21 minute read

Giti Tyres Big Test

TIMBER TRAIN

Story Colin Smith Photos Gerald Shacklock

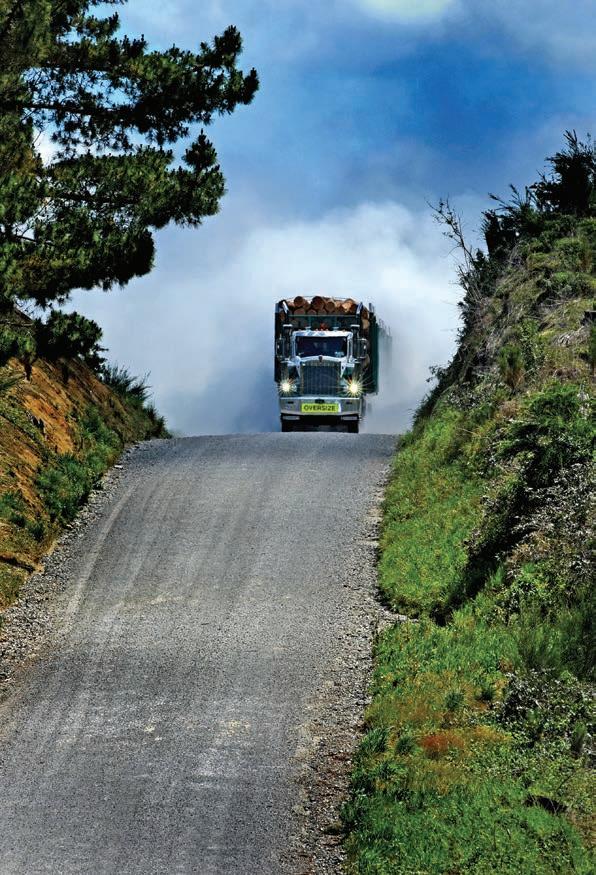

Monsters such as the RFH treble work away from the public eye on the Kaingaroa Forest roads.

BIG TEST

With 15 axles, 58 tyres and measuring 53-metres in length, the Kenworth C509 treble is the largest unit in the RFH fleet.

IT’S AN INTERESTING SLICE OF TRIVIA THAT

New Zealand Truck & Driver started 2022 featuring the new Scania S 770 – the most powerful highway truck to appear on the magazine cover. And the year is ending with the largest truck and trailer combination the magazine has ever tested. The weight and length of the new Rotorua Forest Haulage (RFH) Kenworth C509 logging treble are in another league compared to trucks working on the highway. At 53 metres in length and with eight packets of logs aboard, the C509 is typically working the private forest roads of Kaingaroa at 200-tonnes and more.

Three trailers behind a 6x4 tractor adds up to 15 axles and no fewer than 58 tyres on the road for this green monster of the forest. It’s the biggest unit in the RFH fleet and believed to be the longest truck in New Zealand. And possibly the longest logging truck in the Southern Hemisphere.

Making an early start in Rotorua, we head south to the Timberlands Kaingaroa Processing Plant (KPP) – or `The Web’ as it’s known – to meet up with the C509 on its third day in service.

It’s being loaded when we arrive so it’s ideal timing to catch up with RFH Off-Highway Truck Manager Jake Rogers before climbing aboard with driver Stephen Teddy.

Logging trebles were once a more common sight on central plateau forest roads. The RFH unit doesn’t signal a comeback for trebles, but it does add a degree of flexibility to the company’s offhighway log cartage.

Jake is a highly experienced off-highway driver and was appointed as RFH’s Off Highway Trucking Manager in June 2021.

“It’s a different world out here, totally different to on-highway,” says Jake, leaving little doubt he prefers the off-highway world.

Murupara is Jake’s hometown, and he began driving off-highway trucks as a teenager.

“On your 18th birthday you went to get your licence and you had a job straight away. I started driving the off-highway doubles and trebles at an early age.

“The trebles were only used when they were needed. Certainly not like in the older days with the Pacific’s. They had sort of phased out when the owner drivers took over in the mid-1980s.

