® Nov/Dec 2014 © Copyright 2014 American Trade Magazines All rights reserved. Fabricare & Fashion 2014 Experts Advise How to Handle New Fall Styles

Maineline Computer Systems 1-800-354-2525 www.compassmax.com Emailing so advanced, it's simple. • Customer Service Manager • Unlimited Price List Options • Automated Email Marketing • True Touch Screen or Keyboard Interface • Credit Card Integration • Accounts Receivable • Multiple Auto Assembly Integration Options • Cash and Inventory Control • Customer Loyalty Programs • CSR Alerts • Pick Up and Delivery • Multi Store Capabilities Is your business heading in the right direction? Dynamic Emailing: Compassmax can create unlimited user defined automatic emails with HTML graphics. Options include new customer emails, lost customers emails, notifications when orders are ready, garment pictures, birthdays or anniversaries wishes and more!

Perc users – chlorinated solvent belongs in your machine, not on your board. Alternative solvent users – use stain removers that align with your chosen solvent. Replace traditional POG’s and VDS’s with TarGo® EF and EasyGo®, two of Wilson’s high-performance, cost-effective, California-compliant stain removers. You'll be taking steps to avoid future regulatory and remediation nightmares, while providing your customers with the garment quality they desire!

EasyGo spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to TarGo EF to remove any tough oil based stains that remain behind.

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

Time to Remove

From Your Board! Embrace Your Environmentally Friendly Future with Stain Removers from A.L. Wilson

It's

Chlorinated Solvents

STAIN

at

GreenEarth is a trademark of GreenEarth Cleaning, LLC.

Become a

WIZARD

ALWilson.com For GreenEarth,® use ||G|| Go®

2 American Drycleaner, November/December 2014 www.americandrycleaner.com

AMERICAN AMERICAN Nov/Dec 2014 Vol. 81, No. 8 DEPARTMENTS Pre-Inspection 4 Talk of The Trade 6 The Numbers 10 Management Strategies 18 Attract Fashion Influencers with Specialized Services Diana Vollmer Events Calendar 23 Spotting Tips 26 Sweaters Bring Extra Cash, but Be Cautious Martin Young Industry Observations 40 Learn Every Job in Your Plant

Scott Education & Training Calendar 43 Your Money 46 Retirement: Don’t Outlive Your Money Bill Lynott Around the Industry 50 Classified Advertising 58 Advertiser Index 62 Wrinkle in Time 64 FEATURES

drycleaner

Howard

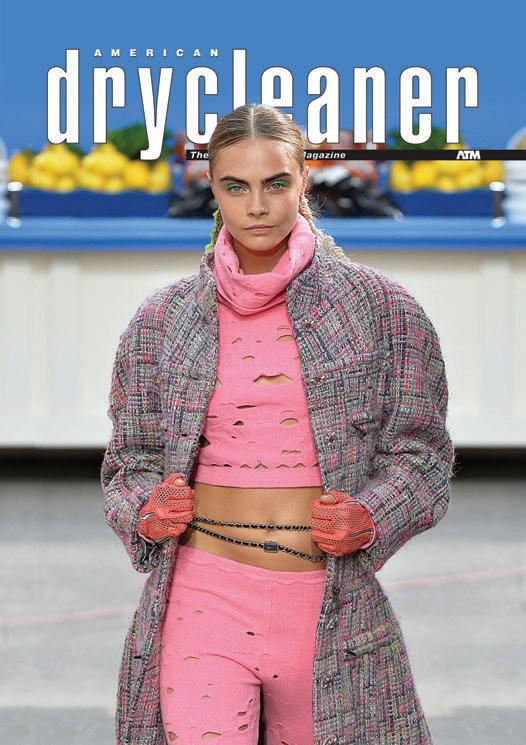

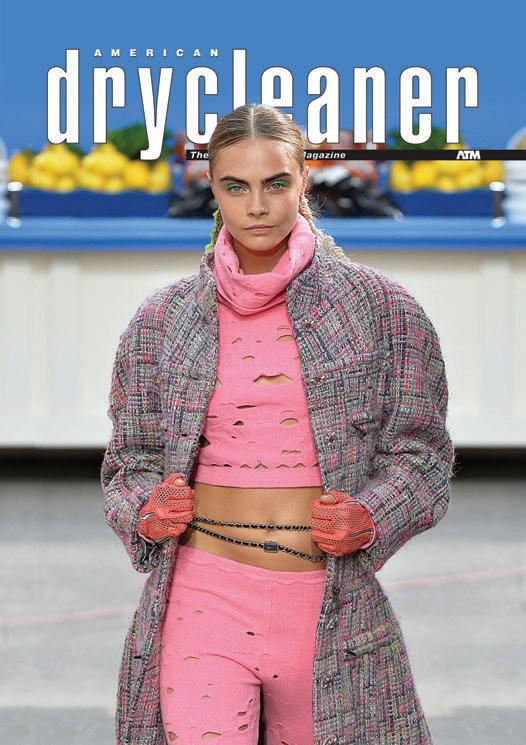

12 Fashion & Fabricare 2014: Could the Outrageous Be Coming to Your Plant? Tips for cleaning garments that emulate fall’s most outré outings Ian P. Murphy 28 Milan’s EXPOdetergo Draws 20,000 A 21% boost in foreign attendance proves trade show’s ‘global leadership’: manager 32 Arrow Fabricare Services Turns 100 Kansas City-based company recounts history, growth through diversification 36 Quick Fixes to Common Problems (Pt. 1) DLI’s Brian Johnson describes how to solve some everyday drycleaning dilemmas Bruce Beggs NEED HELP FINDING THE HIDDEN HANGER? Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck! 12

(Photo: firstVIEW)

“Business has never been better.”

Since 2003, CBS has given me consistent updates and easy to understand tech support, all at a price that our industry can afford. I would recommend CBS, and I have, to anyone who is still wasting their time and money on those over priced POS systems. DanLoesher SunshineCleaners

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

Pre-ins P ection

Fashion & Fabricare

Fall’s runway collections had more than a little of the outrageous this year, reports Ian Murphy. Couture labels known for feminine elegance flaunted sporty street styles, architectural capes, or “extreme turtlenecks.”

match patterns, loud prints, big logos and provocative sayings.

• “Swinging ’60s,” including miniskirts, thigh-high boots and shift dresses emphasizing op-art patterns and retro-futuristic accents.

Bruce Beggs

The haute couture originals may not appear in drycleaning plants anytime soon but gar ments emulating them likely will. Watch for these “looks”:

• “Streetwear,” includ ing brightly colored, form-fitting and sporty outfits that feature mix-and-

Publisher Charles Thompson 312-361-1680 cthompson@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

• “Knit To Be Tied,” featuring head-to-toe knits, many that drape all the way to the floor.

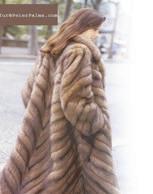

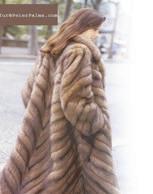

• “Fantasy Fur,” always a fall runway staple. This year’s furs arrived in oversized, multi-colored patchworks of alpaca, shearling, fox and astrakhan.

Read Ian’s complete report starting on page 12. O

Main: 312-361-1700 Fax: 312-361-1685

Contributing Editors

Howard Kaschyk Carolyn Nankervis Howard Scott John Spomar Jr. Diana Vollmer Martin Young

SUBSCRIPTIONS 630-739-0900 x100 www.american drycleaner.com

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies $7.00 for U.S., $14.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 81, number 8. Editorial, executive and advertis ing offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. No material appearing in American Drycleaner may be reprinted without written permission. The publisher reserves the right to reject any advertising for any reason. © Copyright AMERICAN TRADE MAGA ZINES LLC, 2014. Printed in U.S.A.

American Drycleaner, November/December 2014 www.americandrycleaner.com

4

About Iowa Techniques Iowa Techniques is a manufacturer and distributor of unique products that work in a wide variety of industries and applications, and currently focuses on helping dry cleaners make smart choices that impact the bottom line in their plant operations. When your water heater dies, DON’T replace it! Get a DynaFluid 2000 from Iowa Techniques! Getting Steamed? (800) 727+1592 | www.iowatechniques.com With steam from your boiler and a cold water source, this little valve makes an infinite supply of hot water. It outperforms water heaters by every measure, cutting costs and increasing productivity. Call Iowa Techniques today and learn how the DynaFluid Valve will help your business! ASK MATT! (800) 727+1592

Survey: Many dry cleaners give perc another 10 years or less as viable solvent option

CHICAGO — In light of the regulatory environment, roughly 69% of dry cleaners believe that perchloroethylene—perc—will no longer be a viable solvent option for the average operator within 10 years, according to results of October’s American Drycleaner Your Views survey.

Of that group, 35.6% believe perc has another five years while 32.9% is giving it 10 years.

Approximately 15% say perc will remain a viable drycleaning solvent option “indefinitely.” Roughly 12% give it 15 years, and 4.1% give it 20 years.

Roughly 49% of respondents say they use perc. Other solvents in use include high-flashpoint hydrocarbon (34.2% of respondents), petroleum (16.4%), GreenEarth (D5 silicone) (9.6%), and SolvonK4 (6.8%).

A share of cleaners (8.2%) also use “other” solvents not on the list provided within the survey, including DF-2000, DWX-44, and water.

“Perc is still the very best all-around solvent,” writes one respondent. “The horror stories are most generally from incidents that occurred before regulations on handling and disposal, and

* No one (0%) selected liquid CO2, Solvair, DrySolv (n-Propyl Bromide) or Rynex (glycol ether) when answering these questions.

