SAFETY GRATING ®

WHEN SAFETY IS THE UTMOST PRIORITY

i

CONTENTS TABLE OF CONTENTS w Safety Grating Page Diamond-Grip® Channel............................ 1 - 6 Diamond-Grip®Walkway............................ 7 - 8 Safety-Grip® Channel.................................. 9 - 12 Safety-Grip® Walkway.................................13 - 14 Safety-Tread® Channel...............................15 - 16 Safety-Tread® Flooring...............................17 - 18 Safety-Tread® Ladder Rungs....................19 Stair Treads.................................................... 20 Roof Grip®...................................................... 21 Tread Friction Test Report........................ 22 Installation Accessories............................ 23 -24 Diamond-Grip Channel Safety-Grip Channel Safety-Tread Channel Safety-Tread Flooring QUALITY PRODUCTS – AROUND THE GLOBE ALABAMA METAL INDUSTRIES CORPORATION 800.366.2642 • amicoglobal.com Ladder Rungs WWW.AMICOGLOBAL.COM

TABLE OF

SAFETY GRATING

SAFETY GRATING

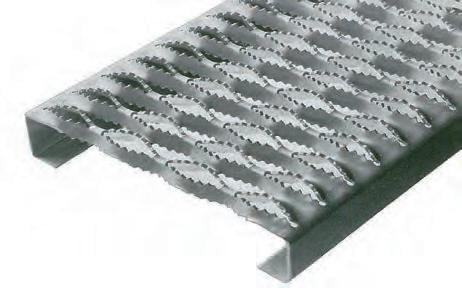

Diamond-Grip® Channel is a one-piece metal plank grating manufactured by a cold forming process in the shape of a channel. The web of the channel is the walking surface and has rough serrated edges around diamond shaped openings.

FEATURES & BENEFITS

•Serrated edges around diamond shaped openings provide slip resistance under slippery conditions such as snow, ice, grease, oil, etc.

•One-piece metal construction.

•Lightweight design provides high strength to weight ratio.

•Long life span requiring little maintenance.

•Simple and economical installation as planks are self-framing.

•Adaptable to cost effective custom fabrication.

•Can be easily formed in standard channel or custom shapes.

MATERIAL SPECIFICATIONS

Grating shall be “Diamond-Grip® Channel,” manufactured from (see ‘Material Options’ below) and complete with a (1-1/2”, 2”, 2-1/2”, 3”) side channel depth, by AMICO.

• MATERIAL OPTIONS

•ASTM-A-653, G-90 (Z-275) Pre-galvanized 14 and 12GA steel.

•ASTM-A-1011, HRP&O 14 and 12GA steel.

•ASTM B209, 5052-H32 Aluminum, .080” and .100” thick.

•ASTM A240, Type 316L 2B Stainless Steel 14GA (up to 11-3/4” width).

•ASTM A240, Type 304L 2B Stainless Steel 16GA (up to 11-3/4” width).

NOTE:

•Tolerances on all dimensions are ±1/8”

•Standard lengths are 121½” & 144”.

•Tolerance on manufactured and cut lengths is ±1/8”.

•When cutting Diamond-Grip®, AMICO® recommends cutting to full or half diamond increments. Contact sales for actual dimensions.

• Camber is an expected condition with sheet metal products. While ASTM allowance is generous, AMICO attempts to lessen the effects. Normal clearances should offset this phenomenon, however where tolerances warrant, contact AMICO for clarification.

1

WWW.AMICOGLOBAL.COM Channel Return Diamond to Width A Flange B Outside C 4-3/4”7/8” 5/16” 7” 1” 1/4” 9-1/2”7/8” 1/4” 11-3/4”1” 3/16” 18-3/4”1” 3/16” 24”1-1/8”7/16”

DIAMOND-GRIP® CHANNEL www.amicoglobal.com | 800.366.2642 1 ®

SAFETY GRATING

SAFETY GRATING

DIAMOND-GRIP® CHANNEL LOAD & DEFLECTION TABLES

Explanation of Load Type

U = uniform load (lb/ft2)

D = corresponding deflection (in) resulting from uniform load

C = concentrated load (lb)

D = corresponding deflection (in) resulting from concentrated load

Note:

•All UDL and concentrated loads include a safety factor of 1.67.

•Spans and loads to the right of the bold line, based on loads indicated, may exceed deflections of L/120.

• 2½” channel not shown in tables. Available by special request only.

2

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 4 3/4 Inch Wide - 2 Diamond 1-1/2".267U1516970674495379299243200168 D0.090.130.190.250.320.410.510.610.73 2.3lb/f t.202C600480400343300267240218200 D0.060.100.150.210.260.330.450.570.59 2".513U2236143199473055944235829624821218315914011089 D0.060.080.130.170.220.290.340.420.500.590.680.780.901.121.38 2.5lb/ft.298C885708590506443393354322295272253236221197177 D0.060.070.100.140.170.230.270.330.400.460.540.630.710.901.11 1-1/2".125U17901147798587451357290240203173150131116 D0.070.100.150.200.270.340.420.510.610.710.830.961.09 3.0lb/ft.278C708568474407357318287262241223208195184 D0.050.080.120.160.210.270.330.410.480.570.660.770.88 2".263U225514451005739567449365302255218188165145116957967 D0.050.070.100.140.190.240.290.350.420.500.580.670.760.981.221.491.79 3.3lb/ft.211C892715597512449400361329303280261245230206188172160 D0.040.060.080.110.150.190.210.280.340.400.460.530.610.780.971.191.43 2".223U139889562245735027722518615613311510189 D0.090.140.200.270.360.450.560.680.810.951.111.271.45 .93lb/ft.233C553443369317277247222202186172160149140 D0.070.110.160.220.290.360.450.540.650.760.881.021.16 2".279U17941148797586448354287237199170146128112 D0.140.210.280.370.460.570.690.830.971.121.291.47 1.16lb/ft.291C710568473406355316284258237218203189178 D0.080.120.170.230.300.370.460.560.660.780.901.031.18 Steel 12GA Alum .080" Type 5052 H32 Steel 14GA 2".339U17301109772568436346281233196168146127113 D0.050.070.100.140.180.230.290.350.420.490.570.660.76 2.5lb/ft.281C685549458394345308278254233216202189178 D0.040.060.080.110.150.190.230.280.330.390.460.530.61 Stainless Steel 14GA Type 316 Alum .100" 0.09 Type 5052 H32

2 www.amicoglobal.com | 800.366.2642 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

DIAMOND-GRIP® CHANNEL LOAD & DEFLECTION TABLES

7 Inch Wide - 3 Diamond

Explanation of Load Type

U = uniform load (lb/ft2)

D = corresponding deflection (in) resulting from uniform load

C = concentrated load (lb)

D = corresponding deflection (in) resulting from concentrated load

Note:

•All UDL and concentrated loads include a safety factor of 1.67.

•Spans and loads to the right of the bold line, based on loads indicated, may exceed deflections of L/120.

• 2½” channel not shown in tables. Available by special request only.

3

CLEAR SPAN PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" 1-1/2".115U76649234325319415412610592 D0.060.090.130.180.240.300.370.450.55 2.9lb/f t.141C447358300258227203183168159 D0.050.070.110.140.190.240.300.360.44 2".235U1374881613451347275223185156134116101907259 D0.050.080.110.150.200.250.310.380.460.540.630.720.831.061.32 3.2lb/f t.186C802642536461404361326297273254237222209188172 D0.040.060.090.120.160.200.250.310.360.430.500.580.660.851.06 1-1/2".154U13048365824283292612121761481271109685 D0.070.110.160.220.290.360.450.550.650.770.901.041.18 3.9lb/ft.194C761609509437384342309282259240224210198 D0.060.090.130.170.230.290.360.440.520.620.720.830.95 2".313U1710109676256143034127723019416514312511188726051 D0.050.080.110.150.200.260.320.380.460.540.630.720.831.061.321.621.95 4.4lb/ft.254C997799667573502447404368339314292274258232211194180 D0.040.060.090.120.160.200.250.310.370.430.500.580.660.851.061.291.56 2".266U9756244343192441931571301099381 D0.100.160.230.310.400.510.630.760.911.071.24 1.2lb/f t.212C568455380326285254229208191177164 D0.080.130.180.250.320.410.500.610.730.851.00 2".333U1169 D 1.5lb/ft.265C682 D Steel 14GA Steel 12GA Alum .080" 3"1.263U324720801446106381564552343336530926723320516313311194 D0.040.060.080.110.140.180.220.270.320.380.440.500.570.730.911.111.33 5.1lb/ft.532C1894151612651086951847763695639585545510479428388355328 D0.030.040.060.090.110.140.180.220.260.300.350.400.460.580.730.891.06 Type 5052 H32 2".383U18191166811597458363295244206176153133118 D0.080.130.180.250.330.410.510.620.740.881.021.181.35 3.2lb/ft.310C1061850710609534476430392361334311292275 D0.060.100.150.200.260.330.410.500.600.700.820.941.08 Stainless Steel 14GA Type 316 Alum .100" 0.08 0.06 748 546 0.12 0.10 520 455 0.17 0.14 231 303 0.37 0.30 292 341 0.30 0.24 382 390 0.23 0.18 130 227 0.67 0.53 155 248 0.56 0.45 187 273 0.46 0.37 83 182 1.04 0.83 95 195 0.90 0.73 111 210 0.78 0.63 73 171 1.18 0.95 Type 5052 H32

www.amicoglobal.com | 800.366.2642 3 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

Explanation of Load Type

U = uniform load (lb/ft2)

D = corresponding deflection (in) resulting from uniform load

C = concentrated load (lb)

SAFETY GRATING WWW.AMICOGLOBAL.COM

D = corresponding deflection (in) resulting from concentrated load

Note:

•All UDL and concentrated loads include a safety factor of 1.67.

•Spans and loads to the right of the bold line, based on loads indicated, may exceed deflections of L/120.

• 2½” channel not shown in tables. Available by special request only.

