51 minute read

Tullyallen Rd Dunagnnon Tyrone BT70 3AF Northern Ireland

profile is correct prior to applying the paint.

External Painting

Advertisement

The most frequently used external coating in the UK for underground tanks is Endoprene solvent free polyurethane.

This is applied to a minimum 800 microns dry film thickness generally whilst the tank is rotating on a specially designed rig.

Following application the thickness is checked and a 100% pin hole check is carried out.

Should there be any areas needing repair these are done to a strict repair procedure.

Base Frame Assembly – Optional Extra

BP has taken the base frame assembly as standard on all their tanks for a number of years and this system received the BP safety innovation award 2006. The assembly consists of a steel frame and cradles, re-bars and mesh, fully rated holding down straps offloading slings and guide ropes.

The installation is easier and quicker and has major safety benefits.

These benefits are encouraging and increasing numbers of customers are including this assembly with their underground tank installations.

OTHER PRODUCTS SHOWING THE VERSITILITYOF CZ

LPG Vessels

From 4 tonne to 30 tonne above ground LPG vessels for industrial or forecourt use. Supplied fully kitted out with sophisticated external paint system.

Cement Vessels

For transportation of dry powder products including cement allowing easier movement and dispensing.

Drilling Mud Storage

Manufactured for bulk storage of drilling fluids. Located on the quayside and available for fluid transport to the offshore rigs for drill lubrication.

Marine Buoys

Fabricated heavy duty vessels for navigational use, kitted out by the client with all the latest sophisticated equipment.

Bunded Storage Units – FuelBank

CZ is a major supplier of bunded storage units with their own product called FuelBank.

All these units comply with the Control of Pollution regulations and can be supplied with end security cabinet and as many facilities and systems as the client may require.

Framed Tanks

Tanks can be supplied as complete ISO framed units or frames designed specifically for ease of transportation and stacking.

Where a quantity of tanks is required, particularly for export the framed units are the perfect choice.

Aviation Fuel Tanks

CZ is the leading supplier of shop fabricated single skin and double sin tanks for the storage of JETA1, Avtur,

Avgas and many of the military grades of fuel. They can also offer a complete aviation fuel system on request.

Stainless Steel Tanks

From the very simple chemical storage tank to the sophisticated process reactor vessel CZ can design and build to clients specification. Segregated manufacturing facilities ensures no cross contamination between carbon and stainless steel plate.

Demonstration Area for UPP pipework, chambers, equipment.

APEA50th Anniversary Meeting and Visit to Cookson and Zinn Factory.

The APEA Eastern branch visited Cookson and Zinn as part of their 50th anniversary meeting in June. Meeting delegates were given an introduction to the company from Managing Director Geoff Lee before being taken on a guided tour of the factory to see for themsleves exactly how a CZ tank is manufactured.

Interestingly, Cookson and Zinn’s sister company, PetroTechnik Ltd. has a UPP Systems product demonstration

area set up in the factory yard showing a full petrol station underground fuel system. This is complete with mock CZ tanks buried in pea-shingle, UPPtanktop manhole chambers and UPP pipework in various diameters for the fill lines, vent lines, vapour recovery lines (stage I and II), electrical duct lines and product pipe-lines in both pressure system configuration (featuring double wall pipework and UPP dispenser sumps) and suction system configuration.

The latest UPP electrofusion tank chambers were being showcased on the site; these two-piece Polyethylene chambers have a base section which can be installed onto a tank and be fully tightness tested at the yard in CZ before arriving on site.

Pipe penetrations into the chambers are made using UPPelectrofusion entry seals. These utilise the same pipejointing electrofusion technology which PetroTechnik introduced into the retail fuel industry in 1991and which has since become well known and well proven throughout the world.

The visitors were interested to learn how the UPPentry seals capitalise on the synergies of having pipework, seals and tank chambers all made from PE material – The UPPEntry seals simply electrofuse to the wall of the chamber and the outside of the pipe electrofuses to the entry seal itself as it passes through.

Once all the pipe connections have been made into the chamber base the riser section is placed on top and the two are electrofused together. This creates one homogenous, vapour and liquid tight unit with no mechanical seals or exposed metallic or rubber parts to come loose or degrade over time.

Also on display was a UPPvacuum test unit which allows all sumps, chambers, spill boxes etc on site to be tested after installation - giving the site owner total peace of mind that the entire system is leak tight and is not going to let any product out or ground water in.

All those who attended the tour found it very interesting and insightful. If you would like to learn more about Cookson and Zinn and PetroTechnik and would like to tour the factory and demo area yourself, then please call 01473 825200 for CZ and 01473 243300 for PetroTechnik.

What is SELCOG?

By Brian Baker

Within the industry we tend to use numerous acronyms and the term SELCOG is another one of these. The term means the South & East Licensing Co-ordinating Group and represents one of seven regions of Regulatory Petroleum Authorities in the United Kingdom.

The group comprises of representatives of 31 Petroleum Licensing Authorities and invitations for a representative extend to the Petrol Retailers Association, UK Petroleum Industries Association and the Environment Agency. The purpose of the group is to:

•Rationalise enforcement through a consistent approach •Provide a forum for topical discussions •Evaluate systems of enforcement, new innovations and techniques •Provide representation to the

National Petroleum Enforcement

Liaison Group (PELG) as well as feeding into this Group and receiving

National Policies •Undertake occasional surveys for statistical and monitoring activities

Whilst all Member Licensing Authorities follow National Guidance, European & British Standards and PETELCirculars there are occasions where interpretations or best practice is called for outside this national guidance framework and consequently the group have their Consistency of Policy Document which is reproduced here. These are then often embraced into the national scene when major revisions take place.

The group meet on the first Friday of March, June, September and December, it is always well attended and supported by all concerned.

Articles

SELCOG - Consistency in Policy

This SELCOG Consistency in Policy guidance is intended to assist member Petroleum Licensing Authorities and help deliver the stated aim of SELCOG "To facilitate consistency in enforcement across PLA's"

PLA's have responsibility for enforcement of:

Health and Safety at Work etc Act 1974 Petroleum (Regulation) Acts 1928 + 1936 Dangerous Substances and Explosive Atmospheres Regulations 2002 Public Health Act 1961, section 73

in their areas.

The above legislation lays down the legal requirements for Petroleum licensees - those storing and dispensing. It also specifies requirements for making safe former petrol storage tanks.

