PETER THOMAS takes up the helm at SKSC

BALLYPRINT’S AARON KLEWCHUK on acquiring Impro Printing and partnering with Fujifilm

PETER THOMAS takes up the helm at SKSC

BALLYPRINT’S AARON KLEWCHUK on acquiring Impro Printing and partnering with Fujifilm

GOING FOR GOLD

ALL THE WINNERS FROM THE IRISH PRINT AWARDS

Handled with care

Fully qualified, friendly drivers trained in paper and board handling ensure your order arrives safely.

EBB Service is based on investment in state-of-the-art route planning, real time vehicle tracking and the latest vehicles that comply with Euro 6 emissions standards meaning increased engine efficiency, better fuel economy and reduced CO2 emissions.

Delivered with care

We take responsibility for your order until the moment it’s delivered to you. Next day and, in some cases, same day deliveries from our warehouse straight to your door (no third party involved).

About 18 months ago, Ballyprint’s Aaron Klewchuk decided to take a leap of faith and purchase Impro Printing. The B2 sheetfed litho firm was struggling to make a profit and news hit the industry that it was facing liquidation. A skilled workforce, a relatively recent investment in a Komori H-UV and a longstanding relationship convinced Aaron that acquiring Impro Printing was a sound idea. A year and a half later, turnover at Impro has doubled. Investment in technology and a change in culture has turned the print firm around, with more investment to come. Alongside Impro, Ballyprint is also getting a tech boost, thanks to a new partnership with Fujifilm. A new Fujifilm Acuity Prime flatbed will, says Aaron, increase Ballyprint’s market share across various sectors. A new Revoria 10 colour press is also on the way and potentially, a new B2 digital press. Investment in innovative technology such as the Acuity Prime is, says the Ballyprint founder, key when it comes to staying competitive. For more on Impro’s transformation, turn to page 11.

On page 14 the new MD at SKSC, Peter Thomas, chats about guiding the business through its next stage of growth and preparing for new investments coming in. Just recently, the high security printing firm invested over €3 million in a bespoke security printing press and ancillary equipment to help it deliver tailored, innovative solutions designed to make the world a safer place. The firm also intends to bring its products to a wider market not just in Ireland, but across the world. Also in this issue, we take a look at all the winners from the Irish Print Awards, held in April at Clontarf Castle Hotel. Once again, the very best of Ireland’s print industry was recognised and honoured at the event, now in its 45th year.

As always, we’d love to hear from you. If you have any thoughts on this issue, please drop us a line at editor@irishprinter.ie. Enjoy!

Editor: Denise Maguire

Email: editor@irishprinter.ie

Creative Director: Jane Matthews

Designer: Lenny Rooney

Production: Nicole Ennis

Contact: Irish Printer, Ashville Media Group, Unit 55, Park West Road, Park West, Dublin 12, D12 X9F Tel: (01) 432 2200

Web: www.irishprinter.ie

Printed by: McGowans Print

Printed on: HP Indigo 10000 using Novatech paper supplied by Antalis.

All rights reserved. Every care has been taken to ensure that the information contained in this magazine is accurate. The publishers cannot, however, accept responsibility for errors or omissions. Reproduction by any means in whole or in part without the permission of the publisher is prohibited. © Ashville Media Group 2024. All discounts, promotions and competitions contained in this magazine are run independently of Irish Printer. The promoter/advertiser is responsible for honouring the prize. ISSN 0790-2026

Papago is available in an extensive range across a choice of 34 colours; perfect for the most demanding applications.

● Laser

● Inkjet

● Copier

● Offset

● Pre-print

The Papago cut-size range is FSC® certified and the folio range is PEFC 100% certified.

For more information or samples, contact your local branch.

Paper & Materials, Delivered Nationally

Canon has launched the next generation of its plotWAVE and colorWAVE large format printers for technical documentation printing. The new monochrome plotWAVE T-series replaces the previous PlotWave range and is available in five different models – the T30/35, T50/55 and T75, producing up to 10 A1 prints per minute and offering a media capacity of up to 1,200 meters on six rolls up to 914 mm wide. The new colorWAVE T-series replaces previous ColorWave models and is available in two versions – the T60 and T65. Both models produce four A1 colour prints per minute, while the T60 offers a media capacity of four media rolls. The T65 provides additional quality modes for users who require higher quality, as well as a higher media capacity of up to 1,200 meters on six rolls. All models are also available as a multi-function printer, including the option of an integrated scanner and a fully integrated stacking or folding solution. The PRISMA Tech Suite, a new set of workflow solutions, have also been added to the ranges. They help customers manage their print operations and stay in control with an efficient and convenient workflow application and a selection of printer tools.

The new issue of Fujifilm’s ‘Women4Women’ magazine was printed live on a Jet Press 1160CFG at drupa 2024 on the Fujifilm stand. More than 20 women from all over the world shared their stories and experiences in an industry that until 1876, the year the Women’s Printing Society was founded, was the prerogative of men. The shots of Turin photographer Paola Agosti, taken in factories in Italy in the 1980s, accompany the reader on a journey in colour and black and white to discover ‘women and the machine’.

expands partnership with XMPie

Fujifilm has announced a European reseller agreement with POD specialist XMPie, a Xerox Company. Fujifilm says the new agreement further enhances its ability to deliver cutting-edge solutions by integrating XMPie’s innovative software seamlessly into Fujifilm’s POD offering. John Davies, Workflow Product Group Manager,

Second life for Antalis exhibition stand

Antalis has donated part of its exhibition stand to a school for students with special educational needs (SEN), close to the company’s UK HQ. Following its delivery, the reassembly of the ‘market stall’ formed part of a problem-solving exercise for students. Now fully reassembled, it’s being used by students as part of their young enterprise studies in which they are learning how to set up and run a business, as well as allowing them to visualise a physical store and house their crafts, designs and business ideas.

