® April 2016 ORGANIC. RETAILESQUE. STOP UPPING YOUR DOWNTIME © Copyright 2016 American Trade Magazines All rights reserved. SpinIt toWinI t Wash -Dry-Fold Overflows withSudsySuccess

When dealing with laundry stains, your reputation rides on getting the outstanding results The Laundry Two deliver.

RiteGo® laundry spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to Laundry TarGo® to remove any tough oil based stains that remain behind.

Use The Laundry Two with confidence on shirts, wedding gowns... anything you're washing or wetcleaning.

Both Laundry TarGo and RiteGo are chlorinated-solvent free, biodegradable, noncombustible and California 2013 VOC and Prop-65 compliant.

Use them to deliver stain-free laundry and wetcleaning. You'll build your reputation for quality - which is what keeps customers coming back.

FROM COLLARS AND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... FROM COLLARS AND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

a STAIN WIZARD at ALWilson.com

Become

drycleaner

April 2016 Vol. 83, No. 1

8

Spin It to Win It

Wash-dry-fold service is more than fluff; aromatic profits smell great. This market overflows with opportunity for sudsy success. Plus you might even fold-over with laughter from the funny stories.

Tim Burke, Editor 14

Organic. Atmospheric. Retailesque. Step into the Clean Factory, an attractive dry cleaner that you might think is a retail store at first. Natural and organic products line the shelves. This sort of innovation may just lead the industry to a whole new way of doing business.

Howard Scott

20

Stop Upping Your Downtime

Regularly scheduled preventative maintenance can reduce those “headache” breakdowns of machinery and put you in control of costs.

Tim Burke, Editor

NEED HELP FINDING THE HIDDEN HANGER?

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

2

www.americandrycleaner.com

American Drycleaner, April 2016

AMERICAN AMERICAN

DEPARTMENTS

4 SDA Cleaners Showcase Preview; 6 Calendar of Events Management Strategies 27 Do Your Employees

Diana Vollmer Spotting Tips 32 Give Smooth Leather Extra Attention Martin

Around the Industry 36 Classified Advertising 38 Advertiser Index 39 Wrinkle

Time 40 A Withholding of Withholdings

Pre-Inspection

Like Their Workplace?

Young

In

FEATURES (Cover Photo: ©iStockphoto/arosoft)

8

“Business has never been better.”

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

“I don’t have to rely on anybody for information. I can see immediately what I have for inventory, orders and accounts receivable.”

800.406.9649 We Speak Cleaner

Afendoulis,

Afendoulis Cleaners

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

Becky

Owner of

has never been better.”

BrentRamenofsky BostonCleaners

Right Off, I’ll Say It: You Guys Rock!

Two stories in this issue offer tips reflective of ways to up the flow of moolah to your wallet. Unrealized profits from the wash ’n’ fold segment of the market is the gist of the feature Spin It to Win It on page 8.

Stop Upping Your Downtime, beginning on page 20, is all about preventative maintenance to slow that headache (or heartache) spending over machine woes.

There is greatness in this business. I can feel it coming right through our conversations, hear the excitement in your voice about new ideas.

I’ll just say this at the outset: you guys rock! So far, it’s been amazing to talk with so many of you, and share in your thoughts and wisdom.

Thrilled ’tis the word, to already be hearing narratives from dry cleaners across the land. We want to turn those insights into great articles about innovation and growth in the field.

Tim Burke

Oh, yeah...hello! Nice to meet you! Already I’ve enjoyed chatting with some of you by phone, connecting by e-mail with others. We’ve not only said our hellos but started a dialogue about the industry and, most importantly, you.

Publisher Charles Thompson 312-361-1680 cthompson@ATMags.com

Editorial Director Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Tim Burke 312-361-1684 tburke@ATMags.com

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Digital Media Director Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Napiwocki

I look forward to speaking with many more of you. Don’t be surprised if I’m calling you up tomorrow to get your opinion—or maybe later today! Thank you for making me feel welcome.

See you around. Rock On! And also I say, Profit On! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 83, number 1. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason. © Copyright AMERICAN TRADE MAGAZINES LLC, 2016. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, April 2016

4

www.americandrycleaner.com

Contributing Editors Howard Scott Diana Vollmer Martin Young

Roger

Advisory Board Steven Dubinski Lawton Jones Mike Nesbit Herron Rowland Fred Schwarzmann

PRE-INSPECTION

Main: 312-361-1700 Fax: 312-361-1685 Subscriptions 630-739-0900 x100 www.american drycleaner.com

SDA Cleaners Showcase

ridin’ into Fort Worth this month

The Southwest Drycleaners Association (SDA) will host the Cleaners Showcase 2016 at the Fort Worth (Texas) Convention Center on April 22-24.

On Friday, April 22, events kick off at the headquarters Sheraton Hotel with an 8:30 a.m. board and members breakfast, followed by board and general membership meetings from 9:30 to 11:30 a.m.

A day-long Coin Laundry Association workshop, titled The Building Blocks To Laundry Ownership, follows from 11:30 a.m. to 5:30 p.m. in the convention center. There is a separate cost for this special workshop; visit www.coinlaundry.org to learn more.

To close out the day, the SDA will host an Early Bird Exhibit Extravaganza 4:30-8 p.m. in the Convention Cen ter with appetizers, drinks, door prizes and featuring the Justin Pierce jazz band.

On Saturday, April 23, from 8:30 to 10 a.m., motiva tional speaker Glenn Shepard will present the keynote ad dress on Managing Employees. Shepard is considered one of the foremost authorities on eliminating problems in the workplace, the SDA reports.

A ribbon-cutting ceremony at 11 a.m. will officially open the convention floor. The event runs until 5 p.m. that day (hours are 10 a.m.-3:30 p.m. Sunday).

Educational sessions will be offered throughout Satur day and Sunday, as industry leaders share their knowl edge on customer service, social media marketing and more.

“We will still have spotting schools and technical training available throughout the day on the show floor,” notes Showcase Chairman Allan Cripe. “But we are changing up the seminars to focus on improving your bottom line.”

A full list of all the educational sessions and schedule, along with show registration and housing information, can be found at www.sda-dryclean.com. ADC

Southwest Drycleaners Association. Cleaners Showcase 2016, to be held April 22-24 in Fort Worth, Texas. Call 512-873-8195.

GreenEarth Cleaning. Earth Day Kickball Tournament fundraiser for Water.org, to be held April 23, in Kansas City, Mo. Call 816-926-0895. To donate, visit www. greenearthcleaning.com.

Textile Care Allied Trades Association. Annual Management and Educational Conference, to be held April 27-30 in Ponte Vedra Beach, Fla. Visit www.tcata.org.

Wisconsin Fabricare Institute. Baseball game outing to see the Milwaukee Brewers on May 3 at Miller Park, in Milwaukee, Wis. For more information, call 414-529-4702.

Coin Laundry Association. Excellence in Laundry Conference, to be held May 18-19 in Ojai, Calif. Call 800-570-5629.

North Carolina Association of Launderers and Cleaners. Annual Convention, to be held May 27-30 in Wrightsville Beach, N.C. Call 704-689-1301.

Texcare International: World Market for Modern Textile Care. To be held June 11-15 in Frankfurt am Main, Germany. Visit www.texcare.com.

Ontario Fabricare Association. 2016 Conference, to be held June 17-18 in Port Credit, Ont., Canada. Call 416-573-1929.

Wisconsin Fabricare Institute. Fitzgerald Scholarship Golf Classic, Summer Conference, Trade Show and Auction, to be held June 21-22 in Mequon, Wis. Call 414-5294707.

South Eastern Fabricare Association. Southern Drycleaners and Launderers Show, to be held June 24-26 in Jacksonville, Fla. Call 877-707-7332. ADC

C A LENDA R 6 American Drycleaner, April 2016 www.americandrycleaner.com

Spin It Win It to

By Tim Burke, Editor

By Tim Burke, Editor

ash... dry... fold... And bank some green!

Making healthier profits in your store is the goal of your drycleaning business. Competitive market forces drive you to look around for new income streams. The buzzword getting spun in the air today is “diversifying.” That means offering services beyond traditional dry cleaning.

Many of you already offer wash and fold. But many don’t. To the latter, we simply say this: It’s worth checking the action.