To support the industry and regulators in this area with interpretation of these legal requirements there are a number of recognised "guides". These include •Health and Safety Executive (HSE) Approved Codes of Practice (ACoPs) •HSE Local Authorities Enforcement Liaison Committee PETEL's •The EI/APEA's guide "Design, Construction, Modification, Maintenance and Decommissioning of Filling Stations" (the "Blue

Book") •Pollution Prevention Guides (PPG's) and other guidance from the Environment Agency •Defra guidance.

The following SELCOG Consistency in Policy document has been prepared and agreed by SELCOG member Authorities to give guidance in those areas where there is no other existing guidance."

Policy No. Date of Meeting Subject Policy

01/02 06 June 2002 06 Sept 2002 Water filling of storage tanks

02/02 02 Sept 2002 Capacity of Storage Tanks Tanks not in use can be water filled for up to 3 years provided they are reviewed at least annually. Liquid sealing of disused tanks should be accepted only as a short-term measure.

The safe capacity of tanks for which a licence has been issued shall be quoted as 97% of the nominal capacity.

03/03 07 March 2003 View of forecourt/parking

04/04 05 March 2004 Single-skinned tanks Building of car parking in circumstances which would cause the parked cars to obliterate kiosk operators’view of dispensing activities is unacceptable unless additional control measures are in place. (See PETEL65/59a)

Single skinned tanks are unacceptable in a new site. However they may be acceptable on existing sites (and therefore be able to be lined) taking into account leak detection, alarms, wetstock monitoring etc.

05/04 11 June 2004 Anti-static clothing In respect of competent persons working in hazardous areas, the only requirement for anti-static clothing is in respect of footwear and in some cases, jackets, subject to a risk assessment.

06/04 11 June 2004 Tank and line testing Routine pressure testing of tanks and lines is not required. Such testing only applies where either no wetstock monitoring is done or where a potential leak has been identified. Dispensers on some non-retail sites are not fitted with totalisers and may require a different approach on a site by site basis.

Policy No. Date of Meeting Subject Policy

07/04 3 September 2004 Method Statements by Site Contractors PLAs should only comment on the suitability of method statements or risk assessments relating to construction work on filling stations in relation to those aspects for which the PLAhas enforcement responsibility (i.e. dispensing activities). All other matters are for comment by the HSE/EHOs.

08/04 3 December 2004 Mobile Phones on Forecourts In relation to Para 11 of PTEL65/59a, the use of mobile phones on a forecourt is allowed except in hazardous areas.

09/06 9 June 2006 Backfilling of new storage tanks

10/06 9 June 2006 Storage of fireworks

11/07 2 March 2007 Purchase of petrol in large quantities

12/07 8 June 2007 Electrical Certificates New tanks should be backfilled with pea shingle unless a risk assessment suggests that pea shingle is not appropriate, when concrete can be used (e.g. where the tank is near water). BS EN 12285 (part 1) refers.

PLAs may authorise the storage of fireworks on petrol stations but this should only be done subject to a satisfactory site-bysite risk assessment. Consultation with the appropriate enforcing authority on any risk assessment produced could also prove beneficial in reaching a decision.

Where contractors wished to purchase large quantities of petrol, for use in fuel generators for a construction project for example, large (exceeding 25 litres) or multiple approved container filling would only be permitted after an appropriate risk assessment under Reg 5 of DSEAR had been carried out and the results of the assessment implemented. PLAs may also append special conditions such as: 1. Coning off the area to restrict general access 2. Dispensing to take place into suitable (approved) containers and on the ground to avoid static build up 3. The operation to be regarded as a workplace operation (so DSEAR applies)

Acopy of the electrical certificate is to be kept on site. The licensee will not be asked to forward a copy; Equipment in a hazardous area is to be tested at least annually; If there is no expiry date on the certificate, it is assumed to be valid for a period of one year from the date of issue; Any advice from a ‘competent person’, such as an electrician, is to be followed. If a ‘competent person’states that a test is required after a particular period (2 years, 5years etc) then this advice should be accepted.

Liaison with Environmental Health Officers may be beneficial.

13/07 8 June 2007 Interceptor Maintenance

14/08 7 March 2008 Notification of incidents (licence condition) Interceptors need to be cleaned out after every spillage and then generally on a yearly basis. However, each site is different and appropriate periods for maintenance should be identified by risk assessment.

A‘crossover’is a notifiable incident under this standard licence condition as it generates some form of uplift which affects the safety of a site.

15/08 9 June 2008 Isolation Switches An isolating button which forms part of a display on a forecourt video screen is not a suitable alternative to a proper isolating button for each control point in the vast majority of cases.

Articles

APEATraining in Oman

By Brian Baker

The Association is again making its presence felt in countries outside the UK and on this occasion has recently carrying out training in the Sultanate of Oman.

The task was to deliver 3 special courses adapted to their needs:

Petrol Filling Stations – Construction, Safety & Environmental Awareness, Petrol Filling Stations – Electrical Installations Petrol Filling Stations – Audit, Inspection and Risk Assessment

And these were successfully delivered over a 5 day period.

The three trainers involved received a very warm reception from our hosts Shell Oman Oil which almost matched the weather which was a very hot 46° C while we were carrying out site inspections.

Presentations were delivered mainly in power point format, with a few video clips, and included site based risk

assessments and site inspections. It was heartening that the delegates had no problem in answering their test papers in English and understood all oral and written communications.

Oman has a population to nearly 2 million people with around 300 Filling Stations serving the whole country. By the nature of its location, the country itself is an oil

producer which exports all across the world. It is inevitable that fuel per litre is around 20p (converting to the UK price) at the pump.

That said the country is huge with great swathes of desert and rocky hills that are very sparsely populated. The capital, Muscat, is where the training took place at Shell’s own air conditioned training suite in its large distribution terminal. Here they also fill around 120 tankers daily, 24 hours a day.

Presentation of the Mayor of Milton Keynes' Plaque to Sali Al-Bursadi, Product Engineering Manager

Typical Modern Omani Shell Filling Station - 1

Delegate Photo - On Site

Typical Site - 2

Gareth Bourhill training on his feet

Oman has an expanding economy and has numerous large construction projects that have either been recently completed or still under construction with more infrastructure on the way in the form of new roads, towns etc.

The network of petrol stations is new by European Standards and there are another 8 sites still to be built within the next 12 months for Shell alone.

Underground tanks are double wall steel and locally made in accordance with European design. Underground piping has changed from steel to plastic in recent years and leak detection is provided on pressure pumping systems. Vapour recovery stage 1b is installed in the main sites and the development of the convenience store is starting to make its presence known.

The sites are all high fuel throughput with attended service as it is felt that self service is not appropriate for the Omani customer.