Our partnership with XMPie underscores our commitment to delivering cuttingedge solutions

Fujifilm Europe, said: “We are constantly seeking ways to innovate and elevate our offerings to meet the evolving needs of our customers. Our partnership with XMPie underscores our commitment to delivering cutting-edge solutions that empower our customers to succeed in today’s dynamic market.”

Launched at drupa, the new Morgana DigiFold Ultra is a creasing/folding machine with full bleed trim capabilities. It can slit, cut, crease, perforate and fold in one pass and has been designed to complement mid-tohigh volume digital and offset production presses. The new machine builds on the capabilities of the DigiFold Pro XL by adding the slitting and cutting functionality for full-bleed trim applications. The Ultra maintains the high productivity seen on the previous generation Pro XL platforms – up to 6,000 A4/8.5 x 11-inch sheets per hour. There are also attachments such as the Trim Waste Conveyor Belt and BST-4000 Belt Stacker which make the Ultra suited for longer unattended production runs.

HP has announced a multi-year global partnership with Canva that aims to benefit both HP Print Service Providers (PSPs) and the Canva community worldwide. Canva, founded in 2013, has over 185 million monthly users, including 95% of the Fortune 500. Through this collaboration, the Canva community will gain expanded access to professionally printed products from HP PSPs across the globe. Canva aims to expand its print service to 150 countries by 2026, enabling shorter turnaround times and reducing its carbon footprint through localised operations.

» User-friendly user interface: key in media parameters and select from standard trim, crease and fold patterns or create custom jobs as desired. No need for external connections to computers

» Save job settings for quick and easy production (unlimited)

» Loading capacity up to 200 mm/7.9 inches

» Utilises latest technology with Plockmatic Group’s vacuum feed capability. Adaptive Fan Control automatically adjusts air flow for varying media sizes and weights

» Ultrasonic double sheet detection

» Up to 30 creases per sheet –

avoiding image cracking or toner flaking on heavier media

» Full cross perforation available, plus up to five inline perforation/ scoring wheels

» Up and down crease in a single pass with the included DynaCrease and (optional) Static Creaser modules

» Equipped with both a belt-stacker for folded sheets and a delivery tray for non-folded jobs

» Easy blade system allows for quick changes of blades without the need for any tools. Changing between di erent tools/blades can be done in less than a minute.

Xeikon launched the Xeikon PX3300HD, a new 1200 dpi digital press, at drupa 2024. Developed for high quality labels, the five-colour machine offers a 330mm printing width and speeds up to 70 m/min, even when printing with high opacity white. It also utilises a newly developed ink series, PX-Cure LED HD, to allow for perfect curing, while supporting sustainability targets for converters. With a small footprint machine, the new PX3300HD can cover up to 88% of Pantone colours within Delta E 2 (rising to 94% within Delta E 3). To meet the specific requirements of the higher resolution engine, Xeikon has developed new PX-Cure LED HD inks which match the sustainability benefits of the recently introduced PantherCure UV LED series for Xeikon 600-dpi inkjet presses. The print workflow presented by Xeikon PX3300HD is driven by the Xeikon X-800 DFE (Digital Front End). Colour management is an integral part of the software; every X-800 comes with a Pantone license so customers can easily convert all the latest Pantone colours for their press and substrates.

Landa and Gelato announce collaboration

Landa Digital Printing and Gelato are partnering up to leverage Landa's Nanographic print technology and customer network, and Gelato's global software platform to deliver high quality on-demand, short-to-medium run, digitally printed jobs. Utilising Gelato’s fulfillment network, present in more than 32 countries, digital print partners will also benefit from streamlined workflows, improved market reach and a shared commitment from both companies towards enhanced sustainability. Gil Oron, CEO, Landa Digital Printing, said: “We are delighted to partner with Gelato who have an excellent global business model with a product and machine agnostic software, GelatoConnect, that will drive volume and increase profitability in our customers’ production facilities, thereby enabling us to broaden the use of Nanography across the globe.”

Irish global packaging company Zeus has announced its acquisition of the Weedon Group, one of the UK’s largest independent integrated corrugated manufacturers. The acquisition underlines the Group’s increased focus on sustainable packaging, investing in paper-based solutions over plastic-based production. Weedon Group has revenues in excess of £30 million per annum and over 250 staff across two UK locations. The acquisition takes Zeus’ expected annualised revenues to €560 million. Keith Ockenden, Zeus Group CEO, said: “The acquisition of Weedon Group is a key facet of Zeus Group’s Vertical Integration Strategy. We now have robust in-house capabilities along the entire paper supply chain, from raw material processing to manufacturing, right through to distribution and retail. Our investment strategy is also focusing on paper-based solutions over traditional plastic-based production.”

Zeus Group’s recent strategic focus on investments in paper-based packaging solutions aligns with its commitment to reduce Scope 3 emissions. Keith Ockenden added: “Our commitment to the Science Based Targets Initiative has put us on a path to net zero by 2050. While we continue to work on reducing our own Scope 3 emissions, our technical-based sustainability teams work with our account managers to support our customers in achieving their own sustainability goals.”

