Copyright20 ■ KEEPING STOCK: PARTS & SUPPLIES ■ COPING WITH HIGHER WAGES 15AmericanTradeMagazinesAllrightsreserved. October 2015 Logistics Transport &

Results on whites are excellent. On colors, you have nothing more to lose and everything to gain by trying YellowGo. YellowGo may take out color you want to keep. But if it removes the unwanted dye without damaging the underlying color, you win! You won’t have to pay for the dye-stained garments and you won’t disappoint your customers.

So use YellowGo to keep your customers happy and keep them coming back.

YellowGo® removes unwanted dye from fabric. For more information visit AlWilson.com or call us at 800-526-1188 or 201-997-3300

2 American Drycleaner, October 2015 www.americandrycleaner.com

AMERICAN AMERICAN October 2015 Vol. 82, No. 7 DEPARTMENTS Pre-Inspection 4 Talk of The Trade 6 Calendar of Events 8 Education & Training 8 Management Strategies 14 Keeping Stock Diana Vollmer Spotting Tips 28 Evaluate Before It’s Too Late Martin Young Industry Observations 30 Find That Uncommon Niche Howard Scott Around the Industry 36 Classified Advertising 38 Advertiser Index 39 Wrinkle in Time 40 FEATURES (Cover Photo: © iStockphoto/Susan Chiang) 10 Transport & Logistics Managing the flow of garments to best meet customers’ needs 20 Improving Profits While Paying New Higher Minimum Wages Upon weighing choices for maintaining margins, finding ways to motivate employees to improve productivity carries the least cost Woodruff Imberman, Ph.D. 26 Product Showcase: Boilers & Water Heaters 34 DLI App Eases Stain Removal, Customer Relations The Drycleaning & Laundry Institute’s newest member benefit seeks to connect with staffers Ian Murphy NEED HELP FINDING THE HIDDEN HANGER? Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck! 10

drycleaner

“Business has never been better.”

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

“We’re moving faster. We’re moving better. We’re moving more efficiently. That means profitability”

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

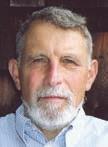

PhilLandauer, OwnerofPierceCleaners has never been better.”

BrentRamenofsky BostonCleaners

Right Place at the Right Time

You’ve probably heard the phrase, “He was in the wrong place at the wrong time.” I’ve heard it used most often following instances of unforeseen catastrophes: a pedestrian walking on a sidewalk is struck by a out-of-control car only because the unfortunate victim happened to be in that spot at that particular time, for example.

Logistics involves being at the right place at the right time. In the case of dry cleaning, nothing should be left to chance when it comes to managing the flow of garments from acceptance to cleaning to packaging to delivery.

Our Transport & Logistics story opening on page 10 examines the tools available to dry cleaners to speed

Publisher

Charles Thompson 312-361-1680 cthompson@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Main: 312-361-1700 Fax: 312-361-1685

workflow and to meet customer requirements.

In our other main article this month, columnist Diana Vollmer examines how a dry cleaner can best manage the parts and supplies that every operation should keep on hand (or at least have access to in short order). The plant consumes supplies, she says, but it’s important to note that stores, fleets, employees and the back office also go through their share. Read her story starting on page 14 to see what recommendations she makes.

Also in this issue, management consultant Woodruff Imberman takes on the topic of motivating employees in light of new higher minimum wages in Chicago and elsewhere, spotting expert Martin Young urges cleaners to “evaluate before it’s too late,” and small-business expert Howard Scott shares a tale about a misdirected e-mail and how it demonstrates that new business might be found in the last place you’d think to look. ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies $7.00 for U.S., $14.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 82, number 7. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason. © Copyright AMERICAN TRADE MAGAZINES LLC, 2015. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, October 2015

4

www.americandrycleaner.com

Advisory

Contributing Editors Carolyn Nankervis Howard Scott Diana Vollmer Martin Young Subscriptions 630-739-0900 x100

drycleaner.com

Board Steven Dubinski Mike Nesbit Herron Rowland Fred Schwarzmann

www.american

PRE-INSPECTION

Bruce Beggs

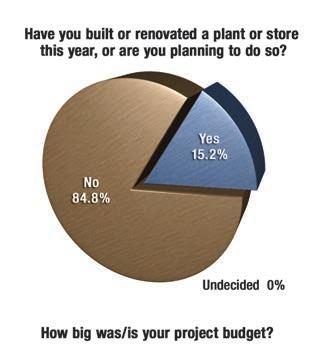

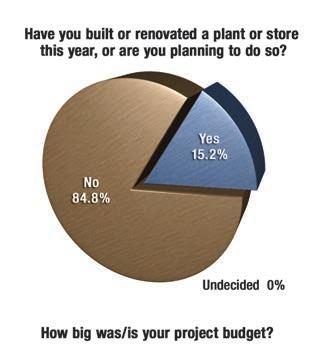

Plant Construction, Renovations Minimal This Year, Survey Results Show

Only slightly more than 15% of respondents have built, restored store during 2015

American Drycleaner is in the final days of accepting nominations for its 55th Annual Plant Design Awards, and it seems only a small share of respondents to September’s Your Views survey will be eligible to enter.

The Plant Design Awards is a recognition of the best new plants and renovation projects completed in 2015. Only slightly more than 15% of respondents have built or restored their store (or are planning to do so) this year.

Projects have ranged from cosmetic improvements or operational renovations to newly built plants or stores. One-third of respondents said they were undecided on their project’s scope.

Roughly 22% of projects cited feature new equipment or fixtures, 67% do not, and 11.1% of respondents are undecided about this.

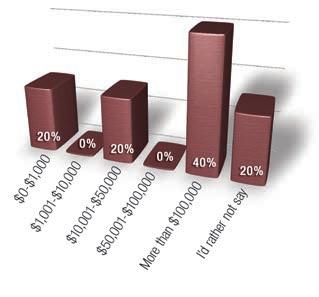

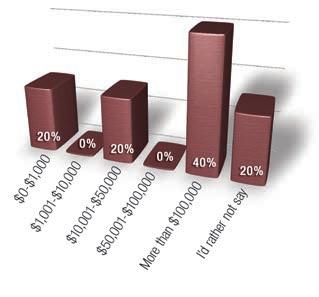

Regarding project budgets among respondents, 20% were up to $1,000, 20% were between $10,001 and $50,000, and 40% were more than $100,000. The remaining 20% of respondents declined to provide this information.

“It was a pretty easy process after we got through the design process,” reports one respondent. “We learned to build bigger than what we intended [and to] run additional wires and plumbing for new equipment. [It’s] much cheaper to do during the time of construction.”

The Your Views survey presents a snapshot of readers’ viewpoints at a particular moment and should not be considered scientific. Percentages may not add up to 100% due to rounding.

Subscribers to American Drycleaner e-mails are invited each month to take a brief industry survey they can complete anonymously. The entire trade audience is encouraged to participate, as a greater number of responses will help to better define owner/operator opinions and industry trends.

ADC

To find past Your Views survey stories or share this month’s with your colleagues, visit www.americandrycleaner.com.

6

www.americandrycleaner.com

American Drycleaner, October 2015

TALK OF THE TRADE

CALENDAR OF EVENTS

National Cleaners Association. TexCare 2015, to be held Oct. 16-18 in Secaucus, N.J. Call 800-888-1622.

JET Expo. To be held Nov. 8-10 in Paris, France. Visit www.jet-expo.com.

North East Fabricare Association. Fall Fest ’15, to be held Nov. 14-15 in Providence, R.I. Visit www.nefabricare.com.

Texcare Asia: International Trade Fair for Modern Textile Care. To be held Nov. 25-27 in Shanghai, China. Visit www.texcare-asia.com.

Drycleaning & Laundry Institute/National Cleaners Association Five Star Brainstorming. To be held Jan. 14-17, 2016, in Cancun, Mexico. Call 800-638-2627 (DLI) or 212-967-3002 (NCA).

Southwest Drycleaners Association. Cleaners Showcase 2016, to be held April 2224, 2016, in Fort Worth, Texas. Call 512-8738195.

Textile Care Allied Trades Association. Annual Management and Educational Conference, to be held April 27-30, 2016, in Ponte Vedra Beach, Fla. Visit www.tcata.org.

