11 minute read

A prebiotic treatment of edwardsiellosis in striped catfish

A prebiotic treatment of edwardsiellosis in striped catfish (Pangasianodon hypophthalmus)

Valentin Eckart, Biochem

A threat, not only to catfish The pathogenic, gram-negative bacterium Edwardsiella ictaluri is widely known as the causative agent of the enteric septicaemia of catfish (ESC) and was first reported in the United States in channel catfish (Ictalurus punctatus) (Hawke et al., 1981). Subsequent reports have shown that this bacterium also infects non-catfish species like Nile or hybrid red tilapia. In general, clinical signs of E. ictaluri infections may vary between species, but visceral white spots have been described in most of them. The misinterpretation of these symptoms, as those of other diseases (Dong et al., 2019), makes the actual spread of edwardsiellosis somewhat unclear and it should be further monitored.

An economic challenge Today, edwardsiellosis has become one of the most important infectious disease problems in the commercial catfish industry. In Asia, E. ictaluri is causing bacillary necrosis of pangasius (BNP) in striped catfish (Pangasianodon hypophthalmus). Natural disease outbreaks are reported in all ages of fish, with high mortality rates of 50 – 90% (Crumlish et al., 2002; Dung et al., 2004). The Vietnamese industry highly relies on striped catfish farming, with an annual production volume of about 1.4 million tons (VASEP, 2019). Hence, declining production, high fish mortality and increased costs for the treatment of E. ictaluri infections can lead to huge economic losses.

Lack of specific treatments In order to counteract the economic impact of E. ictaluri, the industry has been working on the development of pathogen-specific vaccines that already reduce the mortality rate during the production of