Drainage systems are not usually installed, although some recent sites have been constructed to provide some form of spillage control. However such developments are in their infancy. That said there is a cocktail of standards between UL, EN and British Standards that are applied to the construction of sites.

For me it was the first visit to Oman, and for Gareth Bourhill, Jamie Thompson and myself it was a delightful experience.

Was the APEA training presence effective? – we think so as the deluge of questions that followed both during and after many of the presentations suggested that the attending 19

delegates achieved a lot of useful technical information and this was reflected in the very high test results following each course.

I was able to present to the product engineering manager, Salim Al-Busardi a plaque on behalf of the mayor of Milton Keynes, my employer and on conclusion we each received from Salim a beautiful framed Silver Dagger that symbolises Oman

I am hoping our new made friends (now members of the APEA) begin a long partnership with the Association that maybe one day a Branch may even be formed.

Shell Oman Training Venue

Remote Site in Oman

Articles

Short History of Petrol Retailing

By Stuart Howell

How often do we say ‘where did the years go’? I’m thinking of that as I reflect on the last 50 or so looking over the retail fuels petrol marketing scene. Contrary to popular belief, unlike Jamie Thompson, I wasn’t around for all of that time – but there are a few historic foundation stones of the early market place that cannot go unmentioned.

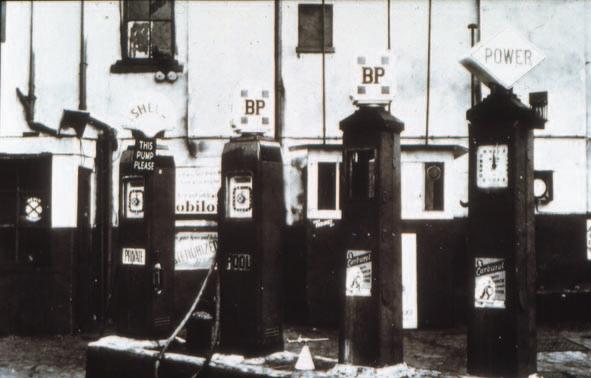

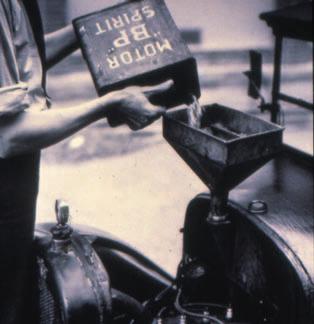

The AA built the first ‘real’ petrol station in Aldermaston in 1920. Before that, petrol was sold mainly from blacksmith’s forges in 2 gallon cans. Drivers travelling away from home used to carry spare full ones strapped outside their cars . But I won’t dwell on the longer term history, because ‘marketing’ in our industry didn’t come into its own until after the Second World War.

You can easily believe that the retail oil market was not always as competitive as it is now. The biggest problem for oil companies in those early years, not long after the war in the 1950’s, was counting their money. Nowadays the biggest problem, in the retail market, is finding enough to count!!

Few of you reading this may know that immediately following the end of the Second World War, food and clothing weren’t the only things to be rationed – so were new cars. The British motor industry was only allowed to sell 100,000 cars a year. Hardly a growing market for the oil industry to target in order to increase profits. If you wanted a new car at that time, you joined a three year waiting list, and by the time the car arrived you’d forgotten you’d ordered it!

A‘Pool Petrol’scheme operated – all fuel manufacturers ‘pooled’ their products so there were no individual fuel brands to distinguish one from another. Fuel rationing to the public also applied, so again, there were no real incentives to inspire oil companies to actively market their products.

The big ‘kick off’so to speak, was in 1950 when pool fuel and rationing were both abolished, as were the barriers to car ownership. Individual oil brands began to ‘politely’entice independent petrol station owners, as they all were in those days, to stock and sell only their brand of fuels. Although some companies were willing to share forecourt representation with other brands in order to try to please as many ‘choosey’ motorists as possible. This was called Selected Representation and was the platform from which branded fuels were marketed and it’s this platform that we have grown to know and love today.

However, at just about the time that the APEAwas incorporated in 1958, the oil companies started to think that sharing facilities with others was inhibiting their businesses. It was time to stand alone and create their own identities for customers, both site owners and motorists, to warm to. The era of competition and marketing was borne into the industry.

New personal freedoms and the green shoots of affluence led to people wanting to spread their wings and ‘Getaway’getaway’from memories of the war and the relative drudgery that followed it. The major oil companies developed products such as Esso Golden and Super Shell, with advertising and promotions to match which said to motorists ‘we are the best at helping you getaway – with good products. ‘ National Benzole based their appeal on open top sports cars, masculine men (Mr Mercury) and pretty girls. The snag with all of this was an unintentional emphasis on speed. The result was that the emergency services were having to cope with a growing road accident rates, (no seat belts, safety cages or breathalysers then), –especially at Bank Holidays.

But eventually the benefits of different fuels gave way to the promotional scene – especially free giveaways, which had many attractive features. Firstly, the strongest marketing word is ‘FREE’. Secondly, when customers are focussed on collecting points or prizes, they pay little attention to the price of fuel, (or even the actual Brand of fuel). Thirdly, many motorists in the UK drove company cars and their employers paid for their petrol – so they are not preoccupied by price. Although at one time during a particularly severe ‘price war’, it was suggested in BPthat we

bought our fuel from competitors because of the high level of price subsidies we had to pay to our own BP sites!

Following its great success in Canada, the first free giveaways to reach our market were drinking glasses, of varying types. One per 4 gallons purchased. They were a great success, not only because they were free, but because they were a stock item required by every household – and they were breakable, so demand was constant! Promotional schemes became more and more sophisticated, although in BP we had the simple adage when choosing a new promotional item to please customers –‘Never come out of the kitchen or fail to please the kids’– in effect, we tried to emulate the days when men were food hunters and delighted the family when they brought something home, (to the ‘cave’!), for them to enjoy! (In those

days wives and were the ‘real’bosses, not so different from today!)

But, without doubt, the most successful UK retail fuels marketing campaign, was Shell’s Make Money. Launched in 1966 and repeated in 1984, it was based on having to match a left and right hand half of a paper voucher, collected at the time of visits to Shell sites. Only one half was given at each visit, but when exactly matched with each other they represented varying monetary prizes of up to £100 in cash - worth a lot more then than it is now.