“They carried on a little, but the doubles became the priority due to access and as the trailers started getting bigger. When they could cart what the trebles used to with a double, the trebles kind of phased out.

“Then in the mid-to-late 90s Mike Lambert had Maroa Logging. Maroa had picked up a lot of work and when they needed extra units, they used to hook a third trailer on.

“They did the treble work when needed but there were no permanent trebles here apart from the twin-engine Marathon.

“That’s where I first drove a treble, for Maroa Logging, roughly 20 years ago,” Jake says.

“After Maroa I went to being an owner-driver in 2008 doing highway work. I had never driven the highway before, and it was the biggest headache I ever had.

“I got out of it and went to work for Holmes who had bought Lambert out. My love was always off-highway, and my thing is: `if you’re going to drive a truck, you might as well drive the biggest truck’,” Jake says.

It was Jake who prompted RFH director Tony Sargison’s interest in adding a treble to the fleet.

“I sat down with Tony one day to discuss some options with him and one of them was, `would he put a treble on the road?’

“He ummed and arrghed and said `we’ll see what we can do.’

Then he rang back a few days later and said it was all sorted out.

“He had a brand new tractor unit coming and had one trailer built at the end of November 2017. By the start of April 2018, the truck went on the road as a double unit and the third trailer was completed soon after.”

Jake did the early testing of the treble before it went to work on a full-time basis.

A key factor to consider for the treble is access in and out of forest skid sites.

“For us, it’s making sure it’s not too steep. It’s a big difference pulling a third trailer and a double can get into a lot of places a treble can’t. And there’s the weather factor too, as conditions change a lot.”

There’s always a recce of any new site and a careful eye on the weather before deploying the treble to a new location.

“I jump in the ute and take a look at the access. If it looks good then we do the paperwork, and it means we can cart out of the place,” Jake says.

“At any time, there are usually three different bush crews we can cart out of as well as `the Web’.”

Jake says the treble has been a useful addition to the fleet.

“I put the idea to him [Tony Sargison] and he ran with it. I had the sense of having to make it work, otherwise it could have been a kick up the arse,” Jake says.

Jake was RFH’s sole driver of the treble until recently.

“I was on it just over three years. Safety is first and foremost and also getting your head around things like throwing more chains, unchaining more chains and stuff like that. It was challenging, but you made it happen.

“In the three and half years we’ve been running we’ve only been a double twice and that was only when something was getting replaced on the trailer. Basically, we never run it as a double.”

The treble combination has a two-packet 3-axle semi ahead of 5-axle and 4-axle trailers. The basic chassis’ come from Patchell Industries and the trailer builds are completed in-house by RFH.

“With the treble we run two three-packet trailers which allows us to cart a bit more product if it’s short wood,” says Jake.

“Our average payload is around 150 out of here [KPP] to Murupara rail.”

The treble is not allowed to cross public roads, but the forest road network means it can work from Kaingaroa to the northern side of the Napier-Taupo highway.

“It can’t cross the highways but the places across the NapierTaupo highway are mostly too steep to cart out of anyway,” says Jake.

“We can do four rounds out of here to Murupara and back in a day.

