COVID-19: ADAPTING SERVICE IN ‘NEW NORMAL’ HERE’S A TRIO OF WAYS TO SET YOUR LAUNDRY APART DOING LAUNDRY PROFITABLY IN A SMALL FOOTPRINT INSIDE: JULYINSIDE:2005 JUNE 2020 WWW.AMERICANCOINOP.COM PERSONAL or PERSONNEL? Staff Training: Mold and Manage to Stay on the Right Path Learning to Delegate: Less Dayto-Day = More Business-Building

“Tap and Go” (Contactless) payment has become the preferred way to pay in Europe, Canada, South Korea and Australia, and the US is finally catching up.

Visa expects more than 100 million contactless cards will be in the hands of American consumers by the end of 2019 and they are currently accepted at 78 of Visa’s top 100 merchants. With SpyderWash, customers simply hold/tap their credit card a few inches from the card reader, and the vend is satisfied.

Sales@setomaticsystems.com |

|

FREE washes

credit/debit

options

516.752.8008

www.setomaticsystems.com Customers can earn

with either a loyalty card or their

card automatically. Pay with a variety of

including credit / debit, coin, loyalty card, or NFC / Mobile wallet. Loyalty Program

No sign-up or app download required

STAFF TRAINING

Attendants and other personnel represent you and your brand through customer interaction and service. But they aren’t born with the skills needed to do the job—they have to be trained.

COVID-19: GETTING USED TO THE ‘NEW NORMAL’

With the U.S. pandemic emergency now in its third month, we’re all getting used to a “new normal.” It’s important to continue following safety and service recommendations while also showing flexibility when circumstances allow for it.

LEARNING TO DELEGATE

The laundry owner who learns to delegate responsibilities where possible can ease his/her daily burden and create opportunities to build business and plan for the long term.

PERSONAL

COLUMNS

18 A TRIO OF WAYS TO SET YOUR LAUNDRY APART

Not all laundry improvements need be complicated or require more labor, says Girbau North America’s Tod Sorensen. Some involve simple changes or additions to existing vended laundry equipment. Singly or comprehensively, they’ll work to set your laundry apart and generate more income per square foot, Sorensen says.

20 DOING LAUNDRY PROFITABLY IN A SMALL FOOTPRINT

Tiny houses, cabins and campers are all the rage, say co-authors Jared Mueller and Andy Goodale. It’s all about downsizing your lifestyle and living a more fulfilling life without a lot of debt and “stuff.” Along that same line, small-scale laundries often make perfect sense. If done correctly, small-footprint Laundromats can be as profitable as larger-scale operations.

2 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

JUNE 2020 VOLUME 61 ISSUE 6

CONTENTS

(Cover image: Image licensed by Ingram Image)

INSIDE

6 10 14

laundry

6 COVER STORY DEPARTMENTS 4 VIEWPOINT 23 AD INDEX 22 CLASSIFIEDS 24 NEWSMAKERS DID YOU KNOW... American Coin-Op releases a new podcast on a different topic of interest the last Wednesday of every month? Give it a listen at AmericanCoinOp.com.

OR PERSONNEL? It’s not uncommon for

owners

to take on a lot of

responsibilities,

especially when they’re just getting started. Prospects for success can be linked to the handling of personnel, both in terms of staff training and in ownership learning to delegate the “day-to-day.”

ADAPTING TO ‘NEW NORMAL’

Bruce Beggs

As I write this column in mid-May, the United States has just entered its third month dealing with the COVID-19 pandemic. We’re all growing more accustomed to the “new normal”: frequent hand-washing, wearing of face coverings while in public and avoiding close contact with others.

For those of you who operate attended or partially attended stores, you’re relying on your attendants and other personnel more than ever to keep your business running. Maybe you’ve had to adjust your operation in some way and that’s required added staff training.

Putting the current situation aside for a moment, the importance of properly training staff can’t be understated, because they represent you and your brand through their interaction with customers and their ability to keep your operation running smoothly day after day.

Another aspect of laundry ownership and management is delegation, entrusting others to handle certain day-to-day responsibilities when possible to free one’s self to work on broader issues important to the life of your business.

Personal or personnel — that’s how I describe my two feature articles this month. Staff Training begins on page 6 and Learning to Delegate opens on page 14.

Remember: your laundry business is essential to our country’s efforts to combat the spread of COVID-19. I thank you for your continued service and hope that you and your employees are remaining safe.

Bruce Beggs Editorial Director

Charles Thompson, Publisher

E-mail: cthompson@ATMags.com Phone: 312-361-1680

Donald Feinstein, Associate Publisher/ National Sales Director

E-mail: dfeinstein@ATMags.com Phone: 312-361-1682

Bruce Beggs, Editorial Director

E-mail: bbeggs@ATMags.com Phone: 312-361-1683

Mathew Pawlak, Production Manager

Nathan Frerichs, Digital Media Director

E-mail: nfrerichs@ATMags.com Phone: 312-361-1681

ADVISORY BOARD

Jaimie

Main: 312-361-1700 SUBSCRIPTIONS

630-739-0900 x100 www.AmericanCoinOp.com

American Coin-Op (ISSN 0092-2811) is published monthly. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Coin-Op, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 61, number 6. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Coin-Op is distributed selectively to owners, operators and managers of chain and individually owned coin-operated laundry establishments in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2020. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Coin-Op does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Coin-Op or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

4 AMERICAN COIN-OP JUNE 2020

www.americancoinop.com VIEWPOINT

Johnson Douglas Pratt Tony Regan Sharon Sager Michael Schantz Luke Williford Andy Wray OFFICE INFORMATION

Oee eeeeeeee eee eeee ee eee eeeeeeeeeeee eeeeeeeeeee eee eeeeeeeeeeeee eee e eeeeeeee fieeeh eee eeeeeeeeee eee eeeee ee eee. The eeeee eeee hee e 3 eeeee eeekeee eeeeee eee exeee eeeeeeee.

info@vendrite.com www.vendrite.com sales@vendrite.com

Rlluminated blue selection buttons inform customer the product is available. Reliable optic sensors confirm coin acceptance, product availability and delivery.

STAFF TRAINING: Mold & Manage to Stay on the Right Path

by Bruce Beggs, Editorial Director

by Bruce Beggs, Editorial Director

If you own an attended or partially attended vended laundry, then you understand the importance of hiring and retaining good employees. They represent you and your brand on the front lines through their interaction with customers and their ability to keep your operation running smoothly day after day.

But attendants and other laundry staff aren’t born with those skills — they have to be trained.

And while there are similarities among all self-service laundries no matter where they’re located, a small-business owner likes to run their operation in their own way. Training staff is necessary to ensure that they perform to the business owner’s satisfaction and they’re able to run things properly even if their supervisor isn’t around.

American Coin-Op spoke to four laundry business owners and managers this month to learn how they go about training their staff.

WHALE OF A WASH, WEST VIRGINIA

Anne Sechler manages Whale of a Wash, a West Virginia-based business operation that includes 10 Laundromats and three car washes, for her father, owner Hank Walter.

Three of the stores are partially attended and offer wash-dry-fold (WDF), ironing and drycleaning services; the other locations are visited by a “detail cleaner” at least once a week. These cleaners are also trained in WDF and can fill in when someone is sick

or takes a day off. Three full-time service technicians attend to equipment maintenance and share on-call duties across all stores (and car washes) so someone is available 24/7.

Sechler says staff training is important because job satisfaction “comes with becoming an expert.”

