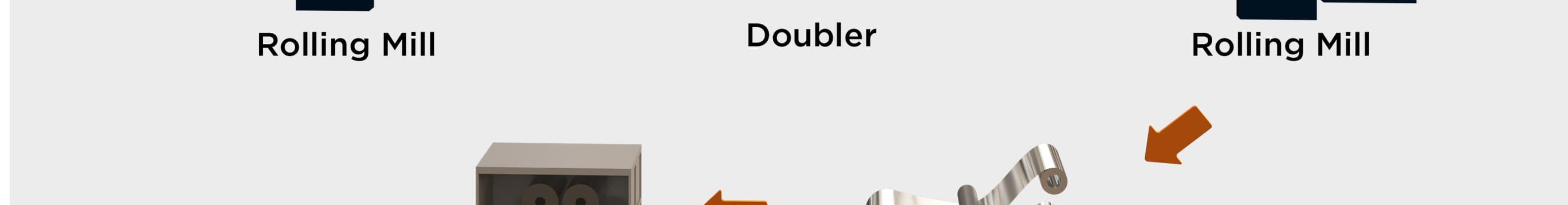

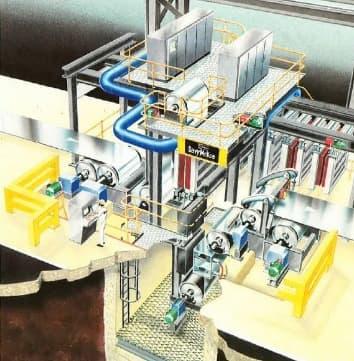

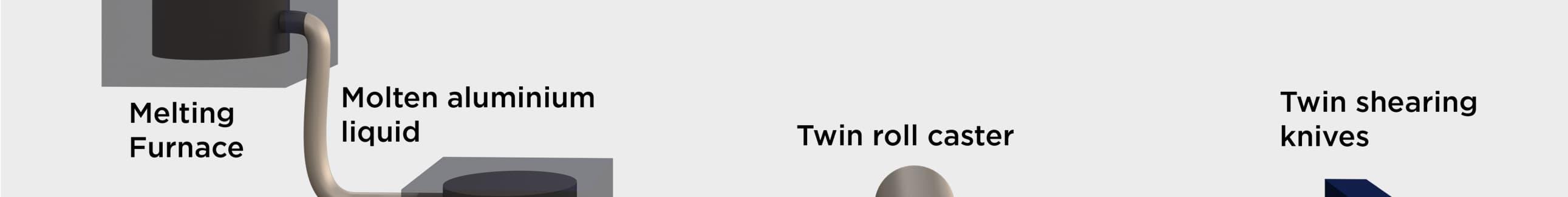

Process Overview Typical Process Route from Casting to Final Product

Restricted © Primetals Technologies2021-2023. All rights reserved.

Can to coil to can Light Cold Mill 3-Stand Finish Mill Slitters Packaging and Shipping Distribution Clean coat cure shears Heavy Cold Mill Filtration Caster Ingot Preheat Furnaces Ingot Scalper Induction Furnace Scrap Heater Process Scrap Purchased Scrap Purchased Pig Hold Furnace Melt Furnace Ingot Scalper 3-Stand Tandem Mill The Customer 6 September 2023 22

Aluminium Hot Mills Throughputs and Products

Restricted © Primetals Technologies2021-2023. All rights reserved. 23 6 September 2023 Aluminium Hot Band Production Tonnes / annum Products Alloys Widths mm Thickness mm Thin Slab Belt Caster + Hot Tandem Mill <120,000 Coil# Non Homogenised 800-1600 1.5 -4 Reversing Plate Mill <120,000 Plate All inc. H.T. 800-4350 10+ Single Stand, Twin Coiler <200,000 Coil & Plate All inc. H.T. 800-2650 3+ Rougher mill and Twin Coiler Finishing Mill <400,000 Coil & Plate All inc. H.T. 800-4350 2.5+ Rougher(s) and Hot Tandem Finishing Mill (3-5 stands) <900,000 Coil & Plate All inc. H.T. 800-3000 1.8+

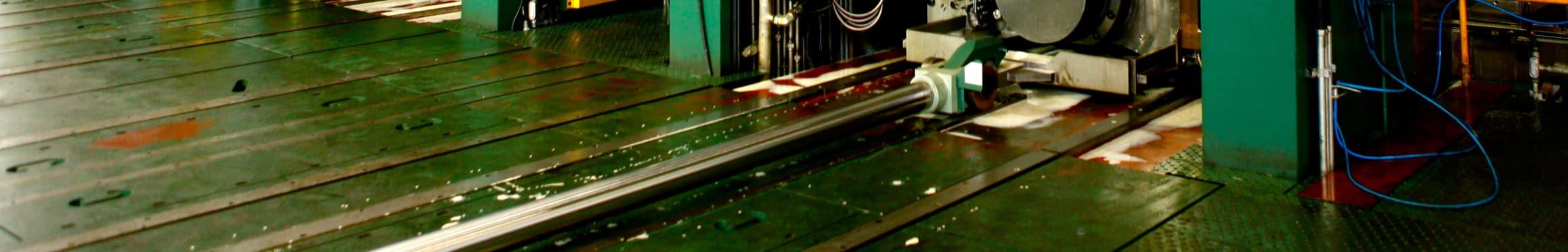

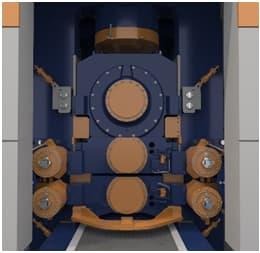

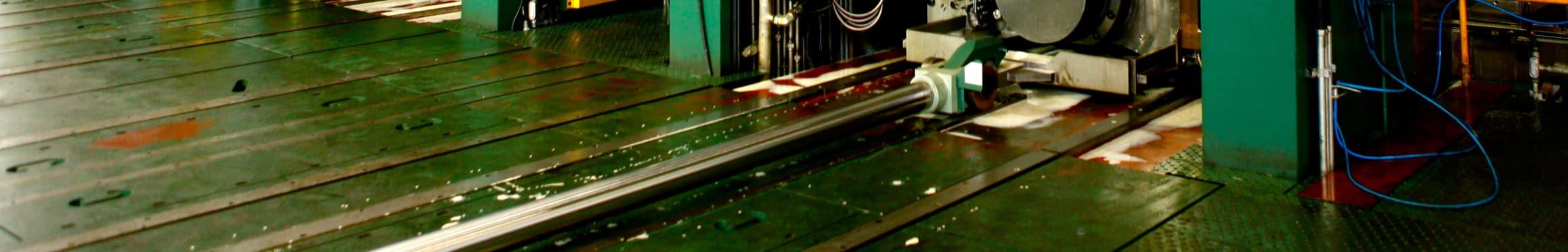

Can to coil to can Slab Roughing mill (reversing) Finishining mill (tandem mill) Coiler

Process Overview Hot Rolling of Aluminium Can body stock

• Hot rolling generally takes place with the workpiece temperature in the 350oC temperature range.

• A large number of passes at the roughing mill.

• The material is reduced in thickness from a slab at typically 450 to 600mm thick to a plate at some intermediate thickness

• Transfer bar (at around 20mm) sent to finishing mill.

• One pass through the 4 stand finishing tandem mill.

• Coiling takes place around 350oC –material recrystalisesin the coil ready for cold rolling. Coiling thickness is around 1.8mm.

Restricted © Primetals Technologies2021-2023. All rights reserved. 24 6 September 2023

Can to coil to can

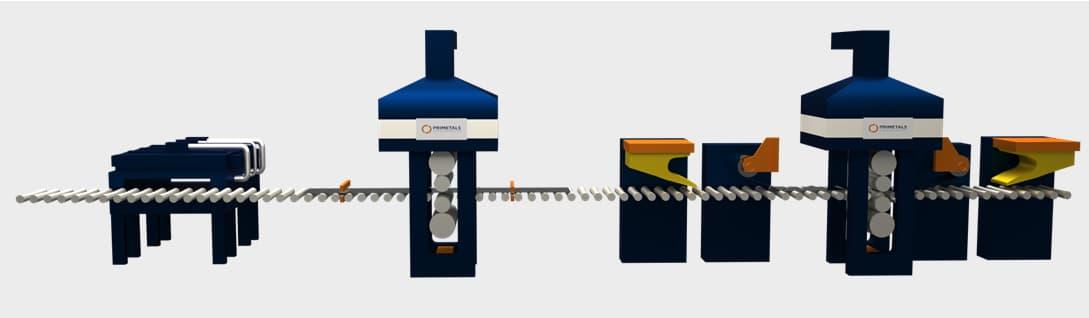

AluminiumHot Mills Key Features & USP’s

Features

• Fully hydraulic vertical edger

• Bottom mounted double acting roll load cylinders on roughing & plate mills

• ISV spray bars with PWM*

• Mill Stability Control (MSD) actuators

• Fully hydraulic shears**

• Minimise plate and transfer bar camber

• No risk of equipment damage / mill downtime

Benefits

• Up to 2% coil yield improvement and reduced side guide wear

• Reduced refusals and increased production

Advantages

• Reduced edge cracking on 5XXX series and removal of “fishtail” ends

• Optimum pass line adjustment of bottom rolls

• High reliability and dirt tolerant valve for effective roll thermal profile / strip profile control

• Lower transfer bar profile required (lower thickness deviation across width) and easily maintained equipment

• Easier treading at finishing mill, reduced plate wedge & reduced maintenance

• Increased production

Restricted © Primetals Technologies2021-2023. All rights reserved. 25 6 September 2023

