June/July 2023

NZ’S AUTHORITY ON FOOD TECHNOLOGY, RESEARCH AND MANUFACTURING

FEATURED IN THIS ISSUE:

June/July 2023

NZ’S AUTHORITY ON FOOD TECHNOLOGY, RESEARCH AND MANUFACTURING

FEATURED IN THIS ISSUE:

World Avocado Congress in Auckland

Dry Ageing of New Zealand Red Meats - Study

NZFSSRC – Annual Symposium, July, Dunedin

JUNE/JULY 2023 | VOLUME 23, NO.3

ISSN 2744-7308 (ONLINE) ISSN 1175-4621 (PRINT)

Copyright © 2023 Peppermint Press

No part of this publication may be reproduced or copied in any form by any means (graphic, electronic, or mechanical, including photocopying, recording, taping information retrieval systems, or otherwise) without the written permission of Peppermint Press. The views expressed in this journal are those of the writers and do not necessarily represent the view of the Publisher, the Scientific Review Board or NZIFST

Director and Editor

Anne Scott, Peppermint Press Limited anne@foodnz.co.nz

Director and Writer

Dave Pooch, Peppermint Press Limited davep@me.com

Advertising

Anne Scott, anne@foodnz.co.nz 021 901 884

Design and Layout

Johanna Paynter, Pix Design

Regular Contributors

Phil Bremer, John D Brooks, Laurence Eyres, Ben Sutherland, Dave Pooch, John Lawson

Published by Peppermint Press Limited

Notice to Contributors

When submitting editorial for Food New Zealand please observe the following, Editorial to be submitted as plain text files, NO FORMATTING please. Images should be sent as high resolution .jpg or .tiff files. Do not embed images in word documents, send separate files. Any images smaller than 500 kb may not be printed as the clarity of the print may be compromised.

Advertisers

Material specification sheet and rate card on website, www.foodnz.co.nz

Executive Manager, Wendy Bayliss

PO Box 44322

Pt Chevalier Auckland 1022

New Zealand

Phone: 022 549 8483, Email: wendy@nzifst.org.nz

Website: www.nzifst.org.nz

Conference Handbook page 41

24 PACKAGING

2023 Australasian Packaging Innovation & Design Awards

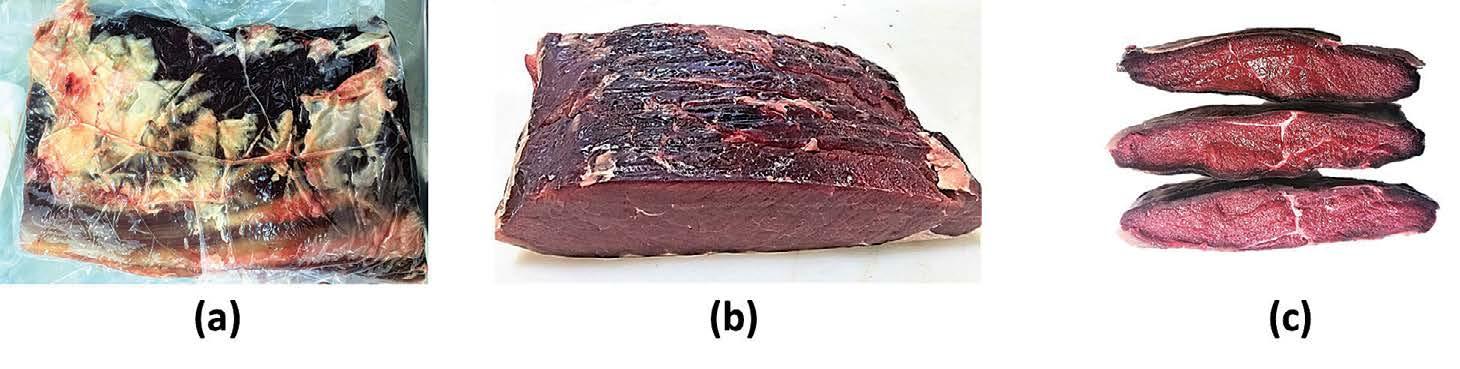

27 RESEARCH

Dry aging of red meat

Renyu Zhang, Carolina E. Realini & Mustafa M. Farouk

31 NZFSSRC

Cold plasma: a hot topic in food safety research

34 NZIFST N EWS INCLUDING

59th Conference update New Members

EHEDG Report Branch News

39 BOOK REVIEW

Meeting Change: – The New Zealand Red Meat Story, 1997 - 2022

Margot Buick FNZIFST

JOIN NZIFST NOW for Professional Development Networking – connecting with your peers

Regular information about your industry

Recognition through awards, scholarships, travel grants www.nzifst.org.nz/join/

Cover image: What is a conference or congress for? It’s for like-minded people to gather and connect – and learn, both from presentations and from each other.

Next editorial and advertising deadline: July 20th, 2023

Features for August/September 2023

NZIFST Conference Review: Awards, highlights

As this will be my last editorial as President I would like to take the opportunity to say how much I have appreciated the privilege of being the President of the NZIFST and how much I have enjoyed my time in that role. I would also like to sincerely thank all the people who have supported me over the many years I have been involved with the NZIFST. I look forward to continuing my association with you and the Institute in the slightly less responsible role of Immediate Past President. Notable events during my two years as President include the retirement of our long serving, well respected, extremely competent and universally liked executive manager, Rosemary Hancock. While Rosemary is irreplaceable I was delighted when after a very thorough recruitment process, Wendy Bayliss accepted the position as our new Executive Manager. It has been very pleasing to see how well suited Wendy is proving to be to that role.

Highlights over the last two years include the success of our Annual Meetings and the grand way in which we discharged our obligations to IUFoST at their Congress in Singapore late last year. I would like to sincerely thank our sponsors for supporting us through the challenging times after the COVID mandated cancellation of our 2020 IUFoST Congress and express my deep gratitude to the conference team who ably guided us out of what could have been a significant financial hole.

During the IUFoST Congress in Singapore I was impressed by the role that IUFoST plays in giving scientists from developing countries a voice on the scientific world stage and I look forward to building a closer relationship between IUFoST and our membership.

The activity over the last two years that I believe will be of most value to the NZIFST in the future is the effort that has been devoted to reconsidering the purpose of the NZIFST, in the light of the rapid changes that are occurring in the food industry, and to considering how we can consequently best add value to our members and the food industry.

This activity has been led by our very able, savvy and hard-working Vice President Esraa El Shall, with strong support from the Executive, the Board and many Branch Committee Members. The review has led to the development of new Vision and Mission Statements and a planned series of goals (pillars) and workstreams which we will outline over the coming months. There will be an opportunity for all members to contribute to helping us to achieve our goals and I strongly encourage you to get involved.

The 2023 AGM will see Professor Richard Archer’s term as Immediate Past President come to an end. Richard's astute leadership and broad experience has been a great boon to the Institute and on your behalf I would like to thank him for the long hours he has spent on our behalf. It is due to his canny guidance that the Institute is in its current sound position. There are many more people I would like to thank including many former Presidents and long serving members who continue to support the Institute. However, the one other person that I will thank by name is the Editor of FoodNZ and long serving NZIFST member and former President, Anne Scott who was always willing to provide sage advice to me.

The programmes for the joint New Zealand Food Safety Science & Research Centre Annual Symposium and NZIFST Annual meeting in Dunedin are looking fantastic, the social activities are top notch and the long range weather forecast for Dunedin in July is looking spectacular. Once again I warmly invite you to our Annual Conference and encourage you to register ASAP.

I wish the incoming President and Executive all the best

Phil Bremer, FNZIFST, President, NZIFST

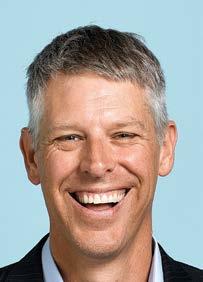

Mark Piper has been appointed as CEO at Plant & Food Research. He takes over from David Hughes who has been CEO since 2018 and announced his retirement in late 2022.

Mark is an experienced senior leader with 30 years’ global experience in the food and primary sectors. He is passionate about leading and developing teams, building a strong positive culture, and bringing out the best in the people he works with. He has a strong track record of delivering financial results and operational impact.

Board Chair of Plant & Food Research, Nicola Shadbolt, said the Board made the appointment from a field of high calibre applicants.

“Mark’s passion for science is clear and he takes great energy from its potential to create a more positive and sustainable future. I know that Mark will lead Plant & Food Research with innovation, integrity, and impact,” she added.

Mark joins Plant & Food Research from Fonterra Cooperative Group, where he spent the last five years as Director Research & Development, Category Marketing & Strategy, leading a team of around 400 staff. During his 30 years with Fonterra, Mark held roles based in New Zealand and internationally.

Mark has a strong connection to the Manawatū and will be formally

based at Plant & Food Research’s Palmerston North site. David Hughes will work alongside Mark in an advisory capacity during May, with a particular focus on supporting Mark to make strong connections with Plant & Food Research’s key external partners, customers and stakeholders.

Nicola Shadbolt acknowledged the significant contribution made by David Hughes during his time at Plant & Food Research, building the platform that Mark can now use to take the business to the next level.

“The Board offers its sincerest thanks to David for his commitment and huge contribution to Plant & Food Research,” she said.

NZ’s original oat milk brand ends a four-year search for a New Zealand factory to turn Kiwi oats into world-class oat milk Otis co-founders Tim Ryan and Chris Wilkie have been on a mission to return to making their oat milk in New Zealand ever since they launched in Lincoln, Canterbury in 2018, as the very first New Zealand oat milk brand.

