Robust and reliable cloud based options which include scalable virtual servers, geo-redundant backups, security and support/upgrades.

Compassmax is a trusted technology partner with 28 years of service to the drycleaning industry.

Increase revenue with powerful Compassmax marketing tools which include automated emails, customer promotions, frequent loyalty programs and data mining.

We are making investments in product research, development and innovation.

Compassmax has dozens of unique and customizable features to boost your success.

Simple to navigate screens with two distinct interfaces: touch screen and keyboard.

Feel secure in your Compassmax software investment: from tokenization of credit cards to reliable secure data.

Full featured point-of-sale software platform that combines simplicity and proven competence.

We are here for you 24 hours a day, seven days a week with an experienced and trustworthy staff.

With our proven track record, you can be assured peace of mind, quality, stable software and a solid vision for the future.

Perc users – chlorinated solvent belongs in your machine, not on your board. Alternative solvent users – use stain removers that align with your chosen solvent. Replace traditional POG’s and VDS’s with TarGo® EF and EasyGo®, two of Wilson’s high-performance, cost-effective, California-compliant stain removers. You'll be taking steps to avoid future regulatory and remediation nightmares, while providing your customers with the garment quality they desire!

EasyGo spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to TarGo EF to remove any tough oil based stains that remain behind.

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

September 2016 Vol. 83, No. 6 DEPARTMENTS

(Cover Photo: ©iStockphoto/ mattjeacock)

COVER: Finish Strong Automation and cross-training are now walking hand-in-hand in drycleaning plants and that saves owners money. Find out what manufacturers think of new machines, new technology, and where it’s all leading to in the near future.

Tim Burke, Editor

To keep your personnel and plant safe each day, develop a culture of safety. Dry cleaners from across the United States share their views and practices for a safe workplace.

Tim Burke, Editor

Can you smell that?! Identify clothing fibers by lighting them on fire and paying attention to the look, feel and smell of the burnt residue of the fiber. When in doubt, always check the ash.

Tim Burke, Editor

Pre-Inspection 4 Winners Win: That’s You! Talk of the Trade 6 Management Strategies 24 Visionistics Diana Vollmer Spotting Tips 30 Chocolate Ice Cream, Meet Clean Tee Martin Young Closer Look 34 Firbimatic Industry Observations 38 How to Value Your Dry Cleaner Howard Scott Glitter On! Clean Returns in ’17 40 Coming back to Las Vegas in June; expect new ideas and innovations Around the Industry 42 Classified Advertising 46 Advertiser Index 47 Wrinkle in Time 48 Tears Over TV

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

Since 2003, CBS has given me consistent updates and easy to understand tech support, all at a price that our industry can afford. I would recommend CBS, and I have, to anyone who is still wasting their time and money on those over priced POS systems.

Everyone from California talks like The Dude: “Far out, man.” We all know if you’re from Chicago: “Al Capone, Bang-Bang!” New York? You know someone in “Da Outfit.” Florida? Just all retirees and bad drivers! And all Texans wear cowboy hats. Stereotypes [Ugh!] are everywhere.

I’ve been to L.A. and San Fran many times and found only friendly, generous people. Folks in Texas are equally great. Same with New York and Florida. My hometown of Chicago has great folks, too.

Wondering how this relates to dry cleaning?

In our industry, I’ve found people to be generous of their time and energies, open, professional, funny, and down-to-earth. (And running killer-good operations!)

And....you tell it like it is.

You tell me we fight a stereotype of the “dusty old cleaner” and you tell me it’s sometimes accurate. But you want better.

So many of you I meet each day operate inviting, cleanlooking businesses with modern technology, and you hire hardworking people with great personalities.

You’re crushing old stereotypes. Winners can’t be stopped. And you’re winning!

Check out all the “winning” content this issue: from features on finishing equipment and safety to our winning team of columnists, and so much more.

• • • • •

P.S. Join me in welcoming our four new editorial Advisory Board members: Ellen Tuchman Rothmann, president, Tuchman Advisory Group in San Francisco; Beth Shader, marketing, Milt & Edie’s Dry Cleaning & Tailoring Center in Los Angeles; John-Claude Hallak, president, Hallak Cleaners in New York City; and Mike Bleier, owner, Greener Cleaner in Chicago.

