5 American Trade Magazines All rights reserved. TEXCARE ASIA’S SHANGHAI RETURN SHARING GLOBAL BEST PRACTICES 15 Nov/Dec 2015 ‘Netflix’ of Haute Couture Fashion Fabricare &

Perc users – chlorinated solvent belongs in your machine, not on your board. Alternative solvent users – use stain removers that align with your chosen solvent. Replace traditional POG’s and VDS’s with TarGo® EF and EasyGo®, two of Wilson’s high-performance, cost-effective, California-compliant stain removers. You'll be taking steps to avoid future regulatory and remediation nightmares, while providing your customers with the garment quality they desire!

EasyGo spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to TarGo EF to remove any tough oil based stains that remain behind.

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

Time to Remove

From Your Board! Embrace Your Environmentally Friendly Future with Stain Removers from A.L. Wilson

It's

Chlorinated Solvents

STAIN

at ALWilson.com

use

GreenEarth is a trademark of GreenEarth Cleaning, LLC.

Become a

WIZARD

For GreenEarth,®

||G|| Go®

drycleaner

2 American Drycleaner, November/December 2015 www.americandrycleaner.com

AMERICAN AMERICAN

4

FEATURES

Nov/Dec 2015 Vol. 82, No. 8 DEPARTMENTS Pre-Inspection

Talk of The Trade 6 Calendar of Events 8 Spotting Tips 28 Arrival of Cooler Weather = Outerwear Martin Young TCATA Report 30 Industry Observations 32 Improving Productivity Behind the Counter Howard Scott Around the Industry 36 Classified Advertising 38 Advertiser Index 39 Wrinkle in Time 40

10 IDC: Sharing Global Best Practices The

dry cleaners

16 Texcare Asia Returns to

The

trade show offers opportunity to reach growing markets 20

26

NEED HELP FINDING THE HIDDEN HANGER?

20

(Cover Photo: Bruce Beggs)

Japan Cleaning Productivity Council-hosted event drew

from around the world Diana Vollmer

Shanghai

biennial

The ‘Netflix’ of Fashion: Rent the Runway The designer apparel rental business’ prodigious growth means the country’s largest drycleaning plant is about to double in size Bruce Beggs

Closer Look: A. L. Wilson Chemical Co. First in a new series of profiles of manufacturers, distributors and other businesses that serve the drycleaning industry

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

“Business has never been better.”

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

Since 2003, CBS has given me consistent updates and easy to understand tech support, all at a price that our industry can afford. I would recommend CBS, and I have, to anyone who is still wasting their time and money on those over priced POS systems.

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

DanLoesher

better.” 800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

SunshineCleaners

BrentRamenofsky BostonCleaners

Fashion & Fabricare by Mail

I’ve seen plenty of massive, high-volume operations, from my days covering the industrial laundry segment of this industry for American Drycleaner’s sister publication American Laundry News.

But when I was fortunate enough to tour Rent the Runway’s plant in Secaucus, N.J., recently, I was surprised that a plant turning out that kind of volume was doing so in service of dry cleaning.

ness, and VP of Operations Charles Ickes kept his tablet in hand as he led me and a handful of other attendees of NCA’s TexCare through the apparel rental biz’s plant that will be doubling in size shortly.

Rent the Runway has found success catering to women in their 20s and 30s who want to wear haute couture but can’t afford to buy from top designers.

Just as Netflix provides its customers with the hottest new movies and TV shows via DVDs by mail, Rent the Runway offers customers the opportunity to rent a dress or gown for four days—long enough for the fashionconscious to look stunning at that wedding, gallery opening or a special night on the town.

Bruce Beggs

The simple sign out front and the warehouse-like exterior gave no hint of the highly choreographed production inside or the fact that millions of dollars of designer apparel and accessories can be found there on any given day.

Data is the driver behind this multimillion-dollar busi-

To maintain its huge inventory of the latest styles, Rent the Runway has to build and maintain relationships with designers. It’s fashion and fabricare working hand in hand to keep customers looking fabulous. ADC

Publisher

Charles Thompson 312-361-1680 cthompson@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Main: 312-361-1700 Fax: 312-361-1685

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies $7.00 for U.S., $14.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 82, number 8. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2015. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner,

4

November/December 2015 www.americandrycleaner.com

Advisory Board Steven Dubinski Lawton Jones Mike Nesbit Herron Rowland Fred Schwarzmann Contributing Editors Howard Scott Diana Vollmer Martin Young Subscriptions 630-739-0900 x100 www.american drycleaner.com PRE-INSPECTION

About Iowa Techniques Iowa Techniques is a manufacturer and distributor of unique products that work in a wide variety of industries and applications, and currently focuses on helping dry cleaners make smart choices that impact the bottom line in their plant operations. When your water heater dies, DON’T replace it! Get a DynaFluid 2000 from Iowa Techniques! Getting Steamed? the (800) 727+1592 | www.iowatechniques.com With steam from your boiler and a cold water source, this little valve makes an infinite supply of hot water. It outperforms water heaters by every measure, cutting costs and increasing productivity. Call Iowa Techniques today and learn how the DynaFluid Valve will help your business! (800) 727+1592

High Percentage of Dry Cleaners Believe Prices Being Charged are ‘Too Low’

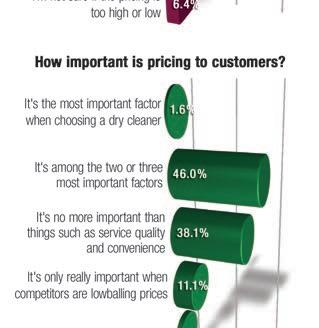

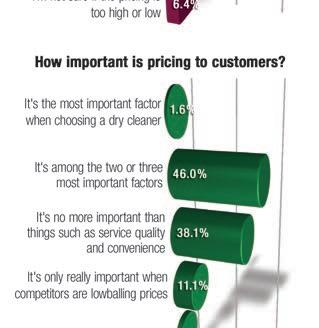

A majority of dry cleaners (44.4%) believe that— based on what dry cleaners in their area (including their business) are charging—prices are “too low.” That’s the key finding from October’s American Drycleaner Your Views survey.

About 22% believe that operators are charging a “fair price,” while 20.6% say pricing “varies too much to make a general statement.” Equal shares of 6.4% say that prices are “too high” or that they are “not sure” if pricing is too high or low.

Nearly 54% of dry cleaners polled have raised service prices this year. Reasons mostly related to keeping up with rising labor, utilities and supply costs.

Do you offer any type of explanation to customers when you raise your drycleaning prices? Among respondents to the anonymous survey, 41.3% do but 58.7% do not.

Nearly 80% of dry cleaners sometimes add upcharges based on a garment’s condition, its size, the type of fabric, etc.

Only 25.4% say their prices are “clearly displayed” in their stores.

How important do you think pricing is to customers? Among respondents, 46% believe “it’s among the two or three most important factors,” and 38.1% say it’s “no more important than things such as service quality and convenience.”

Roughly 11% believe that “it’s only really important when competitors are lowballing prices.” Roughly 2% say it’s “the most important factor when choosing a dry cleaner.” The remaining 3.2% aren’t sure how important pricing is to customers.

The Your Views survey presents a snapshot of readers’ viewpoints at a particular moment and should not be considered scientific. Percentages may not add up to 100% due to rounding.

Subscribers to American Drycleaner e-mails are invited each month to take a brief industry survey they can complete anonymously. The entire trade audience is encouraged to participate, as a greater number of responses will help to better define owner/operator opinions and industry trends. ADC

American Drycleaner,

6

November/December 2015 www.americandrycleaner.com

TALK OF THE TRADE

DLI, NCA members ready to head back to Cancun for annual Brainstorming

The Drycleaning & Laundry Institute (DLI) and the National Cleaners Association (NCA) are now ac cepting registrations for their annual joint Brainstorming & 5 Stars Conference in Cancun, Mexico.

Hosting the Jan. 14-17 event will be the all-inclusive Akumal Riviera Maya, a Secrets Resort. It’s located farther south along the same coast where 2015 attendees enjoyed their stay at Secrets Playa Mujeres.

“The Secrets Resort at Akumal Riviera Maya promises to deliver the exceptional atmosphere, customer service and amenities you know and love,” DLI says.

“Only at Brainstorming & the 5 Stars 2016 can you find so many great speakers, so much learning, camaraderie and food, drink, fun, activities and entertainment, all in one place,” says NCA.

After the welcome cocktail party on the evening of Jan. 14, the educational program tailored to help dry cleaners grow their businesses will begin.

The agenda includes:

• Friday morning, Jan. 15 — Rory Vaden, Procrastinate on Purpose: The 5 Permissions You Need to Say NO.