4

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" 9 1/2 Inch Wide - 4 Diamond CLEAR SPAN 1-1/2".128U77949934625519515412510387 D0.090.120.190.260.330.410.520.620.74 3.5lb/f t.170C617494411353309274247224206 D0.060.100.150.200.270.330.410.500.60 2".264U10636814743492682131731441211049079705646 D0.050.080.120.160.210.260.330.400.470.560.650.750.861.101.38 3.7lb/f t.224C841674563484425379342312288267249234221199181 D0.040.060.090.130.170.210.260.320.380.450.520.600.690.881.10 1-1/2".172U98863444132524919816113311396847365 D0.080.120.170.230.300.390.480.580.690.820.951.101.26 4.8lb/ft.225C782627524450395352318291268248232218205 D0.060.090.140.190.240.310.380.460.550.650.760.881.01 2".354U13828866164533482762241861571341161019072594942 D0.050.080.120.160.210.270.340.410.490.570.670.770.881.131.411.722.08 5.1lb/ft.306C1094876732628551491443404372345321301284255232213198 D0.040.070.100.130.170.220.270.330.390.460.540.620.710.891.131.381.66 2".300U8005123562612001581281068976655750 D0.120.190.270.370.500.620.760.941.121.301.491.731.97 1.4lb/ft.256C633507422362317282253230211195181169158 D0.100.160.230.300.400.490.620.740.881.041.211.381.57 2".143U75048033024018614712099827058473927 D0.060.090.130.180.240.300.370.450.530.630.700.750.800.90 3.2lb/ft.165C455455398341299265239217199184171159149133 D0.040.070.110.150.190.240.300.360.430.510.590.670.760.97 Steel 14GA Steel 12GA Alum .080" Stainless Steel 16GA 3"1.363U2270145310097415675484443673082632261971731371119277 D0.040.060.080.110.140.220.280.330.400.470.540.620.700.891.101.351.60 5.8lb/ft.605C13551355135512551098976878799732676627586549488439399366 D0.020.040.070.110.150.180.220.270.320.380.430.490.560.710.891.041.27 Type 5052 H32 Type 304 2".401U154088768750638830725020717514912911310080 D0.070.110.160.220.280.360.440.540.640.760.881.021.171.49 3.7lb/ft.287C915915816700614548494451415384358336316284 D0.040.080.130.170.230.290.360.430.520.610.710.820.931.19 Stainless Steel 14GA Type 316 2".375U897 D 1.75lb/ft.32C710 D Alum .100" 0.07 0.06 574 568 0.11 0.09 399 473 0.15 0.13 177 316 0.35 0.28 224 355 0.27 0.22 293 406 0.21 0.17 100 237 0.61 0.49 119 258 0.52 0.42 143 284 0.43 0.34 64 189 0.96 0.77 73 203 0.84 0.67 85 218 0.72 0.58 56 178 1.09 0.88 Type 5052 H32

DIAMOND-GRIP® CHANNEL LOAD & DEFLECTION TABLES 4 www.amicoglobal.com | 800.366.2642 ®

SAFETY GRATING

SAFETY GRATING

DIAMOND-GRIP® CHANNEL LOAD & DEFLECTION TABLES

Explanation of Load Type

U = uniform load (lb/ft2)

D = corresponding deflection (in) resulting from uniform load

C = concentrated load (lb)

D = corresponding deflection (in) resulting from concentrated load

Note:

•All UDL and concentrated loads include a safety factor of 1.67.

•Spans and loads to the right of the bold line, based on loads indicated, may exceed deflections of L/120.

• 2½” channel not shown in tables. Available by special request only.

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 11 3/4 Inch Wide - 5 Diamond 1-1/2".146U543349243179138110897463 D0.060.100.150.200.260.330.410.500.60 4.1lb/f t.178C493427357307270242219201185 D0.050.080.120.160.210.270.330.400.48 2".314U8955744002952261791461211028775655745 D0.050.080.120.160.210.270.340.410.490.570.660.760.861.09 4.5lb/f t.247C493493493493443395357326299276259239224199 D0.020.050.080.130.170.220.270.330.390.460.530.600.690.87 1-1/2".195U8425403762762121681371139582716255 D0.080.130.180.250.320.410.510.620.730.871.011.161.33 5.7lb/ft.244C815661552474415370334305280260242227214 D0.060.100.140.200.260.330.410.490.590.690.810.931.06 2".419U12437975544083132482001661391191028978625041 D0.060.090.130.180.230.290.360.440.520.610.720.820.921.191.441.75 6.1lb/ft.338C815815814699613545491446409378351327307273245223 D0.030.060.100.140.190.240.290.350.410.490.570.650.750.941.151.41 2".355U715457319233179141114947968585145 D0.150.230.330.450.580.740.901.101.321.541.772.072.38 1.6lb/ft.283C362362362362350311280254233215200187175 D0.060.120.210.320.460.600.740.881.051.231.441.651.88 2".143U60642629621816713210788746354484129 D0.050.080.110.160.210.260.320.380.460.530.630.730.800.90 3.7lb/ft.165C376376376376333296266242222205190178166148 D0.020.040.070.100.160.210.250.310.370.430.500.570.650.82 Steel 14GA Steel 12GA Alum .080" Stainless Steel 16GA 3"1.672U16661363946695532421341282237202174151133105857059 D0.030.070.100.130.180.230.280.340.400.470.550.630.710.901.131.341.60 6.7lb/ft.702C815815815815815815815758695642596556521463417379347 D0.010.030.050.070.110.160.220.270.320.380.430.500.570.730.891.071.29 Type 5052 H32 Type 304 2".427U1276812565416319253206171144123107938266 D0.090.140.200.270.360.460.560.690.820.971.131.301.481.90 4.5lb/ft.313C899899830713625557503459423392365343323290 D0.050.100.160.220.290.360.450.550.660.770.901.041.191.52 Stainless Steel 14GA Type 316 1.5".207U493 D 1.9lb/ft.254C483 D Alum .100" 0.08 0.07 316 386 0.13 0.11 219 322 0.19 0.15 97 215 0.42 0.34 123 241 0.33 0.27 161 276 0.25 0.21 55 161 0.74 0.60 65 176 0.62 0.50 79 193 0.52 0.42 35 129 1.16 0.93 40 138 1.01 0.81 47 149 0.87 0.70 31 121 1.32 1.06 2".444U725 D 2.0lb/ft.354C710 D Alum .100" 0.06 0.05 464 568 0.09 0.07 322 473 0.13 0.11 143 316 0.29 0.24 181 355 0.23 0.19 237 406 0.18 0.14 81 237 0.52 0.42 96 258 0.44 0.35 116 284 0.36 0.29 52 189 0.81 0.65 59 203 0.71 0.57 69 218 0.61 0.49 45 178 0.92 0.74 Type 5052 H32 Type 5052 H32

www.amicoglobal.com | 800.366.2642 5 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

DIAMOND-GRIP® CHANNEL LOAD & DEFLECTION TABLES

Note:

•Strut deflection may become a limiting factor on 18” and 24” widths resulting in lower load values as indicated in tables.

•Web stiffeners can be supplied for ends and junctions of planks to even deflection if required.

6

PRODUCT DETAILS CLEAR SPAN Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" 18 3/4 Inch Wide - 8 Diamond 1-1/2".178U41126318213410381665446 D0.080.110.180.240.310.390.490.580.70 5.9lb/f t.216C555513428365321285257233214 D0.060.100.140.190.250.310.380.470.55 2".347U60638826919815212097806757494338 D0.060.080.120.160.210.270.330.390.480.560.640.730.84 6.1lb/f t.319C555555555541474421379245316292271253237 D0.020.050.080.130.170.210.270.320.380.450.520.600.67 1-1/2".240U553354246181138109897361534640 D0.070.110.170.230.300.380.480.580.680.800.941.09 8.2lb/f t.291C818691576494432384346314288267250235 D0.060.090.140.190.250.310.380.460.540.640.750.87 2".473U825528367269206163132109927867595241 D0.060.090.120.170.230.290.350.430.510.590.680.790.901.14 8.5lb/f t.434C818818818737644573516496430397368344322286 D0.030.060.090.130.180.230.280.330.400.470.550.630.710.90 3"1.245U10479426544803682912351951631391201059273594941 D0.030.060.100.130.180.220.270.330.390.450.530.610.690.881.071.311.55 9.3lb/ft.774C818818818818818818818818766707657613575511460418383 D0.010.020.040.070.100.140.190.260.310.360.420.480.560.700.871.051.24 2".573U51432922916812910283695849 D0.160.250.360.480.610.790.971.181.401.65 2.7lb/f t.525C537537537460402353323299269249 D0.090.150.280.390.500.630.780.931.121.31 Steel 12GA Alum .100" Type 5052 H32 Steel 14GA PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 24 Inch Wide - 10 Diamond Steel 14GA 1-1/2".221U36723516312092725949413530 D0.090.140.200.270.340.440.560.660.792.703.11 7.3lb/f t.247C571571489419367326293267245226210 D0.060.100.150.210.280.350.440.530.622.162.51 2".427U53934524017613510686716051.0044383427 D0.050.090.130.170.230.290.350.430.510.600.690.780.901.18 7.6lb/f t.363C571571571571539479431392359332308287270240 D0.020.050.080.120.180.240.290.350.410.480.550.640.720.92 1-1/2".299U4963172201621249879665547 D0.080.130.180.250.320.410.500.610.720.86 10.1lb/f t.334C861794661567496441397361332305 D0.050.100.140.200.260.330.410.490.580.68 2".584U738472328241185146118988270605246 D0.060.090.140.180.230.300.360.450.540.630.720.821.22 10.8lb/f t.497C861861861843738656590537492454422394369 D0.030.060.090.140.180.240.290.360.420.500.570.670.76 3"1.513U861835580426326258209173145124107938264524336 D0.030.070.100.140.180.220.280.330.400.470.550.630.710.891.091.341.61 11.3lb/ft.879C861861861861861861861861861803746696653580522475435 D0.010.020.040.060.090.130.180.240.310.370.440.500.570.720.881.081.28 Steel 12GA

6 www.amicoglobal.com | 800.366.2642 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

PRODUCT DESCRIPTION

Diamond-Grip® Walkway is a one-piece metal plank grating manufactured by a cold forming process in the shape of an inverted channel. The web of the channel is the walking surface and has rough serrated edges around diamond shaped openings. The extended flanges support the load and provide a built in kickplate (toeboard).

FEATURES & BENEFITS

•Serrated edges around diamond shaped openings provide slip resistance under slippery conditions such as snow, ice, grease, oil, etc.

•One-piece metal construction complete with a full height toeboard on each side of the walking surface.

•Lightweight design provides high strength to weight ratio.

•Long life span requiring little maintenance.

•Simple and economical installation as walkways are self-framing.

•Adaptable to cost effective custom fabrication.

MATERIAL SPECIFICATIONS

Grating shall be “Diamond-Grip® Walkway,” manufactured from (see ‘MATERIAL OPTIONS’ below) and complete with an (4-1/2”, 5”) integral toeboard, by AMICO.

• MATERIAL OPTIONS

SAFETY GRATING WWW.AMICOGLOBAL.COM

•ASTM-A-653, G-90 (Z-275) pre-galvanized 14 or 12GA steel.

• ASTM-A-1011, HRP&O 14 or 12GA steel.