They join standing members Steven Dubinski, Mike Nesbit, Herron Rowland and Fred Schwarzmann. I’m thankful to all of them for their service. ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 83, number 6. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2016. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, September 2016

Publisher

Charles Thompson 312-361-1680 cthompson@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Tim Burke 312-361-1684 tburke@ATMags.com

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production

Napiwocki

Political seasons always draw our attention sharply to the issues of the day.

Sixty-one percent of dry cleaners who responded to August’s American Drycleaner Your Views survey say that, among today’s chief political issues, the economy will most influence the ballot they cast for president this fall.

No other choices—homeland security (14%), “other” (10%), immigration (5%), gun control (4%), healthcare (4%) and the enviroment (2%) —were even close.

Nearly two-thirds of dry cleaners responding (65%) say they support the Republican ticket of Donald Trump and Mike Pence. Twelve percent favor Democrats Hillary Clinton and Tim Kaine, and 4% support Libertarians Gary Johnson and Bill Weld.

Nineteen percent aren’t sure who they will vote for. We asked what political issues, whether national or local, are having an impact on their drycleaning business:

• “The strength of the economy.”

• “Lack of jobs for middle class, our customer base.”

• “Economy, immigration, homeland security, environment are all critical.”

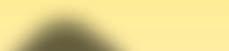

Which election do you think influences your business more? Respondents say presidential (48%), then state (25%), congressional (20%), local (4%) and “other” (3%). The polling question that received the most individual comments was this one: “Regardless of who is elected, what is the one issue that the next presidential administration must address immediately and why?” Some examples:

• “If we raise minimum wages across the board, we as retailers will in turn raise our price to the consumer. Economics will increase and we can all say we’re doing better as a nation. But our bottom line will still remain the same.”

• “Balance the budget, stop government waste, gridlock.”

• “Conscience protections. If we are not free to live by our conscience and must bend to the heavy hand of government, we are not free.”

• “Violence and gun control.”

• “Increasing pay levels for people that have had stagnant wages.”

• “Economic growth, because we’ve got to grow ourselves out of this malaise.”

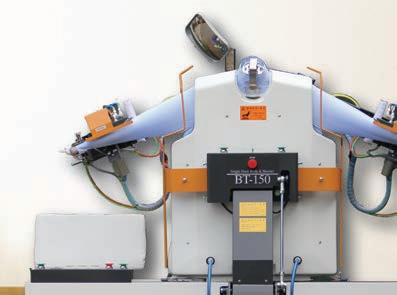

Today’s tensioning and up-air equipment now have a smaller footprint, are easier to operate, and can save on costs — and that’s not all!

By Tim Burke, Editor“We are seeing consistent growth in demand for equipment that is easy to use and produces highquality finished garments,” says Wes Nelson, vice president of sales and chief operating officer at Elk Grove Village, Ill.-based Sankosha USA, a manufacturer of tensioning equipment for the drycleaning industry.

“Demand,” he adds, “for both semi- and automatic bagging equipment continues to grow.”

Finishing equipment, like other segments of the drycleaning process, is going through a metamorphosis. The shift to casual styles in our world is partly the reason. But it has to do with the need to reduce labor costs as well.

“Tensioning equipment is now seen as the most efficient way to finish ‘relaxed style’ garments,” says Nelson.

About these relaxed styles, Tom Stites, sales manager at finishing equipment (continued)

manufacturer Unipress in Tampa, Fla., says, “A shift in styles to a more relaxed look is a major concern to the industry, as a whole. In my opinion, we are a service industry that has prospered by offering a service that can’t be duplicated in a home laundry.”

By training consumers to accept less than a true professional cleaning and finishing, this makes it easier for the garment industry to achieve these results at home, he says. “We must maintain high quality standards to protect our industry.”

Quality is always important. It’s tops on the list. But there’s always the issue of cost and that drives innovation. You may already feel that you need to upgrade your finishing equipment.

Many manufacturers hear from store operators about this topic.

“The need to upgrade or replace shirt finishing equipment,” Nelson indicates, “continues to be the dry cleaner’s No. 1 priority.”

Yuriko Tanabe, vice president for Secaucus, N.J.-

based European Finishing Equipment, which sells European-style finishing equipment under the Hi-Steam brand, says that many of her drycleaning customers “ask for less expensive, smaller, high-production shirt finishers.”

Automation is a keyword in finishing today. With it, drycleaning owners can more quickly train their operators to use more efficient machines to produce higherquality finished garments at a lower cost.