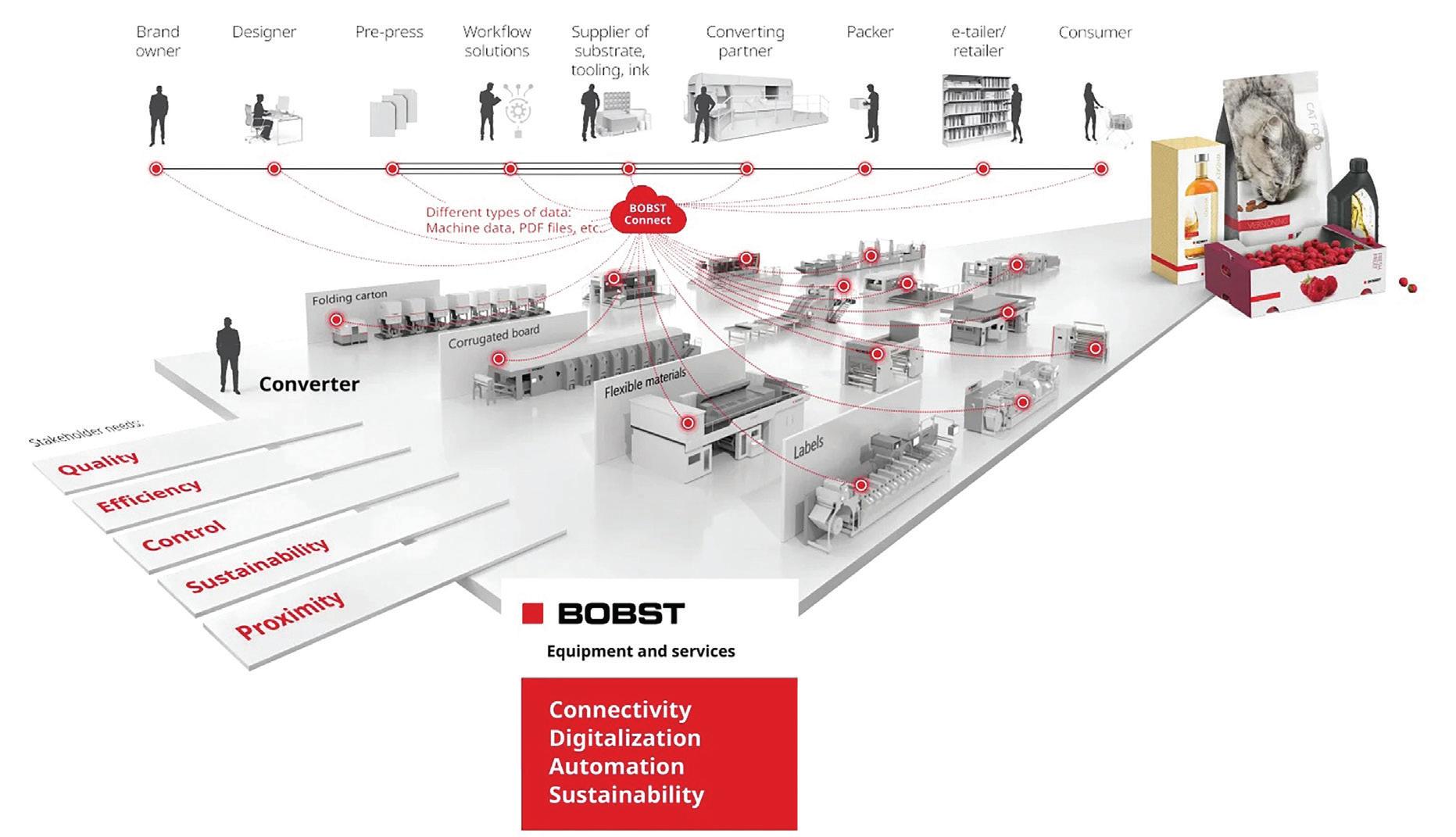

BOBST reveals new solutions at drupa

A new end-to-end, all-in-one digital printing and converting platform for folding carton along with a new version of its flagship flatbed die-cutter were among the new solutions launched by BOBST at drupa. The DIGITAL MASTER 55, a new all-in-one digital printing and converting platform for the folding carton industry will, says the company, open up new possibilities for short-to-mid-size runs and increase opportunities with short lead times and high product quality. The new platform combines printing,

XSYS introduced new innovations specifically aimed at reducing the environmental footprint of flexo at this year’s drupa. nyloflex eco plate series, Catena ProServX equipment monitoring software, EcoFillX solvent saving imaging software and rotec eco sleeves were launched at the event, all developed to reduce waste, add value and enhance productivity. nyloflex eco plates are made with up to 29% renewable raw materials and boast 25% faster processing speeds. nyloflex eco ACT is a medium-hard photopolymer plate for paper and board, well-suited to water-based inks. It’s compatible with tube and LED exposure

BOBST also launched a new version of the MASTERCUT 165 PER, its flagship flatbed die-cutter

embellishment, quality control and die-cutting inline at 100 mpm, ensuring the shortest time to market and the best Total Cost of Ownership among printing and converting solutions. BOBST also launched a new version of the MASTERCUT 165 PER, its flagship flatbed die-cutter. Able to handle corrugated board and folding carton equally well, the machine delivers perfect batches or pallets of blanks thanks to its Dual Stream system. A new carbon gripper bar enables an increased running speed of up to 7,500 sheets per hour, while in-line quality control with automatic waste ejection delivers zero-fault packaging.

systems for maximum efficiency and flexibility. For corrugated post-print, the softer nyloflex eco FAC is a robust and durable plate that tackles rough and uneven or pressure-sensitive surfaces and soft paper substrates with ease. The ThermoFlexX Catena+ plate processing line running live on the booth was a real visitor magnet says XSYS, with over 200 demos conducted during the show. As a breakthrough in fully automated, low waste platemaking, the Catena+ contributes to sustainable, Industry 4.0 production, while offering excellent OEE (Overall Equipment Effectiveness). Software introductions were also a major

attraction as XSYS launched its Catena ProServX monitoring software and EcoFillX solvent saving imaging feature. New sustainable solutions for the pressroom included the rotec eco family of sleeves, featuring a new structured sleeve surface that facilitates the escape of air bubbles to minimise waste and ensure quality.