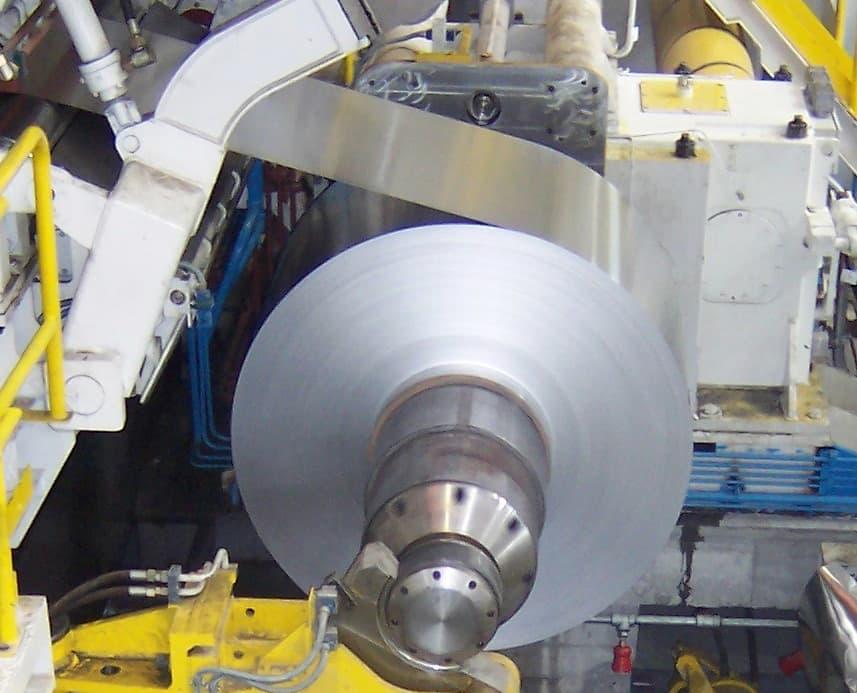

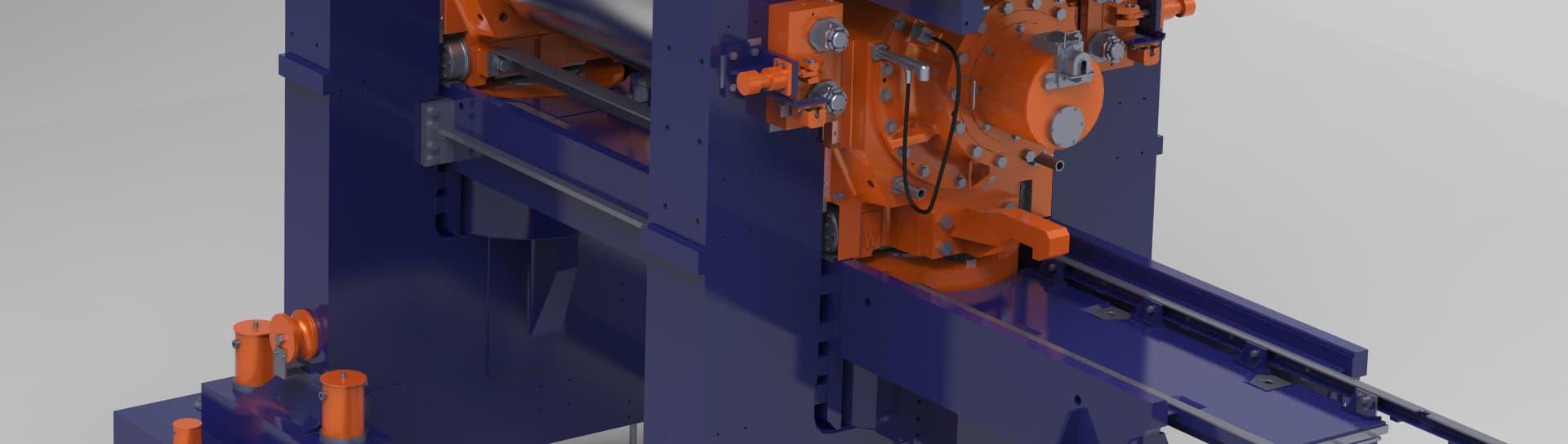

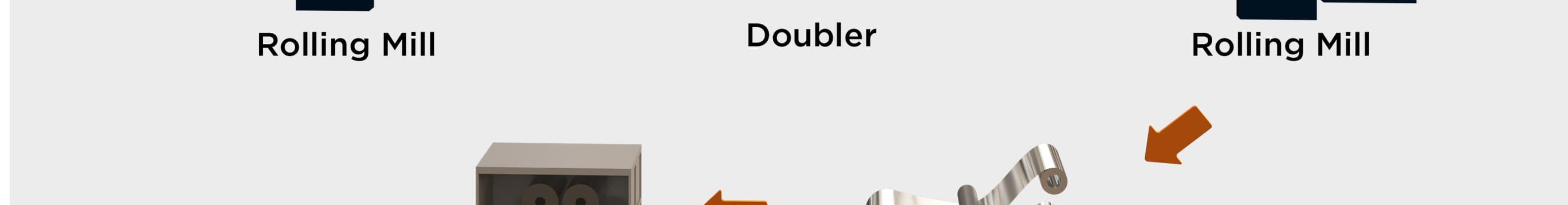

Can to coil to can

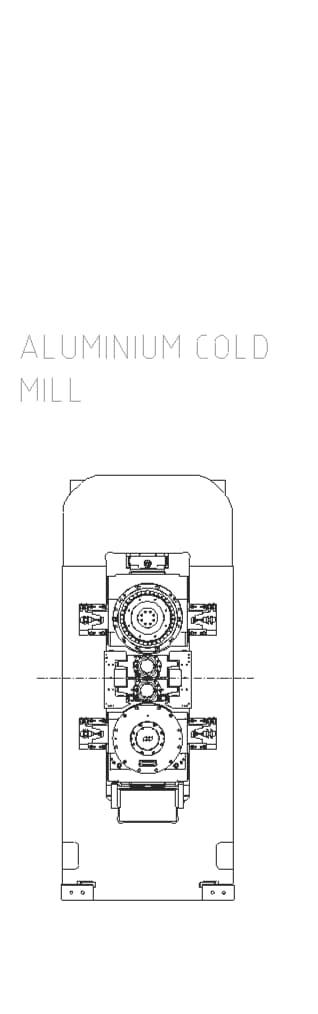

AluminiumCold Mills

Cold Rolling Mills

• Single Stand

• Tandem Mills

• Thin Strip Mills

Foil Rolling Mills

• Roughing Mills

• Intermediate Mills

• Finishing Mills

• Universal Mills

• Bright Finish Mills

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 26 Can to coil to can

Aluminium

Cold Mills Throughputs & Mill Types

Restricted © Primetals Technologies2021-2023. All rights reserved. 27 6 September 2023 Alu Cold Band Production Tonnes / annum ProductAlloysWidths mm Thickness mm Foil Mill ≤12,000 Coil All inc. H.T. 8002000 0.07 –0.006 Thin Strip Mill ≤30,000 Coil All inc. H.T. 8002000 2.5 –0.07 Single Stand Cold Mill ≤200,000Coil All inc. H.T. 8003000 10 –0.1 Tandem Cold Mill (2 stand) ≤300,000Coil All inc. H.T. 8003000 10 –0.1 Tandem Cold Mill (3 stand) ≤500,000Coil All inc. H.T. 8003000 10 –0.1

Can to coil to can 4 Stand FinishingMill

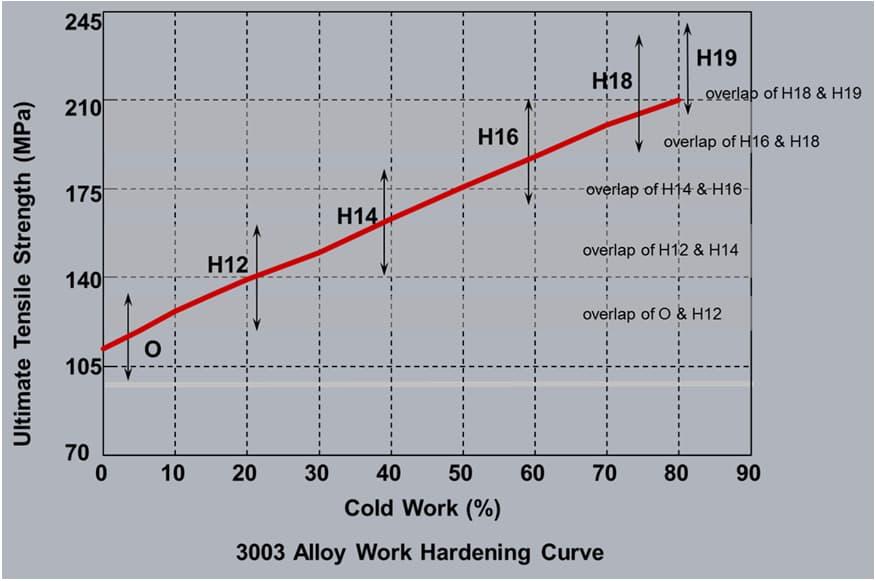

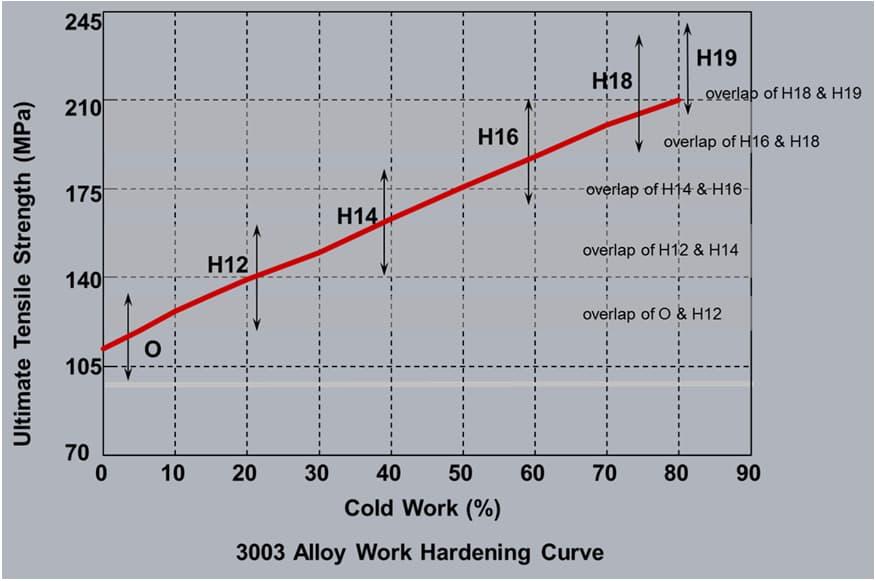

Cold Rolling Process Overview

• The process after hot rolling and before foil rolling.

• Strip entry temperature generally from ambient to 100 to 150OC. In any case less than 0.3xTm (where Tm is absolute melting temperature).

• Enables better dimensional control and surface finish than can be obtained in hot rolling.

• Generally in open gap.

• Material work hardens as successive passes are rolled.

• Depending on final temper, total reduction is typically 80 to mid 90% level.

• The amount of cold work imparted goes towards defining properties such as the amount of work hardening and texture (earing).

Alloy 3003

work hardening curve

Restricted © Primetals Technologies2021-2023. All rights reserved. 28 6 September 2023

to coil to can

Can

Example of earing in cans

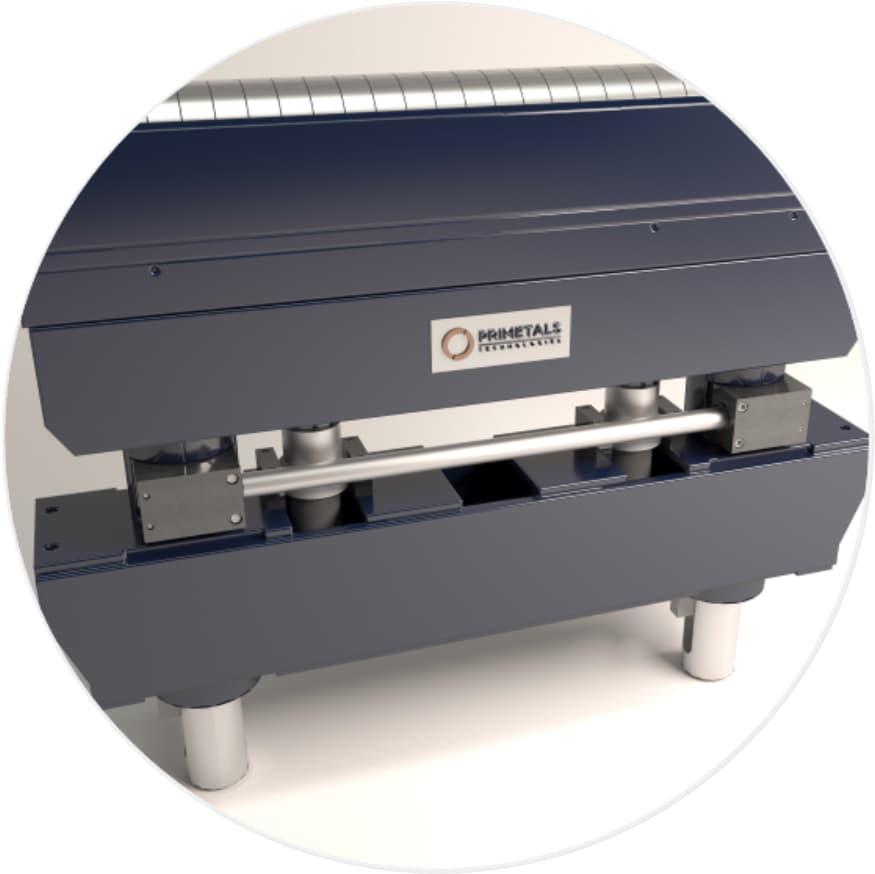

Aluminium Cold Mills

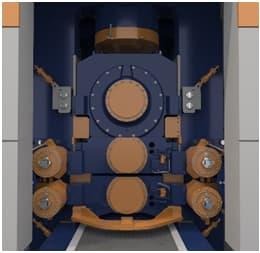

Four High

• Max rolling width 2400mm

• All alloy production

• Single & Tandem mill solution

• Smaller operational window capability than 6hi

• Multiple work roll cambers required

• Works with shape control actuators such as VC roll

Six High

• The ideal mill (Flexibility, control)

• Mid to wide products (up to 3000mm wide)

• Broad product mix (capable of rolling all alloy grades)

• Single & Tandem mill solution

• Cylindrical roll grinds for all rolls

• Best solution for high quality surface finish products

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 29 Can to coil to can

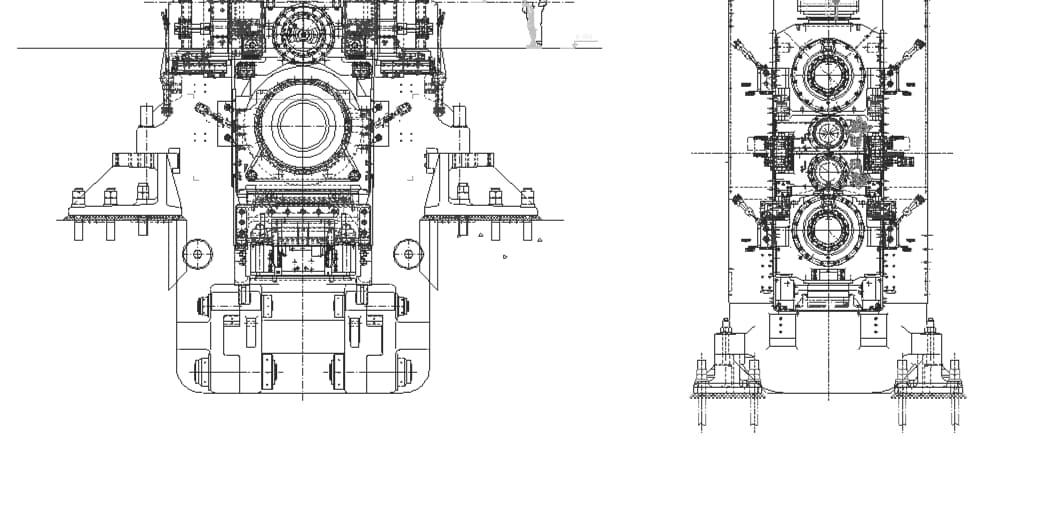

Aluminium Cold Mills UACJ #2 Case study

Milestones

Order Placed March2017

First Coil April 2019

Finished Product

Alloys 1000, 3000, 5000 & 8000

Strip Thickness 0.15-8.00 mm

Results

• The most powerful mill in operation -at point of commissioning

• Rapid design and installation timescale -First coil achieved 25months after contract signing

• High Throughput -One week after the first coil the mill achieved a rolling speed of 2000 m/min @ 0.23mm

• Excellent product quality and shape control -across complete strip width and full range of alloys

Restricted © Primetals Technologies2021-2023. All rights reserved. 30 6 September 2023

Can to coil to can

2500

W.R. Ø 510/470 mm W.R. face width 2400 mm I.M.R Ø 640/600 mm I.M.R face width 2365mm B.U.R. Ø 1460/1280 mm B.U.R. face width 2400 mm Speed LG 0/404/983 m/min Speed HG 0/919/2000 m/min

StripWidth 1000-2250 mm Coil Diameter Up to

mm Mill-stand EquipmentData

Power 9000 kW

AluminiumCold Mills Key Features & USP’s

Features

• Parallel ground Work Rolls (UCM)*

• E block roll bending**

• ISV spray bars with PW***

• Vibration monitoring

Advantages

• Even surface contact during rolling,

• Independent +ve& -vebend rams remove risk of deadband

• High reliability and dirt tolerant valve for effective roll thermal profile / strip flatness control

• Equipment installed to detect chatter and prevents strip breaks Benefits

• Product quality, simple maintenance procedures

• Gauge & Flatness quality, reduces risk of strip breaks

• Improves strip flatness

• Improved productivity

Restricted © Primetals Technologies2021-2023. All rights reserved. 31 6 September 2023