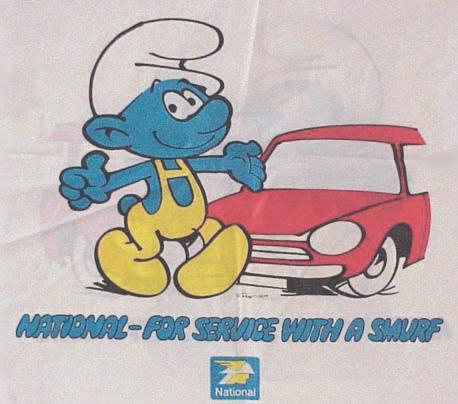

National Benzole had a long running campaign for collecting Smurf figures, still current in some mainland European countries. BPhad a ground breaking scheme connected with the TV show Dallas, where the main prize was a walk on part in an episode filmed in California. There were numerous other schemes across the industry. Scratch card campaigns were very popular, until one oil company mistakenly printed a preponderance of winning cards and had to withdraw the scheme at very short notice!

Eventually voucher collection schemes were replaced by the more efficient, (and controllable), electronic points systems which in turn have now given way to electronic ‘loyalty’ schemes which also specialise in assembling customer information which in turn is used to better ‘meet their needs’.

Most promotional campaigns like Make Money & Free Glasses etc. were ‘tactical’- they run for relatively short periods of time. In comparison, the most successful ‘strategic’campaign, i.e. part of a company’s foundation, is Esso’s ‘Tiger in your Tank ‘. Launched in 1964, it is still around today in various formats. Mention the word ‘Tiger’in relation to petrol or diesel to anyone and 99.9% will immediately connect it with Esso.

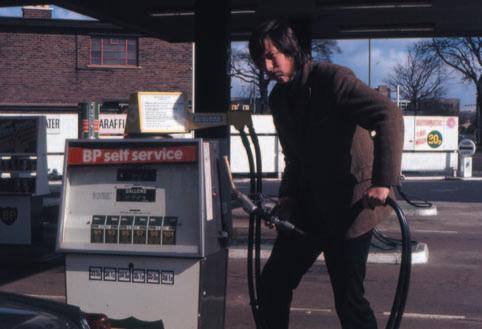

However, the outstanding marketing feature of the industry over the last 40 years is undoubtedly t h e introduction of fuels self service to forecourts. Although originally introduced to help reduce site operating costs, it soon became the platform on

which to base even more marketing activities. The principal accelerant to the industry wide acceptance of Self Service was the presence of Green Shield stamps at that time. These were greatly valued by customers and oil companies alike. They were not available at every service station, because exclusive franchise schemes operated between sites in the same trading area. This increased their attraction. In order to preserve their value, Green Shield restricted the amount of stamps issued to customers to ‘treble’ (In face value terms), the amount they would normally give on fuels purchases as opposed to other types of purchases of the same monetary value. When self service sites appeared, they alone were given the privilege of increasing the issue to quadruple stamps – but the franchise scheme remained in place and ensured some sites were excluded from the scheme, Hence the helter skelter by oil companies to be the first to build self service stations. Green shield stamp franchises drove the introduction of self service – site operation cost savings became secondary.

Acornerstone of e n s u r i n g customers accepted and understood the ‘art’ of serving themselves was how you introduced them to the process on site. The rapid expansion of the self service facilities took place in the ‘masculine’‘60s, when there were far more men than women drivers – and at a time when sexism was a feature of life yet to be thought of. Putting two and two together, the

solution at that time was to use attractive personable women to meet and greet car drivers, (including women), and show them how to cope with the latest in forecourt equipment. I am almost blushing as I write this because of the crude approach we adopted – but I must say it did work. Crucially, in order to get not just a pretty face for this work, they staff had to be personally interviewed and trained to make sure they could communicate with customers and understand the process themselves, as well as be prepared to wear the fashion craze of

the era – Hot Pants !! Guess who got the job of interviewing and ‘personality selection?! The interviews were arranged at local hotels through our Regional offices- and on one occasion I arrived at an hotel to do the ‘work’and became conscious of admiring glances from the hotel staff. I understood why when I found out that in order to see as many candidates as possible, our office had said to the hotel, ‘Mr. Howell will be seeing a different woman every 15 minutes throughout the day, and will only have an occasional 10 minute breaks for coffee!!!! This was all the more easily misunderstood as the only meeting rooms hotels had in those days were bedrooms!!

Even today the major oil companies argue between themselves as to who was the first to build a self service site in the UK, and when, and where! My own research suggests it wasn’t an oil company at all, but an independent site in Plymouth around 1960.

There were amusing ‘early day’side

issues to self service – like pumps that supposedly accepted pound notes to authorise a pump to dispense that amount of fuel without site staff being present. Some ‘customers’ put plain pieces of paper with ‘£1 Ha Ha’written on them – and the pumps accepted them!!! In other cases, because customers were getting confused and put diesel instead of petrol into their tanks, ‘talking pumps’ were introduced. On pulling up alongside pumps a recorded voice said ‘This is a diesel pumpare you sure you want diesel?’ This often led to customers being more confused because they couldn’t see who was speaking. In BP, we received a letter from a shocked customer which complained that ‘a bloody pump had said good morning to him’.

Amongst all of this marketing activity, various oil companies came and went. The likes of VIP, Agip, and Amoco. A number of Government Monopolies Inquiries into the held industry were held, and the continued volatility of some Middle Eastern countries affected prices and supplies. None of these matters resulted in measureable benefits to those with the principal interest in our industry – the forecourt customers.

I guess that was left to the entry of the Supermarkets to the retail fuels trade. They had been tentatively entering the market for a few years in the late 1980’s. Following in the footsteps of the market in France. But the invasion of Kuwait by Iraq in 1991 led to such disparities in ‘prices on the pole’ between the Supermarkets and the more traditional service stations resulted in a big increase in the number of supermarket forecourts. Far m o r e importantly, it led to their expanding their fuel throughputs and has reached such a level that they now have around 40% market share of UK fuels volumes sold. This is because many customers chose them as opposed to remaining loyal to the long established oil companies. Many of us in the industry asked incredulously, (and mistakenly), ‘who would buy petrol from a grocer?’The result as we see it today has at least served to reinforce what has always been a corner stone of marketing –‘ignore customers’ wants needs and preferences at your peril’! It took oil companies until 1996, 5 years after the invasion of Kuwait, to wake up to the threat of the supermarkets. Stable doors and horses and bolts come to mind!

Marketing can help create, or destroy, corporate reputations. Basic simple matters such as the cleanliness, adequacy and reliability of equipment that customers’have to use is taken for granted. But the big differentiator between Brands in the eyes of forecourt customers, and the most difficult one for oil companies & site operators to achieve, is courteous and knowledgeable treatment of customers. This is the one area where most companies fail, despite the fact that it is the one that can bring the greatest rewards.

