19 minute read

Offshore expertise and experience

from Port of Peterhead

by andybullen1

Co-operation, collaboration and cost-effectiveness are just some of the ingredients that make Peterhead an ideal offshore hub.

When it comes to the offshore oil & gas sector, location is everything. As the most easterly deepwater port on the Scottish mainland, Peterhead’s important role in supporting the North Sea oil & gas sector was clear from the start.

Advertisement

In the decades since the emergence of the North Sea oil & gas industry in the late 1960s, Peterhead has maintained and built on its position as a key hub in the development, logistics, servicing and maintenance of the offshore oil & gas and subsea sectors.

Its facilities and skills are in demand as much as ever – but today the port has an even broader perspective, as it establishes its reputation as a key hub for decommissioning of oil & gas infrastructure and for supporting the offshore renewable energy industry.

What is the offshore sector looking for? Safety, above all; and then efficiency, cost-effectiveness, easy access, co-operation and collaboration. Peterhead offers all of these in spades, with key players working together to deliver the very specific and high-quality services required by this demanding set of clients.

Peterhead provides deepwater access and berths, with round-the-clock straightforward access and no waiting for tides or locks. There is plenty of space for marshalling equipment and cargo, to store heavy and project cargo, and to carry out operations such as fabrication of spool pieces and other offshore equipment.

Peterhead is also flexible enough to work with the inevitable ups and downs of the oil & gas industry. The oil price downturn in 2014 led to a rebalancing of costs and activities – which has delivered a more sustainable business in the North Sea. Since then, Peterhead has seen activity pick up again, with a rise in the number of new small tie-ins and other investments.

“We still see a long-term future for oil & gas. We recognise that it is a sector under pressure from the environmental lobby but we also see that it is an industry making tremendous efforts not only to reduce its own carbon footprint but also that of the product they are creating”, says Stephen Paterson, Peterhead Port Authority Chief Financial Officer. “Yes, there are alternative sources to oil for power generation but there are other areas where oil can’t be replaced – here we are talking about the petrochemical and pharmaceutical sectors. We still see a healthy industry here for a generation to come. It is a combination of some new developments happening and some replacement and renewal of infrastructure”.

Peterhead is well placed to support fields that are continuing to yield oil for longer than previously expected, as well as decommissioning of infrastructure no longer needed. “We are seeing a slow but steady swing from new developments to decommissioning, although not as quickly as people predicted”, says Stephen Paterson.

Meanwhile, much of what has been learned in the oil & gas sector is now being used in the development and support of wind farms and other renewables projects – for example, a deep understanding of seabed conditions, wave patterns, wind and climate.

Some of the oil & gas infrastructure is set for a new life too, with pipelines and equipment likely to play a key role in future carbon capture, use and storage (CCUS) activities.

Peterhead offers modern infrastructure, including long, deep, sheltered quays with extensive laydown space – together with more than 40 years of experience and knowhow.

All of that adds up to consistently smooth and successful operations across logistics, subsea, renewables and oil & gas decommissioning.

Substantial recent investment by the Port Authority has delivered more quayside and more space for this important sector.

ASCO Base

ASCO, the global integrated materials and logistics management company for the energy industry, opened its Peterhead offshore supply base in 1974. The site remains the world’s busiest private offshore support facility, handling 460,000 tonnes of deck cargo and more than 2,000 vessel turnarounds each year.

Strategically located in close proximity to offshore assets in the UK North Sea, it delivers a comprehensive one-stop-shop of logistics and materials services, including cargo, liquid/dry bulk storage and supply, marine gas oil, materials management and operations co-ordination.

ASCO says it continually invests in its Peterhead facility, improving the efficiency of the supply base, leveraging new best-practice Lean 6 Sigma process improvement tools, and implementing technology such as iLMS track and trace to stay at the leading edge of offshore supply base operations.

“This continual service improvement eliminates the risk associated with the management, control and transportation of materials, enhancing materials efficiency across the supply chain and meeting our safety and service delivery obsessions”.

