Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Aptean Apparel

After robust growth in the fashion and apparel industry last year, brands and manufacturers face more challenging economic conditions. In the Aptean 2023 Fashion and Apparel Manufacturing Report, 56% of apparel manufacturers reported concern about inflation and 36% were challenged with rising costs. According to the US Purchasing Managers’ Index (PMI), the apparel manufacturing industry contracted in May 2023, with manufacturers citing both high costs and reduced demand.

Inflation will typically show up in a company’s costs for materials and labor. Inflation also impacts consumer purchasing. Although year-over-year inflation has been dropping, 71% of retailers surveyed still worry consumers will cut back on 2023 holiday spending due to inflation. A consumer survey found higher prices have caused nearly 80% of shoppers to reduce spending on nonessential goods, including home décor and clothing.

How can brands and manufacturers continue to drive growth in a challenging market? Successful companies focus on improving internal operational efficiencies to offset external threats like rising costs and optimize profitability by trimming costs intelligently without sacrificing production capacity or product quality.

Apparel-specific automation solutions have proven to drive higher revenue and help manufacturers achieve growth, even when the sector as a whole faces challenges. A strong foundation of integrated fashion solutions enables brands to streamline business processes, run leaner and implement meaningful cost-saving measures.

2 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

36% of fashion and apparel manufacturers are challenged by rising costs.

Aptean 2023 Apparel Manufacturing Report

3 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

“Retailers with a clear, distinctive brand and very clear value proposition, where product quality is key, will emerge as the winners from a tougher environment.”

Explore Aptean Apparel

Erin Brookes, Head of Retail, Alvarezy & Marsal

Five Opportunities for Cost Savings

Cutting costs now can enable brands and manufacturers to protect their profit margins, conserve capital and build agility to drive future growth. Investing in technology doesn’t only reduce costs; it can also help improve product quality and order accuracy—both critical factors in customer retention and organic growth.

Aptean 2023 Apparel Manufacturing Report

Essential automation solutions for fashion and apparel brands and manufacturers are:

» Enterprise Resource Planning (ERP) collects and centralizes business data, automates order management, standardizes processes and improves financial visibility and control.

» Electronic Data Interchange (EDI) automates the exchange of transactional data between companies and their suppliers and customers.

» Shop Floor Control (SFC) streamlines production, assembling and processing while enhancing labor productivity.

» Product Lifecycle Management (PLM) integrates product design, development and vendor communications.

4 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

53% of brands are pursuing technology to automate more tasks.

Brands using an apparelspecific ERP solution grew revenue by 7% last year, compared with only 1.4% growth for those using non-industry-specific ERP and a 4.5% decline for those not using ERP.

Read on to find out how the right automation solutions can help:

1. Mitigate mistakes and delays with automated sales and order management workflows

2. Reduce chargebacks through improved vendor compliance

3. Make better sourcing decisions with a single source of truth

4. Reduce wasted inventory with better forecasting and inventory control

5. Optimize warehouse operations through real-time visibility into stock

5 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Apparel

Aptean 2023

Manufacturing Report

This paper explores five tactics to tailor internal cost-cutting by using the four integrated, apparel-specific solutions listed on the previous page. We share vital trends from the fashion and apparel industry and reveal five areas of hidden costs to explore further.

Tactic #1: Mitigate Mistakes and Delays With Automated Sales and Order Management Workflows

Mistakes in sales and order management can be costly. At best, mistakes or delays get caught by other employees and corrected. At worst, your customers can experience incorrect orders, delays and frustration, leading to cancellations or reduced business in the future.

In a challenging economy, declining order volume from retailers will spark greater competition between brands. A great customer experience is critical to capturing maximum market share.

43% of retailers are ordering less than last year for the holiday season.

To enhance the sales experience, companies can use ERP with EDI to automate and streamline the order management process in ways that:

» Make it easy for customers to review products, get a quote and place an order.

» Avoid typos or errors by eliminating manual order entry.

» Ensure sales order travels through the organization without becoming lost or stuck in internal process.