The other area that creates a real impression with customers is fuel pricing. Not as competitive now as it was in the 1990s, when it was precipitated by the supermarkets, it is still in the customer’s consciousness.

So what of the future for marketing fuels? Obviously the environment will take centre stage – with differentiation on fuels quality and various distinguishable attributes will be to the fore. Customers will be less swayed by ‘fripperies’than in the past, and they will look for sites that offer complementary facilities to fuel, shops, refreshments and car care, so that they can enjoy one stop replenishment.

What will never change though is the customer’s appreciation of being treated properly and courteously by professionals. Woe be tide those who might forget or decry that – even after 50 years !

British Fireworks Association Profile

By John Woodhead, Chairman

Twenty five years ago, virtually all consumer fireworks on sale in the UK were manufactured in British factories. The industry was close knit and well organised through the auspices of the Fireworks Makers Guild which had been the Trade Association from as early as 1912. Things were about to change radically, and by 1999 the consumer firework market was made up of virtually 100% imports.

The old manufacturing companies had become history with a much larger number of importers supplying the wholesale and retail trade. Many of these companies were new and members of no Trade Association, and therefore not easy to control; with the adherence to British Standard BS7114 seemingly being their only concern.

Until the turn of the century, firework related accidents had been the major concern for government, but with accident numbers remaining relatively low, the new and rapidly growing problem became noise, nuisance and anti-social behaviour.

In 2001, the then Consumer Affairs Minister, Melanie Johnson, decided that for consumer fireworks to continue, the industry needed to sort itself out and to put forward constructive proposals to do something about the new problems. The outcome was a meeting in January 2002 at the Harrogate International Toy Fair, at which fifteen importing companies decided to form a new Trade Association, the British Fireworks Association, with the writer, having “volunteered” to instigate the move, becoming Chairman.

We would like to think, and believe that government would agree, that the actions we took with regard to the removal from the market place of the high volume Air Bomb type fireworks, along with the millions of cheap “whistle-bang” rockets had an almost immediate impact, and our ready cooperation with the former Scottish MP, Bill Tynan, paved the way for the 2004 Firework Safety Regulations which firmed up our voluntary actions as well as introducing other measures to make consumer fireworks more acceptable to the general public. We were also involved, for better or for worse, in liaising with HSE in the formulation of MSER.

From the outset, it has been our policy to work as closely as possible with both government departments and all enforcement bodies. We are delighted that, following the attendance of John Brooks and Ian Hillier at a BFA meeting, there will be future collaboration between our two organisations. We feel that there will be benefits on both sides, and alongside our close relationships with LACORS and CAFOA, will do our utmost to help with anything which can smooth the way through what will be a slightly unusual 2008 season resulting from the re-classification exercise which is ongoing for all firework importers.

Finally, whilst the BFAis strictly a consumer fireworks organisation, many of our members are also involved in the display sector, so any problems APEA members might have with regard to any aspect of fireworks, our members will do their best to help. For instance, exchanging intelligence or, depending on time of year and individual circumstances, we may be able to help with storage of confiscated goods. The latter can never be a total promise, but a call to our secretary, Mrs. Purveen Hira, on 01344 425321 will fairly quickly ascertain the situation. Equally, from October 7th onwards, the writer will be contactable on 01484 609952, in what will probably be his final year of active involvement after 46 years in the industry and will try, in any way, to help APEAmembers through the short but intense firework season.

Chairman: John Woodhead Direct Tel/Fax: 01484 609952

Vice Chairman: Stuart Garner Fireworks International Ltd, Home Farm, Foremark, Milton Derby, DE65 6EJ Tel: 01283 704849 Fax: 01283 704064 e-mail: stuart@fireworksinternational.co.uk

Secretary/All correspondence: Purveen Hira Star Fireworks, 2 Bullbrook Row, Bracknell, Berkshire, RG12 2NL Tel: 01344 425321 Fax: 01344 861006 e-mail: purveen@starfireworks.co.uk

BEN and the APEA

By Alfred Friday, BEN

BEN is the Automotive Industry Charity and is very grateful for the support that we have received from the APEAand its members over a number of years. We congratulate the Association as it celebrates its 50th Anniversary.

BEN was founded in 1905 as the Cycle Trades Benevolent Fund and now provides care to all those working in any part of the Automotive Industry, as well as their dependents, including the down-stream oil and petrol sector. The care and support we offer is reaching 15,000 people either living in their own homes, or in one of our four residential care centres, or our work place day centre in Coventry. As part of this we have 130 beneficiaries who have a direct connection with the oil and petrol sector and where we have provided financial help this amounts to over £140,000.

These are people like members of the APEAand like the Davis family. Mr Davis worked as a petrol pump attendant. Mr & Mrs Davis were never wealthy and struggled to save. Things got worse when Mr Davis developed emphysema in his sixties and became less physically able. The British Legion visited and realised that they had many needs. The Legion raised money for a scooter and also called in BEN. Our welfare officer went to see them and did a full benefits check to claim the appropriate benefits for them. We also provided some money and arranged for Social Services to come in and provide home care.

Following this Mr & Mrs Davis found that their income had increased by £70 per week and they managed to start saving for the first time in years. However, we still keep an eye on them, and they enjoy telling their BENfriend voluntary welfare visitor all about what’s happening in their lives.

If you would like to know more about BEN and the work we do please see our website www.ben.org.uk or contact Alfred Friday on 01344 294717 or email alfred.friday@ben.org.uk

Articles Evolution not Revolution

By Anton Martiniussen and Stefan Kunter, Elaflex

Feel The Difference –

ELAFLEX is introducing to the market the new generation of ZVASlimline 2 and ZVA Slimline 2 GR nozzles on September 1st 2008 when they will be in full production. These nozzles replace the standard ZVASlimline and ZVA200 GR vapour recovery versions.

Many improvements have evolved into the well-known ZVASlimline types over the past decades. Over time new industry requirements, environmental concerns, meeting customer wishes, improved grip and handling with reduced lever force, improved cleanliness on forecourts and even better delivery rates for the “to the penny dispensing” required further radical developments.

Here we highlight some of the most significant improvements:

Cleanliness with diesel

It starts with more cleanliness and the Diesel Drip catcher which is now integrated into the nozzle body and comes as standard. The diesel fuel that remains on the outside of the spout is captured within the nozzle body once the nozzle is replaced in the nozzle booth. This assists in keeping the nozzle and scuffguard cleaner. For even better cleanliness and safety the optional DRIPSTOPversion can be factory fitted. There is a comfortable handle designed for smaller hands combined with the contoured and convenient composite lever, where the force has been reduced by 1/3 without compromising safety. This is especially beneficial in countries where the latch pin is not allowed. An improved flow stream has been achieved by repositioning the poppet/valve arrangements which also improves shut off with foaming and gassing fuels.