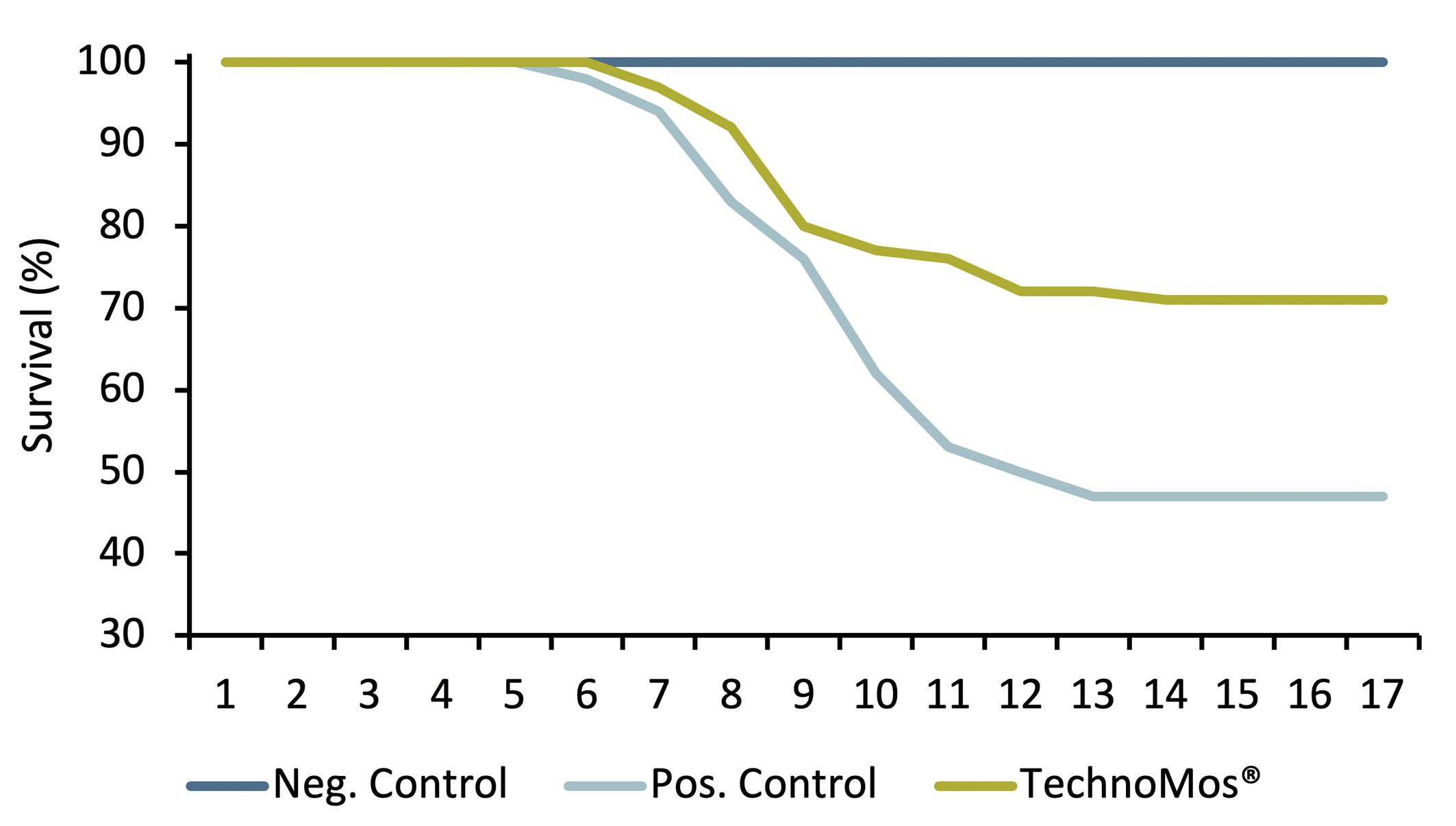

Figure 1. Accumulated survival of striped catfish after infection with E. ictaluri. Fourteen days post- infection, 100% of fish from the negative control, 47% from the positive control and 71% from the TechnoMos ® survived (p = 0.01). Positive control and TechnoMos ® groups were both challenged with E. ictaluri.

Treatment (g/kg) Yeast cell wall extract Control 0.0

TechnoMos ® 1.0

Nutritional value (g/kg) Crude protein 299.0 Crude fat 62.9 Crude fiber 29.4 Ash 85.2 Moisture 87.1 309.0 80.1 29.4 84.7 77.5

Table 1. Treatment and nutritional value of diets.

fingerlings. In addition, breeders have also made significant improvements in breeding more resistant catfish strains. Unfortunately, these measures are mainly confirmed for the channel catfish (Zhou et al., 2018). To date, comparable treatments are lacking for most Asian catfish species such as striped catfish, leading to an overuse of antibiotics in affected farms. But work on more advanced vaccines and breeding programs continues (Triet et al., 2019; Vu et al., 2019).

A protective treatment, not only against E. ictaluri A third alternative has presented itself as beneficial to generally increasing the bacterial resistance in aquaculture species: the supplementation of yeast cell wall-based prebiotics in aquafeeds (Meena et al., 2013). TechnoMos® is a cell wall-extract of the primary grown yeast, Saccharomyces cerevisiae, and thus consists of highly concentrated mannan-oligosaccharides (MOS) and β-1,3-1,6-glucans. The β-glucans act as nonpathogenic polysaccharides which are able to activate white blood cells such as macrophages. As a result, immune functions like phagocytosis (the cellular uptake and digestion of intruding cells and particles), the release of cytokines and finally antibody production are significantly improved. This also enhances the efficacy of vaccines and of adaptive immunity (Meena et al., 2013). Moreover, ß-glucans have been reported to increase the expression of mucin- and defensin coding genes for improved mucus production within the intestine, but also at the outer gills and skin level – a strong physical barrier against pathogens (van der Marel et al., 2012). The MOS content in TechnoMos® is able to block pathogenic adhesins and receptors and thus prevent the binding and proliferation of gram-negative bacteria to the intestinal wall (Aronson et al., 1979).