» Support the timely and accurate delivery of customer orders.

6 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to

Propel Growth

CNBC Supply Chain Survey

Explore Aptean EDI

What creates extra cost in the sales and order management process?

Costs in the sales and order management workflow primarily add up in two ways. First, customers need help finding the products they want, configuring them how they want and placing the order. Your team has to field more inbound calls and emails than would be necessary if the quote and sales order process was more streamlined. Additionally, orders entered manually may introduce typographical errors. And unfortunately, somewhere along the route from initial sales order to shipping and invoicing, orders get dropped, or information gets changed, causing an error or missed delivery.

How automation can help you reduce order management errors

ERP streamlines order-to-cash with sales order management functionality that keeps orders moving and reduces opportunities for manual data entry errors. ERP provides the ability to create quotes and convert them to sales orders which turn into job orders for production and move on to fulfillment and billing. The original data on the sales order drives every subsequent step in the order management workflow, reducing the need for employees to manually reenter data during production, fulfillment, shipping or invoicing. This streamlined process saves time and improves accuracy, thereby lowering costs.

An apparel-specific ERP can also enable you to manage products at the design level, so you do not have to spend so much time individually managing SKUs. Instead, you can sell your customers pre-packs with various sizes kitted together that ship as a single unit. Pre-packs simplify the ordering process for your customers, strengthen order accuracy and reduce the time involved in SKU management.

7 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

“Aptean Apparel ERP EDI functionality and the interface with customers is fantastic. Before, we retyped the same information in six different places. Now, we key it in once, and everybody taps into that information and views reports.”

Iain Scorgie, CEO and Founder, MindsInSync

Hidden Costs: Manual, Error-Prone Processes

Labor is a significant part of costs for fashion companies. Maintaining the right workforce is essential, and the automation solutions can help you enhance the productivity of your current team so you can accomplish more with the same level of labor costs. Automating manual processes helps avoid costly errors and saves time by eliminating manual data entry. Find out how fashion organizations use technology to increase efficiency and lower labor costs when you download our eBook: Are You Getting the Most from Your Workforce? Download eBook

8 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Tactic #2: Reduce Chargebacks Through Improved Vendor Compliance

Chargebacks, also referred to as expense offsets, are retailer-imposed penalties for failing to meet agreed upon guidelines. A number of problems can result in chargebacks, including late deliveries, incorrect labeling, improper packaging or fulfillment discrepancies in product quantity or quality.

Chargebacks are an unnecessary cost for apparel brands that can add up quickly. Not only are chargebacks a drag on profitability, they also reflect errors that could negatively impact customer relationships.

What creates the conditions for chargebacks to occur?

Chargebacks are usually a reflection of the following:

› Failure to deliver on time or mistakes in quantities, sizes, etc.

› Supply chain management problems

› Product quality issues

› Documentation mistakes

pay chargebacks.

How automation can help you improve vendor compliance to reduce chargebacks

Fortunately, as your operation becomes more automated and streamlined, chargebacks should occur more rarely. At every stage of your operation, EDI, ERP and SFC work together to help ensure timely and accurate order deliveries that avoid chargebacks.

First, EDI streamlines data transfer between manufacturers and their customers. Using the standardized format of EDI, you can transfer and receive information like RFQs, sales quotes, purchase orders and shipping information. With EDI, staff will not manually enter data, reducing the potential for typographical errors that could cause downstream mistakes in production and fulfillment.

9 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

On average, 1% of top line revenue for apparel manufacturers and distributors goes to

Weber Logistics

EDI streamlines and speeds communication, keeping customers well informed. As an integrated functionality of your ERP, EDI helps ensure what goes on the Advanced Shipping Notice (ASN) is what is contained in the shipment (mismatches are a common cause of chargebacks), that labeling is correct and that invoices reflect the products received by customers.

EDI enhances visibility and tracking to help identify potential issues before they result in chargebacks. In fact, EDI improves accuracy so much that many major retailers will not order from vendors who do not use EDI.