Vaden will discuss the strategic challenge behind an overwhelming workload and present information that will cause hard-working owners and managers to rethink their calendar, get control of their workflow, and shift their thinking from “urgent” to “relevant.”

• Saturday morning, Jan. 16 — Jonah Berger, the bestselling author of Contagious: Why Things Catch On, will share the secrets about why things go viral and share the six principles of what makes people talk about you online and offline.

• Sunday morning, Jan. 17 — Amanda Johns Vaden, Best Marketing Approaches to the Generations: Millennials, Gen-X and Boomers I and II. There are four main generations in the workplace, Vaden says, and every single one prefers a different channel of communication. Knowing how to connect and reach each generation is crucial to business success.

DLI and NCA promises there will be plenty of time to socialize with friends and to meet other dry cleaners outside the daily presentations.

To learn more, or to register for this limited-space event, call DLI at 800-638-2627 or NCA at 800-8881622. ADC

American Drycleaner,

CALENDAR

JET Expo. To be held Nov. 8-10 in Paris, France. Visit www.jet-expo.com.

North East Fabricare Association. Fall Fest ’15, to be held Nov. 14-15 in Providence, R.I. Visit www.nefabricare.com.

Texcare Asia: International Trade Fair for Modern Textile Care. To be held Nov. 25-27 in Shanghai, China. Visit www.texcareasia.com.

Drycleaning & Laundry Institute/National Cleaners Association Brainstorming & 5 Stars Conference. To be held Jan. 14-17, 2016, in Cancun, Mexico. Call 800638-2627 (DLI) or 800-888-1622 (NCA).

Southwest Drycleaners Association. Cleaners Showcase 2016, to be held April 22-24, 2016, in Fort Worth, Texas. Call 512873-8195.

Textile Care Allied Trades Association. Annual Management and Educational Conference, to be held April 27-30, 2016, in Ponte Vedra Beach, Fla. Visit www.tcata.org.

Coin Laundry Association. Excellence in Laundry Conference, to be held May 18-19, 2016, in Ojai, Calif. Call 800-570-5629.

Texcare International: World Market for Modern Textile Care. To be held June 1115, 2016, in Frankfurt am Main, Germany. Visit www.texcare.com.

South Eastern Fabricare Association. Southern Drycleaners and Launderers Show, to be held June 24-26, 2016, in Jacksonville, Fla. Call 877-707-7332.

California Cleaners Association. Fabricare 2016, to be held Aug. 26-28, 2016, in Long Beach, Calif. Call 916-239-4070. ADC

Post notices of your organization’s events on www.AmericanDrycleaner.com

www.americandrycleaner.com

8

November/December 2015

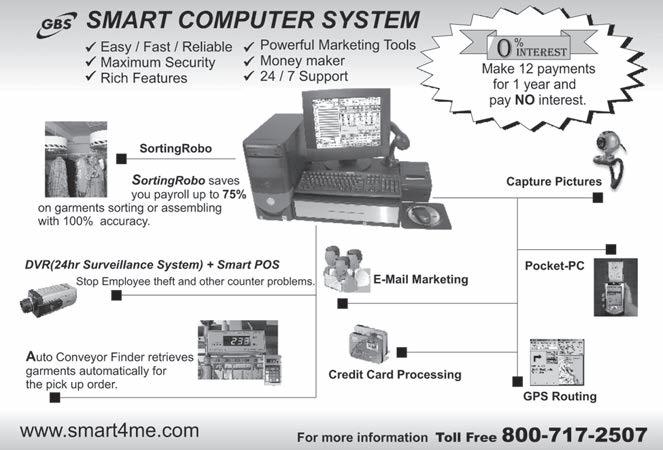

www.fabricaremanager.com • 888.299.9493 Drycleaning Management at Your Fingertips Fabricare Manager Fabricare Manager’s point of sale system is the ultimate blend of power and simplicity. And if you ever need help, our technical support is known as the friendliest and most responsive in the industry. Now also available in the Cloud. Touch and Go!

IDC: Sharing Global Best Practices

By Diana Vollmer

By Diana Vollmer

The International Drycleaning Congress drew more than 250 participants during its Sept. 13-16 stop in Osaka, Japan.

The Japan Cleaning Productivity Council (JCPC) hosted the international gathering, arranging venues, events and logistics in a thoroughly professional and gracious manner, including simultaneous translations that rivaled the United Nations General Assembly.

Toshiyuki Izumi, president of IDC 2015, presided over the event from initial welcome to the closing Sayonara Party.

JAPAN’S DRYCLEANING INDUSTRY

In Japan, there is one cleaning shop for every 800 people; in contrast, there is one shop for 16,250 people in the United States (approximately). Yoshio Nishikawa, president of NIC Corp., offered insight into why the Japanese drycleaning industry has been able to achieve such impressive market penetration and success.

He attributed the initial achievement to high economic growth that resulted in white-collar job expansion, combined with a program of industry craftsmanship and apprenticeship from the 1950s through the 1970s. Later growth resulted from learning from external global best practices and then customizing and improving upon them.

This approach, Nishikawa says, applied to the franchising model, reducing inventory through pre-payment, promot-

ing the “clothes changing seasons,” TV advertising, direct marketing, central plants supplying dry stores, more efficient equipment and robotics, and professional management characterized by the Peter Drucker principles of “thinking, acting, passionate, participation.”

Nishikawa closed by reviewing the challenges the industry faces in Japan as its population continues to shrink and the country becomes more dedicated to preserving limited natural resources.

ENSURING FUTURE GROWTH

Shuhei Numazaki of U-GO Corp. spoke on Ensuring Future Growth in the Business. His company has increased sales by 3000% since 2000 by operating 140 shops under the Cleaning Senko brand that targets families with the logo of “The Most Fun Cleaners in Japan,” and 20 MIXMAX operating locations targeting millennial professionals as the “Coolest Cleaner in Japan.”

The brands have profiled consumers for maximum cleaning usage and honed their messages to a fine point for those targeted customers and prospects. Cleaning Senko stores are decorated for maximum family entertainment so the entire family enjoys the experience.

For example, the mascot is a black rabbit named after a popular movie star, and promotional efforts are built around an ongoing story about the rabbit and his family. In-store décor and games are designed to engage and challenge all ages. Walls are painted black to create fun messages to engage and interact with visitors to the stores.

10 American Drycleaner, November/December 2015 www.americandrycleaner.com (continued)

International Drycleaning Congress (IDC) attendees were aided by translators in a scene reminiscent of the United Nations General Assembly. (Photos by Diana Vollmer)

Computer Systems Free cordless scanner with our Garment Verification System! SOFTWARE FAST EFFECTIVE AFFORDABLE!& POWERED BY DAJISOFT LET’S WORK TOGETHER: (888) 325-4763 www.dajisoft.com ❱❱ DryClean PRO Enterprise (DCPe) is even simpler to use than before SUPPORT LIKE NO OTHER Ask us about our DCPe Rental ❱❱ Built in marketing and e-mail functionality Designed for both small and large stores THAT IS

The associates are called “cast members” to help engender the sense of interaction to delight the customers. This culture is reinforced by a companywide retreat (families come, too) to a Disney resort.

MIXMAX uses clever promotions with TV ads, videos, social media and customer newsletters. The “race to the store” ad, which rewards every seventh customer, and the “Tuesday” ad are especially entertaining and effective.

U-GO is strategic in its management recruitment, attracting university graduates that aspire to corporate career paths. It has designed its recruitment, training, promotions, unique headquarters, and company vision all with dedicated quality management in mind.

To keep its team of 850 people informed and trained in a consistent manner, U-GO uses CYBOS, a cloud-based interactive trackable communication system that is now being upgraded to an even more advanced alternative.

Homedry Cleaners in Kobe, a family-owned operation of 71 dry-store outlets including 10 franchises, welcomed attendees to its facility. It is a mid- to high-range cleaner with quality evidenced by the pride exhibited by staff in the plant. During the “clothes changing season,” customers line up outside the store for as long as an hour waiting to be served, or they will take a number and run other errands until it is their turn.

Another factory visit was to Hakuyosha Osaka, part of the largest drycleaning and laundry operation in Japan. Its services cover quality cleaning of clothing as well as shoes and bags, household, garment storage, courier services (anywhere in the country), and corporate and hotel cleaning services. The company employs 1,500 people.

LEARNING FROM WORLD CHAMPIONS

On IDC’s second day, Ray Lambert of Lambert Associates and former CEO of Jeeves of Belgravia, began the program with Learning from Successful World Champions. He focused on Jeeves’ worldwide operations and highlighting the Jakarta franchise with its spotless plant featuring a white marble floor, and the cutting-edge fashionable stores that attract wealthy global patrons. The business has grown with prices that are exponentially higher than the average through exceptional quality and service for the discerning fashion- and ego-driven customer with means.