Can to coil to can

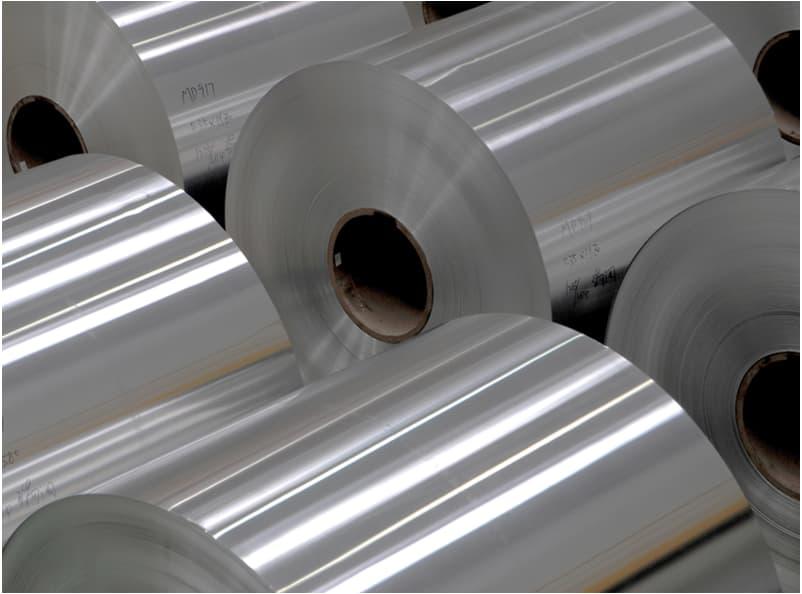

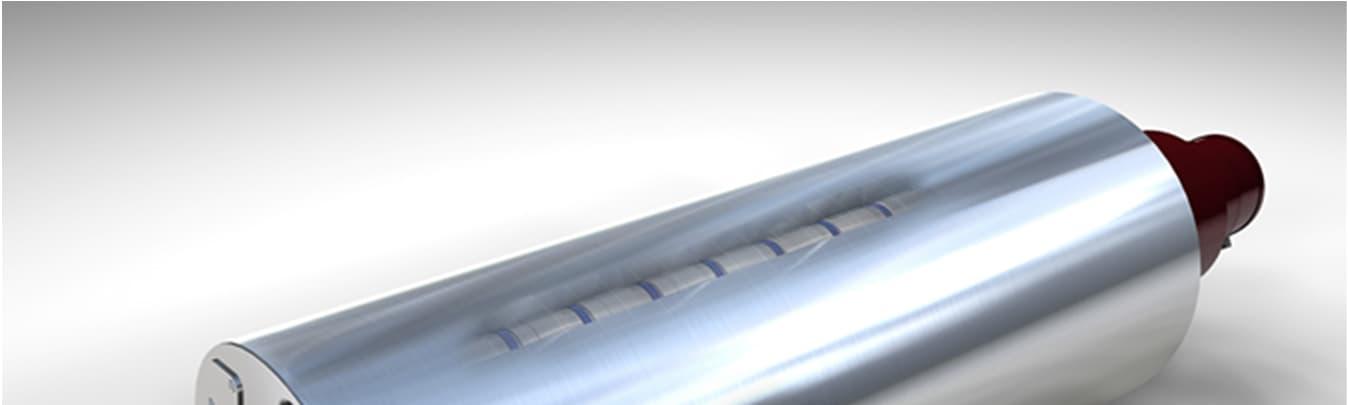

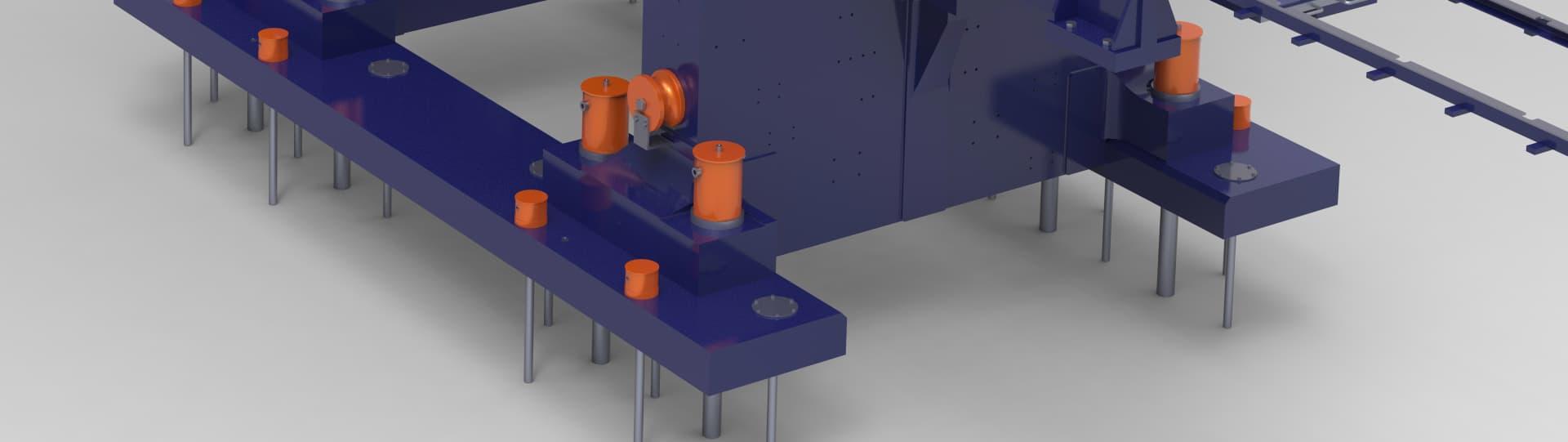

COIL TO FOIL

Restricted © Primetals Technologies2021-2023. All rights reserved.

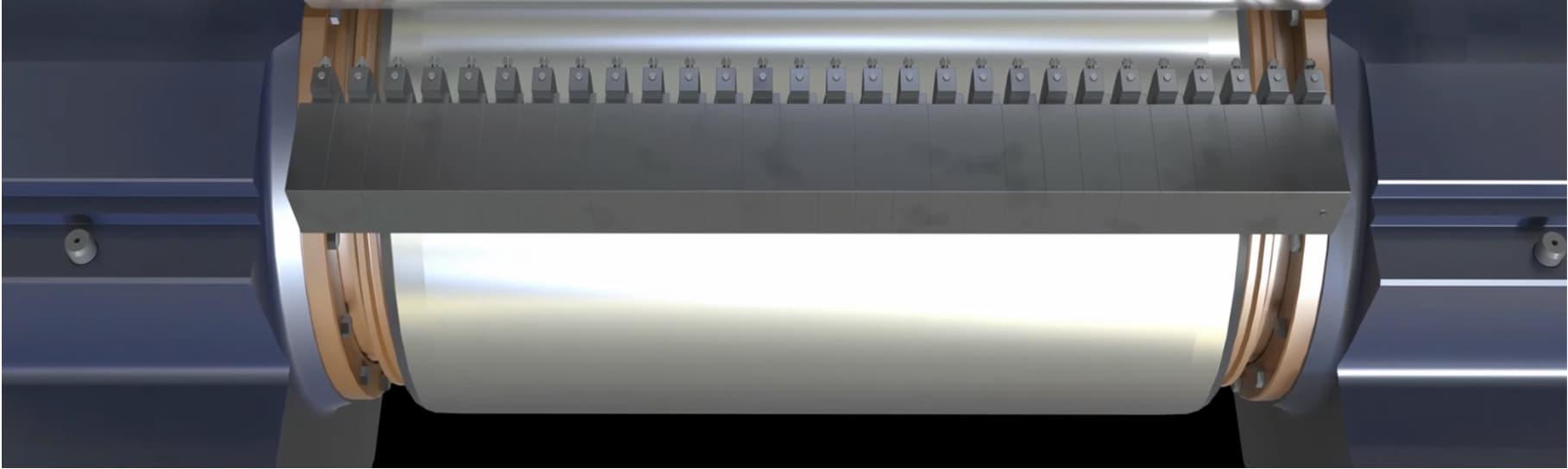

Process Overview What is Foil?

• Ultra thin gauge aluminium.

• Commonly down to 6 microns (human hair is 60 to 80 microns).

• Heavier gauge foil at some tens of microns for finstock(radiators & heat exchangers) and ready meal containers.

• Housefoil-typically 10 to 18 microns –or 20 to 25 microns for heavy duty grade.

• Some specialist applications such as capacitor foil go to 6 microns.

• Battery foils typically around 8-10 microns

• Closed gap rolling

• Thinnest gauges rolled as a double web. (dull side and shiny side)

Restricted © Primetals Technologies2021-2023. All rights reserved.

Coil to foil 6 September 2023 33

Aluminium Foil UK

• Globally foil has changed from commodity to premium product due to battery foil demands and production quality

• China dominates the global production of foil and has maximised the battery foil opportunity.

-Chinese market estimated at 400 running foil mills

-Average production from 3 mills is 1000T/month

-Over 150 new foil mills in progress in the Chinese market

• Some growth in India, Europe and USA

• All UK foil is currently imported

• Foil plants are a comparatively low investment and low operational costs.

Restricted © Primetals Technologies2021-2023. All rights reserved. 34 6 September 2023

Coil to foil

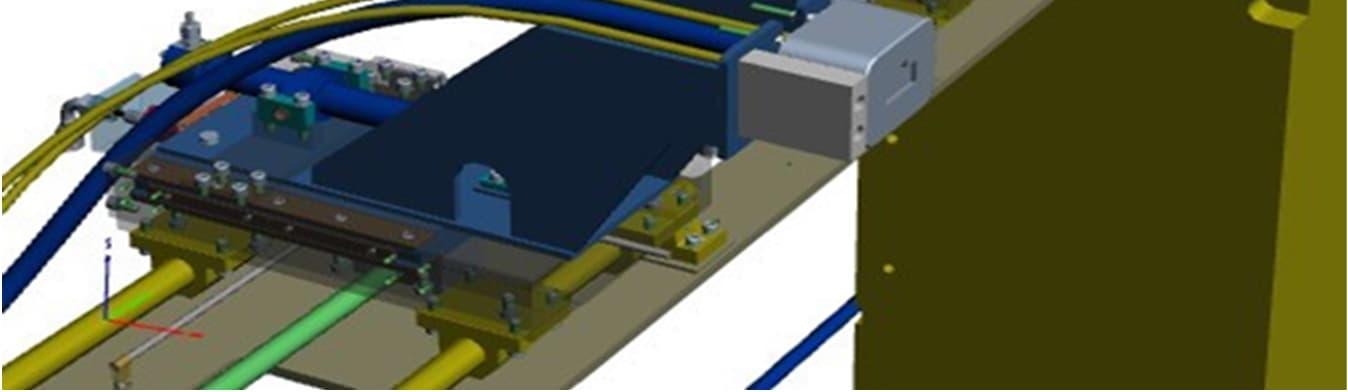

Aluminium Feed Stock for Foil Process Overview

Coil to foil 6 September 2023 35

Coil to foil 6 September 2023 36

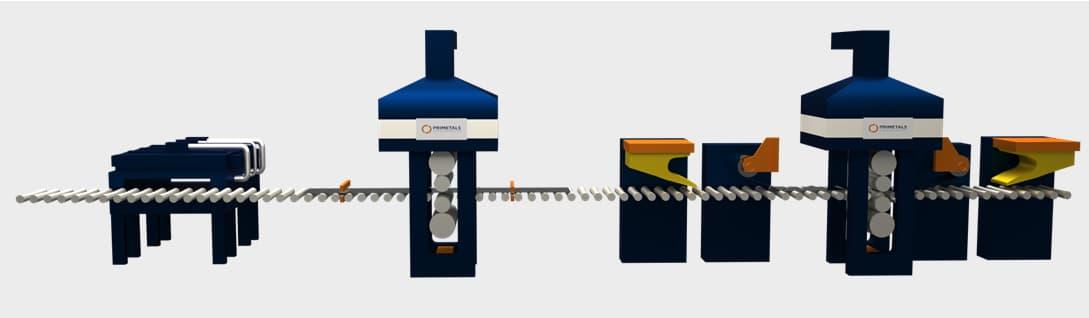

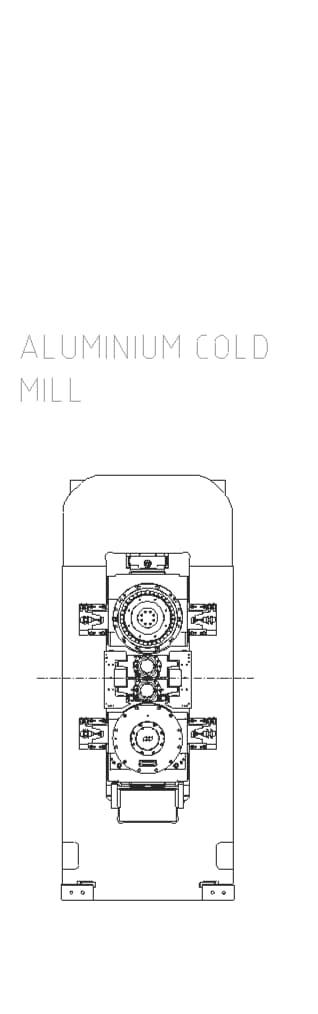

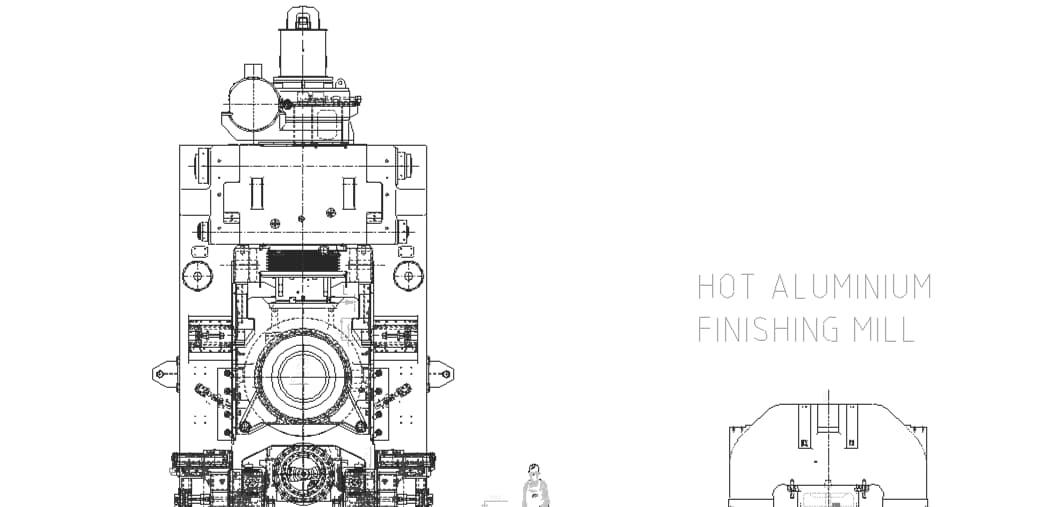

Process Overview Mill Size Comparison

Restricted © Primetals Technologies2021-2023. All rights reserved. Page 37 6 September 2023

Coil to foil 5m Wide Plate Mill NELA Hot Alu Finishing Mill Chinalco Southwest Alu Cold MillShenhuo Int Foil Mill 2x10,000kW 6,000kW 5,000kW 2x600kW 11,000 tonnes 3,500 tonnes 2,260 tonnes 800 tonnes