The 20-acre site provides mixed laydown, warehousing and office accommodation, in addition to 13 berths with water depths of between six and 14 metres.

Clients supported in Peterhead include Apache, BP, CNOOC, Equinor, EnQuest, Spirit Energy, Serica, INEOS and Fairfield Energy, in addition to a range of drilling, subsea and EPC companies.

ASCO Peterhead Facts & Figures

l Fuel and water are available at all berths at South Base and at the North Base Jetty. l The North Breakwater quayside accommodates vessels up to 250 metres in length and 100,000 dwt. l ASCO Fuel and Lubricants provides a range of services for marine and landside customers, including marine gas oil, diesel and kerosene. l A complete range of dry bulk, cement and liquid mud products are available at South Base. l In Peterhead, ASCO has more than 450,000 square feet of warehouses, as well as pipe yards at Dales Industrial Estate – all sites are close to the port. l ASCO Waste provides waste management solutions including monitoring, processing, treatment and disposal/recovery of all waste streams, as well as transport services and offshore and onshore training.

ASCO Services

Logistics - supply base services, warehousing, fuel, transport & freight, personnel, training and assurance.

Materials - process optimisation, business transformation, inventory optimisation and planning.

Fuel

Marine - vessel/fleet optimisation, marine co-ordination, marine monitoring, chartering, marine technical and assurance.

Waste - integrated waste management, industrial services, bulk waste disposal, NORM, decommissioning, training and compliance.

Headquartered in Aberdeen, Scotland, ASCO operates from over 70 locations worldwide and employs about 1,500 people.

Digitalisation and modernisation are at the heart of its operations at ASCO – the group’s innovative processes and systems keep it at the forefront of driving supply chain efficiency.

“ASCO offshore supply bases are the hubs through which our customer materials flow. Since the opening of our wholly owned Peterhead supply base in 1974, ASCO has progressed to become the world’s leading operator of multi-user energy supply bases offering a fully integrated range of services that are carried out with safety, efficiency, reliability and transparency as our guiding principles”, says ASCO spokesperson.

CNOOC Petroleum Europe

In February 2020, CNOOC Petroleum Europe awarded ASCO a five-year extension, with options for a further six years, to support all of the operator’s North Sea assets.

The contract, worth in excess of £100 million, will see ASCO continue to provide a fully managed and integrated logistics, materials management, waste and marine gas oil supply service. ASCO has supported CNOOC Petroleum Europe’s assets since 2006. The service will be predominantly delivered from ASCO’s Peterhead supply base.

Lochnagar/Rosebank

Cambo

Cuillin

Alligin Foinaven Schiehallion

Claw

Laggan Tormore

Clair

Lancaster

Solan

Flotta

KnocKinnon

Lybster Jacky PollyBeatrice Laxford

Glenlivet

Victory

Captain

Phoenix Tain

Blake

Ross

Cromarty Golden Eagle

Hobby

Buzzard

PETERHEAD

Penguin Otter Don Ythan Visund N

Falcon Eider

Thistle Dunlin Hudson Harris Uist Tern Cladhan Osprey Visund S Fionn Gullfaks KvitebjornKestrel

Cormorant S Hutton Pelican Lyell Brent Skinfaks Valemon

Broom Heather StrathspeyStaffa Alwyn N Huldra Columba Kells Oseberg Ninian Cheviot Ronan Dunbar Ellon Islay Oseberg

Nuggets

Rhum

Bressay

Bentley Frigg Frigg

Mariner Bruce

Keith Nevis Boa

Beryl Skene Buckland Brora Jotun Harding

Devenick Crawford Braemar

Cairngorm Brae E Jakob

W Cable

Brae S Brynhild Kingfisher Apollo

Mchenry

Fingal Piper

Tudor Rose

Hoylake Larch Birch Sycamore Iona Saltire Yeoman Chanter Tartan Galley Balloch Lochranza Bladon