“No employee likes to have to call a manager for every little question they might have, and vice versa,” she says. “Providing training, especially in the beginning, will pay off big time when that employee is faced with a difficult situation.”

New Whale of a Wash employees meet Sechler at the company’s office and largest WDF store. After Sechler leads a new worker through the employee handbook and laundry attendant handbook (they must sign off to show they have read and understand the documents), the worker trains at the company’s flagship store with its most trusted employee.

“They shadow her for at least four shifts after which we evaluate if that person can work on his/her own,” Sechler says. “Next, the new employee is sent out on a detailing run with our designated detail cleaner. They shadow her for 1-2 days and we again evaluate autonomy. After this week of training, we feel we have provided friendly resources for him/her to feel like part of the team and we trust that he/she will act in the best interest of the company.”

6 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

▼

Anne Sechler (seated) and Hank Walter pose in one of their Whale of a Wash stores. (Photo courtesy Whale of a Wash)

(Image licensed by Ingram Image)

Once on duty, employees know they have the handbooks to help guide them but also that a service technician or supervisor is available by phone.

“We never like the employee to be stuck, say with an angry customer or a flooding store with no one to call,” Sechler says. “We keep a schedule at every store with the ‘on-call’ service tech and cell phone numbers for the owner.”

Whale of a Wash training had to be adapted when the business added full-service laundry.

“Prior to this, our employee model was only self-service vended laundry with a staff of seasoned service techs that did not need much oversight,” says Sechler.

QUEEN CITY LAUNDRY AND HAPPYNEST, OHIO

Dave Menz owns and operates a chain of four retail Laundromats in Cincinnati, Ohio, under the Queen City Laundry brand (three are fully attended with drop-off wash-dryfold service, the other is partially attended), plus he runs a HappyNest laundry pickup and delivery franchise.

“We have 20 to 25 store attendants; most of them are part-time. We have three store managers … and we have a general manager that runs the whole company (plus oversees day-to-day operations at one store). We have anywhere from seven to eight delivery drivers … and then we have a third-shift processing crew that processes laundry overnight from our pickup and delivery business.”

Training is important to the success of his businesses “because we have really high standards for the experience the customer gets, whether it’s pickup and delivery or in our stores,” says Menz. “We want our attendants going above and beyond. … We look for people that have what we call ‘the heart of a servant.’”

Attendants undergo four days of training in four-hour shifts with a store manager and are cross-trained so they can work at any of the locations; management has the option to extend training if needed, and new hires are subject to a 90-day probationary period.

“The first two days of training is exclusively customer service and cleaning. … We focus on cleaning on a shift-by-shift basis and then also what we call deep cleaning. These are things that don’t necessarily have to happen every shift but if we never do them, (the stores are) going to really start to look bad.”

The second half of training is on drop-off service: “They’re physically processing laundry, organizing things, packaging, folding, these type of things.”

Once completed, they can typically be released to work independently, with the understanding that if a manager is not in the store, one is only a phone call away.

Driver training incorporates two days of shadowing an experienced driver, then two days of driving themselves with the trainer on board.

“Once you get through those four days of training, the job isn’t that complicated, so you have to kind of let them sink or swim on their own,” Menz says. “But you also want to be there to support them, sort of in the background.”

Training then shifts to coaching, and management could begin grooming someone for a higher-level position within the company.

“To date, we haven’t hired a store manager that wasn’t already a store attendant,” Menz says. “We’re not opposed to it but if we have the right person, it’s such a natural progression.”

A manager in training will first spend 40 hours with the GM to learn the responsibilities of the new post. Then, the GM will spend extra time with the trainee over several weeks before deeming them fit to officially step up.

SCRUB-A-DUDS, INDIANA

Wayne Meyer co-owns a pair of fully attended Scrub-a-Duds locations in Lafayette, Indiana, with son Chris and daughter-inlaw Chris; day-to-day management is handled by the younger generation. Besides walk-in and pickup/delivery service, Scrub-aDuds processes laundry for commercial clients, including the local Subaru automotive production plant and Purdue University. Meyer opened the first store in 1992 and the second three years later.

Scrub-a-Duds employs six people fulltime and six people part-time. Employees are able to work at either store. They can work their way up from basic attendant to senior attendant and then to what Meyer calls a shift manager entrusted with collecting and handling money; Scrub-a-Duds currently has four.

“These are people who, through our training, have shown that they will take on (added) responsibility,” he explains.

“If our employee demonstrates that they have the ability to be a shift manager, then we make them a shift manager. We don’t go out and hire someone specifically for that.”

Meyer worked as a management consultant before taking on laundry ownership, so he was quick to implement detailed guides for opening and closing the stores as well as cleaning them.

For Meyer, training is essential to communicate management expectations to new hires: “They have to know what’s expected of them. You can’t just hire somebody and say, ‘Here it is. You take care of it.’ They have to know up front what is expected of them. … How can you criticize somebody who’s not doing their job unless you let them know what their job is?”

When a new employee arrives, they spend the first week working with somebody else, he explains.

“They owe allegiance to the person that hires them. That’s typical. I try to have my daughter-in-law do the hiring because she’s there on the front lines all the time, while my son is doing other things such as repairing equipment and stuff like that.

“She does initial training during the first shift, then we turn it over to one of our senior shift managers, who goes through the rest of the training and what they have to do. Some people catch on immediately, others you have to give a little nudge along the way.”

The final step is working independently, understanding that management visits each store multiple times each day. Through the process, a checklist is used to indicate what they’ve been trained in. It is maintained in their personnel file for reference later if needed.

8 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

(continued on page 16)

(From left) Dave Menz and his general manager, Marlene Adams, pose amidst bundles of processed wash-dry-fold goods. (Photo: Laurance Cohen)

Many Coin Laundries Has Your Insurance Agent Handled? One or Two? Three? We’ve personally handled insurance for hundreds of coin laundries! We’ve already dealt with most any issue your business is likely to face. If you have any questions about insuring coin laundries, we can and will give you a prompt, clear answer. Skeptical? Call us with a question and find out for yourself. There’s more: We’re just three members of NIE’s team of experts. NIE has been handling fabricare insurance since 1915! Quote Request .............................................................. ............................................................ Coin Laundry Dryclean Plant Dryclean Drop Store Attended? Gross Sales Hours of Operation Coin Laundry Dryclean Plant Dryclean Drop Store Coin Laundry Dryclean Plant Dryclean Drop Store NIE Insurance • 6030 Bancroft Avenue, St. Louis, MO 63109 • 1-800-325-9522 • fax (314) 832-6775 • www.NIEinsurance.com “Insuring Small Businesses Since 1915” Ann Hawkins Vice President Hawkins@NIEinsurance.com Director of Korean Operations Kang@NIEinsurance.com 강 명순 입니다. 지금, 연락만 주십시요.

Fabricare Specialist Russell@NIEinsurance.com

Fabricare Specialist Simpson@NIEinsurance.com

How

Amy Russell

Chuck Simpson

COVID-19: GETTING USED TO THE ‘NEW NORMAL’

RESTRICTIONS EASING AS STATES MOVE TO REOPEN BUSINESSES IN PHASES

Laundromats remain essential to our nation’s continuing effort to help prevent the spread of coronavirus disease 2019, or COVID-19. The U.S. pandemic emergency entered its third month on May 13.

As this issue went to press, there were roughly 1.3 million COVID-19 cases in the United States. Deaths attributed to the disease surpassed 78,000 as of May 11. There is no vaccine, so the best way to prevent illness is to avoid being exposed, says the Centers for Disease Control and Prevention (CDC).