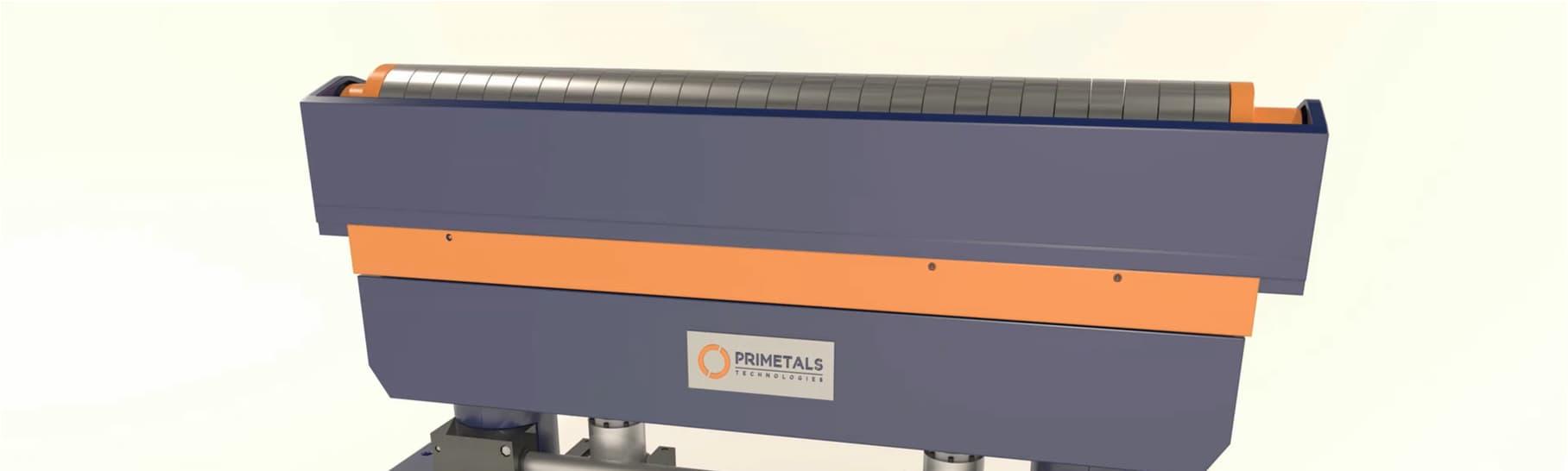

AluminiumFoil Mills Key Features & USP’s

Features

• Rolling speeds of 2,000 m/min

• Product widths of > 2,000 mm

• Final thickness of 0.0055 mm (5.5 microns)

•ABSMRoll & ISV Spray flatness control

• High performance automation system

Benefits

• High production rates

• Flexible production

• Tight tolerances for strip thickness and flatness

• Low costs operation, maintenance, and minimum downtimes

Advantages

• Highly reliable Shape and flatness control

• High yield production with limited waste foil

• Battery foil tolerances achievable

Restricted © Primetals Technologies2021-2023. All rights reserved. 38 6 September 2023

Coil to foil

Expectations for the UK Flat Rolled Circular Economy

Summary

• Significant opportunity and justification to peruse a circular economy for UK can production

• The growth of UK battery production creates a increasing demand for battery foil

• Importing flat rolled aluminiuminto the UK will continue but is not a green solution

• As UK industry expands again we hope that the aluminiummarket will follow this trend

Restricted © Primetals Technologies2021-2023. All rights reserved. Page 39

6 September 2023

THANK YOU

Restricted © Primetals Technologies2021-2023. All rights reserved. 40 6 September 2023

MAXIMISING PRODUCTIVITY: NEW V OLD EQUIPMENT

Panel Discussion

Restricted © Primetals Technologies2021-2023. All rights reserved. 41 6 September 2023

MAXIMISING PRODUCTIVITY: NEW V OLD EQUIPMENT

Restricted © Primetals Technologies2021-2023. All rights reserved. 42 6 September 2023

Panel Discussion

Jan Lukaszewski Technical Manager ALFED Michael Brammer Director Primetals Technologies David Parkin Primetals Technologies Grant Shoebridge Head of Downstream Primetals Technologies

Moderator

Panel

ENSURING PRODUCT QUALITY THROUGH CLASS LEADING FLATNESS & CONTROL

Rhys Verrinder

Primetals Technologies

Restricted © Primetals Technologies2021-2023. All rights reserved.

Overview

• What is meant by flatness control

Instrumentation

• What is available to measure on-line flatness

Actuators

• What we can use to control flatness

Summary

• A brief overview of our webinar

Restricted © Primetals Technologies2021-2023. All rights reserved. 44 6 September 2023

Agenda

What is Flatness

Flatness Definition

Center Waves

• Strip center is longer

• Strip edges are shoter

I-Unit Definition

• The results are relatively small values.

CenterWaves

Edge Waves

• Strip center is shorter

• Strip edges are longer.

• For better handling, the I-Units was introduced:

• 1 I-Unit = 10μm / m

• 1 I-Unit = 10-5 * ΔL /

Flatness Definition

• ΔL / L

• ΔL = Elongation of the individual stripe

• L = Mean length of the whole strip

Edge Waves

Restricted © Primetals Technologies2021-2023. All rights reserved. 45 6 September 2023

ΔL L L ΔL L+

L

Measurement Principle

flatness error zone

specific tension

radial force sensor

average radial force

Restricted © Primetals Technologies2021-2023. All rights reserved. 6 September 2023 46 Flatness Challenges

������ ∆���� �� =− �� �� ∗ ������−�������� �������� ∆���� �� �� �� ������ �������� :

:

:

:

i :

E Modulus (N/m2) is used to convert strip Tension deviation (N/m2) to µm/m

i

E modulus

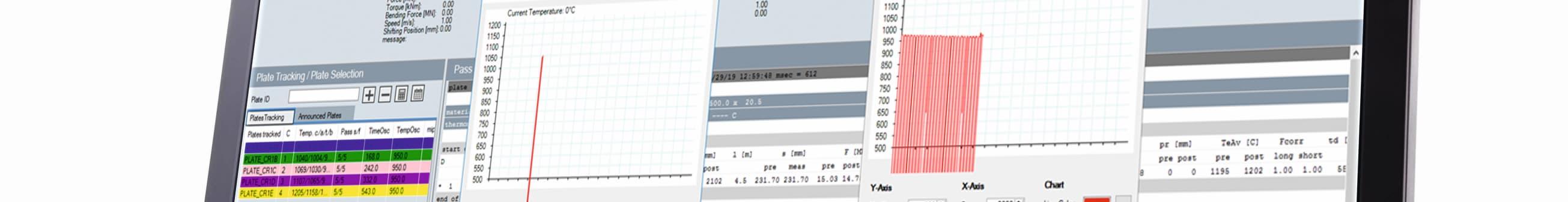

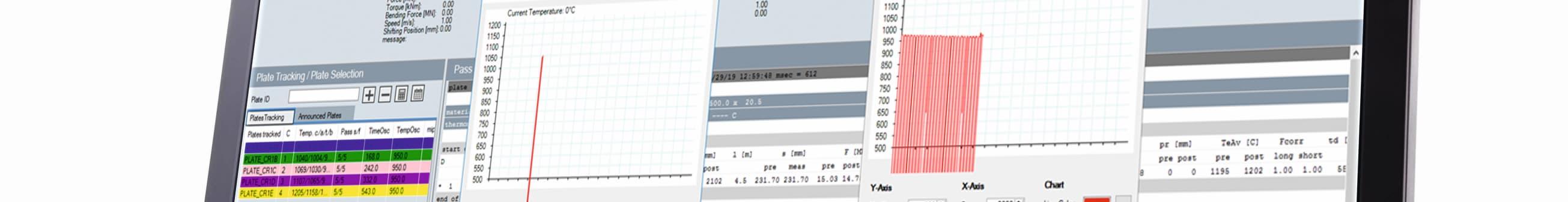

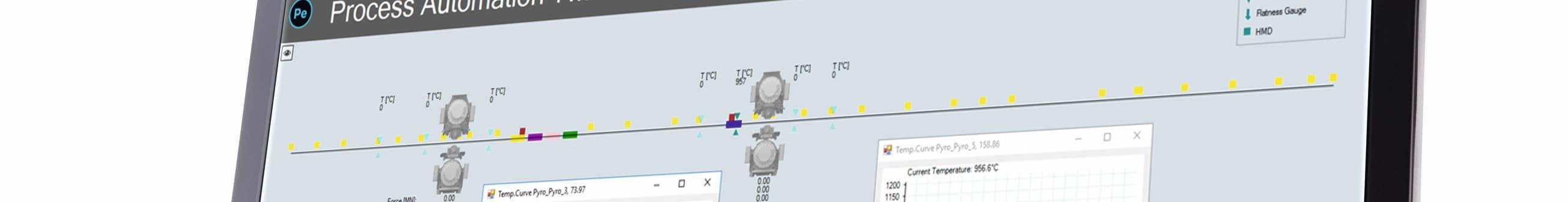

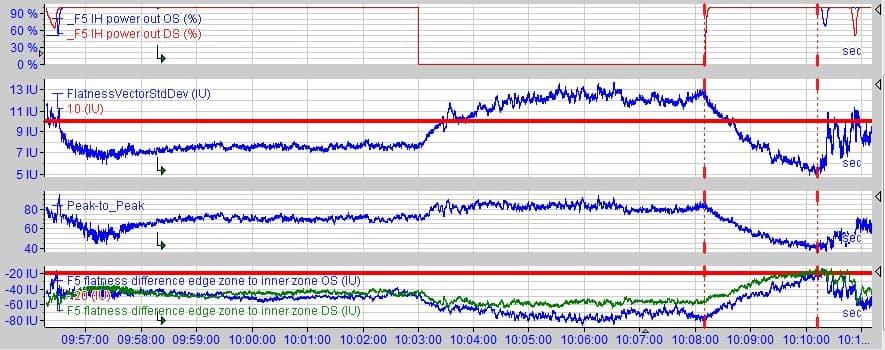

Flatness Challenges

Process Control

Actuator Control Reference

Additional Corrections

Flatness Measurement

Flatness Optimizer

Model Based Efficiency

Flatness Setpoints

Restricted © Primetals Technologies2021-2023. All rights reserved. 47 6 September 2023

+

Flatness Challenges

Process Control

Restricted © Primetals Technologies2021-2023. All rights reserved. 48 6 September 2023

σT(x) = σt(x) + σb(x) + σs(x) + σc(x) σt(x)

order)

s(x)

rd

5thorder)

Tilting (linear

σ

shifting (3

or/and

Restricted © Primetals Technologies2021-2023. All rights reserved. 49 6 September 2023