6 American Drycleaner, November/December 2014 www.americandrycleaner.com TALK OF THE TRADE ▲

even containment systems, were in place. Perc is the single most investigated and regulated solvent in existence.”

“Dry cleaners need to be flexible,” urges another respondent. “As perc is phased out, we need to understand that the customer still expects clean, spot-free cleaning. We must become better at stain removal in or der to maintain these standards.”

“All the alternative solvents have some kind of environmental impact,” writes a third. “None can be consumed or poured down the drain. Even water has its prob lems, due to shortages in many parts of the country and world. Education of the con sumer and the politicians is the key to keep ing our industry strong and viable no matter the solvent choice.”

Dry cleaners were asked which solvent system they expect to use in the next dry cleaning machine they buy. The majority say high-flashpoint hydrocarbon (28.6%), while other popular choices are GreenEarth (17.8%), SolvonK4 (13.7%) and petroleum (9.6%). A stubborn 9.6% say they’ll stick with perc. Approximately 21% of respon dents say they do not plan to buy another machine.

Wet cleaning has become an important alternative for cleaning clothing, and 85% of those surveyed process at least some garments using professional wetcleaning techniques.

While American Drycleaner’s Your Views survey presents a snapshot of the trade audience’s viewpoints, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Drycleaner e-mails are invited each month to partici pate in a brief industry survey they can complete anonymously. O

Topstories@www.AmericanDrycleaner.com forthe30daysendingOctober15

TOp News sTOries

1. The EJ Thomas Co. Acquires M&L’s Supply Business 2. Pressed 4 Time Added to Growing Franchise Network 3. Kreussler’s SYSTEMK4 Receives U.S. Patent Approval

TOp cOlumNs & feATures 1. Do They Clean UGG Boots in Australia?

Working with Wools and Silks

Use Empathy to Defuse Unhappy Customers

Passing On Your Drycleaning Plant

StatShot: West Posts Largest Gains in August Drycleaning Sales... web eXclusiVe!

TOp sTOries @ Our sisTer siTes www.AmericancoinOp.com:

Replace Equipment, Increase Profits

Electrolux to Acquire GE Appliances web eXclusiVe!

Attitude Check

What It Takes to Go Commercial www.AmericanlaundryNews.com: 1. CDC: Forgo Laundering Ebola Patient Linens, Discard as Regulated Medical Waste

Business Opportunities in Hospitality: The Role of a Business Plan

Lapauw International Opens U.S. Subsidiary, Adds Leadership

www.americandrycleaner.com

8

November/December 2014

American Drycleaner,

2.

3.

4.

5.

1.

2.

3.

4.

2.

3.

Time to Switch?

Not satis ed with your point of sale computer hardware and software? Move to Fabricare Manager’s a ordable, reliable and secure system. You (and your customers) will be happy you did. Just tell us you’re ready to make the change. Or, If you’re not yet using a POS, why not start with the best?

fabricaremanager.com • 888.249.5142 Drycleaning Management at Your Fingertips Fabricare

Manager

THE NUMBERS

THE U.S. EMPLOYMENT rate fell to 5.9% in September, its lowest level since July 2008. “The nation’s economic recovery continued in September with the addition of 248,000 new jobs,” says U.S. Secretary of Labor Thomas E. Perez. “It was the 55th consecutive month of privatesector job creation, during which time businesses have created 10.3 million jobs. In 2014, we have experienced the most robust year-to-date private-sector job growth since 1998.”

IN THE BEIGE BOOK issued Oct. 15, reports from the 12 Federal Reserve Districts generally described modest to moderate economic growth at a pace similar to that noted in the previous Beige Book. Cleveland, Chicago, St. Louis, Minneapolis, Dallas and San Francisco districts reported moderate growth, while modest growth was reported by the New York, Philadelphia, Richmond, Atlanta and Kansas City districts. Most districts reported overall growth in

consumer spending that ranged from slight to moderate.

Several district reports indicated that retailers were relatively optimistic about the remainder of the year. Meanwhile, tourism activity remained upbeat in several areas, with some reports of higher occupancy rates and solid advance travel/lodging bookings.

MORTGAGE APPLICATIONS for the week ending Oct. 10 increased 5.6% on a seasonally adjusted basis from a week earlier, according to the Mortgage Bankers Association (MBA).

“Growing concerns about weak economic growth in Europe caused a flight to quality into U.S. assets,” which led to sharp drops in interest rates, says MBA Chief Economist Mike Fratantoni. “Mortgage rates for most loan products fell to their lowest level since June 2013. Refinance application volume reached the highest level since June 2014 as a result, with conventional refi-

nance volume at its highest since February 2014.”

THE CONFERENCE BOARD’S Consumer Price Index ® , which had increased in August, declined in September. As of Sept. 30, the Index stood at 86.0, down from 93.4. The Present Situation Index fell to 89.4 from 93.9, while the Expectations Index dropped to 83.7 from 93.1.

“Consumer confidence retreated in September after four consecutive months of improvement,” says Lynn Franco, director of economic indicators at The Conference Board. “A less positive assessment of the current job market, most likely due to the recent softening in growth, was the sole reason for the decline in consumers’ assessment of present-day conditions.

“Looking ahead, consumers were less confident about the short-term outlook for the economy and labor markets, and somewhat mixed regarding their future earnings potential.” O

—Bruce Beggs

10 American

November/December 2014 www.americandrycleaner.com

Drycleaner,

Our new generation of Point Of Sale system is designed for both small and larger cleaner stores. DryClean PRO Enterprise (DCPe) is even simpler to use than before. With user friendly screens and menus, DCPe will make your life easy. We offer, promise, and guarantee the best after sales support to our end users.

Save time and money and add to your profits by contacting existing clients and reaching out to new clients through DryClean PRO Enterprise’s built in MARKETING and EMAILING functionality. You’ll be able to send Thank You emails to new or Top 100 customers, Customers with overdue inventory, Customers that have not visited you for a while, Route customers & e-mail coupons to all your customers.

Call us about our new version of Uniform Tracker

Computer Systems (888) 325-4763 www.dajisoft.com

THINK OUTSIDE YOUR SYSTEM WITH Free cordless scanner with our Garment Verification System Contact us TODAY! LIMITED TIME OFFER Ask us about our DCPe RENTAL

Fabricare & Fashion 2014

Could the Outrageous Be Coming to Your Plant?

Tips for cleaning garments that emulate fall’s most outré outings

By Ian P. Murphy

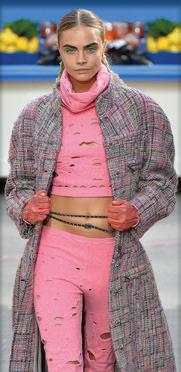

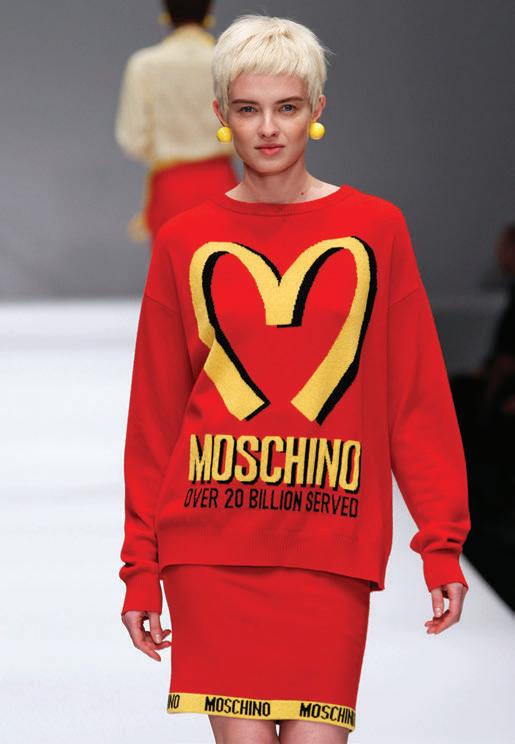

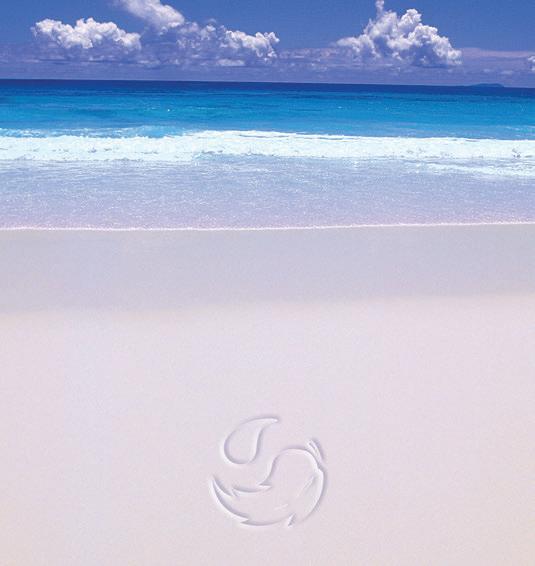

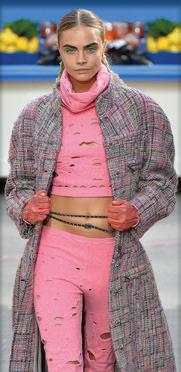

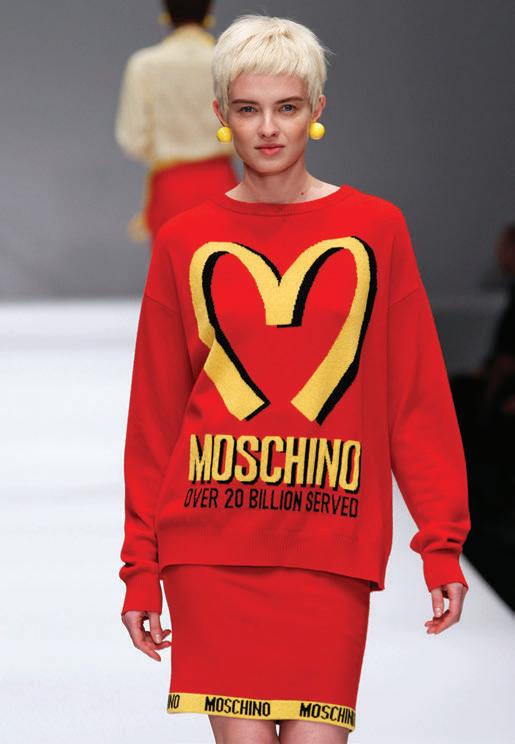

Fall’s runway collections had more than a little of the outrageous this year. Couture labels ordinarily known for their feminine elegance flaunted sporty street styles that recalled ninja warriors and the joys of slumming at the dollar store. Others produced architectural capes and “extreme” turtlenecks to protect against winter’s chill.