Scott Macculloch Bowmore Ptarmigan Rubie Beauly Alder Mabel CyrusRochelle E Rochelle EttrickHannay Callanish Chestnut Andrew Nicol Polecat Blackbird Buchan Glenn Brodgar Torphins Shelley Bacchus Fleming Scolty Tonto Forties Howe Sigyn

Varg

Dauntless Goosander Grouse Phoenix Montrose Durward Kittiwake Gadwall Dalziel Mungo Mallard Gannet D Fiddich Lomond

Sheryl

Harbour Pilot Gannet Gannet C

Bittern Centurion Varadero Orchid

Scoter Heron Shearwater Glenelg Elgin W Franklin Kyle Marconi Bonneville Curlew Jade

Judy

James Auk Leven

NorSea

NorSea Group, a leading supplier of integrated logistics solutions to the oil & gas industry, entered the UK market in 2014. Since then, NorSea has reported steady growth and expanded its footprint to include additional berthing, quayside and laydown areas. The entire shore base is managed from a recently developed logistics centre situated on Merchants Quay.

NorSea UK first operated at Smith Quay, an all-weather deepwater berth created in a £31.5 million development project by Peterhead Port Authority. Four years later, in November 2018, the operator expanded its site to include Merchants Quay, vacated by PPA after the demolition of the old fish market.

“This expansion increased our capacity in terms of the number of berths, quayside working areas and storage”, says Karen Russell, UK Country Manager for NorSea UK. “Not only are we now able to accommodate more vessels, we have also benefited from the major land reclamation at Smith Quay, which provides another 30,000 square metres of storage space.

“Our shore base now extends to over 60,000 square metres and nearly 300 metres of berthing. We have also been able to move our offices into a new logistics centre, provided by redeveloping the old museum building”.

NorSea has invested heavily in its Peterhead base, including spending NorSea UK first operated at Smith Quay, an all-weather deepwater berth created in a £31.5million development project by Peterhead Port Authority. Four years later they expanded their site to take in Merchants Quay, vacated by PPA after demolition of the old fish market

NorSea group activity at Smith Quay.

“Why do customers choose Peterhead? It’s all about location and service. The location of the installations our customers are working on, primarily, Central North Sea (CNS) and lower Northern North Sea (NNS) are close to our Peterhead facility....” Karen Russell, UK Country Manager for NorSea UK

nearly £2 million on two 1,500 cubic metre tanks for marine gas oil, which enables the supply to vessels by pipe or truck. As well as marine fuels, the base provides water, warehousing, craneage, plant and equipment, supports crew changes and provides stevedoring and heavy lift services.

“We offer deepwater, sheltered berthing and our aim is to deliver high-tech, innovative and complete supply chain solutions, tailored to our customers’ needs”, says Karen Russell. “Why do customers choose Peterhead? It’s all about location and service. The location of the installations our customers are working on, primarily, Central North Sea (CNS) and lower Northern North Sea (NNS), are closer to our Peterhead facility, reducing marine transportation costs, and NorSea delivers a consistently high level of service to its customers”.

NorSea UK has recently redefined its operations strategy at the base, to focus mainly on providing services to vessels engaged on project-related activities. Its customers represent contractors within the subsea construction and maintenance, decommissioning and renewables sectors, all supporting the UK energy industry.

“We are predominantly working with project and subsea vessels”, says Karen Russell. “We are looking to maximise our offering to the clients, providing a wide variety of integrated services. In effect, our aim is to take up more links in the supply chain, offering the customer everything they need when in port”.

NorSea UK is focusing particularly strongly on developing skills locally and on transferring skills and knowledge from

colleagues across the group through its recent regionalisation with NorSea Denmark. “We work with Global Port Services Scotland and Genesis Personnel, our primary resources suppliers in Peterhead, to ensure we have access to the right skills, competencies, experience and quality of assets”, says Karen Russell.

“We work to our strengths and understand when we need to rely on outside experts, so we have alliances with partners to bring in the expertise when required. If a customer needs something different, we will go out of our way to meet their requirements”.