7

DIAMOND-GRIP® WALKWAY www.amicoglobal.com | 800.366.2642 7 ®

SAFETY GRATING

SAFETY GRATING

DIAMOND-GRIP® WALKWAY LOAD & DEFLECTION TABLES

Explanation of Load Type

U = uniform load (lb/ft2)

D = corresponding deflection (in) resulting from uniform load

C = concentrated load (lb)

D = corresponding deflection (in) resulting from concentrated load

Note:

•All UDL and concentrated loads include a safety factor of 1.67.

• Strut deflection may become a limiting factor resulting in lower load values as indicated in table.

Note:

•Tolerances on all dimensions are ±1/8”

• Standard lengths are 121-1/2” & 144”.

•Tolerance on manufactured and cut lengths is ±1/8”.

•When cutting Diamond-Grip®, AMICO® recommends cutting to full or half diamond increments.

• Camber is an expected condition with sheet metal products. While ASTM allowance is generous, AMICO attempts to lessen the effects. Normal clearances should offset this phenomenon, however where tolerances warrant, contact AMICO for clarification.

8

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 4-1/2"2.457U475475475475475429348287240203177150135107877160 D0.450.460.470.490.520.510.470.430.420.410.430.430.480.540.620.720.84 12.5lb/ft1.171C475475475475475475475475475475475475475475475475475 D0.360.360.360.360.360.390.410.430.440.460.490.510.540.600.700.810.95 4-1/2"1.447U300300300300300263213176145124110948467554437 D0.500.510.520.550.580.550.490.460.450.430.470.460.510.580.670.750.87 8.9lb/ft.776C300300300300300300300300300300300300300300300300300 D0.400.400.400.410.420.430.440.460.480.500.530.560.600.690.800.951.10 5"1.929U300300300300300263213176145124110948467554437 D0.500.500.520.540.560.550.460.420.390.380.400.390.420.470.530.580.67 9.6lb/ft.917C300300300300300300300300300300300300300300300300300 D0.400.400.400.400.410.420.430.450.460.480.500.520.550.620.700.820.97 5"3.247U475475475475475429348287240203177150135107877160 D0.450.460.460.480.500.490.440.390.370.360.370.360.390.430.490.560.65 13.1lb/ft1.385C475475475475475475475475475475475475475475475475475 D0.360.360.360.360.370.380.400.410.420.430.440.470.490.550.610.690.80 24" Wide 12GA 24" Wide 12GA 24" Wide 14GA 24" Wide 14GA

8 www.amicoglobal.com | 800.366.2642 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY-GRIP® CHANNEL

PRODUCT DESCRIPTION

Safety-Grip® Channel is a one-piece metal plank grating manufactured by a cold forming process in the shape of a channel. The web of the channel is the walking surface and has large debossed holes, surrounded by smaller embossed traction buttons.

FEATURES & BENEFITS

•Embossed traction buttons provide superior slip resistance in all directions and in all weather conditions.

•Large debossed holes provide maximum drainage of debris and allow up to 50% free air opening depending on channel width.

•Self-cleaning due to resilience of walking surface.

•One-piece metal construction.

•Lightweight design provides high strength to weight ratio.

•Long life span requiring little maintenance.

•Simple and economical installation as planks are self-framing.

•Adaptable to cost effective custom fabrication.

•Can be easily formed in standard channel or custom shapes.

MATERIAL SPECIFICATIONS

Grating shall be “Safety-Grip® Channel,” manufactured from (see ‘MATERIAL OPTIONS’ below) and complete with a (1-1/2”, 2”, 3”) side channel depth, by AMICO.

• MATERIAL OPTIONS

•ASTM-A-653, G-90 (Z-275) Pre-galvanized 13 or 11GA steel.

•ASTM-A-1011, HRP&O 13 or 11GA steel.

•ASTM B209, 5052H32 Aluminum .125” thick (up to 18” width).

•ASTM A240, Type 316L 2B Stainless Steel 14GA (up to 12” width).

•ASTM A240, Type 304L 2B Stainless Steel 16GA (up

Note:

1.Tolerances on all dimensions are ±1/8”

2.End-hole pattern shown on diagram is even. Widths indicated with ** have a staggered end-hole pattern.

3.Outside traction buttons on all widths except 18” & 24” width.

4.Standard lengths are 120” and 144”.

5.Tolerance on manufactured and cut lengths is ±1/8”.

6. Camber is an expected condition with sheet metal products. While ASTM allowance is generous, AMICO attempts to lessen the effects. Normal clearances should offset this phenomenon, however where tolerances warrant, contact AMICO for clarification.

9

CHANNEL RETURN CL HOLE WIDTH FLANGE CHANNEL EDGE “A” “B” “C” **5” 7/8” 1 21/32” **7” 1” 1 13/16” **10” 7/8” 1 5/8” **12” 1” 1 25/32” **18” 1” 1 13/32” **24” 1 1/18” 1 7/8” **30” 1 1/18” 2 11/32” SAFETY GRATING www.amicoglobal.com | 800.366.2642 9 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY-GRIP® CHANNEL LOAD & DEFLECTION TABLES

Explanation of Load Type

U = uniform load (lb/ft2)

D = corresponding deflection (in) resulting from uniform load

C = concentrated load (lb)

D = corresponding deflection (in) resulting from concentrated load

Note:

•All uniform and concentrated loads include a safety factor of 1.67.

•Spans and loads to the right of the bold line, based on loads indicated, may exceed deflections of L/120.

10

CLEAR SPAN PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" 2".377U3295210914641076824651527436366312269234 D0.050.070.110.150.190.240.300.360.430.500.580.67 2.5lb/f t.312C13731098915784686610549499458422392366 D0.040.060.090.120.150.190.240.290.340.400.470.53 Stainless Steel 14GA Type 316 5 Inch Wide - 2 Hole 1-1/2".228U19471248868639490388315261220188163142126 D0.060.100.140.190.250.320.390.480.570.670.780.901.03 2.6lb/ft.247C811650542466408364328299275255237222209 D0.050.080.110.150.200.250.310.380.460.540.620.720.82 2".449U29431885131196473958547539333128324521418815012210286 D0.050.080.110.160.200.260.320.390.460.540.630.730.831.051.311.601.92 2.8lb/ft.372C973973819703616549495451414383357334314281255233216 D0.030.060.090.120.160.210.250.310.370.430.500.580.660.841.051.281.54 2".603U247915871102809620490397328275 D0.080.120.170.240.310.390.490.590.70 1.3lb/f t.449C1033826689590516459413379344 D0.060.100.140.190.250.320.390.470.56 Alum .125" Type 5052 H32 Steel 13GA

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 2".426U21481375955701537424344284239203175 D0.040.060.090.120.150.190.240.290.350.410.47 2.8lb/f t.348C12531002835716626557501456418385358 D0.030.050.070.090.120.160.190.230.280.320.38 Stainless Steel 14GA Type 316 7 Inch Wide - 3 Hole 1-1/2".260U148995466448937529724120016914412510997 D0.060.090.140.190.240.310.380.460.550.650.760.881.00 3lb/ft.277C793696581499437390352321295274255239225 D0.040.080.110.150.190.250.310.370.440.520.610.700.80 2".509U2229142899373156044436029825121518616214311493 D0.050.080.110.150.200.250.310.370.450.520.610.700.801.021.27 3.3lb/f t.415C793793793746654582525479440407379355334299271 D0.020.050.080.120.160.200.250.300.360.420.490.560.640.821.02 1-1/2".330U19211231856630483382310257217185160140124 D0.060.100.140.190.240.310.380.470.560.650.760.881.00 4.2lb/ft.353C1098897749643564502453413379351327306288 D0.050.080.110.150.200.250.310.370.440.520.610.700.80 2".655U29951918133398175259548339933629325322119515512610589 D0.050.080.120.160.210.270.340.410.490.560.620.710.811.031.281.561.87 4.5lb/ft.534C1098109810981001877781704641586556517484455407368337311 D0.030.050.090.130.170.220.270.330.390.440.490.570.650.821.021.251.50 2".686U19841270882648496392317262220 D0.080.130.190.250.330.420.520.630.75 1.5lb/f t.559C1157926771661579514463421386 D0.060.100.150.200.270.340.420.500.60 Steel 13GA Steel 11GA Alum .125" 3"1.726U376536022503184014101115904748629537464404356282229190161 D0.020.050.080.110.140.180.220.260.310.370.430.490.560.710.881.071.28 4.8lb/ft.966C1098109810981098109810981098109810981018946885831741669611563 D0.010.020.030.050.070.110.140.190.250.290.340.390.450.570.700.851.02 Type 5052 H32

10 www.amicoglobal.com | 800.366.2642 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

SAFETY-GRIP® CHANNEL LOAD & DEFLECTION TABLES

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 2".401U946762529388298235190157133 D0.040.080.110.150.200.250.310.370.45 3.2lb/f t.287C394394394394394394394360331 D0.020.030.050.090.130.170.210.290.37 Stainless Steel 14GA Type 316 10 Inch Wide - 5 Hole 1-1/2".271U1128722501368282223181149125107928071 D0.060.090.130.170.230.290.350.420.500.570.650.750.87 3.5lb/ft.259C625625625537470418376342313289269251235 D0.030.060.100.130.180.230.290.340.410.470.530.610.78 2".536U1500107674855142233427222519016214012210785685748 D0.040.070.100.140.180.230.290.350.420.490.570.660.750.951.161.411.69 3.9lb/ft.393C625625625625625625566516474439409380357317290259238 D0.020.030.050.090.130.190.230.280.330.390.460.530.600.760.931.131.34 1-1/2".343U13438615994413382682181801521301139887 D0.060.090.130.180.230.290.360.440.530.620.720.840.95 4.5lb/ft.329C861861749643564502453413380352328308290 D0.040.070.100.140.190.240.290.350.420.500.580.670.76 2".689U20671402975717550435353291245209180157138109887361 D0.060.090.130.180.230.290.360.420.470.540.570.660.760.911.131.381.63 4.8lb/ft.506C861861861861861861735668612565528490459408367334306 D0.020.040.070.120.170.200.290.350.390.430.480.530.580.740.911.091.30 3"1.844U20672067181613341021807654540454387334291255202163135113 D0.020.040.070.110.130.170.210.260.310.360.420.480.540.700.841.031.22 5.1lb/ft.938C861861861861861861861861861861861861851757681619567 D0.010.010.020.040.060.080.110.140.190.240.300.360.440.550.680.830.98 2".722U1278871605445341269218181152 D0.080.140.200.280.360.460.570.680.82 1.8lb/f t.530C533533533533533505455414380 D0.030.070.110.180.270.370.450.550.65 Steel 13GA Steel 11GA Alum .125" Type 5052 H32 PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 2".427U871600417308236187152126106 D0.040.070.090.130.170.220.270.330.39 3.8lb/ft.313C435435435435435435434394361 D0.020.030.050.090.130.190.250.300.36 Stainless Steel 14GA Type 316 12 Inch Wide - 6 Hole 1-1/2".350U99163544232625019816113411397847465 D0.050.080.120.170.220.280.340.420.500.580.680.780.89 4.3lb/ft.291C866794663570500446403368338315294276260 D0.040.070.100.130.180.220.280.340.400.460.540.620.71 2".630U1457934649478367290236195165141122107947561 D0.040.070.100.130.170.220.270.330.400.470.540.630.710.911.14 4.6lb/f t.437C866866866836733653590538494458427400376338307 D0.020.040.070.110.140.180.220.270.320.370.430.500.570.730.91 1-1/2".406U1118717499367282223182151127109948273 D0.060.090.130.170.220.280.350.430.510.600.700.810.92 5.3lb/ft.373C1118896748643564503454414381353329309291 D0.040.070.100.140.180.230.280.340.410.480.560.650.74 2".812U1875120183561447137330325121118015613612096786555 D0.060.090.140.180.240.310.380.460.550.650.750.860.991.261.571.912.30 5.5lb/ft.570C1362136212531075942839757690634586546511481431391358331 D0.030.070.110.150.190.250.300.370.440.520.600.690.791.011.251.531.84 3"2.158U2725237016471211928734595492414354305266235186151126106 D0.030.060.080.110.140.180.230.270.330.380.450.510.590.740.921.121.34 6.2lb/ft1.045C13621362136213621362136213621354124311491069999939838757692632 D0.010.020.040.060.090.120.170.220.260.310.360.410.470.600.740.901.07 2".851U1245797554407312247200165139 D0.090.150.210.290.380.480.590.720.86 2.1lb/ft.597C839839831713624555500455417 D0.050.100.170.230.300.380.480.580.69 Steel 13GA Steel 11GA Alum .125" Type 5052 H32