Against expectations, designers raised hemlines to “mini” lengths and introduced new layers of boots, leggings and pants for warmth, while showing off sweater sets that go all the way to the floor.

And always toying with shape and texture, they employed everything at their disposal— fur, feather and fabric—to create the looks that wowed the crowds.

ABOUT THE EXPERTS

• Jim Kirby is chief analyst at the International Textile Analysis Laboratory (ITAL), Drycleaning & Laundry Institute (DLI), Laurel, Md.

• Alan Spielvogel is garment analyst for the National Cleaners Association (NCA) in New York, N.Y.

• Chris Allsbrooks is director of store operations for ZIPS Franchising LLC in Greenbelt, Md., and a former garment analyst for DLI.

The haute couture originals seen on the runways of Milan, Paris and New York may not appear in drycleaning plants anytime soon, of course, but garments that emulate the season’s most outré outings will be arriving shortly.

The following are four fashion trends that dry cleaners will likely see in the months ahead, and expert advice on handling them.

Photo: firstVIEW

12 American Drycleaner, November/December 2014 www.americandrycleaner.com

▲

See us at Cleaners Showcase Booth 500

Drawing inspiration from consumer culture, Moschino introduced bright, sporty streetwear styles that spoof brands such as McDonald’s.

Photo: firstVIEW

Photo: firstVIEW

Fabricare & Fashion

LOOK #1

STREETWEAR

Aconsumerist, fast-fashion aesthetic with an undertone of apocalypse, this year’s streetwear is ready for anything the urban jungle can dish out. Brightly colored, form-fitting and sporty outfits feature mix-and-match patterns, loud prints, big logos and provocative sayings—perfect for standing out on the subway or standing in line at the Megamart.

“Bright colors send up a flag that there is a dye process that may have some problems in cleaning,” says Jim Kirby, chief garment analyst at DLI’s International Textile Analysis Labora tory (ITAL).

Operators should be sure that their solvent is moisturefree, and avoid the use of heat, says Alan Spielvogel, garment analyst at the National Cleaners Association (NCA). “Dyes have a tendency to migrate from the darker portions of a garment to the lighter portions.”

Vibrant colors often get their pop from fluorescent brighten ers, he adds, which solvents can strip from the fabric, dulling colors.

In-your-face logos and imprints are often pigment dyes or stencils that bind to the fabric with an adhesive that also may prove soluble to the drycleaning process.

“Double-check the care label, and test for colorfastness,” says Chris Allsbrooks, director of store operations for ZIPS Cleaners and a former DLI analyst, and be prepared to go against care-label instructions when necessary.

“A lot of these garments are labeled incorrectly,” Kirby says. “They may be better off in a wetcleaning process.” ▲

www.americandrycleaner.com American Drycleaner, November/December 2014 15

Fabricare & Fashion

LOOK #2

SWINGING ’60s

Mad Men ingénue Peggy Olson would feel right at home on this year’s runways, where designers set the time machine to “Mod” with miniskirts, thigh-high boots and shift dresses emphasizing op-art patterns and retro-futuristic accents such as mohair and vinyl.

“Nancy Sinatra is back in town,” Spielvogel quips. Cleaners should protect against dye migration on geometric prints by pre-testing with the solvent of choice, he says, control reclamation temperatures, and be wary of the extended drying times many alternative solvents require.

“Op-art patterns are usually surface designs,” Kirby notes. “They are held to the fabric with a binder, and dry cleaning may not be the desired method” since it can quickly strip the bind ers from the fabric.

Shiny and see-through accent materials such as vinyl, polyurethane and polyvinyl chloride (PVC) should never be processed in dry cleaning, the experts add.

“A lot of times, these materials have softening agents to keep them pliable,” Kirby says, “but they can crinkle, blister or peel off in solvent.”

Again, using a water process may be a better option, Allsbrooks says. “Vinyl washes beautifully—but if you dry-clean it, it will come out rock-hard.” (Page 20) ▲

16 American Drycleaner, November/December 2014 www.americandrycleaner.com

Miu Miu’s ultra-mod minidress features metallic embroidery, semiprecious stones and a see-through yoke of yellow PVC.

Photo: firstVIEW

Photo: firstVIEW

management strategies

a ttract Fashion i nfluencers with s pecialized s ervices

Several times each year, in style centers around the world, designers and their fans gather for the unveiling of the newest designs on the fashion runways.

Fashion devotees range from the mega-wealthy wearing one-of-a-kind haute couture to mass-market purchasers. Their buying power may differ, but they have in common that they all want to look their best and to have their clothing fit like it was custommade for them. They also want and need you to protect the significant investment they have made in their apparel.

These “vogue disciples” are important to your success since they are the influencers whose style and advice can sway many prospects and send them your way.

This fall, the key runway trends included ever more black and white, sometimes accented with a pop of vibrant color. Frills, lace and mesh detailing, as well as cutout backs and sides, were also prevalent. Retro maxi dresses, pinafores and crop tops added a juvenile playful tone, especially when trimmed with silver ribbon detail. Billowy tulle and silk contributed a touch of the bohemian.

These styles may already be hitting your inventory, and you are giving them the expert TLC they need to stay in like-new condition. They often require careful pre-testing, delicate spotting, deft pressing technique and supportive (always attractive) packaging. Your fabricare skills are much appreciated by the fashion-focused because you keep them looking the part of style guru.

Beyond your essential expert professional care, there are many additional ways to attract this customer segment to your services.

Some of the services that go outside traditional apparel cleaning and pressing will instill loyalty and create raving fans who will tell their friends, families and colleagues how wonderful you are.

Your imagination can expand the possibilities but some wardrobe services include:

• Storage, which can be seasonal or longer

• Photography for insurance and/or image planning purposes

• Detailed cataloging of collections for insurance or event appearance scheduling purposes

• Management, including full fabricare, transportation and documentation

18 American Drycleaner, November/December 2014 www.americandrycleaner.com

Diana Vollmer

• Preservation for archiving or future availability for events or persons currently known or unknown

• Delivery and/or pick-up to/from the client’s temporary or permanent location

An extremely crucial service that will solidify the fashion leader loyalty is expert tailoring that incorporates:

• Alterations to a current wardrobe that are needed due to weight gains/ losses, changing hemlines, trends that are more fitted or less form-fitting, or reuse by a younger family member.

• Customization of new purchases are particularly popular because a newly purchased garment moves immediately to favored status and clients will pay a premium for expedited alterations. While-you-wait hems are a prime example of a quick alteration that can delight a client because they can wear the purchase immediately.

design to reality.

Of course, this skilled service requires expertise that is often difficult to identify, locate and attract. It is talent that can also be challenging to manage. The talent search can be problematic and can require creativity in itself. In addition to the traditional sources of sewing skill, you might find the following possibilities helpful as sources of expert seamstresses:

• Sewing instructors can be found through schools, craft clubs and bulletin boards.

• Fashion institute students like working with the fine fabrics and quality clothing that a fine cleaner handles regularly.

Fashion devotees range from the mega-wealthy wearing one-of-a-kind haute couture to massmarket purchasers.

• Modifications to special-occasion garments, of which bridal is the most obvious, but life events occur at all ages from christening through old age. Think of the effort made to appear fit at school reunions or the desire to fit into the old uniform for a gathering of comrades.

• Creation of a new garment utilizing a beautiful fabric or trim from a vintage one.

• Creation of a custom garment from

• Skilled tailors and seamstresses are more plentiful offshore, and you can sponsor them through select immigration programs. Eastern Europe seems to provide a number of tailors with exceptional ability levels.

• You might benefit from contacting organizations that are providing help to newly arrived refugees.

• Fabric stores attract customers and associates with sewing skills.

• Online searches of related keywords will uncover new sources of proficiency.