Texcare International: World Market for Modern Textile Care. To be held June 1115, 2016, in Frankfurt am Main, Germany. Visit www.texcare.com.

South Eastern Fabricare Association. Southern Drycleaners and Launderers Show, to be held June 24-26, 2016, in Jacksonville, Fla. Call 877-707-7332.

California Cleaners Association. Fabricare 2016, to be held Aug. 26-28, 2016, in Long Beach, Calif. Call 916-239-4070. ADC

EDU CAT I ON & T RA INING

How to Keep Your Business Out of Trouble, and Finding and Keeping the Employees You Need. PDCA seminar, to be held Oct. 3 in Harrisburg, Pa. Call 800-822-7352.

Understanding and Delivering Exceptional Customer Service. NEFA workshop, to be held Oct. 6 in Albany, N.Y.; Oct. 7 in Rochester, N.Y.; and Oct. 8 in Buffalo, N.Y. Call 800442-6848 or visit www.nefabricare.com.

Total Training for CSRs. NCA webinar, to be held Oct. 7. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Human Resources. Michigan Institute of Laundering and Dry Cleaning seminar, to be held Oct. 10 in Okemos, Mich. Call 877-390-6453.

Introduction to Drycleaning. Five-day DLI course, to be held Oct. 12-16 in Laurel, Md. Call 800-638-2627 or visit www.dlionline.org.

Advanced Drycleaning. Ten-day DLI course, to be held Oct. 19-30 in Laurel, Md. Call 800638-2627 or visit www.dlionline.org.

Wet Cleaning (UGGs). NCA course, to be held Oct. 23 in Bronx, N.Y. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Wedding Gowns. Midwest Drycleaning & Laundry Association seminar, to be held Oct. 28 in Notre Dame, Ind. Call 765-939-6630.

NY State DEC Certification. Two-day NCA course, to be held Nov. 8 and Nov. 15 in Nanuet, N.Y. Call 212-967-3002 or e-mail ncaiclean@ aol.com. ADC

Check out www.americandrycleaner.com/ drycleaning-events for updates between issues!

American Drycleaner, October 2015 www.americandrycleaner.com

8

www.fabricaremanager.com • 888.299.9493 Drycleaning Management at Your Fingertips Fabricare Manager Fabricare Manager’s point of sale system is the ultimate blend of power and simplicity. And if you ever need help, our technical support is known as the friendliest and most responsive in the industry. Now also available in the Cloud. Touch and Go!

Transport &

Logistics

With dry cleaning sometimes described as being a “place-based” industry— one that exists largely in physical locations that customers traditionally must visit in order to take advantage of an operator’s services—logistics plays an important role in the success of a particular operation.

What is logistics? The simple definition, according to Merriam-

Webster, is “the things that must be done to plan and organize a complicated activity or event that involves many people.” When focusing more tightly on business, it is managing the flow of goods between their point of origin and their point of consumption so that the requirements of a customer can be met.

So, in the case of a dry cleaner, it’s the acceptance of a garment

from the customer, including markin; handling of the garment through cleaning; packaging and storage of the cleaned garment; and either transportation of the cleaned garment to the customer or presentation of the cleaned garment to the customer upon their return visit.

Volume and turnaround times stand to have the greatest impact on

10 American Drycleaner, October 2015 www.americandrycleaner.com

(continued)

Managing the flow of garments to best meet customers’ needs

(Photo: ©iStockphoto/Susan Chiang)

Computer Systems Free cordless scanner with our Garment Verification System! SOFTWARE FAST EFFECTIVE AFFORDABLE!& POWERED BY DAJISOFT LET’S WORK TOGETHER: (888) 325-4763 www.dajisoft.com DryClean PRO Enterprise (DCPe) is even simpler to use than before SUPPORT LIKE NO OTHER Ask us about our DCPe Rental Built in marketing and e-mail functionality Designed for both small and large stores THAT IS

drycleaner logistics.

Frequently, dry cleaners use sophisticated point-ofsale (POS) software, peripherals and identification technologies such as bar codes and radio frequency identification (RFID) instead of simple tags to keep track of orders. Moving toward central processing facilities adds to the travel and tracking that orders require.

Initially, bar-coding takes slightly longer than traditional tagging, says consultant Diana Vollmer, but once the procedure becomes routine, the timing difference on initial mark-in disappears. After a substantial percentage of work is bar-coded, markin becomes much faster because many items need only be scanned.

POS systems have long been able to track customers and inventories, and to support new identification technologies. In recent years, dry cleaners have begun enhancing their order-tracking capabilities in greater numbers, using bar-coding and RFID chips to streamline a garment’s trip through every step of the cleaning process.

Cleaners who have big commercial accounts or restoration business regularly use such technology, but these tools can assist smaller cleaners in sorting and mark-in for everyday items such as shirts.

Conveyor or rail systems often play an important role for drycleaners, as they use them to handle and store hanging garments. They can be adapted to fit the space available, and to make best use of the vertical space in smaller operations. Automated assembly systems can enable a single employee to assemble hundreds or thousands of garments per day.

Good plant design also lends itself to good logistics. But make a mistake in a plant renovation or new

build, and you’ll pay for that mistake every day thereafter with inefficient space, or, worse, increased costs. Chris White and Ed D’Elicio point out these five mistakes to avoid:

1. Failing to start with the end in mind — Have a business plan that accurately reflects the reasons, costs and anticipated revenues of the new or renovated plant.

2. Scrimping on design services — Professional plant designers bring with them a wealth of experience and expertise that will give you the optimum results for your investment.

3. Falling prey to the ‘bigger is better’ myth — Determine a “just right” size for you by determining current market niche, current volume, plans for the addition of new services, pricing, and anticipated future volume, for a start.

4. Forgetting the three most important words: location, location, location — Any new facility should be centrally located within your market area, and near your labor pool and, if possible, public transportation.

5. Not doing the math — Establish the potential return on investment: the ratio of your costs to the benefits, which are future cost savings and/or profits.

If a dry cleaner offers pickup and delivery, then the acquisition and use of appropriately sized and styled vehicles is a must. Sprinter,

mini, regular and stretch vans are some of the more com mon choices in drycleaning delivery vehicles. Onboard rails and rolling garment racks enable drivers to access orders easily and transport them to a customer’s home or business.

Logistics don’t stop when transport begins. Most current drycleaning software packages include functions that map routes for the most efficient delivery manifest; vans can also be equipped with global positioning systems to tell drivers where to go next.

Drivers can be more effective if they are driving efficiently in a pattern that minimizes drive time and maximizes time available for sales and delivery. POS route management systems focus on efficiency and route geographical concentration to minimize cost and maximize efficiency and sales.

The traditional approach to running drycleaning routes two days per week per route has historically resulted in substantial swings in production during the week, says Vollmer, so scheduling must be done accordingly to maintain productivity and profitability goals.

The plant must also accommodate storage for the finished work awaiting delivery. For operations where space is tight, vertical storage/distribution towers can be an alternative.

Is there a limit to what technology can do for dry cleaners? There doesn’t seem to be.

Forward-thinking dry cleaners use every type of automation that is available and appropriate to speed workflow inside their plant and to make delivery seamless to the customer. Buoyed by technology, they can reduce costs, cut labor, and stand ready to take on additional business when the opportunity presents itself.

12

October 2015 www.americandrycleaner.com

American Drycleaner,

ADC

Forward-thinking dry cleaners use every type of automation that is available and appropriate to speed workflow inside their plant ...

MANAGEMENT STRATEGIES

Keeping S tock

Supply costs are a significant expense in a fabricare operation, so it is important to control supply inventory. Conversely, it is crucial to operational efficiency that supplies be on hand when they are needed to avoid downtime caused by delivery delays. To control both considerations, it is critical to achieve balance between cost and need.

The supply chain decisions necessary for smooth operations are many due to the various facilities and processes that occur throughout the company. The facility most common for supply discussions is the plant, but the stores, fleets, employees and the back office also consume supplies regularly. They, too, must be provided with a regular stream of replenishment determined by usage, delivery time, periodic bid price and desired safety cushion.

Managing these various streams of supplies can keep costs down while simultaneously providing for seamless operational functions.