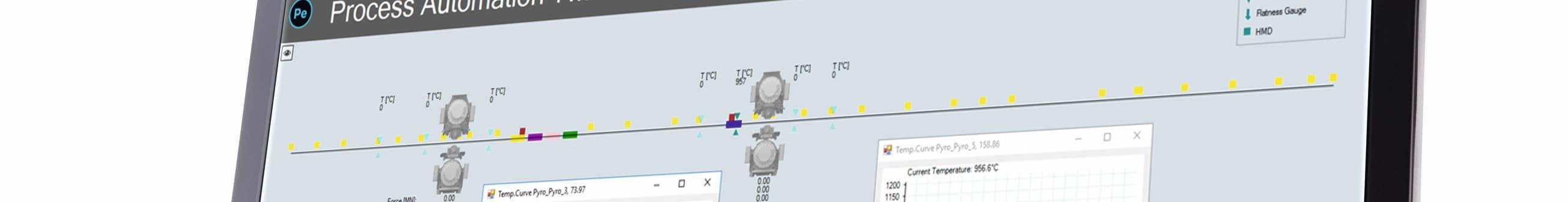

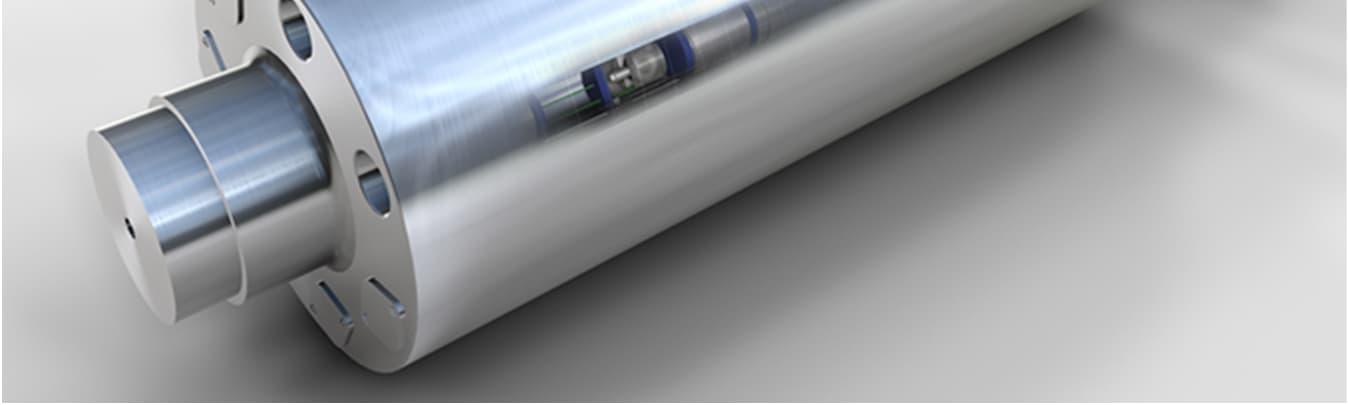

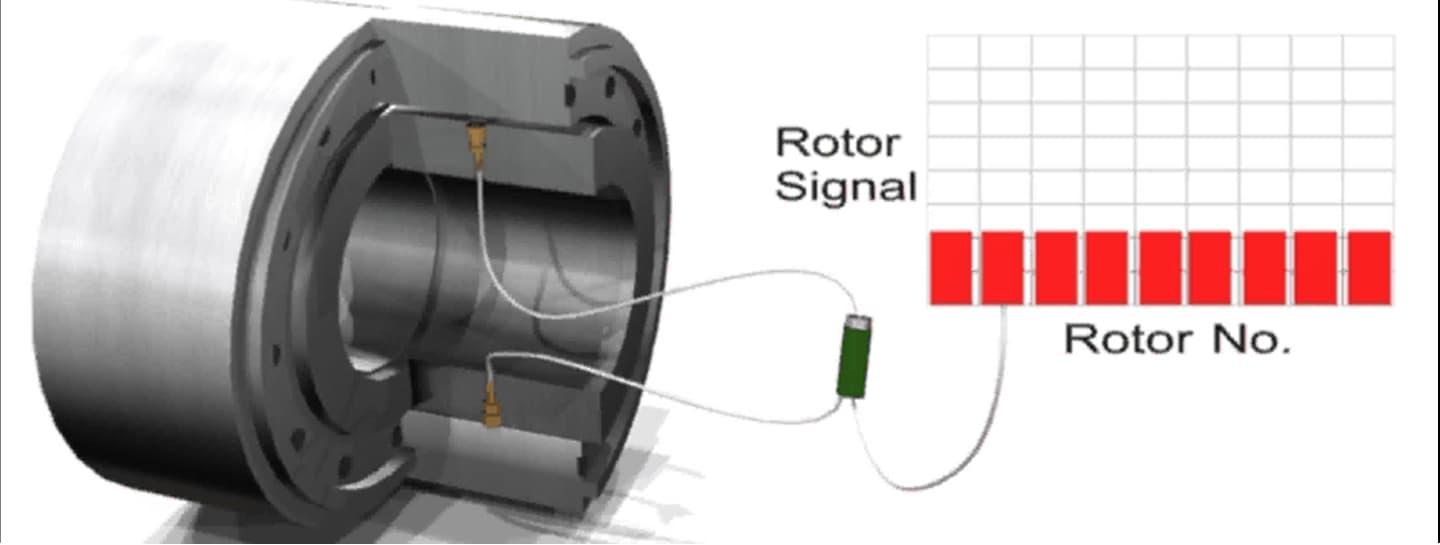

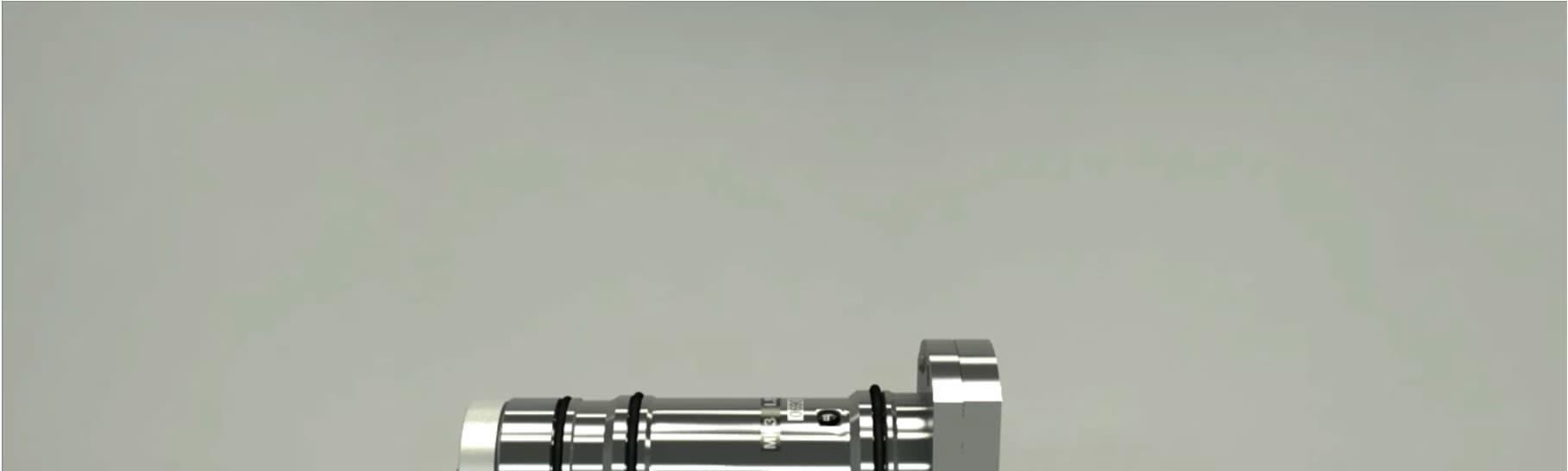

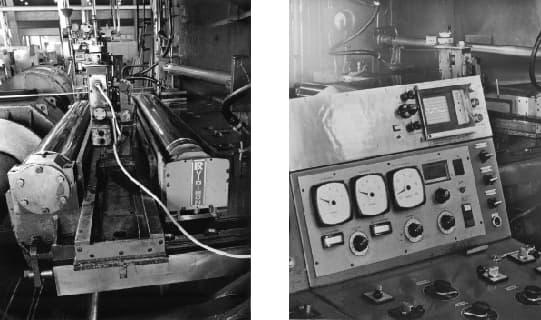

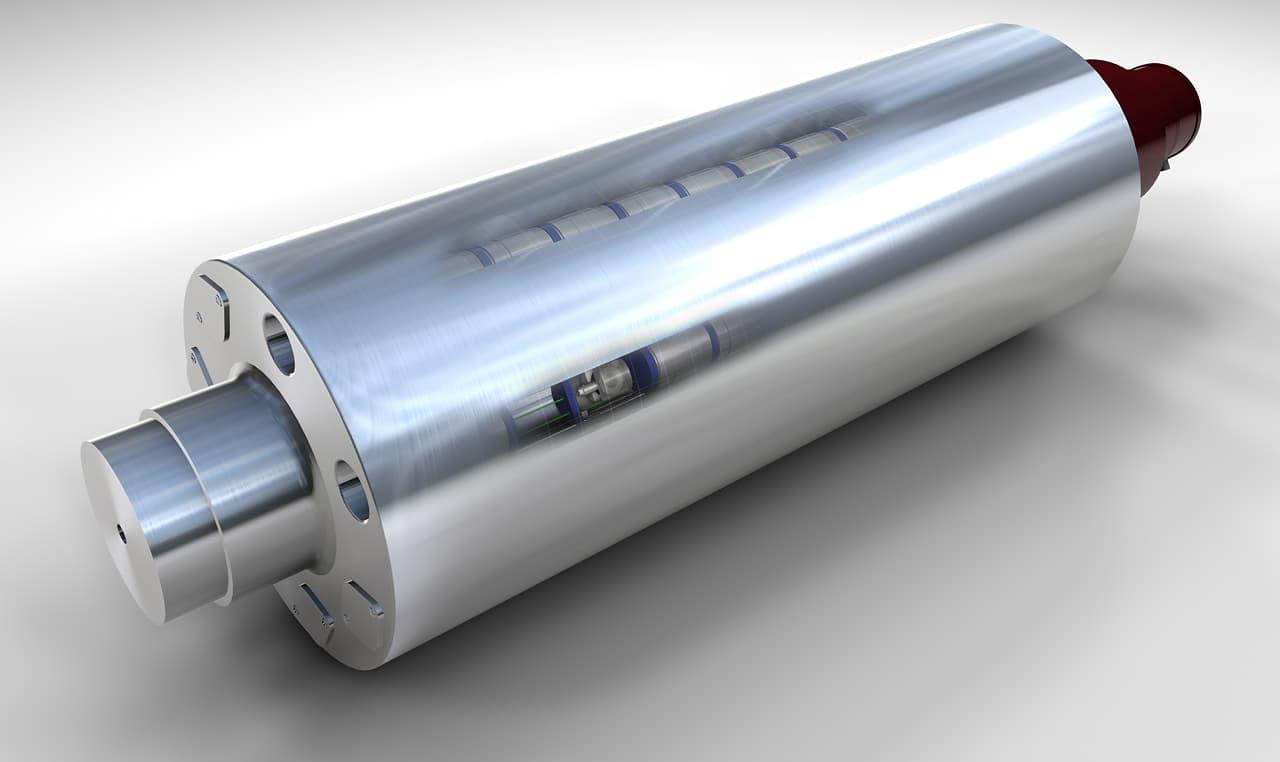

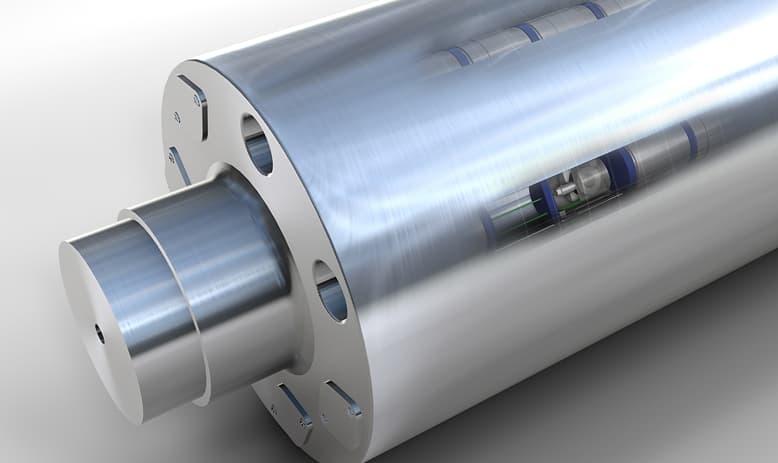

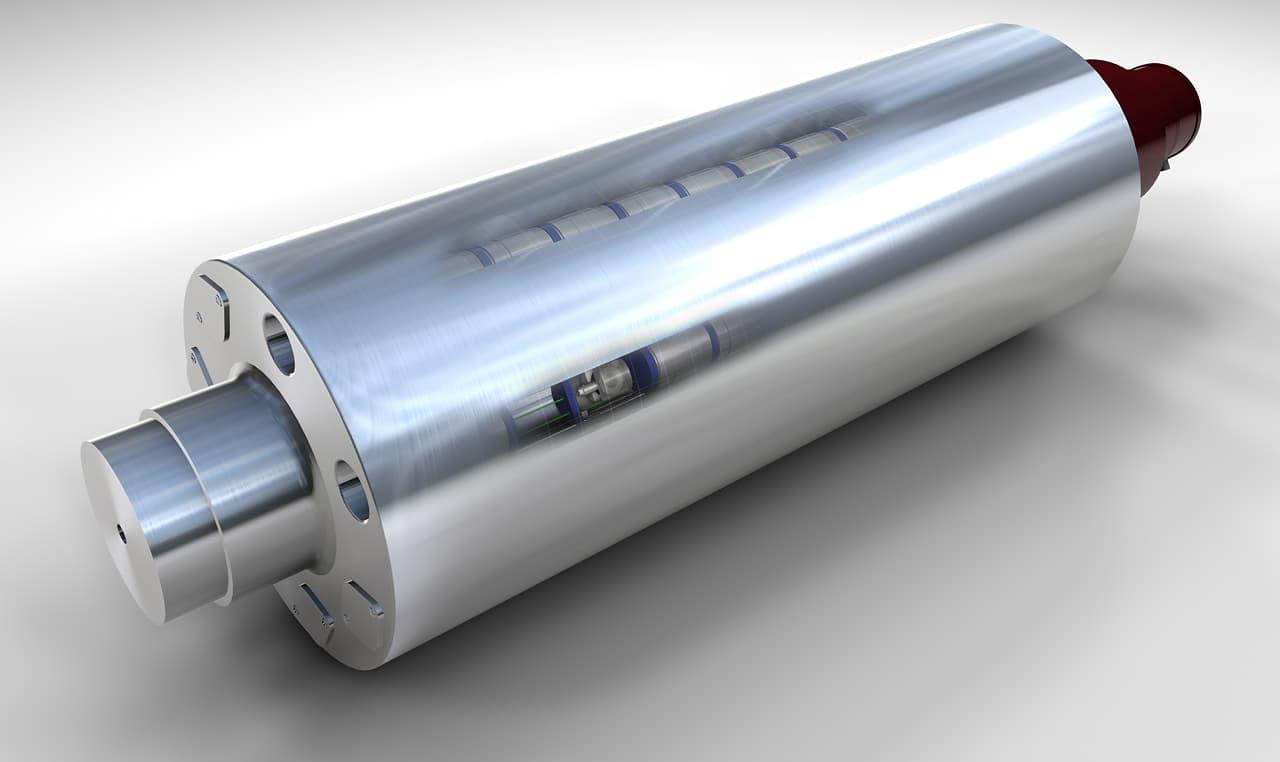

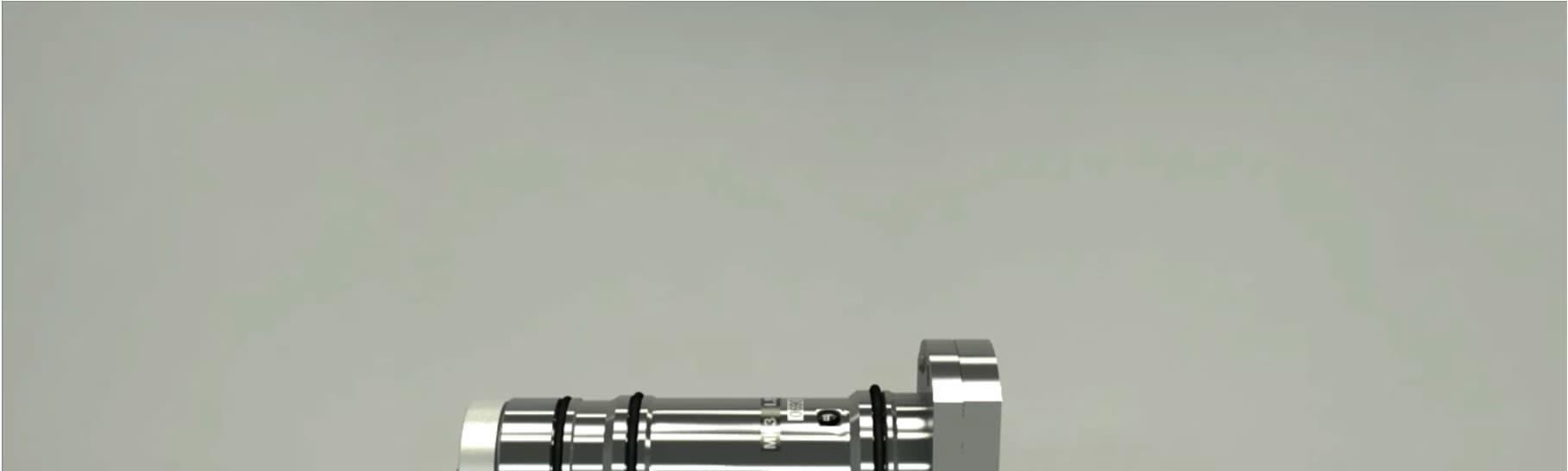

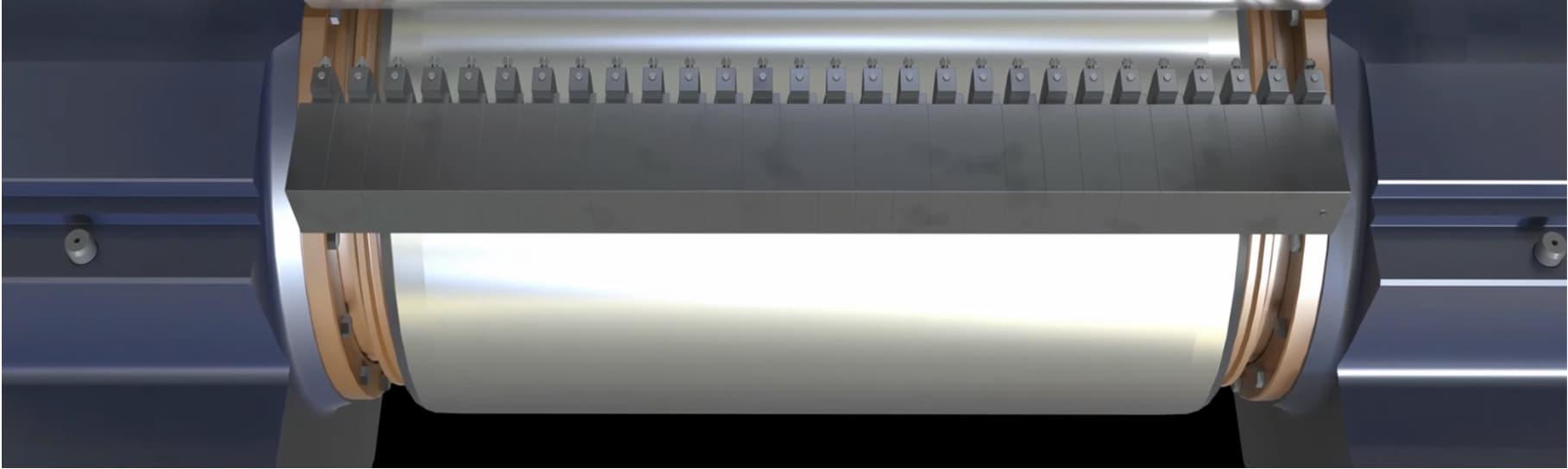

Instrumentation Instrumentation

An effective AFC system requires highly accurate and reliable measurement.

“

Air Bearing Shapemeter

Whatever You Roll

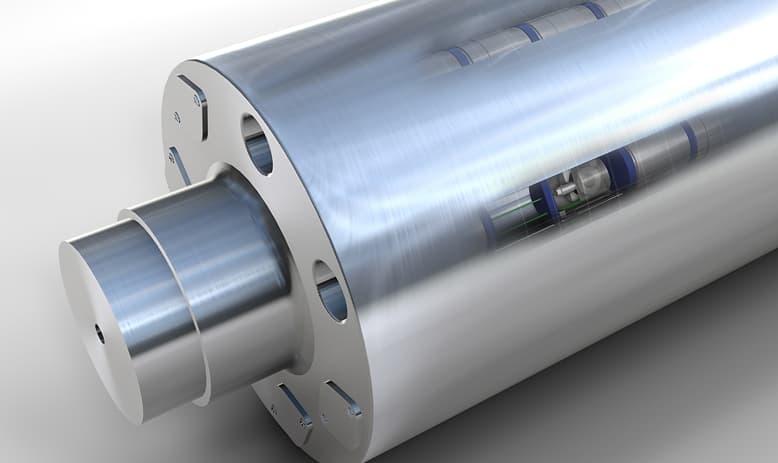

• Roll diameters from 147mm to 200mm to cater for process line, foil and cold mills

Easy to Integrate

• The small installation envelope allows for fitment next to the roll bite

High Accuracy

• Measurement zones from 25mm, with industry leading resolution

Continuous Measurement

• Signal monitored at each point of the roll

Restricted © Primetals Technologies2021-2023. All rights reserved. 50 6 September 2023