“We weren’t prepared to compromise on the nutritional quality of our oat milk so we shipped our New Zealand-grown oats to Sweden for manufacture due to the lack of a local factory with the technology required to produce premium oat milks to the gold-standard we demand.”

“The journey to setting up our own factory has involved seven feasibility studies over eight different sites across New Zealand, costing a lot of money and years of graft for our small start-up. We’re thrilled to have finally cracked this in a partnership with Aucklandbased Free Flow, signing on as their first customer, with Otis rolling off their lines from late 2023,” said Ryan.

The new Free Flow manufacturing plant will be one of the world’s most technically advanced plant-based milk manufacturing facilities, capable of making 50 million litres of plant-based beverages each year.

It is being developed with the world’s leading expert on oat milk, Sweden’s Angie Triantafyllou. Referred to as the “godmother of modern oat milk” for her patented innovations, the ex-Oatly founder is now Chairman of the Board at Swedish plant-based technology

company Cerealiq and has been heavily involved in the development of the new facility.

Otis was the first oat milk maker in New Zealand to use Cerealiq’s patented enzyme technology. Now, the technology will be available in New Zealand for the first time, enabling Otis to produce oat milk in their backyard.

“The new facility will produce oat milk to world-standard levels of beta-glucan, the nutritional gold component found in Otis and premium oat milks. It helps the body to maintain stable cholesterol levels,” she said.

Ryan says Free Flow and Cerealiq’s state-of-the-art technology will be available to other plant-based beverage makers in New Zealand, putting an end to reliance on importing goods in favour of New Zealand-made products.

The plant-based business works closely with the New Zealand Oat Industry Group, Harraways, and around 50 arable farmers who operate a crop rotation system, ensuring New Zealand-grown oats remain nutritionally superior to other varieties in the world.

Ryan says sales of plant-based milk alternatives have skyrocketed in recent years, outpacing traditional dairy milk, with no sign of slowing. “Grocery spending on plant-based milks in New Zealand increased by 44% from 2019 to the end of 2022, with sales jumping from $61 million to $88 million.”

“We’re beyond excited to return Otis’ manufacturing to its home in New Zealand. It’s been a hard slog to find the right partner to make our world-class milk in New Zealand, but we’ve cracked it, and finally we can say Otis is 100% homegrown – from crop to cup.”

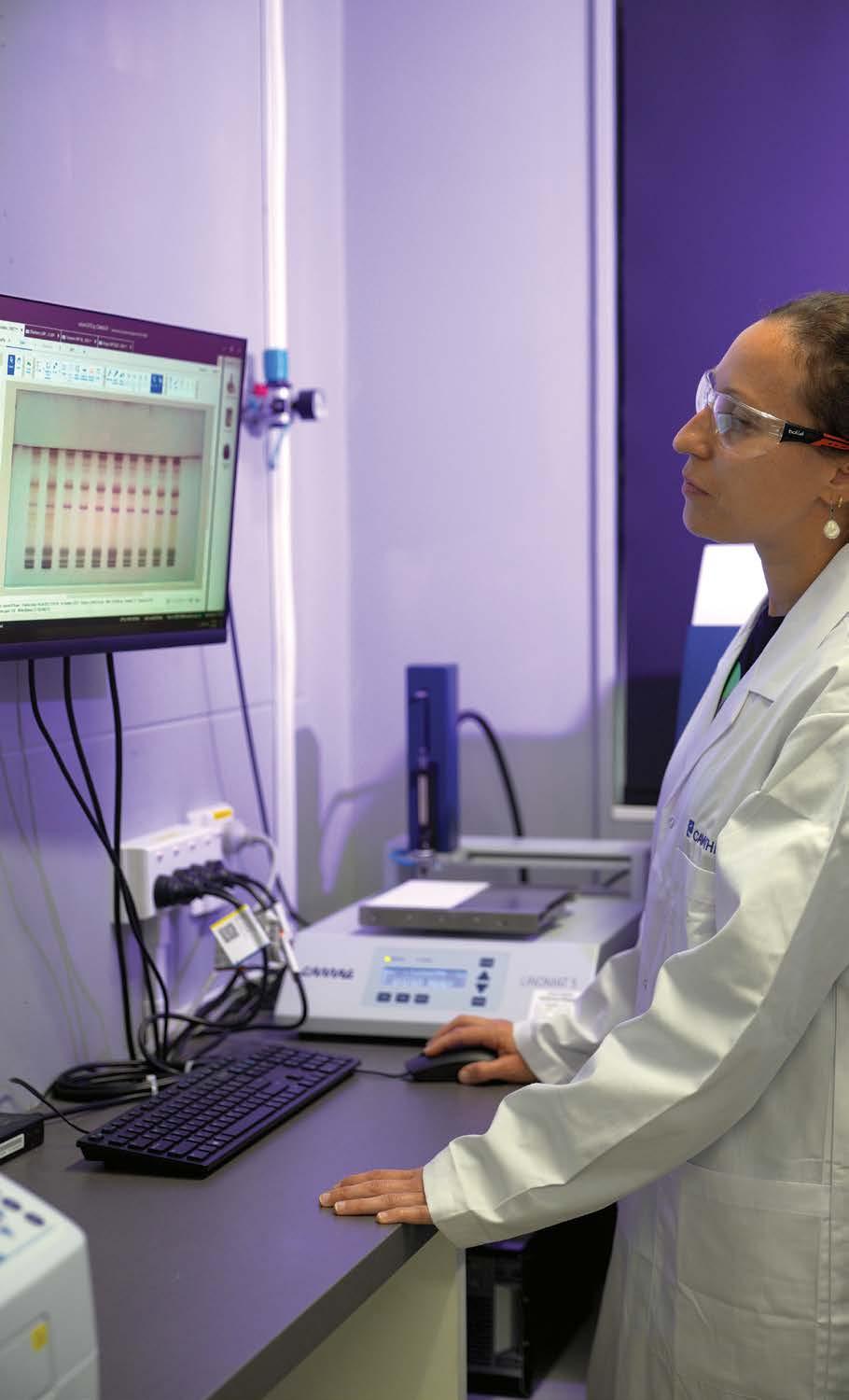

Cawthron Laboratories, the analytical testing arm of Nelson’s Cawthron Institute, has announced it will open a new analytical testing laboratory in Auckland in mid-2023.

Cawthron Laboratories offers customers a broad spectrum of food testing and product analysis services.

Located in Māngere, the new facility expands Cawthron Laboratories’ service capacity and will provide a full spectrum of testing services to customers in any part of the country, with prompt turn-around times for results, regardless of location.

Cawthron Laboratories Manager, Paul Parker, says this expansion builds on the strong relationships Cawthron already has with customers in the North Island and creates opportunities for new customers by increasing confidence in the accessibility and reliability of their testing services.

“Our fully accredited laboratories have provided testing services to New Zealand’s food and natural products sector for over 40 years and we’re really proud of our continued growth.”

“Opening a North Island laboratory is an exciting new chapter for us and one that will help us forge new relationships in the North Island.”

Parker says Cawthron Laboratories’ customers highly value the flexibility and tailored solutions that his team of technicians and research and development scientists can offer, which is why accessibility is an important element.

“Many of our customers absolutely depend on us to give them line-of-sight and direct access to technical support because they have tight timeframes to meet for export and food safety requirements.”

Cawthron’s testing capabilities range from seafood, oils and milk powder to a range of other food and natural products playing a critical role in supporting New Zealand’s food system.

Although the new laboratory isn’t set to officially open until mid-year, customers in the North Island are welcome to make enquiries now about the services available.

“We will officially hit the ground running in early July, but we are eager to start talking to customers now about the difference we can make to their business.”

Cherries can join the ranks of blueberries and other colourful fruits grown in New Zealand with their impressive antioxidant and vitamin profile, according to work done at the Riddet Institute, at Palmerston North’s Massey University.

The research into New Zealand cherries was jointly funded by a grant from the High-Value Nutrition National Science Challenge, Cherri Health and Manufacturing (CH&M) and the Bioresource Processing Alliance with Cherri Global.

The work was carried out by the scientists at the Riddet Institute and Plant & Food Research over the course of several months late last year.

Riddet Institute lead scientist Dr Ali Rashidinejad says this study is the first of its kind to systematically analyse the nutritional and bioactive (phytochemical) compositions of the main cherry varieties grown in New Zealand. Earlier research has focused on cherries grown overseas.

Cherries have been recognised for providing significant health benefits such as reducing markers for oxidative stress, inflammation, exercise-induced muscle soreness and loss of strength. They are also thought to improve blood pressure, arthritis, and sleep. There are 17 main varieties grown in New Zealand. This study focused on six top-selling varieties grown in Cherri Global orchards in Otago: Bing, Rainier, Kordia, Lapins, Sweetheart and Staccato.

The study also compared fresh and packaged cherries to learn if nutrients were lost during processing.

Researchers looked at proteins, carbohydrates, sugars, fats, fibre, fatsoluble vitamins, and water-soluble vitamins.

“Basically, in terms of nutrient profiles, we have explored everything we could. And the same with the bioactive compounds,” Dr Rashidinejad says.

“We concluded that all six varieties were rich sources of different nutrients: minerals, vitamins, amino acids, and phenolic compounds – the antioxidants. The phenolic compounds, were what most interested us because they are potent antioxidants with numerous scientifically proven health-promoting properties.”