Ideally located 5 minutes from the M50, 2 minutes from the M3 DAMASTOWN INDUSTRIAL ESTATE, D15 RYY9

We provide Trade Finishing Services such as: Gluing | Die Cutting, Window Patching | Laminating & Handwork with 48,000 square feet spread across two warehouses

EXPERTS IN PRODUCING CARTONS FOR THE MEDICAL DEVICE AND PHARMA SECTORS.

TEL: 01 254 1985 E: patrick@venturefinishing.ie | www.venturefinishing.ie

Eighteen months on and Impro Printing has doubled its turnover. Irish Printer chats to Ballyprint founder Aaron Klewchuk about the acquisition and the importance of taking chances

About 18 months ago, Ballyprint founder Aaron Klewchuk took a leap of faith and decided to purchase Impro Printing, a long-established B2 sheetfed litho firm struggling to remain profitable in a post-Covid market. Aaron was familiar with the company and its staff, which at the time outsourced its large format requirements to Ballyprint. “Impro had been trading for 40 years. I knew the staff, I knew how the business operated and I saw an opportunity for both myself and for Ballyprint. I also knew Impro had installed a Komori H-UV back in 2016, so that was a big draw. I thought, I’m 35 so if I’m going to do it, now’s the time,” says Aaron.

Impro had been trading for 40 years. I knew the sta , I knew how the business operated and I saw an opportunity for both myself and for Ballyprint

A year and a half later, Impro has been transformed. Aaron’s experience in digital, print on demand, automation and lean manufacturing has been applied across all facets of the business, resulting in a firm that has managed to double its turnover in the first year. “We completely overhauled pre-press, we installed new MIS, we introduced Switch and we implemented various automation processes which have made a massive difference. I think it can sometimes be easy for print firms to just keep on doing things the way they’ve always done them. That’s why profit margins at Impro were down and the company was facing liquidation. It took a lot of time and there was obviously some kickback, but once we got those changes implemented, everyone could see the benefit.” Those changes have led to increased orders. Jobs are no longer outsourced; Aaron has invested in a new Horizon Perfect binder and 3 knife trimmer while gathering, folding and gluing have also been brought in-house. “Those investments were necessary if we were to start increasing our margins and thankfully, they’ve worked.”

Building confidence with customers and suppliers was top of the priorities list 18 months ago, says Aaron. “Instilling that confidence was crucial, that was our biggest task straight out the door. It meant a lot of meetings, a lot of trips for myself and Sales Director Gavin Leitch to ensure we visited each and every customer and supplier. We wanted to make sure they knew our roadmap for the future and that we were focused on making a success of the business.” Gavin joined the company as sales director from W&G Baird, while long serving employee Kirk Dominy has taken up the role as Operations Director. “Impro already had an excellent foundation, with seasoned staff who know what they’re doing. With Gavin and Kirk, we’ve added to that and I think we’ve got a pretty good platform for continued growth.”

Change is hard, but I think once we explained that our aim was to make Impro the best it could be, sta were reassured

The first 12 months required significant cash injections and efforts to build up credit with suppliers. “Thankfully I knew a lot of suppliers in the trade and hoped that maybe my name held a little bit of clout. Ballyprint has good trading histories and we’ve built up good relationships with most of the suppliers. Since the acquisition, we’ve been building up credit slowly but surely and we’re definitely in a much better position now than we were a year ago.”

Staff wellbeing has also been key, says Aaron. “Change is hard, but I think once we explained that our aim was to make Impro the best it could be, staff were reassured. We also gave the office a complete makeover. We spent £90,000 refurbishing all the offices and that has really created a new lease of life for staff. They’re now excited to come into work. We wanted to make a serious investment and create a positive workplace culture. It really is a completely different place than what it was two years ago.”

Amalgamating the two firms is something Aaron is frequently asked about. “For now, we’re still running as two different companies and that’s working out quite well. There’s considerable inter-company trading and there’s sheetfed digital on both sites. I think the issue is that we would need a bigger site for both businesses. It’s not off the table, but it’s something to consider in the future.”

At this year’s drupa, Aaron formed a new strategic partnership with Fujifilm. “At Ballyprint, we’ve just installed a Fujifilm Acuity Prime 30 flatbed. We’ve signed up for a Revoria PC1120 Press with 10 colours and Revoria EC1100. We’re also thinking about investing in a B2 digital press, but that will be a purchase for next year.” The new 6 colour press with the option of 10 colours will open up new markets for the firm.

“There’s a lot of opportunity there to increase our market share across various sectors, especially with creatives. I think new, innovative technology like this gives us the edge. We’ve definitely found that with previous technology we’ve installed. It brings in new customers and shows that we’re not afraid to diversify and really branch out.”

Aaron is confident the new partnership with Fujifilm was the right step to take. “They’ve filled me with great confidence with their roadmap for the future and their growing resources. I’ve got great faith in their brand and people.”

Investment in sustainability measures have also been a key priority this year. Over £100,000 has gone into solar panels, EV chargers and an electric fleet in an effort to lower the company’s overall carbon footprint.

In the future, further acquisitions aren’t off the table. “I’ve learned a lot over the past 18 months and it’s been challenging at times, but we’ve come out the other side. For now, we’ll let the dust settle and work on growing turnover at both businesses, but there are a few print firms I’m keeping an eye on. I’d like to grow our presence in the packing sector; we do some high-end packaging at the moment but I’d like to expand on that.”