The past four years in particular have witnessed some very difficult market conditions within the oil & gas market, she notes. “However, our focus has been and will remain on the delivery of a safe and efficient operation”.

Smith Quay:

l 160-metre berth capable of berthing vessels up to 165 metres long l Minimum 10 metres draft l 3,000 cubic metre MGO storage and distribution facility l 500 tonne capacity heavy lift pad with capability for skidding items up to 2,500 tonnes l 16,500 cubic metre laydown and up to 30,000 square metre hardcore storage area l Waste Management License

Merchants Quay:

l 135 metre berth, 7.5 metres draft l New offices and meeting rooms l Internal storage facility l 16,000 square metres quayside and laydown area

Reels being lifted onto ship at Merchant’s Quay.

Boddam, Peterhead, AB42 3AR Tel: 01779 871471 info@buchanbraes.co.uk www.buchanbraes.co.uk

PBP Services

PBP Services (Scotland) Ltd main office is in Fraserburgh and have been providing services in Peterhead and surrounding area’s for over 50 years. They employ around 40 people although this rises to 60 or 70 in the busy season.

PBP Services was set up in 1968 by Patsy Bruce and are still a family run firm.

PBP Services provide blast cleaning, surface preparation and finishing services, specialising in all types of protective coating applications as well as safety deck and flooring resin systems specific to the marine, industrial, commercial and residential markets.

In the early days PBP Services was focused entirely on serving the fishing fleet but they diversified around 20 years ago, so today, operations are split 50-50 between fishing and offshore oil & gas vessels and service companies. Being well placed, they also support and provide services to the offshore wind factor as they are close to the location of major wind farms. The company also have a team supporting local fish factories as well as, engineers, workshops and the wider local community carrying out multidisciplined tasks.

PBP Services have a store and equipment within the port, outside and inside facilities and regularly use the port’s ship lift and ship hall. In the early days PBP Services was focused entirely on serving the fishing fleet but they diversified around 20 years ago, so today, operations are split 50-50 between fishing and offshore oil & gas vessels and service companies.

The skills, the space and the supply chain – all that has been built up in Peterhead in support of the North Sea oil & gas industry is being readily translated across to the new opportunities in offshore Green Power renewables. The UK’s first offshore wind farms were built in the 2000s, and Peterhead is well placed to play its part in supporting developments and providing O&M (operations and maintenance) services. Peterhead is providing the base for Support Equinor’s Hywind project – the world’s Peterhead is providing the base first floating wind farm, which is just off for the world’s first floating wind farm. Peterhead. “Most wind turbines today are fixed to the seabed in waters less than 60 metres deep – but the next generation of offshore wind turbines are being designed to float further out to sea, where winds

are stronger, but the water depths make bottom-fixed designs uneconomic”, says Equinor.

Hywind is based on a spar buoy design and its great stability is provided by gravity. The floating wind turbines are moored to the seabed with multiple mooring lines and anchors, in much the same way that a floating oil platform is moored, says the operator.

Crew transfer vessels serving Hywind have a permanent location in Peterhead harbour, where personnel and workshops are also located at ASCO’s base.

Peterhead also handled the foundation pieces for the Aberdeen offshore wind farm, which was installed in 2019.

“We have also handled a number of shipments of turbine components for onshore wind farms – we are expecting more of these in 2020 and beyond”, says Chief Financial Officer Stephen Paterson.

Renewables in Operation

Peterhead Port Authority is working hard to reduce its carbon footprint and step up its green credentials. l The new fish market has solar panels on the roof. l The port already secures 80% of its power from renewable sources, and it is steadily transitioning across to 100%. l Fishing boats plug into onshore power, which is provided on a renewable energy basis. l The Port Authority is carrying out feasibility studies looking at the potential for installing wave energy devices in the port. l The port also supplies onshore developments. A giant transformer destined for the new onshore substation supporting the 950MW Moray East offshore wind farm was shipped into Peterhead in October 2019. Measuring almost 12 metres long and weighing 260 tonnes, the transformer was moved by heavy lift specialist Allelys. After unloading at the port, it was transported 35 miles by road, in a 70-metre convoy complete with police escort.