Next was the management team from Chicago’s CD One Price Cleaners: CEO Rafiq Karimi, VP Marketing John Morocco and VP Store Operations Steven J. Skonecke. The company founded in 2001 is now 33 stores strong, and it plans to aggressively expand into multiple markets in the next three years.

The men attribute the unique combination of superior quality combined with free same-day service at a single price for revolutionizing the customer experience in the United States. Volume drives CD One Price’s model of providing superior customer service through efficient standardized processes. Its stores do four times the dollar volume and 10 times the item volume of the average cleaner in the U.S., the representatives say. They serve their customers complimentary Starbucks coffee and rely heavily on the results of a customer feedback tool (Listen360) to continually improve the customer experience.

REPORTS FROM AROUND THE WORLD

Various members presented reports from their countries: United States — Richard Aviles, co-owner of Bridge Cleaners and King Garment Care, both in New York state, believes that future success is dependent upon building strong bonds between the targeted niche customer and the cleaner “family” by being responsive to their range of needs. One way his company is meeting those needs is an extensive tailoring capability and similar specialty services that support the core cleaning business.

United Kingdom — Collin Murray, managing director, Columbine Cleaners of Distinction, described how he took the IDC Fellowship experience and implemented what he learned in his own company. He adopted the “American Shirt Laundry” with automated equipment from Sankosha, computerized POS tills (SPOT is in UK (continued)

12

November/December 2015 www.americandrycleaner.com

American Drycleaner,

IDC attendees visit U-GO, “The Most Fun Dry Cleaners in Japan.”

International Drycleaning Congress attendees visit a temple while sightseeing in Japan.

thanks to IDC), and stayed nimble, growing ever more efficient and profitable when other larger companies struggled.

Holland (and Europe) — Peter Wennekes, executive director of CINET, reports that the total PTC (Professional Textile Care) volume in Europe is €18.3 billion compared to €19.6 billion in Asia and €13.3 billion in North America. In addition to the “Miscellaneous” not included in those three regions, the total PTC global volume is €82 billion, he says.

Wennekes mentioned three trends: efficient logistics, i.e. 24/7 access through kiosks and lockers; specialized services such as boats, RVs, fire retardants, and Uggs; and the personal care and aid industry, i.e. personal robotic aids in healthcare for delivering clean clothing and aiding in dressing.

Australia — Karl Chehade, CEO of Karl Chehade Cleaners, described his company as driven by innovation. It moved from 25 package plants to a cutting-edge centralized plant and dry stores with automated efficiency and environmental responsibility being prime goals to protect the investment for the third generation.

The company produces 1,000 pieces per hour using GreenEarth, solar power, and co-generation, producing a waste stream of 2 kilograms less per garment than the average cleaner, Chehade says. Focusing on high quality, high volume and commitment to service, Chehade Cleaners is the price leader in each market (20% higher than competition) and believes the next generation of drycleaning customers is focused on “convenience on call,” not on price.

Indonesia — Marcus Taslim, CEO of Jeeves of Belgravia, says that Jakarta has 13 million people but its drycleaning and laundry business is in its infancy (only about 25 years old). No industry statistics exist there, and there is no professional association. The only foreign brands in the market are Cinc a Sec from France, Jeeves from the UK, and Martinizing from the United States. Because of their success, small local brands are now sprouting up.

As an engineer, Taslim always used dry cleaners and observed many service providers but couldn’t find a “good” cleaner in Indonesia. His wife visited her brother in London and acquired the Jeeves franchise and needed his help. Taslim became passionate about the business, which now has eight locations in Jakarta, one in Surabaya and a new one in Pondok Indah, all of which are serviced by a central plant.

PARTING THOUGHTS

At the IDC business meeting, 2016 officers were announced. Lynette Watterson of California’s Crystal Cleaners is incoming president. The board has decided to have one-day IDC mini-conventions at major global events— such as Texcare International in Germany and the Clean

Show in the United States—in addition to the regular conventions during offClean years.

This year, the formal conference was preceded by an optional tour of Kyoto. Post-conference, a large group of participants continued to an extended tour.

Visited were Haduseisha Cleaners in Kobe, operating 53 stores. It maintains high quality with techniques that include using the same water source as the famous local sake production, distilling the solvent after every load (rare in Japan), and using unique spot-removal skills on delicate garments that include heirloom kimonos.

Also visited was Sankosha headquarters in Hachioji, outside Tokyo, to see the manufacturer’s vertical and automated ever-expanding factory.

Between drycleaning field trips, attendees toured a sake factory, dined on Kobe beef and other Japanese delicacies, and did other sightseeing. Anyone who has not participated in an IDC conference is in for an educational and experiential treat in the future. ADC

Diana Vollmer is a managing director for drycleaning consultancy Methods for Management and a regular columnist for American Drycleaner. She can reached at dvollmer@mfmi. com or 415-577-6544.

14 American Drycleaner, November/December 2015 www.americandrycleaner.com

Keisuke (Ken) Uchikoshi (right), president of Sankosha USA, was presented with the IDC Drycleaner of the Year Award.

Sankosha welcomed IDC attendees to its headquarters in Hachioji, outside Tokyo.

Shanghai Texcare Asia Returns to

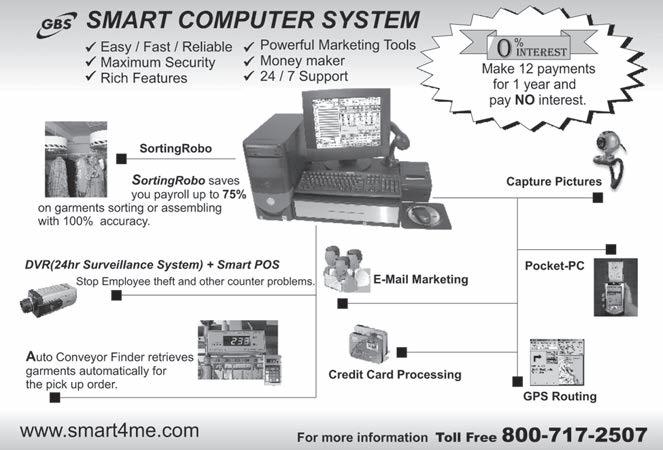

Texcare Asia, the region’s largest international trade fair for the textile care industry, returns here Nov. 25-27 at the Shanghai New International Expo Centre, eager to welcome technology and market leaders alike.

Organized by Messe Frankfurt Shanghai Co. Ltd. and China Light Industry Machinery Association (CLIMA), the biennial show will occupy more than 17,000 square meters of exhibition space and feature more than 150 exhibitors from 15 countries and regions, showcasing the latest equipment, machinery and solutions in laundry, drycleaning, ironing and dyeing in addition to textile management systems.

International exhibitors regard the show as an important event to enhance their presence in the Asian market and update the industry on their recent achievements.

Gerda Jank, head of communication for the JENSENGROUP, a long-term exhibitor at Texcare Asia, shared her company’s plan: “Visitors to our booth will be introduced to the latest technologies for the washroom, flatwork and garment finishing sections. We will also focus on automation solutions and performance improvement features that guarantee the highest productivity with the lowest impact for the environment.”

The United States’ Alliance Laundry Systems has confirmed the biggest booth at the 2015 show to date, occupying 500 square meters of booth space. The brand will collectively display products from six brands, including Speed Queen, UniMac, Huebsch and IPSO, together with the recently acquired Deli and Primus.

Jennifer Yang, the company’s marketing manager for Asia/Australia-Pacific, shared her excitement: “Texcare Asia is a golden opportunity for us to present our brands and innovations to global customers, especially those from the Asia Pacific region. At the 2015 show, we will highlight the Speed Queen washers and dryers for coin laundry, as well as the latest commercial-grade home laundry machines. Key products also include the newest Deli washer, extractor and dryer, in addition to the recent designs for soft-mount washers.

“Greater China has become a new business region for us since early 2015. Texcare Asia is the perfect channel

where we can spread the news and show people our efforts in the region.”

Returning exhibitor Tolon Laundry Machines hails the success of its debut at the 2013 fair, which enabled the company to expand market share and strengthen distributorships in the Far East.

“Texcare Asia offers us the perfect platform where we can promote our latest machines and search suitable buyers,” says Ali Riza Ozkan, foreign trade minister for the 70-year-old Turkish enterprise. “In 2015, the key products at our booth will be the latest variety of Tolon washers, extractors, tumble dryers and towel folders.”