Dr Rashidinejad says almost 30 phenolic compounds were studied, in collaboration with Plant & Food Research, using high pressure liquid chromatography techniques.

Most of these compounds were present in differing amounts, with vitamins A, C, E, B1, B2, B3, B6, B9 (folate), and K also detected and quantified in the fresh, packaged, and frozen cherry samples. High concentrations of vitamin C were confirmed.

The cherry season is quite short, with early varieties ripening in late December and all finished by early February. The delicate stone fruit are not easy to grow, requiring extensive bird protection, and cherries are labour intensive to pick and process.

After picking, cherries are washed at pack houses and exported or distributed around the country, either as fresh or frozen product. The comparison between fresh and packaged fruit found processing had varying effects on the nutrients and bioactive compounds of the fruit.

“We found only some minor differences and little effect from the time and the process of washing, drying and packing,” Dr Rashidinejad says. “It’s good news that the transport and packing does not have a major effect on the health-promoting compounds.”

Cherries grown in New Zealand are officially jam packed with components essential to human health, confirmed by recent research

“This has been a comprehensive study. The hypotheses have been confirmed: New Zealand cherries are a great source of antioxidants and nutrients, and that processing has a little or no impact on their nutritional properties.”

He says future steps would be finding ways to use the waste products produced during cherry processing. It has been estimated that 8000 tonnes of cherry waste are produced in New Zealand every year. Because washing and packaging does not significantly reduce the nutrient profile of the fruit, this could lead to new uses for the waste or the seconds that don’t get to shop shelves.

Dr Rashidinejad says such waste from cherries could be converted into a high-value ingredient for the food industry in the future. This could be in powdered or frozen form, or as a component in another food product.

The Riddet Institute is a Centre of Research Excellence (CoRE), hosted by Massey University, which focuses on fundamental and advanced food research. Cherri Global, based in Hawke’s Bay, has a business division focused on developing a range of Cherry products focused on health and eliminating waste.

As traditional farmers and growers invest in new technology and equipment – automation in fresh produce operations is on the rise. Check weighing is an important part of the packaging and inspection process. While the primary function of this equipment is to monitor end weight of your product – it also helps you to gain peace of mind for your business, and your customers.

Check weighing is key to delivering what your consumers expect by providing accurate verification of the package weight or count and detecting missing components. A variety of check weighing equipment is available — for a wide variety of applications and this equipment will bring speed and accuracy to your operation.

In a perfect world, every package would weigh the same. But weighing processes are not infallible and equipment issues, problems with base line zeroing, product build up, or even product density can cause variations. Product characteristics, product piece weight, temperature and moisture can all affect the accuracy of what is portioned out.

Ready to take your product inspection to the next level?

Industry-leading check weighing equipment will help you to make informed decisions; like identifying trends periodically during production, or on a continuous live basis. They are easily programmed — with a range of features that can handle different types of produce.

The checkweigher is a compact piece of equipment. The best ones will be simple to operate and easy to clean. They are also available with integrated metal detection and reject systems for expanded produce inspection — should your operation require it.

Consumer regulations dictate that a packaged product cannot be sold under the marked weight. To comply, many fresh produce processors increase pack weight to such a level that an “underweight” will not occur. When portioning uses methods such as multihead weighing, volumetric weighing (auger or rotary cup filler), or even piece counting, statistical mean and standard deviation will occur in every batch.

Example: A 200 gram pack weight has a standard deviation of 2 grams. A processor may set the packaged weight to 206 grams, as a mean number and to ensure no under weights. This translates to an extra 6 grams per package and around 3 standard deviations, resulting in a shift of the statistical “bell curve”, so that a max weight of 212 grams can be produced.

Using a checkweigher allows you to easily monitor where the mean is trending and the equipment will raise the alarm if weights start to drift too high.

Heat and Control is a privately-owned company with a global team that has built an extensive knowledge bank and developed a wealth of experience and expertise. Access to production and technical support from a network of engineers, food technicians, field service technicians, skilled tradespeople, and support teams provide food manufacturers with confidence to achieve production goals.

The new Lory® IsoCrisp variety is made from European wheat, has a neutral taste and can be individually flavoured

Ingredients specialist Loryma is expanding its Lory® IsoCrisp range with a variant made from wheat. The extruded crispies are low in sugar but rich in protein. This means they not only add a pleasant crunch to biscuits, bars, muesli and granola, as well as other snacks, but also provide a plant protein boost. The new Lory® IsoCrisp variety is made from European wheat, has a neutral taste and can be individually flavoured.

The crispy, round extruded product consists of wheat protein, wheat starch, rice flour and cocoa powder. As a result, the new variant contains little sugar and saturated fatty acids, and has a protein

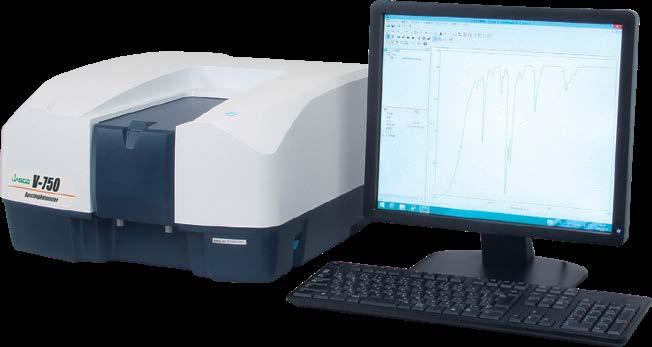

The JASCO V-700 range of UV/Vis-NIR spectrophotomers are high-quality instruments with a variety of sampling and data analysis options for a broad spectrum of users. The V-700 series comprises five distinct models covering the entire spectrum ranging from the far-UV (187 nm) to near-IR (3200 nm). These instruments are also compact in optical design, therefore reducing their footprint in the laboratory. All models in the V-700 range are double-beam types for superior performance, reliability and data quality.

JASCO also offers optional software to meet specific user requirements. As an example, for food & beverage applications, one optional software available is the PLS quantitative programme. This allows users to perform simultaneous quantitative analysis of multi-components in food products. Subtle differences in spectra, which may not be identifiable by human eye, can be extracted by the PLS software for better visual comparisons.

As part of the standard Spectra Manager software, users will also have access to validation and daily check software. This allows users to perform regular check-ups of the instrument; to monitor

content of 71g per 100g. The vegan, tasteless crispies are suitable for end products in the high-protein, low-carb and sports nutrition segments, among others. Manufacturers can also offer the proteinrich crispies, which have a diameter of about two millimetres, in their original form – for example, as crunchy highlights for muesli. For further information, please visit: LinkedIn

Loryma, a member of the Crespel & Deiters group, is a producer of globally distributed wheat proteins, native and modified wheat starches, extrudates and functional blends with an expertise of more than 40 years. The company is located in Zwingenberg (Germany).

performance; and quickly identify issues that may require service assistance. All spectroscopy products from JASCO utilise the Spectra Manager software hub, with each instrument having their own specific software. Familiarity with one instrument then opens the door to using other JASCO instruments.

For customers with limited budget or bench space, JASCO also offer an LCD touch display: Intelligent Remote Module (iRM1000). This accessory contains a simplified version of the Spectra Manager software, allowing users to easily acquire spectra and export data (via USB) without the need for direct connection to a PC. www.bio-strategy.com

Enjoy your cup of java

John Brooks' view of the food world through the lens of a microbiologist.

Much of my work as a food microbiologist has involved food spoilage and food poisoning, with from time to time a large helping of singlecell protein and biofilm research. I have written about these things both in Sliding on and my own food safety blog here. As Monty Python would say “Now for something completely different”. There is mounting evidence that our gut biome significantly impacts our health and may even affect our brains. It follows that our food and drink may interact with our gut biome and thus indirectly affect our behaviour.

In the past it has been claimed that coffee can cause cancer. It will no doubt come as a relief to many of us that a review of more than 1,000 studies by the International Agency for Research on Cancer (IARC) in humans and animals failed to find adequate evidence to indicate that coffee is a carcinogen. There may indeed be an inverse relationship between drinking coffee and some cancers.

In a relatively small survey, a team from Baylor College of Medicine in Houston, Texas examined “the association between caffeine consumption and the composition and structure of the colonic-gut microbiota.” They managed to find 34 male participants with a normal colon in one hospital, prepared to undergo a screening colonoscopy and endoscopy to determine the health of their colons. The researchers obtained snap-frozen colonic mucosa biopsies from various segments of these individuals’ colons, and extracted microbial DNA, then performed 16s rRNA gene sequencing analysis. The researchers claimed that their work was different from most studies which focus on the faecal biome. In addition to this invasive investigation, the participants completed a food frequency questionnaire that was actually designed to evaluate the daily intake of coffee. The results were divided into “high” and “low” coffee consumption’ based on the resultant intake of caffeine. The questionnaire did not reveal any information on how the coffee was prepared or the brands used.

Perhaps not surprisingly, a high intake of caffeine did have an effect on the gut microbiome but the effect was independent of the participants’ age or the quality of their diets. High caffeine consumption was associated with high levels of the bacterial genera Faecalibacterium and Roseburia, but low levels of Erysipelatoclostridium. These bacteria are regarded as part of the normal gut flora, but elevated levels of E. ramosum have been linked with metabolic syndrome and were found in animal studies to be associated with diet-induced obesity. Several other genera of bacteria were also found to be present at higher levels in the flora of the high-intake volunteers.