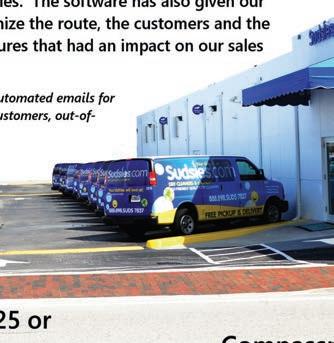

“Our return business is phenomenal,” says Rita Foley, president of Regency Cleaners in Durham, N.C. “Because clothes are clean, smell great, dried with a fabric softener which is folded between the clothes returned, folded professionally, wrapped in shrink-wrap and labeled with our logo and always ready when promised.”

She recommends that “If an operator can provide additional services: pre-spotting, hang-dry, hanging the dry

(Photo: ©iStockphoto/arosoft)

(Photo: ©iStockphoto/arosoft)

clothing, then they should charge for it!” Wash and fold, or fluff ’n’ fold as it’s called, is a topic on many drycleaning owners’ minds. Those business owners are reaching out for more customers who put convenience at the top of their list. Who are you specifically reaching? Who do you want to reach?

Nicholas Sanderson, CEO of Laundry Locker in San Francisco, which has thousands of specially designed lockers located in and around the city and operates its laundry service as a wash-and-fold facility, says, “The trend in our area in businesswear is shifting toward a more casual appearance, requiring less of the owned clothing to undergo the drycleaning/pressed laundry service.”

“Wash-and-fold laundry plans are very popular,” Sanderson says, “especially with families that are doing a significant amount of laundry every week.”

Sanderson believes that, in the next three to five years, the service will outgrow his drycleaning

8 American Drycleaner, April 2016 www.americandrycleaner.com (continued)

service is more than fluff; aromatic profits smell great, plus this market overflows with opportunity for sudsy success, and you might even fold-over from the funny stories

Wash-dry-fold

W

www.fabricaremanager.com • 888.299.9493 Drycleaning Management at Your Fingertips Fabricare Manager Fabricare Manager’s point of sale system is the ultimate blend of power and simplicity. And if you ever need help, our technical support is known as the friendliest and most responsive in the industry. Now also available in the Cloud. Touch and Go!

service, as more multifamily, high-rise residential is being built with no in-unit washers and dryers.

Reaching the specific segment of your wash-fold market might be the ultimate key to success.

Foley talks about her own company’s efforts: “In all of our locations, we offer full-service washdry-fold (wdf). In addition, we provide student wdf for two major local colleges. We work with two bobtailers instead of running our own routes. They are responsible for the pickup and delivery of the wdf to the two colleges and to multiple retirement homes and hotels.”

©iStockphoto/JannHuizenga)

For the college students, she indicates that her company contracts with the bobtailer for a flat number of bags per week depending on student contracts. The students are contracted to pay for a 13-week service, whether they use the service or not.

“We have to provide the equipment, labor and supplies,” Foley says, “to provide the service regardless of the number of bags that come in. We receive about 97% of the contracts each week. The bobtailer is responsible for billing and collecting from the students.”

CHALLENGE ACCEPTED

Businesses that set out on the wash-dry-fold path will no doubt discover challenges and surprises.

“One major challenge is tracking orders between scanin, separated wash according to preferences, separated drying according to preferences, and folding tables,” Sanderson relates.

“There are a lot of touch points the clothing goes through, and the individual items are not uniquely identified as they are in the drycleaning service through ironed-on bar codes,” he adds.

Circumstances that differ from dry cleaning involve not only process but people as well.

Training is important in providing wash-dry-fold service to customers, Foley says. The challenge is making sure that the customer understands the limitations of the service. Communication is key, she emphasizes.

“A lot of operators want to cater to ‘soccer moms and dads.’ Great idea,” says Foley. “But as a woman, when I do my laundry at home, I pre-spot, separate into about four different loads, dry on low, hang-dry and hang up the clothes after they are dry.

“In the commercial wdf service, providing this detailed amount of labor is not profitable and is unattainable unless the operator is doing it on a very small scale.”

Foley notes, “The customer has to realize that their clothing is not pre-treated. Pockets are quickly checked, but not guaranteed; care labels are not checked (so that wool sweater you throw in there could get shrunk); and clothing is returned neatly folded. Not on hangers.”

It’s all about knowing your customers’ tendencies. Foley talks about some of the situations she’s encountered in the business her company has been in since 1984.

“College students are in a hurry. Making sure that the information on sign-up and on the website is followed is like herding cats. But you must state the obvious or else their parents are going to blame you for their mistakes. Such as putting that wet red towel in the bag against their new, white polo shirt. It has red dye on it before we even get it.

“Or putting their fraternity blazer in with the clothes,” she continues. “We train our staff to remove all garments which cannot be washed and return them to the customers with a note stating that those garments need to be dry-cleaned, hand-washed, scrubbed on a rock or whatever.”

Are there some tips for those ready to “open the lid” in pursuit of the wash-dry-fold customer?

In Foley’s words: “A wdf can be worth a lot of money if the order is damaged or lost in cleaning. It is a profit center to take very seriously, and I think that operators tend to think that it is ‘just washing laundry.’ It is much more than that.”

The proper use of equipment, applying ozone or not, detergents, fabric softeners, wash/dry temperatures, separation of clothing, checking pockets, folding and packaging are of utmost importance, she continues.

“My advice is for the owner to spend a day in the service just as his employee would. There is nothing that will solve a problem better than experiencing the service firsthand,” says Foley.

“Do you need gloves to separate? How do you track orders? How long does it take from start to finish? Does your back hurt after standing all day? (continued)

10

www.americandrycleaner.com

American Drycleaner, April 2016

“Wash and fold ... is the way we are reaching out to young people... ”

— Steven Toltz, president, Dependable Cleaners (Photo:

Computer Systems Free cordless scanner with our Garment Verification System! SOFTWARE FAST EFFECTIVE AFFORDABLE!& POWERED BY DAJISOFT LET’S WORK TOGETHER: (888) 325-4763 www.dajisoft.com ❱❱ DryClean PRO Enterprise (DCPe) is even simpler to use than before SUPPORT LIKE NO OTHER Ask us about our DCPe Rental ❱❱ Built in marketing and e-mail functionality Designed for both small and large stores THAT IS VisitusatSDA Booth117

Should you invest in a fatigue mat? Do you have enough space, equipment, supplies?

“Is your staff eating or drinking at the fold table? All of these questions can be answered if you occasionally immerse yourself in the job,” she advises.

TIME HAS COME

On the surface, selling wash-dry-fold service is a matter of pure convenience to your customer via pickup and delivery. But folded into that model is the ability to offer the time-savings aspect of “doing your laundry,” a chore many people despise.

Millennials, it would seem, just by their casual style of dress, could be one of the main recipients of the service today.

“Wash and fold service,” says Steven Toltz, president of Dependable Cleaners in Denver, “is the way we are reaching out to young people who don’t care as much about dry cleaning like previous generations did.”

During a phone interview, Toltz shared his analysis of the wash-dry-fold segment and his business plan to reach potential customers.

“I want them to become familiar with our brand,” Toltz explains. “We sell our customer on time savings. The laundry is neatly folded and can be delivered and,” he adds with a chuckle, “if we could put it away in the dresser in their house for them, we would do that, too.”

What is the advantage of offering wash-and-fold service?

“We have the dry-store labor already — so we put in place washers and dryers in all our stores,” Toltz says. “As soon as we offered the service, we got business.”

And it isn’t all walk-in. He says that about 20% of his total drycleaning business is route-driven but he’s not sure how much of that is wash-and-fold, as it’s not exclusive.

OH, THE HUMOR IS ON US NOW

We like to laugh, and so do you. We asked the cleaners interviewed to share a few surprising and humorous tales from the wash-dry-fold experience.

John-Claude Hallak, president of Hallak Cleaners in New York City, relates this: “Once I received a washand-fold order that contained a silk-crepe Armani suit. This was a dry-clean-only ensemble with a value in excess of $2,500. Needless to say, we did not wash and

Drycleaner,

fold it! When the drycleaning price was quoted, the client requested that we return the suit unprocessed.”

Foley says, “Having the new hires, especially guys, fold a load of young college women’s clothes is a hoot. The thongs get them every time! There is no correct way to fold a thong. But they sure try.”

She also shares this tale of cartoon happiness: “We clean the power company linesmen’s clothes when there are weather events. The power company gets our big wdf department up on the grid, and we bring in the crew. So, to fold a bag of power company linesmen’s clothes and see that they are wearing Tweety Bird boxers can be quite humorous.”