Second, as discussed in the previous section, ERP moves orders from origination through distribution in an automated fashion. Once the order is created, ERP automatically reserves the right quantity of materials for production and creates a production order. If finished goods are already available in inventory, ERP reserves them in the correct SKUs, sizes, quantities and colors to fulfill the order. ERP provides the warehouse team with accurate picks and shipping information.

Finally, SFC helps keep production running smoothly and ensures quality control. ERP and SFC work together to maintain production schedules, increasing the probability of on-time deliveries to customers.

10 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

MindsInSync enjoys 90% fewer chargebacks with EDI transactions after implementing Aptean Apparel ERP.

Hidden Cost: Consumer Returns

Chargebacks occur at the retailer level but product returns from direct-to-consumer sales can also drag against profitability. As brands establish their own retail stores or offer more online omnichannel fulfillment, returns become an increasing fact of life. To resell or recycle returned goods efficiently, brands need to optimize financial and inventory operations to deal with returns.

11 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Tactic #3: Make Better Sourcing Decisions with a Single Source of Truth

Brands cannot entirely avoid cost increases in the present era. But armed with insightful information and a broad enough supply chain, you can level up your sourcing decisions to get the best pricing possible. Buying materials and vendor services at the best value helps lock in better profit margins.

What creates extra cost in purchasing?

Several aspects of sourcing can contribute to significant added costs for apparel manufacturers. First, the prices of raw materials like fibers, cotton and fabrics fluctuate with inflation, availability and different suppliers. Second, labor costs can vary by geographic region, roles and skill levels. Brands may also face compliance and sustainability costs and endure extra costs associated with natural disasters, logistics, transportation and other geographic challenges.

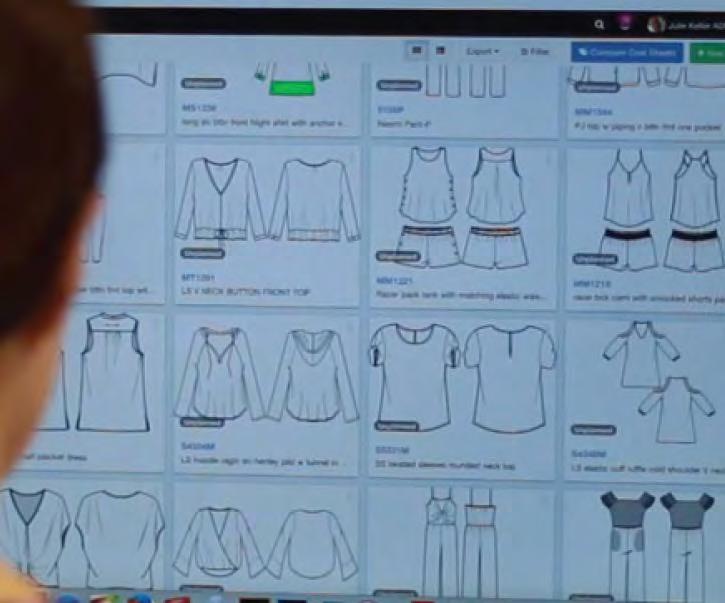

How automation can help you improve sourcing

Apparel ERP and design-centric PLM systems work together to enhance vendor relationships and inform purchasing decisions. Product teams need good real-time and historical PLM data to optimize designs and materials for quality, aesthetics and cost. Centralizing supplier data in PLM helps brands pick out the best raw materials and apparel manufacturing partners to develop a supply chain agile enough to contain costs while maintaining schedules.

PLM makes working with vendors on new products more straightforward and efficient. Your internal product team will enjoy a simplified design process and save time with drag-and-drop material ordering and colorway pitching in the BOM. Advanced tech pack development capabilities in PLM increase the accuracy of data sent to your vendors.

12 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

In a survey of the apparel industry, only 19% of companies have visibility of all stakeholders operating across their supply chain, and just 15% have full traceability of materials.