The authors concluded that “Higher caffeine consumption was associated with increased richness and evenness of the mucosaassociated gut microbiota, and higher relative abundance of antiinflammatory bacteria, such as Faecalibacterium and Roseburia, and lower levels of potentially harmful Erysipelatoclostridium.”

Many studies now are suggesting that there is a two-way interaction between the gut microbiome and the brain. Some of it reads like science fiction, but there is good evidence to support this. For example, production of short-chain fatty acids, such as butyrate, by bacteria in the gut when they break down fibre, may be associated with brain function. Butyrate-producing Faecalibacterium and Coprococcus bacteria were consistently associated with higher quality of life indicators. Depletion of Dialister and Coprococcus spp. is consistently associated with depression. The term ‘psychobiotic’ has been coined for microbiota-based interventions that have a beneficial effect on the human brain (2). We know that certain microbes in the gut can modulate the immune response in ways that affect the brain and also produce signalling molecules that regulate neuron activity.

Of course, studies with humans are fraught with difficulty. We eat a wide variety of foods and consume all sorts of alcoholic and nonalcoholic beverages and all of these in different amounts. Some of us take medication or have high-stress jobs, while others are able to take life at a much slower pace. There appears to be no barrier to our effecting change in our gut biota by altering our diets and this doesn’t involve buying special foods from specialist stores. A Mediterranean diet that's high in fibre, particularly from vegetables, is thought to be beneficial and in a small study in which subjects were given high fibre, prebiotics and fermented foods, the experimental group reported being less stressed than the control group. Perhaps it’s time for us to concentrate more on looking after our microbiota.

Now, I’m off to make a strong cup of coffee with cream.

References:

1. Dai, A. Et al. (2023) The Association between Caffeine Intake and the Colonic Mucosa-Associated Gut Microbiota in Humans – A Preliminary Investigation. Nutrients, 15, 1747. https://doi. org/10.3390/nu15071747

2. https://www.bbc.com/future/article/20230120-how-gut-bacteria -are-controlling-your-brain Caffeine. (2023, May 2). In Wikipedia. https://en.wikipedia.org/ wiki/Caffeine

World Food Safety Day this year is 7 June 2023. It’s a day that could easily pass under the radar for most people, however it is an important date in the calendar for food and health regulators, and for our communities. We all have a role to play in upholding food safety, right along the chain from pastures to home kitchens. This is the fifth year that the day has been marked around the globe – driven by the World Health Organisation (WHO) to draw attention and inspire action to help prevent, detect and manage foodborne risks, contributing to food security, human health, economic prosperity, agricultural production, market access, tourism and sustainable development.

This year’s theme, chosen by the WHO, fittingly for New Zealand Food Safety (NZFS) is ‘Food Standards Save Lives’. Our team of science and policy experts are passionate on this subject as it is one of the driving forces behind our overall mission to ensure that food produced and imported into New Zealand is safe and suitable. One in ten people world-wide fall ill from contaminated food each year – or 1.6 million a day on average. Here in New Zealand around 200,000 people a year get sick from food-borne illness. We know that microbial, chemical or physical contamination of food can be reduced or minimized through the implementation of food safety standards. To quote the WHO, “food safety standards are designed to protect the lives of all, and the livelihoods of many” They establish the criteria which food should meet to protect consumers and establish confidence in the product.

New Zealand actively contributes to the development of world food safety standards at various international fora. From the Codex Alimentarius Commission for Food Safety, part of the WHO, to the World Organization for Animal Health (OIE) – to name a couple New Zealand works closely with Australia to develop joint food standards for food labelling and composition through arrangements such as the Australia New Zealand Food Standards Code and the Trans-Tasman Mutual Recognition Agreement.

In New Zealand our food safety system is underpinned by four key pieces of legislation including the Food Act 2014. The Ministry for Primary Industries, via NZFS, develops food standards that food businesses must meet. This includes setting thresholds for contaminants and residues, including those left by pesticides and veterinary medicines used in growing plants and animals for food.

The fortification of flour with the B vitamin folic acid is a good example of how food safety standards benefit populations. On 8 July 2021 the Government announced its decision to mandate the fortification of non-organic wheat flour used for bread making

with folic acid. This decision, to change from the current voluntary fortification of bread to mandatory fortification of flour for bread making, aims to improve health outcomes and health equity, while considering cost-effectiveness and consumer choice. The health benefits and risks of folic acid fortification of food authored by thenPrime Minister's Chief Science Advisor Sir Peter Gluckman FRS FRSNZ and the Royal Society, states: “There is compelling evidence that mandatory folic acid fortification is associated with lower rates of Neural-Tube Defects (NTD), and that taking folic acid supplements at the recommended doses in pregnancy has no adverse effects on pregnancy outcome or the child’s health.”

We will be looking closely at NTD data post-mandatory fortification of flour in New Zealand. It is expected that results will follow a similar pattern to other countries where bread flour and bread have been fortified with folic acid. The Gluckman and Royal Society report notes that, “New Zealand’s NTD rate is 10.6 per 10,000 total births (live births, foetal deaths, and terminations), similar to other countries with a voluntary regime, such as Ireland (with a rate of 10.4) and the United Kingdom (with 12.6). However, it is higher than countries where mandatory fortification has been introduced, including Australia (with a rate of 8.7), Canada (with 8.6) and the United States (with a rate of 7).” For New Zealand, Māori babies are over-represented in the statistics, the prevalence of NTD live births for Māori, Pasifika and European/other women was, respectively 4.58, 4.09 and 2.81.

There was a 2-year transition period for the flour millers to make the necessary changes, which ends on 14 August 2023. By mid-August 2023, flour millers must comply with Standard 2.1.1 – 5 (a) Cereal and Cereal Products of the Australia New Zealand Food Standards Code, which outlines that non-organic wheat flour that is sold as suitable for making bread must contain no less than 2mg/kg, and no more than 3mg/kg, of folic acid.

New Zealand Food Safety has developed guidance with the millers dosing the flour with folic acid and the food businesses using the fortified flour to help them understand and meet the standard. Guidance will cover the monitoring and testing of folic acid levels at the mill to ensure desired public health benefits are achieved, and for food businesses who are using the fortified flour, the information they must provide customers on food labels or in-person.

World Food Safety Day is a timely reminder of the essential work that people in our food safety sector across New Zealand carry out every day for the benefit of the health and wellbeing of our people, ensuring food security and maintaining and growing our important food and beverage international economy – thank you for everything you do.

You can find more information on our website or contact info@mpi. govt.nz

Good things come to those who wait and now it seems food technologists are having their moment in the sun. I know this as my boss asked me what it’s like to be a superstar – in the world of food technology, that is. Our time to shine has come as venture capitalists and entrepreneurs look to us to help save the planet through the advent of cellular agriculture.

At Food Standards Australia New Zealand (FSANZ) we have certainly been waiting and preparing ourselves for the development of cellbased meat. It’s almost 10 years since Mosa Meat produced the first cell-based beef patty. In that time we have been watching from afar developments in the US, Europe, Israel and other regions. But we’ve not been idle. FSANZ has published information, spoken to a host of companies, engaged with other regulators and presented at many forums. We’ve also had a guiding hand in the recently released WHO Report on Safety of Cell-based Food Products posted here.

Everything seems to be aligning for the rapid development of cellbased foods. Concerns around food security, biodiversity loss, land clearing, climate change and unsustainable use of terrestrial and marine ecosystems are highlighting the increasing challenges in producing food and fibre for the planet's growing population. Given the urgency to address these issues, can cell-based foods provide part of the solution? Only time will tell, but at FSANZ we are starting our regulatory journey in assessing the safety of these foods.

FSANZ recently received its first application from an Australian company vowing to pioneer cell-based food in Australia and market their product in the wider Pacific region. The assessment of this application is a welcome challenge, not only for our food technologists, but all the scientists at FSANZ – microbiologists, biotechnologists, toxicologists, nutritionists and dietary exposure analysts. We’re now busy with our assessment of the public health and safety considerations of this new ‘novel food’, having regard to the potential for adverse effects in humans, composition or structure of the food, its production process, the source from which it is derived, patterns and levels of consumption and any other relevant matters. This new food requires a complex and involved assessment of not only the final food, but also the process to produce it and other relevant matters. These include a range of sociocultural aspects:

• How will it be perceived by consumers?

• What is the economic impact or benefit of the new food?

• What should the all-important naming and labelling of such products look like?

Our social scientists, labelling experts and economists will diligently work through the pre-market assessment, the findings and recommendations of which will benefit the entire sector and help smooth the path for the next applications coming through.

We’ve also engaged heavily with other regulatory agencies such as the Singapore Food Agency and US Food and Drug Administration to ensure best practice in and harmonisation of risk assessment. FSANZ is also engaging with Cellular Agriculture Australia, a not-for-profit organisation enabling the future of cellular agriculture in Australia through awareness, education, research and advocacy to enable a path to efficient regulation for this sector. After all, being entrepreneurs does not necessarily mean they are regulatory experts as well.

Our planning and assessment of this first application will stand us in good stead as cell-based products could potentially come in thick and fast when the sector overcomes high costs and scale up challenges. Mosa Meat have just opened a vast "scale-up plant"’ in the Netherlands as it edges closer to commercialisation. And we also need to be ready for the plethora of other products this technology lends itself to. OK, there’s the run of the mill mincemeat, but think caviar, Wagyu steaks, Dokdo Shrimp, precision fermentation of specific proteins, lipids and even, potentially, Woolly Mammoth meatballs! Any potential businesses or start-ups reading this are encouraged to contact FSANZ to support the pre-assessment and application processes.