While the federal government works to manage the pandemic response and offer various means of financial support for impacted workers and businesses, state governments have set quarantine guidelines for their residents.

By press time, many states had relaxed stay-at-home orders or safer-at-home guidances in favor of plans defining when certain business sectors could reopen and how public gatherings were to be treated. Still, governors routinely encouraged residents to avoid large gatherings and to stay home as much as possible to avoid becoming ill.

Frequent hand-washing, wearing of face coverings in public and avoiding close contact with others remain the “new normal.”

Laundry businesses are continuing to refine their operations in response to the ever-evolving situation.

For example, Tane Smith says she supplied employees of her two At Your Service Coin Laundries and the 5th Street Laundromat in the Dayton, Ohio, area with gloves and face masks and emphasizes maintaining the 6-foot social distancing guidelines.

Her 5th Street store is “a small Laundromat, located in a residential neighborhood. It is unattended and is open from 8 a.m. to 8 p.m. We have removed all of the seating (asking customers to wait in their cars while their laundry washes and dries) and folding tables (asking customers to please fold at home). We are sending employees in several times a day to sanitize.”

Seating and folding tables were also removed from the 24-hour At Your Service location, says Smith. “We have hung signs asking customers to remain in their car

while laundry washes and dries and to take their laundry home to fold it. To maintain social distancing, the posting requests one family member in the store, and no more than 10 customers in the store at a time.”

The other At Your Service location is open 7 a.m.-9 p.m. It is attended all day, is sanitized every hour using a hospital-grade sanitizer, and offers wash-dry-fold service.

“We implemented curbside service for customers not wanting to get out of their car. They call the location when they arrive in the parking lot, the attendant goes out and retrieves their laundry/soap. We wash it, dry it, and bag it. At that point, we call the customer to tell them their laundry is ready.”

There will be opportunities in these uncertain times, as poor, underfunded Laundromats close and “old timers” who’ve had enough want out of the business, Hinrichs wrote.

“This may be a great time to expand your Laundromat portfolio or retool your Laundromat. As I write this, my stores are down one-third in volume but this will not last forever.”

Washtime Laundromat in Grand Junction, Colorado, has also focused on social distancing and cleaning during the pandemic, according to owner Mike Sitz. The business enacted special senior (60 and older) hours in the mornings. All seating was removed, and TVs were kept off.

“People have to leave the building for 30 minutes after starting their machines,” Sitz says. “We marked off areas for folding that are 6 feet apart but strongly encourage people to fold at home. We currently do not allow children (in the store). There is a limit of eight customers in the building at once.”

Smith says customers have been appreciative of the store restrictions and that she hasn’t seen much of a decline in business.

Karl Hinrichs, who runs distributor HK Laundry Equipment in New York state, updated customers via newsletter in April.

“I want to let you know that we are alive and well here in Westchester County, N.Y. You have been watching the news and reading the papers about the refrigerator trucks behind NY hospitals and how funeral homes are being overwhelmed. Well, that is all true. But from the COVID hot spot, the vast majority of us are surviving and doing OK with the ‘new normal.’”

Hinrichs recounted speaking to a Pittsburgh woman who imagined the worst in New York. “She was shocked when we told her that two of our installers caught the virus, stayed at home for two-plus weeks and are now back at work,” he wrote.

HK technicians are on the road, servicing laundry equipment just like they always have, but are now equipped for safety, according to Hinrichs. Office staff is working from home but the customer experience when calling is no different, he adds.

Every arriving customer is greeted by a Washtime employee who explains the rules. Anyone who doesn’t take the restrictions seriously is “invited” to leave.

“Feedback is 99% ‘Thank you’ and 1% ‘F-you,’” he says. “The folks who are not taking the situation seriously are now doing business elsewhere.”

Washtime personnel wear masks and gloves. Hand sanitizer stations are available in several spots. Store personnel wipe all contact surfaces with a 5% bleach solution.

Sitz made the decision to close on Wednesdays and said closing another day was possible depending on sales.

Adapting to the ever-changing situation has been challenging.

“I have been watching the progression very closely and have been ready each time that the rules change if we had not made the changes prior to the new recommendations,” Sitz says. “Some days, it felt like a day-old plan was obsolete!”

The pandemic and our nation’s response to it changes daily. It’s important that laundry owners continue to follow the appropriate recommendations for safety and service while also showing flexibility when circumstances allow for it.

10 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

ACO

(Photo: © CascadeCreatives/Depositphotos)

Over 120,000 Parts IN STOCK & READY TO SHIP YOUR ONLINE PARTS SUPERSTORE Fast & Free Shipping on Most Orders Over $99 • Selling Laundry Parts Nationwide for Over 59 Years (800) 328-1974 • parts@bdslaundry.com

Here for our customers The

ESD® is honored to support an industry that provides a critical and necessary service to those who need clean laundry. We want to thank those Laundromat store owners who have remained open for business in these difficult times and let you know that ESD® continues to support your efforts.

To show our support, ESD® would like to provide every card operated store owner with 500 generic money cards, either Vanilla (plain white) or generic print, at no charge. Personalized and custom money cards are excluded from this proposal. This offer is valid for both magnetic stripe and embedded chip money cards and is limited to a maximum of 500 cards per store owner, regardless of the number of stores or licenses utilized.

All card orders redeemed from this ad must be received by ESD® no later than the print date. ESD® will process and produce orders when time and resources Please contact ESD® with your store and license information for processing by e-mailing sales@esdcard.com, faxing to 215-643-4623, or calling 800-523-1510.

COVID-19

changed

our

www.esdcard.com Toll Free: 270 Fort Diamond Center Plus 5 TM DeskTop VTM TM Super Diamond Center 5 TM ClearView - W TM “SLIM” TM “SLIM 2” TM ClearView TM Value Adder Plus

pandemic has forever

all of

lives.

than 45 days from resources are available. by customers so that you can be there for yours. ©ESD Inc. All Rights Reserved www.esdcard.com Phone: 215-628-0860 Free: 800-523-1510 • Fax: 215-643-4623 270 Commerce Drive, Suite 101 Fort Washington, PA 19034

Learning to Delegate: Less Day-to-Day = More Business-Building

by Bruce Beggs, Editorial Director

by Bruce Beggs, Editorial Director

In a small-business setting like a laundry, where there can be many tasks but only limited manpower to complete them, the owner who learns to delegate certain responsibilities to others when possible can ease his or her daily burden and create opportunities to further build the business and plan for the long term.

It brings to mind a familiar phrase: work on the business, not in the business.

“My employees are better than I am at the basic job,” says James (Clark) Sowers, who owns four Laundromats and two dry cleaners in and around Rapid City, South Dakota. “But it is important for me to do what I am supposed to do: build business.”

Adding son Randy Sowers as chief operations officer freed him to do just that.

“When Randy came on board, I could trust him completely,” he says. “I knew he would be with me through thick and thin.”

Sowers gave his son the freedom to implement a greater management plan: “He has had more experience working for others than I have and has a better perspective on managing, and is very skilled on many things I am not. Allowing him to train and educate managers helps us to free ourselves of day-to-day tasks.”

Sowers admits feeling like he’s “lost touch with the ‘pulse’ of the company” and that he can’t answer every question in the business.

“But I believe the freedom to be a mentor, teacher and guide is greater for me.”

He continues to handle one chore himself—hiring and firing, though he does consider input from his son and store managers.