Management of this specialized talent can be especially perplexing but can also be simplified through compensation that aligns the tailors’ interests with your profitability interest. Samples of this approach to compensation include:

November/December 2014 19

www.americandrycleaner.com American Drycleaner,

▲ 22

(Photo: © iStockphoto/pashyksv)

Photo: firstVIEW

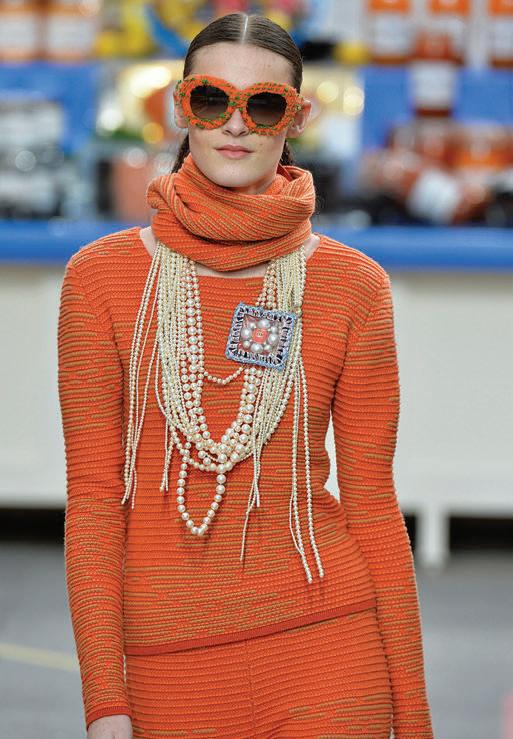

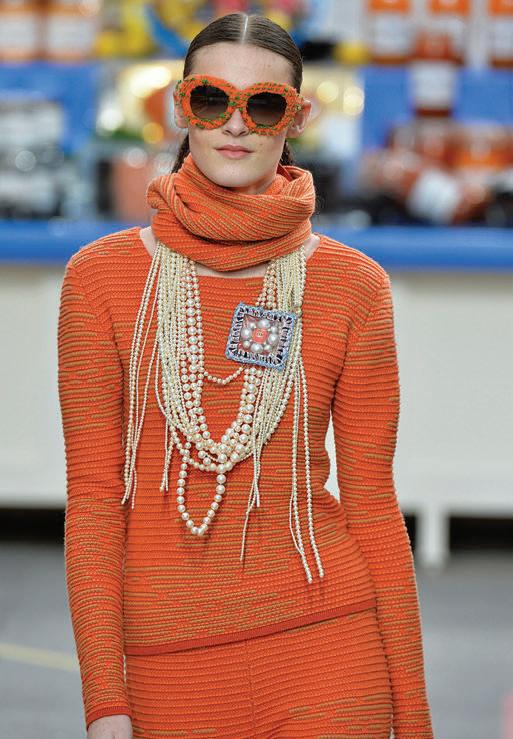

Chanel champions the head-to-toe knit trend with a ready-foranything four-piece ensemble that includes crocheted sunglasses.

Photo: firstVIEW

Chanel champions the head-to-toe knit trend with a ready-foranything four-piece ensemble that includes crocheted sunglasses.

Fabricare & Fashion

KNIT TO BE TIED

Designers took head-to-toe knits a step further this year, producing long, loose knit garments that often drape all the way to the floor. Ensembles like this are stylish and warm, but stretch and shrink easily, so operators should examine weaves and garments carefully.

“You have to understand the construction,” Allsbrooks says. “If something is intentionally oversized, that’s how it is supposed to be. Measure before you clean—you can block them back to size if they shrink, but you need to know how big they were to begin with.”

This is especially true for specialty wools such as alpaca and angora, Spielvogel adds.

Many knit-centric garments feature elegant drapes that “are not very stable because they are cut on a bias,” Kirby says. “They are already out of balance; you don’t want to distort them any further.”

Decide whether or not you can clean knit garments in solvent based on fiber content, and use short cycles and net bags to avoid snags and distortion regardless of the process.

Acrylics can be wet-cleaned, but “stretch like crazy” when exposed to steam, Spielvogel says.

And if a long knit drags in winter muck, treat the stain as an insoluble. “The problem is that snow and ice is usually followed by a chloride salt, and that can cause color loss,” he warns.

(Page 24) ▲

www.americandrycleaner.com American Drycleaner, November/December 2014 21

LOOK #3

Management Strategies...

Continued from page 19

• Revenue sharing, most commonly on a percentage of total revenue

• Hourly rates, although usually the least motivating for the specialized skill, however, can add desired income stability when that is the associate’s financial goal.

• A flat rate per garment, which is similar to revenue sharing but with a menu of labor rates by garment type, is becoming more common. Other services that win loyalty of trendsetters are:

• Handbag cleaning, which is especially appreciated since finding the appropriate purse is challenging and the perfect color, line and configuration of pockets is valuable to preserve.

• Shoe care and repair encompasses the same considerations as handbags with the added complication of comfortable fit.

• Home textile design is as important to these clients as their wardrobe design and so is the fabricare associated with these domestic textiles. Fashionforward clients own extensive home fabric wardrobes as well.

• Seasonal cleaning of patio and other exterior cushions is an opportunity that most clients don’t know you can provide.

• Automotive interior cleaning is a natural extension of your service on the other fashion textiles in the trendsetter’s life. Often the car designs are as dramatic, or even more so, than the personal apparel design.

• Cleaning of textiles used on private planes (personal, domestic and interior) is another extension of the fashion lifestyle. Many of these clients enjoy the benefits of owning, leasing or sharing private planes and they need specialized fabricare.

• Boat interiors create the same opportunities as the private plane market. Although not a service for which you will be paid directly, creating a fashion calendar on your company’s website will generate buzz and show that you are “tied in” to the fashion community. All of your social media efforts can capitalize on the interests of this active and passionate group. Creating unique events in conjunction with relevant joint-venture partners, i.e. designers and retailers will provide an implied endorsement. The trusted and admired advisers within the fashion culture wield powerful influence over their fans, and you can become a member of that trusted team. O

Diana Vollmer is managing director at Methods for Management (MfM) Inc., which has served the dry cleaning and laundry industry with affordable man agement expertise for improved profitability since 1953. For assistance with your quest to attract fashionistas, contact Vollmer at dvollmer@mfmi. com or 415-577-6544.

22

American Drycleaner, November/December 2014 www.americandrycleaner.com

Your fabricare skills are much appreciated by the fashion-focused because you keep them looking the part of style guru.

(Image licensed by Ingram Publishing)

Joint dl I- n C a winter conference in Cancun sells out well in advance

No room remains for the 2015 Brain storming & the Five Star Conference co-hosted by the Drycleaning & Laundry Institute (DLI) and the National Cleaners Association (NCA), the organizations report.

Space sold out four months ahead of January’s scheduled event in Cancun, Mexico, prompting promoters to consider expanding for the next conference.

Cleaners will meet in the mornings on Jan. 16, 17 and 18, allowing attendees to spend the rest of the days their way. Each presentation will be followed by a round table discussion among participants, facili tated by the speaker.

Sydney Biddle Barrows, author of the best-selling The Mayflower Madam and co-author of Uncensored Sales Strategies: A Radical New Approach to Selling Your Customers What They Really Want - No Matter What Business You’re In, will be the featured speaker on Jan. 16.

The next presenter, Doug Dvorak, is a contributing author of The Masters of Suc cess. A top-rated motivational speaker, Dvorak will be tailoring his message for dry cleaners.

Finally, John DiJulius, author of Secret Service: Hidden Systems that Deliver Un forgettable Customer Service and What’s the Secret?, will join the discussion. O

Nov. 16-17 North East Fabricare Asso ciation Fall Fest Educational Conference. To be held in Portsmouth, N.H. Call 603-6350322.

Jan. 15-18, 2015 Brainstorming & the Five Star Conference. To be held in Cancun, Mexico. Call NCA, 212-967-3002, or DLI, 800-638-2627.

Jan. 29-30, 2015 70th Annual New Eng land Sanitone Licensees Meeting. To be held in Boston. Call 800-543-0406.

April 16-19, 2015 Clean Show. To be held in Atlanta. Visit www.cleanshow.com.

June 14, 2015 Dry Cleaning Alternatives Trade Fair, sponsored by the Rocky Moun tain Fabricare Association. To be held in Den ver. Call 866-964-RMFA.

July 29-Aug. 1, 2015 Textile Care Allied Trades Association Annual Management & Educational Conference. To be held in Napa, Calif. Visit www.tcata.org

Sept. 9-11, 2015 Textile Rental Services Association Annual Conference. To be held in Isle of Palms, S.C. Visit www.trsa.org

Sept. 14-15, 2015 International Dryclean ers Congress Convention. To be held in Osa ka, Japan. Visit www.idcgroup.org.

Nov. 25-27, 2015 Texcare Asia. To be held in Shanghai, China. Visit www.texcareasia.com. O

Post notices of your organization’s events on www.AmericanDrycleaner.com

www.americandrycleaner.com American Drycleaner, November/December 2014

23

Calendar

Up C om I ng e vents

Fabricare & Fashion

LOOK #4

FANTASY FUR

Always a fall runway staple and only occasionally an ethical dilemma among the well-to-do, furs arrived on the runways this year in oversized, multi-colored patchworks of alpaca, shearling, fox and astrakhan.

While they’re meant to keep wearers warm, “don’t get them anywhere near heat,” Kirby says.

Sending real furs to a furrier is often the best choice, especially with patchwork skins. “The age of the skins can differ, and that will affect how they react to cleaning,” Allsbrooks says. “And even if they are made of the same skin, cleaning can change the direction of the pile.”

Synthetic shags are also in style, with designers using bright faux furs as a foundation fabric for items such as pants and jackets.

“If it’s a faux fur, you should follow DLI’s pile cleaning method,” Kirby says, and avoid putting it in a hot dryer.

While some faux furs will withstand a short drycleaning cycle, Spielvogel adds, others will emerge “looking like a dead rat.”