Chinese exhibitor Shanghai Shenguang Laundry Machinery Group Co. Ltd. is preparing product launches for the fair.

“Texcare Asia offers the best platform for us to display our laundry equipment for clients and to communicate with suppliers and partners,” says Qian Zhigen, company chairman. “We will once again utilize the shows to unveil our new products, such as the customizable heating solutions by SNS (Shenguang Non-steam-heated System), the newest generation of high-capacity, tilting, auto washerextractors, as well as the auto folder which was added to our finishing series recently.”

Staged concurrently with Texcare Asia on Nov. 25-26 will be the Texcare Forum Asia, a series of educational presentations. Jointly organized by Messe Frankfurt, CLIMA and CINET, the International Committee of Textile Care based in the Netherlands, the forum will address the latest market developments and offer a networking platform for industry experts and professionals.

The theme for the Nov. 25 agenda is The Exciting Asian PTC Business Perspective. The half-day session will cover the latest technological advancements and market updates in Asia. Scheduled speakers include Dr. Geert Bottger, liaison officer of CINET; Stefan Phang, director, sustainability and corporate social responsibility, Sealed Air; and Timme Lucassen, technical project manager, TKT.

Also planned are an “Implementation of New PTC Technologies Panel” featuring representatives from BÖWE, Büfa, Ecolab, JENSEN, Kannegiesser and VEIT, and a roundtable panel discussion

16 American

November/December 2015 www.americandrycleaner.com

Drycleaner,

(continued)

Biennial trade show offers opportunity to reach growing markets

Sometimes We Like To Strut Our Stuff.

No assembly required. The complete Drapery Strut hanger from M&B Hangers is produced totally in-house from 10.5 gauge wire and a strong high-quality tube. Ideal for drapes, table cloths, and comforters, the M&B Drapery Strut hanger comes complete in a 200-pack box 100% assembled and ready to strut its stuff.

To try our Drapery Strut, go to www.mbhangers.com to find your local distributor, or call 888-699-5644 to speak with one of our customer service representatives.

including top managers and association representatives from around the world.

The full-day session on Nov. 26 is themed The Trick of Earning Money in PTC. It will feature distinguished specialists who will share cost-saving and margin-maximizing strategies applicable to the ever-evolving industry.

Among the scheduled presenters are Riccardo Mazzolini, general manager of the Textile ID business unit of

Datamars; Aad van den Berg, CEO of Senso Technics; and Masashi Shimenoki, chairman of the Japan Textile Care Institution.

Texcare Asia is a sister event of Texcare International, which is staged every four years in Germany. The next Texcare International is slated for June 11-15 in Frankfurt.

To learn more about Texcare Asia, visit the show’s website at www.texcare-asia.com. ADC

TEXCARE ASIA 2015 EXHIBITOR LIST (as of Oct. 15)

American Drycleaner,

18

November/December 2015 www.americandrycleaner.com

D & K Equipment 3715 Northcrest Road, #30 Atlanta, GA 30340 Phone: 678-873-2623 Fax: 770-910-7170 Email: sales@dnkequipment.com

&

Rent Runway the

nation on any given day.

The 6-year-old company created by two 20-something Harvard MBAs rents dresses and accessories (necklaces, jewelry, handbags, etc.) via a photo-rich e-commerce website. Customers looking for something special to wear to a wedding, gallery opening or just a night out on the town click through the latest fashions available from some 300 designers—they include Diane Von Furstenberg, Halston, Helmut Lang, Hervé Léger, Jill Stuart, kate spade, Oscar de la Renta, Vera Wang and Versace— and make their selections, which are then shipped to them via UPS.

All inventory is available every weekend for rent, which means the company has to stay on top on receiving, cleaning and shipping at all times.

To support the apparel rental business, Rent the Runway maintains what it says is the largest drycleaning operation in the country. During the National Cleaners Association’s recent TexCare exhibition, it hosted a tour of the company’s Secaucus, N.J., facility.

“People rent dresses for the weekend,” says Charles Ickes, Rent the Runway’s vice president of operations. “They get them, typically, for four days. They rent for Thursday/Friday, wear it Friday/Saturday, return it Sunday/Monday. Everything that we do comes back to us in two days. It’ll either be one- or two-day ground, then we expedite to two-day air to get everything back on Tuesday/Wednesday so we can make it available for the next weekend.”

By Bruce Beggs, Editorial Director

Are you familiar with Netflix? It’s the subscription-based film and TV program rental service that offers popular media to subscribers via Internet streaming and via U.S. mail.

Now, Rent the Runway hasn’t yet figured out how to stream a designer gown to a subscriber, but it’s worked hard to master a reverse logistics system that has tens of thousands of haute couture garments criss-crossing our

Prices vary depending on the garment—a $650 Badgley Mischka dress rents for $95, a $1,395 Marchesa Notte gown for $200, for example—but Rent the Runway also is trying out an “unlimited” service for $99 a month, Ickes says.

“We have what we call a classic model; you pick a date, we send it to you and you get to keep it for four days,” he explains. “We also have a subscription service that’s in beta [testing]. There are 3,500 customers in that. It’s basically Netflix. Pick any three items you like. Keep one, two, three as long as you like.

20 American Drycleaner, November/December 2015 www.americandrycleaner.com FASHION

FABRICARE

The ‘Netflix’ of Haute Couture: (continued)

Once you return one to us, we flip it, look at your queue and send you another one.”

There is rail space for some 300,000 pieces of inventory, according to Ickes. On the day of the tour, a Friday in October, the plant housed 100,000 dresses and 23,000 accessories.

Customers can order a dress in two different sizes (for example, sizes 2 and 4) so that there are limited “fit” issues, Ickes says.

High-utilization dresses “turn” approximately four times per month, he adds. Rent the Runway attempts to get 32 rentals out of each dress before it is removed from inventory and offered in a “sample sale.”

BUILDING TO CRESCENDO

This time of year, it’s busy at the Rent the Runway drycleaning plant. The week prior to the NCA tour, the company shipped 25,000 units, which is the equivalent of 50,000 dresses. The plant as currently equipped and staffed can process about 2,000 dresses per hour; every garment that goes in or out is bar-coded.

“We are in season right now. Back to school. There are events going on. Rush [week] is going on. Christmas, of course, is our peak. Right now, we’re building to the crescendo.”

When Ickes started working for Rent the Runway four years ago, the company utilized a 9,000-square-foot space in Manhattan. It moved to a 40,000-square-foot facility 3½ years ago, but then outgrew it and moved to its current site in November 2014.

It’s now outgrown the one side of the plant—80,000 square feet—and, at the time of the NCA-organized tour, was preparing to double the production area to 165,000 square feet. The expansion, which will include automating the fulfillment system, will cost an estimated $13 million, Ickes says. It’ll be adding 17 drycleaning machines, 22 washers, 22 dryers and other equipment; the current plant utilizes 18 drycleaning machines, all with 80-pound wheels.

Rent the Runway employs 400-plus people in Secaucus. Workers are hired on a temporary basis and must reach certain performance criteria to advance to permanent status. Current ratio is 70-30 temporary to permanent (10% of staff are trainers, Ickes says).

“Every person has a metric. I could show you every person, how fast they went in the last minute. This is why I walk around with this [tablet]. I can see it at

department level. How fast the throughput is going. I know how much [inventory] I need for the day. I’m watching every department to see that the throughputs are high enough.”

22

November/December 2015 www.americandrycleaner.com

American Drycleaner,

Charles Ickes (right), VP of operations, describes Rent the Runway’s operation as NCA’s Alan Spielvogel listens.

When a returned dress is in need of repair, it’s routed to this department to make it like-new again. (continued)

Rent the Runway’s drycleaning department currently utilizes 18 machines, all with 80-pound wheels.

Pluslux Never purchase laundry equipment again! Professional L aundry U tility S ervice • New Electrolux Professional laundry equipment with no capital expense • No long-term lease or contract • Huge savings on chemicals, water, & energy • Lifetime Parts and Service Warranty No money down. Pay only for what you use! It‘s as easy as 1-2-3! Call 866-575-1010 info@plusluxllc.com • www.plusluxllc.com PLUS is the perfect solution. Call today to learn more.

DESIGNER RELATIONS

Ickes previously worked for Madame Paulette, a wellknown New York City dry cleaner, and is no stranger to working with designers. Rent the Runway is constantly working to develop relationships with designers and to position the company so that it has early access to the latest styles.

“We have to order six months in advance, tell them how much product we want in a certain line. It comes in, we put it in [inventory] and it starts the rental cycle.

“People say, ‘Ah, if it’s popular, you just reorder.’ Nah, you can’t do that. You’re at market. It’s gone.”