This year, the plan is to add another million to turnover. “It’s pretty ambitious. There’s only a certain amount of market share in the whole of Ireland, never mind the North. We’ve positioned ourselves well though and we’re trying to keep as nimble as possible so that when we do have bad months, it doesn’t affect us too much. I’m positive that we can reach our goals. I’m passionate about this industry and the people in it – I live and breathe print. Going to drupa reminded me how much I love it. Driving growth and working to ensure the two businesses are successful, that’s what it’s all about right now.”

PETER THOMAS, the new MD at SKSC, has his sights set on expansion and growth

How are you finding your new role at SKSC (SmurfitKappa Security Concepts)?

It’s going really well. In a way, it’s like coming back home. I first joined the business in 1997 as a Sales Manager, before taking up the General Manage role at the Northern Ireland site from 2010 to 2015. That business was sold to the TALL Group of Companies, which ended up being a good move for me as it meant going from a GM role to an MD role. Towards the end of my time there, I felt like it was time to move back home so in 2023, I took up the Managing Director designate role at SKSC. I’m taking over from Tom O’Mahony who has been with the business for 33 years and who incidentally, was my boss when I held the GM role at the Northern Ireland site!

The MD role involves guiding the business through the next stage of its growth and preparing for new investments coming in. Just recently, we invested over €3 million on a bespoke security printing press and ancillary equipment which will help us deliver tailored, innovative solutions designed to make the world a safer place. One of the solutions we have invested in is a RotateK press which has been designed and developed to our exact and unique specification. The industry we’re in is quite niche; we provide high security printing and identity management solutions to clients ranging from government departments to large corporates. That means the technology we invest in must be bespoke and capable of meeting our very specific needs. The new RotateK will enable us to continue to deliver high security printing of items to existing and new clients across the globe including passports, birth certificates, motor tax and excise labels.

Yes, for sure. The RotateK will allow us to introduce new products, such as self-adhesive security labels,

My role is about expanding our solutions, not just in Ireland but across the world

to an even wider market. The new press also includes ancillary finishing equipment which will complement our existing range of production machinery at our high security print facility near Dublin. My role is about taking the business to the next stage, expanding our solutions to more governments and corporates, not just in Ireland but across the world. I think in any company, new ways of looking at things is important and that’s what I’m bringing to the table. We have a fantastic team here; I’m not teaching them anything new in terms of how they do their job but when it comes to how we present and market ourselves, I think we can make improvements. As a company we tend to somewhat hide our light under a bushel, but how can we increase our market presence if people don’t know about us? We have so many strengths and we can provide so many solutions to clients, whether it’s variable data or the use of security printed features to add value to existing products, labels or tagging on packages. We want to ensure we get that message out there.

our cars and we thought we were the height of technological advancement! Digitisation has been hugely beneficial, it enables everything we’re doing but it’s still important for me to be able to sit in front of a customer and have a conversation. Also, I think in the noughties price became key and it turned into a race to the bottom. Technology has allowed that to happen, so it’s up to us to take ownership of that again. This industry is about relationships, they come first.

Business is good. Like every other company, we’d like it to be better but in the Irish market, I’d say we’re number one across the spaces we’re active in. I believe we need to look beyond our borders to where the next big opportunity is. We’re currently investigating opportunities in areas like digitalisation, automation and track and trace. We need to look beyond what we’re doing and use our expertise to springboard into new areas and that’s a key element of my role.

What’s the biggest change you’ve seen in the industry since your career began?

Definitely computerisation. When I started off, there were no emails, no mobiles. We had walkie talkies in

I like building relationships with clients and with staff. I’ve always had an interest in providing a good service, in new product development and in sales. As a previous boss of mine said, if you’re not selling, you’re reducing! I also enjoy the camaraderie with staff, some of whom have been with the company for 20 years. Staff retention is excellent and I think that’s down to SKSC’s efforts to provide employees with a healthy, safe working environment. There’s also a big focus on career development. When I joined the organisation, I got the opportunity to do a degree and a Masters. If people want to grow and develop, the opportunity is there.

My ambitions are to get our new equipment up and running and go to market with it. In some cases, we’ll be offering increased capacity to our trade customers and a whole new set of dynamic, innovative solutions to new clients. Our new equipment will also give us an opportunity to look at new markets. Essentially, we’re looking to create a platform for growth. We’re waving our flag and looking to identify agents and willing partners in the marketplace. Also, I think the opportunity to lead this amazing team into the next stage is so exciting; as technology continues to evolve and the digital transformation rolls on, our solutions will continue to play a vital role in helping to secure borders, protect people, prevent fraud and strengthen brand integrity for clients.

Smur t Kappa Security Concepts is the local market leader in passports, biometric cards, scal stamps, ballot papers and other security products. https://www.smur tkappasecurityconcepts.com/

After eight years since the last drupa, the printing industry has undergone a transformation and is barely recognisable. We recall Benny Landa, the creator of Indigo, predicting that the world would become digital and printing would not escape this shift. Undoubtedly, he was correct and visionary. Going beyond digitalisation or perhaps because of it, everything can indeed be dematerialised, but more importantly, everything can be printed – on any material!

This evolution has undeniably shaken the market, especially for printing companies. Commercial printing has seen a decline, to say the least, with major brands once deemed “too big to fall” such as American Kodak, Belgian Agfa Gevaert or German Heidelberg, having to reinvent themselves. Paper and cardboard suppliers – both producers and distributors – have had to transition into the packaging sector. For instance, French company La Galiote has shifted away from direct mail advertising, expanding its services to clients by offering packaging solutions, including boxes and folding cartons. The sector has experienced a remarkable transformation in a short period. But what does the future hold?