The challenge It sounds good in theory – but does it work? To investigate the protective effect of TechnoMos® against bacterial diseases like BNP, a feeding trial in striped catfish has been conducted. Over a period of six weeks, two different diets were fed to two groups of young

striped catfish (~20 g) – five replications with 90 fish per hapa. The control group was fed on a standard diet, while the treatment group had 1 g/ kg TechnoMos® added to its feed. For the following challenge, 20 fish from each iteration were randomly assigned to 100L-fiberglass tanks and then given injections of a 0.15 ml E. ictaluri solution at a previously tested 50%-lethal dose (LD 50 ) with 5.67 x 10 4 CFU/mL. A third group, taken from the untreated control groups, received an injection of NaCl solution as negative control. At a constant water temperature of 26 °C, optimal for bacterial growth, mortality was monitored and either dead or moribund fish were collected for laboratory testing for E. ictaluri infestation.

Significantly increased survival Fourteen days post-infection, 71% of the TechnoMos®- treated fish survived in comparison to 100% in the negative control and only 47% of the positive control group. The applied direct injection was the favorable method for exact dosing (47% is prove for a very accurate LD 50 -dose). It also guaranteed that the pathogen invaded the organism. Since the pathogen bypassed the common ways of infection, through the intestine and gills, the protective properties of TechnoMos®, like improved physical barriers such as internal and external mucus production, against E. ictaluri could not be measured by this method. Nevertheless, the trial confirms the sustained support of the immune system by TechnoMos® resulting in an increased survival rate by nearly 25% compared to the control group (p = 0.01).

There is huge potential A new infectivity model using an immersion bath with E. ictaluri and striped catfish has been established after this study was finished (Ngoc Phuoc et al., 2020). Paradigms such as these, in which a natural outbreak is better simulated, are likely to show even lower fish mortality in feeding experiments with TechnoMos®. One reason is the above mentioned improved physical barrier, the other is the pathogen binding ability of MOS. Since E. ictaluri is a gram-negative bacterium, there is a chance for binding to MOS and being removed from the intestine without proliferation. This can significantly reduce the risk of infection.

However, the present results confirmed the protective effect of TechnoMos® against bacterial diseases like BNP in striped catfish.

Acknowledgements Many thanks to the researchers from the Faculty of Fisheries of Nong Lam University in Ho Chi Minh City, Vietnam, who conducted this trial.

References available upon request

More information: Valentin Eckart Research and Development Biochem, Germany E: veckart@biochem.net

Trends and developments

C. Greg Lutz, Ph.D.

The best of both worlds: in-pond raceways and split ponds

Throughout the globe, most aquaculture is practiced in earthen ponds and with good reason. Ponds offer a lot of benefits for fish or crustacean production. They incorporate natural cycles to break down nutrient inputs and support internal productivity while the energy requirement for these treatment processes is easily met by incoming sunlight. But ponds are big and awkward when it comes to harvesting, disease treatment and predator control. And although aeration allows us to push the envelope to some degree, ponds exhibit some pretty inflexible natural limits in terms of intensification. Now… tanks, on the other hand, are compact, efficient, provide ease of feeding, allow for rapid disease treatments and facilitate or even eliminate the need for predator control. Tanks are great, in their own way. But unless you’re farming sharptooth catfish or some comparable species, the artificially high densities associated with tanks require aeration and water exchange, or in some cases a number of other processes such as mechanical and biological filtration as in the case of RAS.

This, of course, leads to the question: what if you could combine the best attributes of both

approaches? Containing the fish crop in a relatively small space, like a tank, and using an open pond area to promote natural waste treatment and nutrient cycling dependent on phytoplankton and benthic processes? Ring a bell? Well, to be fair, this strategy was proposed and explored long ago. As the song says, everything old is new again.

In 1972, Howard J. Freemont was awarded a patent (US Patent number 3653358, application filed by assignee Marine Protein Corp.) for a floating fish grow-out tank composed of a watertight liner with a means to add and remove water from the vessel. In 1977, Arlo Fast was granted a US Patent (No. 4044720A) for a floating fish rearing system that confined fish in raceways and was also constructed of flexible pond liner material. Water circulation was based on airlifts that supplied aerated water from depths below the thermocline with the option to attach a waste settlement tank to each raceway. In 1991, Fast published a summary of the performance of a system adapted from the one described in his patent application.