Dave Menz owns and operates a chain of four retail Laundromats plus a laundry pickup/delivery service in Cincinnati, Ohio. He’s been in the industry since 2009 and intimately involved in business operations since day one. Today, he employs roughly 50 people.

“All the things that all of our positions in our entire store do, I have either done myself or … I’ve created the positions as we’ve grown as a company,” he says. “I’ve been the one documenting things, making checklists, making cheat sheets. ... A lot of times, (my attendants) think I’m disconnected from the business because I’m not working in the store 40 hours a week but they don’t realize that the entire foundation, it’s all come from me.”

Even when Menz maintained a full-time job while managing his first store, it was always his intention to build a team through training and attractive compensation: “My thing was, I didn’t want to own a job, I wanted to own a business.”

His general manager, Marlene Adams, oversees the stores and pickup/delivery. She’s worked for Menz for eight years.

“When I brought her on, she was a very high-character person, very hard-working person. Anything else beyond that, compared to what she is today as a GM, I’ve taught her. But she’s the type of person that will take it out of your hand and say, ‘Don’t show me, let me do it while you’re standing here.’”

14 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

▼

PROGRAMMER TIMER $399.99 Each. List Price $677.21 KEYBOARD $59.99 Each. List Price $111.38 DIAPHRAGM $1.99 Each. List Price $7.11 BELT L1075 $26.99 Each. List Price $47.47 TEMP PROBE NTC $10.99 Each. List Price $19.62 WWW.LCPARTS.COM (800) 845-3903 During June, most orders received by 3pm CST will be shipped same day. Phone orders only. Up to 20 lbs. Does not include oversized items. WE SELL PARTS FOR : HUEBSCH, SPEED QUEEN, CONTINENTAL, DEXTER, ALLIANCE, WASCOMAT, GE, UNIMAC, MAYTAG AND MORE Call Us At 1-800-845-3903 | These Prices Are Also Available At Our Web Store www.lcparts.com | Open Monday - Friday 8am to 5pm | Sales price cannot be combined with any other o er *Free shipping excludes baskets, trunnions, some motors and oversized packages. Please call for details (Some sale items limited to quantities on hand) *Prices subject to change without notice, O er valid until June 30th. $7.99 FLAT RATE SHIPPING EVERY THURSDAY EXPIRES 0 /3 /2020 ADC PARTS P/N 348524 P/N 129288 4 TRACK VALVE 12V $33.99 Each. List Price $58.57 P/N 323311 P/N 348979 P/N 300202 GLO BAR 80V $9.99 Each. List Price $23.79 P/N ADC-128910 1/4 SENSOR TEMP/PROBE $29.99 Each. List Price $44.23 P/N ADC-880251 BELT FOR STACK DRYER $19.99 Each. List Price $85.41 P/N ADC-100173G SE HABLA ESPANOL P/N 193862 All Orders Over $250 RECEIVE FREE DELIVERY UP TO 20 LBS* Please call for pricing. 40%OFF LIST PRICE KIT HANDLE SWEEPSHEET KIT P/N F730155 P/N 430884P RELAY 24V IGNITION CONTROL P/N M406789P DOOR SOLENOID P/N F300128P PUMP P/N 201566P ROLLER ASSY P/N 430019 P/N 70210901P Original/Limit 2 GREENWALD MG3000B COIN BOX 8" $25.99 Each. P/N 8-1270-42-6 UG800C COIN BOX $39.99 Each. P/N 8-1286-42-6 V8 COIN SLIDE $36.99 Each. P/N 20-00-000 QUARTERMASTER MECH 115V 10 MIN $141.00 Each. P/N 59-3200-15 V5 COIN SLIDE $33.99 Each. P/N 27-00-00 BLOW OUT SALE ON WHIRLPOOL & MAYTAG PARTS.

On a big-picture scale, Menz says he’ll always be involved in overseeing his “baby.”

“That being said, there isn’t any individual task in our company that I don’t have other people that have been built up to the point where they can do (it), and that includes payroll, collecting at the stores … making bank deposits.”

Wayne Meyer co-owns a pair of fully attended laundries in Lafayette, Indiana, with son Chris and daughter-in-law Chris; the senior Meyer now lives in Florida, and the younger generation handles day-to-day management.

Meyer built his first store in 1992 and opened the second three years later. The junior Meyer has been working in the stores since graduating from college in ’92.

“When we first moved to Florida (in 2003), my wife had a hard time delegating to our son to make sure he was doing things the way she would want them done,” Meyer says. “It was a training process to ‘cut the umbilical,’ let him get bloodied, but be there behind him to catch

him in case he did trip.”

Before he became a Laundromat owner, Meyer provided management consulting services to major companies, hospitals and other clients, both domestic and international.

“Having been in consulting, I knew we had to train people and trust people to do things on their own. We began delegating at a very early stage,” entrusting certain employees to open and close the stores among other responsibilities, he says.

“But the key with delegation is following up, because you don’t want them to think they can get away with this, that or something else if you’re not there.”

Computer systems in place allow Meyer to check on store operations anytime but he’s left the day-to-day stuff behind: “You have to delegate to have a life.”

Hank Walter owns Whale of a Wash, a West Virginia-based business operation that includes 10 Laundromats and three car washes. In the beginning, when he had no partners or employees, he “had to do everything” himself, he says.

He thinks some small-business owners might have trouble learning to delegate: “Everyone has a tendency to micromanage. It is normal to initially expect too much from those to whom you delegate tasks.”

Today, he’s delegating responsibility for everything except capital investment decisions to Anne Sechler, his daughter.

“My daughter is chief administrator now and a gift from heaven,” he says. “Trustworthiness is the hardest attribute to find in an employee, but it is essential to the delegation success formula.”

Walter favors analyzing the choice to delegate through three lenses: the hard cost offset saving, the functional cost saving, and the opportunity cost saving: “If you think your choice through this matrix approach, you should not get ahead of yourself or lose control.”

His last advice on the subject? Don’t tell anyone to do something that you can’t do yourself.

“From there, you will gain the respect of your employee and harvest the results of productivity that go along with it.” ACO

Scrub-a-Duds’ training process hasn’t varied greatly over the years, Meyer says. The only adaptations have involved learning the functionality of new or upgraded equipment or meeting the specific needs of commercial accounts.

LAUNDRY WORLD, SOUTH DAKOTA

James (Clark) Sowers owns four Laundromats in and around Rapid City, South Dakota, including Laundry World, Belle Laundromat, Spearfish Laundry and Dry Cleaning, and Sturgis Laundry and Dry Cleaning. Three of the stores are attended and offer WDF and drop-off dry cleaning. Also, there is pickup and delivery service for commercial customers such as hotel/motels, plus a route service to the southern Black Hills communities.

His son, Randy, is chief operations officer: “Everything runs through him, either down from me or up from our managers,” Sowers says. “He is taking care of accounts payable/receivable and payroll with our accountant, repairs, and general business operations.”

Each attended store has a manager. There is an “overall” manager under Randy who covers operations in Rapid City; the man-

ager of the Belle Fourche drycleaning plant oversees the Sturgis and Spearfish stores.

Attendants, once trained, generally work by themselves, with possible overlap if they are busy, Sowers says. Each are considered shift managers, because he expects them to manage themselves.

“(Training is important because it’s about) customer service,” says Sowers, whose Laundromat attendants also check in and tag in clothes for two drycleaning plants. “Does the candidate treat customers the way they want to be treated? Do they understand billing and charging the correct amount for the service? … Understanding

use of cleaning products, understanding care labels, inspecting pockets all need to be understood.”