Instrumentation

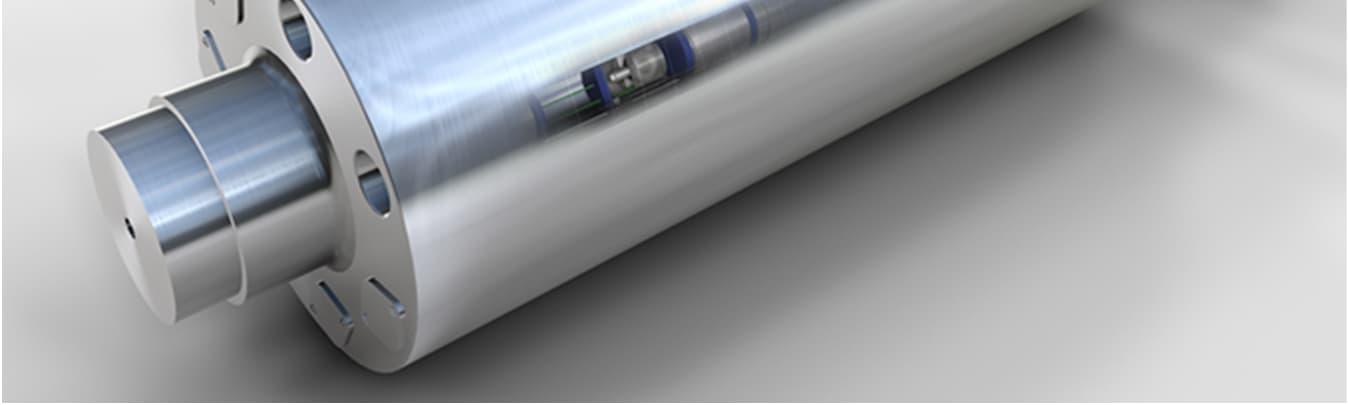

Air Bearing Shapemeter

Carrier Beam & Roll

Automatic Alignment Device

Retraction Mechanism

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 51 Instrumentation

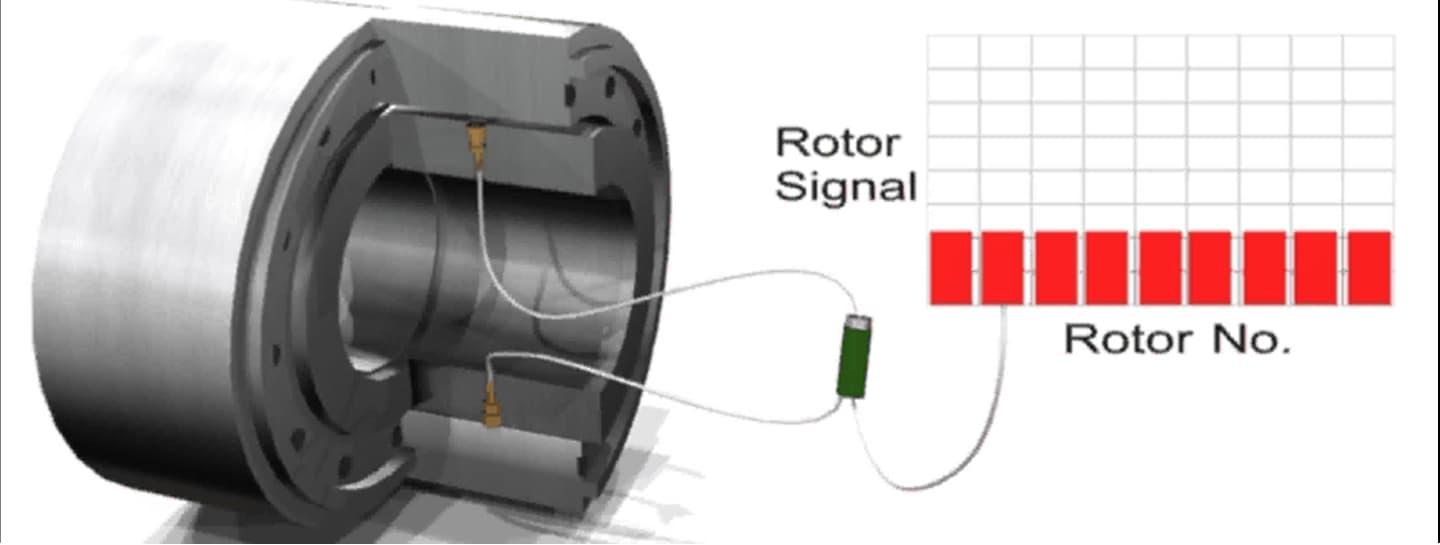

Air Bearing Shapemeter

Rotors

Thrust Pads

Arbor

Sensing Ports

Umbilical Cord

Jets

Thrust Bearing Assembly

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 52 Instrumentation

Air Bearing Shapemeter

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 53 Instrumentation

5 micron Filter

Spring Dampers

Air Supply

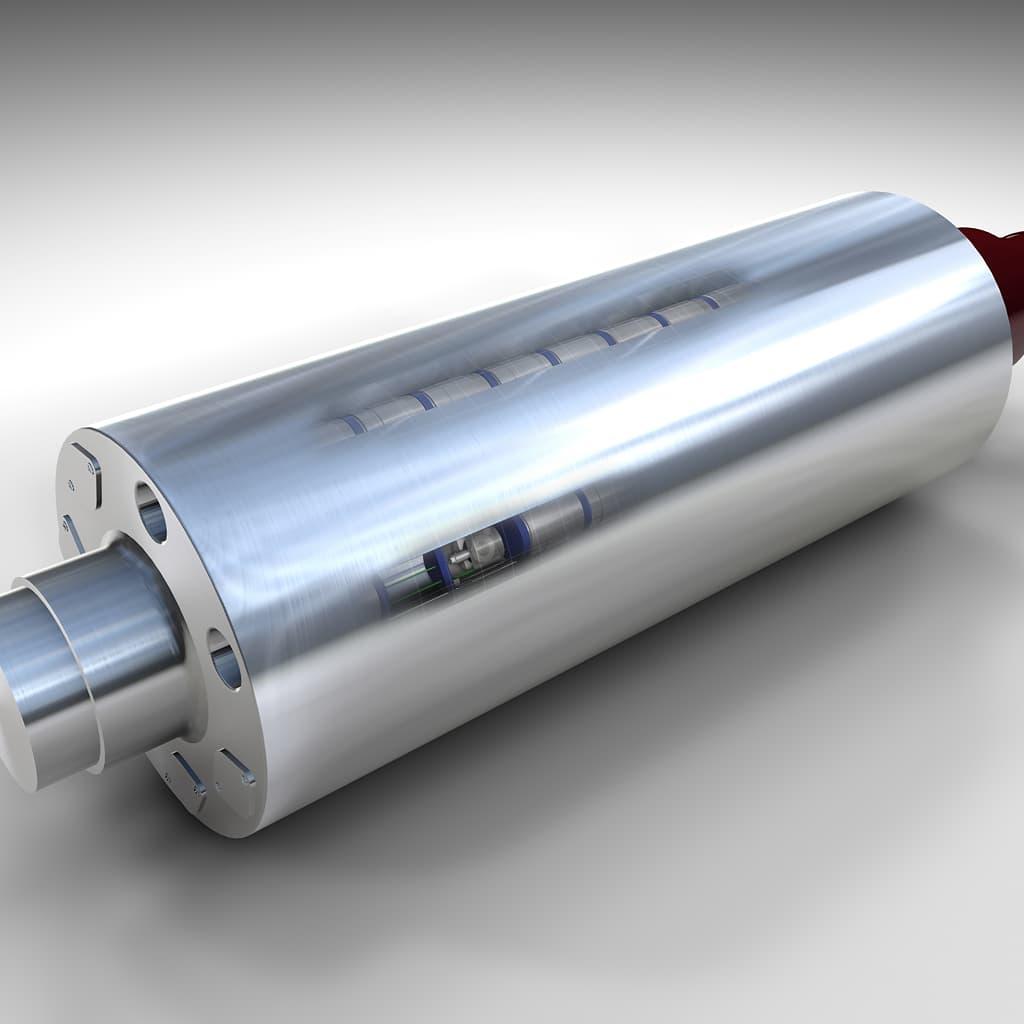

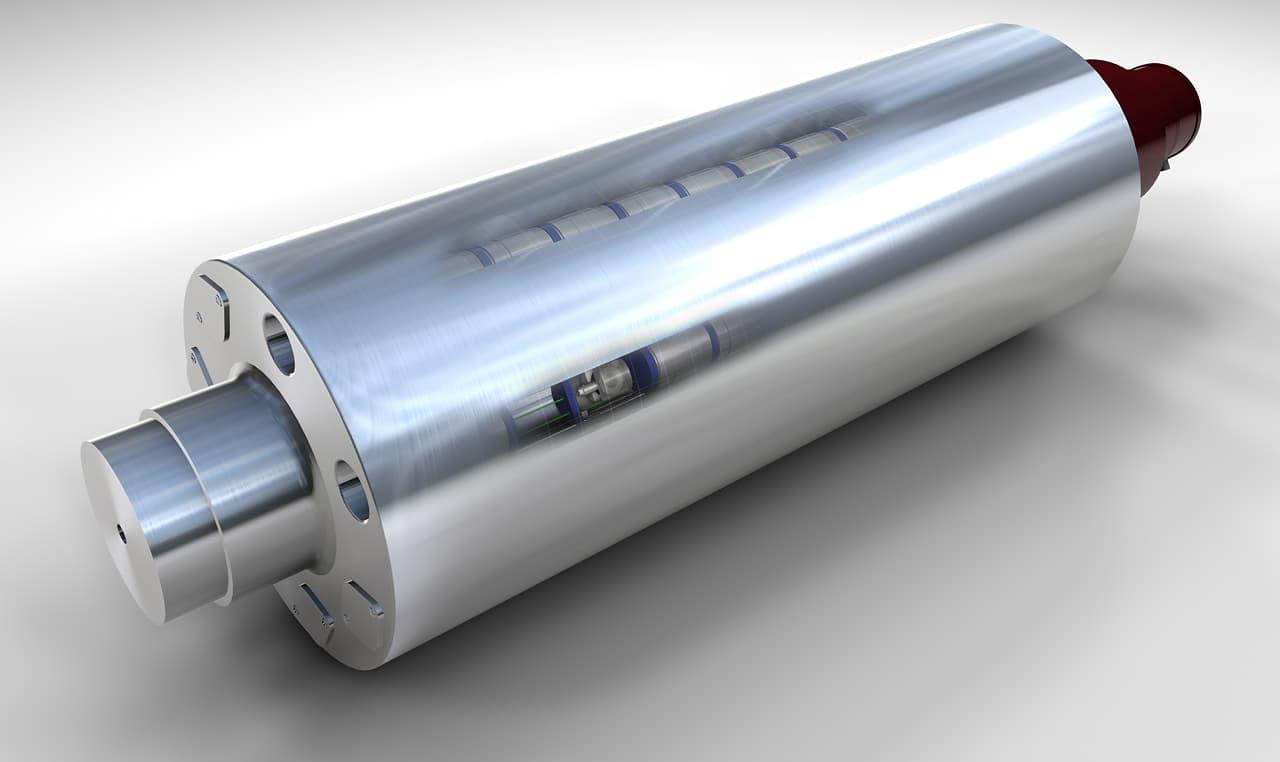

Instrumentation

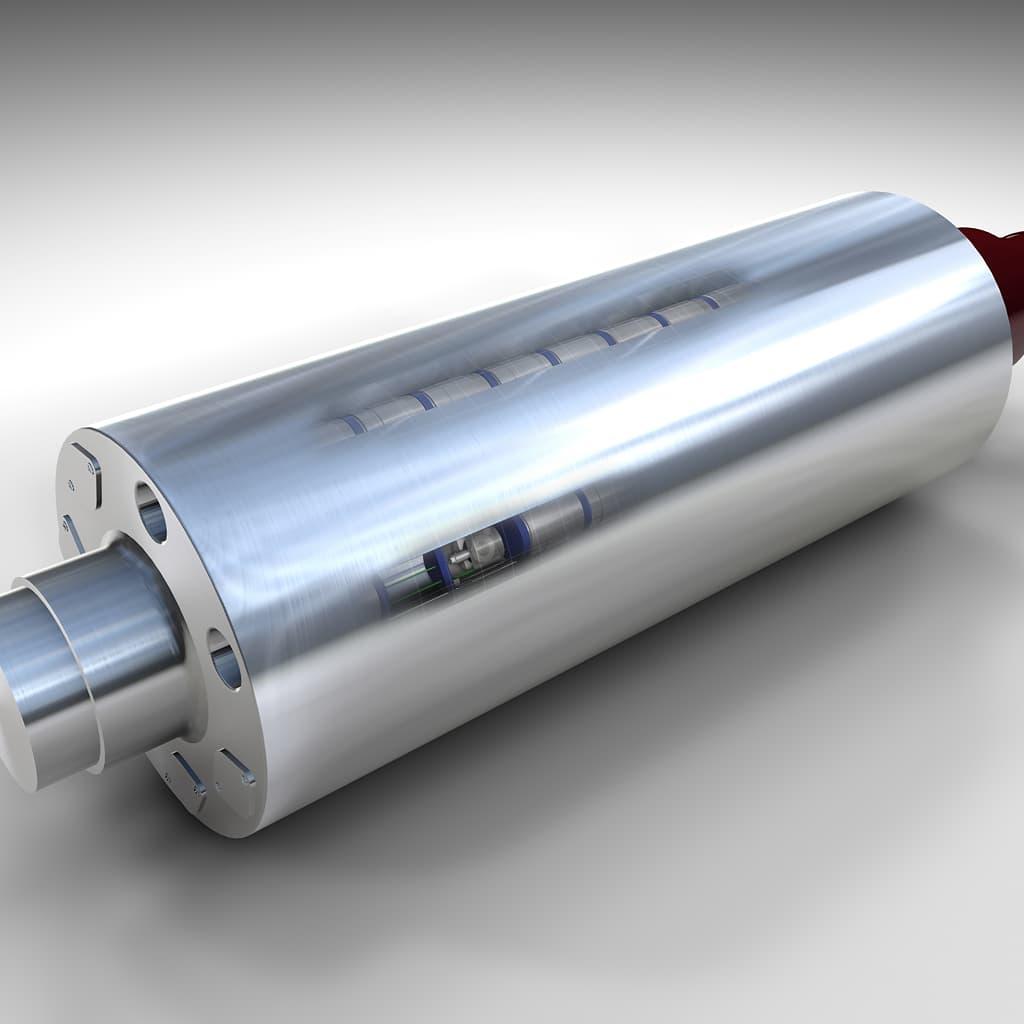

Solid Roll

Whatever You Roll

• Roll diameters typically from 200mm to 400mm to cater for foil and cold mills

Low Maintenance

• The sealed nature of the solid roll is inherently low maintenance

High Accuracy

• Nominally less than 2 I-unit deviation across the roll

Heavy Duty