Last but not least: “Pulling a Patagonia jacket out of the dryer in about 45 pieces was quite interesting. Patagonia (or a knock-off) uses glue on the seams, then says to dry on the care label. The glue definitely didn’t hold,” Foley says.

Some surprises and humor naturally can be expected in any freshly developing market segment.

Foley believes that wash-dry-fold will continue to grow: “We have become a society of now. There are more dual working parents whose kids are involved in after-school activities. Marketing to this sector is key, as long as the marketing is accurate and the expectation of the service explained.”

Hallak seems to concur on the future of the trend: “As people’s time becomes an ever-scarcer commodity, I expect this to grow — especially in the middle market.”

If this segment is revealing to you an “agitation” toward growth, then “grow get it.” Many dry cleaners who pick up and deliver wash-dry-fold business discover an increase in dollar traffic right to their cash registers.

One tip to keep on your dial if you are thinking of jumping in: “Understand the logic before getting involved,” shares Hallak. “Separating lights and darks — regulars and delicates — and getting it all back together in the end!”

“What you name your service is important based on your region,” adds Foley. “Wash and fold? Fluff and fold? Wash-dry-fold? Be creative. This is an area where we can still be true entrepreneurs.”

Can you afford not to check out this service? The opportunity to suds up your revenue beckons, almost as loudly as, say, a lineman’s Tweety Bird shorts! ADC

12

www.americandrycleaner.com

American

April 2016

“We have become a society of now. ”

— Rita Foley, president, Regency Cleaners

(Photo: ©iStockphoto/JannHuizenga)

Organic. Atmospheric. Retailesque.

Clean Factory dresses like shiny, new retailer

Every so often, a new idea comes along, and the idea I’m about to describe might be Mike Baroni’s contribution to the industry. It’s not exactly a completely new idea, but his execution makes his business unique.

By Howard Scott

By Howard Scott

not give them upscale lines of products that will help them be attractive? At the same time, this retailing will make it a pleasure to walk in. It will be exciting to see new products that they wouldn’t see in the big box or even department stores.”

In simple form, it dresses a drycleaning operation to look like a shiny, new retailer and sell products that align with dry cleaning. That is, anything to do with maintaining appearance.

Baroni explains it this way: “People who come into a dry cleaner are interested in their appearance. So why

All this enhances the customer’s experience at the dry cleaner, Baroni says. “This is so different from walking into the dull, industrial, unclean look of so many dry cleaners.”

His new business, Clean Factory — with a cog logo in place of the letter ‘o’ — fits the bill as an upscale place to do business. The Hanover, Mass., shop (continued)

14 American

April 2016 www.americandrycleaner.com

Drycleaner,

Mike Baroni, owner of the Clean Factory, Hanover, Mass., stands in front of attractive retail products and tuxedos. Polished hickory floors accentuate the clean, modern look. (Photos by Howard Scott)

has polished hickory floors, LED spotlight lighting, soft music, and about 500 square feet of retail showroom.

The retail space completely integrates with the drycleaning area, as the counter is in the middle of the store and covers its length. In back of the counter are clothes racks.

Alongside the counter is a display of tuxedos, a small sideline. Shelves stick out from both front walls. A few pointof-purchase circular displays sit on the floor.

Product lines include shaving kits, shoe cleaning products, garment rain repellents, clothing detergents, wallets, toiletry bags, briefcases, cleaning cloths, odor reducers, body lotions/ointments, stain solutions, aerating hangers, bleach alternatives, static solutions, sports detergent, wool and cashmere shampoo, and umbrellas.

ATTRACTIVE INTERACTIVE

All products are natural and organic, and have terrific packaging. For example, Naked Bee, Baroni’s line of personal skin care products, comes attractively packaged in yellow and black tubes and bottles in a yellow display.

All told, the store’s retail items represent a dozen vendors, so management has an easier time of merchandise control. Another example is the cleaning cloths, called ECloths because they are environmentally sound. Simply add water and the products are ready for use. And they

last. The display of E-Cloths churns out a continual video to explain their use.

Several products have private labels that read “Clean Factory.” According to Baroni, this adds to the image. All of the products are attractively packaged.

For example, the line of detergents come in glass bottles with white caps and artful white and black labels. There is the sense that these products are high-end. Maybe there are items that customers will treat themselves to, and when they find out how much they like them, will make regular purchases.

As a former retail executive, Baroni knows the world of upscale retail. Merging the two worlds just might work. At any rate, he has created an interesting place to visit, and that’s as good a beginning as any. Clean Factory is a drop store and not a plant. For that reason, the investment hasn’t been huge.

Rather, Baroni has been able to focus his dollars on the storefront. To get started, he hired drycleaning consultant Bob Devaney to help strategize his plans as well as find a location, negotiate a lease, choose vendors, and do all the things a new business has to do to be up and running.

With 30-plus years in the industry, Devaney’s help was invaluable, particularly in choosing a drycleaning partner and negotiating the contract, which was tricky.

“You get what you pay for, and we needed to deliver high-quality cleaning,” Baroni says. “So we demanded a dry cleaner who turns out clothes at a certain quality level and who has some excess capacity and who wants the business.”

The arrangement struck is a varying margin according to the item. Having a chargeper-item basis gives management more control. So far, it is working out just fine. The dry cleaner picks up and delivers six days a week.

Clean Factory does its part in the processing end to turn out a quality product. It does many things that high-end cleaners do, such as clipping shirt sleeves together and stuffing blazers to give a full-bodied look. At the same time,

16

www.americandrycleaner.com

American Drycleaner, April 2016

the

(continued)

A nifty feature is the VIP bag, given free to customers. This is a suit cover bag that doubles as a dirty-laundry bag.

Baroni behind the front counter of his upscale store.

Available in 25 lb, 40 lb, 50 lb, 60 lb, 75 lb and 90 lb. All components that come in contact with liquid solvent or solvent vapors are constructed of high grade stainless steel including the tanks, piping, valves and outer shell. No distillation. After 15 years of experience, using EM Technology, our customers are averaging one filter change every 9-18 months (depending on volume). No water, no steam with the ability to use water and steam when needed. Uses EM technology. Two tanks, no need to store extra solvent. UNISEC USA/ DIVISION OF NEW YORK MACHINERY 609 Chancellor Ave, Irvington, NJ 07111 TEL: 973) 372-0100 855) 600-3636 FAX: 973) 375-0200 Info@unisecusa.com Visit our website at www.unisecusa.com The Standard of Excellence in Dry Cleaning ®

company maintains e-mail contact with its customers.

Finally, regular customers receive 401 garment bags. “It would be silly to have a great-looking place with highquality merchandise and turn out clothes that look like they weren’t cared for,” Baroni says. “It wouldn’t make sense, so our dry cleaning needs to be high-quality.”

HIGH-END ETHOS

To gain business, the company is embarking on a heavy marketing campaign. This includes Valpaks, ad books, supermarket receipts, Groupon, radio ads (Baroni is running ads voiced by him on local WATD radio), and e-mails that announce deals.

As for the chosen location, it’s on a busy main street in a shopping sector. A large mall is up the street. “Sure, there’s competition,” Baroni says. “There are several dry cleaners along this road. But there’s also plenty of business. This particular retail strip has a high vacancy rate now, so it was relatively easy to negotiate a pretty good five-year lease with a five-year option. Plus, its 1,500-square-feet space works for us.”

After retail volume is going, Baroni will go after commercial and group retail volume. He says, “Both my manager, Tom Fitzgibbons, and I will approach law offices, banks, industrial companies, and offer to do their dry cleaning in return for gaining easy pickup and delivery service, becoming a VIP member and receiving a 10% discount.

“We will also go after commercial trade, from barbers to restaurants. We’ll get business in here through the back door.”

Along with this, Clean Factory will set up its website so customers can order their clothes to be picked up, processed and delivered. With this additional service, Baroni will be able to convert some of his office customers to pickup service. The company’s motto is: “Whatever is most convenient for the customer.”

An alterations department will generate additional volume and secure business. The seamstress comes in three days a week from 9 to noon, but that time could increase. A “Tailoring by Elizabeth” sign hangs out front. Her seamstress skills will also help with the tuxedo trade.

A nifty feature is the VIP bag, given free to customers. This is a suit cover bag that doubles as a dirty-laundry bag. It’s a twofer and is all the more useful. A showroom display highlights the two-use feature of the bag.