Ickes finds corporate-based designers easy to deal with, because they look at things from a dollars-andcents perspective. Other designers are more particular about granting Rent the Runway access to their top lines. He called some of them “prickly.”

But Rent the Runway’s accelerated growth has gone a long way in convincing many designers that making their lines available to it is a positive and won’t interfere with their own market strategies.

“For the most part, we’ve proven to the designers, and to the retailers, that we’re not your demographic,” Ickes says. “Our key demographic is out of college, some disposable income, can’t afford to buy.”

Sometimes, designers will work with Rent the Runway to provide garments that are more durable and longlasting.

“We have to evaluate the units to see if they’re serviceable. Can we actually clean [them]? We buy very specifically, and if [the designer has] a lot of silk chiffon, we’ll say, ‘Can you do synthetic chiffon?’ It’s more durable for us. A lot of them will go ahead and make those switches for us, surprisingly so. It’s amazing how much custom work they’ll do for us.”

Rent the Runway is projecting its growth years into the future.

“We know we’re going to outgrow this building in 2018,” Ickes says. “As soon as I finish the expansion of the other side, we immediately start looking for a West Coast facility. We’ll probably buy 200,000 square feet out there. Based on our current trajectory, two years after that, we’ll probably be in Dallas or Houston with another 200,000-plus-square-foot facility.”

Eventually, Rent the Runway wants to be able to transport a garment anywhere in the country by one-day ground shipping, he says.

Aside from ensuring that sufficient infrastructure is in place, Rent the Runway is always looking for something else: more designers to expand its ever-growing roster and high fashion that’ll keep customers coming back for more.

“We never have enough inventory,” Ickes says. ADC

24

November/December 2015 www.americandrycleaner.com

American Drycleaner,

A Rent the Runway worker hangs dresses for processing in a steam tunnel.

Another fulfilled order rolls down the conveyor en route to shipping.

There is rail space for some 300,000 pieces of inventory, all bar-coded for tracking purposes.

Hoffman Manual Utility Press (Used) $1,995* UniMac 50-lb. Washer (Used) $4,200* Columbia 80/80 Tandem (Used) $34,995* Forenta 32VB Body Press (Used) $3,295* Hoffman Form Finisher $3,295* Rema RP5 Air Vacuum $2,295* Forenta Double Topper (Used) $3,500* Cissell 120-lb. Gas Dryer $6,375* Lattner 20hp Boiler $12,400* Milnor 60-lb. Washer $6,995* Unipress Single Buck SB1 (Used) $10,500* Unimac UM202 Washer $3,800* Bowe 40 Hydrocarbon Machine $26,500* Forenta Triple Puff Iron 33PS $1,700* Speed Queen 75-lb. Gas Dryer (Used) $1,800* 1/2” Steam Traps $35 each, 5 trap minimum 86 6 - 73 4 - 364 4 Monthly Specials Online: MustangEnterprises.com New & Used Equipment for Drycleaning & Laundry Huge Selection of Parts for Most Brands of Equipment Prices valid until December 1, 2015 | *Freight Not Included

A. L. Wilson Chemical Co.

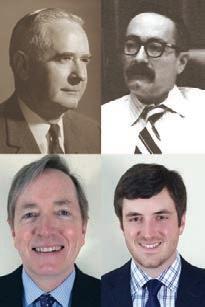

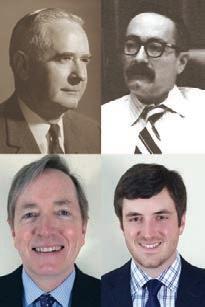

Beginning this month, American Drycleaner will profile a manufacturer, distributor or other business that serves the drycleaning industry. The magazine shines its spotlight this issue on A. L. Wilson Chemical Co., Kearny, N.J., a longtime maker of stain removal agents. Owners are Fred and Randy Schwarzmann.

Q: How long has your business been serving the drycleaning industry?

A. L. Wilson Chemical Co. has been manufacturing stain removers of unsurpassed quality for more than 85 years. From the beginning, Wilson spotters have been great tools for dry cleaners and launderers who accept the challenge to deliver the quality garments and linens that their customers are looking for. Wilson stain removers allow them to remove more stains completely and safely.

In 1928, when Wilson Chemical was founded, the art of stain removal was in its infancy. In that year, Aura

AT A GLANCE

Company name: A. L. Wilson Chemical Co.

Location: Kearny, N.J.

Owners: Fred Schwarzmann and Randy Schwarzmann

Type of business: Designs, manufactures and markets stain removal agents, and sells them through distributors to professional drycleaners and launderers around the world.

Products/services: YellowGo, RustGo, TarGo EF, EasyGo/“G” Go, Laundry TarGo, RiteGo, TarGo Dry, SpotsGo, InkGo, QwikGo, BonGo, SoGo “1” and more

Area served: Worldwide

Phone number, local: 201-997-3300

Phone number, toll-free: 800-526-1188

Corporate e-mail address: Info@alwilson.com

Website URL: www.alwilson.com

Social media: Facebook.com/WilsonChemical • LinkedIn.com/ company/a-l-wilson-chemical-co- • Twitter: @WilsonChemical

L. Wilson, a successful spotter, decided to bottle his effective formulas and sell them to friends in the industry.

Two years later, John Schwarzmann saw the potential in Wilson’s idea, joined the company and launched it on its current path. His philosophy was simple: Wilson products must be not only the most effective at removing stains but also the safest for delicate fabrics and colors. It’s a business philosophy that has endured for four generations.

Recent research and development has resulted in many new products that not only provide high levels of performance but also address the environmental concerns that have surfaced in recent years. Without compromising effectiveness, Wilson’s newly developed products are designed to be safer for workers and the environment.

Our manufacturing philosophy has not changed in more than 85 years.

We continue to manufacture highperformance, high-value stain removers that contribute to the success of the cleaners and launderers who use them.

We supply valuable tools that let our customers deliver the quality stain removal that their customers desire. Our customers know they can count on Wilson spotters to help them earn a spotless reputation and keep their customers coming back.

Q: Tell our readers, generally, about your company’s current product and/or service offerings.

Wilson Chemical makes stain removers that are effective and ecofriendly; chlorinated solvent free; California compliant; aligned with

Four generations of Schwarzmanns: (top, from left) John, Fred, (bottom, from left) Fred Jr., Randy.

alternative solvents; and physically safer.

Q: Where are your company’s products made, and how are they sold/distributed to end-users?

Wilson Chemical designs, manufactures and markets our stain removal agents at our facility in Kearny, N.J., USA, and sells them through distributors to professional dry cleaners and launderers around the world.

Q: Why is your company successful?

Our products are effective, workerfriendly and eco-friendly. And our customer service and support are equally valuable to our customers. From the lab, through manufacturing, the office staff and out into the field, we focus not only on helping our customers remove more stains safely and completely, but also on helping them protect their business from environmental and regulatory nightmares.

26

November/December 2015 www.americandrycleaner.com

American Drycleaner,

CLOSER LOOK

Q: How does your company keep up with the industry to ensure it is offering the products and/or services that potential customers want or need?

Every day, our regional vice presi dents are in the field, interacting with dry cleaners and launderers, keeping their fingers on the industry’s pulse.

We actively participate in industry trade associations such as the Dry cleaning & Laundry Institute, the National Cleaners Association and the Textile Care Allied Trades Association.

We constantly monitor national and local regulatory agencies to ensure ongoing product compliance. For ex ample, the new OSHA [Occupational Safety & Health Administration] GHS Hazard Communication Standard requires all workplace chemicals to be properly labeled with pictograms, sig nal words, hazard statements, etc. by June 1, 2016. As of June 1, 2015, ev ery container leaving Wilson Chemi cal has been compliant with this new Standard.

Q: What do you think will change about the drycleaning industry in the next five years?

Existing environmental and worker safety regulations will inevitably continue to tighten and will spread from jurisdiction to jurisdiction. At the same time, new, more stringent regulations will be added. Consider that the U.S. EPA [Environmental Protection Agency] is now threatening to ban traditional POGs and VDS na tionwide. Ultimately, all dry cleaners will be operating in a hyper-regulated environment and will need to become more environmentally conscious.

At first glance, this might appear to be unrelentingly bad news. But con sider what is happening today in Cali fornia. There is a silver lining hidden in this regulatory storm that appears to be threatening our industry. Yes, perc is being driven from the market, but

partially as a result of these regula tions, environmentally friendly alter native solvents have been developed that allow dry cleaners to continue to offer the high-quality cleaning their customers desire.