Tanabe sees this: “Cleaners will look for more automa tion, less hand-finishing, (and) smaller, simpler and highproduction finishing machines that are energy-efficient to create the cooler work environment.”

The ultimate outcome all dry cleaners seek is a highquality finished garment to satisfy customers. Dry cleaners look at finishing equipment to help them get there.

“Overcoming fear of new technology,” Tanabe says, is one of the challenges in the industry today. “Once the cleaners discover that tensioning equipment is easy to operate and produces a fine finish, they change their minds.”

“Up-air boards are for those cleaners who are very particular and serious about producing a beautiful finish on fine garments. For other cleaners, vacuum boards will produce a good finish on most garments,” she adds.

Other obvious challenges come with automating the finishing process. Employees need to be properly trained on tensioning equipment, and the finishing process itself needs to run efficiently.

“The big challenge is to educate the dry cleaner to forget the traditional ways that they have worked in the past,” insists John Harper, director of sales, pressing and finishing division of Denver, N.C.-based finishing equipment maker Leonard Automatics.

“(Dry cleaners) need to look at what can be done with automated machinery and think of it as a system to finish a garment,” he says. “They need to understand that no automated machine will do 100% of a job all the time.

“The use of tensioning machinery in conjunction with vacuum/up-air tables will increase production which in turn will give (the owner) a good return on investment,” says Harper.

Styles are more relaxed in today’s society but quality never fades.

Speed in production is also vital, which Harper points out: “Using modern systems such as tensioning machines, up-air blowing tables as well as tunnel finishers finishes all types of garments (using) faster production with semi-skilled labor.”

Your workforce is a big part of the

picture today, so training on automated equipment, or any equipment for that matter, is important to safely maintain the level of high-quality finishing the customer has come to expect from your business.

“Automation is the only way to stay competitive in this business,” says Harper. “As labor rates continue to increase, dry cleaners have to find ways to decrease labor content yet maintain or improve productivity and quality.”

He indicates that investing in automated machines can easily be justified when an operator reduces direct labor by 35-50% and then the operator can teach their employees to be loaders.

With automation becoming more of an option and a daily discussion topic among dry cleaners, can it be stated that any employee may be able to be trained to operate these machines?

Stuart Ilkowitz, president of garment pressing equipment manufacturer Trevil America, Mamaroneck, N.Y., says, “The operations of many machines are very similar, which allows for the cross-training of operators; the same person who can operate a shirt unit can also operate a pants finishing machine.”

He notes that his company recently introduced a pants finishing machine to the United States. “An operator who has never pressed pants before can be taught very quickly how to operate a pants presser machine and produce 35-40 pair of pants per hour.”

The Trevil machine operates like a tensioning pants topper. After that cycle is completed, instead of going to a legger press, the top mechanism raises up and a vacuum panel moves forward, he notes. The operator simply has to clip the pants in position to line up the creases and then push two buttons to close the vertical presses.

“Very simple, very easy to operate,” Ilkowitz says, “and does not require an experienced operator.”

“Dry cleaners today are more in tune with labor issues, which is why we see the market moving more and more in the direction of equipment that is designed to simplify the job and reduce the level of skill needed by the operator,” he adds.

American Drycleaner asked some of these industry ex perts where they see the tensioning and up-air equipment market headed in the near future.

“Our industry is becoming more progressive in areas of efficiency and (being) energy-conscious, while focusing on improving customer service,” Nelson says.

Before deciding if tensioning equipment is right for any plant, it is crucial that the owner and plant manager have a good understanding of their current production

American Drycleaner, September 2016

and quality levels, indicates Stites.

“Without this information, it will be next to impossible to evaluate the ultimate success of the investment. Converting to tensioning equipment typically increases production between 10 to 15%,” he says.

“One hidden advantage of increased production is being able to shut the boiler down earlier in the day, lowering utility costs. Shutting down the boiler 30 minutes earlier each day could save between 5-6% on gas or oil bills each month and that goes directly to the bottom line,” he adds.

What are the biggest changes going on? And how best can dry cleaners move forward to get the best bang for their buck—or double buck, as the case may be?

“What is new,” says Tanabe, “is the high-production, inexpensive shirt finisher, and self-contained pressing equipment.”

In regard to growth, she indicates that dry cleaners need to embrace new technology to automate timeconsuming tasks.

“Those include using a blouse-tensioning

machine, instead of a hand-iron or on a lay-down,” Tanabe says. “Just as cars, washing machines and dishwashers changed our lives, automation will improve the lives of dry cleaners.”