To encourage volume, there are always specials going on, such as “Three sweaters for the price of two.” To that end, Clean Factory is open seven days a week with convenient hours. In addition, a 24-hour lockbox has been installed in front.

“We don’t want to give the customer any reason not to come to us,” Baroni says. “We want to make it as convenient as possible.”

This is Clean Factory’s first year of operation. Getting volume up to a profitable level takes time, while he attempts to remake the industry into his personal notion of what the drycleaning experience should be about.

The innovator is one who is willing to do something different. It’s the way the industry advances. ADC

Howard Scott is a longtime industry writer and drycleaning consultant. He welcomes questions and comments, and can be reached by writing him at Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027 or via e-mail at dancinghill@gmail.com.

18

www.americandrycleaner.com

American Drycleaner, April 2016

... the line of detergents come in glass bottles with white caps and artful white and black labels.

The Clean Factory storefront is cleverly highlighted by a stylish cog instead of the letter ‘o.’

J & B Service & Supply 13035 243rd Avenue Zimmerman, MN 55398 Phone: 612-840-7294 Email: jbserviceinc@gmail.com

Stop Upping Your Downtime

By Tim Burke, Editor

By Tim Burke, Editor

“

What, me worry?”

You’ve heard that expression. It’s especially humorous when used in movies and on television shows.

But in business, it can lead to some trouble. Don’t get caught shrugging your shoulders and putting off regular drycleaning plant and equipment maintenance.

Hoping you can just ignore any potential problem until sometime in the future is a recipe for trouble. Keeping to your scheduled preventative maintenance plan will actually save you money, helping you to avoid expensive “machine-down” situations. And that, it turns out, pleasantly lowers costs and gives more “bottom line” to you.

A drycleaning plant’s preventative maintenance schedule should include daily, weekly, monthly and quarterly tasks that will keep your business well-oiled and operating smoothly and cost-effectively.

Orville Johnson, vice president of sales and marketing for FabriClean Supply, a Dallas-based distributor of drycleaning, laundry and janitorial products to North America customers, notes some of those key tasks to be aware of.

For daily maintenance, dry cleaners should clean laundry press heads, remove creases from shirt unit air bags,

cycle the bucks without a garment when production stops for lunch and at the end of the day, and wipe down drycleaning press pads and head plates at the end of production.

As for weekly tasks, Johnson reminds dry cleaners to rotate collar and cuff padding front to back, and also check and clean all air filters, replacing them as needed.

Monthly maintenance jobs include a check of laundry press heads for proper temperature (325 F is optimum), a check of all vacuum hoses for leaks, cleaning lint from the vacuum motor, and removing any lint buildup from steel base pads and vacuum ports in shirt body presses.

Lastly, on a month-to-month basis, check air-bag attachment swivels and replace as needed, he says.

As far as quarterly responsibilities go, dry cleaners should rotate collar and cuff steel base pads front to back, Johnson notes, as well as clean the inside of all vacuum hoses, check for holes, and replace if needed.

The drycleaning industry is evolving with new technologies. Preventative maintenance is a planned program of regular service to your equipment so that you run efficiently and keep the threat of costly downtime at bay.

“Tight margins are the issue today in dry cleaning,” says Shawn Hopkins, sales manager for A-1 Products Inc., a distributor of drycleaning equipment based in Birmingham, Ala. “It’s hard to convince

20 American Drycleaner, April 2016 www.americandrycleaner.com

(continued)

Make your wallet happy: Regular preventative maintenance can reduce breakdowns, and that controls costs

(Images: ©iStockphoto/alengo and Big_Ryan)

Sometimes We Like To Strut Our Stuff.

No assembly required. The complete Drapery Strut hanger from M&B Hangers is produced totally in-house from 10.5 gauge wire and a strong high-quality tube. Ideal for drapes, table cloths, and comforters, the M&B Drapery Strut hanger comes complete in a 200-pack box 100% assembled and ready to strut its stuff.

To try our Drapery Strut, go to www.mbhangers.com to find your local distributor, or call 888-699-5644 to speak with one of our customer service representatives.

some dry cleaners to change-out parts regularly, such as steel pads. Maintenance saves money on all the touch-ups that have to be done when old equipment isn’t getting the job done.”

Hopkins believes that utilities such as electricity and gas aren’t viewed as negotiable, but preventative maintenance is seen that way. In tight economic times, some dry cleaners don’t consider it to be a priority. However, others see things differently and take the long view, scheduling regular maintenance for their machines.

Organize your plant schedules and make preventative maintenance requirements and tasks known to all your employees.

“The most important key to preventative maintenance is having the proper training, and understanding the importance of each task,” says Jason Smith, technical service for drycleaning equipment manufacturer Union Drycleaning Products USA, headquartered in McDonough, Ga.

“For example, when the customer cleans the lint filters, they are not cleaning just the lint off the filters,” says Smith. “But they are providing proper air flow for the drying and preventing the refrigeration coils from building up any lint that could cause the refrigeration system not to reclaim the solvent as it should. So, having proper training and the knowledge of each task is key.”

KEEP MACHINES RUNNING AND HUMMING

Manufacturers recommend maintenance. At your drycleaning business, you have to take action and ensure performance of the tasks — or have it scheduled.

Allan Cripe, owner of Valet Cleaners, Temple, Texas, has presented preventative maintenance seminars on the responsibility and awareness necessary for business owners to maintain their plants and equipment.

He says we can divide the topic of regular maintenance into three major areas: compressed air, steam and vacuum lines (or systems).

“One thing in our industry is inevitable: downtime,” says Cripe. “This is a dirty word where I come from. If we are fortunate, we can do a few things to make this a much smaller part of our lives.”

On the topic of compressed air, he says a simple motto helps: Clean, dry compressed air is good; moist, dirty compressed air is bad.

“Put a dryer or heat exchanger on the line after the compressor before it goes to the machines. This will pay dividends in the long run.”

Make sure all your machines and presses have individual, properly functioning filters at the inlets feeding the air supply, Cripe suggests. “This is the last line of defense because condensation can occur in the air lines

despite being treated beforehand.”

Drain your air compressor tanks daily, and change the oil in the heads according to the number of hours operated. “A good rule of thumb is twice a year, minimum,” he says.

Next is the vacuum system. This is a critical component to proper finishing and spotting on the drycleaning side, according to Cripe.

“The vacuum is needed to ‘set’ the press job on the drycleaning side. Make sure you drain your vacuum tank daily here as well.”

This tank “stores all of the condensed steam you’ve sucked out of the clothes,” Cripe notes, suggesting you keep the vacuum valves properly lubricated to ensure long life. There are machines that have self-contained vacuums requiring little maintenance, but make sure to clean any filter screens according to manufacturer’s recommendations, he counsels.

Also, inspect the hoses for small holes or cracks that occur over time. You can repair them with silicone tape temporarily until the hose can be replaced, he advises.

“Finally, the big kahuna,” Cripe says, “the steam system.”

He says the “boiler is the most important piece of equipment we own, and unfortunately, the most neglected.” There are two key duties that need to be taken care of “as religiously as brushing your teeth.”

“First, blow the thing down (both water level safety and the main) every day,” he implores.

“This seems easy to do, but people fail to do this and suffer the consequences. The ideal steam pressure to blow down the boiler is between 15-50 psi,” he notes. “Any more just blows out steam and does not pick up the particulate matter.”

The second key duty Cripe insists be taken care of is treating the feed water. This means using a good-quality boiler compound and, depending on your city water, a water softener.

“If possible, don’t add the boiler compound directly into the return tank unless you flush it right into the boiler by opening the blowdown drain and activating the pump,” he says.

If the compound sits in your return tank, it’s highly corrosive, he notes, both to the tank as (continued)

22

www.americandrycleaner.com

American Drycleaner, April 2016

Better care over the lifetime of your machines means better control of your budget ...

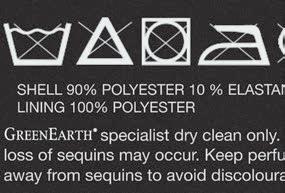

The most recommended brand in dry cleaning UK 8 EURO 36 US 4 SHELL 90% POLYESTER 10 % ELASTANE specialist dry clean only. Some loss of sequins may occur. Keep perfume away from sequins to avoid discolouration. BLACK RN 132258

well as the impellers on your feed pump. Ideally, you want it to go downline from the pump. “These two steps alone,” Cripe says, “will add years to your boiler’s life.”