Observe faux furs’ limitations in finishing, too: “If you do any direct heat on a faux fur, you will singe the ends of the fibers and they will form a hard, brittle bead,” Allsbrooks says. “You can try to shave that off, but the garment will have a rougher texture than it did before. Wash them or dry-clean them using the pile method. All they need is a nice brushing at the end—no heat.” O

Ian P. Murphy is a freelance writer and editor based in Chicago. He served as the editor of American Drycleaner magazine from 1999-2011.

24 American Drycleaner, November/December 2014 www.americandrycleaner.com

With an enchanted forest theme, Dolce & Gabbana’s fall 2014 runway show offered up a bloodred riding hood made of fox and alpaca.

Photo: firstVIEW

Photo: firstVIEW

Sweaters Bring Extra Cash, but Be Cautious

Fall weather means cooler temperatures, and cooler temperatures mean adding outerwear to the mix of incoming garments to be cleaned. That means sweaters, and sweaters mean additional revenue. Sweaters also mean caution for the cleaner/spotter. Sweaters come to the counter in many configurations. The fiber can range from cot ton to cashmere, the weight can range from ultra-light to bulky, and the choices in trim can range from sophisticated to downright tacky. It is the cleaner’s responsibility to: “First, do no harm.”

Sweaters bring with them a variety of considerations while in the care and control of the cleaner. The most obvious is the lack of dimensional stability. It should be policy to turn sweaters inside-out and then clean and tumble them in a net bag; this is true for both dry cleaning and wet cleaning. Let me make my case before you dismiss this practice as too timeconsuming. The knit construction can lead to stretching, shrinkage, pulls, picks and pills. This is before we take into con

To find past Spotting Tips columns or share this month’s with your colleagues, visit www.americandrycleaner.com.

sideration the fabric, the weight, or the trim. Any stress placed on the garment during cleaning and drying can “knock it out of shape,” by stretching the un stable loop construction.

While shrinking protein fabric (felting) is a result of poor training, a more common problem is relaxation shrinkage. This is where the garment’s original shape has been altered to “fit” the customer’s unique body contours while being worn, but returns to origi nal dimensions when agitated during cleaning and tumbling. This is a char acteristic that the cleaner must be aware of, even if it is not one the cleaner can control.

During cleaning and tumbling, the hook at the top of a zipper can cause a great deal of damage to an unprotected knit; that is an avoidable claim. Any low-twist yarn is subject to pilling when rubbed against itself or other garments. Reducing mechanical action can greatly reduce this pilling. You can reduce mechanical action on a sweater by turning the garment inside-out and placing it in a net bag for cleaning and tumbling.

Always take into consideration the basic fabric in the sweater you are cleaning. When the sweater is a blend of fibers, treat the most fragile fiber in the sweater. When the sweater is 20%

Spotting t ip S 26

November/December 2014

American Drycleaner,

www.americandrycleaner.com

Martin Young

silk, for example, it must be treated as if it is 100% silk.

A silk sweater could be damaged by untreated water or the alkali in a detergent or protein spotter. A wool sweater could be damaged by these same conditions, but is more commonly damaged by shrinkage (felting) when exposed to water, alkaline detergent, and drying with heat and me chanical action. Sweaters constructed of synthetic fibers are extremely sensitive to heat, to the point that I would recommend folding an acrylic sweater over a hanger after drying, not sending it to the finishing department.

Cotton sweaters are the most durable. There is a high probability that a cotton sweater will do well in wet cleaning, with the color/dye being the major consideration. Most cotton sweaters can be successfully soaked in a solution of 1 ounce of NSD per gallon of water, if you have not joined the growing number of cleaners that are wet cleaning on a regular basis.

I remember a customer that initially refused a garment as not her sweater. The CSR listed the sweater as “tan” when it was marked in at the counter, but the gar ment was bright yellow after having been soaked in wetcleaning detergent and rinsed. The customer had worn the sweater for so long, without having it cleaned (because of its trim), that she had forgotten its original color.

When spotting a sweater, you must re member that you are working on a construc tion that has extremely limited dimensional stability. I have made it a habit to “pin down” an area of the knit garment between my thumb and forefinger and working only on the area between my fingers, to protect the area from spreading when using steam

and air under pressure.

When you are spotting on the wet side, you must also increase the minimum dis tance of the spotting gun from the surface of the garment from 4 inches to 6 inches. To further protect the garment during wet-side spotting, you should invest in a “padded” spotting brush (excellent for silk and satin) or at least wrap your current brush in some type of cloth before tamping the sweater.

Always test chemical tools on an un exposed seam before applying them to the garment for effect. It is common for the care label to identify a percentage of fibers in a sweater as “Other Fibers.” There are times when you cannot be sure of the exact fiber content in the garment or how those unidentified “Other Fibers” will react to your chemical tools.

I have this “thing” about acrylic sweat ers. Experience has convinced me that less is, in fact, more. Acrylic is a monofilament thermo polymer, which means that it is a single thread of synthetic fiber and sensitive to heat. Be extremely careful with an acrylic sweater, as it is dimensionally unstable by construction and highly sensitive to distor tion from any form of heat. A spotting gun or buck steam can cause irreversible dam age, and there is no remedy. Cold-water wet cleaning is preferable if the care label, dye and trim will allow this procedure.

Sweaters will fill in many of the gaps in cash flow that are present during the warm months, so do them right and keep them coming. O

Martin L. Young Jr. has been an industry consultant and trainer for almost 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Con cord, N.C., Young Cleaners, which he operates to this day. Contact him by phone at 704-786-3011, e-mail mayoung@vnet.net.

American

November/December 2014 27

www.americandrycleaner.com

Drycleaner,

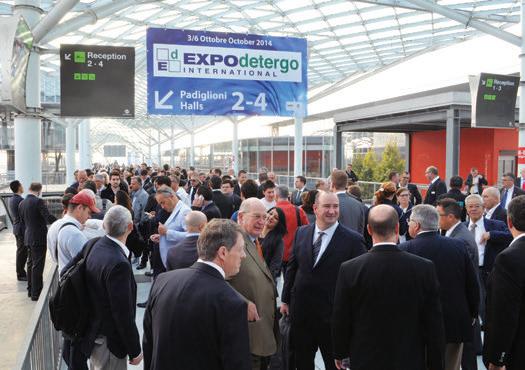

EXHIBITION REPORT

Milan’s EXPOdetergo

Draws 20,000

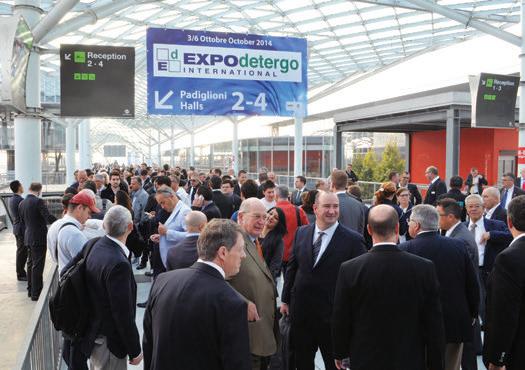

More than 20,000 visitors from five continents—half of whom were from abroad—crowded the booths of 298 exhibitors during the recent 17th edition of EXPOdetergo International, the four-day Milan, Italy, exhibition that occurs every fourth year, show manager Fiera Milano reports.

The early October exhibition featured new products and technologies in the field of equipment and machinery for professional laundries and fabricare, a segment that represents a “leading Italian market,” Fiera Milano adds.

21% boost in foreign attendance proves ‘global leadership’: show manager

Professionals arriving in Milan for the show confirmed “the successful attendance recorded four years ago, while demonstrating a 21% increase from the countries participating.”

There were 102 countries represented amongst the attendees, compared to 84 in the 2010 show. The breakdown: 42 European countries, 30 Asian nations, 16 from North and South America, 12 African

28 American Drycleaner, November/December 2014 www.americandrycleaner.com

▲

John Riddle (center foreground, facing camera) and Brian Wallace (right, facing camera), representing the Clean Show, were among those waiting to enter EXPOdetergo. (Photo: EXPOdetergo International)

▲

how one cleaner

his business

PLUS! Pluslux (866) 575-1010 • www.plusluxllc.com • New laundry equipment with no capital expense • No long-term lease or contract • Huge savings on chemicals, water, and energy • Lifetime Parts and Service Warranty • Superior quality and longer linen life No money down. Pay only for what you use! Never purchase laundry equipment again! P rofessional L aundry U tility S ervice

Scan QR barcode to read how PLUS saved Park Avenue Cleaners. To learn more, visit: www.laundryluxblog.com See

saved

with

countries, and two from the South Pacific.

“EXPOdetergo International has essentially confirmed the visitors attending the exhibition four years ago, underscoring its role as a benchmark event in a mature industry, which has increasingly found its key markets in tourism, hospitality and nursing homes,” says Luciano Miotto, the event’s president. “The quality, level of innovation and research in ergonomics typical of Italian production continue to earn interest on the foreign markets, as demonstrated by the results of the event days when the exhibitors closed deals and submitted orders.”

Examples of innovations displayed included large-scale, fully automated processing lines that promote energy conservation and reduced water usage; washers that can hold more than 100 kg of laundry in a small space; RFID labels to identify goods; and garment sorting systems designed to reduce loss.

New pressing equipment, designed for Asian and American markets but which is making headway in Italy, can press more than 100 shirts per hour with “significant energy savings,” Fiera Milano reports.

EXPOdetergo paired its extensive exhibition with educational programming. For example, an English-language seminar tackled the role of laundries and dry cleaners in participating in constructive dialogue with clothing manufacturers and consumers. Later, the supply chain of textile care was covered in an Italian-language presentation with English translation.