Supply decisions should be made on both strategic and tactical levels to align with your company’s business goals. Major purchasing decisions such as the acquisition guidelines and built-in controls of the system will initially require a higher level of management involvement to achieve competitive advantage. Once those guidelines are in place, the daily decisions, inventorying and ordering process become easier to delegate and administer, keeping relationships and logistics in balance with expense considerations.

A first step in accomplishing this balance is to identify the list of supplies that are critical to the smooth operation of your business. Include all of the daily, predictable intermittent needs as well as the less predictable but critical items necessary. Then, all of the alternative sources

of the needed supplies should be identified, reviewed and, when appropriate, included in the periodic bid process.

“Just-in-time” delivery offered for daily supplies reduces the necessity of stockpiling many predictable items of need, such as chemicals, packaging, hangers, bar codes and store register tape. For example, if you can place the order for next- or second-day delivery, there is no need to keep a four-week supply and invest your capital in on-site stocks. If the need is unpredictable but truly critical, and the delivery time is six weeks, then the inventory investment cost must be weighed against the impact and duration of a breakdown and the alternatives available before order receipt.

K EEP-O N -HAN D C RITERIA

There are many criteria to identify which supplies are essential to keep on hand and which need a greater safety cushion of inventory. Some are listed here:

Extent of Downtime — How much downtime will be caused by a delay in delivery of the needed item? Will the delay create a bottleneck that slows the entire operation? Will the pieces per operator hour (PPOH) be affected?

Can your team still be productive during the delivery period? For example, are they cross-trained so they can work elsewhere during the period of the replacement and/or delivery delay?

Is there an alternative solution (or backup station) that can produce the work until the new part arrives?

If the item is expensive but absolutely necessary to operations, and the need not predictable, do you know a friendly competitor that could provide

14 American Drycleaner, October 2015 www.americandrycleaner.com

(continued)

Diana Vollmer

Managing parts and supplies that every dry cleaner should keep on hand “‘Just-in-time’ delivery offered for daily supplies reduces the necessity of stockpiling many predictable items of need...”

interim capacity (such as a cleaning machine that you can use in the off-hours) or can an alternative be readily leased (such as a portable boiler on a trailer)?

Can the labor force be sent home without disruption of the plant and/or employees for a short period while the piece is rushed overnight or during the installation of the part?

Predictable Usage — Is the supply item usage predictable? How often does the part need to be changed?

Item Cost — How expensive is the part or supply?

Financial Flexibility — Do you have the financial flexibility to buy in bulk to achieve a cost savings? If so, would a bulk purchase disrupt your local supplier relationship, and to what extent would that affect your costs and delivery on other items you need regularly?

Needed Resources — Do you have the resources (cash and space) to build in a reasonable but larger margin of safety to protect your plant efficiency?

Level of Necessity — Is the supply necessary to achieve and maintain your desired level of quality of cleaning, finishing, packaging as well as tracking/control over consistency?

Customer Experience — Does it contribute to a consistent or improved customer experience at your target level?

Management Effectiveness — Will it increase management effectiveness?

Operational Efficiency — Will it improve efficiency? For example, will the addition of a supply or part reduce the amount of support staff needed? This can happen with a retrofit part that corrects a weakness, such as an added sleeve placket pressing attachment. It can also be affected with a chemical that improves the cleaning in the wheel and reduces the need for individual spotting.

Capacity — Will it improve capacity, i.e. faster throughput provided by bar codes?

Customer Impact — Will the lack of stockpiling impact the customer in any way?

Image/Brand Impact — Will the lack of inventory impact your image and branding message, i.e. logo zip comforter bags vs. plain packaging?

Employee Morale — Will the lack of a reserve stock of the item impact employee morale? For example, worn-out padding is far less efficient than properly functioning pads and will negatively affect employee morale because it is more difficult to make productivity goals.

Leaking steam traps have a similar impact, as does the absence of paper products in the restrooms.

Dependence on Staff — Will it make you less dependent on your current staff or make them “smarter”? As recruitment and retention challenges increase, less reliance on people is a major consideration. Example:

Drycleaner,

Scanners help eliminate human error.

COMPILING THE INVENTORY SUPPLY LIST

The easiest way to compile a central list is from supply invoices over a quarter and a year. Your suppliers can usually provide these aggregated lists to you. By comparing all items ordered last quarter against those ordered last year, you will be able to identify the predictable items and your consumption rate.

Items that were ordered less frequently than quarterly will help you identify the non-predictable but critical items that must be monitored, i.e. weekly testing of the compressor for operational efficiency.

A basic list by category and item from which to build

is offered by most suppliers and may simplify the process initially.

For control and consistency, it is recommended to have a central coordination of the supply ordering, including the use of sequential purchase order numbers. This might be part of one person’s responsibility in a small company or a part of the accounting department in a larger one.

This function controls the daily application of the strategic and tactical decisions relating to supply inventory, which should clarify:

• How will the critical items be made visually prominent for the person counting them?

• How often must the supplies be inventoried and replacements ordered?

• Who is responsible for counting the stock and/or writing the order?

• How is the purchase order controlled and approved?

• How is the resulting shipment, packing slip and price compared to the contracted purchase order? (Note: In many jurisdictions, by law the supplier cannot increase the price over the original price printed on the purchase order.)

• Ways to keep costs down, i.e. by combining items on a single order, implementing the periodic bid process, etc.

• Who calculates how many days or weeks of supply are needed on hand for a given item, and what is the desired safety cushion needed (continued)

16

www.americandrycleaner.com

American

October 2015

“The easiest way to compile a central list is from supply invoices over a quarter and a year.”

for that item?

• Where will the inventory be stored: centrally vs. on site at facility? Central stores can provide a less expensive safety-cushion alternative, but it must be clear who is responsible for fulfilling and delivering the order to the site that needs it. Consistency in these procedures and guidelines will ensure a more reliable stream of supplies to the relevant operating units.

INVENTORY CONTROL AND ORDERING FORMS

A consistent and easy-to-use inventory control and ordering spreadsheet will help keep supplies stocked at designated levels. It will also help identify if the target levels continue to be optimum or if they need to be revised. This may be necessary on a seasonal basis, with sales trends, or as different individual items trend up or down.

Most accounting programs have inventory control and ordering components, so check to see if your program has an integrated inventory component.

Pictured below is a simple sample of a few items that are necessary in a typical cleaning operation. It is selfcalculating (including total expenditures for the period)

and provides searchable historical data regarding your supply list, the related costs, the supplier that won bids at various points in time, delivery timing, and actual usage.

In reality, your list will be much more comprehensive as you list all of the items you order regularly.

If you have not yet set up an inventory control and ordering system, keep in mind that once it is completed, your ability to track, manage and predict your supply costs will become a simple process that is easily delegated. ADC

Methods for Management (MfM) has served the drycleaning and laundry industry with affordable management exper tise and improved profitability since 1953. For assistance with supply purchasing decisions, contact Diana Vollmer at dvollmer@mfmi.com or call her at 415-577-6544.

18 American Drycleaner, October 2015 www.americandrycleaner.com “A consistent and easy-to-use inventory control and ordering spreadsheet will help keep supplies stocked at designated levels.” Inventory Date: _____________________________ Order Date: _____________________________ CategoryItem Contract Price Bid Supplier Used/ Week Del. Days Safety Margin Base TotalOn HandOrder QtyTotal ProductionPackagingPrice/Unit ZipBag$1.21XYZ90310019030160$193.60 Logoclip hanger $0.89ABC50035001,000600400$356.00 Hanger 18” Hanger Knit StoresRegister Tape BarCods Deposit Slips Hanger Caddy Etc.Etc. Etc.Etc. Total Order This Period $549.60

Century Laundry P.O. Box 5818 Cedar Rapids, IA 52406 775 Kacena Road Hiawatha, IA 52233 Phone: 319-364-1592 Email: rmalcolm@centurylaundry.com

Improving Profits

While Paying New Higher Minimum Wages

Scheduled increases take effect in Chicago, elsewhere

By Woodruff Imberman, Ph.D.

Dry cleaners across the nation will soon face the same problems now confronting those in Chicago: how to maintain profit margins

new local ordinances raising minimum wages.

The Windy City’s $8.25 minimum wage jumped to $10 an hour on July 1 and will increase incrementally to $13 an hour by 2019. These higher minimums make higher productivity a must for dry cleaners.