• High load bearing capacity suited to heavier cold rolling applications

Restricted © Primetals Technologies2021-2023. All rights reserved. 54 6 September 2023

Solid Roll

Sensors

Signal Coupling

Homogenous Surface

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 55 Instrumentation

Actuators

Restricted © Primetals Technologies2021-2023. All rights reserved. 56 6 September 2023

Actuators

Accurate measurement is great, but it’s what you do with it that matters. “

Actuators

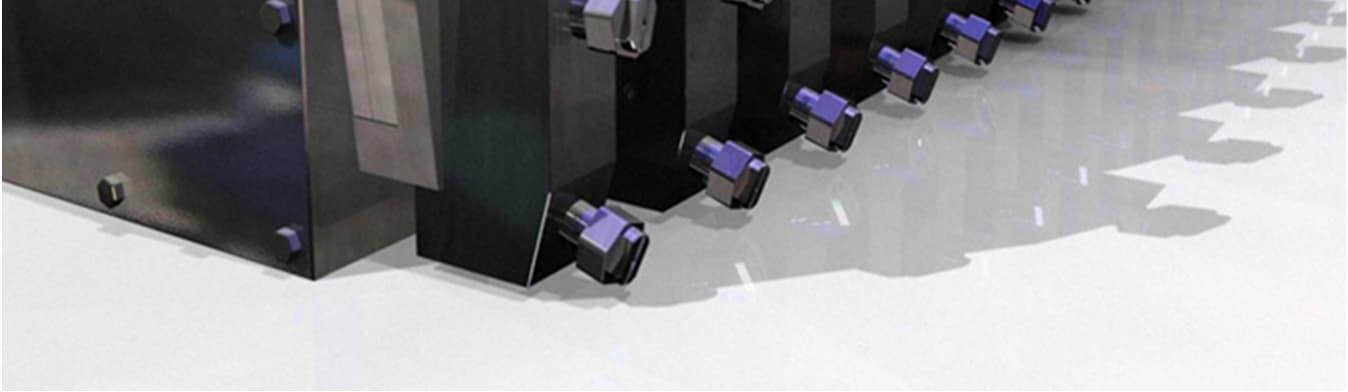

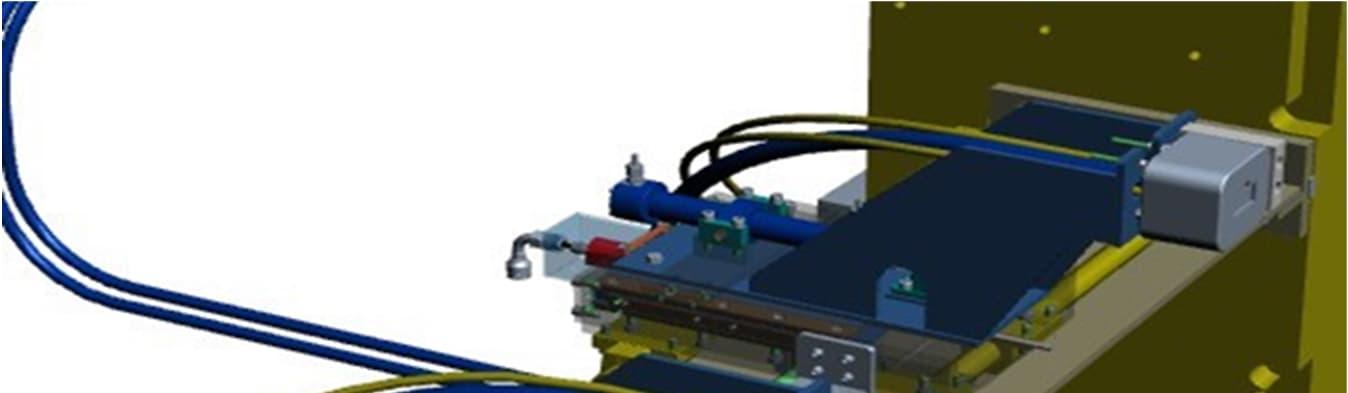

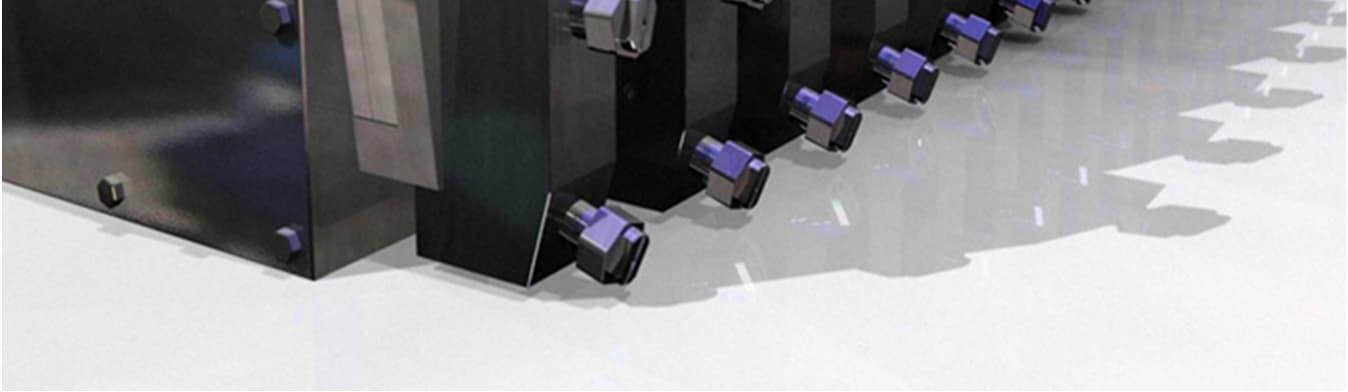

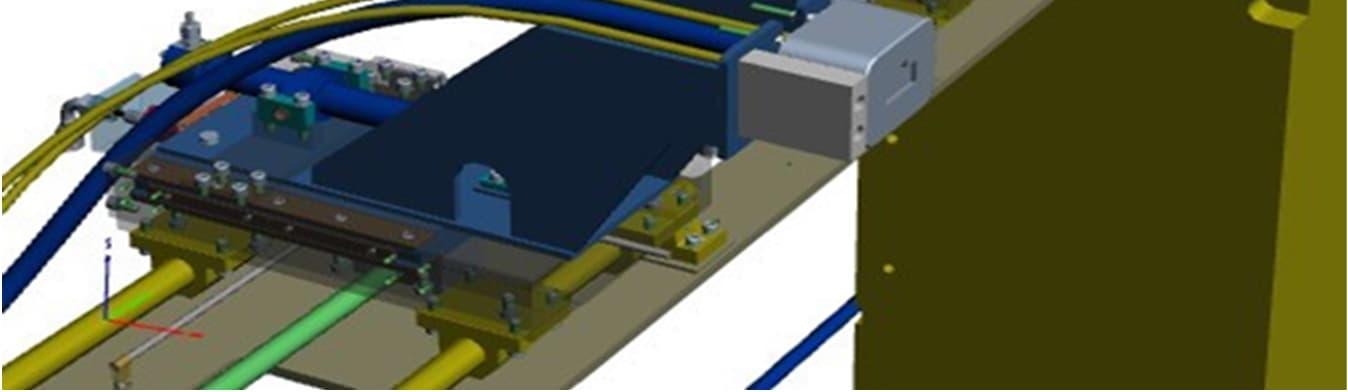

ISV Spray System

Whatever You Roll

• Hot Mills to Foil Mills and zones widths from 25mm

High Reliability

• No sliding seals and increased tolerance to coolant contamination

Low Maintenance

• Typically, 2 years between routine servicing

Industry Experience

• Advanced thermal modelling and process knowledge

Restricted © Primetals Technologies2021-2023. All rights reserved. 57 6 September 2023