Harper sees this: “As the economy is coming back slowly, the market will be going in the direction of small, 300-500-pound-a-day package stores.”

There’s a shift in labor, Ilkowitz indicates, as machines make it easy for an operator to learn and excel at pressing.

“Essentially, we are reducing the ‘skill’ level needed for the operator and putting it into the machine,” he says. “The operator essentially just has to load and unload the machine.”

Ilkowitz advises that rather than “simply looking at tensioning equipment the way it was looked at 10-20 years ago, today’s dry cleaners need to look further to understand how the machines can help them reduce labor costs, increase quality, and maintain or improve productivity.”

Tensioning-style finishing equipment was first developed to work in conjunction with the wetcleaning process, reflects Stites.

“Garments that were wet-cleaned presented a unique set of challenges when finished on conventional-style finishing equipment. Shrinkage and heat-set wrinkles were two of the main issues that were routinely encountered.”

The basic concept of tensioning equipment hasn’t changed drastically over the years, he says. “A major emphasis has been placed on making the units more userfriendly, requiring less training while enhancing quality

and improving production.”

This has created an opportunity for tensioning equipment to grow and expand beyond wet cleaning and be used with more traditional solvents because of the advantages in production and quality, Stites says.

Simpler training for employees and the flexibility to quickly learn how to use the equipment in a costsaving way is where we find ourselves today.

At the end of the cleaning operation, after the garments have been cleaned, you want efficiency and high quality — you want to finish strong and impress your customers and keep them coming back.

The equipment opportunities in the industry keep getting better.

“We are bullish for the future,” says Nelson.

Safety is a state of mind. You look at risks and take steps to minimize. You eliminate or minimize hazards and you communicate safe steps and practices. You have regs to follow; you use warning labels; you talk about dangers; you teach safe operations, safe practices, what to do in case of emergency, and you constantly remind all to be safe daily. So....are you? Will you? Do you?

Danger never sleeps, so make sure safety doesn’t either

By Tim Burke, EditorS-A-F-E-T-Y. Safety. Dance.

Hear the music playing in your head right now? Maybe you’ll go check out the ’80s hit Safety Dance

Sing a song of safety — about keeping your plant and personnel safe every day. Sing it when you get home, when another day of safe work is behind you.

But then get right back at it tomorrow. Because the pursuit of safety is never-ending.

The biggest challenge to keeping plant and people safe every day, in the words of Grant Carson, owner of Alameda, Calif.-based Martinizing Dry Cleaners, and part of the Martinizing franchise: “Developing and maintaining a safe culture, constantly reminding people of the benefits of working safely.”

Reaffirming a commitment to safety on the job is key. Not only in the work itself but in how personnel go about their workday.

“Most accidents in drycleaning and laundry operations are not industry-specific,” notes Jon Meijer, membership director at the Laurel, Md.-based Drycleaning & Laun-

dry Institute (DLI), an organization that serves to help member professional dry cleaners in the garment care industry.

He relates that most accidents resulting in workers’ compensation claims are similar to those that impact many other types of operations. They involve slips and falls, ergonomic-related issues, heavy lifting (back) and so on.

“Rarely are violations brought about because of a chemical-related concern,” says Meijer. “Common maintenance and an awareness of routine concerns can usually be addressed quickly and easily before an accident occurs.”

Generally speaking, Meijer offers these tips you can follow as a checklist to help with your drycleaning operational safety routines and also to remind all personnel about how to be safe each day: “Keep your plant clean, free of debris, and teach common sense. Take care of the easy stuff.

“Most accidents happen because of just plain carelessness and a lack of routine maintenance in the plant. Plant and personal safety begins with the owners

and then managers of the plant,” he indicates.

If the owner or manager doesn’t care, no one else will either, points out Meijer.

“Doing the easy stuff might include making sure that spills are cleaned up, taking care of equipment leaks, sealing hazardous-waste drums, locking out or placing signs on equipment that is in maintenance or repair,” he notes.

And, he adds, “Storing chemicals in a safe place when not in use, removing common tripping hazards and just keeping the plant clean.”

Common sense is a common thread. Sometimes it’s easier said than done. When you skip safety steps, you gamble. Take each day anew. Treat the workplace with respect.

“Safety in the workplace is an everyday occurrence,” notes Griffin Quinones, owner, Vapor Sudden Service Cleaners in Monterey, Calif. “Be proactive. Walk throughout the plant and look for things that might become a problem, such as steam leaks, hoses, and hangers on the floor.”