Pressure controlled active safety switch off (DSA)

The pressure controlled active safety sensor (DSA) is an option available for new dispensers with volume or price pre-payment requirements The DSA ensures that upon non completion of a “preselected” quantity, the automatic shut off is activated approx 60 seconds after the nozzle is returned to the nozzle booth. This occurs whether the lever is in the „open“position or not. For example no fuel can be dispensed until the lever is reset and activated.

ZVASlimline 2 GR Vapour Recovery Nozzle

ZVASlimline 2 Integrated Drip Catcher

ZVA Slimline 2 GR Vapour recovery nozzle

Not only the “Open“/Shut“ GRV vapour valve but also the GRVP

GR Vapour Spout

Integrated vapour valve

are now fully integrated into the vapour recovery nozzle and no longer extends beyond the nozzle body. This innovation allows for a simplified adjustment of the vapour recovery DRY TEST system especially with the GRVP vapour proportional valve.

Service friendliness

Servicing of the ZVAhas been further improved during the development process. In addition to the stainless steel capped spout, which protects the spout, the spout is now a “push fit” fixed with a retaining pin on all the versions and provides simplified and quick assembly during service and maintenance as well as extending the nozzle longevity. The ZVAcan also be completely rebuilt by recycling its parts saving valuable materials and costs. A tool kit is available for repairs to avoid damage to the parts.

Approvals

Fully certified. The ZVASlimline 2 and ZVASlimline 2 GR are ATEX approved. EC-type examination certificated according to EN13012. TÜV-Süd - VR approved ZVASlimline 2 GR Stage II vapour recovery nozzles. SIRA approved.

The new ZVASlimline 2 generation is a package of innovative improvements and developments that enhance the fuelling experience with the motorist and environment in mind. www.elaflex.com

APEA- British Fireworks Association

By John Brooks, Trading Standards Officer, Essex County Council

I am delighted to welcome the British Fireworks Association as Corporate members to the APEA, I hope that this will be a long and fruitful relationship for all. I would like to thank John Woodhead for his help in bringing the BFAand the APEAtogether. John has over 40 years experience in the fireworks industry and has made an enormous contribution towards modernising it.

Since the last edition of ‘The Bulletin,’ Ian Hillier and myself have had a further meeting with representatives of the BFA – Stuart Garner (Fireworks International) and Andy Jarman (Men Shun Fireworks). There is great enthusiasm from within the fireworks industry to forge closer working relationships with regulators via the APEA.

The purpose of the meeting was to discuss the way ahead for the fireworks industry within the APEA. The BFAhave expressed a desire to assist with training, intelligence sharing, storage of seized fireworks. This is subject to availability of both staff and storage at the time. It has also been suggested that a fireworks seminar is held, to which any enforcement body with an interest in fireworks could attend.

There were some items of concern expressed by the BFAand assistance in these will be given where possible. Further details will be given in a later edition of ‘The Bulletin’.

I hope that this is the beginning of a long, successful and mutually beneficial partnership.

Branches

Southern

The summer 50th anniversary celebratory meeting was held at Beaulieu, with over 50 members in attendance.

The Southern branch Chairman, Barry Jenner, welcomed everyone to the meeting, and especially our guest speakers.

The first speaker, Mike Lugg, gave an illustrated presentation on the history and foundations of the APEA, and showed some very interesting photos, including kerb side erections, £2 nozzles, and current equipment.

Mike advised that the APEA was formed in 1958 by 66 licensing authorities to encourage uniformity of application of the then recently published code of practice.

The Southern branch was formed in 1965 and initially called the Oxfordshire and Surrey branch; it is now the largest branch in the country.

Mike's vast knowledge of the petroleum industry from the conception of the APEAto present day activities was evidently vast and comprehensive; our thanks were extended to him on behalf of all present by Barry Jenner.

Our second speaker was the APEA Chairman elect, Gareth Bourhill; Gareth advised that the APEAwill continue to be run to provide information/assistance to all members; he also mentioned that it may be necessary in the foreseeable future to re-name the association, as petroleum increasingly becomes a lesser used fuel in favour of diesel and bio-fuels.

Gareth accepts that the APEA's original aims and objectives remain valid, but may need to adapt, to encompass new requirements in the future.

The APEAcontinues to grow outside of the UK, with regular training courses and advise increasingly given throughout the world; Gareth hopes that all of the branches keep functioning, and continue to prosper, and that more members will come forward to assist in achieving this.

Again, grateful thanks were given to Gareth for making the extremely long journey down to be with us on this special occasion.

Barry concluded the presentation

69

aspect of the morning by thanking all for attending, and welcomed any suggestions for future meeting topics from all members.

Abouquet of flowers was then presented to Sue, from the committee members, to thank her for all her efforts in organising the day, which was very much appreciated.

After a brief interlude outside for a team photo, a ploughmans lunch was served in the Domus building, with a choice of two home made cakes for desert; those of us who could not decide which one looked nicer were treated to a small slice of each!

Everyone then made their way to the motor museum, which exceeded expectations; some members were caught on camera.

The committee would like to thank central council for subsidising the day's event, which otherwise would not have been possible.

Sue Meadowcroft Branch Secretary

Eastern

June 12th 2008

The Eastern Branch Celebrates the 50th Anniversary of the APEA at Hintlesham Hall under the banner “Now and Then”

Hintlesham Hall Hotel (Ipswich) is a magnificent 16th Century Grade I listed country house hotel set in 175 acres of beautiful Suffolk countryside. The entrance to the conference hall was decorated with large posters compiled by Petro Technik giving a glimpse of how the Forecourt industry has evolved over the decades.

The meeting was well attended by current and past members of the APEA as well as those who still continue to do so after many years which added to the magic and nostalgia of the Eastern Branch’s contribution to the 50th Anniversary celebration of the APEA. From such an event you hurriedly pen down a number of interesting points from the speakers and here are some (cant vouch for precise accuracy). One of the earliest mentions of the APEA was in 1958 when there were 66 licensing authorities. The first Bulletin was published in 1962. The first self service station opened in 1965. The national association started in 1965.The first branches were the West Midlands, East Midlands, Oxford, Surrey, Yorkshire and Teeside. The Eastern Branch was established inn 1968 so we have been around for some time too and we expect many more. For the industry and many members, innovation, design and manufacturing has been the key, faced by the challenges of regulations and safety for the benefit of the public, motorist, and the environment. It shows the intertwining of a responsible and proactive industry which has far reaching involvement, even internationally. One needs only to look at the design of tanks, dispensers, tank fittings and nozzles all manufactured to stringent demands, to high end electronics and integrated system to see how much thing have changed between “now and then”. Fascinating conversations could be heard of peoples memories, of how the industry certainly sparked many a debate and battles over the years as well as reminding people how far we have come in F o r e c o u r t Design/Construction and Safety. For the APEA, The Blue Book, overseas branches, training courses, contributor to Standards, and several Eastern members who have gone on to be Chair of the Association, a forum for debate and sharing of views and ideas and networking.