Regardless of whether we food technologists can save the planet or not, what’s certain is that we require innovative technologies if we are going to feed the planet into the future. Just as fermentation, drying and salting were used in prehistoric times, we are now seeing innovation in science and modern technologies that can be applied to food manufacturing, cellular or otherwise.

What will the next 10 years hold? Certainly more choice for the consumer in terms of protein sources. While we might not see a cellbased meat fermenter sitting on the kitchen bench next to the slow cooker, we could see 3, 4, 5 or 6D printers make an appearance to help you get your protein fix. All this means exciting times ahead for the superstar food technologists and our regulators who must continue to ensure a safe food supply while supporting a strong, sustainable food industry that benefits consumers and offers diverse, affordable food choices.

A regular roundup of news and opinion from the Oils and Fats Group of the New Zealand Institute of Chemistry.

The Australasian section of the American Oil Chemists' Society (AAOCS) is hosting a conference on "Future of lipids; health and sustainability"

It will be held at Noah's on the Beach in Newcastle Australia Nov 13-15th 2023

The theme of this year's event is Future of lipids: health and sustainability and aims to look at the future of fats and oils in research and industry.

The programme will present the latest science and industry updates relating to edible oil and ingredient supply, biotechnology, manufacture of fat-based products, nutritional research, oil analysis, latest developments with omega-3 oils, dairy lipids and other activities that support the industry. Furthermore, planned workshops led by international experts, are in planning to occur prior to the conference.

Two workshops will be held on Monday 13th November 2023. These workshops will run concurrently and are:

• Sustainable ingredients for food and feeds (focus of novel lipids and protein products entering our food systems)

• Lipids in the health of our futures (focus on nutrition)

AAOCS2023 aims to provide an opportunity to learn and share science and industry progress related to all aspects of fats and oils. We aim to continue to provide a social setting where the latest in the oil and fats industry, science and health can be discussed and connections made or renewed.

For many people dealing in oils there is come confusion between enforceable legislation/compliance and standards for identity. This was recently illustrated at the World Congress on Avocado Oil where an afternoon session debated the whole issue of standards and adulteration. Professor Selina Wang, a keynote speaker, has published several articles showing that of 82% of avocado oil in the USA is adulterated, hence why the bottles are so cheap and are threatening the existence of genuine Avocado oil from countries such as New Zealand.

When the situation was looked at a few years ago by this reviewer many samples were seen to be fraudulent and not disguised particularly well. So, everyone knows what is going on but what can be done about it?

In Australia, a new Australian standard for olive oil was created around a decade ago and fortunately the supermarkets welcomed it

and insisted suppliers of Virgin oil met the standard. This resulted in a vast improvement of oils on the shelves: you need the active involvement of the retailers to make any progress. It appears that in the USA, price is the most important criteria, and they ignore fraud.

Codex standards and related texts are voluntary in nature. They need to be translated into national legislation or regulations to be enforceable.

General Standards, Guidelines and Codes of Practice: These are the core Codex texts and apply to all products and product categories. These texts typically deal with hygienic practice, labelling, additives, inspection and certification, nutrition and residues of veterinary drugs and pesticides.

The Codex Alimentarius, or "Food Code" is a collection of standards, guidelines and codes of practice adopted by the Codex Alimentarius Commission. The Commission, also known as CAC, is the central

Inform Magazine, April 2023 contains an article on the adulteration of Avocado Oils in the US

part of the Joint FAO/WHO Food Standards Programme and was established by FAO and WHO to protect consumer health and promote fair practices in food trade. It held its first meeting in 1963. The term "Codex Alimentarius" is Latin and means "food code.” Codex standards are international food texts, i.e., standards, codes of practice, codes of hygienic practice, guidelines, and other recommendations, established to protect the health of the consumers and to ensure fair practices in the food trade. The collection of food standards and related texts adopted by the Commission is known as the Codex Alimentarius

There are three major areas of regulations concerning the global trading of oils and fats. Firstly, there is the international arena such as that of the International Maritime Organization (IMO). Secondly,

there are the standard international contracts for trade such as the FOSFA (Federation of Oils, Seeds, and Fats Associations) contracts and NIOP (National Institute of Oilseed Products) trading rules, as well as regional or national legislations such as those of the European Union (EU). Finally, there are some international codes of practice that are becoming increasingly important, for example, the use of the principles of HACCP (Hazard Analysis Critical Control Points) and the Codex Alimentarius Code of Practice for Oils and Fats.

Traders must understand all these laws and rules, and they should be completely familiar with their contracts. Also, recall that most of the time, we are dealing with the food industry and that the copious amounts of oils and fats produced in the world are for human consumption.

Today, food production involves risk management and this risk must be managed at all stages of the food chain, from farm to fork. One of the most critical areas of risk is the transport of bulk cargoes of oils and fats by sea, from the producing countries to the consuming countries. The main reason the risk is high is that oils in transit are not under the direct control of any of the trading parties. For the duration of the voyage, they are the responsibility of a third party, that is, the shipowner. During this link in the food chain, a vessel carrying edible oil must comply with the legislation developed by the IMO.

This article is based on a presentation from John Hancock to the Oils & Fats International Congress held in Kuala Lumpur, Malaysia, in October 2010. John Hancock is the technical manager of FOSFA International, based in London. He has represented and promoted the interests of the oils and fats trade in many national, regional, and international technical arenas.

An estimated 85% of the current world trade in oils and fats uses FOSFA contracts, and it is interesting to consider the reasons for this. The main advantage is that the use of standard form contracts reduces the risk of trading parties misunderstanding the procedures they need to follow to enable the trade to go smoothly. The contracts also reduce the risk in trade as the clauses in the contracts are well known by all parties and reflect long-standing trade practices. This allows the parties to discuss and agree on the notable features such as quality, quantity, price, and shipment/delivery dates. Their confirmation letters include these details and usually a statement saying, "All other terms as per FOSFA 80" (for crude palm oil, by way of an example). This means that they do not have to read all the other parties' contracts, which would be necessary if standard contract forms were not available or used. All trading parties would like the contracts to be in their own language and refer to their own national legislation, but this is not practical. Thus, the trade agrees to use one

common language and one authority, and, by virtue of history, these happen to be English and the rule of English law, as is common to all internationally traded commodities.

The contracts also reduce risk as they include rules for the hygienic carriage of oils and fats in bulk by sea. These rules are tried and evaluated and have been developed now over two decades and with much experience. For a FOSFA contract, these rules are contained in the publication referred to as "The Carriage of Oils and Fats." Of particular importance in these rules are the two lists of banned previous cargoes and acceptable previous cargoes.

Certain regions such as the EU and the United States (via NIOP acting as the US trade body) have already made this choice for the trader by virtue of their wish to protect the health of the consumer. EU legislation requires that all food products be carried in dedicated transport. However, FOSFA approached the European Commission (EC) on behalf of its members and persuaded the EU that dedicated shipping, initiated in 1995, was not in the interests of any country. The distances are large, and the freight is expensive, so ships returning with empty tanks are not economic. More recently, this has been supported by the need to minimize the carbon footprint of the whole transport chain. Thus, the EU adopted a similar list to the FOSFA list of acceptable previous cargoes, but the European Food Safety Authority (EFSA) did not agree with the inclusion of a few of the products on the list. They felt that data were insufficient to make a judgment and changed the FOSFA list slightly. But most of these cargoes are not carried in great volumes, and they could be removed from the FOSFA and NIOP Acceptable Lists without reducing the available ship space or the flexibility that charterers and owners seek. The recent decision by the EC to re-evaluate their acceptable list has meant that the decision to amend these trade lists has been postponed.

The CCFO is in the lengthy process of developing its acceptable list. It currently has a draft list at Step 7 and a smaller proposed draft list at Step 3. These steps relate to the progress of the standards as they move toward general acceptance, from Step 1 to Step 8. Thus, a major part of the acceptable list is in an agreed draft form. There have been no health issues with any of the substances in the draft list at Step 7, which is effectively equivalent to the FOSFA list as it was in 1996 when the EU adopted it. However, the proposed draft list at Step 3 is more contentious. CCFO has developed a set of draft criteria that it feels could be used to assess the suitability of a substance being regarded as an acceptable previous cargo.

Briefly, these criteria state that an oil is to be carried in appropriate containers with cleaning, inspection, and recording systems. The previous cargo must have a minimum Acceptable Daily Intake (ADI) of 0.1 mg/kg of body weight/day, it must not contain a known food allergen that is not removed by further processing, and any known reaction products with oils must also comply with these criteria. However, these criteria are deemed extremely cautious. As

representing the industry, FOSFA supports these criteria but feels that the further processing of the oils at their destination should be considered, thus allowing a lower ADI to be allowed in this case. There is also the problem of assessing materials that do not have an ADI value. Nevertheless, we believe that overall, the criteria have a 10× safety margin built into them, but they are the only set of criteria that have a defined level of toxicity for previous cargoes. The criteria have been discussed by the EFSA, which concluded that they do not contradict the criteria used by the EU to consider previous cargoes. Thus, the hope is that these amended criteria will be agreed at the next meeting of the CCFO in February 2011 and allow the acceptable list to be adopted. There will be opposition to this adoption from the US delegation as they are against Codex having any lists, believing that the trade lists are adequate. However, this would leave the industry with at least three major lists of acceptable previous cargoes, namely, FOSFA, EU, and NIOP. Harmonization of the lists is a praiseworthy goal as this would prevent any potential of costly errors being made in the allocation of tank space. But this should not be pursued if it were to reduce the ship tank space available to the trade.