New hires are first trained as attendants in a drycleaning plant for a week.

“If they can learn this, then we will send them to the Laundromat to be trained in operations there,” Sowers says. “We suggest they bring their own clothes and get them cleaned for free so they can understand pricing; the value of good, tight wash-dry-fold packaging; making sure packages are complete; our policies on WDF service, and to prioritize. There are store cleaning lists to complete as well.”

He says they tell attendants “it will take several months to be good. But a full year to understand exactly what it takes.”

As the business group grew, it became necessary to adapt training to keep things running smoothly: “Where before I could visit my stores during a morning round trip, with the acquisition of the Rapid City location and tripling the number on the payroll, adapting was a requirement.”

Sowers says training and learning are never-ending: “The secret is and will always be hiring good people who want to do good work. Who respect the effort it takes to get a business to the point where we can offer a job to someone.”

16 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

ACO

(continued from page 8)

(From left) Clark and Randy Sowers take a break inside Laundry World, described by Clark as the largest Laundromat in western South Dakota. (Photo courtesy Clark Sowers)

9379-183-012 Original Water Valve $48.50 each 9122-005-004 Soap Box $31.70 each 9539-479-009 Temp. Selector Switch $39.51 each 1.800.451.2676 or WWW.DANDMEQUIPMENT.COM Monday, Tuesday, Wednesday & Friday | 7:30 AM - 6:00 PM CST Thursday | 7:30 AM - 5:00 PM CST YOUR MIDWEST DEXTER PARTS & EQUIPMENT SOURCE. SERVING THE INDUSTRY FOR OVER 50 YEARS. Order parts online 24 hrs a day at dandmequipment.com/shop-online D&M Equipment Company KNOWLEDGEABLE PARTS STAFF | EQUIPMENT | GENUINE PARTS | SERVICE | FINANCING | CONSTRUCTION & DESIGN | QUICK DELIVERY 9732-258.001 Coin Accumulator Board $208.00 each 9571-362-001 Timer $173.91 each 9536-074-001 Door Lock Solenoid $62.61 each 9571-360-001 Reversing Timer $151.13 each 9857-134-001 Gas Valve $128.95 each 9501-004-003 Heat Sensor DL2X30 3.5” $30.92 each 9501-006-001 Heat Sensor Express 9.5” $35.31 each 9206-164-009 Dryer Glass Gasket $29.44 each 9857-116-003 Original IEI Board 3-Start $88.16 each 9576-207-008 Safety Shut-Off Thermostat $19.68 each 9108-095-005 Soap Box Lid $10.70 each 9892-015-001 Washer Door Lock Kit $79.04 each 9857-147-010 Stack Dryer Control Now Just $398.42 each GREAT SAVINGS ON VALUED ITEMS 9473-009-005 Computer Board A-Series Washer Now Just $379.11 each 9473-004-007 Computer Board V-Series Washer Now Just $379.11 each WE’RE IN THIS TOGETHER. WE’RE OPEN TO SERVE YOU DURING THIS TIME. SAVE 10% ON ORDERS OVER $250 PLACE YOUR ORDER TODAY 9576-203-002 Stack Dryer Hi-Limit Stat $19.68 each 9875-002-003 Electrode Ignition $26.43 each FREE FREIGHT ON ORDERS OVER $50 OVERSIZED ITEMS NOT INCLUDED Offer ends June 30, 2020.

A TRIO OF WAYS TO SET YOUR LAUNDRY APART

Not all laundry improvements need be complicated or require more labor. Some involve simple changes or additions to existing vended laundry equipment. Singly or comprehensively, they’ll work to set your laundry apart and generate more income per square foot.

OZONE SANITIZATION

In the right concentrations, ozone gas almost completely eradicates bacteria, superbugs and viruses from the wash. A microbe-free wash is important anytime, not just during a global pandemic like we are facing today. It’s also relatively simple to integrate an ozone system with the washers you already have on the floor.

These systems work by injecting ozone gas into the cold water supply of the washer. In addition to sanitizing laundry, ozone loosens fibers and breaks down and washes away soil and stains. Moreover, ozone results in cleaner laundry and requires less hot water, which helps lower utility costs.

Ozone sanitization can be used as a marketing hook to attract and retain both self-service and full-service wash/dry/fold customers. It’s also a way to differentiate a laundry from competitive vended laundries, apartment laundries and home laundries.

Heather

Valconesi, co-owner of Evans Express

Laundry Center in Evans, Colorado, attests that ozone delivers peace of mind.

“Our customers want to know that their laundry, and our machines, are sanitized,” she says. “They don’t have to worry about who used the machines before them, and the ozone leaves laundry fresh-smelling, bright and clean.”

AUTOMATIC CHEMICAL INJECTION

While not all vended washers have the capability to automatically inject detergents, softeners and disinfectants, some washers do. If your washers have this capability, then consider activating this feature, especially on larger machines.

There are new chemical injection products on the market designed specifically for vended laundries that automatically dispense specially formulated detergents, brighteners, softeners and disinfectants into compatible washers. They’re intended to provide excellent, consistent cleaning results in less time.

Using automatic injection on your biggest washers means customers don’t have to lug and manually load detergents. Even better? Simultaneously provide ozone in combination with automatic chemical injection for faster cycle times and higher profits.

Pearl Laundromat, in San Diego County, California, recently added automatic chemical injection to a 90-pound washer. Ever since, it’s turned 8 to 10 times per day during the week and 12-plus times per day on weekends, according to owner Mark Mariani.

WASHER CONTROLS

Finally, give customers more options and control over how they wash their laundry. There are two ways to do this: invest in new washers with controls offering extra wash options, or upgrade existing washer controls so they feature these “extras.”

Customers will appreciate customizing the wash process to better fit their needs, and as an owner, you’ll have the tools to make more money on every vend.

For example, Continental offers a control for vended washers that offers four

18 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

(From left) Pete and Heather Valconesi, owners of Evans Express Laundry Center in Evans, Colorado, chose washers with ozone injection to set their laundry apart. (Photos: Girbau NA)

Tod Sorensen

primary cycle options: “Superwash,” an extra-long cycle for heavy soil; “Hot,” for whites; “Warm” for colorfast and permanent press items; and “Cold” for colors. It also allows customers to add an extra wash, rinse and/or spin. Each time customers choose an “extra,” the vend price goes up — contributing to increased revenue. Plain and simple, if your washers don’t

offer extras, you won’t benefit from additional income.

Phil Irwin, owner of Waters Express Laundry Center in Tampa, Florida, maintains that customers enjoy these options.

“(The) ProfitPlus® (Control) has been a benefit for us,” he says. “Anytime you can offer customers more choices and options, it sets you apart from the competition. The control is absolutely impacting our bottom line. Customers select an ‘extra’ 28% of the time, and with each selection, pay an additional 50 cents.”

California vended, on-premise and industrial laundry markets. He holds more than 20 years of experience in vended laundry development and market analysis. You can reach him at tsorensen@cgilaundry.com or 866-950-2449.

At the end of the day, owners don’t have to make gigantic changes to realize the advantages. Start out with baby steps by outfitting one washer with automatic chemical injection, a new control and/or ozone. After a few months, analyze the impact of those changes on that machine’s daily turns and revenue. Then, assess whether it makes sense to expand to an aisle of washers or an entire store.