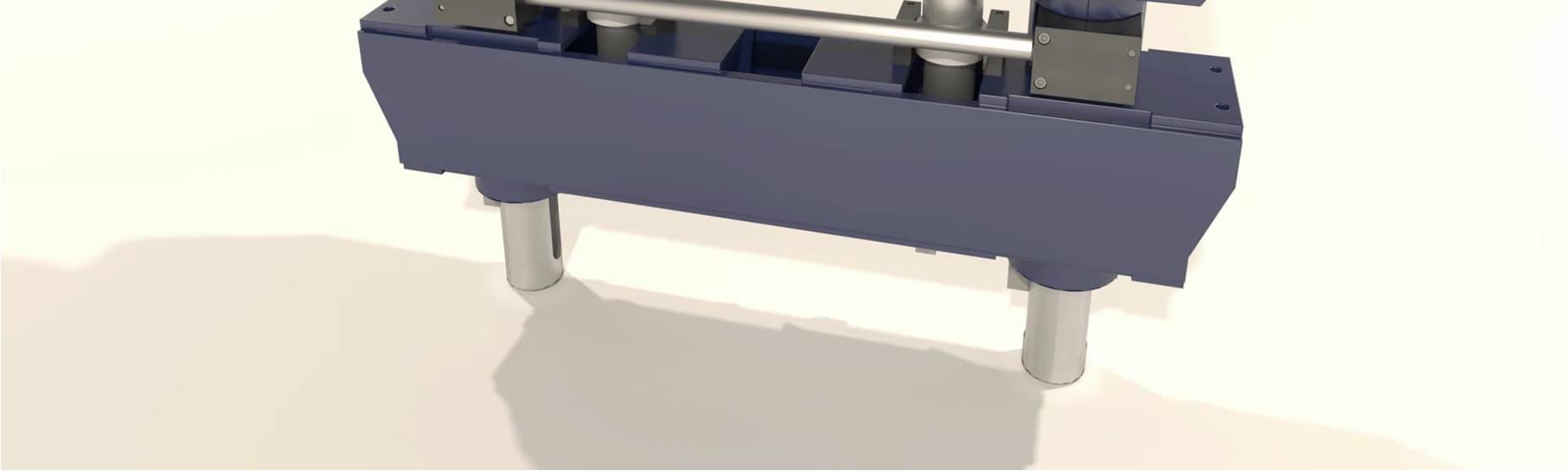

ISV Spray System

• All Mill Types

• Pulse Width Modulated

• Optimum Thermal Control

• Fully Integrated or Remote Mounted Headers

• Highly Adaptable

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 58 Actuators

ISV Spray System

• Full Stainless Construction

• 2 Years Between Servicing

• Highest Dirt Tolerance

• No External Wiring Harness

• Gold Plated Contacts

• No Sliding Seals

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 59 Actuators

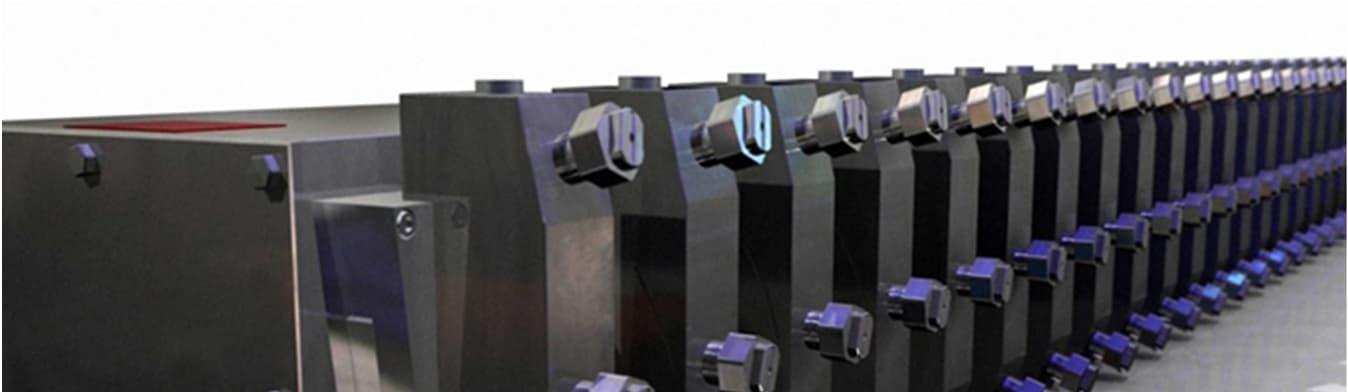

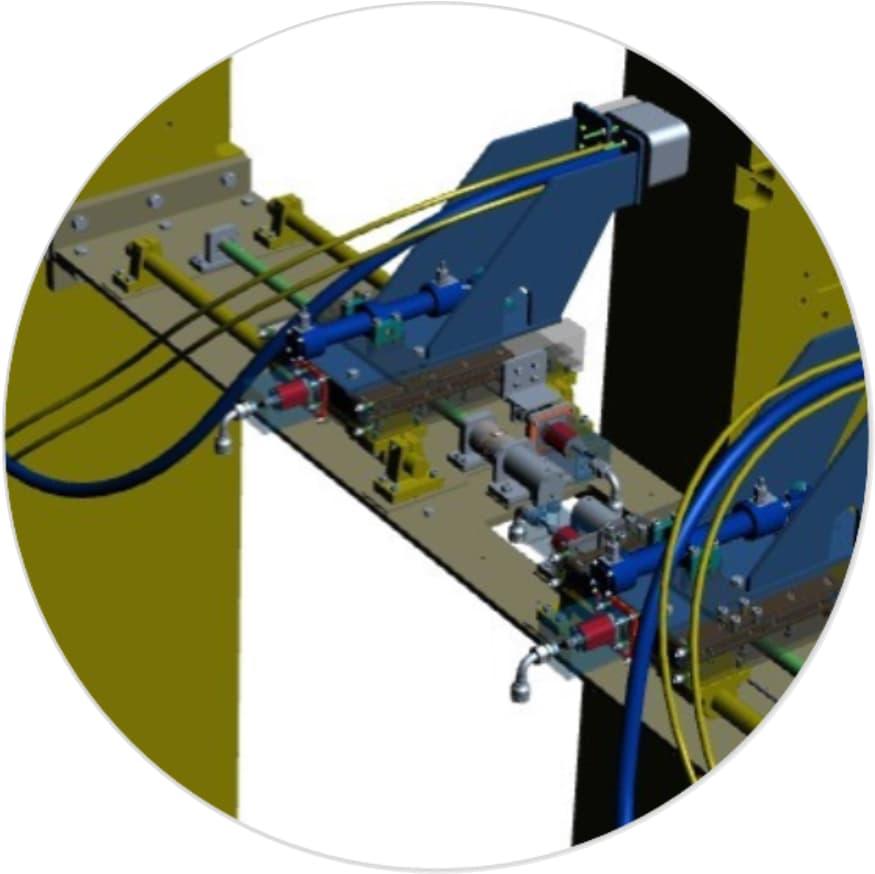

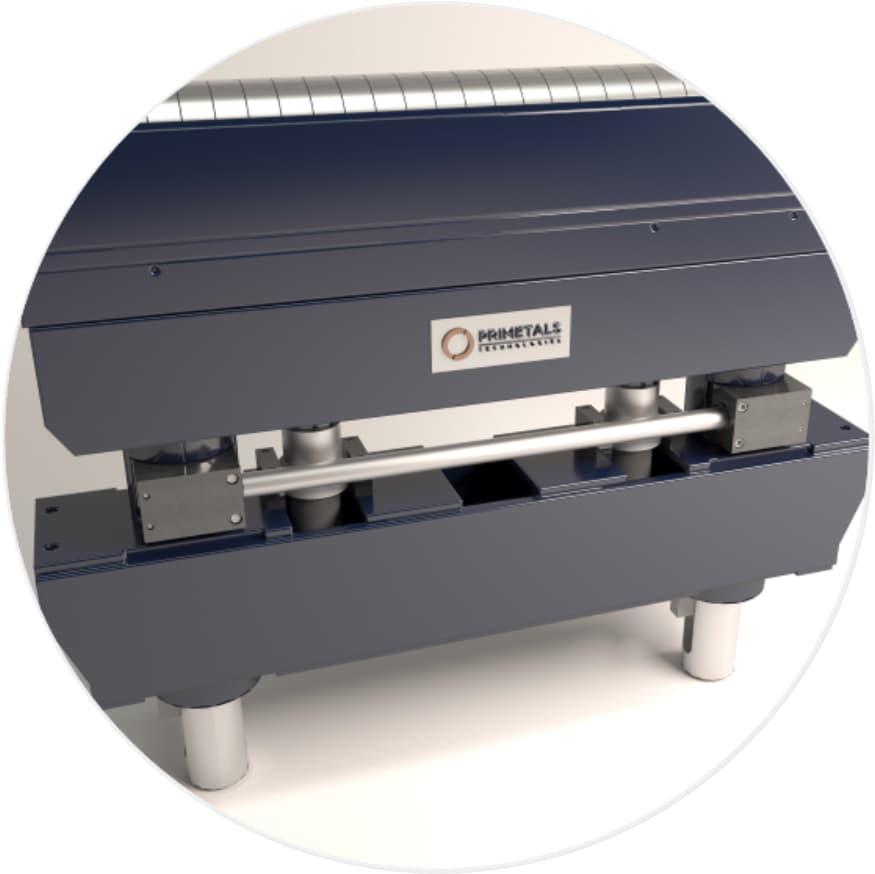

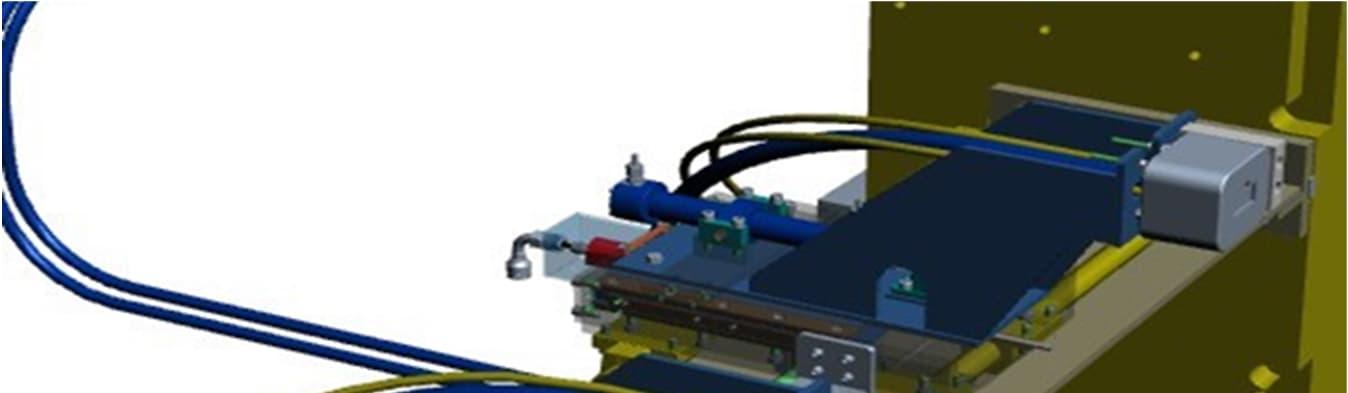

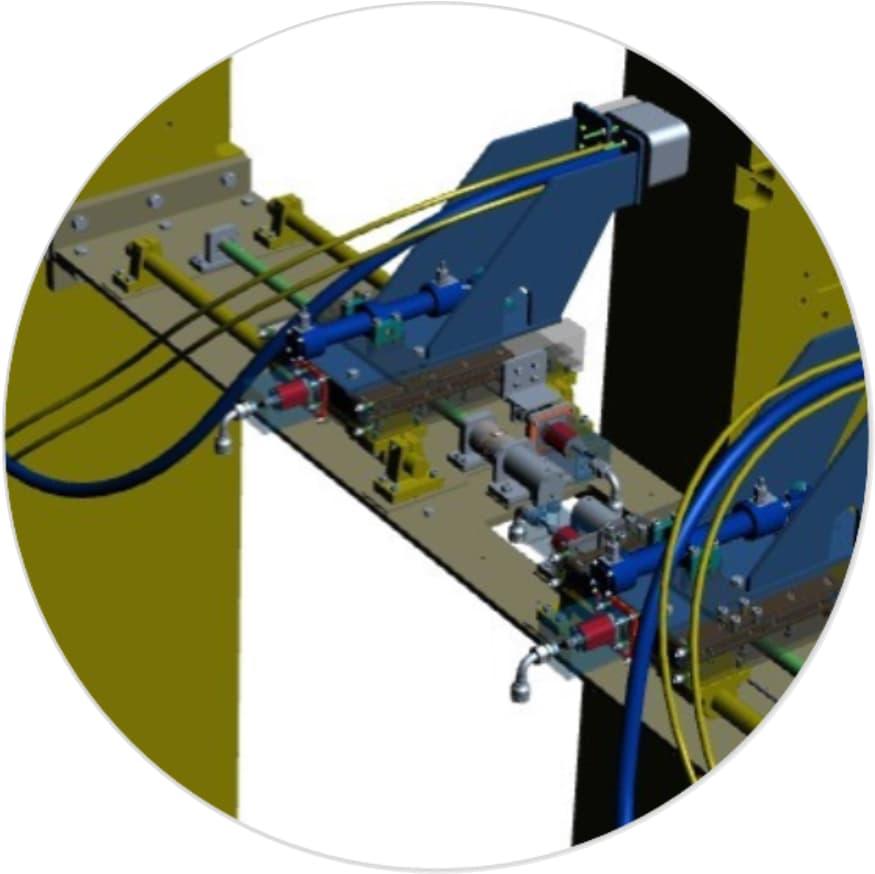

Actuators

Hot Edge Inductors

Whatever You Roll

• All Cold Rolling applications

Easy to Integrate

• New mill and retrofit options available

Low Maintenance

• Mill-duty design with ease of maintenance in mind

Industry Experience

• Advanced thermal modelling and process knowledge

Restricted © Primetals Technologies2021-2023. All rights reserved. 60 6 September 2023

Hot Edge Inductors

Strip Heat Transfer

Thermal Camber

Coolant Sprays

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 61 Actuators

Hot Edge Inductors

Heater Head

Hydraulic Cylinder

Position Feedback

Restricted © Primetals Technologies2021-2023. All rights reserved.

6 September 2023 62 Actuators

Restricted © Primetals Technologies2021-2023. All rights reserved. 63 6 September 2023 Hot Edge Inductors Actuators Inductor Off Flatness Deviation Increase Flatness Improvement Inductor On

In Summary

• Flatness is one of the most diverse and challengingsubjectsfor Aluminum producers.

• There are several time-honored solutions available for effective measurement and control.

• Process know-how is invaluable in achieving the best results.

• Choosing the right solutions can…

-Provide access to highlyprofitable markets

-Ensure consistentrollingoperations

-Better utilize existing equipment

-Reduce unplanned downtime

-Improve productivity

-Drive down costs

Restricted © Primetals Technologies2021-2023. All rights reserved. 64 6 September 2023

Any Questions?

Restricted © Primetals Technologies2021-2023. All rights reserved. 65 6 September 2023

WORKSHOP TOUR

Yongzhi Luo & Cameron Parsons

Primetals Technologies

Restricted © Primetals Technologies2021-2023. All rights reserved. 66 6 September 2023

Contact Grant Shoebridge

Head of Downstream

T +44 7468 477588

E grant.shoebridge@primetals.com

Primetals Technologies Limited

A Group Company of Mitsubishi Heavy Industries

9 Enterprise Way

Christchurch

United Kingdom

BH23 6EW

The information(including,e.g., figures and numbers) provided in this document contains merely general descriptions or characteristics of performancebased on estimatesand assumptionswhich have not been verified. These estimates and assumptions have to be analyzed on a case-to-case basis and mightchange as a result of further product development.

It is no representation, does not constituteand/or evidence a contract or an offer to enter into a contract to any extent and is not binding upon the parties. Any obligation to provide and/or demonstraterespective characteristicsshall only exist if expressly agreed in the terms of the contract.

PrimetalsTechnologies excludes any liabilitywhatsoever under or in connection with any provided information,estimatesand assumptions. The provided information,estimates and assumptionsshall be without prejudice to any possible future offer and/or contract.

Any informationprovided by PrimetalsTechnologies to the recipient shall be subject to applicable confidentialityobligationsand shall be used by the recipient at their own convenience and at their sole risk.

Restricted © Primetals Technologies2021-2023. All rights reserved.

primetals.com

6 September 2023 67

THANK YOU

Restricted © Primetals Technologies2021-2023. All rights reserved. 68 6 September 2023