As most of you are entrepreneurs, your interest lies in what can be built and what can be hoped for. Here are some questions that must be pondered to move forward. I use the word “ponder” because I’m uncertain if I have the answers.

WILL SUSTAINABILITY continue to be a crucial driver?

Here are some questions that must be pondered to move forward. I use the word “ponder” because I’m uncertain if I have the answers

WILL DIGITALISATION continue to advance? IS SPECIALISATION still the key to success? IS WEB-TO-PRINT AND WEB-TO-PACK the ultimate solution?

It’s hard to deny the crucial importance of environmental issues however, who can say for sure if the responses we offer now will remain the same tomorrow? In November 2022, I witnessed the anxious faces of paper and cardboard industry players during the CEPI congress, the European Confederation of Paper Industries. Everyone was awaiting the European directive – the famous PPWR – and trembling because it seemed that the future of packaging might solely rely on reuse, eradicating the term “recycling” from the equation. Ultimately, both concepts are included in the directive, giving some relief to paper and cardboard, which are relatively less reusable. The guillotine was narrowly avoided. But for how long?

It must be noted that the fervent backlash against plastics gave way to a plastic-loving trend thanks to reuse. We aimed to eliminate plastic, yet it has become stronger. When plastic checkout bags had to disappear in France, polymer industry actors compensated by producing thicker film bags of over 50µ thickness. The intention was to reduce plastic usage but ultimately, we ended up increasing the total tonnage used! Therefore, yes, we must engage in the environmental debate, but in my opinion, we need to stay ready to react quickly in the short term – what is true today may be contradicted tomorrow and vice versa.

Yes, digital printing is a process that continues to grow and will keep evolving so it should not be overlooked – but who would want to or more precisely, who could afford to ignore it today? Nonetheless, so-called conventional processes have improved and developed responses that allow them to compete with an all-digital approach. The breakeven point regarding print run length, which determines when to switch from digital to offset or flexo and vice versa, has significantly decreased.

Printing 100 posters on a sheet-fed offset press or a large-format inkjet press is practically the same and in all likelihood, the quantity can even be reduced. Moreover, it doesn’t take any more time. Let’s not deceive ourselves – very small print runs are not so common among “industrial” printers. In the label industry, digital printing represents less than 10% of the printed area but accounts for nearly one-third of the value added. In corrugated packaging, digital printing constitutes an infinitesimal portion of the total output. The CEO of a digital press manufacturer for this sector stated during the last drupa that if digital printing reached 2% of the market, it would be a boom for manufacturers. We are far from that point.

A printer who utilises various printing processes recently confided that while they offer digital services, it doesn’t constitute a significant portion of their revenue or livelihood. Perhaps that’s why hybrid printing is gaining traction – a combination of different printing methods or for the more ambitious, all possible printing techniques with a single production line and above all, it holds unmatched appeal for the younger generation, which is vital for recruitment in an age where the term “industry” is met with resistance in schools.

In the label industry, digital printing represents less than 10% of the printed area but accounts for nearly one-third of the value added

Undoubtedly, it’s the big question – should one specialise to be the best, the sharpest, the most responsive? Or on the contrary, is specialisation a thing of the past and should businesses now offer the widest range of services to their clients? It’s not easy to answer this question definitively, as there will always be counterexamples. One thing is certain – the economy and entrepreneurial priorities work in cycles and the cycle of specialisation has lasted for a long time in an era of rapid acceleration. Moreover, market reconfigurations compel companies to find substitutes for declining activities.

It’s evident that commercial printers, witnessing a decline in volumes and orders, had to adopt the firefighters’ motto, “save yourself or perish.” Many initially offered complementary services and eventually expanded to provide large format printing, labels and even folding cartons. Similarly, label printers ventured into boxes or flexible packaging or large format printers producing Americanstyle boxes.

In an ultra-competitive world where price pressures are immense, buyers often lack time for small orders or ancillary purchases, leading them to rely on their well-referenced suppliers. Everyone benefits from this approach. Therefore, keeping an eye on diversification is essential; it not only generates revenue but also fosters customer loyalty.

I may receive some backlash from most online print service providers but the rise of web-to-print or web-to-pack corresponds to a shift in priorities from quality to price and above all, service. Let’s begin with quality. Printing has made such progress, aided by software advancements that optimise images, resulting in nearly everything being printed reasonably well. Consequently, web-to-print has managed to find its place and quality of prints is satisfactory enough to please the customer, offering local brand owners a chance to bring products to market without significant risk. However, not everyone can engage in web-to-print, as this activity requires volumes and sophisticated processes to achieve profitability. It demands an extensive catalogue of print types and enough materials, a precise and complementary machine park and above all, a qualified workforce to manage the print flow and a considerable team to manage shipments. Printers have recognised this and are increasingly providing collaborative tools that offer kind of web-to-print, but they remain reserved for their regular customers. For web-to-print, the decisions regarding the machine park and the software around it remain critical.

JEAN PONCET IS CHIEF EDITOR AT MP MÉDIAS - FRANCE

INa night to remember, the 45th Irish Print Awards were held at Clontarf Castle in Dublin on April 26th, 2024.

The annual event saw the industry’s finest talents gather to honour the achievements of their peers. Over the course of the evening, winners from 30 categories were announced, judged by a panel of independent experts from across the sector, with Anglo Printers taking home the top award of the night.