“The growth in the international representation is further confirmation that Fiera Milano is capable of attracting buyers from around the world who recognize the exceptional Italian production and choose to do business in our region,” says Michele Perini, president of Fiera Milano.

The next EXPOdetergo International has been scheduled for Oct. 5-8, 2018. O

30 American

November/December 2014 www.americandrycleaner.com

Drycleaner,

(Photo: EXPOdetergo International)

(Photo: EXPOdetergo International)

CESCO 20830 Pacific Highway So. Seattle, WA 98198 Phone: 206-824-9055 Fax: 206-878-2658 Email: rich@cescoequipment.com

Arrow Fabricare Services Turns

Reaching the century mark in business is no easy feat. Arrow Fabricare Services, Kansas City, Mo., certainly has reason to celebrate its 2014 centennial, which it plans to do in style with current, former and retired employees in December.

Polish immigrant Joseph Gershon planned to call his new business “Gershon Tailors,” but his cousin suggested “Arrow,” like popular shirts sold during the time. The name remains a perfect match for current owner Bruce Gershon, the third generation of his family to helm the business.

“Dad (Bob Gershon) and Grandpa (Joseph Gershon) always stressed doing a good job and doing it the right way,” says Bruce. “That’s one of the main reasons we’re still in business today.”

ON TARGET. Joseph Gershon married and raised a family in Kansas City. His business grew through the 1920s and ’30s. Son Melvin worked alongside his father, and then son Bob returned from World War II in 1947. It was around that time that Joseph decided to bring dry cleaning in-house.

Bob was hands-on, running deliveries, pressing clothing and growing the family business, which eventually earned the title “Kansas City’s Exclusive Specialty Cleaners.” Arrow also developed a solid reputation among dry cleaners, thanks in part to some innovations developed by Melvin.

“My uncle Mel actually invented two things in the time he was here in this plant,” says Bruce Gershon. “One of those things was the foam press pad, which is still used in many dry cleaners even today, and after a 17-year run with the patent, Qualitex bought that out.”

The other invention, which he didn’t patent but was adopted and made widely popular by Cissell, was the electric thumb switch on a steam iron.

When Melvin left Arrow to pursue a career in engineering, Bob remained and assumed more day-to-day responsibilities. ▲

32 American Drycleaner, November/December 2014 www.americandrycleaner.com

100

Bruce Gershon

Arrow Fabricare Services’ headquarters in Kansas City, Mo. (Photos: Arrow Fabricare Services)

Our name means a lot.

GreenEarth has always stood for green cleaning. Where does the green in our cleaning come from? Sand. That’s what GreenEarth solvent is made from. Simple, natural sand. Unlike perc or petroleum-based solvents, GreenEarth is good for the earth, and for people, so the EPA doesn’t regulate it.

The cleaning in our green is pretty impressive, too. Studies show GreenEarth cleans as well as perc

on a much wider variety of garments. Fabrics actually look and feel noticeably better.

But green cleaning is just the beginning. GreenEarth can green up your bottom line, too. Unlike the alternatives, GreenEarth is cost effective. And our Affiliates who market their GreenEarth difference have seen their sales increase by more than 20%.

GreenEarth. Another name for opportunity.

For more information, scan this code with your smartphone or visit www.greenearthcleaning.com/GreenEarthVideo ®

In the mid-1950s, Bob and a partner jumped into the leather cleaning business.

Joseph died in February 1963. Bob persevered through the polyester and washand-wear craze of the 1960s that proved fatal to thousands of dry cleaners.

GROWING PAINS. The company has had its share of growing pains, especially since Bruce began working full-time in 1974. Arrow had some half-dozen employees then, half of whom were family members.

During a major remodeling project of the original building in 1978, a new front was erected and the building connected to the cleaning plant. The following year, the family bought a vacant store across the street to expand its fur cleaning business and accommodate employee parking. Next came a vault for fur storage.

In 1985, Arrow acquired its largest local competitor in the leather, fur and specialty cleaning business, bought two adjacent buildings to the south and expanded.

The company rebranded and began doing business as Arrow Fabricare Services, to emphasize its diversified services.

In 1994, it added 4,000 square feet of space to its distribution and check-in area to accommodate expanding retail routes.

In 2001, Bruce Gershon purchased Blanc Plume Fine French Laundry. This accommodated expansion of Arrow’s fire restoration division, which moved into the north Kansas City facility and immediately doubled its volume.

When local officials approached Arrow about a plan to build a bus waiting station and early childhood development facility nearby, it meant the loss of 4,200 square feet of space plus employee parking, but the chance to expand to the north, add 6,300 square feet to the leather and fur department, and revamp its production flow. The new building opened in 2004.

In October 2010, the company acquired the drapery cleaning equipment from its retiring vendor and set up shop in Kansas City, Kan.

Arrow’s resources are divided between two buildings totaling more than 48,000 square feet, and its workforce numbers approximately 80, depending on the season.

While Bruce Gershon admits Arrow’s diversity can make the business “more challenging to operate,” he is quick to point out the company’s focus remains simple.

“The emphasis today in our business is on quality,” he says. “We’re constantly studying different ways to improve our quality and training, investing in our greatest resource, our people. We want our customers to come to Arrow and feel like they are going to a place where they can get answers.”

And it’s possible that a customer may even see Bob Gershon, now age 88, who still comes down to the business for a few hours each weekday morning. Continuity may also have something to do with Arrow’s longevity. O

34

November/December 2014 www.americandrycleaner.com

American Drycleaner,

This undated photo shows Bob Gershon in front and Melvin Gershon behind the truck.

Melvin Gershon and two women pose behind the counter in this 1947 photo.

Multimatic 30-lb. SL-30 $18,500* Forenta Dry Cleaning Topper (used) $3,600* Form Finisher $3,250* Forenta A19VS Topper $3,895* Huebsch 75-lb. Steam Dryer $3,700* Lattner 20hp Boiler $11,900* Milnor 60-lb. Washer $6,450* Bowe 40 Hydrocarbon Machine $28,500* New & Used Equipment for Drycleaning & Laundry Huge Selection of Parts for Most Brands of Equipment Prices valid until January 1, 2015 | *Freight Not Included MUSTANG enterprises 1/2” Steam Traps $35 each, 5 trap minimum 86 6 - 73 4 - 364 4 Monthly Specials Online: MustangEnterprises.com

Part 1:

Fixes to Common

By Bruce Beggs, Editorial Director

By Bruce Beggs, Editorial Director

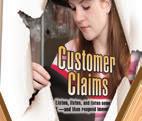

There are problems that require a great deal of time and resources to solve, and then there are problems that can be solved easily with a quick fix.

Enter Brian Johnson. He’s the director of education and analysis for the Drycleaning and Laundry Institute (DLI) and recently marked his 15th year with the organization. Before that, he spent 15 years working for a drycleaning and laundry company.

Johnson oversees DLI’s garment analysis lab and says he “talks to lots of cleaners

36 American Drycleaner, November/December 2014 www.americandrycleaner.com

Problems

all day, every day” about the garments that give them processing nightmares. On this day, he is speaking to a South Eastern Fabricare Association audience about Quick Fixes to Common Problems.

“It’s surprising how frequently we get the same questions from dry cleaners all across the world,” he says. “A lot of their questions can be easily answered.”

And so Johnson began ticking off work-related problems involving drycleaning, pressing and stain removal and what can be done to address them. “These (solutions) are all cheap—nearly free—and can be done in a matter of seconds.” ▲

www.americandrycleaner.com American Drycleaner, November/December 2014 37

(Photo: ©iStockphoto/mariusz_prusaczyk)

WRINKLES AT THE COLLAR TIPS. This is caused when the interfacing shrinks more than the outer fabric, Johnson says. When a presser pushes the excess material to one end of the collar, you end up with wrinkling.

“You start at one end of the collar, you press, and you stop at the center,” Johnson says. “You push the extra material to the center. Then you go to the other end of the collar and you press in the opposite direction, pushing the material to the center of the collar. That way, when the shirt is hanging or being worn, all the excess material is in the back.”

STEAM WRINKLES. Commonly found when processing lightweight fabrics, these are caused by using bottom steam on the press, Johnson says. “Whenever you have a light weight, use top steam on your silks, your polyesters.”

General rule of thumb when finishing: heavyweight garments, use bottom steam; lightweight garments, use top steam.

COLLAR FABRIC SHOWING ON MEN’S SUIT JACKETS. This is caused most frequently by improper finishing, Johnson says, especially when a presser lays the curved collar out flat and runs the iron from one side to the other. “That’s one of the worst things you can possibly do when finishing a man’s suit coat,” he says.

If it’s necessary to press a collar, fold the collar face up and press with the curve, or, alternately, fold it face down and use the same approach.

Using a wire hanger instead of a curved hanger can also distort a suit jacket and

cause the collar fabric to show, Johnson says.

BROKEN BUTTONS, SEQUINS, ETC. ON DELICATES. This is often caused because cleaners believe they should clean delicates alone. Doing so subjects the garment to tumbling against an unforgiving metal surface.

“If you have a delicate piece, I do recommend short cleaning cycles, but put some other clothes in so it bounces and smacks against soft fabrics and not against a hard metal drycleaning or washing machine.”

Placing such garments inside net bags can also protect their delicate trims and adornments during cleaning, he says.

SHINE ON DARK FABRICS. This effect can be caused by a number of things: fibers being flattened due to wear, using a hot iron, or using too much steam and softening the fabric. When fibers become soft, a press head flattens them, causing light to reflect off them.

“If it came from just wearing down fibers, or the iron has melted it, there’s not much you can do for that,” Johnson says. “If it came from steaming, making it too soft … you can re-wet the fabric with steam to make the fibers soft again, take a hard-bristle brush and brush across the fibers to lift them back up.”