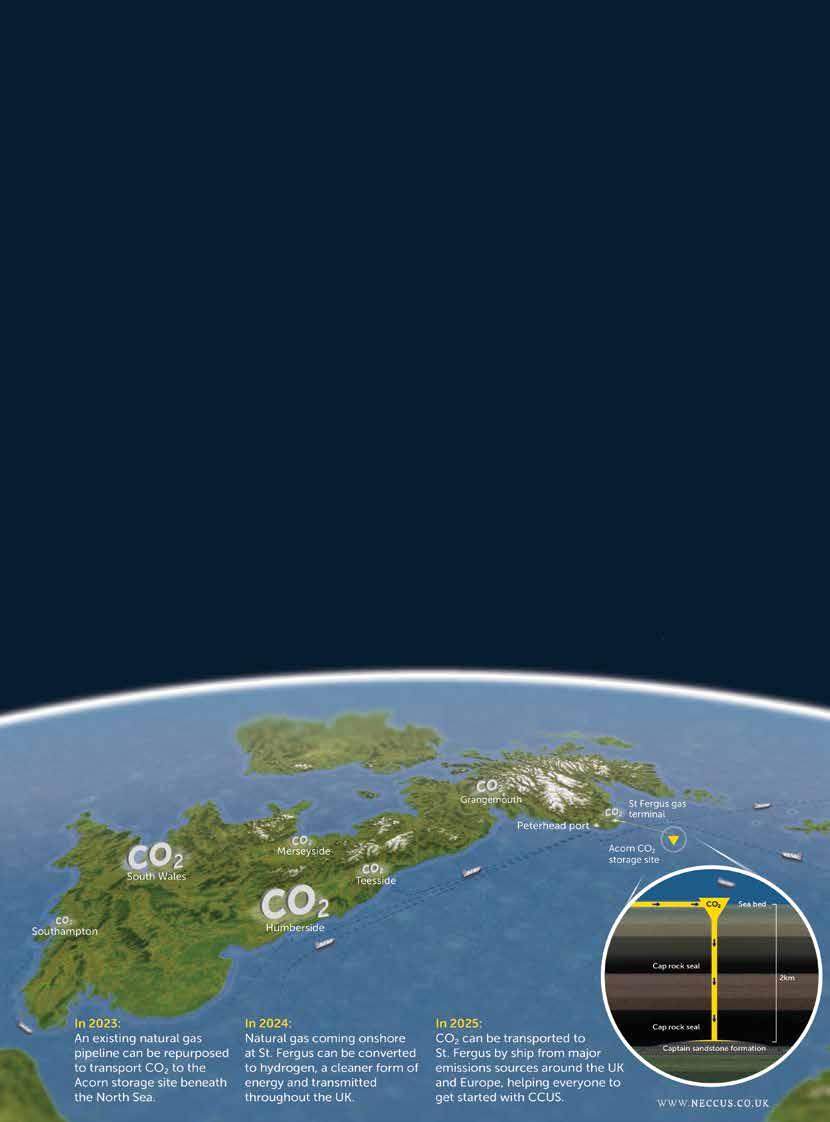

The ACT Acorn project has been recognised as a European Project of Common Interest.

Carbon Capture Ahead

The Port of Peterhead has been named as the ideal UK-wide hub to facilitate a carbon capture and storage (CCS) boom in the north of Scotland.

A report by the ACT Acorn CCS project has singled out Peterhead’s deepwater port as the key location for the transfer of 16 million tonnes of CO2, thanks to its location close to existing North Sea pipelines and infrastructure. The CO2 could come from industrial hubs around the UK and also from mainland Europe.