On a parallel track, many manu facturers of stain removers have responded to the ban on the sale of traditional POGs and VDS in Califor nia, and have developed alternative

stain removers that meet or exceed the current strict environmental restric tions without sacrificing effectiveness or garment safety.

The choice dry cleaners face today, both inside and outside California, is to comply reactively as regulations tighten and new ones come online, or to gain a competitive advantage by embracing their inevitably more envi ronmentally friendly future today. ADC

www.americandrycleaner.com American

November/December 2015 27

Drycleaner,

Ide

World T oll free : 1-888-720-4080 ww w. ai rw or l dp ads.c om ai rw or ld@ gm ail .c om 126 Chr is t ie A ve M ah wa h, N J 07430 AVAILABLE THROUGH FINE DISTRIBUTORS EVERYWHERE IMPROVING RESULTS FROM YOUR SHIRT PRESS Our high quality products perform better than traditional systems. Try the “Red, White and Blue” - Air World’s next innovative idea for a busy industry. AI R WORL D INTRODUCING THE NEW AIR WORLD PERFECT SHIRT SYSTEM: RED HI-TEMP COVER, WHITE MICROFIBER AIR BAGS and PATENTED BLUE SILICONE FLANNEL PAD P US Patent Number 8062742 THE PERFECT SHIRT SYSTEM WORKS GREAT ON ALL SHIRT UNITS If someone could help you reduce broken buttons and touch-ups you’d listen, right? Everyone is in search of the perfect shirt pressed right off the machine. And at Air World, we believe there’s always room for improvement in your finished shirts. We call it the RED, WHITE and BLUE... MENTION THIS AD AND RECEIVE 10% OFF YOUR ORDER Offer good though December 31, 2015

Innovative

as from Air

Arrival of Cooler Weather = Outerwear

Cooler weather has arrived and, along with it, outerwear. You can look forward to sweaters, jackets, parkas and overcoats. But you will find, with this influx of seasonal garments, that customers will present a consistent set of stains and problems.

The first consideration is the fiber and fabric connected to cold weather. Protein fibers have come to dominate the cold months, followed closely by moisture-resistant products of modern chemistry. Wool, camel hair, angora and cashmere are all fibers that originate with animals. They have characteristics that make them desirable for warmth and durability. For the sake of discussion, they can be broken down into soft (angora, cashmere) and hard (wool, camel hair) types.

Soft protein fabrics should be considered as “delicate” and handled accordingly. The longer strands are subject to tangling during heavy mechanical action.

Sweaters of soft protein fibers should be run in a net bag, one to a bag, and strictly classified by color to avoid “lint” transfer in the run.

If you choose to run a white angora sweater with a navy overcoat, you are going to need a fresh lint roller. Cashmere is also used in high-end sport coats and overcoats; this gives a soft look and feel that must be protected. I recommend pre-spotting of angora and cashmere and running a short cycle to reduce mechanical action.

The hard protein fibers are woven to provide a durable surface and provide warmth to the consumer. In relatively new condition, these worsted wools will contain a certain level of lanolin, which will act to reduce stain penetration. As wear and cleaning reduces the lanolin, stains will penetrate the fiber. These garments dry-clean well since they are sensitive to water, but consideration must be given to trim such as real leather buttons.

The consumer does not always present garments that have been stored in the off-season, under ideal conditions. Garments that were put away stained present a challenge for the cleaner/spotter. Greasy food stains will oxidize over time, making them hard to remove. They

should be pre-spotted on the dry side with a good POG. Use mechanical action and time to your advantage.

Allow angora and cashmere to “sit” after applying the POG and using reduced mechanical action. Wool and camel hair can tolerate normal tamping before cleaning.

If there is a crust on an old stain, brush it away while dry, before pre-spotting. Use protein spotters sparingly on protein fibers. I recommend using a digester on old protein stains, wait about a half-hour, then use normal protein stain protocols. A word of caution: Using any bleach on protein fibers other than hydrogen peroxide can cause damage that cannot be reversed or hidden.

Gore-Tex® is the trade name of a “miracle” fabric that allows body moisture to escape while blocking rain or snow. This makes the fabric extremely comfortable for wearers of winter outerwear, and is made possible by the minute size of the fabric’s pores. Thus, these pores must be protected when cleaning Gore-Tex garments.

Follow the care label strictly. I recommend at least one rinse in new or distilled solvent to ensure that no detergent or NVR has accumulated in the fabric pores. If supplemental stain removal is required, use the least aggressive stain removal agent, proceed slowly, and rinse repeatedly. Do not deviate from the manufacturer’s care instructions. Use solvent that is in excellent condition. Do not use fabric softener or sizing.

Nylon is a synthetic fiber derived from petroleum. It is a great fabric choice for outerwear to provide protection from wind and showers. But cleaning and stain removal are impacted when petroleum-based stains are allowed to remain in the garment over time and then form a bond with the petroleum fiber. It is extremely difficult to break this bond and retain the garment’s

28 American

November/December 2015 www.americandrycleaner.com

Drycleaner,

SP O TTING TIPS

Martin Young

“

Protein fibers have come to dominate the cold months, followed closely by moisture-resistant products of modern chemistry.”

original structural integrity.

Time and heat are two major enemies of stain removal. Their effects are compounded when the consumer chooses to store the off-season garments in an area that is not temperature-controlled, like an attic. A baked chicken casserole may be appealing, but baking spaghetti on the front of a sweater is trouble for even the most experienced cleaner/spotter.

When you are told that the stain “has probably been in there since I last wore it in March,” set the garment aside for further inspection. Pre-condition old stains before attempting any stain removal.

Soften old, oily sauces with a general pre-spotter or mild POG for a period of 15 minutes.

Soften old protein stains with an enzyme digester for 45 minutes to an hour, unless the stain is in a protein fiber. In that case, cut the time in half to protect the fabric.

Soften old tannin stains with a tannin formula for 30 minutes. Follow normal stain-removal protocol from this point.

You may well receive a light-colored protein garment, such as a wool sport coat. The stain will be almost symmetrical, and will vary in color from dark yellow, through orange, to brown. Examine it closely. On many occasions, such stains are chemical burns, the result of

the consumer attempting to remove them using chlorine bleach on the protein fabric. This cannot be corrected.

It is worth repeating: As a professional, you should never apply chlorine bleach to any protein fabric.

Being a garment care professional is far more than chasing pieces—it is providing garment restoration that the consumer cannot duplicate at home. ADC Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates to this day. Contact him by phone at 704-786-3011, e-mail mayoung@vnet.net.

www.americandrycleaner.com American Drycleaner, November/December 2015 29 ADC_Hhalf.indd 1 9/30/15 3:49 PM

(Photo: ©iStockphoto/Romanchuck)

Success Annual TCATA Conference Deemed

Activities included business sessions, board elections, honors

The 2015 Annual Management & Educational Conference of the Textile Care Allied Trades Association (TCATA) was “clearly an overwhelming success,” say conference organizers.

With another good turnout of first-time attendees for the July 29-Aug. 1 event at the Silverado Resort & Spa in Napa, Calif., members enjoyed a strong business program, beautiful weather, a memorable dinner party at a local winery and much more, TCATA says.

The business sessions covered a variety of topics. Lead speaker and industry veteran Steve Kallenbach, director of market solutions at ADI American Dawn, discussed key ways that companies can both delight their customers and “onboard” new customers.

The following day, Dr. Chris Keuhl, a managing director of Armada Corporate Intelligence, presented the good, the bad and the ugly of the national and global economy in a humorous and easily understood manner. Closing out the business program was Rory Vaden, cofounder of Southwestern Consulting, who outlined how

everyone needs to “take the stairs,” doing what is necessary to succeed in life and business.

Attendees gathered one evening at the historic V. Sattui Winery for a reception and dinner, making for another memorable event, TCATA says, where old friendships were renewed and new ones made.

Three member companies celebrating anniversaries were honored at the closing dinner: Fabritec International, which is celebrating 75 years of TCATA membership; Horwath Laundry

30

November/December 2015 www.americandrycleaner.com

American

Drycleaner,

Attendees of the 2015 Textile Care Allied Trades Association (TCATA) Annual Conference listened to speakers presenting on topics such as gaining new customers, doing what needs to be done to succeed, and the national and global economy.

(Photos: TCATA)

Six former TCATA presidents and the current president at the 2015 TCATA Annual Management and Educational Conference: from left is Lawton Jones of F.H. Bonn, Rick Kelly of Pellerin Milnor Corp., Alex Atwater of A-1 Products, Steve Mathews of M&B Hangers [current president], Bryant Dunivan of Energenics Corp., Bruce Johnson of Chicago Dryer Co. and Bill Odorizzi of Sankosha USA.