The industry has never been known for paying high wages in laborintensive central plants, where labor is about 45% of operating costs. These new rules will not only affect dry cleaners in areas covered by the new rules but also those in next-door communities, because some workers are ambitious enough to make extra efforts of

job-hopping to cleaners offering extra pay, despite the “PITA Factor” (more on that in a moment).

Who will be most affected? margins.

• Dry cleaners now paying wages below the newly mandated minimums. They will be forced to raise their wages immediately as the new regulations dictate. These cleaners will either have to raise prices, improve employee productivity, or accept lower profit

• Dry cleaners in communities “next door” to those directly affected by the new regs. They will be forced to raise their wages to prevent their best workers from job-hopping to local competitors paying the higher mandated rates. Ambitious workers with the drive and ambition to make extra efforts for extra pay are most likely to switch jobs. These are the best

(Photo: ©iStockphoto/ChrisGorgio)

20 American Drycleaner, October 2015 www.americandrycleaner.com

(continued)

shirt pressers, clerks and assistants that cleaners want and need to retain, even at higher pay levels.

• Dry cleaners within and near the areas covered by the new rules who now pay just over the new, mandated minimums.

They will be forced to raise their entire wage scale for two reasons: first, because their higher-skilled central plant employees—spotters and dry cleaners—will want higher pay than their lower-wage counterparts; and second, because of the egotism and self-respect of higher-skilled workers who view themselves as “better” than minimum-wage workers, and will demand more. Their sense of entitlement is powerful. Again, boosting employee productivity is the best way to maintain profit margins.

(maybe a 10% chance) to move. The effort of the extra commute isn’t worth it.

The second is convenience. The fewer headaches involved in the commuting, the more likely an employee will switch jobs.

If the commute just means a longer bus or rapid transit ride, a worker is far more likely to switch than if the commute to the new job involves several buses or trains, or walking more than several blocks at either end of the ride. The PITA factor means many job seekers choose ease over ambition.

Employers wanting to retain top-notch workers will have to increase their pay rates. The PITA factor is less of an irritant to ambitious workers than to their more indolent counterparts for whom a sense of entitlement builds so large.

Dry cleaners face declining profit margins unless they improve current worker productivity so they can afford the newly mandated pay rates. The alternatives are investing in labor-saving equipment or increasing their prices to cost-conscious consumers. But how to improve employee performance, and what is the better performance worth?

TWO TYPES OF EXPENSE: OVERHEAD AND OPERATING COSTS

THE ‘PITA’ FACTOR AND WHY IT’S IMPORTANT

Simply put, the “PITA” factor—or what I call the “Pain in the Arse” factor—is the ease and convenience with which an employee can switch to a job paying the higher mandated wages—and the need to raise their wages to retain them.

Because ease trumps ambition, how quickly employees will seek the higher-paying jobs depends upon the PITA factor. It has two elements, says Antonio Baxton, spokesman for the Regional Economic Development office of the Illinois Department of Commerce and Economic Opportunity.

The first element is distance. If a higher-paying job— say a store clerk/assembler or shirt presser—opens up in a cleaner less than a mile away from an employee’s home or current job, there is about a 95% chance the worker will make the effort to switch jobs. If the job is about three miles from home, there is a 60% chance the worker will job-hop. But if the higher-paying job is more than five miles away, the worker is extremely unlikely

Dry cleaners are faced with two types of expenses: overhead costs and operating costs.

Good examples of overhead costs are rent; real estate taxes; initial capital investments in equipment; computer software and hardware systems; websites and marketing; and professional services like accounting. Whether business is good or slow, these costs remain fixed. Prudent dry cleaners try to keep their overhead low and watch these expenditures like hawks.

Good examples of operating costs are labor, the cost of materials (hangers, plastic garment wrap, etc.), and utilities. The greater the volume of business, for example, the larger the inventory that is needed. The longer the hours of business are, the more hours that employees must be there—and paid—to attend to customers.

Labor is often more than 40% of a dry cleaner’s total operating costs. Materials are another 15-20%, and utilities are about 10%. Obviously, the more productive employees are, the fewer of them are needed, thus lowering a cleaner’s biggest cost segment. By improving

22

www.americandrycleaner.com

American Drycleaner, October 2015

(continued)

“Because ease trumps ambition, how quickly employees will seek the higher-paying jobs depends upon the PITA factor.”

employee productivity, a dry cleaner can keep prices level and maintain profit margins despite the higher pay rates mandated by the new minimum wage laws.

Although many dry cleaners are aware of high labor costs, few focus on measuring employee productivity and/or asking themselves how they can improve it. Obviously, better employee productivity has an immediate impact on a dry cleaner’s bottom line, especially those that have typically paid at or near the minimums.

THREE CHOICES FOR SMALLER BUSINESSES

To maintain their already thin margins, dry cleaners have three options: 1) they can raise prices, 2) substitute costly new equipment for labor, or 3) find ways to improve the productivity of current staffers.

Each has its cost. Raising prices irritates customers. Paying for new equipment is expensive, and few banks are interested in financing such purchases for smaller businesses. But the third way—finding ways to motivate current employees to improve their productivity and performance in order to offset the new, higher pay rates— costs only thought and ingenuity.

Faced with higher minimum wages, thoughtful dry cleaners are now trying to find ways to motivate central plant employees to improve their productivity and boost quality, thus creating fewer internal re-dos or customer returns. (Most recently, I discussed the most effective ways of doing this in my October 2012 American Drycleaner article, Boosting Productivity.)

EFFECTIVE MOTIVATORS

A few years ago, I published the findings of three nationwide surveys we conducted before, during, and after the Great Recession. Their purpose was to discern how employers were trying to motivate their workers to improve their performance, and their perceptions as to which methods were effective.

The results clearly showed that the Great Recession made a severe impact on employees at all levels. Faced with job loss, reduced pay levels, and the general insecurity of the time, most wage earners said job security and paycheck size were the most important motivators. Second, short-term economic motivators like Gainsharing plans seemed to match employees’ short-term horizons and had the greatest impact on worker performance.

Gainsharing is a group pay-for-performance program under which employee performance is quantified and

American Drycleaner, October 2015

given a dollar value. When it improves over a threshold pre-set by management, the value of the improvement is split with the workers. So, for every dollar paid out to workers in Gainsharing bonuses earned by specific measures of short-term performance, dry cleaners save a like amount in higher productivity (less overtime, fewer staffers) and better quality (fewer internal re-dos and customer complaints).

Since Gainshare earnings are paid on a short-term basis (often monthly), they have to be earned and re-earned each short Gainshare period. This negates any notion that Gainsharing is an entitlement.

Gainsharing dovetails nicely with employee expectations: Central plant workers expect to receive “extra” rewards for any “extra” efforts expected of them. Fulfilling these expectations is critical for the long-term success of any initiative attempting to boost employee performance. If the “extra” is absent, employee cooperation in any new venture will be short-lived.

In most central plants, the most effective way to motivate employees to improve their performance is to design and implement a group Gainsharing plan, tying better performance to increased pay with short-term payoffs.

Much ink has been wasted in newspapers and magazines, and much time spent on Sunday talk shows as talking heads debate the wisdom of raising minimum-wage rates.

Rather than wrangling with the issue, astute dry cleaners can make better use of their time by finding ways to motivate employees to improve their performance.

When are you going to start? ADC

Dr. Woodruff Imberman, Ph.D., is president and CEO of Imberman & DeForest Inc., a management consultancy based in Evanston, Ill. He has written several articles for American Drycleaner over the years on employee productivity, employee motivation and supervisory training. For more information, e-mail Imberman at info@imbdef.com or call him at 847-7330071.

24

www.americandrycleaner.com

“

...finding ways to motivate current employees to improve their productivity and performance... costs only thought and ingenuity.”