Diarmuid Dawson

Chairman of the Judging Panel and

Managing Director of Innovative Print Solutions

Judging Panel

Andrew Horan

The Irish Print Awards highlight the creativity and resilience that define the print community in Ireland. More than ever, this year’s event showcased the depth and breadth of talent in the field, recognising the firms that are committed to providing only the

College Lecturer

Technological University Dublin

Darren Finn

Managing Director

Flexographic Plate Plan

job in whittling down entries and finally selecting just one winner from the impressive crop we received. Such was the standard of entries that Silver and Bronze awards have been awarded in most

just categories again this year.

indeed

Congratulations to all of our winners and indeed to everyone who

Dave O’Reilly

Owner

Mediainc

David Mahon

Managing Director

Evad IT Solutions Ltd

Louise Reddy

Lecturer

Technological University Dublin

Jane Matthews

Creative Director

Ashville Media Group

Adrian Matthews

Print Project Manager

Keith Redmond

General Manager

Flint Group

David Fitzgerald

Owner

Scapegoat Design

Print of the Year

Anglo Printers – Roisin Murphy Hit Parade (Deluxe Edition)

Best Use of Print

Gold: Anglo Printers – Roisin Murphy Hit Parade (Deluxe Edition)

Silver: Northside Graphics – Titanic Village

Bronze: P+D – Peroni F1 Box

Book Printer of the Year

Gold: Impress Printing Works – President Higgins Machnamh 100, Volumes 1 & 2 with Slip Case

Silver: W&G Baird – Sparks from the Flagstones Dance Book

Bronze: Print Media Services – Portrait of a Family, The Conollys of Castletown

Digital Label Printer of the Year

Gold: Watershed Group – Thin Lizzy Double Charred Irish Whiskey

Silver: Label Tech Ltd – The Whistler Dark

Symphony French Cognac Aged Irish Whiskey

Bronze: Label Tech Ltd – JJ Corry Irish Whiskey - The Flintlock 21 Year Old

Digital Packaging Printer of the Year

Gold: McGowans – Aine’s Chocolates

Silver: CoLab Packaging – JJ Corry Cliffs of Moher (Rest of the World)

Bronze: P+D – 7up Flat Influencer Box

Digital Printer of the Year

Sponsored By: FujiFilm

Gold: P+D – Hendricks Suitcase Influencer Box

Silver: Display - Smurfit Kappa – It’s

Showtime

Bronze: Multi-Color Labels Ireland Ltd (MCC) – Galway Bay - The Space Between Red Rye IPA

Magazine, Brochure & Supplement Printer of the Year

Gold: W&G Baird – Anthology

Silver: KC Print Ltd – Newbridge Silver

Catalogue

Bronze: Print Media Services – The Blue Rooms

Connacht/ Ulster/ Munster Small Printer of the Year

Gold: Ballyprint – New Year CMYK+ Calendar

Silver: Harvest Moon Print & Deisgn Ltd

–Memorial Booklet

Bronze: MW DESIGN PRINT & SIGNS –Steeltech Sheds

Food and Drink Packaging of the Year

Gold: Boran Packaging Limited – Strings & Things

Silver: Print Library – Dunvilles Whiskey Box

Bronze: Impact Labelling Ltd –Nutritional Layers

Large Format Digital Printer of the Year

Sponsored By: GPMI

Gold: Horizon Digital Print – Jameson

Bar

Silver: P+D – House of Peroni Bar

Bronze: McGowans – Glendalough Gin FSDU

Flexographic Label Print of the Year

Gold: Multi-Color Labels Ireland Ltd (MCC) – Finvara The King’s Gambit Triple Distilled Irish Whiskey 700ml

Silver: Label Tech Ltd – Boann Winter

Solstice Cask No.2 Pot Still New Make

Bronze: Nuprint Technologies –Bushmills Rare Cask 28 Year Cognac Cask

Graphic Design & Print Collaboration Award

Sponsored By: Canon

Gold: Anglo Printers – Roisin Murphy Hit Parade (Deluxe Edition)

Silver: K Print – My Palitoy Story Case Bound Book

Bronze: Journey Creative – Bespoke

Narnia Christmas Card

Innovation & Print Technology of the Year

Sponsored By: Business Post

Gold: P+D – Faster Displays

Silver: Dublin Gazette/The Public House

– The Bionic Edition

Bronze: New Dimension 3D Ltd – OP Printer

Gold: Vision 3D Solutions – Nexa3D XiP

Ultrafast Desktop 3D Printer

New Dimension 3D LTD – OP Printer

Presentation Models – Exhibition Model of Newgrange Burial Chamber

Litho Packaging Printer of the Year

Gold: Print Library – Dunville’s Whiskey Box

Silver: Boxpak Ltd – Asda Extra Special

Chocolate Orange Cookies

Bronze: Boxpak Ltd – Mini Shortbread Reindeer Bites

Magazine, Brochure and Supplement Printer of the Year

Gold: W&G Baird – Anthology Autumn 2023

Silver: KC Print Ltd – Newbridge Silver

Catalogue

Bronze: Print Media Services – The Blue Rooms

Newspaper & Freesheet Printer of the Year

Gold: The Irish Times – The Guardian

Silver: Interpress – Irish News

Bronze: Adenium T/A Webprint – Connacht Tribune

Print Finishing Award

Gold: Print Media Services – AirBnB Belong Anywhere Guestbook

Silver: The Printed Image – Barnardo’s This is Me

Bronze: Northside Graphics – Titanic Village

Printed Wrap of the Year

Sponsored By: Trimwel

Gold: Horizon Digital Print – Cirque Bus

Silver: P+D – Barbie Lift Wrap

Bronze: Wrap-it Design Ltd – Smart Coffee

Reports & Accounts Printer of the Year

Gold: McGowans – Dublin Zoo Annual Report

Silver: Print Media Services – Concern

Worldwide Annual Report and Financial Statements 2022

Bronze: NeoGen – Coillte Annual Report 2022

Screen Printing of the Year

Sponsored By: Irish Printing Federation

Gold: CB Forms – CB Forms ITEN project

Silver: Walsh Print & Graphics –McLoughlin’s Veterinary Clinic

Bronze: ND Signs Ltd – Tesco Home Delivery Fleet

Sheetfed Colour Offset Printer of the Year

Sponsored By: EBB

Gold: W&G Baird – Sunseekers 2024

Silver: Anglo Printers – Roisin Murphy Hit Parade (Deluxe Edition)