OLD HEMLINES. When altering pants, for example, an old hemline may remain. If it’s the result of broken fibers, there’s no easy fix for that, Johnson says. But if the old hemline is just a fold, he advises to place a metal coat hanger along the fold and steam the garment from the bottom.

“This will cause water to form on the

38 American Drycleaner, November/December 2014 www.americandrycleaner.com

Brian Johnson

hanger. That water will form right along that hem. The wetter the fabric is, the softer it becomes, the easier it is to reshape it. Press it smooth.”

If that doesn’t work, mix up a 50-50 solution of your drycleaning solvent and drycleaning detergent and brush it across the hemline, then process it in a normal cleaning cycle. That might do the trick.

WET-SIDE SPOTTING RINGS. There are many causes to such “rings” being left over after pre-spotting, Johnson says.

“The ring is caused by disturbing something on the surface of the fabric,” he says. “It could be sizing and starch. … It could be dye. It could be dirt. At some point, you disturbed something, and it moved to form that ring.”

If you pre-spotted a garment without

first placing a towel under the stain, the fabric became too wet. Next time, lay a towel on the spotting board, then the garment on top of the towel, he says.

Sometimes, a spotter will use too much of the product needed to remove stains. So use less, Johnson says. “All you need are a few drops.”

Another cause is holding the steam gun at an angle, which pushes the stain, water, or “whatever is loose on that fabric” across the fabric. “What you really want to do is have your steam gun at a 90-degree angle, where you push all the impurities out of the fabric and not straight across the grain of the fabric,” he says. O

For more quick fixes from Johnson, look for the conclusion to this story in the January issue of American Drycleaner!

2014 39

www.americandrycleaner.com American Drycleaner, November/December

industry observations

Learn e very Job in y our Plant

Awhile ago, I consulted a prospective buyer of a drycleaning establishment. He was cocky and confident, the former manager of a large software company. In fact, he was so sure of his abilities that he hardly listened to my advice, despite the money he paid for my services. He wound up buying the dry cleaner.

It was an old, established operation, but five years later it went bankrupt. I never exactly found out why, but I wondered if it was something he told me: As memory serves, he said, “I’m a manager of people. That’s my primary talent. I don’t have to know what they do as long as I can motivate them. In other words, I’m not a nitty-gritty operator; I’m a guy with the big-picture outlook. I let my people do the work, so I can concentrate on wider horizons. That’s why I’ll grow this business. The last thing I want to do is waste my time.”

I disagreed with him then, and I disagree with him now.

It is vitally important that the boss can do everyone’s job. Not that he/she will have to perform the work when

To find past columns from Howard Scott or share this month’s with your colleagues, visit www.americandrycleaner.com.

the worker is absent. Rather, knowing each person’s job is important to manage the operation well. Here, knowledge is power.

It is mandatory to grasp what is required of each staffer so the person can be motivated and made to do his/ her best. It is necessary to understand everyone’s job and how it fits in with the overall performance of the operation. It is important to grasp what each individual in the chain has to do so that the next person can do that work without impediment. It is critical to understand the overlap of work to untangle bottlenecks. It is valuable to

40 American Drycleaner, November/December 2014 www.americandrycleaner.com

Howard Scott

▲

(Photo: © iStockphoto/IPGGutenbergUKLtd)

Sure, you buy new equipment all of the time. But few pay for themselves the moment you turn them on, replace up to two paid positions and help you run a more efficient shop as well as QuickSort . It will become a vital part of your team.

P. O. Box 241610 • Little Rock, AR 72223 501-216-8093 • www.quicksortac.com

to

Simple to Maintain.

Simple

Operate.

THE BEST CUSTOMER SERVICE REP CUSTOMERS NEVER SEE.

industry observations

be able to make changes with full knowledge of the implications of the change.

My advice is, if you are entering the industry fresh, learn all jobs to the point where you understand what the workers do. That doesn’t mean that you have to be an industry veteran. That doesn’t mean you attend drycleaning school and work at each position for a month. That doesn’t even mean that you spend several months learning everyone’s job. Rather, spend some time with staffers each day.

Say the magic words, “Teach me your job.” The operator will not be offended.

If you are entering the industry fresh, learn all jobs to the point where you understand what the workers do.

He will not be concerned that you will take over his position, eliminating the need for his employment. Rather, he will be pleased that you are taking an interest in what he does.

The basics of teaching a process apply: The operator tells you how to do it, you actually do it, then the operator tells you what you did right and what you did wrong. Then you do it again. This getting your hands on the equipment is important. Otherwise, it’s cursory learning, and that’s insufficient.

For instance, the inspector walks you through her work, talking about what she is looking for and how she spots the problems and what procedure she uses to make sure the problems are fixed to her

satisfaction. Then she watches you inspect garments and adds pointers as you go from one outfit to another.

For another example, the presser discusses his presser machine, how to work it, how to lay down the different garments, what to look for to see that the outfit is properly placed, what motions he makes, how his moves change with different types of clothing, what could go wrong, and what to look for to see that the garment is done properly. Then you do the work for a few hours or so. The presser offers suggestions, until you become pretty comfortable with the work. He suggests when to use steam and how suzies help mold outfits. That should be sufficient time for you to understand the basics.

A few examples will illustrate the need to be able to perform everyone’s job:

• The cleaner can’t remove a stain from a delicate fabric, and he is afraid to proceed further. He approaches you with his concern. Because you have bothered to learn about stain removal, you have some ideas. Together, you knock around the problem and come up with a new approach. It works, and the stain is removed. The cleaner is a hero, and you made this possible. Plus, the cleaner knows he can come to you for advice in the future.

• You’re bringing in a lot of commercial work that is creating bottlenecks with the regular cleaning processing. Because you understand each job, you can reconfigure each position in the assembly line to churn out the commercial volume without delay to the regular workload. You do this by setting up a second processing line ▲

42 American Drycleaner, November/December 2014 www.americandrycleaner.com

Education & t raining

Basic Pressing & Finishing. NCA course, to be held Nov. 8-9 in Bronx, N.Y. Call 212967-3002 or e-mail ncaiclean@aol.com.

NY State DEC Certification. Two-day NCA course, to be held Nov. 9 and Nov. 16 in Nanuet, N.Y. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Boss 2 Coach Seminar. SCCA event, to be held Nov. 12 in Commerce, Calif. Call 714-494-9350 or visit www.socalcleaners.org.

Avoiding Claims: What You Need to Know About Fabrics & Stain Removal. NCA course, to be held Nov. 23 in New York City. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Basic Spotting 101. NCA course, to be held Dec. 7 in Bronx, N.Y. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Stain Removal Seminar. SEFA event, to be held Jan. 31 in Fort Lauderdale, Fla. Call 877-707-7332 or visit www.sefa.org.

Shirt Laundry and Drycleaning Finishing Seminar. SEFA event, to be held Feb. 1 in Fort Lauderdale, Fla. Call 877-707-7332 or visit www.sefa.org. O

www.americandrycleaner.com

American Drycleaner, November/December 2014

43

industry observations

and positioning bins beside machines for storage. Also, you reconfigure staffing needs to spread out over longer shifts. You can solve the problem because you understand everyone’s job and how each position interacts with the overall process. This is called balancing the production process.

Employees want a boss who can relate to them and is not afraid to roll up his/her sleeves and get involved with the work.

• You think your driver/delivery person is not doing his job. His speediness leaves something to be desired. He says that he is moving as fast as he can, but the neighborhoods are too far apart. But you have gone with drivers and observed the delivery process.

You know that a driver who is not hurrying will take a much longer time than one who is hurrying. So, you break down the route into four segments and assign time completions for each and monitor the driver to get the work done in a timely manner. Furthermore, you assign him extra tasks because you know that a busy worker will push harder to complete his chores. Because you understand route delivery, you can force the driver to increase his effort.

• One daytime counter person says her replacement is not completing her shift assignment. When you confront the night counter person, she insists that the daytime counter person isn’t doing her job. Because you understand the counter procedures,

and have a good sense of how each person completes her shift without burdening the replacement, you can investigate the claims of each person and adjudicate a decision. Your decision will be based strictly on the facts, and no one can accuse you of playing favorites.

• Due to a location move, you’re setting up a new plant. Because you understand the needs of every staffer, just what he/ she requires to do his job well, you create efficient workstations. Because you understand the need for communication between the departments, you create an effective flow for communication. Because you understand where bottlenecks could arise, you can design a floor plan that will minimize the chance of problems occurring.

There’s another reason that you should learn all jobs. On a motivational level, nobody likes a boss who sits in his “ivory tower” office and monitors business from computer reports and manager meetings. Employees want a boss who can relate to them and is not afraid to roll up his/her sleeves and get involved with the work. Become a man of the people and find out how your staffers do their work.

The former dry cleaner said that the last thing he wanted was to waste his time. Possibly, if he had taken the time to learn jobs—to “waste time”—he would be in business today. O

Howard Scott is a longtime industry writer and dry cleaning consultant, and an H&R Block tax preparer specializing in small businesses. He welcomes ques tions and comments, and can be reached by writing Howard Scott, Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027 or via e-mail at dancinghill@ gmail.com.