Hoffman Manual Utility Press (Used) $1,995* UniMac 50-lb. Washer (Used) $4,200* Columbia 80/80 Tandem (Used) $34,995* Champion 5 HP Air Compressor (Used) $950* Hoffman Form Finisher $3,295* Rema RP5 Air Vacuum $2,295* Forenta Double Topper (Used) $3,500* Cissell 120-lb. Gas Dryer $6,375* Lattner 20hp Boiler $12,400* Milnor 60-lb. Washer $6,995* Unipress Single Buck SB1 (Used) $10,500* Unimac UM202 Washer $3,800* Bowe 40 Hydrocarbon Machine $28,500* Forenta Triple Puff Iron 33PS $1,700* Speed Queen 75-lb. Gas Dryer (Used) $1,800* 1/2” Steam Traps $35 each, 5 trap minimum 86 6 - 73 4 - 364 4 Monthly Specials Online: MustangEnterprises.com New & Used Equipment for Drycleaning & Laundry Huge Selection of Parts for Most Brands of Equipment Prices valid until November 1, 2015 | *Freight Not Included

BOILERS & WATER HEATERS

Lattner Boiler Co.

Since 1918, Lattner Boiler Co. has been a major supplier of steam boilers to the laundry and drycleaning industry. Now, in its fourth generation of family ownership, it continues to ensure that its products are safe and dependable, the company says.

Pictured is the newest of the Lattner line, a 4 pass WLF boiler equipped with the latest, highly efficient, low-emission power burner.

The boiler’s features include:

• 150-psi design pressure

• ASME valve and trim package

• Fully modulating gas valve for optimum operating efficiency

• Night operating pressure control

• Fully insulated, high tech ceramic sleeves with powder coated metal jacket www.lattnerboiler.com | 800-345-1527

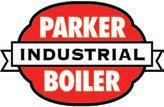

Parker Boiler Co.

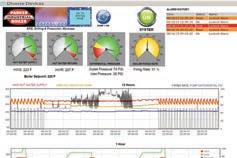

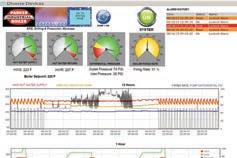

ParkerView Lite (PV Lite, pictured above right) and ParkerView Modbus (PV Mod), from Parker Boiler Co., are cellular-based boiler control and monitoring systems custom-designed for each application that allow owners and operators to be offsite yet know their boiler system is ready to provide heat for their building or industrial process.

System status can be viewed on a web dashboard at anytime from anywhere, the company says.

Facilities can schedule start-ups and shutdowns, which can save energy and ensure the plant is ready when production is started. Offsite owners or operators can gain a high degree of confidence in knowing

their facility is ready to go when heat is needed, Parker says. When an alarm condition is detected, PVLite or PV-Mod will send a text or e-mail to indicate there is a problem.

The devices come standard in a 12x12x4 plastic, weather-proofed NEMA 1 enclosure to improve cellular transmission. They can be mounted indoors or outdoors, and require a 115V/60Hz/1Ph power source. They contain a UL Listed power supply and a Verizon Network-certified cellular modem.

Options exist for a remote antenna for basement boiler rooms.

Either system can be purchased as a standalone device and installed in the field by others, or they can be provided mounted on a new boiler.

A low-cost, one-year cellular plan is required at time of purchase, Parker says. The initial purchase can be made through Parker or a third party, but subsequent plans must be purchased from the third party.

www.parkerboiler.com | 323-727-9800

Fulton

The Classic™ is Fulton’s original vertical tubeless boiler, first sold into the laundry and drycleaning market in the 1940s.

Available for steam or hot water applications, the Classic™ features a simple and compact design that minimizes footprint and maximizes production, the company says.

Along with its proven reliability, the Classic™ achieves efficiencies to 80% and is available with oil and/or gas fuel capabilities and an optional Low Emissions burner (gas only)—all packaged and

26

www.americandrycleaner.com

American Drycleaner, October 2015

PRODUCT SHOWCASE

trimmed for heavy-duty application, Fulton says. No additional fuel train items or electrical wiring is needed.

Fulton reports that it has sold more than 100,000 Classic™ boilers in a wide range of sizes to locations around the world, securing it as a mainstay in Fulton’s product collection.

In addition to the Classic™ boiler, Fulton offers a full range of vertical and horizontal steam and hydronic boilers for the industrial and commercial markets, the company says.

www.fulton.com/steam | 315-298-5121

Ludell Manufacturing

Ludell Manufacturing’s “Mini” Direct Contact Water Heater is designed for energy efficiency. This direct contact technology is fully condensing and heats water by a method different from that of a conventional boiler, the company says. Efficiencies up to 99% can be achieved and hot water provided instantaneously with this technology, it adds.

Customer benefits, according to Ludell, include:

• No special pressure vessel permits required

• No certified boiler inspections required

• No tubes to rod-out or replace

• No need to chemically treat or deaerate feed water

• Stainless steel construction for equipment longevity

• Availability of hot water instantly

• Rapid return on investment (with 30% water

www.americandrycleaner.com

heater fuel savings being typical, the company says)

• Minimal equipment maintenance

• Reduces thermal pollution

• Stack exhaust temperature of less than 100 F

• Easy operation and equipment installation www.ludellmanufacturing.com | 800-558-0800

Hamilton Engineering

Hamilton Engineering’s 15-plus years of condensing water heating production have led to the next generation of high-efficiency water heaters, departing from what the industry has offered before, the company says. The newest addition to its line is the 3VO.

Made in its Michigan plant, Hamilton Engineering’s 3VO water heaters range in capacity from 750,000 to 4 million Btu/hr. All models fit through a 36-inch doorway, which Hamilton says is the smallest footprint in the industry.

It offers fully assembled packages, providing single-point utility connections on systems with up to eight appliances (as much as 32 million Btu/hr). Category IV common venting is available using the company’s proprietary non-return valve and operating software, which Hamilton says is proven with more than 25,000 installations of its EVO™ product.

Other machine features including a fully serviceable heat exchanger, with removable heads with straight tubes that are individually cleanable and replaceable; service access from front and rear, with zero clearance required on the sides; and a pressure drop that Hamilton says is the industry’s lowest in any water-tube product, and lower than the majority of fire-tube products.

Controls are Hamilton’s own HOT™ (Heating Optimization Technology), providing full remote access for both observation and control. Systems ship from factory fully configured, the company says, and no additional programming is required during system start-up.

www.hamiltonengineering.com | 800-968-5530

American Drycleaner, October 2015 27

Evaluate Before It’s Too Late

To get the most out of your stain removal efforts with the least amount of risk, you must take into consideration the unique characteristics of the garment. Foremost in these characteristics are the fiber content, the weave construction, the intensity and method of dye, and any ornamental trim.

The garments you receive are as varied as the fashion taste of your customer base. I once had a three-piece ladies suit that seemed to contain enough “hardware” to make a full set of harnesses for a team of Clydesdales. Unfortunately, stain removal is not one size fits all. The stain removal specialist must quickly assess the garment and make decisions on a course of action based upon the characteristics I listed.

The fiber is the smallest part of the thread/yarn that makes up the fabric, and the various types are classified by their origin.

Cellulose fibers come from a plant and are reasonably durable. This fiber is sensitive to acid pH, so you must neutralize any tannin or rust remover as quickly as possible. Experience has shown me that a large number of cellulose items contain surface dyes that are easily disturbed by the mechanical action used in stain removal.

Protein fibers come from an animal and are easily damaged by alkaline pH, so you must neutralize any protein formula as quickly as possible. This also means that any salt (perspiration) or alcohol (mixed drink or perfume) can damage the fabric and may not be noticeable until after the loosened dye is flushed away during cleaning. Never use chlorine bleach on a protein fabric, as it will produce an irreversible chemical burn.

Silk grows weak when wet, so go gently with mechanical action when spotting wet-side.

Be aware that low-twist yarns are common in wool and its “cousins,” which can lead to pilling if subjected to aggressive mechanical action during spotting.

There are a multitude of synthetic fibers; examples are nylon, spandex, acrylic, acetate and polyester. All are

products of modern chemistry and are heat-sensitive to some degree. Steam is hot, so take a hint.

Acrylic is so sensitive that it can lose its shape just by pulling it across the spotting board while still warm. Most synthetics can trace their origin back to petroleum, and there is additional difficulty in removing oily stains from these garments.

Rayon is a hybrid; it is cellulose (wood pulp) that has been treated with chemicals to break down into individual fibers. It is subject to color loss, weakening when wet, and damage from acid pH. Time and patience are required for successful supplemental stain removal in rayon.

Fabric construction will weigh heavily on the choices you can safely follow when performing supplemental stain removal.