ACO

Tod Sorensen is a regional sales manager at Girbau North America and vice president of Continental Girbau West, a fullservice distributorship serving the Southern

www.americancoinop.com JUNE 2020 AMERICAN COIN-OP 19

77 Steamwhistle Dr., Ivyland, PA 18974 | E: info@acpowerco.com www.acpowerco.com THE BEST EQUIPMENT AVAILABLE AT THE BEST PRICES! The #1 Regional Distributor of Commercial Laundry Equipment, proudly serving businesses throughout Pennsylvania, New Jersey, Delaware, and Maryland for over 47-years! We are experts in Commercial Laundry Solutions. CALL US TODAY 800.362.1900 Repair Service Genuine Parts Laundry Equipment AUTHORIZED DEALERS FOR: ACO Standard_half_horz.indd 1 4/1/20 12:59 PM

The staff at San Diego County’s Pearl Laundromat, owned by Mark Mariani, reports being pleased with the results of a 90-pound Continental ExpressWash Washer with added automatic chemical injection.

competition.

(From left) Lois and Phil Irwin, owners of Waters Express Laundry Center in Tampa, Florida, say their Continental vended washers equipped with the ProfitPlus® Control are a real benefit to customers and have set them apart from the

Goodale

DOING LAUNDRY PROFITABLY IN A SMALL FOOTPRINT

Tiny houses, cabins and campers are all the rage. It’s all about downsizing your lifestyle and living a more fulfilling life without a lot of debt and “stuff.”

Along that same line, small-scale laundries often make perfect sense. If done correctly, small-footprint Laundromats can be as profitable as larger-scale operations.

INSIDE THE NUMBERS

Depending on the population, a small-footprint laundry in a metro area is about 2,000 square feet, in a more rural area 1,000-1,500 square feet. But just because they have a smaller footprint doesn’t mean you install smaller washing machines and dryers to fit the space. In many struggling small-footprint Laundromats, machines with low capacity and large utility usage are found taking up valuable floor space. Try to maximize space and capacity, and that means going with some larger-capacity equipment.

In fact, some smaller laundries in rural areas have had success with washer-extractors ranging in capacity from 40 to 60 pounds. The same can be said of dryers. You generally want larger dryers, such as 45-pound stacks and 75-pound singles. There is much debate about washer-to dryer ratios in the industry, but when working with small Laundromats, try to match pockets as much as possible.

In a metro area, include some 40-, 60- and even a few 80-pound washer-extractors. But if you’re retooling, you should include some 20-pound models, too, as they will help your customers adapt to the new equipment. To maximize throughput, the core of your equipment should be the larger-capacity machines.

LOOKING AT LAYOUT

Not surprisingly, the shape and size of your building will determine the equipment layout. For example, we’re working on a very narrow store. Another distributor had worked up a layout with 5 feet of space between the washer fronts and dryer fronts. We’re using extractor and tumbler combo machines to maximize the actual space and put in the same amount of equipment. The washer-extractor/tumble dryer unit also reduces customer movement in the store, an important benefit during the COVID-19 crisis when we are trying to limit customers’ time in the laundry.

At another small store of roughly 1,000 square feet, we put dryers on one wall and spread the extractors on two separate walls, giving the layout a U shape. That left the center open for a very large folding table.

With the coronavirus impacting every state, it is more important than ever to make Laundromats roomy. COVID-19 has made people uneasy, and they don’t want to be close to others. Go for a walk in your neighborhood and you’ll see people walk out onto the roadway to avoid being near you. It’s no different in a Laundromat.

People don’t want to be squeezing between people. People want wide walkways to come in and spread themselves out, not narrow aisles and machines that are too close to one another. Spreading things out can be a bit tricky, but it can be done, particularly when you keep in mind throughput vs. the total number of machines.

EYE ON DÉCOR

There are also things you can do within your building’s décor to make your Laundromat look larger. Adding in surfaces that reflect light will make your facility look roomier. Be sure people can see out of the windows and have clear line of sight to the doors. Add as much glass as possible. Higher ceilings can also help make buildings look larger.

A lighter-colored paint can also help a building look larger. The lighter the color, the better, particularly if a building has a lot of windows and natural light.

20 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

(Image licensed by Ingram Image)

Jared Mueller

Andy

THE BASICS

Whether your laundry is big or small, make sure you have adequate parking and that it is visible from the street — it’s all the basic things you see in large stores that you still want in small ones. Cleanliness is also important, no matter whether your Laundromat is large or small. For many customers, cleanliness is a top priority when they decide which Laundromat to use.

But you also need to ensure that your machines are always in order, if you are to maximize your profit. If a laundry doesn’t have an attendant—and not many small stores do—then you need to have a phone number that people can call to reach someone immediately with their question or comment. Calls going to voicemail just irritate customers, and that can mean they may not come back to your store.

It’s also important to offer multiple payment options. Coin alone will limit your revenue potential, so be flexible in what payment options you offer, be it cash, cards, apps or whatever. In fact, going cashless for payment can pay for itself quickly.

FINAL COMMENTS

While it’s difficult for a small-footprint facility to offer wash-dry-fold and still be profitable, it can be done with sufficient planning. It takes a lot of space, and you will really need to manage the times your employees will be doing WDF work there if you are to make money. You certainly don’t want to be doing it during your busiest times.

With the pandemic likely causing some businesses to close, there will be some opportunities to open new laundries. Dry cleaners lend themselves well to being converted to laundries. Not only is the size of the building usually ideal, but people already think of the building as a place to

clean their clothes, blankets or comforters, so converting the building to a laundry makes obvious sense.

ACO

ACO

Jared Mueller is chief operating officer at Coin Meter Co., a Speed Queen laundry equipment distributor in Oregon and southwest Washington. He’s been in the industry for more than 20 years.

Andy Goodale is a Laundromat and OPL salesman for Cleaning and Laundry Equipment, a Coin Meter Co. company. It distributes Speed Queen equipment for Laundromats, hotels/motels, nursing and care facilities, athletic facilities and fire stations in Oregon and southwest Washington. He’s been in the industry for more than 20 years.

www.americancoinop.com JUNE 2020 AMERICAN COIN-OP 21 Dedicated Hands-on Distributors voted “TOP-RATED DISTRIBUTOR NETWORK” in Commercial Laundry * Let us help with your Laundromat BEST WEST IN THE NV 800-915-4311 W TX & NM 800-750-1841 westequip.com WA, OR, ID, MT 509-459-4300 cozzettocommercial.com Southern CA 877-630-7278 acelaundry.com AZ 602-248-0808 cpec-laundry.com UT, MT, NV, WY 801-912-0061 rhinolaundryequipment.com Central CA 800-488-2526 alcoservices.com STAY CONNECTED. RUN YOUR BUSINESS FROM ANYWHERE...ANY TIME. *According to an August 2014 Leede Research Customer Value Analysis on Overall Distributor Quality Your SMART Laundry Partner 0420aco_Distributors Network_rev.indd 1 3/10/20 12:25 PM “With the coronavirus impacting every state, it is more important than ever to make Laundromats roomy. COVID-19 has made people uneasy, and they don’t want to be close to others.”