The Vice Chairman Jamie Thompson stood in for our Chairman John Boudry who was, as is not unusual, away in some far flung country drumming up business for his company and aiding the UK’s balance of payments. The meeting conducted its formal business incumbent on the AGM. The notes of the previous meetings were accepted. The accounts for the past year have been audited and were accepted. New officers have been elected to serve for the coming year. We are delighted to see so many “new faces” and heartily welcome you (the names are listed below).

Chairman: John Boudry Vice Chairman: Jacquie Holst Secretary & Treasurer: Anton Martiniussen Branch representative: Adrian Holyomes

Branch Events Committee: Mike Alston, Jean Fincken, Alex Boudry, Jamie Thompson, John Brooks

Welcome to the Eastern branch (Miri) Adrian and Ian looking rather relaxed

Brian, Eileen & Terry sharing a joke

We thank all those who served in the past year and the contribution they brought by their involvement and dedication.

After the formalities the speakers were introduced. We thank them for

giving their time to come and support us and the APEAon this special occasion. The Eastern Branch aims to provide good speakers with interesting topics and this time was no exception as we had Ray Holloway, Annie Risbridger, Jamie Thompson and Brian Baker. Ray is Director of the RMI and Petrol Retailers Association (PRA), you may have heard or seen him expressing opinions on TV and Radio on topics related to Petrol and Forecourt Industry. Ray spent 28 years with BP, a career that included a variety of European management positions associated with the oil business.

Ray gave us an extremely interesting “ Now and Then “ talk on changes in the Forecourt Industry, the decline in the number of filling stations, Oil Price changes over the past

50 Years, and the impact this has had on us all. He also contributed with some amusing anecdotal stories too! Annie Risbridger of Risbridger Ltd. spoke about the beginnings of Risbridger which started back in 1922 and the manufacturing philosophy her grandfather and his successors have held over the past 86 years. An absolutely fascinating history. While some companies have opted to look to The Middle Kingdom for production of components, Risbridger have invested in state of the art technology to make aesthetically pleasing quality engineered products.

Jamie Thompson talked about the influence of regulation over the 20th Century on petrol station forecourts. We were treated to an array of photographs taken over the years and one could see the positive influence regulations have had on the construction and usage of forecourts over the years. Whilst it was once acceptable to store barrels of petrol in the front of your grocers shop or sell and carry it in glass jars, those days have gone. Needless to say the

next 50 years will bring still more changes.

Ashort presentation by Brian Baker updated us on current issues including DSEAR which has now been with us six years .

After the talks a fine three course lunch was served in an equally impressive dining room. The buzz of the meeting continued through to the end of the meal, with flowing conversations about the changes that people have experienced over the past 50 years on Forecourts and within the APEAand also memories of those who are no longer with us or could make the event. At this point I feel this paper would be incomplete without a special mention of

Eastern Branch members

Mike, Stuart and Ray

Brian, John, Alex and Brian

Ray, Jamie and Anton Familiar faces

how delighted we were to have Brian Taylor and Eileen with us on the day.

After lunch a Eastern Branch members were bussed and welcomed to the premises of Cookson & Zinn where a guided factory tour was conducted. It was clear to see the pride and precision taken with the fabrication of their award winning products. Its good to see that UK manufacturing is alive and well.

There was also a display set up showing a tank top setup, as you would see it at a petrol station forecourt before the top layer of back fill and concrete is added. Athank you to Trevor Mason for the explanations.

The Eastern Branch would like to thank all too numerous to mention for making the day an enjoyable and memorable event for everyone. It would also like to thank the APEA Association, Cookson and Zinn and ELAFLEX for its generosity, support and patience. Also thanks to Sue Eden, Angela Nice, Miroslava Kozakova. If you are inspired by what you have read here and would like to join the APEAor participate at any of the Branch activities, give a presentation, have something to say or would like to welcome our small group to your premises please contact us, alternatively Jane Mardell who will be delighted to put you in contact with the various Branch Sec.

Anton Martiniussen Branch Secretary c/o ELAFLEX LTD

(the views and expression given by participants/contributors written or oral do not reflect any endorsement by the APEA. It is solely intended as general information)

Brian Baker and John Reynolds

Jamie Thompson

Brian & Eileen Taylor

At the recent 50th Anniversary meeting of the Eastern Branch, we were absolutely delighted to welcome Brian and Eileen Taylor to our special meeting. Brian for many years was a big supporter of the Association and the work he put in when serving on Council in particular was phenomenal.

Always with Eileen not far behind, helping out whenever she could whether dealing with telephone enquiries, signing members in at the AGM or conference. Their contribution over the years has played a major part in our success of the Association and this issue could go to print to reflect without such recognition.

Editor

North West

The branch commemorated the APEA,s 50th Anniversary with a meeting and tour at The Jaguar/Landrover Plant at Halewood on Merseyside on Thursday 5th June.

Bob Conlin, Chairman, welcomed everyone to this special day and thanked all for attending.

The day’s events were outlined, the morning having two technical review sessions, the first presentation by John Robinson of Subscan Technologies, dealing with the location of underground services, the second by Phil Lambeth of BP Global Fuel Technology. The technical sessions were followed by a first class buffet lunch after which a tour of the Landrover/Jaguar production line was arranged.

Technical Reviews

Survey Techniques for locating underground equipment on Petrol Forecourts.

John outlined the various techniques employed to determine both above ground and below ground features, above ground items being established by traditional topographical methods, underground services are established by a number of ways, contact with main Utility Bodies, electromagnetic tracing and Ground penetrating radar.

John explained the process of GPR and demonstrated its ability to locate and identify sub-surface targets, the process works by launching pulses of electromagnetic energy into the ground and recording its reflectance from underground media.

Phil Lambeth

Phil presented an extremely informative review of the current

policies for the use of High Blend Ethanol Fuels and in particular the most common E85. Phil briefly outlined the current legislation and also the latest guidance notes available for download from the APEA.