GRATING www.amicoglobal.com | 800.366.2642 11 ® WWW.AMICOGLOBAL.COM

SAFETY

SAFETY GRATING

SAFETY GRATING

SAFETY-GRIP® CHANNEL LOAD & DEFLECTION TABLES

Note: Strut deflection may become a limiting factor on 18” and 24” widths resulting in lower load values as indicated in tables.

12

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 18 Inch Wide - 10 Hole 1-1/2".345U641441307226174138112937968595146 D0.050.100.140.190.250.310.390.470.560.670.780.901.03 5.7lb/ft.292C480480480480480466421385355327304284266 D0.020.040.080.120.180.250.310.380.450.530.610.710.80 2".677U6416414603392602061681391171008776675343 D0.030.070.110.150.190.240.300.360.430.510.600.690.791.011.26 6.0lb/f t.440C480480480480480480480480480480456426399355319 D0.010.020.040.060.090.130.180.240.320.400.480.550.620.781.06 1-1/2".444U7524823362471901511231028674645650 D0.060.090.130.170.230.290.360.440.520.620.720.830.95 6.8lb/ft.381C1116904755649570509460420387359335315297 D0.040.070.100.140.180.230.290.350.420.490.580.670.76 2".894U120777353839630424119516213711710188786251 D0.050.080.120.160.210.260.330.400.470.560.650.750.851.091.36 7.1lb/f t.583C1116111611161039911812733668615570531498469421383 D0.030.050.090.130.170.210.260.320.380.450.520.600.680.871.09 3"2.400U1488148811538476495124153432882462121841621281048672 D0.020.040.070.100.130.150.190.230.270.320.370.430.480.610.760.921.08 7.9lb/ft1.070C111611161116111611161116111611161116111611161038973865778708649 D0.010.010.200.040.060.080.110.140.190.240.300.340.390.490.600.730.87 2".936U7925813602652031601301089177 D0.080.130.190.250.330.420.520.630.750.88 2.8lb/f t.612C594594594594594630567515472436 D0.030.060.110.170.260.380.480.580.700.81 Steel 13GA Steel 11GA Alum .125" Type 5052 H32 PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 24 Inch Wide - 13 Hole 2"1.017U5245244673442642091701411191028877685444 D0.030.070.130.170.230.290.360.430.520.610.710.820.941.201.50 8.9lb/ft.634C524524524524524524524524524524524524524489445 D0.010.020.040.060.090.130.180.240.310.390.480.600.720.961.20 3"2.694U52452452452447337430425221218115613712096786555 D0.010.020.040.070.110.140.180.220.260.300.350.400.460.590.730.891.07 9.8lb/ft1.149C524524524524524524524524524524524524524524524524524 D0.000.010.010.020.030.040.050.070.080.110.130.170.200.290.390.520.68 Steel 11GA PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 30 Inch Wide - 16 Hole 2"1.985U275275275251231183148122103 D0.020.040.090.170.240.310.380.470.56 11.8lb/f t.777C343343343343343343343343343 D0.010.010.020.040.060.080.110.150.20 3"2.728U2752752752752752512191811521301129786 D0.010.010.030.060.090.130.180.220.260.320.360.420.45 12.7lb/f t1.152C343343343343343343343343343343343343343 D0.000.000.010.010.020.020.040.050.060.080.100.120.15 4"5.402U275275275275275275275275240205177155136108887362 D0.000.010..010.030.040.070.110.160.200.230.270.310.360.450.560.680.82 13.5lb/ft1.769C343343343343343343343343343343343343343343343343343 D0.000.000.000.010.010.010.020.020.030.040.050.060.070.100.140.190.24 Steel 11GA

12 www.amicoglobal.com | 800.366.2642 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

PRODUCT DESCRIPTION

Safety-Grip® Walkway is a one-piece metal plank grating manufactured by a cold forming process in the shape of an inverted channel. The web of the channel is the walking surface and has large debossed holes, surrounded by smaller embossed traction buttons. The extended flanges support the load and provide a built in kickplate (toeboard).

FEATURES & BENEFITS

•Embossed traction buttons provide superior slip resistance in all directions and in all weather conditions.

•Large debossed holes provide maximum drainage of debris and allow up to 50% free air opening depending on channel width.

•Self-cleaning due to resilience of walking surface.

•One-piece metal construction complete with a full 5” toe-board height on each side of the walking surface.

•Lightweight design provides high strength to weight ratio.

•Long life span requiring little maintenance.

•Simple and economical installation as walkways are self-framing.

•Adaptable to cost effective custom fabrication.

MATERIAL SPECIFICATIONS

Grating shall be “Safety-Grip® Walkway,” manufactured from (see ‘MATERIAL OPTIONS’ below) and complete with an integral 5” toe-board, by AMICO.

MATERIAL OPTIONS

•ASTM-A-653, G-90 (Z-275) pre-galvanized 13 or 11GA steel.

• ASTM-A-1011, HRP&O 13 or 11GA steel.

Note:

•Tolerances on all dimensions are ±1/8”

• Standard lengths are 120” & 144”.

•Tolerance on manufactured and cut lengths is ±1/8”.

•Nominal 36” walkway has a 34” walking surface. 36” dimension is to outside of return flange.

WWW.AMICOGLOBAL.COM

13

SAFETY-GRIP® WALKWAY www.amicoglobal.com | 800.366.2642 13 ®

• Camber is an expected condition with sheet metal products. While ASTM allowance is generous, AMICO attempts to lessen the effects. Normal clearances should offset this phenomenon, however where tolerances warrant, contact AMICO for clarification.

SAFETY GRATING

SAFETY GRATING

SAFETY-GRIP® WALKWAY LOAD & DEFLECTION TABLES

Explanation of Load Type

U = uniform load (lb/ft2)

D = corresponding deflection (in) resulting from uniform load

C = concentrated load (lb)

D = corresponding deflection (in) resulting from concentrated load

Note:

•All uniform and concentrated loads include a safety factor of 1.67.

• Area in bold outline–contact AMICO for recommendations.

•Strut deflection may become a limiting factor resulting in lower load values as indicated in table.

14

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 5"6.610U355355355355355355355355355355346301245209169140118 D0.000.000.010.020.030.050.070.100.150.200.260.300.350.440.530.650.78 8.7lb/ft2.078C355355355355355355355355355355355355355355355355355 D0.000.000.000.000.010.010.010.020.020.020.030.040.050.070.090.120.16 5"9.968U657657657657657657657657619528455396348275223104155 D0.000.010.010.020.030.050.080.120.160.190.220.260.290.370.450.540.65 11.8lb/ft2.880C657657657657657657657657657657657657657657657657657 D0.000.000.000.000.010.010.010.020.020.030.040.040.050.080.110.140.18 5"10.090U384384384384384384384384384355306267234185150124104 D0.000.010.010.020.040.060.090.160.200.230.260.300.340.450.550.660.78 13.6lb/ft2.889C480480480480480480480480480480480480480480480480480 D0.000.000.000.000.010.010.010.020.020.030.040.050.060.080.110.150.19 5"N/AU18518518518518518518518518518518518518515812810689 D0.000.000.010.010.020.040.060.090.120.170.220.290.380.520.650.780.94 15.9lb/ftN/AC273273273273273273273273273273273273273273273273273 D0.000.000.000.000.000.010.010.010.020.020.030.030.040.050.070.100.13 24" Wide 11GA 36" Wide 11GA 24" Wide 13GA 30" Wide 11GA

14 www.amicoglobal.com | 800.366.2642 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