In the early 1990s, Yoo, Masser and Hawcroft refined and evaluated an in-pond raceway and waste removal system for catfish production at

Dr. Greg Lutz is a Professor with Louisiana State University Agricultural Center. He is also an author and consultant. E: lutzaqua@att.net

Auburn University. The research was the basis of Hawcroft’s Master’s thesis, and was largely motivated by both the desire to intensify catfish production systems and concerns over nutrient loads in pond effluents. Although Masser and Lazur subsequently wrote a factsheet in 1997 outlining a DIY approach to the in-pond raceway system, the concept was not immediately nor widely adopted. During this period, several publications emerged in various parts of the world presenting variations of the raceway-in-a-pond idea, but the strategy did not gain much traction.

Over the past decade, however, Auburn has revisited the approach. Significant time and resources have been devoted to upgrade and promote this production system in other countries and in conjunction with the US Soybean Export Council. The systems have been installed in a number of countries in recent

years and the concept is quite similar in that fish are confined to a relatively small area in an open pond, solid wastes are concentrated and collected, water circulation is provided to constantly refresh and aerate the culture area and the rest of the pond serves to process wastes generated during grow-out. In most of these systems, air-lift pumps at the head end of the raceways push water through the containment area, aerating it at the point of entry. This approach has been shown to be suitable for any number of species including tilapia, catfish, largemouth bass, grass carp and bluntnose black bream.

But no matter where you try to build one, the state of the art in-pond raceway (currently promoted as the IPRS) requires capital. Actually, a LOT of capital. However, there are some lower-cost alternatives emerging. Perhaps, the most interesting of these is the Split Pond production method. Although somewhat less productive than in-pond raceways on a per-hectare basis, split ponds are also less capital and energy intensive and can therefore be more easily adopted in developing nations.

So how do split ponds work? It’s not rocket science, but it’s ingenious. An existing (or new) pond is divided into two separate sections in a ratio of roughly 80%-20%. The small section

is used to raise fish, while the larger section serves as a treatment pond to break down and cycle wastes generated throughout the grow-out process. As a rule, the overall pond size should not exceed four to five hectares. A means of circulating high volumes of water between the two sections is required, as is a return channel or culvert. Once the pond is up and running the smaller (20%) section is stocked with the same number of fish that would normally be put into the entire pond area.

Circulation in a split pond configuration requires movement of a minimum of roughly 1 m 3 of water per minute for every MT of fish present in the small section – with pumping capacity sized for the maximum load expected at the time of harvest. A number of different means have been used to circulate water between pond sections, including slow moving custom-constructed paddlewheels, commercial paddlewheel aerators set for greater paddle submergence (catfish industry designs – as opposed to shrimp farm aerator designs), high-speed screw pumps (not unlike those used to fill distribution canals in many shrimp farms around the world) and horizontally mounted axial flow pumps. All appear to have tradeoffs between investment costs, maintenance requirements and operating costs per cubic meter of water moved. Since the paddlewheel designs require large cross-sectional areas, extra accommodations must be made when installing them in the levees separating the split-pond sections. Apart from circulation, energy is also required for nighttime aeration in split-pond based farms, but research suggests that aeration is much more efficient when fish stocks are confined in the smaller area of a split pond system.

Preliminary research with hybrid catfish production in the U.S. suggests that feed prices above $500/MT or farm-gate fish prices below $2 US/kg can result in economic losses when using some split pond designs and management practices. However, when researchbased designs are strictly followed, net yields of 19.1+3.2 MT/hectare and modified internal rates of return (MIRRs) of 15% and 28% could still be achieved, respectively, under each of these difficult scenarios. With the prevailing market and feed prices, split pond units that tended to stray from the research-based recommendations still exhibited MIRRs ranging from 12% to 21% for a single four hectare split pond. As pond producers throughout the world strive to intensify production, split ponds may offer simpler design, easier management and reduced environmental impacts per unit of production, at least when compared to in-pond raceways. And in regions where climate and regulatory environments allow the use of tilapia as a primary or polyculture species, producers will have more flexibility not just in converting wastes into phytoplankton, but also in turning that pond algae into edible protein.