The environmental implications of the use of blended Ethanol fuels are complex with indirect effects on food supplies, deforestation and greenhouse gas emissions.

Due to the current political nature of the introduction of Ethanol fuels we are discussing with Phil the possibility of a full article in a future copy of the Journal.

After the technical reviews we broke for a buffet lunch with ongoing discussions on the morning’s topics and renewing old acquaintances.

Once fed and watered we then prepared for a tour of the Halewood production facility, taking in the Press shop, Body Plant, trim and final assembly. The tour was an excellent experience for all and the sight of the assembly lines where robots carry out precision assembly tasks was quite awe inspiring, the tour gave a great insight on complexities of car assembly from the raw sheet materials to the finished product, unfortunately no free samples!

The day’s events finished at approx. 3.30pm and the committee would like to thank the speakers for giving the time to make their presentations, we would also thank all the staff at the Landrover /Jaguar production plant for a memorable day.

John Bruce Branch Secretary

Ireland

Nothing to report at present

Scotland

Nothing to report at present

Midlands

Nothing to report at present

North East

Nothing to report at present

Branch Representative and Secretary Contact Details

Eastern

Adrian Holyomes - Rep HYTEK GB LTD Delta House Green Street, Elsenham Bishops Stortford Hertfordshire Tel: 01279 815600 email: adrian@hytekgb.com

Anton Martiniussen - Sec ELAFLEX Ltd Riverside House, Hoddesdon, Herts EN11 0PA Tel: 01992 452 950 Mob: 07831 595620 email: elaflex@aol.com

Midlands

Keith Gater - Sec Suresite Limited 3 Eastway Business Village Olivers Place, Fulwood Preston PR2 9WT Tel: 07985466639 email: keith.gater@suresite.co.uk

North East

Mike Silmon - Rep and Sec W O Silmon Ltd Industry Road, Heaton Newcastle upon Tyne Tyne & Wear NE6 5XB. Tel: 0191 224 0777 Fax: 0191 224 0707 email: associationtreasurer@apea.org.uk

North West

John Bruce - Branch Rep and Sec David McLean Contractors Ltd 28 Parkway Deesside Industrial Park, Deeside Deeside, Flintshire CH5 2NS Tel: 01244285815 email: john.bruce@davidmclean.co.uk

APEAtel/fax 0845 603 5507

Scotland

Ian Hillier - Rep North Ayrshire Council Bridgegate House Irvine KA12 8BD Tel: 01294 324969 email: ian.hiller@north-ayrshire.gov.uk

Paul Devine - Sec South Lanarkshire Council Consumer and Trading Standards North Stand, Cadzow Avenue Hamilton ML3 0LU Tel: 01698 476170 Fax: 01698 476180 Mobile: 07795 090903 email: paul.devine@southlanarkshire.gov.uk

Southern

Philip Monger - Rep Petrol Retailers Association Meadowside, West End, Sherbourne St John, Basingstoke, Hants. RG24 9LE. Tel: 01256 850164 Fax: 01256 851273 email: phil.monger@ukonline.co.uk

Sue Meadowcroft - Sec 1 Rock Cottage, South Cornelly Bridgend CF33 4RN Tel: 07795 841891 email: sue@high-cross.com

Ireland

Killian Tallon - Rep Topaz Energy Ltd Topaz House Beech Hill, Clonskeagh Dublin 4, Ireland Tel: + 353 1202 8705 email: killian.tallon@topazenergy.ie

Michael O’Kane - Irish Sec Michael O'Kane Associates Gransha Beg, 27a Gilford Park, Sandymount, Dublin 4, Ireland Tel: +353 87 2671675 Mob: +353 (0) 7718 146033 email: mokplusa@eircom.net

Cyprus

George Gregoras - Rep and Sec Hellenic Petroleum Cyprus Ltd 1st Erecthiou Str., 2413, Engomi Nicosia, Cyprus Tel: +357 22 477000 Fax: +357 22 453792 email: ggregoras@hellenic-petroleum.gr

Training 2008 Course Dates

Petrol Filling Stations Construction, Safety and Environmental Protection

15/16th September Dublin

17/18th November Glasgow

8/9th December Manchester

Petrol Filling Stations Risk Assessment, Audit and Inspection

17/18 September Dublin

22/23 October Glasgow

26/27 November Newcastle

Electrical Installations An Awareness

LPG Installations

30 Oct York

DSEAR

10th Sept Glasgow

15th Oct Newcastle

12th Nov Luton

3rd Dec Manchester

Explosives and Fireworks 4 Sept Newcastle

11 Sept Manchester

24 Sept Luton

25 Sept Cardiff

Wetstock Management

23rd Sept Southampton

New For 2008 Petrol Filling Stations –Enforcement Procedures An Awareness (One day)

6 hours Continued Professional Development 8 Sept Luton

22 Sept Manchester

20 Oct Southampton

27 Oct Derby

10 Nov Cardiff

24 Nov Birmingham

8 Dec Swindon

15 Dec York

Courses will be designed around the new TCB Document, Guidance for Design, Construction, Modification, Maintenance and Decommissioning of Filling Stations.

Please contact the APEABusiness Manager on 0845 603 5507 or at admin@apea.org.uk if you wish to find out about purchasing a copy. APEAMembers can purchase the guide at the discounted rate of £40 (non member rate £120). It is strongly recommended that attendees have access to this document during courses.

All courses can be booked online at www.apea.org.uk on the ‘Training’page.

Bespoke courses can be made available provided the minimum number of Delegates is 8. This offers a discount. For details of this and any other training enquiry, please contact: Jane Mardell - Training Coordinator, (contact details on page 3)

or

Brian Humm, Training Chairman 84 Dunblane Road, Eltham, London SE9 6RT Mobile: 07818 097141 e-mail: brian.humm@london-fire.gov.uk

APEATraining Team

Jamie Thompson Independent Consultant

Brian Humm Deputy Head of Petroleum LFEPA

Brian Baker Fire Safety & Petroleum Officer Milton Keynes Council

Gareth Bourhill Principal Training Consultant Electrical Safety Forth Valley College of Further and Higher Education

Richard Wigfull Consulting Engineer J. Wigfull & Son

Phil Lambeth Senior Engineer BPGlobal Alliance

Kim Bennett, Senior Environmental Health Officer Milton Keynes Council Bob Conlin Director Fairbanks Environmental

Tom Armstrong Senior Project Engineer

Joe Maerz Operational Manager Rural & Public Protection Team Essex Trading Standards

Jean Fincken Petroleum Inspector LFEPA