KPMG

Cut the cost of miscommunication and manual spreadsheets when you automate vendor collaboration. PLM centralizes and streamlines communications between your product teams and vendors, helping everyone stay on top of design modifications and the status of samples and signoffs.

Managing vendor bids is integral to controlling production costs but it is often a manual and time-consuming process. When evaluating bids, it is critical to understand the cost quoted and the vendor’s performance history in terms of timeliness and quality. An RFQ tool and a vendor management portal can help you automate bid management and provide the insights needed to select the best vendor for every job.

13 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

“Everything is now in one place from development through production. Communication in Aptean Apparel PLM messaging keeps everything together and reduces the email madness for dayto-day follow up—especially sample status for development samples.”

Michelle Heyman, Senior Technical Designer, ADPL

Hidden Cost: Tech Packs Lacking Sufficient Detail

Tech packs include images to give vendors a visual representation of designs as well as overcome any language barriers. But static renderings often don’t fully convey all the data vendors need to create prototypes and begin production. Modern apparel PLM solutions now include digital 3D capabilities. Designers can share 3D imagery with vendors to bring new designs to life with full specification data embedded within the image. Vendors can zoom in and out with the 3D model for a detailed view of the stitching, buttons, seams and other elements. 3D design imagery will help ensure the bids you receive are accurate and you will not have cost surprises during production.

14 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Tactic #4: Reduce Inventory Waste with Better Forecasting and Inventory Control

It’s no secret the fashion industry creates excessive waste. Often a focus of ESG initiatives, waste also impacts the bottom line for many brands.

Waste happens throughout the entire apparel manufacturing process. Designs that produce too much scrap fabric are common and it’s estimated as much as 15% of fabric in garment manufacturing is wasted. Production quality problems can force unsellable garments to be discarded. Yet another important area of waste occurs with mismanagement of the finished goods inventory.

What creates waste in the finished goods inventory?

If too much of a style, color or size gets manufactured and fails to sell, brands may have to offer deep discounts or try to recycle this unwanted inventory. If poor inventory control results in products sitting in the warehouse unnoticed until they become damaged or outdated, those items may become a total loss.

15 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

With better access to accurate information, Gold Medal International’s inventory analysts find it easier to sort and search inventory data. The company has been able to decrease inventory while increasing control over stock positions.

How automation can help you reduce inventory costs

ERP improves the accuracy of demand forecasting and helps avoid wasted inventory and markdowns. Being able to fine-tune demand predictions helps ensure manufacturers purchase the right amount of materials. You need enough fabric and other materials to avoid production delays, but not so much that waste occurs. More accurate forecasts combined with the inventory control features of an ERP will also help you avoid stocking out of popular items. By imparting a better understanding of variances in demand, you can manage safety stock more tightly to ensure you maintain adequate inventory without overstocking and creating potential waste.

Explore Apparel Warehouse Management

16 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

“We really didn’t know what our inventory position was before we got Aptean Apparel ERP…we had to conduct quarterly inventory counts manually.”

Robert Fagan, CFO, Johnny Was

Hidden Cost: Production Errors

Mistakes on the shop floor can lead to unnecessary costs. Quality issues can slow down workers, leading to missed deadlines. And mistakes lead to more waste as poor-quality items must be scrapped or reworked. SFC integrated with an apparel specific ERP can provide complete traceability back to the source of a quality issue so that you can remediate it quickly.

17 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Tactic #5: Optimize Warehouse Operations Through Real-Time Visibility Into Stock

Inventory and warehouse costs represent a significant expense for brands, whether you operate internal warehouses or partner with 3PLs. While warehouse costs are a necessary part of the fashion and apparel industry, inefficient warehouses with outdated practices incur more expenses than more modern automated ones.

What creates costs in the warehouse?

Warehouse costs vary by facility, services and the amount of space required. Leased space ranges from $4 to over $7 per square foot, and operational expenses can add another $2 to $3 per square foot for utilities and other costs. Warehouse equipment, such as forklifts, tiered racks and picking shelves, are added expenses. Labor costs are one of the largest parts of warehousing expense, with the average warehouse worker with three to five years’ experience now earning close to $17 per hour and warehouse supervisors earning nearly $65,000 per year on average, with overtime.