To put it in context, it’s anywhere from 600-700 tonnes a day

carting out of here. “When we start carting out of the bush from crews near the Napier-Taupo, that cuts our loads down. Two loads from here to one from the bush is the usual time factor, depending on where the location is. “The treble is good when we need to cart more product. It’s basically a double unit plus a single unit with one driver. It’s carting 50% more than our doubles and the road speed and time isn’t that much different.” There remains just one treble unit in the RFH fleet. The brand new C509 featured here replaces the original after four years of service. “The original treble unit is being dropped back to working as a double with the option of running it as a treble. So, it’s still only one treble unit but with a few new sites there may be an opportunity to run a second unit,” Jake says. “It’s been a good consistent unit for us that gets the wood moved and gives a bit of flexibility to the operation. It means we can use it to cart out of here [KPP] when the double units are busy in some of the tighter places. And when we have some of the bigger bush crews with more wood on the ground and we can access it, we can go in there.” Both the new C509 and the trailers it’s working with are only slightly different to the previous treble unit. “The difference with this unit is it’s a couple of tonnes lighter than the previous one. “I know tare weight doesn’t mean a hell of a lot out here. The truck is about the same, but the second trailer is about a tonne Both at a distance and in detail, the C509 is an impressive sight. lighter.” Overall, the new treble is close to 46-tonne while the last one was 48-tonne. Another Kenworth C509 was the obvious choice for the new treble. “For what we are doing with the treble, the Kenworth is the truck for the job. We had no issues with the truck we have just replaced, so fingers crossed this one will be the same. It’s been bloody good,” says Jake. “About the only difference on the new tractor unit is a few new gauges on the dash and the radio. The air tanks are mounted within the chassis on this one and they were outside on the old one. “The back trailer is still the old one off the original treble because the new one we can’t get into paint at the moment. It’s all finished and complete just waiting for paint.” Another role played by the treble has been to introduce new components and technology. The first treble unit adopted the V.Orlandi 250-tonne trailer hitches supplied through T.A.T.E.S. and they have since become standard fitment on each new RFH off-highway unit. “They are on about 90% of our trucks now. They are safer and

Above: Stephen Teddy secures one of the 24 chains required on the treble. Below: New RFH developed chain tensioning system is air-powered from the brake chambers. Bottom: Classic Kenworth dash layout with multiple gauges and woodgain finish.

they are easy to maintain – replace the bushes and things,” Jake says.

The latest C509 treble also has a new RFH developed chain tensioning system that conforms with the Timberlands requirement that every log packet must be chained, and belly stropped.

Chains are still manually thrown over the log packets (three per packet) and then connected by the driver. After that the system is automated.

“This one has an air system that runs off the brake chambers. You just flick a switch, and it tightens the chain for you. It’s a system set up by Sam Sargison – it was his brain wave that came up with it,” says Jake. It’s part of RFH strategy to introduce new systems.

“All our new trucks are coming specced with the latest things to make it easier for the drivers,” says Jake.

“Between RFH and Timberlands they are always working to make things easier on the driver. RFH have poured a lot of research and money into making things easier for the drivers and now its showing. At the moment this is the best set-up we can have, and this is our second off-highway unit with this system.”

With Jake moving into a management role another driver had to be selected for treble work.

“Over the previous three years we just parked the truck up if I had to take a day off. No one else drove it.”

Jake says driving a treble isn’t for everyone.

“You have to have someone who isn’t in any rush. Someone who has good attention to detail, and I have to say a lot of our drivers are like that.

“We’ve got experienced drivers who can drive the truck no problem but it’s not for everyone.

“Stephen was the ideal person with his experience. He’s come from a driving background with his father Eddy Teddy driving for Kaingaroa Logging Company before transitioning to become an owner driver in the mid-1980s. Stephen started on the Pacific’s, and he was the logical choice.

“He’s cruisy. He gets the job done and the load from A to B and the truck gets looked after,” says Jake.

Perhaps the most remarkable thing about the 220-tonne certified C509 is how similar it is to on-highway Kenworth’s working at a quarter of the combined vehicle mass.

The 15.0-litre Euro 5 spec Cummins X15 develops 431kW (578hp) at 1800rpm and has 2508Nm of torque available at 1200rpm. It has an 18-speed Eaton Fuller Roadranger gearbox.

Taking into account the treble is working laden to over 200-tonnes – and still weighs 46-tonnes on return runs without a payload –

the fuel consumption remains respectable at roughly one litre per kilometre.

“There are actually a couple of other models in the Kenworth range that could do the same job and it comes down to personal preference,” says Adam McIntosh from Southpac Trucks Rotorua branch which supplied the C509.

“The C509 has the benefit of the slipper spring front suspension which is a bit more of a heavy duty option,” Adam says.

Above: Loading another eight packets of logs for the trip from KPP to the Murupara rail yard. Below left: Stephen Teddy has taken over as RFH’s treble driver in the new C509. Below right: V.Orlandi 250-tonne trailer hitches are used on new RFH double and treble units (top); At 53-metres in length and working at 200-tonne the C509 is exactly what the sign advises (bottom).