Next step: –implement the new standard for Codex using the analyses and specifications by Professors Wang and Wong (NZ). Then it’s up to the trade to lobby the retailers to ensure they get their suppliers to adhere to the Codex specification

Additional meetings on this topic

The Codex Alimentarius Commission (CAC) 45th meeting was held November 21 to December 13, 2022, during which the draft revision to the Standard for Named Vegetable Oils (CXS 210-1999) for inclusion of Avocado Oil was adopted at Step 5, noting that there are pending technical comments that should be submitted at Step 6. The CAC committee endorsed the extension of the deadline for completion of the work to CCFO28.

AOCS 5th Avocado Oil Expert Panel Meeting at the AOCS conference in Denver 30 May, 2023.

The meeting will be chaired by Selina Wang (scwang@ucdavis.edu)

Its purpose is to discuss areas of interest regarding Avocado oil. A further meeting in the first quarter of 2024 will be given an update by Jill Moser. She will provide a summary of the data that has been collected. USP has submitted a standard and it was published by the FCC and was effective on June 1, 2022. Current published Monograph is for refined avocado oil. Monographs are updated in June and December each year. Requests for a monograph for virgin/ extra virgin oil would require more data. USP has updated the format of the Avocado Oil standard by deleting some tests and replacing them with the relevant reference tests in FCC Appendix VII. But there is no content change to these tests.

A transdisciplinary and computational approach in food flavour creations using meat co-product as an exemplar

Authors: Santanu Deb-Choudhury1, Munir Shah2 and Carolina Realini1

Affiliation 1: AgResearch Limited Affiliation 2: Waka Kotahi NZ Transport Agency

Introduction

Most meat co-products have traditionally generated little economic value, with some even having a negative value due to their disposal costs, representing a significant waste. From a sustainability perspective, it is important to reduce this waste and create more value from meat co-products, especially targeting the food industry. Many of these meat co-products contain an appreciable amount of nutrients like essential amino acids, minerals and vitamins, and could be developed into higher value ingredients for a range of industries including food service. They can also be considered as raw materials for the generation of bioactives [1] and to produce extracts with excellent functional properties suited for a wide variety of food industry applications.

Novel approaches to flavour development create opportunities to develop new applications from co-products. The creation of unique flavour profiles to satisfy consumers’ continuing craving for novelty and their growing interest in flavour pairing is a major challenge for food companies. Chefs also must master the ability to develop flavours that create balance and harmony in the final product and create a complex multi-sensory experience in consumers. Traditional approaches to flavour development, whereby development chefs attempt to create new sensory experiences through applying previous experience, trial-and-error, and panel tasting, will not be able to identify the full opportunity-set of flavour combinations. This is because there are many possible combinations and interactions between the numerous chemical compounds of ingredients that largely determine how consumers experience flavour. To be able to identify and exploit this opportunity-set of possible flavour combinations more rapidly and comprehensively, traditional approaches to new flavour development need to be complemented with science-based computational approaches that are better equipped to systematically explore a large range of possible combinations of chemical compounds.

In recent years, there has been a significant increase in understanding of food flavour from knowledge developed by the traditional fields of physics and chemistry [2], sensory [3], psychology and neuroscience [4], and more recently, by the emerging fields of molecular [5] and computational gastronomy [6]. On one hand, volatile and non-

volatile chemical compounds may directly or indirectly contribute to taste and odour profiles and hence greatly influence food flavour. Volatile compounds in food make up the characteristic aromas and contribute to their flavour. These are chemicals which are easily given off in the form of a gas and affect our olfactory senses. Non-volatile compounds, such as peptides, free amino acids, nucleotides, organic acids, soluble sugars, polyols, or carbohydrates, interact with our taste buds in our tongue. Published cooking recipes are a great starting point for identifying successful ingredient combinations. Thus. with an instrumental analytical approach, combined with information from recipes, followed by a computational methodology that analyses chemical compatibilities and frequencies of combinations from recipes, unique ingredient pairing outputs can be identified that would not be achieved by chefs alone.

Computational methods can assist in further flavour creation process in three main ways:

1. Making historical knowledge about culinary practices more accessible to flavour scientists and chefs by modelling data from countless published recipes so that they are easily searchable and comparable.

2. Helping to develop unique flavour ideas that are relatively free of human biases about which ingredients mix well and which do not by uncovering ingredient relationships using chemical signatures.

3. Reducing the time and cost associated with the flavour creation process, by proposing novel and plausible food pairing ideas for further creation and validation.

Modernist cuisine takes the approach of novel combinations of ingredients and preparation methods and is more open to scientific methodologies [7]. This approach is highly dependent on the chef’s experience in ingredient manipulation and processing. However, the flavour of food is quite complex, requiring chemical, instrumental and sensory techniques and/or sophisticated modelling and equipment to create a complete description. A traditional scientific approach to sensory analysis uses classical experimental designs and statistical analysis, such as linear multivariate analysis. However, computer algorithm-based methods such as non-linear regression and artificial intelligence may be used in conjunction with more traditional methods to optimise and overcome potential shortfalls in existing approaches. We envisioned a New Zealand platform where machine learning algorithms support chefs to easily identify complementarity or contrasting flavours that would form the backbone of creative dishes.

Culinary expertise and flavour-matching algorithms in conjunction with advanced analytics were used for the discovery of new flavour combinations. Both conventional and novel ingredients, including New Zealand edible native plants, were paired by the algorithm to create unique flavour combinations for an in-restaurant consumer tasting experience.

The chefs accessed the flavour-matching algorithm and started by choosing one ingredient. Subsequently, the system, using the flavour profiles of analysed ingredients, then suggested 10 further options to pair with the starting ingredient. The chefs continued this ingredient selection process until a new dish was conceived. Two such dishes were tasted by diners at a restaurant

To be able to successfully link and combine different methods and integrate knowledge from both science and non-science disciplines, a transdisciplinary approach is needed. We have followed such an approach to create value addition for meat co-products that have traditionally been viewed as waste. In this approach, we combined traditional food knowledge and food preparation methods with advanced analytics and flavour-matching algorithms to develop new food formats with intense and desirable flavours from meat co-product streams. Algorithms, based on genetic algorithms and generative adversarial networks, were developed to sift through this database and model relationships among ingredients. Based on this information, recipes and chemical features, the algorithms recommend new combinations of ingredients paired with the given group of starting ingredients and target flavour.

Our approach has several advantages over traditional approaches to innovation in the food flavour development space, including:

1. It drastically reduces the time and cost associated with developing

in Wellington: a dish using a more conventional pairing of beef, orange, ginger and potatoes, pictured left, and a unique combination of boiled chicken, camembert, passionfruit, cocoa and Kawakawa (Macropiper excelsum) endemic to New Zealand. Diners commented that they loved that the chicken dish was “challenging in terms of ingredients” and that they “were quite excited by that”. They felt that using the flavour-matching algorithm to enhance and embellish the food industry was a positive step forward. The chef remarked, “Looking at how these products work together is definitely the beginning of a new cuisine. I’m looking forward to using this approach further.”

new flavours by using advanced computational processes to rapidly search, compare, and match ingredients based on recipes and the ingredients’ chemical signatures.

2. It helps to uncover unexpected relationships (e.g., similarities) between ingredients, thereby enabling food scientists and development chefs to find novel uses for ingredients.

The suggested ingredients and flavours are then validated by development chefs and consumers. Our approach is novel in that heuristic evaluations are made to customise flavour to create unique eating experiences.

In further work, we aim to use this platform to help address broader opportunities in our food systems. The application of this platform is not limited to just one product of one industry sector, but to all food applications. For example, the platform can be used:

• To create new flavours, potentially replacing artificial flavourings.

• To enhance flavours for the elderly population experiencing reduced taste-sensation, thereby increasing their enjoyment of

food and encouraging a higher food intake and better health.

• To provide more ‘natural’ flavours for alternative protein products, which are gaining momentum with consumers, using native ingredients and turning them into unique New Zealand flavours.

• To create a digital recipe platform for the service industry to create food that is not only tasty but also meets nutritional requirements.

This research was funded by the Strategic Science Investment Fund (SSIF; AgResearch Ltd.) - A27235, Consumer Experience: pathways to premium foods.

1. Martínez-Alvarez, O., S. Chamorro, and A. Brenes, Protein hydrolysates from animal processing by-products as a source of bioactive molecules with interest in animal feeding: A review. Food Research International, 2015. 73: p. 204-212.

2. Vega, C. and J. Ubbink, Molecular gastronomy : a food fad or science supporting innovative cuisine? Trends in Food Science and Technology, 2008. 19: p. 372-382.

3. Novel Techniques in Sensory Characterization and Consumer Profiling. 2016: CRC Press.

4. Spence, C. and M.U. Shankar, The influence of auditory cues on the perception of, and responses to, food and drink. Journal of Sensory Studies, 2010. 25(3): p. 406-430.

5. Spence, C. and J. Youssef, Assessing the long-term impact of the molecular gastronomy movement on haute cuisine. International Journal of Gastronomy and Food Science, 2018. 14: p. 35-44.

6. Spence, C., Food and beverage flavour pairing: A critical review of the literature. Food Res Int, 2020. 133: p. 109124.

7. Linden, E., D. McClements, and J. Ubbink, Molecular Gastronomy: A Food Fad or an Interface for Science-based Cooking? Food Biophysics, 2008. 3: p. 246-254.