22 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com WASCO GEN 5 DOOR LOCKS & TIMERS REBUILT Door Lock $75 • Gen 5 & 6 Timer $85 WASCO Gen 4 Timer $85 • Continental Timer $95 DRYER COMPUTER BOARDS ADC Stack $60 • Single $45 Huebsch SQ Board $45 Huebsch Old Style Board $55 Stack Dexter/Continental $75 Washer Coin Boards $65 Some prices may vary!!!! JECON INC. THE UPS STORE 204-17 HILLSIDE AVE. # 394 HOLLIS NEW YORK 11423 One-Year Warranty on All Parts Send Core Unit with S&H Fees Call Toll Free: 1-888-532-6677 (888-JECON77) Local: 718-525-3733 • Fax: 212-656-1913 718-525-2266 Visit: JECONINC.COM We Now Accept All Major Credit Cards CLASSIFIEDS EQUIPMENT WANTED I BUY LAUNDRY EQUIPMENT 954-245-2110 Why haven’t laundry owners added credit card acceptance on their washers and dryers? • They Say It’s Unaffordable • They Think There Are Too Many Choices • They Heard It’s Difficult to Install and Use CryptoPay answers ALL of these concerns. To see how, give us a call! 719-822-0294 www.getcryptopay.com/laundry.php (800) 446-2719 imonex.com COIN DROP for a Buck & a Quarter EQUIPMENT FOR SALE PAYMENT SYSTEMS EQUIPMENT FOR SALE SERVICES AND SUPPLIES ELECTRONIC REPAIRS DRYER BOOSTER & EXHAUST FANS BUSINESS OPPORTUNITIES Repair Front Load WASHER Bearings. Rebuild drums available. Call Tony: 516-805-4193 Used Dexter Equipment Visit us at www.centurylaundry.com EQUIPMENT REPAIRS 18 Select Laundry Center Vending Machine Sales 515-480-4613 www.vendingmachinesales.com Add pro t to your establishment by vending your patron’s favorite laundry goods. POSITIONS AVAILABLE Experienced Vended Laundromat Sales Representative needed for our North Carolina, Southern Virginia and Eastern South Carolina territory. Previous Vended or OPL sales preferred. Please forward resume to sales@tlctristate.com Check Out More Listings ONLINE www.AmericanCoinOp.com

www.americancoinop.com JUNE 2020 AMERICAN COIN-OP 23 WASHERS and DRYERS COMPUTER BOARD REPAIR Dexter VFD Inverter (Delta Motor Control) All Models (9375-xxx-xxx) $245.00 VFD-A & VFD-B (9732-237-001) . . . . . . . . call Stack Dryer (9875-xxx-xxx) . . . . . . . . . $65.00 Coin Accumulator . . . . . . . . . . . . . . . . $65.00 Igniters (Fenwal only) . . . . . . . . . . . . . . $40.00 Wascomat / Electrolux Inverters (MotorControl) All $245.00 471977101,105,115 . . . . . . . . . . . . . . . . . call Emerald Selecta Gen. 6 Washer Main Computer PCB $175.00 Emerald Selecta Washer Door Lock Control PCB $75.00 Compass Control Assembly Gen. 6 . $125.00 Selecta II Dryer PCB Assembly $155.00 Maytag Computers . . . . . . . . . . . . . . . . . . . . . $65.00 23004118 . . . . . . . . . . . . . . . . . . . . . . . . . call W10343020 . . . . . . . . . . . . . . . . . . . . . . . call ADC 137213, 137234, 137240 . . . . . . . . . . $65.00 137253,137260,137274,137275. . . . . . . . call Igniters (Fenwal only) . . . . . . . . . . . . . . $40.00 Speed Queen / Huebsch Computers . . . . . . . . . . . . . . . . . . . . . $65.00 Motor Control . . . . . . . . . . . . . . . . . . . . . . call IPSO 209/00440/70 (Micro 20). . . . . . . . . . $125.00 Volume Discounts • One-Year Warranty Free Return Shipping El- Tech, Inc. 26 West St. Colonia, NJ 07067 For Complete Price List Please Call: 908-510-6520 or visit us at www.eltechlab.com SINGLE-COPY SALES To order any current or back issue of American Coin-Op by phone, or to subscribe, call our circulation customer service department at: 1-630-739-0600 www.AmericanCoinOp.com CLEANERSUPPLY.COM WASH N’ FOLD BAG $349 LOWEST PRICE WB-5*SP1 American Coin Op Ad.indd 1 2/6/20 11:27 AM SERVICES AND SUPPLIES SERVICES AND SUPPLIES SERVICES AND SUPPLIES www. AmericanCoinOp .com TIMERS REBUILT — IPSO main & reverse, Dexter, Primus, Speed Queen, Maytag & Continental Girbau, Wascomat Generation 4, 5 and 6. Reeco Timer Co., 1855 Union Blvd., Ste A Bay Shore, NY 11706 631-498-6999 Contact classified sales to place your ad! classifieds@atmags.com AC Power ................................................ 19 ACE Commercial Laundry Equipment .........21 American Switch ...................................... 23 BDS Laundry Systems............................... 11 CleanCloud 3 Cleaner’s Supply 23 Continental Girbau 1 CryptoPay 22 D&M Equipment 17 ESD Inc. 12-13, BC Gold Coin Laundry Equipment 7 HHC Electronic Service 23 Imonex Services ........................................ 22 Laundry Concepts 15 LG Electronics IBC Metro Laundry Tech Corp. 23 Mountain Electronics 22 NIE Insurance ............................................ 9 Setomatic Systems ................................. IFC Tjernlund Products 22 Vending Machine Sales 22 Vend-Rite 5 WASH Commercial Laundry 22 Advertiser Page Advertiser Page ADVERTISERS’ INDEX

GIRBAU

NA NAMES FOWLER, SPARKLE ITS 2019 DISTRIBUTORS

OF YEAR

Girbau North America (GNA) recently honored Fowler Laundry Companies, Union, New Jersey, and Sparkle Solutions, Concord, Ontario, Canada, for their outstanding sales and service.

Fowler earned 2019 Distributor of the Year honors in both the vended laundry and the multi-housing laundry markets. Sparkle was named the Canadian Distributor of the Year for a third time.

Fowler is a full-service company and one of the largest laundry equipment distributors in the Mid-Atlantic region.

“Everything is done really well at Fowler, especially in the vended and multi-housing sectors,” says GNA Vice President of Sales Joel Jorgensen. “A regional powerhouse for years, Fowler does a great job capitalizing on the LG and Econo washer/dryer brands for multi-housing customers and discovering profitable solutions for their vended laundry partners with the Continental, Express Laundry Center and Express Clean brands, in one of the world’s most competitive markets.”

Sparkle Solutions, managed by Ray Helwig, serves on-premise, multi-housing and vended laundry markets within its Canadian territory of Ontario. The distributor works closely with laundries to cut utility costs and maximize profit through expertise on energy conservation, equipment and technical services.

“The Sparkle Solutions team is extremely versed in all aspects of vended, multi-housing and on-premise laundry development, productivity and efficiency,” says Jorgensen. “They are perpetual performers because of their dedication to customers and service after the sale.”

JETZ SERVICE ACCEPTING MOBILE PAY ACROSS COMPATIBLE MACHINES

Laundry service and equipment provider Jetz Service Co. has signed an agreement with PayRange Inc. to provide mobile payment acceptance across its entire fleet of compatible machines. Previously, Jetz had PayRange available in 60% of its machines.

The economic fallout from the COVID-19 pandemic motivated Jetz to accelerate plans to enable its remaining machines to accept mobile payment, PayRange says. Consumers who are spending much of their time daily in their homes are finding it increasingly difficult to find change for the essential service of laundry, the company adds.

The shutdowns related to the pandemic have made access for collections and service difficult, putting a strain on cashflow and raising safety concerns for operations teams.