“Otherwise, the truck is remarkably similar to the modern Kenworth’s you see every day on the Auckland motorway. The biggest differences are the SISU hub reduction rear axles with 5.56:1 final drive ratio and the 13R tyres.”

The tyre choice is Bridgestone M840 13R 225 steerers and Bridgestone L317 13R 225 drive tyres.

The typical run to from KPP to Murupara is completed in just under an hour. Loaded speeds are mostly under 60km/h and never

TRANS-TEX 220 NEW ZEALAND’s TRUSTED TRUCK and trailer DECKING

EUROPEAN BIRCH PLYWOOD - Certified to withstand the most demanding applications

12mm / 9 ply 2440 x 1220 2440 x 1525 2440 x 1850 3050 x 1525 3650 x 1850

18mm / 13 ply

2400 x 1200 2440 x 1220 2440 x 1525 2440 x 1850 2600 x 1900 3050 x 1525 3650 x 2000

21mm / 15 ply

2400 x 1200 2440 x 1220 2500 x 1500 4000 x 1500 3650 x 2000

15mm / 11 ply

2440 x 1220 2440 x 1850 3050 x 1525 At Roadmaster, we only use Plytech Trans-Tex 220. It’s simply the best product available in the country. It gives us peace of mind, adds great value, and the service and support we get from the guys at Plytech is first-class.

Colin Patchell CEO Roadmaster

Another trip though the under highway tunnel at Kaingaroa.

much above. Jake says the run is about 60% downhill as Murupara is at a lower altitude than the KPP. But it’s undulating terrain with a few moderate climbs.

There are three different routes the treble can take to reach Murupara. We keep the C509 clean by taking the tarmac route for the first load and then try the gravel in search of more interesting photography for the second run.

There’s no surprise the treble starts in bottom gear and that speed builds slowly. The impression of weight and size is immediately apparent, and when it’s loaded getting the C509 up to speed requires splitting every gear.

Stephen has to stop and turn left at a T-junction just after leaving the KPP. It’s a late turn and a wide swing. I count 10 gearchanges before the speedometer is showing 30km/h and although we are headed straight, I check the passenger side mirror and the third trailer has only just finished making the turn.

Stephen says driving the treble is a mixture of patience, planning ahead and being in the right gear.

He’s unhurried and very smooth with the gear shifts and with the tachometer rarely dropping below 1500rpm there is the impression the C509 is working reasonably hard with its big load, but never seemingly to struggle.

“As soon as the revs drop to 1500rpm you think about another gear. If you know the climb is levelling out, you can let it lug a bit.

“But you wouldn’t want to have to start off on any sort of hill,” he says.

Climbing a very gradual incline, the treble is at 40km/h using 1500rpm in sixth-high.

On a longer and steeper downhill run using the engine brake and fan the C509 is held at 18km/h in fourth-low with the engine holding 1500rpm until Stephen makes another shift to third-high and the tachometer nudges toward 1800rpm.

“This is where the patience side of it comes into play,” Stephen says.

“You let the engine do most of the braking and maybe give the brake pedal a quick push if you need to.”

At the weighbridge there are three dockets to collect. Our first load is 144t which Stephen says makes all up weight of 190-tonne.

“That’s actually a bit of a light one,” he says.

“Normally we’re in the 150 to 160 tonne range – about 50 tonnes per trailer. It depends on how fresh the logs are. When they sit out in the sun, they dry out real quick.”

Stephen says he’s driven trucks for 33 years, mostly off-highway. He has no need for maps or navigation in his home area.

“We hunted up here when we were younger. I know most of the forest roads,” he says.

The occasional deer or wild pig can still be seen alongside the forest roads, but Stephen says it’s not as common now.

Above: Jake Rogers is RFH’s Off Highway Truck Manager and loves working with the biggest trucks in the fleet. Below: The C509 has twin 420-litre fuel tanks. The Cummins X15 is same 578hp unit used in many Kenworth on-highway trucks.

For the most part Stephen says driving the treble isn’t a great deal different to driving an off-highway double. But there is more work to do.

“Generally, its four loads a day but you might get five on the odd day. Each run is 24 chains, so it’s almost 100 a day if I do four loads.”