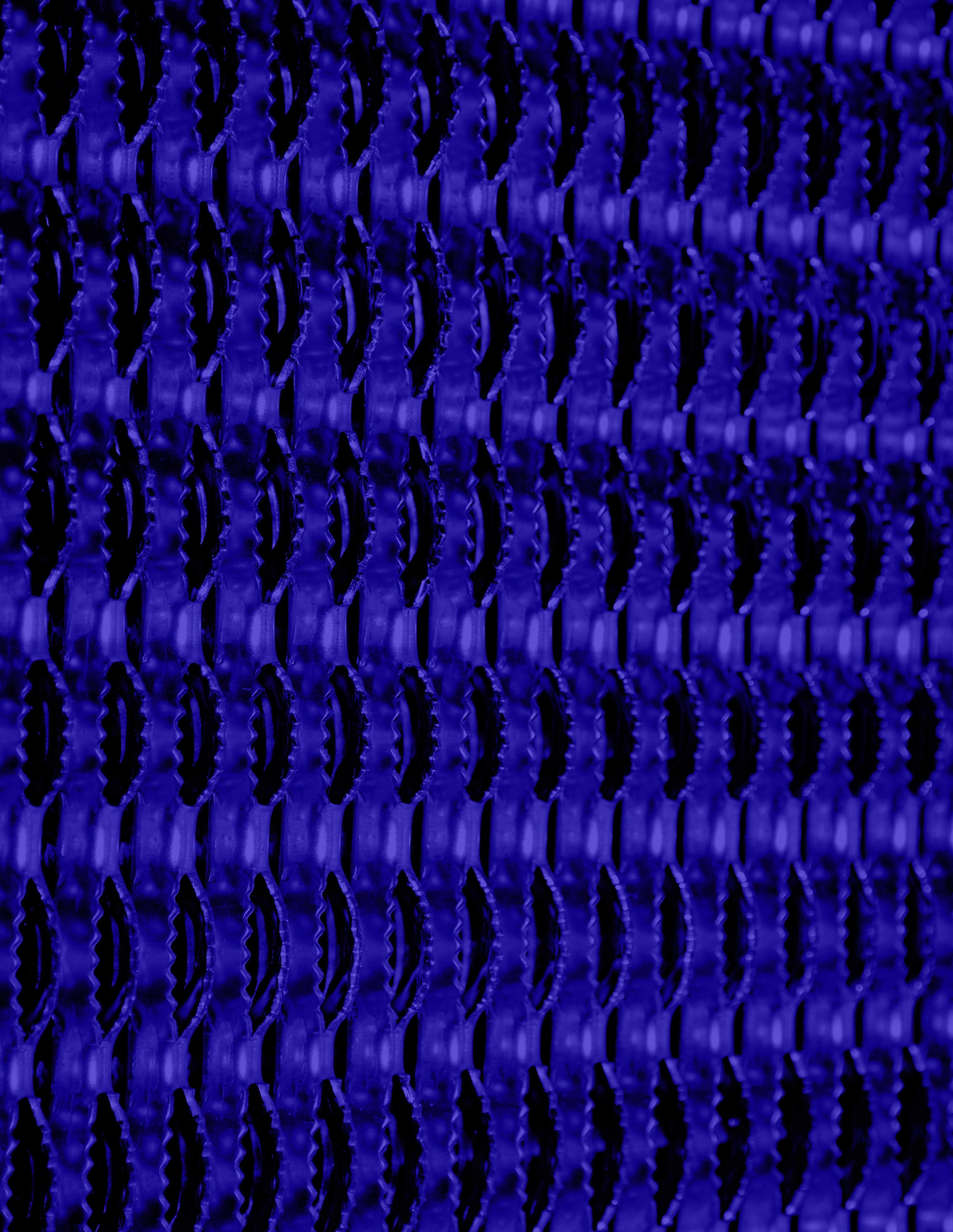

SAFETY-TREAD® CHANNEL

PRODUCT DESCRIPTION

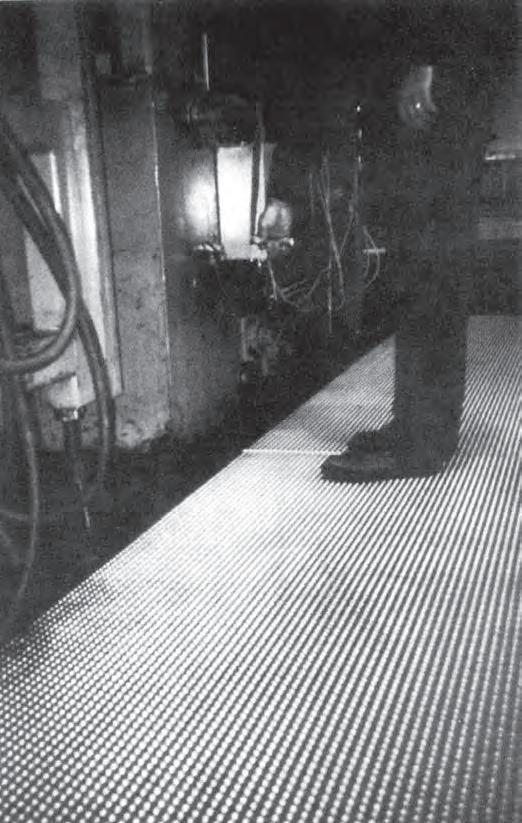

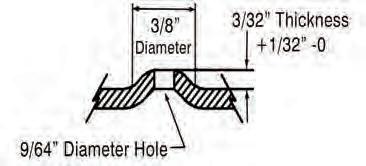

Safety-Tread® Channel is a one-piece plank grating manufactured by a cold forming process in the shape of a channel. The web of the channel is the walking surface which is covered with small perforated dimples.

FEATURES & BENEFITS

• Perforated dimples provide superior slip resistance in all directions. Quantity of dimples under foot provides exceptional adhesive friction.

• One-piece metal construction.

• Lightweight design provides high strength to weight ratio.

• Long effective life span requiring little maintenance.

• Can be easily formed in standard channel or custom shapes.

• Simple and economical installation as planks are self-framing.

• Adaptable to cost effective custom fabrication.

• Low projections and closed area provide an acceptable walking surface for industrial as well as institutional applications (i.e., women in heels can walk comfortably and safely).

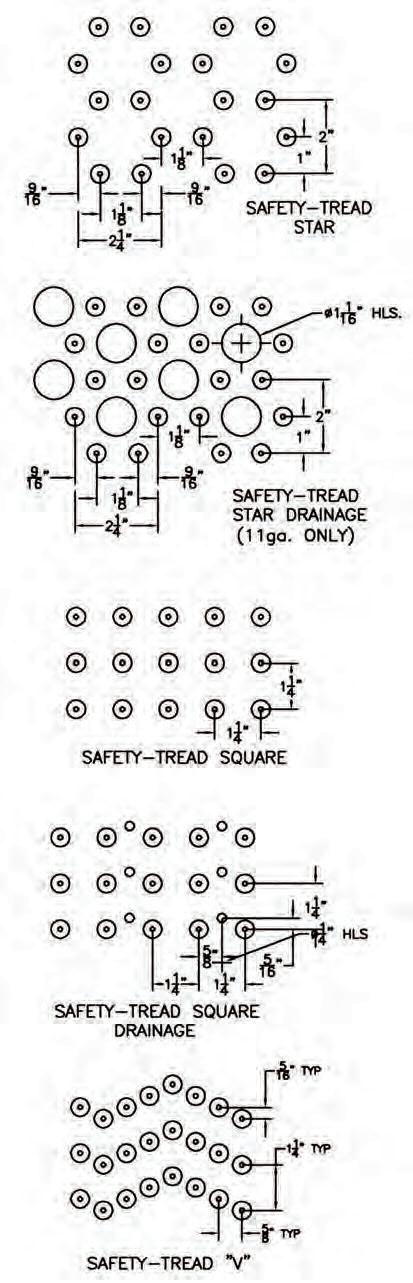

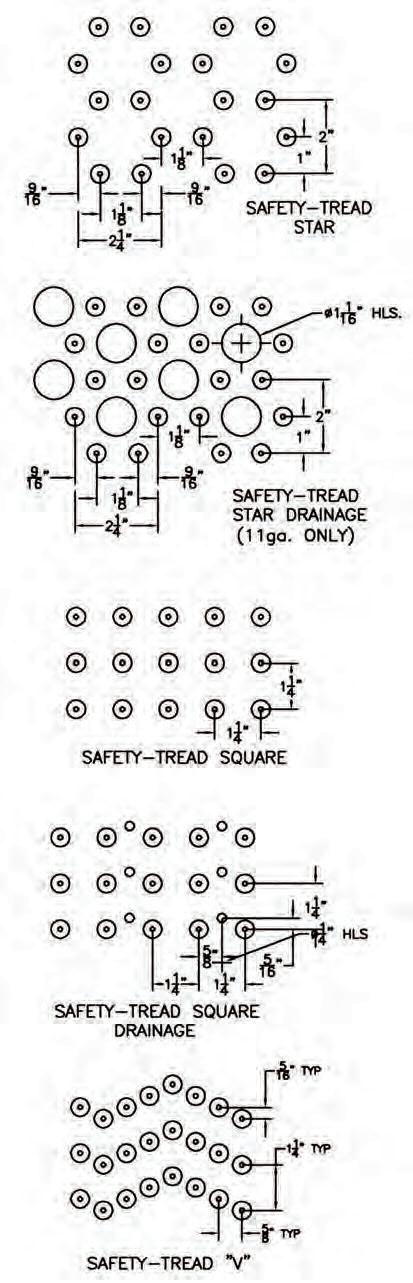

• Available in four dimpled patterns (see opposite page for specifications).

MATERIAL SPECIFICATIONS

Grating shall be “Safety-Tread® Channel,” (Standard Patterns - full, square, star, “V”) pattern or Safety-Tread® Drainage Channel (Drainage Patterns square, star) pattern manufactured by AMICO from (see ‘MATERIAL OPTIONS’ below):

STANDARD CHANNEL MATERIAL OPTIONS

•ASTM-A-1011, HRP&O, 13 or 11GA steel.

•ASTM-A-653, G-90 (Z-275) Pre-galvanized 13 or 11GA steel.

•ASTM B209, 5052-H32 Aluminum, .125” thick

•ASTM A240, Type 316L 2B Stainless Steel 14GA. (“V” pattern only)

•ASTM A240, Type 304L Stainless Steel 16GA. (“V” pattern only)

DRAINAGE CHANNEL MATERIAL OPTIONS

• ASTM-A-1011, HRP&O, 13 or 11GA steel.

• ASTM-A-653, G-90 (Z-275) Pregalvanized 13GA steel.

• ASTM A209, 5052-H32 Aluminum, .125” thick.

Safety Tread® Channel and Safety-Tread® Drainage Channel are manufactured in nominal 10’ and 12’ lengths. Other combinations or gauges, channel depths, and widths are available by special request

Note:

1.Tolerances on all dimensions are ±1/8”

2. Camber is an expected condition with sheet metal products. While ASTM allowance is generous, AMICO attempts to lessen the effects. Normal clearances should offset this phenomenon, however where tolerances warrant, contact AMICO for clarification.

See next page for optional dimple patterns.

15

www.amicoglobal.com | 800.366.2642 15 ®

WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY-TREAD® CHANNEL LOAD & DEFLECTION TABLES

Optional Dimpled Patterns

LOAD & DEFLECTION TABLES

Explanation of Load Type

U = uniform load (lb/ft2)

D = corresponding deflection (in) resulting from uniform load

C = concentrated load (lb)

D = corresponding deflection (in) resulting from concentrated load

Note:

•All uniform and concentrated loads include a safety factor of 1.67.

•Shaded areas, based on loads indicated, may exceed deflections of L/120.

Note: Due to the low profile of the walking surface, 11GA material is recommended to help reduce strut deflection.