A plain weave is when the yarn is woven with one over, one under, the horizontal yarn at a 90-degree angle to the vertical yarn. A twill weave is when the yarn is woven with one over, one under, the horizontal yarn at a 45-degree angle to the vertical yarn. Both these constructions are reasonably stable and thus can endure mechanical action well.

Chiffon is an ultra-sheer plain weave that is prone to snags and yarn slippage. You should cover the bristles of the brush with a cloth, or purchase a “padded” brush, for tamping chiffon.

Satin is a type of construction, not a fiber. It produces a sheen by going over one, under four, with the yarn. This floating weave makes satin prone to yarn slippage when mechanical action is applied. Satin should be worked from the underside; a padded brush reduces the risk of yarn slippage. Like chiffon, never brush—tamp only.

Velvet is commonly seen in two fibers: cotton and acetate. Cotton velvet is a delicate in the eyes of the stain removal specialist. Work the stains from the surface side with little or no mechanical action. When using steam, double your distance to 6-8 inches away to reduce the chance of disturbing the surface appearance.

When you are presented acetate velvet to clean and spot, stop and think. To say that acetate velvet responds poorly to any moisture is a gross understatement. Acetate

28 American Drycleaner, October 2015 www.americandrycleaner.com

SPOTTING TIPS

Martin Young

velvet maintains its appearance (nap standing) through the use of a sizing that in most cases is water-soluble. Moisture and any pressure will cause the nap to collapse, and this condition is difficult to restore.

Color is probably the first thing you notice about a garment. The darker, deeper, more intense the color, the easier it is to leave a light area after mechanical action. You should also judge the probable method of dyeing. Ask yourself if the garment appears to contain an excess of surface dye. Take a dry, white towel and wipe over the surface of the garment. Any trace of dye remaining on the cloth is a warning as to the result of using steam and mechanical action in supplemental stain removal.

Often a designer/manufacturer will add decorative trim to make the garment more appealing to the consumer. There are various ways to attach trim: paint, adhesive, sewing and metal prongs are only a few. Decorative trim must be protected. Routinely using a POG on an ink mark could damage the painted trim. Steam and pressure could loosen trim that is glued on the garment’s surface.

Evaluating each garment in relation to fiber content, construction, color and trim takes only seconds. Making that evaluation a part of your stain removal protocol will make your supplemental stain removal safer, quicker, and more effective.

So, a customer presents a navy rayon blouse, chiffon construction with glued-on glitter along the button placket and a half-dollar-size mustard stain at the third button from the bottom. How do you proceed? ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates to this day. Contact him by phone at 704-786-3011, e-mail mayoung@vnet.net.

www.americandrycleaner.com American Drycleaner, October 2015 29 ADC_Hhalf.indd 1 9/1/15 3:26 PM

(Photo: ©iStockphoto/Romanchuck)

Find That Uncommon Niche

Irecently received this e-mail: “Hello. My name is Jane Smith. I am a martial arts teacher, and my students are on vacation, so I want you to clean and press my students’ tae kwon do uniforms. The man that always does the cleaning is not available. That is why I want you to do it. I usually pay $12 per uniform, so I want you to give me a discount, OK?”

Obviously, this is some sort of mistake. I write about dry cleaning, but I do no dry cleaning. Perhaps she meant to send it to a dry cleaner, but mistakenly sent it to me. Anyway, we can learn something from her mistake. Who knew that tae kwon do uniforms needed to be

dry-cleaned? And why would her students need to be on vacation?

Most likely, they are outfits that can be processed in a day or two. (Or is there some special care required?) Furthermore, $12 is quite a good price. If she had 50 students, that’s $600. Maybe she cleans them three times a year. That’s $2,000 worth of business. Not bad for an erroneously received e-mail.

I would ask these questions: How many tae kwon do studios are in the area? Do some general gyms offer tae kwon do? Could I grab the urban tae kwon do business? And what is tae kwon do anyway? (I believe it is some sort of karate, but I don’t know.) Which leads me to this question—do any other martial arts practitioners clean their uniforms?

If I were a dry cleaner, I would reply to the woman’s

30 American

October 2015 www.americandrycleaner.com

Drycleaner,

INDUST RY OBSERVA TI ON S ADC_R_Hhalf.indd 1 11/3/14 2:27 PM

Howard Scott

e-mail and tell her I would love to clean the uniforms. Then, I would follow up with a phone call. Next, I would visit her studio and examine the uniforms, feeling them and evaluating how much work cleaning them would entail. Then I would inquire how they are used, which also would help me get a feel for the nature of the cleaning required. If she were teaching students at the time, I would watch. Mentally, I would figure how much it would cost to dry-clean the uniforms.

She says she pays $12 a uniform, so I would offer to clean them for $10 each, if I could. If $10 won’t give you a profit, offer to clean the uniforms at $11 a piece. The point is, if you are handed business, it is always good to better the competitor’s offer. Later, you can raise the prices so that your full profitability is achieved. On the other hand, I certainly wouldn’t do the work at a loss.

After I did the job, I would seek out other tae kwon do studios in the area, casting myself as an expert. You could say, “I’ve had a lot of experience cleaning tae kwon do uniforms. I know how the fabric folds and bends, and how to process the outfit so that it comes out looking new. In fact, I consider it one of my specialties.” A little exaggeration perhaps, but with a few more jobs under your belt, you’ll truly become an expert. This is the way to develop niche businesses. Seek out

the opportunities. Discover how the garment is used. Figure out the best way to clean and process the garment. Print up a one-page sheet, mentioning the special handling done with these outfits. Hand out the sheet to prospects, or mass-mail to an organization of prospects. Building on that base, go after more business.

Let’s go over each step:

SEEK OUT OPPORTUNITIES

This e-mail erroneously sent to me provided the opportunity, but such serendipitous offers don’t always fall into your lap. So, you must always be on the lookout for potential trade. When in business districts, look around. Consider a business’ special needs.

Perhaps that karate studio teaches tae kwon do. It’s possible that restaurant uses linen tablecloths that must be dry-cleaned. Might that hotel dry-clean its concierge outfits? Does that second-floor medical lab dry-clean its lab coats?

Does the factory at the end of the retail district dryclean some of its work outfits? Does the school up the street dry-clean its graduation outfits? Might the theater on the second floor need to dry-clean some of its props?

Does the Masonic organization have any outfits that need to be periodically dry-cleaned? Does

www.americandrycleaner.com

October 2015 31

American Drycleaner,

MADEIN THE USA MADE IN THE US A Connect with Us PARISER INDUSTRIES, INC. www.pariserchem.com 91 Michigan Ave. info@pariserchem.com Paterson, NJ 07503 973-569-9090 USA LAUNDRY Aqua Velvet Complete One Shot Wet-Cleaning detergent with stain remover and conditioner. Hydrocon Highest Quality Wet-Cleaning conditioner and re-texturizer with Optical Brightener. Shot Spot Multi-purpose wet-side spotting agent/collar solution for a wide range of spotting applications Activate Advanced, color-safe de-staining and safe-bleaching formulation containing a low temperature catalyst LS-100 Natural starch and synthetic sizing blend. WET-CLEANING Shouldn't you know what Hundreds of New Customers already know... for Laundry, Wet-Cleaning, Dry-Cleaning & Fire Restoration Chemistry...count on PARISER INDUSTRIES For nearly half a century, smart cleaners have been using Pariser Industries’ family of wet & dry cleaning products manufactured RIGHT HERE in the USA. Start saving on your Cleaning Chemistry Costs today by asking your local distributor for samples of Pariser Products. Citrazyme Complete “One Shot” powdered laundry detergent w/enzymes, oxygen bleach and citrus degreaser. Napthol-T Powdered laundry detergent formulated to clean dark shirts in cool water temps. Mega Bryte Premium “One Shot’ powdered laundry detergent w/non-phosphate water conditione rs Citrasol Concentrated Citrus based liquid degreaser additive. Excellent for oil and grea se stains. Stand Up Highly advanced synthetic liquid starch for shirts and denim jeans. Superior sti ffness when desired. ADC_Hhalf.indd 1 4/10/15 1:49 PM (continued)

the church at the end of the block dry-clean its vestments? Does the beekeeping club need to dry-clean its keeper outfits? Do fencing club members dry-clean their costumes?