The ACT Acorn project, recognised as a European Project of Common Interest, has eight European partners and is led by Aberdeenshire company Pale Blue Dot, a specialist in carbon capture, utilisation and storage.

It has received funding from the UK Government’s Department for Business, Energy and Industrial Strategy, the Research Council of Norway and the Netherlands Enterprise Agency, with co-funding by the European Commission under the Accelerating CCS Technology (ACT) programme.

Studies were completed in 2019, and the project is working towards a demonstrator in 2021.

The first phase would involve capturing CO2 directly from St Fergus Gas Terminal, sending it offshore via existing pipelines due for decommissioning, and storing it in sites under the North Sea. Further ahead, the project is looking at the potential for hydrogen manufacture at St Fergus as a way of ‘decarbonising’ gas.

In a subsequent phase, ACT Acorn has set out plans for importing CO2 by ship and transferring it by pipeline via Peterhead Power Station to St Fergus.

Peterhead Port has plenty of capacity for the import quantities of CO2 envisaged for the early build out phases of Acorn CCS, says the project report. A fleet of three or four tankers of 30,000 to 50,000 DWT (equivalent to 24,000 to 40,000 tonnes CO2) would be required to service routes from CO2 export hubs within the North Sea area.

The ships carrying CO2 could come from the UK or across the North Sea, says Steve Murphy, finance director of Pale Blue Dot. “Access to the port could provide an integrated CO2 transport and storage service”, he says. “Within 50 kms of pipeline, there is 40-50% of the UK’s storage resource. We are talking about a great geographical asset in terms of storage, pipelines and port infrastructure”.

Peterhead was also one of the founder members of NECCUS – an alliance of industry and government formed to develop a framework for the deployment of carbon capture to industrial sites around Scotland. The project will also enable hydrogen to be used as a source of clean energy. Together, these techniques are essential components of Scotland’s journey to carbon net zero by 2045. A report by the ACT Acorn CCS project has singled out Peterhead’s deepwater port as the key location for the transfer of 16 million tonnes of CO2, thanks to its location close to existing North Sea pipelines and infrastructure

NIRAS Group

The consultancy firm NIRAS Group UK has a long history of providing planning and engineering services at the Port of Peterhead.

During the 1990s, NIRAS carried out detailed design and construction supervision of the Princess Royal Jetty and a new breakwater for the marina. This included studies into possible measures for reducing wave activity in Peterhead Bay, followed by navigation simulation studies and physical model testing of the harbour.

NIRAS says that the design and build of Smith Quay in Peterhead, opened in 2011, was one of its proudest port projects in Scotland. The facility was built to provide 120 metres of new quay, including heavy lift capability to serve both cargo and pelagic vessel traffic, and an extension was built to the Sir Albert Quay breakwater, after extensive numerical and physical modelling, to allow the berth to be used in all weather. NIRAS received a design commendation from the Saltire Society for the project’s innovative design.

NIRAS’s environmental teams have provided Environmental Impact Assessments and other services to the port over the years, including some support to the major harbour reconstruction and deepening project completed in 2018.

Peterhead Port Authority, recognising the importance of the breakwaters in protecting the harbour from the full force of the North Sea, is committed to closely monitoring these structures.

For more than 25 years, NIRAS has also been providing assessment and recommendations on Peterhead’s vital breakwaters by gathering information using the latest technology. Dive surveys have been replaced or supplemented with high-resolution multibeam echo sounders and laser scanning.

Since 2000, digital asset surveys have been conducted approximately every three to four years, or following any major storm incident or visible damage. In 2020, NIRAS resurveyed the breakwaters to ensure that the blockwork, foundations and moundprotection – vital to the structural integrity of these critical assets – remain serviceable and functional.

Jamie Christie, NIRAS UK maritime director, says: “It’s reassuring to work with a port authority which value its assets and is committed to the input of engineers in the proactive construction, monitoring and maintenance process. This approach demonstrates a commitment to provide shipping and related industries with the best facilities possible – and at NIRAS, we are delighted to be a part of this process”.