Bronze: Print Media Services – Colours of the Crib

Signage Printer of the Year

Gold: Horizon Digital Print – Emerald Park

Silver: Little Poppy Limited – Print & Signage re-brand of 16 SISU Aesthetic clinics nationwide in four months

Bronze: P+D – Disney + Window Wrap

ANGLO PRINTERS ROISIN MURPHY HIT PARADE (DELUXE EDITION)

Small Printer of the Year

Leinster/Dublin

Gold: Plus Print – Orior Archive

Silver: Print Media Services – Messy Cocktail Book, Jameson

Bronze: Reads Direct – HER SPORT AWARDS NIGHT signage and printing

Sustainability Printer of the Year

Le Skinny Chef Soup Sleeves

Silver: P+D – Faster Displays

Bronze: The Printed Image – The Printed Image #HomeofSustainability

Textile Printer of the Year

Gold: Jill & Gill – Boundless Radicals

Gold: Esmark Finch Print and Packaging –

Silver: Pixalili – Print perfect - on-demand

Bronze: William Clark & Sons Ltd –Sketched Róisín Dubh for Éadach by Sara O’Neill

BOOK PRINTER OF THE YEAR IMPRESS PRINTING WORKS

DIGITAL PACKAGING PRINTER OF THE YEAR MCGOWANS

DIGITAL LABEL PRINTER OF THE YEAR WATERSHED GROUP

DIGITAL PRINTER OF THE YEAR SPONSORED BY: FUJIFILM

P+D

CONNACHT/ULSTER/MUNSTER SMALL PRINTER OF THE YEAR BALLYPRINT

FOOD AND DRINK PACKAGING OF THE YEAR

BORAN PACKAGING LIMITED

LITHO PACKAGING PRINTER OF THE YEAR PRINT LIBRARY

PRINTED WRAP OF THE YEAR | SPONSORED BY: TRIMWEL

HORIZON DIGITAL PRINT

LARGE FORMAT DIGITAL PRINTER OF THE YEAR | SPONSORED BY: GPMI HORIZON DIGITAL PRINT

FLEXOGRAPHIC LABEL PRINTER OF THE YEAR

MULTI-COLOR LABELS IRELAND LTD (MCC)

MAGAZINE, BROCHURE AND SUPPLEMENT PRINTER OF THE YEAR

W&G BAIRD

NEWSPAPER & FREESHEET

PRINTER OF THE YEAR

THE IRISH TIMES – THE GUARDIAN

SCREEN PRINTING OF THE YEAR CB FORMS

REPORTS & ACCOUNTS PRINTER

MCGOWANS

INNOVATION & PRINT TECHNOLOGY OF THE YEAR | SPONSORED BY BUSINESS POST P+D

SHEETFED COLOUR OFFSET

PRINTER OF THE YEAR

W&G BAIRD

PRINT FINISHING AWARD

PRINT MEDIA SERVICES

PRINTER OF THE YEAR LEINSTER/ DUBLIN PLUS PRINT

RISING STAR AWARD

LITTLE POPPY LIMITED

SUPPLIER OF THE YEAR TREAD DIGITAL PRINT

SUSTAINABILITY PRINTER OF THE YEAR

ESMARK FINCH PRINT AND PACKAGING

FUTURE OF PRINT RONAN QUINN

TEXTILE PRINTER OF THE YEAR JILL & GILL

DAVE HEARY

Sales Manager AUDREY FROST on the family atmosphere at Canon Ireland

How did you get into the print industry?

I started out working for Epson Ireland as a marketing assistant back in 1997. My cousin worked for them in the UK and I had recently graduated, so she put me forward for the opportunity in Dublin.

What do you like about working at Canon?

Despite Canon being a large global organisation, Canon Ireland has a real family feel to it. I work with a great bunch of people too and that’s really important. What do you see as your biggest success in life?

First and foremost my two daughters, Abigail (16) and Lydia (10), followed closely by my career. It wasn’t always easy juggling the two, especially in the early years, but thanks to the support of my husband Paul, I think we managed to find a good balance.

What’s the worst job you’ve ever had?

There have been some challenging times over the years but I’ve learnt something from every job and nothing sticks out as the worst!

What’s your dream job?

Something working with animals, maybe in a zoo, getting a chance to look after loads of different ones. But not as a vet – I couldn’t do the hard stuff!

Favourite film?

Anyone who knows me will know it’s Dirty Dancing. I can’t count how many times I’ve seen it and I know every word, song and dance. It’s such a coming-of-age film and

I spent many years looking for my own Patrick Swayze!

What’s your guiltiest pleasure?

Glass of wine, savoury treats and dips with a good film or TV series.

What’s your favourite band/musician?

There’s been many over the years. Bon Jovi is an old favourite but more recently, The Script and of course Taylor Swift!

Who or what makes you laugh?

My husband. One thing we always say is no matter what he does, he can always make me laugh and I think that goes a long way to a happy relationship.

What superpower would you most like to have?

The ability to blink and transport myself to wherever I need to go. I travel a lot with work and have family in the UK, so that would make the whole process a lot easier.

How would you like to be remembered?

As a good person, someone who put family and friends first and was always there when needed.

Life is…

But a moment in time.