16

PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 10 Inch Wide 1-1/2".272U1070773476370267219171145119103877767 D0.050.090.120.170.210.270.330.410.480.560.650.750.85 4.24Ib/ft.267C625610594519445400356326297275254238223 D0.030.060.100.140.180.220.270.330.390.450.520.600.69 2".536U150011087165604043322612211821581341181028065 D0.040.080.100.140.170.220.270.330.390.470.540.620.700.881.08 4.84Ib/ft.404C625625625625625582539494449418387359332300274 D0.020.030.050.090.130.180.220.270.320.380.440.500.560.720.91 1-1/2".343U134397159946833827821818515213211310087 D0.060.100.130.190.230.300.370.450.530.630.730.850.96 5.54Ib/ft.369C861805749656564508453416380354328309290 D0.040.080.110.150.190.240.290.360.430.510.590.680.77 2".689U188113668516765014103202712231941641451269980 D0.040.070.100.150.190.250.300.370.430.510.580.670.760.961.18 5.95Ib/ft.511C861861861861861757681624568527487456426378340 D0.020.040.060.110.160.200.240.290.350.410.480.550.620.780.97 Steel 13GA Steel 11GA PRODUCT DETAILS Depthlx lN.4 Load Type WeightSx IN.3 Type24"30"36"42"48"54"60"66"72"78"84"90"96"108"120"132"144" CLEAR SPAN 12 Inch Wide 1-1/2".320U99171644234625020516113711397827263 D0.050.090.120.170.210.270.330.410.480.570.650.750.85 4.83lb/ft.302C866764663581500451403370338312287269251 D0.040.070.100.140.180.230.280.340.400.470.550.630.72 2".630U14571053649508367301236200165143122108947560 D0.040.080.100.140.170.230.270.330.390.470.540.630.710.901.04 5.13Ib/ft.453C866866866800733661590542494460427401376335300 D0.020.040.070.110.140.180.220.270.320.380.440.510.580.730.90 1-1/2".406U1118808499390282232182154127110948372 D0.060.100.120.180.220.290.350.430.500.600.690.810.93 6.33Ib/ft.376C1118933748656564509454418381355329310291 D0.050.080.110.150.190.250.300.370.440.520.600.690.79 2".792U187512018356144713733032512111801561361209678 D0.060.090.130.180.240.310.390.460.550.640.750.860.991.271.57 6.79Ib/ft.571C136213621253107594283975290634586546511481431391 D0.030.070.110.150.200.250.310.380.450.530.620.710.821.041.297 Steel 13GA Steel 11GA

16 www.amicoglobal.com | 800.366.2642 ® WWW.AMICOGLOBAL.COM

SAFETY GRATING

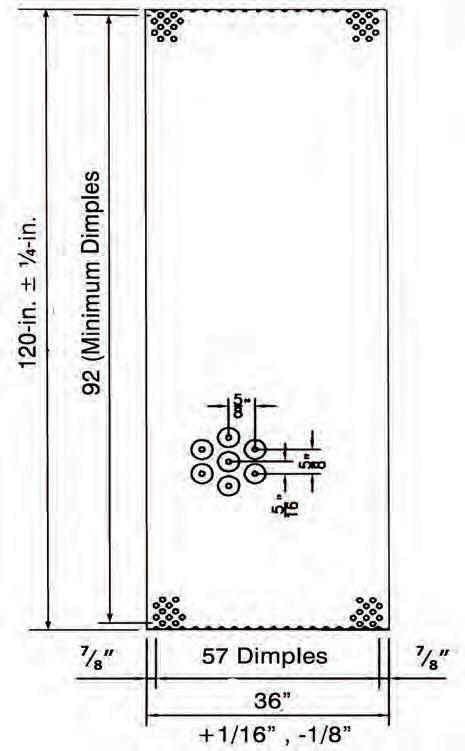

SAFETY-TREAD® FLOORING

PRODUCT DESCRIPTION

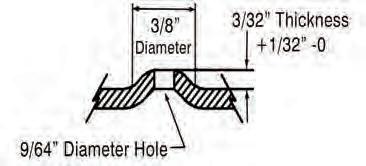

Safety-Tread® is a metal flooring product which is covered with small perforated dimples manufactured by a cold forming process.

OPTIONAL FEATURE:

Safety-Tread® flooring is available in two drainage patterns which incorporate embossed holes (staggered) between raised dimples.

FEATURES & BENEFITS

•Perforated dimples provide superior slip resistance in all directions and in all weather conditions. The quantity of dimples under foot provides exceptional adhesive friction.

•Long life span requiring little maintenance.

•Can be easily formed into custom shapes.

•Adaptable to wide range of applications.

•Easily adaptable to cost effective, custom fabrication.

•Low projections and closed area provide an acceptable walking surface for industrial as well as institutional and commercial application (i.e., women in heels can walk comfortably and safely).

•Available in four dimpled patterns

•Optional drainage flooring features smaller unembossed holes (location and size variable with dimple pattern) providing drainage for liquid which may pool on walking surface in wet environments.

MATERIAL SPECIFICATIONS

Grating shall be “Safety-Tread® Flooring” (Standard Patterns full, square, star, “V”) pattern or Safety-Tread® Drainage Flooring (Drainage Patterns square, star) pattern manufactured by AMICO from (see ‘MATERIAL OPTIONS’ below):

STANDARD FLOORING MATERIAL OPTIONS

•ASTM A1011, HRP&O, 16, 13 or 11GA steel.

•ASTM A653, G-90 (Z-275) Pre-galvanized 13GA steel.

•ASTM B209, 5052H32 Aluminum, .125” thick.

•ASTM A240, Type 316L, Stainless Steel 14GA (“V” pattern only)

•ASTM A240, Type 304L, Stainless Steel 16GA (“V” pattern only)

DRAINAGE FLOORING MATERIAL OPTIONS

•ASTM A1011, HRP&O, 11GA steel.

•ASTM A653, G-90 (Z-275) Pre-galvanized 13GA square pattern or 11GA star pattern.

•ASTM A209, 5052H32 Aluminum, .125” thick.

17

Square Drainage

SAFETY GRATING www.amicoglobal.com | 800.366.2642 17 ® SAFETY

WWW.AMICOGLOBAL.COM

Star Drainage

GRATING

SAFETY GRATING

SAFETY-TREAD®

Saffety-Tread Flooring Full Pattern (Standard)

18

FLOORING Safety-Tread® Flooring Gauge Material Wt/Sq Ft 11GA HRP&O 5.0 lb 13GA HRP&O 3.8 lb 16GA HRP&O 2.5 lb 13GA Galvanized 1.7 lb .125” Aluminum 1.6 lb 14GA 316 L 3.28 lb 16GA 304 L 2.4 lb Drainage Flooring Gauge Material Wt/Sq Ft 11 GA HRP&O 4.7 lb 13 GA HRP&O 3.5 lb 16 GA HRP&O 2.3 lb .125” Aluminum 1.6 lb

GRATING 18 www.amicoglobal.com | 800.366.2642 ® Typical Dimple Detail

SAFETY

WWW.AMICOGLOBAL.COM

SAFETY-TREAD® LADDER RUNGS

Safety-Tread® Ladder Rungs are small channel shaped sections; the web of the channel being the walking surface which is covered with small perforated dimples, produced by a cold forming process.

FEATURES & BENEFITS

•Perforated dimples provide superior slip resistance in all directions and in all weather conditions. The quantity of dimples under foot provides exceptional adhesive friction.

•Cross sectional design provides significant load carrying capacity on spans up to 24”.

•Three widths of rung to choose from.

•Leading row of dimples projected on the edge of the rung provides slip resistance to the foot approaching at an angle to the walking surface.

•Long life span requiring little maintenance.

•Adaptable to a wide range of applications.

•Easily adaptable to cost effective, custom fabrication.

•Ideal for retrofit applications as rungs fit over slippery pipes, bars, etc. on existing ladders.

MATERIAL SPECIFICATIONS

Ladder rungs shall be “Safety-Tread® Ladder Rungs,” manufactured from (see ‘Material Options’ below) by AMICO.

MATERIAL OPTIONS

•ASTM A1011, 13 or 11GA, HRP&O steel.

•ASTM A653, 13 or 11GA, G-90 (Z-275) Pre-galvanized steel.

NOTE:

C = Allowable concentrated load (lbs) D = Corresponding deflection (in) resulting from C.

All concentrated loads include a safety factor of 4.0, based on ultimate strength.

Ladder rungs showing concentrated load “C” at 200 lbs or above comply with OSHA standard 29CFR 1910.27(a)(1)(i) under the title “Walking-Working Surfaces—Fixed Ladders.”

Ladder rungs showing concentrated load “C” at 250 lbs or above comply with OSHA standard 29CFR 1917.120(b)(1) under the title “Terminal Facilities— Fixed Ladders.”

Tolerance of all dimensions + – 1/8”.

Standard lengths are 5ft.

19

1/2” Inside Radius 1/2” Inside Radius Carbon Steel 1.2 C375 333 300250200 11ga D 0.02 0.02 0.03 0.04 0.07 Stainless Steel 1.0 C375 333 300250200 14ga D 0.03 0.04 0.05 0.07 0.11 Aluminum 0.52 C 313 278 250 208 0.125in D 0.04 0.05 0.06 0.08 16” 18” 20” 24” 30” Type Weight Load/ lb/ft Type CLEAR SPAN (in) 1¼” wide (2 hole) Carbon Steel 1.3 C 313 278 250 209 13ga D 0.02 0.03 0.04 0.06 Stainless Steel 1.1 C 250 222 200 14ga D 0.03 0.04 0.04 Aluminum 0.5 C 250 222 200 0.125in D 0.04 0.05 0.06 16” 18” 20” 24” 30” Type Weight Load/ lb/ft Type CLEAR SPAN (in) 15/8” wide (3 hole) Carbon Steel 1.5 C375 333 300250200 13ga D 0.02 0.02 0.03 0.04 0.07 Stainless Steel 1.2 C468 416 375312250 14ga D 0.03 0.04 0.05 0.07 0.10 Aluminum 0.5 C375 333 300250200 0.125in D 0.03 0.04 0.05 0.07 0.11 16” 18” 20” 24” 30” Type Weight Load/ lb/ft Type CLEAR SPAN (in) 2¼” wide (4 hole)