18 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Retail industry investment in warehouse automation is estimated to grow by 6% to 8% per year through 2025.

McKinsey & Company

How automation can help you reign in warehouse costs

To control warehouse costs, focus on improving space and labor utilization because those are the two greatest costs. Having an ERP with warehouse management functionality (WMS) helps optimize receiving and putaway to maximize storage space. When you can leverage your space more efficiently, you may be able to avoid building or leasing a larger warehouse.

WMS functionality can also empower warehouse employees and equipment to operate more efficiently. ERP with WMS reduces errors in order processes, picking and shipping. Warehouse workers and supervisors benefit from real-time stock information, and the ERP reserves inventory against orders, so it is ready for picking and packing.

Warehouse and inventory management capabilities in Aptean Apparel ERP enabled Trend Marketing with realtime stock locations making it faster and easier to locate goods, prioritize picking and fulfillment and optimize their use of 3PL, if needed.

Pickers spend their days moving around the warehouse, and WMS helps minimize their walking time in several ways. First, intelligent putaway strategies help place the items picked most often in convenient locations, such as closest to the packing and shipping area or on the ends of warehouse aisles. Next, the WMS uses directed pick-and-pack to guide workers around the warehouse on routes optimized for efficiency. Advanced picking and packing strategies such as wave picking and cross-picking further streamline labor usage, helping lower costs.

By streamlining warehouse operations, WMS can shorten lead times and enable faster order fulfillment. This way, you can lower operating costs and delight customers with early order delivery.

19 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Hidden Cost: SKU Management

One hallmark of the fashion and apparel industry is inventory complexity. Managing all of the SKUs associated with so many styles, colors, sizes and retailers is time-consuming and difficult. For example, one shirt in five sizes and five colors typically requires you to manage 25 SKUs. However, an ERP with effective multi-retailer SKU management functionality allows you to manage the shirt as a single style, regardless of the number of sizes and colors. When you need to make adjustments, you can apply the changes to the style once, rather than making 25 changes within the ERP solution. Multi-retailer SKU management saves time and helps brands more efficiently manage their styles and inventory.

20 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

Positioning for Growth: Offsetting Uncertainty with Automation

After a period of exciting growth in the fashion and apparel industry, economic conditions are causing uncertainty in the future. Brands report rising costs and some shifts in consumer demand amid higher inflation. Many brands seek new ways to reduce costs and protect profit margins so they can weather economic uncertainty and be positioned for renewed growth and new opportunities.

Apparel-specific automation offers a strategic way to lower costs through internal efficiency gains while retaining hard-to-replace skilled workers and maintaining high production quality. An apparel-specific ERP with WMS and EDI functionality provides a single source of truth and the core of the efficiency strategy. Paired with integrated, apparel-specific PLM and SFC solutions, ERP optimizes business processes and streamlines workflows, wringing out extra costs and inefficiencies in every operational area. From sales and order management to procurement, production and fulfillment, the right automation imparts greater resilience and agility.

21 Whitepaper | Running Lean: 5 Ways Apparel Brands are Lowering Costs to Propel Growth

“Aptean is a true partner, always looking for ways to help us improve and enhance our business. As we have grown, Aptean Apparel software has grown with us.”

Derek Karnatz, Director of Operations & IT, johnnie-O

About Aptean

Aptean is one of the world’s leading providers of purpose-built,

tors effectively run and grow their businesses. With both cloud and on-premise deployment options,

services and unmatched expertise help businesses of all sizes to be Ready for What’s

Georgia and has offices in North America, Europe and Asia-Pacific.

To learn more about Aptean and the markets we serve, visit www.aptean.com.

Copyright © Aptean 2023. All rights reserved.

industry-specific software that helps manufacturers and distribu-

Aptean’s products,

Next, Now®. Aptean is headquartered in Alpharetta,

Are You Ready to Learn More? Contact us at info@aptean.com www.aptean.com.