Look through the Yellow Pages—yes, they’re still around—and try to spot opportunities. For example, maybe the costume shop cleans some of its rentals. Small-equipment rental shops may dry-clean their uniforms because those outfits get dirty and uniform rental is too expensive. Read the local newspaper; maybe an ad can lead you to a customer. Whenever you meet someone who works in an unusual business, question the need for dry cleaning. For example, does a funeral director need to dry-clean its formal wear?

Of course, an Internet search can reveal professions that might require drycleaning services. As a 30-year beekeeper, I wrote a little book, Bee Lessons, and sold 30,000 copies. One type of customer is retail honey

stores, which are now cropping up around the country. But how do you find out who and where they are? I Googled “retail honey stores in Texas,” and did the same with the other states. Ultimately, I obtained a long list of prospects, which I called.

DISCOVER HOW THE GARMENT IS USED

This will help you figure out how it needs to be drycleaned and what special treatment can improve the clean ing. For example, it is usually hot when beekeepers don their outfits and work with hives. Therefore, a beekeeper’s outfit develops perspiration stains under the arms on the inside of the garment. Perhaps you could suggest an inside-the-garment treatment to remove perspiration.

Secondly, beekeeper uniforms accumulate a lot of yellow and tan stains. Maybe you can borrow an outfit and figure out which chemical used in combination with another would remove these stains. Armed with such

32

www.americandrycleaner.com

American Drycleaner, October

2015

INDUSTR Y OB SERVATIONS CONGRATULATIONS! to the winners of our iPad and Android tablet give away at the Clean Show. Join them in reading our digital edition on your tablet too!

Lori Benson e Towel Guy LLC, Toms River, New Jersey

0915adc_House Tablet Winner_Hhalf.indd 1 8/14/15 10:30 AM

Heidle Baskin Baskin Laundry LLC, Canton, Texas

knowledge, you could attend several bee club meetings and discuss your service. Sure, the beekeeper could launder his outfit, but you could provide a better cleaning that will make his bee outfit look like-new.

PRINT A PROMO SHEET

Talking it up is good, but handing out a sales sheet reinforces the sales pitch. Furthermore, it gives you credibility. It demonstrates that you are a specialist. It states facts that may entice the prospect. If you could obtain a list of beekeeper organizations, you could send out promo sheets to all of their members. Most likely, a certain percentage (5% if a poor mailing, 20% if an effective mailing) would take up your offer.

SELL YOUR SERVICE IN PERSON

Whenever you encounter a niche practitioner, make an argument why they should dry-clean their clothes and why you should be the one to do it. Point out your experience. Cite a few customers, saying something like this: “You know that tae kwon do school in the next town. They’ve brought all their uniforms to me for three or four years. We’ve figured out all the tricks that make them come out really clean and looking like-new. My process adds years to the outfits.”

PROMOTE YOUR EXPERTISE

Speak about the cleaning service at club meetings. Write articles about the service that could be published in the local newspaper. Add a slogan that anoints you with specialized skills, such as, “We Can Do Tae Kwon Do.”

GO AFTER MORE NICHE BUSINESS

Once you master tae kwon do volume, go after other niches. This specialty work is good business because it is something that not everyone does. Therefore, you can charge a premium price. Also, you’ll develop a reputation. More customers will come to you.

Create four or five specialties and you might be increas ing volume 20%. That’s not breaking down the doors, but, because of the exclusivity of the work, it could double your profit. At any rate, you could schedule the processing so that it takes up the slack in your production cycle.

Who knows. Maybe becoming a “tae kwon do cleaner” will be just the kick your business needs. ADC

Howard Scott is a longtime industry writer and dryclean ing consultant. He welcomes questions and comments, and can be reached by writing Howard Scott, Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027, or via e-mail at dancinghill@gmail.com.

www.americandrycleaner.com American

October 2015 33

Drycleaner,

DLI App Eases Stain Removal, Customer Relations

By Ian Murphy

By Ian Murphy

The Drycleaning & Laundry Institute (DLI) debuted its latest member benefit—a mobile app offering step-by-step instructions on removing common stains, information on problem garments, and more—at the Atlanta Clean Show. Now available for both Apple and Android mobile devices, the app is yet another added value of membership.

“People are happy with it, and we’re excited,” says Jon Meijer, DLI’s membership director. “It’s a product that’s designed to strengthen the package we offer to members at no additional cost. It’s a benefit that’s hard not to like.”

SOLVING HUNDREDS OF STAINS

Designed for use by staffers in the back of the plant and at the front counter, the app’s most distinctive feature is the Stain Solver, an easy-to-use, comprehensive guide to the techniques required to remove hundreds of common stains.

“DLI typically works with the owners or managers of plants, but we never really have any interaction with the staff—the people pressing and removing stains,” says Ricardo Gonzalez, who built the app as DLI’s web developer. “The idea was to create something that would be useful to them while they’re working in the plant.”

but ate “What we are trying to do is get deeper into cess to readily at the spotting board, so they can

“What we are trying to do is get deeper into organizations,” adds Mary Scalco, DLI’s CEO. “We frequently know the owner of the store, but we wanted something employees would have access to readily at the spotting board, so they can get the training they need when they need it.”

The Stain Solver offers a selection of more than 40 staining substances, grouped into Beverage, Food, Pets, Oils, Cosmetics, and Personal categories. It cross-references users’ stain selections with 17 base fabrics—including angora, metallic, mohair and spandex in addition to cotton and wool—to produce complete stainremoval instructions.

DLI is already updating the Stain Solver with Spanishlanguage instructions, more staining materials, and other features.

EASING EXPLANATIONS AT THE COUNTER

DLI has also incorporated archives of its popular Technical Analysis Bulletin Service (TABS) to explain potential garment failures and other problems that can occur in processing to customers with questions and complaints.

All TABS appearing in the app have been checked for accuracy, updated, and rewritten when necessary, Gonzalez notes. And if the first two functions of the app don’t answer every question, there’s an additional option at the bottom of the screen: a “Contact” button members can click to call or e-mail directly from their tablet or smartphone.

ON-THE-JOB TRAINING

Houston-based MW Cleaners is testing the app in two stores. “I don’t know how you could get the interface to be much simpler,” says Mike Nesbit, company president and DLI treasurer. “If we have a stain we’ve identified, and there’s a question whether to go at it on the acid or alkaline side, it’s easy to come up with the answer.”

stores. “I don’t know how you could get the interface to

simpler,” there’s whether to go at it on the acid or alkaline side, it can be used without an Internet connection, untethering employees from stores’ point-of-sale (POS) systems or networks. first tool cleaning Online are actively moving DLI’s technological

Following initial download and log-in, it can be used without an Internet connection, untethering employees from stores’ point-of-sale (POS) systems or networks. The app is the first tech tool DLI has released since the Encyclopedia of Drycleaning Online debuted in 2011. “We are actively moving DLI’s technological level up to today’s standards,” said Gary Maloney, the operator of Nu Yale Glacier Cleaners in Jeffersonville, Ind., who helped spearhead app development as DLI’s District 4 Director and chairman of its Technology Committee. Next up are an app to assist with garment analysis, as well as webinars exploring new-media marketing topics. “As an association, we want to add new members and strengthen our current memberships,” Meijer says. “We want to keep making members happy, and we have to introduce new products to do it.” ADC

Freelance writer Ian Murphy served as editor of American Drycleaner from 1999 to 2011.

34 American Drycleaner, October 2015 www.americandrycleaner.com

(Photo: Drycleaning & Laundry Institute)

■ Have you invested in renovations, equipment upgrades, or an entirely new drycleaning plant? Enter your project in the 55th Annual American Drycleaner Plant Design Awards!

Every year, our magazine honors the best new plants and renovation projects, recognizing them for appearance, efficiency, convenience and comfort. Your plant could be next! You can find our online entry form at: https://americandrycleaner.com/ 55th-annual-plant-design-awardsentry-form

■ Fill out the form completely and upload a layout (blueprint or sketch) and several photos (300 dpi digital files are preferred, but color photos will also suffice) that show off the features that make your drycleaning plant an excellent place to do business.

And include any information you believe is relevant to the way your plant’s design attracts customers and fulfills your production needs. The more detailed the entry, the better!