www.amicoglobal.com | 800.366.2642 19 ®

WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

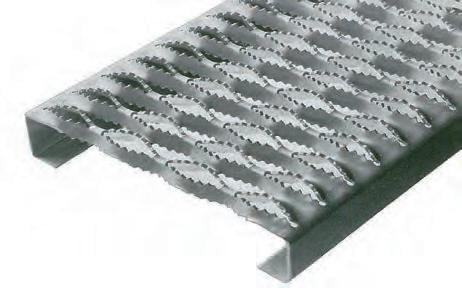

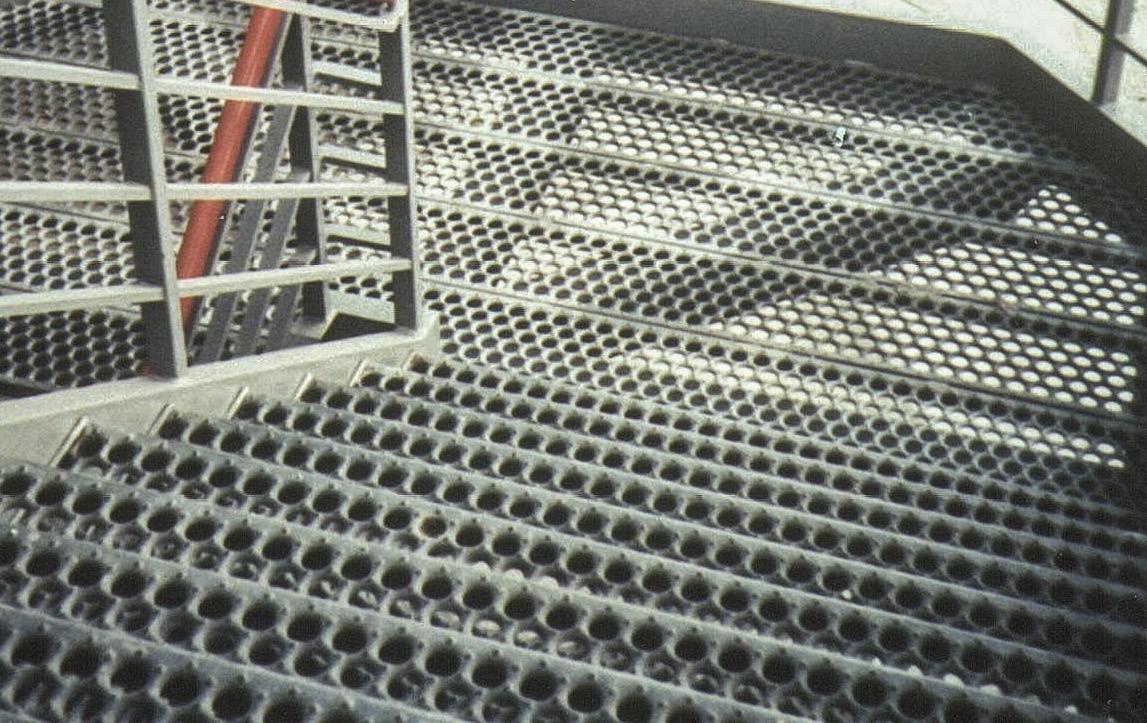

STAIR TREADS

PRODUCT DESCRIPTION

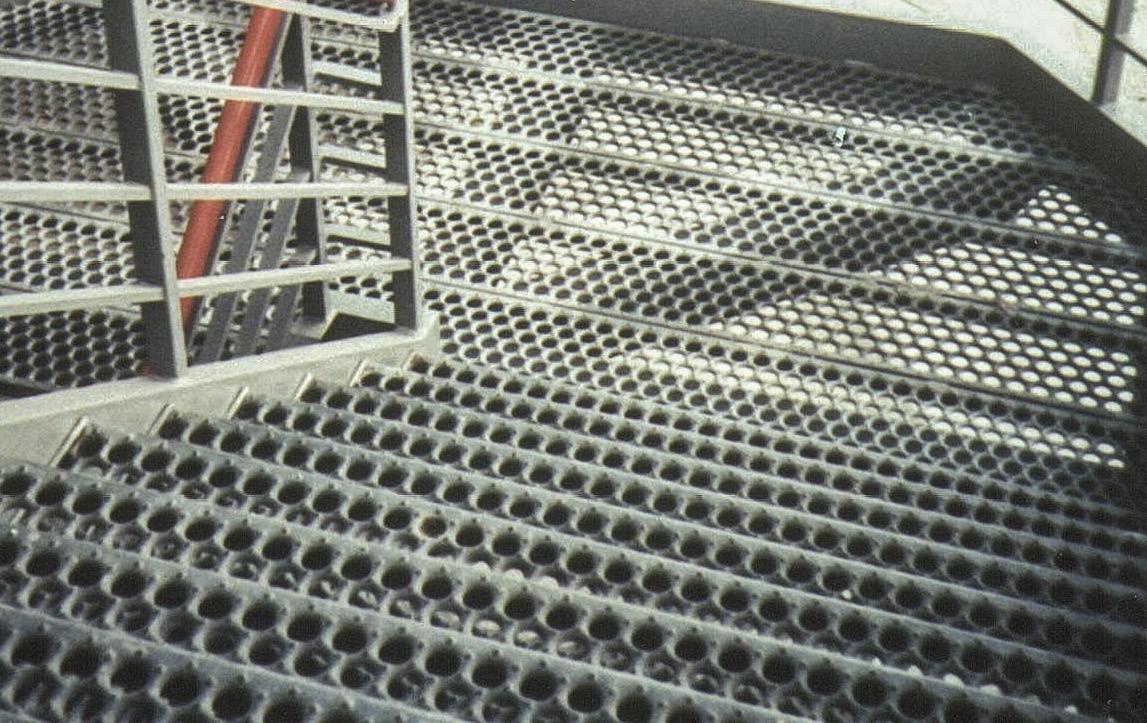

Stair treads are fabricated from AMICO standard Safety-Grip®, Diamond-Grip® and SafetyTread® channel planks (see product specification sheets for technical details). All treads are complete with end plates welded to each end for easy connection to stringers or are available with open ends.

Treads are available from stock in sizes indicated below or can be custom fabricated from any channel product and in any material including G90 galvanized, HRP&O, aluminum and stainless steel.

Diamond-Grip® Treads

Safety-Grip® / Safety-Tread® Treads

For use with 1 1/2” or 2” heights

Standard Stock Sizes of Safety-Grip® Stair Treads:

•S515324E 24”(W) x 10”(D) x 1 1/2” (H)

•S515330E 30”(W) x 10”(D) x 1 1/2” (H)

•S515336E 36”(W) x 10”(D) x 1 1/2” (H)

20

“A” CARRIER TREAD DEPTH PLATE DIMENSION “C” (CHANNEL WIDTH) WIDTH 4 3/4” 4 1/2” 2 1/8” 7” 6 3/4” 3 1/2” 9 1/2” 9 1/4” 6 1/16” 11 3/4” 11 1/2” 8 3/8” For use with 1 1/2” or 2” heights

Stair Treads: •D415424E 24”(W) x 9 1/2”(D) x 1 1/2” (H) •D415430E 30”(W) x 9 1/2”(D) x 1 1/2” (H) •D415436E 36”(W) x 9 1/2”(D) x 1 1/2” (H)

TREAD

DIMENSION “C” (CHANNEL WIDTH) WIDTH 5” 4 7/8” 2 1/8” 7” 6 7/8” 4 1/8” 10” 9 7/8” 7 1/8”

11 7/8” 9

7/8” 15

Standard Stock Sizes of Diamond-Grip®

“A” CARRIER

DEPTH PLATE

12”

1/8” 18” 17

1/8”