Early April saw the 10th World Avocado Congress at the AOTEA centre in Auckland. This was the first time the event has been held in New Zealand. This report covers the discussions on Avocado oil quality

Industry leaders from around the world met to discuss the latest in agricultural technology, business, and nutrition. Total attendance was 1160 people.

Coming out of a turbulent few years, speakers and attendees were eager to talk about what the future held.

International Fresh Produce Association Chief Executive, Cathy Burns, said that despite the challenges of the pandemic, things were looking up.

“What makes this event so special is the opportunity for people to get together to talk about solutions to those challenges," she said. While the industry was facing headwinds, Burns said there had never been such focus on health and nutrition as there was at the conference. With an increase in the world market, she said a small grower like New Zealand was primed for success. "The sky is the limit, quite frankly," she said.

The three-day event was attended by delegates from thirty-three countries. Around the Congress there was lots of excited chatter in many languages, quite an experience. The Congress venue at times appeared overwhelmed by the numbers and the organisers appeared to be struggling with the catering of morning tea and lunchtime with queues clogging the areas. However, the coffee supplied free was delicious and for those that yearn for the traditional sausage rolls, they also were delicious.

This reviewer was particularly interested in the section on avocado oil. This has recently been the subject of a lot of controversy. Our friend and professional colleague professor Selina Wang attended from UC Davis CA. Alan Woolf from Plant and Food Research had organised an afternoon session discussing aspects of oil. Whilst a minor interest for most delegates, oil is a hot topic amongst those who produce it, research it, and trade in it. Whilst virgin avocado oil is a brilliant green and is easy to recognise, refined and deodorised avocado oil is pale yellow and looks like every other vegetable oil on the shelf. So,

unless the oil is fully analysed it is hard to see whether the oil being sold is fraudulent or has some avocado oil in a blend.

Additionally, there is currently no existing codex standard for unrefined or extra virgin avocado oil although one for refined bleached deodorised oil has just been released. This is a frustrating problem for the genuine processors in New Zealand who are trying to ship to export markets. What is happening, particularly in the United States of America, is that the cheaper, fraudulent oils are ruining the market for high quality virgin and genuinely processed oils. This is a similar situation to that which exists for olive oil and a problem which many countries have been battling for 40 to 50 years. In Australia, the problem was partially alleviated by Australia having its own standard which had been worked on by experts in the field for a couple of years and then the supermarkets being convinced to insist on authentication evidence before accepting product into their supermarket shelves.

The Consumer Protection Act (Act 68 of 2008) states that consumers

The New Zealand avocado industry is vibrant, diverse, and innovative. The industry is seeing considerable growth and has an ambitious strategy to grow to $1Billion by 2040 by pursuing exciting opportunities in both export and New Zealand markets, supported by innovation and collaboration with stakeholders including the Crown and Crown Research Institutes.

New Zealand currently produces just 2% of the global supply but is the ninth largest international avocado exporter. There are nearly 5,000 hectares of avocado trees planted in New Zealand, primarily in the Bay of Plenty and Northland

Avocados grow in the North Island of New Zealand which offer a mild climate, plenty of rain and fertile soils. New Zealand is also hilly, and the coastal environment is often windy. The industry has 800 growers who produce mainly the Hass variety of avocados. Several packhouses, fruit marketing companies and exporters are involved in the industry to market and sell New Zealand avocados both in New Zealand and overseas.

Avocado growers in New Zealand register with NZ Avocado and comply with strict rules around avocado quality, food safety and sustainability.

These rules apply right through the supply chain to ensure that our avocados are harvested only when ready and nurtured along their whole journey, so that when they arrive on your plate, you can enjoy their creamy deliciousness.

have a right to high-quality products that are not falsely marketed or misrepresented. In 2017, the CODEX Committee on Fats and Oils (CCFO), an international organisation that develops worldwide standards, codes of practice, and guidelines for fats and oils of animal, vegetable and marine origin, began the process of standardising the definition of avocado oil (https://tinyurl.com/mu3j7u77). This change is necessary because a recent study shows that much of the avocado oil currently on the market is not from the pulpy, green fruit. In 2020, Wang led a team of researchers at UC Davis on the first large-scale examination of commercially available avocado oil. The study consisted of 22 samples obtained from six stores and two online outlets (https://doi.org/10.1016/j.foodcont.2020.107328). They compared the samples to the proposed standards from CODEX and researchers in New Zealand to evaluate quality and purity. Their results set off a ripple across the industry.

The team found that the majority (82%) of the avocado oil in the study was stale or adulterated with other vegetable oils. Of the 22 samples collected, 15 were oxidised, which robs the oil of its flavour and health benefits. Some bottles labelled ‘pure’ or ‘extra virgin’ avocado oil were in fact mixtures of the less expensive, yet healthful, soybean, safflower, and sunflower oils.

These findings illustrate the need for standards to protect consumers and the growing industry from fraudulent products. Most producers can agree that standards are essential, but how to draw those standards is the looming question.

"Based on our ten years of experience working on olive oil, a fair standard would be important for the avocado industry so it can continue to grow," Wang said. "Working with the industry, we can establish standards and make sure customers are getting high-

quality, authentic avocado oil and the companies are competing on a level playing field."

Wang and her team began the process of evaluating the proposed CODEX purity standards for avocado oil in a paper published in January (https://doi.org/10.1016/j.foodcont.2022.109277). She included data obtained from five avocado growing regions to evaluate the natural range of chemical compounds in avocado oil. The fatty acids in avocado oil include saturated fatty acids (palmitic (16:0) and stearic acids (18:0)), monounsaturated fatty acids (palmitoleic (16:1) and oleic acids (18:1)), and polyunsaturated fatty acids (linolenic (18:2) and linoleic acids (18:3)). Triglycerides increase as the fruit matures. To find the right range for each fatty acid in avocado oil to differentiate it from high oleic oils, the team focused on the sum of oleic acid (C18:1 (n-9)) and its isomer (C18:1 (n-7)) (https://doi. org/10.1016/j.focha.2022.100107). Existing analytical methods can quickly determine the concentration of these fatty acids in a sample.

The data from Wang’s lab show the concentration of the oleic acid isomer is commonly between 5.5 and 7 for avocado oil. This concentration falls below 4 for other high oleic oils, like safflower, sunflower, canola, and soybean oil. Comparing the ratio of oleic acid to its isomer (n-9/n-7), pure avocado oil produces values between 5.7 and 13, vegetable oils are closer to 100. To help characterise levels of adulteration, Wang suggests setting the proposed acceptable n-9/n-7 range to between 6 and 11.5 for avocado oil to ensure 75% of the sample is pure. This range may change slightly with more authentic samples from other regions to accommodate natural variances.

In addition to the fatty acid profile, Wang and her team examined two other chemical compounds to fingerprint avocado oil. The analytical technique to identify sterols, a type of lipid that helps maintain the plant’s cell membrane, is complex but provides valuable information to identify adulteration. Stigmasterol is practically nonexistent in pure avocado oil, but it is a common sterol in adulterating vegetable oils. Conversely, clerosterol and beta sitosterol occur at low concentrations in other vegetable oils but are enriched in avocado oil (clerosterol ~ 1.47 to 3.49% of total sterols and beta sitosterol ~ 81.71–85.87% of total sterols).

Tocopherols, which are antioxidants naturally occurring in avocado oil, provide an additional path to verify avocado oil purity. The draft CCFO avocado oil standard proposed a range from 50 to 450 mg/ kg for alpha tocopherol, 10 to 20 mg/kg for gamma tocopherol, and non-detectable to 10 mg/kg for delta tocopherol. Wang’s team found oil pressed directly from the fleshy, green fruit fell below 200 mg/ kg for alpha tocopherol and were non-detectable for the remaining tocopherol varieties. For oil pressed from the whole fruit, the values obtained were close to the top values proposed by CCFO. Past studies on olive oil suggest that the process of refining an oil can remove tocopherols from the composition. This factor, along with how the fruit was pressed can affect the overall concentration of tocopherols, which may require additional scrutiny when developing a tocopherol range for defining avocado oil purity.

Many countries are in the avocado oil market, including Mexico, South Africa, Kenya, Brazil, Peru, New Zealand, and the United

States. Most oil sold in the USA is refined or processed with heat or chemicals to remove flaws. Other countries, like New Zealand, only sell virgin or extra virgin oils, which are pressed from healthy fruit without heat or solvent.

While virgin and extra virgin oils contain a higher concentration of antioxidants that boost the health benefits (https://doi.org/10.1016/j. afres.2022.100190), the draft standard for avocado oil is only being defined for the refined variety. Establishing a separate standard for virgin and extra virgin avocado oil is currently an issue under discussion. This is with Codex and the NZ Avocado team of Woolf, Wong, Eyres and Wang. (Sounds like a rock group.)

It is safe to say that with no standard in place, purchasing a bottle of avocado oil at the supermarket has turned into a game of roulette. For this reason, Wang has a few tips that consumers can follow as they browse the store shelves.

She recommends that consumers check the date of harvest on the bottle’s label to ensure maximum freshness. If the harvest date is not available, Wang suggests selecting an oil that has the longest time before the ‘best before’ date. Remember, all oil, regardless of quality, will oxidise over time. During rancidification, avocado oil takes on an odour like Play-Doh™. To preserve the oil, purchase a bottle that will be finished by the ‘best before’ date and store the bottle away from light and heat. In other words, do not keep your oil next to the stove top. Wang also suggests buying avocado oil packaged in dark glass rather than clear plastic to reduce the impact from oxidation.