“Check first-aid kits. Band-Aids® and burn gel have a way of disappearing. You never know when you’ll need them,” says Quinones.

He notes that OSHA visited his cleaners “about four years ago (and) one of the main things they were concerned about was lockout/tagout (LOTO). They can be

purchased at Home Depot. Make sure they are kept in a safe place and used when necessary, and dated when used.”

The U.S. Department of Labor’s Occupational Safety & Health Administration (OSHA) website (www.osha. gov) provides this explanation of lockout/tagout: The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout), Title 29 Code of Federal Regulations

(CFR) Part 1910.147, addresses the practices and procedures necessary to disable machinery or equipment, thereby preventing the release of hazardous energy while employees perform servicing and maintenance activities.

Quinones says there are “New OSHA HCS rules regarding proper labeling of chemical containers. This not only includes spotting bottles, but everything used inside the workplace. An example would be Windex®. Used at home, it’s OK, but if you have it at work, (continued)

Safety is more than a regulation or a warning label. It’s a culture of responsibility that ultimately falls to each individual.

you need a Safety Data Sheet.”

Safety in the workplace is a high priority. Quinones says he installed cameras in the counter and production areas: “So that we can monitor what is going on. Our concern,” he notes, “is for the safety of the employees on the counter in the event of theft, and negligence in the work area.”

If an injury should occur and you’re not there, you will have it on camera, he adds. “We have outside cameras as well. And our cameras are also remote, meaning we can watch what’s going on from a laptop at home or anywhere.”

Another tip he recommends is for a dry cleaner to have a safety inspection.

“Have a good insurance agent that will help you

of OSHA’s written hazard communication program.

“Training is most important and OSHA dictates what must be covered in training,” notes Henry Parker.

Plant maintenance and housekeeping are also part of best management practices in the plant.

“We suggest that the owner/manager look over the business with the eye of a janitor and make sure there are no real and present dangers for the employee,” says Parker.

He wants operators to ask these questions of their business:

• Is the machinery working correctly?

• Are there cords on the floor that could cause a tripand-fall hazard?

• Is there reason to have employees uncomfortable in the workplace?

“Those kind of things affect the employee morale and work habits,” he notes.

“Taking employee suggestions about safety situations is very important because they work in the business end six to eight hours a day and they know what needs fixing.”

Training is one of the most vital strategies for keeping employees safe in the plant, Meijer notes.

regarding your workplace. Request to have someone from the insurance company come to your cleaners and do a safety inspection,” says Quinones.

“Lastly,” he insists, “document, document, document every safety meeting with your drivers and inside employees.”

Danger doesn’t take a day off, so safety can’t either.

“Be proactive, adapt to a safety-driven culture by being a safety leader yourself,” says Carson.

“Best tip, set up a suggestion type of box for employees to leave you notes whenever they see and correct a potentially hazardous situation. At the end of the quarter (or month), open and read them. Award a bonus to the employee who was the most helpful in securing a safe environment.”

Riverside, Calif.-based Safety & Environmental Compliance Consultants Inc. (S&ECC) (www.complyhere. com) owners Henry W D Parker and Jan Parker work with dry cleaners and launderers to train their employees in the required OSHA programs.

The Parkers do hazard assessment and implementation

American Drycleaner, September 2016

“Some of the most common violations from OSHA in a drycleaning plant,” he indicates, “are lack of documented training; lack of having ‘on-site’ a hazard communication plan; lack of properly labeling of chemicals in the plant based on current OSHA requirements; and missing or no Safety Data Sheets for chemicals used in the plant.”

OSHA isn’t the only standard to be concerned about when it comes to safety. There are also safety practices regarding potential fire hazard.

Nancy Pearce is senior fire protection engineer at the National Fire Protection Association (NFPA), a private, non-profit organization that helps save lives and reduce loss through use of information, knowledge, and passion.

“Part of our mission involves the development of approximately 300 codes and standards related to fire and other hazards,” says Pearce. She states that this process also enables anyone in the industry or public to submit input and comments when the document is revised, which is generally every three to five years.

“One of the standards we oversee is NFPA 32, Standard for Drycleaning Facilities,” says Pearce.

What exactly is NFPA 32, you ask?

“In addition to work practices, NFPA 32 primarily addresses safety through construction features and through the installation and use of electrical equipment associated with particular solvent classes,”

Every day that you and your people go home safe is a victory.

notes Pearce.