Perhaps you’ll join the likes of previous grand prize-winners Wooven, Pompano Beach, Fla.; Corona Del Mar (CDM) Cleaners, Newport Beach, Calif.; and Rainbow Cleaners, Oxford, Miss., at the pinnacle of the drycleaning industry. But you can’t win if you don’t enter!

■ Entries are subject to verification. Contact Editorial Director Bruce Beggs, 312-3611683, bbeggs@ATMags.com, with any questions.

American Drycleaner is accepting entries until Friday, Oct. 23. Good luck!

2014 Best Plant Design CDM Cleaners • Newport Beach, Calif. 2013 Best Plant Design Rainbow Cleaners • Oxford, Miss. 2015 Best Plant Design Wooven • Pompano Beach, Fla. Celebrating 55 Years! Entry DeadlineExtendedtoFriday, Oct.23!

Eastern Funding hires Regan as VP of sales and marketing

Commercial lender Eastern Funding LLC has hired An thony “Tony” Regan as its vice president of sales and marketing.

Regan will be responsible for companywide sales and marketing across the grocery, drycleaning, franchise fast food and coin laundry business lines. He will manage all of Eastern Funding’s loan officers and report directly to senior management.

Prior to joining Eastern Funding, Regan was senior vice president of sales and marketing at American Dryer Corp. (ADC). He has more than 20 years of experience in the laundry industry and was part of the captive finance program at ADC.

“Anthony is a fantastic addition to our team,” says Stephen Gramaglia, chief operating officer of Eastern Funding. “His vast experience in na tional sales and marketing as well as his specific experience in the laun dry industry is invaluable. Anthony will enhance our already strong sales team and create a platform to deliver excellent service to manufacturers, distributors and end-users.”

Private equity firm to acquire majority stake in Alliance Laundry Systems

Private equity firm BDT Capital Partners LLC has agreed to acquire a majority interest in Alliance Laundry Systems from Ontario Teachers’ Pension Plan, accord ing to Alliance. Completion of the deal is expected soon; additional terms were not disclosed.

“Our management team will hold a significant owner ship stake following the transaction and is excited by the new partnership with BDT,” says Mike Schoeb, Alli

ance’s president and CEO. “This partnership will allow us to accelerate the execution of our proven growth strat egy, continue to invest in new and innovative products of exceptional quality and strengthen the value we bring to our premier distribution partners.”

“Our long-term capital will provide a solid foundation and long runway to continue to pursue exciting growth opportunities around the world,” says Chip Dunn, man aging director at BDT.

Alliance Laundry Systems designs, manufactures and markets commercial laundry equipment under the brand names Speed Queen®, UniMac®, Huebsch® and IPSO®, among others.

Teachers’ Private Capital, the private equity group of Ontario Teachers’ Pension Plan that acquired Alliance in January 2005, is expected to retain a minority interest following completion of the transaction.

Bakker joins Sankosha USA sales team

Sankosha USA has hired Bud Bakker as regional sales manager, the company reports; his main territory will be the western United States and Canada.

Bakker comes to Sankosha with more than 30 years of experience, including having owned and operated his own drycleaning business.

“Our pioneering products and the increasing demand from our customers led us to look for an addition to our team who will fit in with our innovation and exceptional service,” says Sankosha USA President Ken Uchikoshi. “It is very fortunate that we were able to find someone of Bud’s caliber to fulfill this role.”

Wes Nelson, vice president of sales, called Bakker “a consummate professional with immense knowledge of the commercial laundry and dry cleaning industry.”

“With more than 30 years of expe rience under his belt, Bud is poised to make an immediate impact on our business, offering support for both our dealers as well as providing endusers with the most cost-effective solutions,” Nelson says.

36 American Drycleaner, October 2015 www.americandrycleaner.com

AR OU ND TH E IND US TRY

Regan

Bakker

Huntington Co. adds pair of franchise development execs

The Huntington Company, an international franchisor for retail and restoration dry cleaners, has added Steve Lajiness and Josh Titler to its team as franchise develop ment executives.

“These two highly experienced professionals have a substantial amount of franchise sales expertise that will enable them to contribute to the future growth of our brands, namely Martinizing and CRDN, the Certi fied Restoration Drycleaning Network,” says Wayne Wudyka, CEO of The Huntington Company.

Lajiness’ 30-year career includes management, training, operations and sales. Previously, he served as vice president of franchising at Service Brands International, han dling Molly Maid, Mr. Handyman and ProTect Painters, following the same position at Electronic Res toration Services (ERS), where he helped launch ERS from conception.

Lajiness also was director of fran chise development for BELFOR Franchise Group, launching the DUCTZ and HOODZ franchises, after three years as a business con sultant with Molly Maid.

Titler joins The Huntington Com pany after a decade in business and franchise development for national brands that include ProTect Painters, Seniors Helping Seniors, DUCTZ and HOODZ. His experience includes recruiting, train ing, and franchise support encompassing sales, IT and operations.

“This team will be involved with franchise develop ment for all of our brands going forward, creating op portunities for new owners and current Partners who are considering expansion, splitting off territory or selling their business,” Wudyka says. “Working with an expan sive broker network, the team will target entrepreneurs looking to capitalize on our opportunities as well as those current business owners who see the value in con verting to one of our brands.

“We now are in a solid position to strategically and systematically expand our global reach that already ex ceeds 750 locations.”

Primus Laundry Equipment makes North American debut

Commercial laundry equipment brand Primus ® is now making its equipment available to North American fabri care businesses, the company reports.

“Primus offers one of the most comprehensive prod uct lines available, with cutting-edge technologies built into each and every machine,” says Mark Schram, North American sales manager. “We look forward to the even greater innovations ahead as Primus equipment contin ues to evolve, backed by Alliance Laundry Systems’ leadership and an accredited distribution network.”

Acquired by Alliance in 2014, Primus offers a full line of equipment for Laundromats and on-premises laundry (OPL) environments. Flagship products include small-chassis equipment and tumble dryers, hard-mount washer-extractors, and an exclusive vended soft-mount washer-extractor line.

Across all segments, Primus is dedicated to develop ing durable, reliable products that use less water and energy, are easy to use, and are more cost-effective than competitive models, the company says, adding that products meet quality standards in four categories—en ergy, ergonomics, ecology and design—to ensure cus tomer requirements for durability and performance are satisfied.

While Primus made its official North American debut in September, its equipment had been sold in the U.S. and Canada for two decades under a supply agreement with another manufacturer. This is good news for store owners, according to Schram, as a “solid history of ex cellence” is already in place, as well as capabilities to provide OEM parts, service and support when replacing existing equipment.

“Primus is already recognized globally for bringing industry-leading efficiency and value to vended laundry owners,” he says. “We’re pleased to now confidently provide this value to North American store owners under the Primus name.”

Primus is poised to provide North American store owners with creative and flexible finance programs tailored to the needs of each customer. Additionally, Alliance’s Customer One™ program gives store owners access to resources that include laundry design and site selection expertise, OEM parts, and dedicated sales and service personnel.

Primus can be reached at 920-748-3121, or e-mail primus.sales@alliancels.com.

www.americandrycleaner.com American Drycleaner, October 2015 37

ADC

Lajiness

Titler

2015 RATES: One- to five-time rate: $2.00 per word, boldface $2.10 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 12-time rates. If box number is used,

add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted.

DEADLINE: Ads must be received by the 1st of the preceding month.

For example, for a June ad, the closing date is May 1st.

PAYMENT FOR CLASSIFIED ADS: Must accompany order.

Volume over $700,000. With or without real estate Located in Lake Worth FL. Contact Gene 561-252

38 American Drycleaner, October 2015 www.americandrycleaner.com

BUSINESS OPPORTUNITIES COMPUTER SYSTEMS CHEMICALS ENHANCE YOUR WET-CLEANING SMARTCare Detergent, Conditioner & Sizing Nature-L In-The-Wash Grease & Oil Remover EnLIGHTen Removes Stains Sodium Perborate Can’t KLEERWITE CHEMICAL www.kleerwite.com 877-553-3794 Own Your Own Drycleaners—Managers, Spotters, Tailors, Pressers! 100% Financing. Plant or Drop, location of your choice. Call 1-561-302-5031 or 1-888-275-6637.

store plus wholesale shirt