Keep in mind there aren’t any regulations or policies on preventative maintenance. A drycleaning owner needs to be fully aware of a plant’s equipment needs. Make good habits concerning your maintenance procedures part of regular life at your business.

A few other things to remember: There are federal regulations on spent filter cartridges and chemical waste disposal for dry cleaners.

Follow regulations issued by the U.S. Environmental Protection Agency (EPA) under the Resource Conservation and Recovery Act (RCRA) laws. RCRA requires the following of certain practices and procedures associated with the safe management of hazardous waste.

Also, insurance coverage requires inspection of boilers. Make sure you are keeping up with the R and R’s (regs and requirements) necessary to run your business. To do this, keep good files, dated and organized, where you can access them if you need to check maintenance track records on any of your equipment.

WALLET-HAPPY TIPS

Do you have a preventative maintenance program in place, one that you follow?

Servicing your equipment regularly is more costeffective than paying employees to wait while you try to repair a failed piece of equipment. You also risk disappointing your customers when they don’t get their garments back on time.

Here are some preventative maintenance nuggets from Cripe to keep in mind.

“Only one-quarter inch of scale on your boiler tubes equals up to a 25% increase in your gas bill,” he notes.

If your boiler loses steam, he says, “you look and the sight glass is empty, but the pump is running, then you have pump cavitation. The temperature of the feed pump is too hot.”

A temporary fix is to drip some water on the pump from a hose, which will cool it off enough to break the vapor lock and function properly, he says. The issue is either a bad steam trap(s), failing valve(s) in the feed line, or the pump impeller is worn out due to compound corrosion, according to Cripe.

Avoid excess moisture in your transfer drycleaning machine by putting a couple drops of food coloring in your solvent bucket, he says. You will always be able

American Drycleaner, April 2016

to see that your separator is working properly.

“Toss a 3-inch stabilized chlorine tablet in your stainless button trap,” he says. “It will help keep any transient bacteria at bay. Do not toss one in the base tank, because these are corrosive.”

Beyond these tips, a dry cleaner has to be willing to acknowledge when it’s time to replace older equipment. Cripe reminds drycleaning business owners that preventative maintenance happens “on your schedule, but breakdowns due to neglect usually happen at the worst time.”

CONTROL COST ‘LIKE A BOSS’

So, back to the phrase, “What, me worry?”

The consequences of doing nothing are breakdowns and loss of time and money. But replace the word “worry” with “upkeep,” which can be recognized as treating maintenance seriously.

Today’s business owners and store managers look for ways to save money and get the best bang for their buck in areas such as supply, service and cost. But why not preventative maintenance, too?

We have pointed out not only the scheduling side of maintaining your equipment but also a few tips on the practical side. Can you stop what you are doing and take a look at your preventative maintenance procedures and then — this is key — make a change, if needed, to how you care for your equipment?

Think of it like you would improving your dental hygiene and doing a better job of flossing and caring for your gums and teeth all the time, not just when you remember to.

“Make sure your equipment is clean,” says Chris Abercrombie, director of technical services, also with FabriClean Supply. “If you have to dig through 3 inches of lint and dirt to service a machine, you have already lost half the battle.”

Abercrombie recommends cleaning machines weekly, paying attention to problems like steam and air leaks that are easier to detect, and keeping frequently used supplies and parts (such as lubricants, hoses and belts) in stock.

He suggests preparing a maintenance schedule and following machine manufacturer recommendations that can be found in most machine manuals.

“Assign tasks such as: blow down the boiler and add treatment compound daily. Also, blow down the air compressor and check the oil level, and blow down the vacuum,” Abercrombie says.

“For weekly tasks, clean the still, spin

24

www.americandrycleaner.com

(continued)

Think of smart maintenance as a way to control the speed of your business costs.

the filter and clean lint from the air channel in the drying chamber on drycleaning machines and dryers.

“Monthly,” he continues, “check drive belts on machines and adjust or replace. Grease machines, and check steam traps.

“On a semi-annual basis, drain and clean tanks on your drycleaning machine and have an HVAC mechanic check the refrigeration on your drycleaning machine. Annually, clean out the boiler and have it inspected.”

Some tasks should be performed per load on a drycleaning machine, he points out. “Before each load, check solvent levels in working tanks. It should be

at least three-quarters full.”

“During each load, monitor how much solvent is used, solvent flow, and check filter pressure,” Abercrombie says. “After each load, clean the lint filter and clean the button trap. Keep records on both preventative and repair maintenance, and a repair log for each machine.”

HAPPY YET?

Maybe you are already following a plan that’s in place and are regularly servicing your machines. If so, it doesn’t hurt to take another look anyway to make sure you’re getting all you can out of your equipment’s performance. It’s money-wise to do so.

Think of smart maintenance as a way to control the speed of your business costs (money flowing outward). Slow it down.

Some industry voices have provided tips here for you to consider. Better care over the lifetime of your machines means better control of your budget and how much you are spending, not wasting, on “headache prevention.”

If you are new to the idea of preventative maintenance, use these ideas and strategies to begin a systematic checklist for charting your drycleaning equipment’s health.

Stop worrying. Use a preventative maintenance program to help limit breakdowns. There’s cost savings in taking regular care of your craft, and there’s greater customer satisfaction when your machines run smooth and efficient.

It’s all up to you. “Prevent” means taking action now to avoid costly reaction later. Start lowering your downtime and upping your bottom line!

26

www.americandrycleaner.com

American Drycleaner, April 2016

ADC Visit us at Cleaners Showcase Booth # 408

... begin a systematic checklist for charting your drycleaning equipment’s health.

Do Your Employees Like Their Workplace?

AFeb. 10 USA Today headline read Job Hires, Quits

Swell to Nine-Year Highs.

According to the U.S. Department of Labor’s Bureau of Labor Statistics report the day the article was published, job openings in the U.S. jumped to 5.6 million from 5.3 million a year earlier.

to land a new job.

According to a Jan. 12 Gallup Business Journal story by Brandon Riggoni and Baily Nelson, “55% of managers and workers are considering a new company.”

Diana Vollmer

The number of hires rose to 5.4 million from 5.3 million — the high est since 2006. Furthermore, there were only 1.4 unemployed workers for each job opening, down from a high of 6.7 in 2009. A 2-to-1 ratio is considered a healthy labor market.

The number of employees quitting jobs is also at a high since 2006, indicating confidence in the ability

This more active job movement and the increasingly dynamic labor market is also starting to push up wages. Despite the indication of a more robust economy, in our labor-dependent fabricare industry, this is less than stellar news. It can be a sharp, double-edged sword. It indicates better sales but also an increase on your highest expense.

Ask yourself a couple questions. How are you going to retain your best employees as other companies are recruiting them? Recruit desirable new employees in the ever more competitive job market?

These challenges have been increasing

(continued)

www.americandrycleaner.com American Drycleaner, April 2016 27

MANAG EMENT S T RATEGI ES ADC_Hhalf.indd 1 3/4/16 10:24 AM

MANAGEMENT STRATEGIES

since the economy has shown the slightest glimmer of improvement, and the new signs of vitality are forcing an ever-growing predicament for operators.

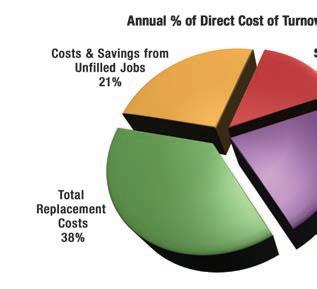

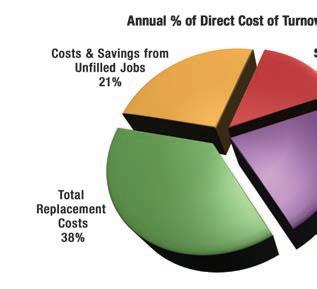

Turnover carries a heavy cost for your business. There are many sources of research that estimate these costs and the general consensus is that the total cost of turnover is:

• 30-50% of annual salary for entry-level employees

• 125-150% of annual salary of mid-level workers

• Up to 400% of salary for high-level employees

These estimates are usually a shock to business owners and are often met with disbelief until they are broken down to show all of the contributing factors, many of which are elusive.

Some of the easily identified costs are loss of productivity while the job is unfilled and during the training of the replacement, not to mention the time and salary spent on the trainer. Recruiting is expensive and time-consuming.