Carrier angle

20 www.amicoglobal.com | 800.366.2642 ®

SAFETY GRATING

SAFETY

WWW.AMICOGLOBAL.COM

Diamond-Grip Stair Treads

GRATING

SAFETY GRATING

SAFETY GRATING

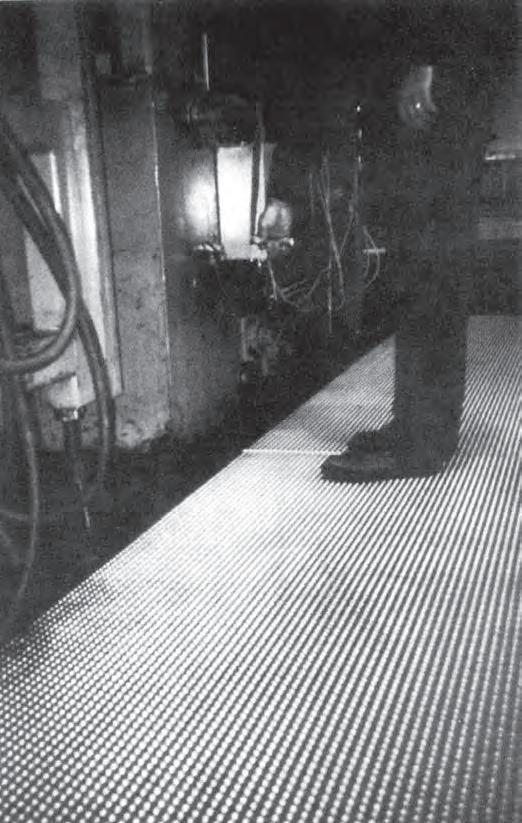

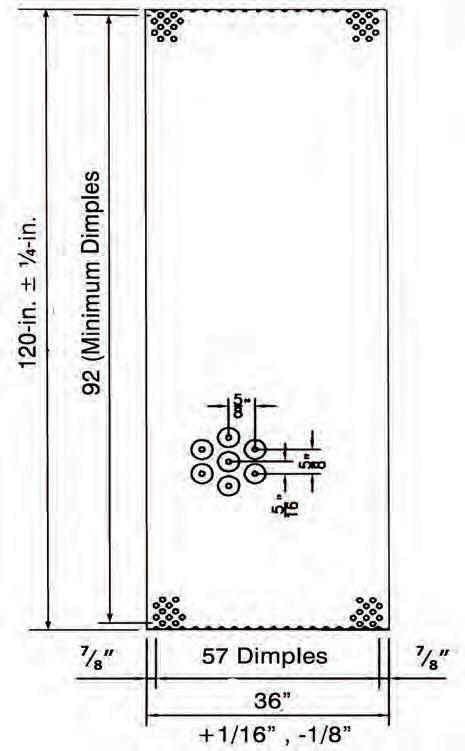

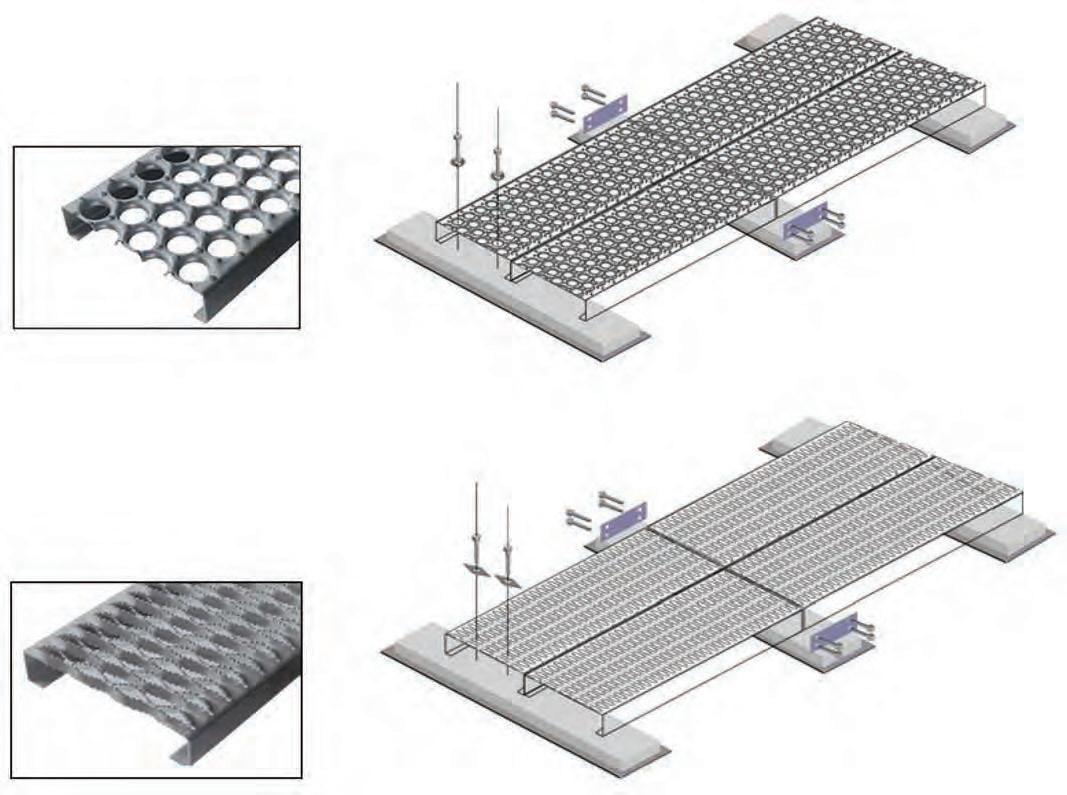

ROOF-GRIP® ROOFTOP WALKWAY SYSTEM

PRODUCT DESCRIPTION

Safety-Grip and Diamond-Grip Planks are fastened together and to sleepers either metal or pressure treated wood.

Safety-Grip® Channel is a onepiece metal plank grating with large debossed holes, surrounded by smaller embossed traction buttons.

24-inch wide RoofGrip® on metal sleepers

Reference specific product pages for Material Options.

36-inch wide Roof-Grip® on 2-in x 8-in pressure treated wood sleepers

Diamond-Grip® Channel is a one-piece metal plank grating with rough diamond shaped

21

www.amicoglobal.com | 800.366.2642 21 ®

AMICO ROOF-GRIP Walkway System allows for a safe, even and reliable walking surface while protecting roofs from damage by maintenance workers.

WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

SAFETY-GRIP® TREAD FRICTION TEST REPORT

PURPOSE

The purpose of this test is to determine the coefficient of friction of SAFETY-GRIP® grating treads.

EQUIPMENT

1.Two (2) SAFETY-GRIP® grating treads

2.Friction skid tester

3.500lbs load

4.Load cell

5.Forklift

PROCEDURE

The procedure for this test is as follows:

1.Anchor both grating treads

2.Place friction skid on treads (one shoe on each tread)

3.Lower 500lbs load on skid using forklift.

4.Attach straps and load cell to skid

5.Pull skid until maximum friction force is recorded

6.Repeat process with wetted surfaces

RESULTS

Dry - F Wet - F

a. 618 lbf e. 564 lbf

b. 649 lbf f. 569 lbf

c. 588 lbf g. 550 lbf

d. 626 lbf h. 573 lbf

CALCULATIONS

Weight of skid + load

Average coefficient of friction

•Dry µ = 1.19

•Wet µ = 1.08

CONCLUSION

The results of this test show that the coefficient of friction for AMICO Safety-Grip® safety grating exceeds anti-slip values as dedfined by OSHA and Federal Speficifcation RR-G-1602D. FS RR-G-1602D is withdrawn though commonly referenced.

May 19th, 2011

The friction tests described in this report were conducted on May 19, 2011 under my supervision. The data presented herein haa been reviewed and approved by me.

22 ® 22 www.amicoglobal.com | 800.366.2642

Lei Zhao, PE (Licensed in FL, GA, LA, MD, NY, and TX

WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

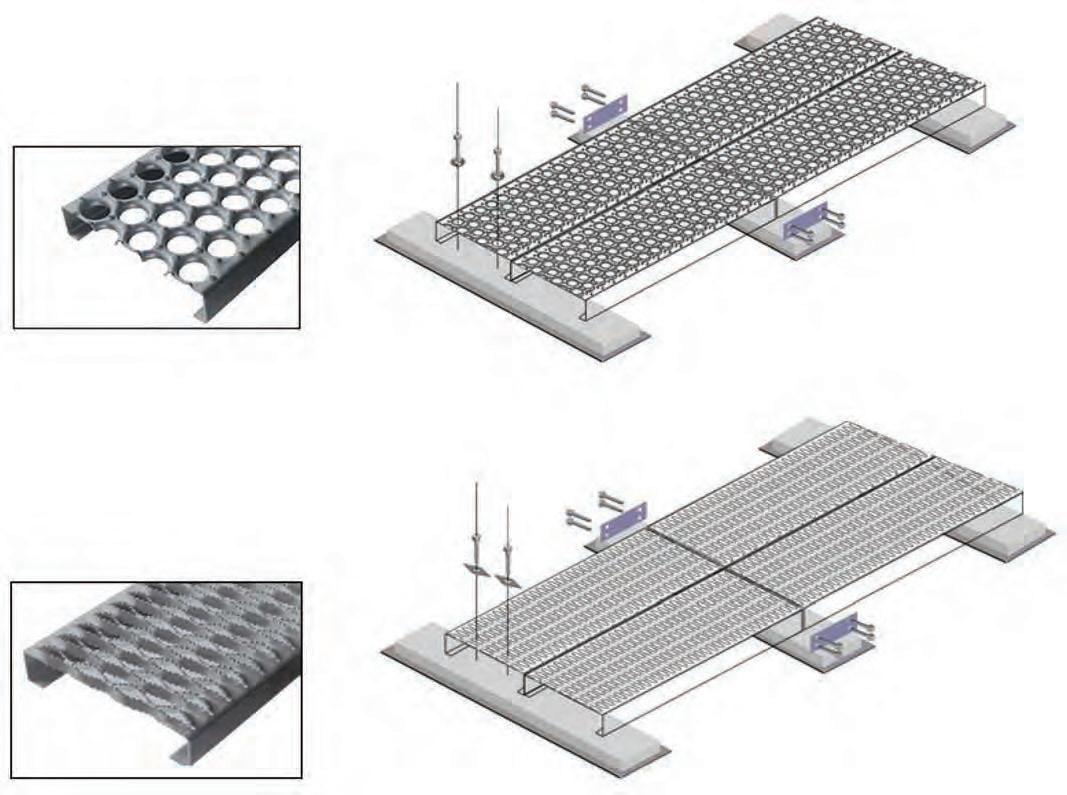

INSTALLATION ACCESSORIES

SAFETY-GRIP® BOLT SEATS

Safety-Grip® planks can be mechanically fastened to a structural support by using specially designed Bolt Seats which seat within the large debossed holes, below the walking surface. Bolt Seats have an oblong hole to accommodate a 3/8” bolt, and are available in:

•11GA, G90 Galvanized (H12264)

•.125” Aluminum (H12264A)

•316L Stainless (H12264S)

DIAMOND-GRIP® BOLT SEATS

Diamond-Grip® planks can be mechanically fastened to a structural support by using specially designed Bolt Seats which seat in between the raised diamonds below the walking surface. Bolt Seats have a round hole to accommodate a 3/8” bolt, and are available in:

•12GA, G90 Galvanized (H12262)

•.125” Aluminum (H12262A)

•Stainless (H12262S) by special request only.

•Optional square hole in bolt seat to accommodate 5/16” carriage bolt available by special request (H12262SQ)

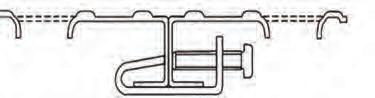

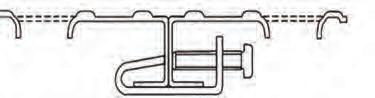

MID-SUPPORT CLIP ASSEMBLY

Between structural supports it may be necessary to tie planks together to minimize relative deflection. This is accomplished by using a Mid-Support Clip which draws the plank’s side channels together by applying pressure between the bolts and the clip edge (clip no. MSCL).

“J” CLIP ASSEMBLIES

In order to alleviate the necessity of drilling a hole through a structural member, a Bolt Seat and “J” Clip assembly can be used. The friction connection is accomplished by wedging the grating between the Bolt Seat and structural support, by applying pressure to the underside of the flange of the supporting steel (clip no. H12296). Not recommended in areas subject to vibration.

23 ®

www.amicoglobal.com | 800.366.2642 23

WWW.AMICOGLOBAL.COM

SAFETY GRATING

SAFETY GRATING

OVER SUPPORT—SPLICE PLATE KIT

Notes:

• This kit is intended to splice two sections of walkway together OVER A SUPPORT ONLY.

• The walkway kit includes two splice plates with slotted holes and 16 fastener sets.

• Holes in the grating walkway are not provided by AMICO and are to be field drilled.

BETWEEN SUPPORT—SPLICE PLATE KIT

Notes:

• This kit is intended to splice two sections of any width of walkway together between supports.

• The walkway kit includes one wrap around plate with fastening hardware for walking surface and side channel connection. The fastener points should be staggered evenly across the plank width on each side of the splice. The side channel (kick plate) connection utilizes four slots provided in the splice flange.

• Holes in the grating walkway are not provided by AMICO and are to be field drilled.

24 ®

24 amicoglobal.com | 800.366.2642

WWW.AMICOGLOBAL.COM

25 NOTES WWW.AMICOGLOBAL.COM

AMICO Locations UNITED STATES Birmingham, AL Bourbonnais, IL San Bernadino, CA Lakeland, FL 800-366-2642 CANADA Burlington, on 800-663-4474 Montreal, QC 800-463-3255 VanCouVer, BC 800-665-4474 Visit amicoglobal.com to view or download data sheets, request a catalog, request LEED information or receive technical assistance. AMICO reserves the right to improve or otherwise change a product design without notice. This catalog is effective 9.1.21 and supersedes all previous information. 7.1.23 ®