“In the current COVID-19 climate, without PayRange on so many of our machines, we’d be losing revenue and facing unhappy customers,” says Scott Schenk, Jetz’s chief financial officer. “Many card customers are also transitioning to PayRange now that building management offices, where most card kiosks are located, are closed.

“We’re also able to engage with our end-users directly, offering them discounts, letting them know that we’re there for them during this national crisis where clean laundry is a public health issue. Getting our entire operation equipped with PayRange where possible is a top priority.”

Jetz Service provides laundry service and equipment to apartment communities, colleges and universities, retirement communities, hotels/motels, trucking plazas, campgrounds, dry cleaners

and Laundromats on a lease or sales basis in 18 states throughout the Midwest.

In March, PayRange added features allowing end-users to continue to do laundry even if they have a negative balance, and for machine operators to instantly transfer their mobile payment settlements on demand to a debit card 24/7.

The new end-user feature inspired Jetz to offer a discount through the PayRange platform, offering some relief for people who may have more laundry to do than normal.

HAPPYNEST BROADENS EXPANSION THROUGH NEW PARTNERSHIPS Tech-enabled laundry pickup and delivery service HappyNest continues to expand with the additions of several U.S. locations, the company reports.

HappyNest has partnered with the following laundry owners in the last few months to add residential pickup and delivery service to their walk-in business:

• Atukwe Newell and his family own and operate two Bubbleland locations in Chicago and own the trademark and rights to the Bubbleland name.

“We have provided pickup and drop-off service to customers for years, and by that I mean we literally pick people up with their laundry and bring them to our Laundromat to do their laundry and we bring them home, but we knew there was another type of customer that we weren’t servicing,” says Newell.

• Mykal Tairu, owner of Midtown Laundry Service in Daytona Beach, Florida, has been in the laundry industry for four years, operating a small commercial space for drop-off service and providing commercial pickup and delivery to the local market.

“I have had success in the commercial laundry delivery space since I started and planned on expanding into the residential market when the time was right. Fortunately, the time is now and HappyNest helped me realize that,” says Tairu.

• Luke Bland has worked in the laundry industry for seven years and owns two Laundry Luke’s locations in the St. Louis suburbs of St Peters and Bridgeton, Missouri.

“I recently launched a drop-off service in my St. Pete’s store and had plans to start a delivery service but wasn’t confident in the consumer demand until I heard about what HappyNest has done so far in the area,” says Bland. “When I heard the number of people that had already signed up for the service and everything the HappyNest team provides, I knew I had to get on board.”

• Joe Jurevicius, former NFL wide receiver, has joined forces with HappyNest to provide a wash-and-fold service with delivery in Cleveland.

Jurevicius played 11 years in the NFL, winning a Super Bowl with the Tampa Bay Buccaneers. After retiring from football following the 2007 season, he embarked on a career in the laundry business. Jurevicius and his business team now own and operate two stores under the Spins Quick ’N Fresh banner, two more under 4th Quarter Laundry, and a commercial laundry division called CLEan.

“Our commercial business has been very successful since starting the service a few years ago,” Jurevicius says. “After hearing about HappyNest, I knew that it would be something we’d do really well with and it was worth looking into.”

NEWSMAKERS 24 AMERICAN COIN-OP JUNE 2020 www.americancoinop.com

ACO

WE’RE COMMITTED TO YOU

During these challenging times, LG’s commitment to providing you with unrivaled energy efficient, quality equipment stands stronger than ever. Our commercial laundry equipment offers advanced programmability of water temperatures, fill levels, cycle times, spin speed and vend prices. GCWL Series Washers feature an easy-touse tub cleaning system equipped with a heater. Unique to the market, this system can heat water up to a target temperature of 158°F — crucial now and into the future. In times like these LG is here to support you. Always has been and always will be.

Contact us at 800.256.1073 or visit cgilaundry.com/lg

0% Financing 90 Days No Payments* *Contact us for details.

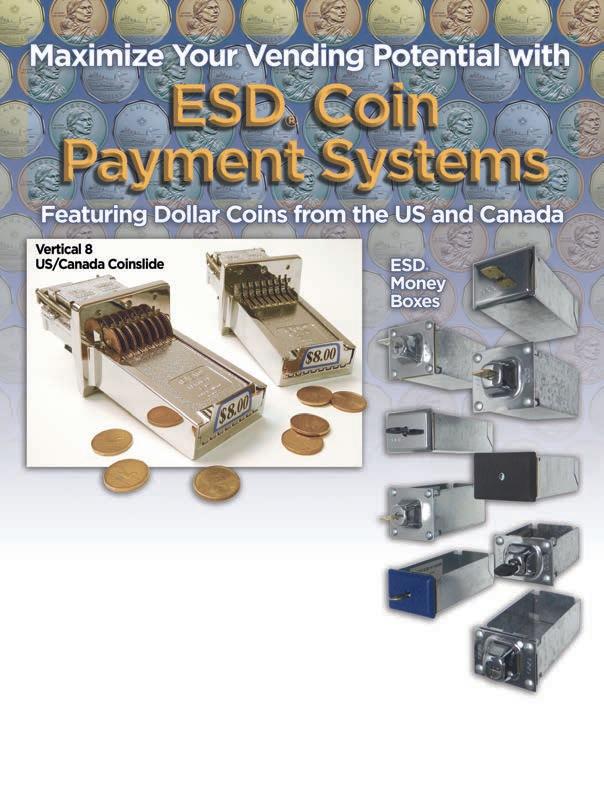

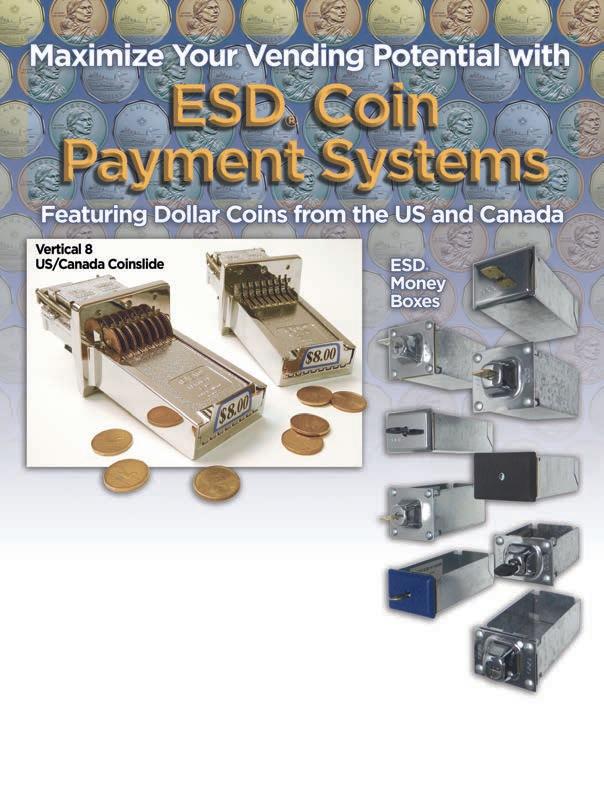

ESD leads the industry in bringing a wide selection of time tested and proven slides, money boxes, locks, key shafts and cams for any laundry or vending application. ESD products are available for Immediate Delivery Contact Your ESD Distributor or visit us at www.esdcoin.com ESD Inc. All Rights Reserved

by Bruce Beggs, Editorial Director

by Bruce Beggs, Editorial Director

by Bruce Beggs, Editorial Director

by Bruce Beggs, Editorial Director

ACO

ACO