Costs of separation can include benefits such as vacation that must be paid immediately instead of on the planned schedule, but often there are high costs of separation with a disgruntled employee, including unplanned lawsuits.

Lost opportunities are often the highest cost of turn-

over when business momentum is interrupted, and those costs are difficult to estimate. Questions to consider: How much does the loss of a high-value client cost due to a failure in service or a lapse in relationship? How much does it cost to lose momentum in the sales cycle?

Of these overall costs, the average allocation is represented in the chart pictured below. Note that it doesn’t include lost momentum with current and potential customers.

A couple more questions to consider: Have you tracked your turnover? What is the percentage of your total current employees that are still employed by your company one year later?

An easy way to start tracking turnover is to count the W-2 recipients from 2014 that were repeated for 2015.

RETAINING, ENGAGING

Retention is an obviously effective way to reduce turnover. It is always a concern, but as others recruit your associates, they, of course, want your stars, not your mediocre or marginal employees.

Just as when you recruit, you want to hire people who will excel in your business. So even though 60-plus% are actively looking for jobs elsewhere, if you are not actively addressing retention, the people who you will have left are not the stars you want to keep.

A key to retaining your team is the level of employee engagement. According to Riggoni and Nelson of Gallup, “54% of disengaged employees are willing to leave their company for a raise of 20% or less, however only 37% of engaged employees” would leave for the same raise.

Engaged employees take fewer sick days, too. “On a monthly basis, actively disengaged employees have 2.17 unhealthy days, compared with 1.25 unhealthy days for engaged employees.”

This is from Gallup’s Well-Being section (Dec. 18, 2015).

Managers play a pivotal role in employee (continued)

28

April

www.americandrycleaner.com

American Drycleaner,

2016

Image based on data and graphic from: http://retensa.com/ solutions/services/diagnose-turnover/turnover-audit/

THE KING OF THE SEA HAS ARRIVED…

Engineered to exceed the professional fabricare industry’s highest standards, Poseidon Textile Care Systems deliver unrivaled programmability for superior wetcleaning results. Poseidon harnesses high-performance Wetcleaning Machines, Dryers and Flatwork Ironers for results and efficiencies that outshine traditional drycleaning. Industry-unique features set Poseidon apart. Contact Poseidon for the professional fabricare solution.

POSEIDON TEXTILE

SYSTEM S ®

CARE

www.poseidonwetcleaning.com 800-482-3400 • 248-457-1140 2329 Alger • Troy MI 48083

MANAGEMENT STRATEGIES

engagement and “are responsible for as much as 70% of the variant in employee engagement,” the same Gallup research shows.

The non-profit Society of Human Resource Management (SHRM) offers a fee-based management tool called People InSight that you can use to measure how engaged your team is.

COMPENSATION, WORK ENVIRONMENT

Compensation is an important factor, although it seldom rises to the top of the list with employees. Several independent organizations regularly poll cross-sections of employees from a variety of industries regarding motivation and satisfaction factors.

The most recent such poll from SHRM shows “Com pensation/pay overall” ranks second after “Respectful treatment of all employees at all levels.” “Benefits, overall” ranks fourth after “Trust between employees at all levels.”

Question to consider: Do you offer profit-sharing to put your employee motivation on the same side of the P&L as the company?

In the SHRM survey, 62% of millennials and 53% of all generations ranked work environment as important to their job satisfaction. A poor work environment slows productivity and often prompts moves to a new job, increasing turnover, which costs your business money. It can damage your reputation among current and former employees, which often reaches customers as well.

TOP FIVE ENGAGEMENT FACTORS

The top two (and three of the top five) engagement factors that were most important to employees on the SHRM survey have to do with individual goals. Autonomy to take action also ranked in the top five. The results by percentile are:

1. I am confident I can meet my work goals (92%).

2. I am determined to accomplish my work goals (88%).

3. I have a clear understanding of my organization’s vision/mission (76%).

4. I am highly motivated by my work goals (74%).

5. In my organization, employees are encouraged to take action when they see a problem or opportunity (68%).

American Drycleaner, April 2016

Questions to consider: Do you give each of your team members individual and/or group goals? Do you give them the authority to act when there is a problem or opportunity?

MORE EFFECTIVE RECRUITMENT

In a tight job market, it is tempting to hire the first candidate that might be able to do the job. Resist that temptation.

Better hiring starts with a clear description of all that the job entails and a list of the skills and attributes needed in that position to excel and reach the goals of the job and the company. Weigh the attributes heavily since hiring for attitude and aptitude has been a successful approach. Be objective and try to clone your best performers.

The norm is to hire (and also retain) someone similar to the interviewer and someone that the interviewer likes and relates to regardless of the requirements for the position. This method is a high contributor to turnover and failure. Hire and retain for competence and success.

Approach to consider: Group interviews are being used effectively to identify the best person for the job. If you haven’t used this technique, you will be pleasantly surprised at the results.

All of the topics relating to recruitment, retention, engagement and turnover are important and extensive enough to explore in great depth. Walk through your entire operation with objectivity and determine if it is an appealing place to work. ADC

Methods of Management (MfM) has served the drycleaning and laundry industry with affordable management expertise and improved profitability since 1953. For assistance with your human resources management, contact Diana Vollmer at dvollmer@mfmi.com or call her at 415-577-6544.

30

www.americandrycleaner.com

“Walk through your entire operation with objectivity and determine if it is an appealing place to work.”

Forenta Dry Cleaning Sandwich Legger $7,175* UniMac 100-lb. Washer (Used) $8,125* Hoffman Utility Press $5,700* Cissell 75-lb. Steam Dryer (Used) $2,195* Hoffman Form Finisher $3,295* Rema RP8 Air Vacuum $2,650* ADC (Coin-Op or OPL) 30-lb stack dryer $3,995* Hoffman Double Topper $5,795* Lattner 20hp Boiler $12,400* Milnor 45-lb. Washer $5,249* Unipress Single Buck SB1 (Used) $10,500* Unimac UM202 Washer $3,800* Bowe 40 Hydrocarbon Machine $26,500* Forenta Triple Puff Iron 33PS $1,859* Huebsch 75-lb. Gas Dryer (Used) $1,800* 1/2” Steam Traps $35 each, 5 trap minimum 86 6 - 73 4 - 364 4 Monthly Specials Online: MustangEnterprises.com New & Used Equipment for Drycleaning & Laundry Huge Selection of Parts for Most Brands of Equipment Prices valid until May 1, 2015 | *Freight Not Included

Give Smooth Leather Extra Attention

My column in the January issue on wetcleaning suede drew a large number of comments. This month, I will revisit the cleaning of skins, by giving an overview of smooth leather and its cleaning. It can be found as trim on a fabric garment as well as comprising the entire garment.

One can usually identify the part of the animal’s body the hide came from by the grain/ texture of the leather. The coarser the grain, the higher on the body the hide originated.

Deep valleys in the hide probably indicate a back skin, while fine grains in the leather are an indication of the skin coming from the belly region. Belly skins are thin, while a back skin is dense. Most motorcycle jackets are of a coarse grain, indicating that they were taken from high on the back of the animal. They are intended more for protection rather than decoration, and the thick hide makes them much more durable.

On the other hand, a lady’s jacket constructed of wellmatched belly skins will be soft and supple in appearance and touch. This leather is thin and will require a level of protection to prevent tearing of seams during the mechanical action of cleaning.

Two major indicators of relative quality in leather garments can be observed by the CSR upon presentation for cleaning.

The first is how well the grain in the leather has been matched together in appearance. A garment that has a small, fine-grain belly skin sewn to a coarse back skin is evidence of little or no attention to detail during construction.

This is apparently the product of “using up” the available hides by piecing together hides without any regard to texture or appearance. Many times, under these conditions, the thin belly skin will tear at the seam due to the

To find past Spotting Tips columns or share this month’s with your colleagues, visit AmericanDrycleaner.com.

relative difference in tensile strength of the two pelts during cleaning.

The second indicator is the use of a filler to camouflage imperfections in the skin from things like barbed wire and thorns. These imperfections are trimmed away in the construction of all but the low-end garments. This filler is similar to the Bondo® used in a auto body shop and is easily loosened during wear and cleaning, leaving the cleaner open to a potential claim.

If the leather has begun to stiffen, even to the point of crackling when handled, it is a good indication that it has been a victim of neglect or abuse. Stiff leather that crackles when bent is a sure sign that the garment is likely to be unserviceable.