“There are numerous provisions in the standard dependent on variables such as the type of machines used and the characteristics of the solvents.

“The latest edition of NFPA 32-2016 has been completely revised and establishes less stringent requirements for facilities that utilize less flammable solvents and have equipment that has built-in fire protection features,” says Pearce.

“This new edition also establishes conditions and limitations on ‘conversions’ of equipment when there is a change of solvent from that originally used in a machine.”

Pearce notes that you can view the current edition of NFPA 32 free of charge at www.nfpa.org/32. Visitors to the website will have to set up a password-protected account using their e-mail address.

When you skip safety steps, you gamble. Take each day anew. Treat the workplace with respect.

Jan Barlow, owner, Jan’s Professional Dry Cleaners in Clio, Mich., says, “There have been substantial improvements in the occupancy code for dry cleaners through the rewrite of NFPA 32. We are currently the most up to date on the solvents, safety and technology ever!”

Safety is more than a regulation or a warning label. It’s a culture of responsibility that ultimately falls to each individual paying attention to their workplace environment, and looking out for the health and safety of their co-workers and themselves.

“Safety must be a priority. It is an iterative process, not just a task to check off your roster,” implores Charles Anton, owner, Anton’s Cleaners in Tewksbury, Mass.

He makes it clear that, at his business, “we have always been proactive in making safety a priority. We first understand the areas of risk by looking at industry data, general business data, as well as our own data and then come up with a strategy,” says Anton.

“We often meet with insurance underwriters, not brokers, and also lawyers who specialize in OSHA-related issues, and other professionals who can objectively look at how we are managing risks,” he continues.

Anton notes that “if safety and reducing risk become

part of your normal business operations, and you develop an ongoing strategy to properly deal with these risks, then the professional consultants will find less and less to comment on and the process becomes a lot easier.”

All seem to agree safety must be part of the culture, woven into the very fabric of the operation. Safety is a mindset, reinforced with training and good habits observed daily.

Meijer uses one word to describe the biggest safety challenge today: “Repetition.”

“Training of employees is an ongoing process. Too many cleaners train once and forget about the constant reminders to employees to keep them sharp and from forgetting to do things that will keep them safe.”

“Training employees can’t be just a compliance issue, done once to satisfy a specific rule or regulation,” reminds Meijer.

Carson says this: “We called in Cal OSHA to help us put together a safety plan. Safety is not something you can forget about. In our plant, we have monthly safety meetings, and I am always looking for ways to keep safety at the forefront of employees’ minds.”

Meijer adds, “Not complying with current rules and regulations is simply like rolling the dice. Sooner or later, the dice with come up snake eyes. It’s just a matter of time.”

“A priority for us is cleanliness,” Quinones says. “We pick up and clean up every day. During the weekend, we mop the plant from stem to stern.”

He adds, “It’s not easy to convey to those hard-working people we all have how important it is to have good housekeeping manners. This is our home away from home. I know personally it is hard for me to work in a place that is dirty.”

“Keeping it cool in the summertime,” says Barlow about safety in the plant. “Cleaning the dust and lint off everything annually. We are a very linty business! Keeping all the machines in good operating order.”

Anton sums up with this: “Improvements can always be made regardless of your company experience. The key is to make it part of the fabric of your culture.”

You can also remind others in the business how important it is to maintain their own safety every day. Don’t take it for granted, don’t skip training, and don’t be lax — lives are in the balance!

Carson’s final refrain: “It is a daily effort.”

Every day that you and your people go home safe is a victory. But tomorrow is another day. The sun will rise on a whole new world full of challenges. Live it safely. Always be safe!

In the July issue, the focus of Dreamcatcher was on the structure CEOs used for training their managers to manage themselves and their teams so owners have their own time to “dream the dream.”

Now in this installment, the focus will be on the reality of implementation of the management system, whichever system you choose to adopt.

One or two mission/vision meetings is just the beginning of the process of getting your managers and associates aligned with your vision for the company. More frequently than not, this topic is dropped after the statement is adopted and so it has very little impact on the business.

To get buy-in and alignment throughout the organization, your vision must be alive on a daily basis.

Your vision needs to be incorporated in the day-to-day operations of the company. It also needs to be clear and concise enough that it can act as a mantra for the running of the business.

Nike’s mission statement, “To bring inspiration and innovation to every athlete in the world,” accomplishes this alignment goal by guiding the company and its associates in their daily activities.