TCATA President Steve Mathews presents Steve Pedelty of M&B Hangers, Leeds, Ala., with a commemorative pen and pencil set in thanks for his service on the TCATA Board of Directors.

Equipment, celebrating 50 years of TCATA membership; and The Minnesota Chemical Company, celebrating its 100th year in business.

Also during that dinner, President Steve Mathews announced that Alex Atwater, president of A-1 Products in Birmingham, Ala., will serve as chairman of the 2016 annual conference. Atwater has been active in TCATA for many years, including serving on the board of directors, on various conference committees and as president in 2006-08. In 2005, he received the “Young Timer of the Year” award, according to the association.

TCATA members also elected two new officers for the board of directors. Gerald Henke of Intex Distributing, Austin, Texas, was elected president-elect; Henry Padron of Industrial Equipment & Supplies, Miami, was elected treasurer-elect. Both will assume their two-year terms at the conclusion of the 2016 conference.

Henke has served on several committees, several terms on the board of directors and as chairman of the 2008 TCATA conference, according to the association. Padron has served on the board of directors and was chairman of the 2014 TCATA conference.

ADC

www.americandrycleaner.com American Drycleaner, November/December 2015 31

TCATA President Steve Mathews presents Steve and Lisa Baker with a silver tray commemorating The Minnesota Chemical Co.’s 100th year in business.

TCATA President Steve Mathews presents Jim and Kay Horwath with an award honoring Horwath Laundry Equipment’s 50th anniversary as members of TCATA.

ADC_R_Hhalf.indd 1 11/3/14 2:26 PM

Improving Productivity Behind the Counter

Ihave walked into many dry cleaners to see the counter staffer sitting there, blindly staring into space. When I entered, she would ask, “Can I help you?” and I would say something. But, before I entered, she was just sitting there doing nothing. Yes, her job is to help customers. But can’t we get more productivity out of that job slot? Can’t we get her to do some work between customers?

One dry cleaner told me that his counter staffer had other tasks to do besides helping customers—she had to mark in jobs, research specific projects, keep the front clean, and attend to other tasks. When I asked him if she ever has “nothing” to do, he said, if she finished her work, she could do nothing. Then he shrugged. “What else could she do?”

What indeed? Couldn’t we motivate her to become a salesperson, or rather a sales agent, during downtime? How do you do that? you ask. There’s a phone right there, and a phone book under the counter—all a sales agent needs.

A two-minute phone call could win a new account. If the sales agent is interrupted by a customer entering the store, she could, depending on how far along in the conversation she is, hold up her index finger and indicate that she’ll “just be a minute.” Or, she could begin processing the customer’s order while manning the phone. Or, she could say, “I’m sorry. A customer just walked in. May I call you right back?”

During the sales call, the counter staffer makes the pitch for patronage. He/she might say, “We’ve recently upgraded all our equipment so that everything is environmentally friendly. If you are worried about your current dry cleaner’s chemical use, please give us a try.” Or she might say, “Our cleaner is a wizard at getting out stains, and we’d appreciate a chance to prove it. Next time you have a stained garment, bring it here.”

Here are examples of other sales pitches:

“When you see our finishing and the way everything is folded and hung, you know we care about your clothes.”

“If you give us a try this month, your first order will be half-price.”

“If you want pick-up and delivery service, our driver is really conscientious. He’ll make it problem-free.”

One might choose the wrong approach, but one rejected inducement could lead to another.

All of these are sales pitches that could entice individuals to give you a try. Some prospects will be dissatisfied with their current dry cleaner, which will be even more incentive for them to give you a try. It could be that you call someone who’s just moved into town and doesn’t have a dry cleaner.

As with all sales, it’s by the numbers. Make enough calls and a percentage will stick. That share might vary from 10% to 33%, depending on several factors. They include your staffer’s sales technique, luck, and the elements of the marketplace, such as whether your store is well known and where it is located. But no matter what’s in place, everyone can win new business.

How are you going to get counter staffers to make calls when they’re not salespeople? That’s where your training ability comes in. You must convince counter staffers that it is an important task and that it is just a matter of talking. Of course, some will be upset when prospects hang up or are rude. Others will be stymied by some questions. So, you must train them.

Go through scenarios. When the prospect hangs up, instruct the staffer to just go on to making the next call. When the prospect asks a question that the counter staffer doesn’t know how to answer, she says, “I’ll find out the answer and get back to you.” When the prospect says she does most business during sales promotions, tout your company’s regular promotion.

Do role-playing. Go over and over each scenario until the counter staffer has it down. Admittedly, this might take work, because you’ll have to train

32 American

November/December 2015 www.americandrycleaner.com

Drycleaner,

I NDUSTRY O B SERVAT IONS (continued)

Howard Scott

“

Yes, her job is to help customers. But can’t we get more productivity out of that job slot?”

Want to send a press release or submit a story or story idea?

Contact Bruce Beggs, Editorial Director, today!

Phone: 312-361-1683 E-mail: bbeggs@ATMags.com

JANUARY

Features: Plant Design Awards Our 55th Annual Plant Design Awards recognize the industry’s best plant projects—new or remodeled for optimum appearance, efficiency, comfort and convenience. Tax Guide Creative tax and financing strategies can help your plant grow and keep more profits.

Editorial Submission Deadline —November 15

FEBRUARY

Feature: Buyer’s Guide Arguably the most complete, widely circulated guide of manufacturers and unique suppliers serving the drycleaning industry today—the go-to issue that readers and advertisers turn to throughout the year for reference.

Editorial Submission Deadline — December 15

MARCH

Features: The Future of On-Demand Dry Cleaning How is the rising popularity of app-driven services affecting the industry? Should traditional cleaners see these virtual facilitators as competitors or entertain partnering with them?

Insurance Update Assessing the amount of risk your drycleaning business incurs and determining the extent of insurance needed to cover potential losses.

Editorial Submission Deadline — January 15

www.americandrycleaner.com American Drycleaner, November/December 2015 33

HERE’S WHAT’S COMING UP IN AMERICAN DRYCLEANER...

1115adc_Edit Cal_Hhalf.indd 1 10/16/15 3:50 PM

several counter staffers and it might have to be on the job as the person is working. But, hypothetically, each counter staffer you train can teach another staffer, and your training will become less necessary.

Why would the counter staffer make calls? Money, that’s why. You would have to compensate him or her in some way. Offer a 50% commission on first orders: if a new customer brings in a $30 order, the staffer would receive $15. If three new customers a week are added, the counter staffer earns an extra $45. Who can’t use extra money these days?

How could you control the payment process? Give the counter staffer a dozen names a week. Keep that list, and when you find the person has placed an order, a sale and commission is triggered. You could do this manually, or set up your computer to automatically spit out commissions. Never flinch from paying a commission, even if you are not sure the counter staffer deserves it. If you want this approach to work, you will be eager to pay out commissions and to brag how well some of your counter staffers are doing. That way, the program will flourish.

How do you make money out of the arrangement? Admittedly, giving 50% of the sales away to the counter staffer the first order doesn’t allow you much profit. You might just break even. But it’s the second order, third order and the 16th where you make money, because you pay no commission.

So, take a customer who came in eight times in the first year and spent $25 each time. That means you’ve paid $12.50 commission for $200 volume (eight times $25). That’s a little more than 6% of total revenue. Not bad. The counter staffer just receives a commission on his/her original order, so he/she must keep selling to earn extra money. Up-front commissions are attractive; if the company makes a mistake and does not satisfy the new customer, the counter staffer still pockets the commission. You must be willing to spend money up front to make money over time.

Where do you come up with names? Simply take names out of the phone book. Possibly circle residents on nearby streets and have your staffer call those people. For in stance, there are streets in affluent neighborhoods that may have good pick-up and delivery prospects and the counter

staffer could tailor his/her spiel to win that trade.

There are resident lists one can purchase. You could obtain organization member lists. One could go to town hall, and search through the assessors’ book of residents. Write down the names and addresses of individuals, then, back at the store, match up names and addresses to phone numbers. Now your counter staffer has a name (and potentially the names of family members), an address and phone number. Compile lists of 12 families and hand them to counter staffers. When they finish those lists, you revisit your sources to produce more lists.

Praise the counter staffers when they win new business. Make a big deal of giving them their sales commissions. Work with the employees who can’t get going.

If someone says, “I just can’t do it,” argue that it’s not selling, it’s conveying information. It is just like telling your friend that your husband is sick. When the person thinks like that, it is easier to take rejection. Even a highschooler can be motivated. Tell him or her that selling is a valuable skill and can make the difference between getting a job and not getting it.