Leathers come in almost every configuration: jackets, skirts, pants, vests, even shorts. Just like suede, the moment the animal’s heart stops, the hide tends to dry.

Modern tanning methods go a long way to slowing down the process of drying. Our job is to continue to retard the drying and keep the leather smooth, soft and supple. Restoring smooth leather requires a virtually identical cleaning process as suede.

You must use a detergent formulated for cleaning animal skins, spotting agents that are compatible with retaining the oils and dyes used on smooth leather, and, most importantly, a conditioner to ensure the garment remains soft and flexible. Ask your distributor about the lines of leather cleaning supplies that are available to you.

Do not use strong chemical tools to pre-spot leathers. It is almost always necessary to clean a leather garment again when post-spotting is required. When I pre-spot leather, I use a 50/50 concentration of my leather detergent and water or a 50/50 concentration

32 American Drycleaner, April 2016 www.americandrycleaner.com

Martin Young

S POTTIN G TIP S (continued)

“ ... use a mineral oil mixture or neatsfoot oil mixture to add luster to the garment surface.”

of my leather degreaser and water.

These have a great shelf life, so they can be made up in advance and kept at the ready. When prespotting, you should be sensitive to your mechanical action and/or chemical tools disturbing the dye or the smooth surface.

Any rinsing of pre-spotter should be done with a bottle of tap water followed by your air gun.

Increase the gun’s distance from the garment by another 2 inches to allow an additional margin of safety for the garment surface. If additional mechanical action is required, use a “worn-out” toothbrush to get into the grain.

The advances in wetcleaning chemistry make the actual cleaning process the least stressful part of restoring smooth leather.

Follow the manufacturer’s instructions for use, based upon the volume of the washer and the number of items

being cleaned. Classify the load just as you would any other cleaning run: white, light, medium and dark.

I recommend that you clean any specialty item, such as painted or ornamental trim, in a load by itself. I prefer to have at my disposal as many chemical tools as possible, to allow myself a greater level of flexibility in the cleaning process.

A leather detergent cycle followed by a leather conditioner cycle will be adequate for most items. After the cleaning and conditioning cycles are finished, tumble the leather until it is at 10-15% RH, not quite dry, using a temperature of 120-130 F.

A jacket, coat or vest can be placed on the suzie using manual air to provide light tension and drying. You should use sleeve forms to shape the sleeves as they finish drying.

Pants can be placed on the pants topper on manual air and using the plastic “clam-shell” cuff forms to shape the

34

www.americandrycleaner.com

American

Drycleaner,

April 2016

ADC_R_Hhalf.indd 1 11/3/14 2:27 PM SPOTTING TIPS

leg and block airflow, thus providing tension to the pant legs.

While some operators may choose to invest no further effort, it is at this point where you can set yourself apart and “sell” the job.

One way is to use a mineral oil mixture or neatsfoot oil mixture to add luster to the garment surface. Simply spray the garment, wait a few minutes, then wipe away the excess.

Another option is to set the garment aside until you have the time to hand-rub the entire garment with mink oil. On several occasions, I have returned a leather garment on which I used mink oil, only to have the customer respond that I have given them the wrong garment. Word of mouth is still the best, and cheapest, form of advertising.

Specialty items make up a small percentage of the market but a large percentage of the problem items when restoring leather.

A few abandoned handkerchiefs and some No. 3 safety pins will provide adequate protection for any heavy buckle. By pinning a doubled handkerchief over the buckle, turning the garment inside-out, and running the garment in a mesh bag, you will prevent damage to the

garment, or having the garment damage your equipment.

Those painted fan/tour jackets will have special sentimental value to the customer. The paint is usually oil-based and should be wet-cleaned. Set these jackets aside until you have a few extra minutes to pre-spot, extensively.

Your goal is to reduce mechanical action as much as possible. Painted jackets will respond well to the time required to rub them down with mink oil. This will enhance both the leather and the painted surface.

Finally, a word of warning. The time will come when someone will bring you a “trail coat,” also called a duster. This is not a hide, but a cellulose fabric impregnated with wax and oil.

The proper and recommended care is to wipe this long coat with a soft cloth while using a water hose to flush away the surface dirt. If you dry-clean it, you will buy it. ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates to this day. Contact him by phone at 704-786-3011, e-mail mayoung@vnet.net.

www.americandrycleaner.com American Drycleaner, April 2016 35 ADC_Hhalf.indd 1 3/16/16 2:00 PM

‘I nstitution’ T arget Cleaners closes doors after 63 years

Jim Longo couldn’t have been any more emotional when he said on the phone recently, “Our customers weren’t just people, they were friends. And they viewed us the same way. One told me, ‘You’re an institution. You even opened your store on your day off to take care of us. We’ll never forget you.’”

After more than six decades, Target Cleaners located in Heidelberg, Pa., owned by Longo and his wife Jacqueline, closed its doors on Feb. 11. The Longos have retired.

When asked why they decided to retire, Jim Longo chuckles, “Well, we’re just gettin’ old.” He adds that they want to enjoy retirement. Their plans?

“We’ll stay local and be near our daughter. And to all our customers, we just tell them, ‘We’ll see you around at the grocery store,’” he says with a laugh.

Customers who visited the couple during their last week in business remembered fondly the years of bringing in clothing. “They drop in, not with cleaning,” Jim Longo shares, “but just to say so long. It’s amazing. All last week and this week, a stream of friends.”

His grandparents opened the first store in the 1940s in

Pittsburgh’s Overbrook neighborhood. “It was called City Cleaners,” Longo remembers. “Their kids all got involved in the store. They would go out and pick up clothes to be cleaned. There wasn’t much walk-in traffic then.” They opened a second store in Carnegie, and other stores fol lowed. Target Cleaners opened in 1952.

For more than 63 years, members of the Longo family cleaned and mended clothes, and cleaned drapes for busi nesses. They also handled band uniforms and choir robes for Chartiers Valley School District.

Amidst the sounds of Jacqueline talking and laughing with friends entering the store, Jim was asked what they wanted to be remembered for.

After a pause, he says, “For fairness and service pro vided. We never advertised. Everything was word of mouth. A few weeks ago, we sent out a letter thanking our customers for their business over the years. That’s when friends began stopping by.”

He doesn’t have one favorite memory, he says. “We’re gonna miss everybody.”

R &B Wire Products marks 70th anniversary

R&B Wire Products, a manufacturer of laundry carts, is cel ebrating its 70th anniversary this year, the company reports. The self-service laundry industry was in its infancy when R-B Company started in 1946. World War II had ended, and the ingenuity of product design and develop ment shifted from the war effort to practical products that improve the lives of everyday Americans. R&B set about filling the need for a handy cart to transport laundry from washers to dryers.

By 1966, Rea Rawlins was at the helm of R&B, while son Rick, a high schooler, worked weekends and summers welding and assembling laundry carts. These wire carts became the foundation for the company. Rea Rawlins ulti mately became chairman of the Coin Laundry Association board in 1983, helping create greater industry value.

As R&B matured and Rick Rawlins graduated from col lege, the father and son became a dynamic team, the com pany says. Rick became R&B’s president and CEO in the late 1980s when Rea decided to retire. Later, Rick followed in his father’s shoes yet again by becoming CLA board

36 American Drycleaner, April 2016 www.americandrycleaner.com AROUND THE INDUSTRY

Jacqueline Longo, co-owner of Target Cleaners, with husband Jim Longo (in back), greeted many well-wishers during their business’ last week. Tar get closed Feb. 11 after 63 years, and the Longos retired.

(Photo: Kristina Serafini/Tribune Review)

chairman in 2001.

Today, R&B Wire Products serves the coin laundry, commercial laundry, healthcare, hospitality, janitorial sup ply and material-handling market sectors with a global company presence, says Rick Rawlins.

“Celebrating 70 years of ‘Manufacturing Excellence’ is overwhelming and hard to conceive,” he shares, “but it cer tainly is something I am very proud of. I look back with a real sense of pride and thanks to our R&B distributors who have been instrumental in the development of R&B over this time.”

He further attributed R&B’s longevity to its commitment to a “Satisfaction Guaranteed” philosophy.

NARD appoints Landefeld

Jill Landefeld recently joined North American Restora tion Dry Cleaners (NARD) as its new national account executive, the company reports.

Landefeld will further develop the growth of regional and national accounts for the fabricare specialists network whose members provide textile restoration services to many of the top insurance carriers in North America, NARD says.