"We need quality criteria to differentiate virgin, refined and crude avocado oil," says Wang. "But to eliminate adulterations, we need purity criteria such as fatty acids and sterols composition which is very similar among different types of avocado oil."

The standards are not codified and are meant to be revised and updated when changes occur. The CCFO agreed to approve the draft revision to include avocado oil at the meeting in 2021, and forwarded it to the CODEX Alimentarius Commission, which accepted the new draft standard except for several provisions that the committee continues to work through. The CCFO is currently collecting more data to update those provisions, which will be further evaluated for their inclusion in the revision at the next meeting in 2023.

According to Wang, the avocado industry could address the purity question by taking a page from their olive oil counterparts and begin the process of developing practices for self-regulation. This optin unity can regain and maintain the trust of their customer base.

Through self-regulation, the avocado oil producers can agree on certain verifiable characteristics and third-party testing can be used to ensure purity and quality of their product while the world awaits the final CCFO standard. A certified seal on an avocado oil’s label would confirm third-party verification and amplify consumer confidence.

"Let’s make sure avocado oil is made from avocados," Wang says. "Honest producers want their customers to know they care about quality and authenticity, and they have a brand that they can trust."

Wang and her team will continue to develop the techniques and refine the limits in the standards that validate the quality and purity of avocado oil, but she stresses the need for more research to understand how fruit characteristics, such as cultivar, harvest time, and post-harvest processing affect oil yield, chemical composition, and shelf-life for oil produced around the world. Wang also welcomes suggestions from and collaborations with oil chemists, especially when it comes to developing rapid and reliable techniques to check for adulteration.

Interestingly enough an article on Professor Wang’s studies and the whole issue of Avocado oil adulteration appeared in Inform a week after the conference concluded. (See Oils and Fats Column, pg 14)

Green, H. S.; Wang, S. C. Food Control 2023, 143, 109277 “Evaluation of proposed CODEX purity standards for avocado oil”

Green, H. S.; Wang, S. C. Food Chemistry Advances 2022, 1, 100107 “Cis-vaccenic acid: New marker to detect seed oil adulteration in avocado oil” ii Green, H. S.; Wang, S. C. Applied Food Research 2022, 2(2), 100190 “Extra virgin grade avocado oil can be achieved using whole fruits or only mesocarp

The Codex Committee on Fats and Oils (CCFO), an international organisation that sets standards for oils and fats, began the process of determining a standard for avocado oil in 2017 but currently the draft is for refined avocado oil.

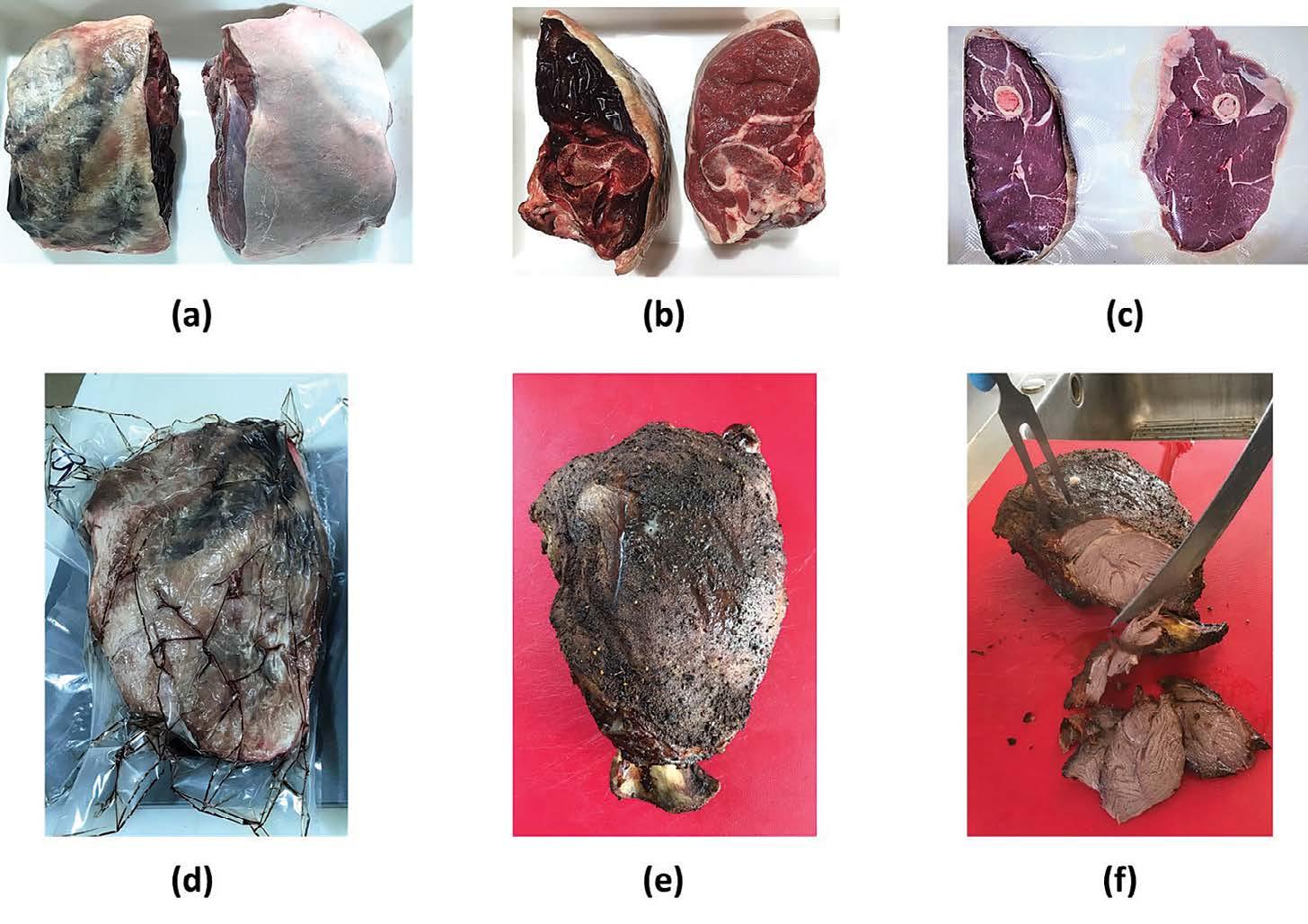

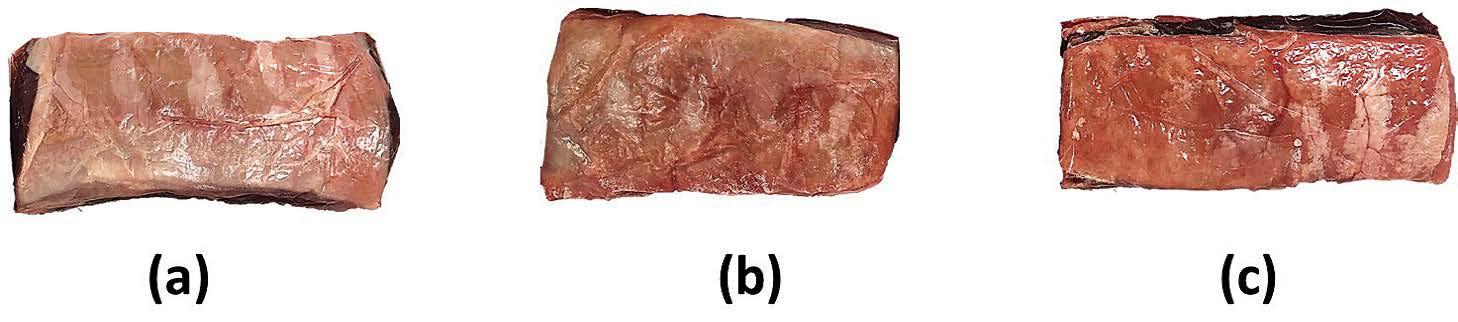

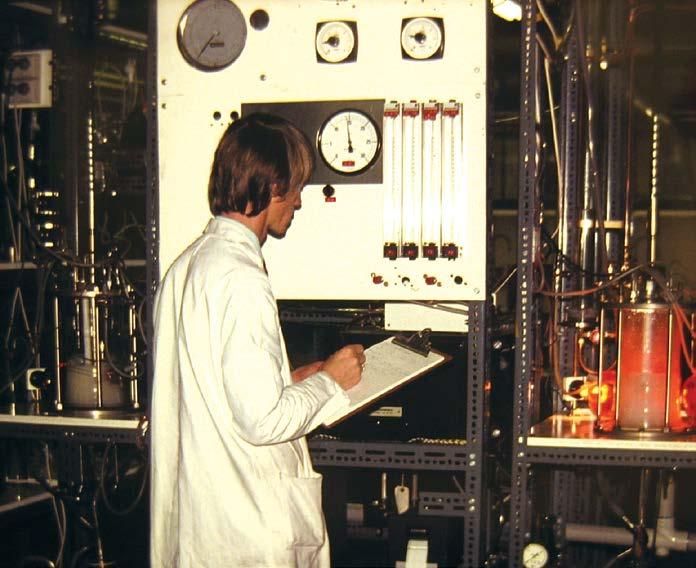

A team of researchers in California found that avocado oil can be differentiated from other high oleic vegetable oils using the profile of specific fatty acids ((C18:1 (n-7) and C18:1 (n-9)) and sterols (stigmasterol, clerosterol, and beta sitosterol). Without an internationally defined standard, consumers are left vulnerable to adulterated or fraudulent avocado oil in the marketplace.