Provide tips to handle all contingencies. When the customer isn’t in, jot an L (for “later”) next to the name to call back. When the prospect’s answering machine goes off every call, leave a message, such as “Please call me, Mrs. Mellon. I understand that you’re new to the area and I want to tell you about our new service at Davidson’s Dry Cleaners.” When a youth answers, ask when is a good time to call the parents.

When there is confusion between two counter staffers, give them both commissions. Or divide the commission in half. Never, ever argue that because there is confusion, no commission will be paid. That will sabotage the program.

Try this sales program to get 100% out of your counter staffers. ADC

Howard Scott is a longtime industry writer and dryclean ing consultant. He welcomes questions and comments, and can be reached by writing Howard Scott, Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027, or via email at dancinghill@gmail.com.

34 American

November/December 2015 www.americandrycleaner.com

Drycleaner,

O NS

INDUSTRY OBSERVATI

“ Praise the counter staffers when they win new business. Make a big deal of giving them their sales commissions.”

Lori Benson e Towel Guy LLC, Toms River, New Jersey to the winners of our iPad and Android tablet give away at the Clean Show. Join them in reading our digital edition on your tablet too! Heidle Baskin Baskin Laundry LLC, Canton, Texas CONGRATS!

Brightleaf Cleaners goes solar, realizes savings

Dry cleaning isn’t an industry that is generally associ ated with ‘green’ practices. Brightleaf Cleaners, with three locations in the Bay area, is looking to change that perception with a host of eco-friendly business practices that are not only kind to the environment, but result in significant cost savings.

Its latest project, the installation of solar panels on the company’s 6,000-square-foot production plant, is expected to reduce utility costs at the facility by 60-70%.

Brightleaf began installation of solar panels on its production facility in Livermore, Calif., in August. Fab rication of solar panels by Vista Solar for the project was under way at press time.

Bob Strong, CEO of Brightleaf Cleaners, cites several reasons why installing solar made sense for his business.

First, he says, is the tax incentive. Strong put 20%, or $28,000, down on the conventional equipment loan se cured for the project, and anticipates a $51,000 personal federal tax credit in 2015 for installing solar. Many of these tax incentives expire in 2016, Strong says, making his decision to go solar now even timelier.

Marketing advantages were another benefit, he says. Brightleaf was recently approved as a green business by the Bay Area Green Business Program in Contra Costa County, which acknowledged to Strong that it was un aware of another dry cleaner using solar in the state.

The main reason for going solar is that it makes busi ness sense, Strong says.

“We anticipate a cost savings of $25,000 a year with the installation of the solar project,” he says. “That’s a savings of about $2,200 per month. My monthly pay ment to finance the debt on the equipment purchase is only $1,900 per month. That makes it a no-brainer.”

The installation also increases the building’s value and the business’ bottom line. For Brightleaf, which is offset ting $25,000 a year in savings, the solar project will add an estimated $100,000-$125,000 to its value.

“As a business owner, solar instantly makes you more profitable without implementing any management pro cedures or increasing the price of your product,” says Strong. “Day one, you’ve added value to your business.”

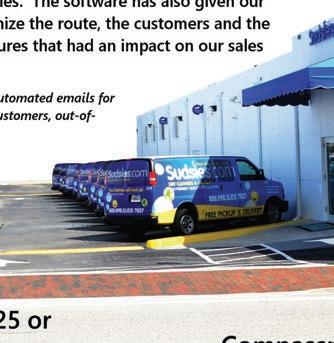

Rent the Runway deepens its executive bench

Rent the Runway, which boasts the country’s largest drycleaning operation in support of its growing designer apparel rental business, is deepening its executive bench with the addition of new executive hires, the company reports.

Joining the company are Scarlett O’Sullivan, previ ously of SoftBank Capital, who will become chief fi nancial officer, and Maureen Sullivan, formerly of AOL and Google, who will become president of the events business.

As Rent the Runway rapidly moves into its next phase of growth, the company continues to attract leaders who can scale the firm, the company says. It will soon announce two additional senior hires from world-class firms as it expands its special-occasion and everydaywear businesses. The executives will report to CEO Jen nifer Hyman.

“In the past few months, we have discovered product market fit for our subscription business around everyday clothing which has hundredfold potential. We have the opportunity now to capitalize on our momentum with an executive leadership team who can drive us to the next phase of growth,” says Hyman, co-founder of Rent the Runway.

O’Sullivan will make certain that Rent the Runway is well capitalized to support the company’s growth and continues to deliver on its financial objectives. The com pany has received $126 million in funding.

Previously, O’Sullivan was a partner at SoftBank Capital where she led growth-stage venture capital in vestments in e-commerce, mobile applications, online advertising, gaming, and cloud computing. She also served as partner and chief operating officer for Soft Bank China and India Holdings where she focused on early-stage investments in the U.S. and Asia. Prior to SoftBank, O’Sullivan was an investment banker at Rob ertson Stephens and Morgan Stanley.

As president of the events business, Sullivan will over see profit and loss for the special-occasion business and set the product roadmap. Previously, she worked at AOL as president of AOL.com and Lifestyle Brands, where

36 American

November/December 2015 www.americandrycleaner.com

Drycleaner,

AR OUND THE INDUST RY

she led all elements of the AOL. com experience including program ming, product, and engineering, as well as overseeing strategy, partner ships, and operations.

Prior to this role, she was senior vice president of brand, marketing and communications at AOL, a role in which she managed brand de velopment and led the global rebranding of AOL. She managed consumer marketing and media in vestments, as well as public rela tions, internal communications, and companywide CSR initiatives.

Beth Kaplan, who served as pres ident and chief operating officer, will continue to play a strategic ad visory role in the company as well as remain on Rent the Runway’s board.

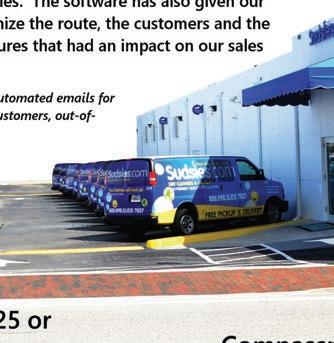

As part of its TexCare 2015 show in Secaucus, N.J., the Na tional Cleaners Association (NCA) organized a tour of Rent the Run way’s nearby production facility. Its 80,000-square-foot plant—which processes 2,000 dresses an hour— will be doubling in size within a few months to keep up with volume, Charles Ickes, Rent the Runway vice presi dent of operations, told the tour group.

Pictured from left are Kristine Zengeler; Adelaide and Elizabeth Mutton; Robert Zengeler Sr.; Oliver Mutton; Charles Tanham; and Tom, Lauren, Robert and Andrew Zengeler. (Photo: Zengeler Clean ers)

ily’s 6th and 7th generations.

Perhaps the most impressive amenity at the new store, Zenge ler Cleaners says, is the Metal progetti conveyor system, fully automating the cleaning work flow from receiving the order, processing the garments, then sorting, bagging and tagging for pick-up.

The benefit for customers: the ability to pick up orders at their convenience using the store’s 24-hour self-serve kiosk. Equally important, the business adds, is this process provides an extremely efficient cleaning process, assuring that the envi ronment is protected.

“Zengeler Cleaners is extreme ly proud of both the appearance and functionality of the new store,” says Tom Zengeler. “Our architect collaborated with the Village of Northbrook to assure this beautiful new facility was consistent with our neighbors and with the community as a whole.

To achieve that while providing a modern, energy-effi cient operation is a tribute to everyone on the team.”

Zengeler Cleaners opens new suburban Chicago store

Zengeler Cleaners recently began serving customers at its new location in Northbrook, Ill., a northern Chicago suburb. The state-of-the art, environmentally friendly facility features many leading-edge amenities that have proven extremely popular with customers, the company says.

One of the highlights of opening the store was repre sentation from four generations of the Zengeler family. The company was founded in 1857 by John Zengeler, the great-great-grandfather of Tom Zengeler, the 5thgeneration president of the family-owned cleaners.

Representing the 4th generation of the Zengeler family at the opening festivities was Robert Zengeler, Sr., Tom’s father. Also attending were several members of the fam

Besides the Northbrook store, the company has seven other stores and eight home pickup and delivery routes in Chicagoland.

Clean Show 2017 has new dates: June 5-8

Riddle & Associates, the show management company for the Clean Show, has secured new, earlier dates for Clean 2017. The show is now scheduled for Monday through Thursday, June 5-8, 2017, at the Las Vegas Con vention Center.

“We are extremely pleased that we were able to find these dates for Clean 2017,” says John Riddle, Clean Show manager and president of Riddle & Associates. “The show was originally scheduled for the very end of June, with move-out dates running through the first week of July. We feel these [new] dates will work better for both our exhibitors and attendees.”