“I am excited to start a new challenge within NARD,”

Landefeld says, “and look forward to working with the team to further develop their already extensive product and service suite. I am fortunate to be joining such a respected company that prides itself on top quality service.”

Landefeld comes with experience within the industry, having spent the last four years at the Independent Mitigation and Cleaning/Conserva tion Network (IMACC) where she was instrumental in acquiring numer ous large corporate accounts, accord ing to NARD.

Manuel Vendelis, president of the NARD board of directors, says, “Jill’s wealth of experience and industry knowledge has already made her a key addition to the NARD organiza tion.”

He adds that “the increasing demand from our custom ers led us to look for an addition to our team who will fit in with our ethos of innovation and exceptional service, and it is very fortunate that we were able to find someone of Jill’s caliber to fulfill this role.”

Vendelis says he is confident “that Jill will play a key role in providing and implementing high-quality solu tions for our clients.”

www.americandrycleaner.com

37

American

Drycleaner,

April 2016

ADC_Hhalf.indd 1 3/3/16 1:57 PM

ADC

Landefeld

38 American Drycleaner, April 2016 www.americandrycleaner.com BUSINESS OPPORTUNITIES COMPUTER SYSTEMS TO PLACE YOUR AD CONTACT: classifieds@ americantrademagazines.com Own Your Own Drycleaners—Managers, Spotters, Tailors, Pressers! 100% Financing. Plant or Drop, location of your choice. Call 1-561-302-5031 or 1-888-275-6637. Beautiful, safe, quiet town in Central PA. Well established Quality Dry Cleaners with the Building, land and all Equipment. In a very nice location to service many close by counties. Great walk-in traffic, also

established routes. Top of the line staff and management team in place. Retiring owner will phase out as soon as you

the routes and take over the day to day business. To see the business in operation and look at the books please call Mr. Danz at 1-262-903-0070 EQUIPMENT FOR SALE CONSULTING Western Wonder Touch POS Systems For Dry Cleaners $990 (refurb) + Free New Cash Drawer Commercial-grade touchscreens (not Dell) Perfect for small to medium cleaners www.westernDCcomputer.com 773-878-0150 westernk@msn.com www.AmericanDrycleaner.com PLANTS FOR SALE We know we can’t make all the cooling towers, so... We Just Make the Best MAGICOOL 2003 E. Perkins Ave., Sandusky, OH 44870 Call 419-625-0539 for details. • Stainless Steel or Galvanized Steel • 7 to 175 Nominal tons PARTS FOR SALE PARTS FOR SALE BOILER DOWN? Boiler Feed Pumps Ship Same Day! 160 EASA service stations around the country. 815-666-4655 • Fax: 630-552-9014 sales@dltelectric.com • www.dltelectric.com Exact AERO Replacement for 7CT7M WESTERN CHICAGO SUBURB $1,300,000+ SALES • Large Plant Bldg. included • Equip. New/Well Maintained • Excess Capability for Merger • Quality DC Chain/High Prices • Drop Stores, Routes & Accts. • 50 Year Profitable Business • Long Term Mgmt & Staff • SBA Financing if Qualified • Retiring Owner will Train Richard Ehrenreich, Cleaner Broker Richard@Ehrenassoc.com 301-924-9247 ADDITIONAL REVENUE

6 well

learn

www.americandrycleaner.com American

April 2016 39 REWEAVING SERVICES WITHOUT-A-TRACE WEAVERS—More than 50 years’ experience. We are the experts in silks, knits, French weaving and piece weaving. Reasonable prices. Send garments for estimate to: 3344 W. Bryn Mawr, Chicago, IL 60659; 800-475-4922; www.withoutatrace.com. SUPPLIES SUPPLIES 800-532-2645 www.comcoil.com Laundry/Dry Cleaning Coils Steam Or Water Replacements Large Inventory • FASTDelivery SUEDE & LEATHER SERVICE 800.542.7769 // www.arrowleathercare.com Specialists LEATHERCARE SERVICES • Wholesale • High Fashion • Cleaning and Restoration Leather Ad American Drycleaner.indd 1 12/8/14 4:19 PM A.L. Wilson Chemical Co. 1 Ally Equipment Co. ............. 35 Arrow Leathercare Services 39 Cleaner Business Systems 3 Cleaner’s Supply 39 Columbia/ILSA ................ BC Commercial Coils 39 Computer Connections 26 Dajisoft ........................ 11 Fabricare Management Systems 9 FH Bonn 27 Firbimatic ...................... 19 Global Business Systems 34 GreenEarth Cleaning 23 Hangers Direct .................. 38 Iowa Techniques 5 Luetzow Industries 39 M&B Hangers 21 Magicool 38 Maineline Computer Systems IFC Methods for Management 38 MTH Boilers 38 Mustang Enterprises.............. 31 Newhouse Specialty Co. .......... 39 Parker Boiler Co. .............. IBC Poseidon Textile Care Systems ..... 29 PROS Parts 38 QuickSort 25 Realstar 33 Royal Basket Trucks 37 Scan Q . . . . . . . . . . . . . . . . . . . . . . . .13 SPOT Business Systems 7 Union Drycleaning Products 15 Unisec USA .................... 17 Scan here to Call & Receive a discount $22.98 Higher Quality, Lower Cost, Bigger Savings! BAG SALE Luetzow Poly is Made in the USA * NEW Roll SIZE 21x4x40, .5 mil 548/roll 21x8x40, .5 mil 472/roll 20 pound carton *Billed at $30.64 less 25% 10 days.. $22.98 Plus Shipping & Handling F.O.B. South Milwaukee, WI Price subject to change without notice. POLY Direct 800-558-6055 LUETZOW INDUSTRIES 1105 Davis Ave South Milwaukee, Wisconsin 53172 www.AmericanDrycleaner.com Dry cleaning plant with two dry store locations. Established 1962. Gross $350 K. 50# Realstar machine only 4 years old, GreenEarth solvent. Northern Ca location. For info call 707.367.0718 SELL OR BUY A DRYCLEANER. WE HAVE BUYERS!!! PATRIOT BUSINESS ADVISORS SPECIALIZES IN SELLING DRYCLEANERS IN NJ, PA, DE & MD. CALL LILIANE AT 267-391-7642. PLANTS FOR SALE RECEIVABLES STRATEGIES If monthly you individually bill 75 or more open accounts? Suffer slow/no-pays? Have finished jobs remain ‘on rack’ too long? My system forever resolves such costs and guarantees to double your cash flow, all for a one time low cost. Worth a look? Call me, Jim Herst, 847/602-7030. (No commitment either side!) LEATHER-RICH INC. • High quality cleaning, refinishing & repair Leather, Suede and Fur; • Free shipping in USA and rewards program FOR MORE INFORMATION: www.leatherrich.com E-mail: leatherrich@att.net Call 800-236-6996 Route Service in Upper Midwest

Drycleaner,

A Withholding of Withholdings

10 YEARS AGO. The MidAtlantic Association of Cleaners (MAC) recently submitted a letter to the U.S. Environmental Protection Agency (EPA) on behalf of IFI and MidAtlantic members regarding the agency’s proposed changes to regulations covering perc emissions. EPA proposed the changes in December, asking for amendments to its 1993 air-toxics standard to further reduce emissions from up to 28,000 drycleaning plants nationwide. The most drastic cuts would affect industrial operations and co-located facilities. In the letter, MAC expresses shock that EPA relied upon what it calls “illfounded” numbers from officials in California to assess risk. … The country’s warmest January in more than a century and a seasonably cold February created economic ups and downs in everything from retail sales to manufacturing. Lower utility usage in January improved industrial outputs, and the warm weather drove shoppers to the malls. But shoppers stayed home in February, bringing declines in sales of autos, clothing and furniture.

25 YEARS AGO. EPA is in the throes of deciding whether to upgrade its cancer classification for a toxic solvent that is used by almost the entire drycleaning industry, responding to both congressional and internal agency pressure to resolve the issue that has remained unsettled for almost five years. If EPA decides to upgrade its classification calling the solvent a B2 or “probable” carcinogen, it could shut down the drycleaning industry, say industry sources. … Good news! The late March SAB meeting to review the status of perc resulted in no new findings to warrant a change in the solvent’s classification. The way it looks now, the EPA’s independent Science Advisory Board would probably favor a continuation of the C (“probable” human carcinogen) classification for perc rather than recommend a change to the B2 (“probable”) designation.