He likes the new automated chain tensioning system.

“So far, it’s taking a bit longer than the old twitches but it’s easier on the body than swinging on a twitch pipe. And if the load moves it will re-tension itself.”

He says the treble trailer combination tracks quite well.

“On the slow 90-degree corners the back trailer cuts in about twofeet more than a double would do,” he says.

In slippery conditions the SISU diff cross locks make a big difference but occasionally getting stuck is an inevitability out in the logging skids.

“It’s no different to a double. It loses traction unless there is weight on the drive tyres. You can’t drive these things and not get stuck from time to time – it’s going to happen. Most times it’s just a nudge from a loader to get going again.

“The best way to load these is a serious load of five-nines [5.9m logs] on the front so it’s got plenty of weight on the drive axles.”

Stephen says his first impression of the new C509 is that it’s a little quieter than the original unit and the engine picks up revs a little quicker. He says the screen for the audio unit is a new design and that’s about it for change compared to the four-year-old C509.

Freed of its 144-tonne burden, the unladen – and uphill – return run offers a marked contrast. The C509 cruises comfortably in top

finance available

WWW.ADVANCEQUIP.CO.NZ

2023

Features including slipper spring front suspension and SISU hub reduction rear axles with 5.56:1 final drive ratio are key components of the C509 for off-highway work.

gear, but you are aware of the shorter gearing and the longer climbs are a reminder the treble still weighs not much less than a fully laden truck on the highway.

Early on the second run Stephen suggests the load feels lighter than our first. There’s a gradual climb at just under 40kph where sixth-high is a gear above what he normally uses.

He’s proven spot-on at the weighbridge where the dockets add up to 141.6-tonne payload.

While we are on the wide but high crowned gravel roads Stephen points out the importance of staying close to the centre of the road while watching for – and listening on the bush radio – for any oncoming traffic.

The further left he moves the more chance the rear trailer will begin to slip down the camber of the road, making a gradual move toward the water table that is tricky to counteract.

Stephen says he enjoys off-highway work and even when making multiple runs a day between KPP and Murupara, no two trips are ever the same.

That’s no surprise when you are working with a truck more than 50 metres long and weighing almost four times as much as large highway units.

“Each load is different and every time the bumps feel a bit different.

You have to be 100% on all the time so you never get behind what the truck is going to do,” Stephen says.

“I’ve been on this a year and a half [driving the RFH trebles], and it still surprises me sometimes. But I enjoy it and it’s definitely a privilege to be given the opportunity to drive it.” T&D

THE OFF-HIGHWAY FOREST ROADS IN KAINGAROA ARE A

special place for me.

I remember the first time I got the chance to visit this amazing place, which is almost shrouded in secrecy. That was back in the days when my father was doing the truck testing…. And maybe I even had a little more hair back then.

I vividly remember the extra-long stem units and doubles at work and thinking `wow, just wow, what the hell are these things doing here? I had never seen them before, and I remember watching my father test doubles and thinking `how the hell did he get in there and just drive that?’

I’ve visited Kaingaroa many times and ever since I took over the NZ T&D test driving it’s been my goal – or maybe a dream of mine – to drive an off-highway unit. And when I heard about RFH’s new Kenworth C509 treble I took my chance with a phone call to Southpac’s Adam MacIntosh. Adam then spoke to Tony Sargison who put me onto Jake Rogers.

Suddenly, what had seemed in my mind to be a major undertaking was becoming a reality. Jake set a date and I was about to make my dream come true.

A dream, but also a challenge. So, I decided to spend a few days with the treble and driver Stephen Teddy so I could build up the confidence to give it a go myself.

After two full days riding shotgun with Stephen, it was my turn to take over the gear stick. Even after watching and learning from Stephen the thought of driving this monster and splitting every gear was enough to put doubt in my mind. Could I actually do it? Or even worse, would I break the bloody thing?

With strict requirements on who is allowed to drive this truck I was well aware of the huge privilege I was being given. With this in mind Jake jumped in the passenger seat to coach me through everything.

This is not a truck you can just jump in and drive. You need to know the terrain - every hill small and large and even the camber changes of

Hayden Woolston