American Drycleaner, November/December 2014 www.americandrycleaner.com

44

Retirement: Don’t Outlive Your Money

“Retirement” has a new meaning these days. For the fortunate ones, it still means a life of leisure: re laxing, gardening, golf, and perhaps an occasional trip. For others, it will mean continuing to work part-time to supple ment Social Security and inadequate re tirement savings. For most, it will mean switching from a lifetime of increasing income to one of decreasing income. For everyone, it will mean a new importance to skillful money management, the need to make sure that we don’t outlive our money. The psychological adjustment necessary to move from saver to spender can be distressing since there’s no magic bullet to melt away all of our concerns, but a carefully planned approach to managing your money in retirement will go a long way to ease the transition. Whether your retirement is a long way off or just over the horizon, following these guidelines will help:

KNOWLEDGE IS POWER. Every month, review your latest statements from banks and brokerages to add up your manage able assets. Don’t forget to include any cash on hand, CDs, etc. This is not a net worth statement; don’t include liabilities or the value of real estate, cars, etc. This way, you will know exactly

where you stand each month in manag ing your money, whether your finances are higher or lower, and by how much. This important knowledge can be a big help in deciding your future course of action.

SIMPLIFY YOUR FINANCES. As we get older, it becomes easier to make mis takes. The less complex your finances, the easier it will be to keep track of the essentials. Wherever possible, consoli date bank accounts, brokerage accounts, and retirement accounts into the fewest possible. Limit yourself to one credit card—two at the most. Simplifying your finances in this way will make it easier for you to analyze and manage your assets. An extra bonus will fall to your heirs, who will benefit from your simpli fied financial picture when you pass on.

MATCH INVESTMENTS TO YOUR RETIREMENT NEEDS. During your savings years, you have probably learned the impor tance of diversifying and allocating your assets. After retirement, this aspect of managing your finances is at least as, if not more, important than ever.

Diversifying your assets so that you are not too heavily invested in one company or industry will avoid the obvi ous damage to your portfolio should a serious failure occur in one company or industry.

46 American Drycleaner, November/December 2014 www.americandrycleaner.com Y OUR M ONEY

▲

Bill Lynott

FEBRUARY

MARCH

HERE’S WHAT’S COMING UP IN AMERICAN DRYCLEANER... Departments: • Product News • Around the Industry • Education & Training • Talk of the Trade • Upcoming Events • Your Views Survey Results • Wrinkle in Time • Classifieds

JANUARY Features: Plant Design Awards The 54th annual edition of our competition spotlights the best new plants and renovations completed in 2014. How to Avoid OSHA Fines Ensuring plants are up to standards and dodging pitfalls that can cost operators big. Editorial Submission Deadline — November 15

APRIL Features: Atlas of Atlanta Here’s what to see and do while in ‘Hotlanta’ for Clean ’15. Coin-Op Laundry A self-service laundry could make a plant a comprehensive fabricare center. Showcase: Point-of-Sale Systems Editorial Submission Deadline — February 15

MAY Features: Routes to Success The pros and cons of taking drycleaning services directly to customers. Clean Show: First from the Floor The big news from the just-completed event. Editorial Submission Deadline — March 15

Feature: Buyer’s Guide This annual directory of manufacturers and unique suppliers is a dry cleaner’s go-to resource anytime they’re looking to buy.

Want to send a press release or submit a story?

editorial

today!

E-mail:

...and much more!

Editorial Submission Deadline — December 15

Contact Bruce Beggs,

director,

Phone: 312-361-1683

bbeggs@ATMags.com

MISS OUT

Feature: Clean ’15 Show Guide Complete listings of the exhibitors, educational seminars and events that make Clean the industry’s can’t-miss show. Editorial Submission Deadline —January 15 DON’T

Once your assets are properly diversified, it’s important to allocate those assets among the three broad classes of investments: stocks, bonds, and cash. For example, your allocations might look something like this:

• During pre-retirement and early retirement years — Stocks, 60%; bonds, 35%; cash, 5%.

• During mid-retirement years — Stocks, 40%; bonds, 50%; cash, 10%.

• During later retirement years — Stocks, 20%; bonds, 50%; cash, 30%. Your actual allocations will vary accord ing to your own risk tolerance and preferenc es. Experts agree, however, that, in general, as one ages, investments in stocks should decrease in favor of bonds and cash.

RE-BALANCE YOUR ALLOCATION AT LEAST ONCE A YEAR. Chances are that at least one of your asset classes has grown or shrunk enough to change your allocations from your plan. When that happens, it’s time to re-balance to get your allocations back on target by selling one asset and shifting the money to the other assets as necessary.

MAINTAIN ONE YEAR’S WORTH OF CASH. Re gardless of your allocation strategy, you should maintain a year’s worth of cash. Add up your dependable income such as Social Security and pension and add enough cash to cover your expected expenses for one year. You don’t want to be put in a position of having to sell an asset at an inconvenient time in order to pay a bill.

BE PREPARED TO TAP INTO YOUR PRINCIPAL. One old admonition warns that you must never touch your principal. But it’s a rare individual who is wealthy enough to live in retirement entirely on dividends and interest

alone. For those who expect to tap into their principal, the 4% rule is widely recommend ed as a guideline. Here’s how it works:

According to many economists, all you need to do is withdraw 4% of your nest egg the first year of retirement, increase that dol lar amount each year by the rate of inflation to maintain your purchasing power, and that will give you 90% assurance that your sav ings will last at least 30 years.

As you might expect, not everyone agrees that the 4% rule will work for all. Still, it’s been around long enough to merit consider ation. Keep in mind that after you reach age 70½, required minimum distributions from your tax-deferred retirement accounts will provide cash in amounts depending on the size of those accounts.

There are, of course, many other aspects of managing money in retirement too numer ous to mention here, including such things as maintaining appropriate insurance coverage, when to file for Social Security benefits, learning what Medicare will or won’t cover, and the importance of creating an estate plan. However, following the basic guidelines in this article will provide you with a solid foundation for creating your total plan.

You may also want to consider reviewing your situation with a professional financial planner. A little personal guidance can help to smooth out some of the inevitable bumps in the road. O

Information in this article is provided for educational and reference purposes only. It is not intended to provide specific advice or individual recommenda tions. Consult an accountant or tax adviser for advice regarding your particular situation.

Bill Lynott is a freelance writer whose work appears in leading trade publications and newspapers, as well as consumer magazines including Reader’s Digest and Family Circle. Visit his website at www. blynott.com or e-mail blynott@comcast.net.

American Drycleaner, November/December 2014 www.americandrycleaner.com

48

Maineline Computer Sys. announces new ownership structure

Longtime owner and CEO Joe McCam mon has partnered with experienced Compassmax consultant Art Bai to take on ownership and management of Maineline Computer Systems, the com pany reports.

Owners Paul and Nancy Goldstein, who with McCammon founded Maine line in 1985, have stepped down to pur sue personal interests, according to a Maineline press release.

Kevin Rowell, a Maineline employ ee with 15 years of drycleaning industry experience and more than 30 years of experience designing software solutions for businesses, has taken on the key role of director of development and innova tion.

“W e’re very thankful for all the years Paul and Nancy put into the com pany. Maineline and Compassmax wouldn’t exist without their dedica tion and hard work,” says McCammon. “Art’s expertise and leadership will be a great asset to Maineline. He and I look forward to implementing many improvements and exciting new features to the software.”

For more than 25 years, Maineline has provided clients with a full-featured drycleaning point-of-sale software prod uct designed to improve efficiency in every aspect of the business, from sale

to delivery.

“Being relevant is all about adapting to changes in technology and the indus try, and continually earning customer loyalty and trust,” says Bai. “We look forward to the challenge and hope for your candid feedback along the way.”

Some changes, such as a new and more efficient support call-management system, are already in place. Clients can expect to see “many significant software improvements in the coming months,” Maineline says.

Caring Partners’ coats collection drive launched

Caring Partners recently kicked off its 20th annual Coats for Kids winter coat drive, sponsored by Anton’s Cleaners, Tewksbury, Mass., and Jordan’s Furni ture. The drive will run through Jan. 10. Coats for Kids is New England’s largest coat drive: more than 848,000 coats have been gathered since the program began.

“Coats for Kids offers an incredible opportunity for schools, local businesses and community organizations to collab orate on an activity that benefits those in need,” says Arthur C. Anton Jr., COO of Anton’s Cleaners. “Anton’s Cleaners is proud to be celebrating two decades of service in partnership with local busi nesses and organizations, and to help make winter a little warmer for children, teens and adults in Eastern Massa

around

50 American Drycleaner, November/December 2014 www.americandrycleaner.com ▲

the indu S try

THE ONE PLACE TO CONNECT, LEARN AND COMPARE.

Clean® 2015 is the only show in our industry where you can:

• Interact with more than 400 exhibiting companies showcasing every aspect of textile care

• Network with more than 10,000 industry professionals

• Gain knowledge through classroom sessions taught by leading experts in the field

• See live equipment demonstrations and compare the industry’s most state-of-the-art offerings, side-by-side

April 16-19, 2015 Georgia World Congress Center Atlanta, Georgia USA

Register now at www.cleanshow.com

C100 M0Y44 K0 PMS 3272 C C36 M0Y29 K0 65% opacity of PMS 346C (Outer ring of logo) C55 M0Y47 K0 PMS 346 C

chusetts and Southern New Hampshire.”

Participating schools, companies and organizations collect good-quality, warm winter coats and bring them to any of Anton’s Cleaners’ 42 locations or one of the five Jordan’s Furniture stores. Once collected and cleaned, coats are distributed free of charge through organizations such as BU Medical Center Outreach

Van Project, Catholic Charities, Community Giving Tree, Salvation Army, and many more. Last year’s drive collected 52,621 coats, with Anton’s donating more than $10,000 in cleaning services.

America’s Best Cleaners adds McCann as partner, operations director