The slogan “Just do it!” brings that mission alive to athletes and would-be athletes around the world, both through the words and through their logo swoosh, which is one of the most recognized logos on the planet.

Pinterest also inspires action with the mission to “Help people discover things they love and inspire them to go do those things in real life.”

Airbnb’s mission is to enable people to “Belong anywhere.”

The alignment of purpose indicated by these statements leads to focused goals to get the job accomplished.

Much has been written about the value of goal-setting and what can be accomplished by the focus

(continued)

that specific goals provide.

Muhammad Ali once said: “What keeps me going is goals.”

Stephen R. Covey, author and speaker, advised people to: “Begin with the end in mind.”

Julius Erving believes that: “Goals determine what you’re going to be.”

If the goal is aligned with the mission, the action steps can be designed to meet the goals and accomplish the mission. There are many resources available to help in designing the specific goal set.

Since most businesses face similar challenges dealing with people (internally and externally), resource allocation, time constraints, competition, operations, logistics, financial control, sales and profit growth, leadership development, site selection, etc., there is a great deal of data that can be accessed.

When reviewing the data, be discerning to distinguish between raw data and usable information. Look at benchmarks, best practices of successful operations of all kinds (both inside and outside the industry) rather than benchmarks or averages of your industry alone.

Many new successful systems and technologies have been developed in various industries that present better, more effective and efficient ways of accomplishing things that have tremendous application in the drycleaning industry.

A good example is customer acquisition through various apps that is just recently being applied to the textile care industry. Avoid assuming it won’t work and instead take the easy solution of testing many approaches to determine the most effective applications for your business.

If you are creative, you may invent a totally new system that will let you leapfrog to a previously unknown level of performance.

An excellent source of ongoing information about current and potential success is provided by industry roundtables, association education programs, and peer management groups (often referred to in this industry as “cost groups”). These groups can align the reality with theory.

The candor that is shared between a group of noncompeting companies can provide a great deal of infor-

mation and detail about specific successes and how they were achieved. The same applies to failed attempts that did not reach the desired result.

Group sharing can prevent wasted time and resourcetesting every idea because someone else may have done it first and that person is willing and able to share the pros and cons of a specific approach to a common problem or goal.

These groups exist for a spectrum of team members from company owners to managers and front-line production and sales staff. They can help align the goals of owners and their teams and provide a shared business language to aid in communicating ideas.

If you haven’t had an encounter with peer groups, sample them to experience the benefits firsthand. They have been the source of business training and internship exchanges as well as lifelong business camaraderie and personal friendships.

Peer groups counterbalance the isolation felt by most owners and help build management and leadership skills among participants at all levels.

Exposure to business practices (again, both inside and outside the industry) is invaluable to moving the knowledge base and appreciation for possibilities forward.

Once you believe what is possible, set a stretch goal to move your performance from the current level to that goal and then go for it. As Wayne Gretzky says, “You miss 100% of the shots you don’t take.”

If you get what you measure, it is necessary to measure what you get.

Making goals measurable is key to the process and to determining what progress (or lack of) is being made. If your goal is to increase sales, a rise of one cent actually might be viewed as a success.

Make it clear how much you want to

If you are creative, you may invent a totally new system that will let you leapfrog to a previously unknown level of performance.

raise sales. Is it by 5% or 50%? Remember, numbers are measurable, feelings are not.

There must also be a timeline specified. Is a 5% increase in five years a success when inflation is 2-3% per year, or is that really an abysmal failure? Both long- and short-term goals need specificity to determine success.

The long-term goals will direct the shortterm goals which direct the specific action plans and the timeframes within which to accomplish them.

Each goal needs a specific plan for achievement that is clear, concise and easy to follow. There should be no ambiguity about what is to be done to accomplish each step along the path to goal achievement.

Most goals require a team to complete them. It should be clear who has the authority, responsibility and accountability for each of the steps to be completed, from the most mundane logistical aspect to the more complex overall management of the project.

For example, if the goal is a three-day turnaround on household work, the household station and boiler must be scheduled to operate with that goal in mind, as must the delivery schedule.

Usually, the same person does not schedule or manage all of the aspects of a project, so there must be teamwork among the line staff as well as among the management of the various departments. They are all parts of the same puzzle, and customers don’t excuse weekends from their expectation calculations.

It is essential that the sales team understands all of the underlying moving parts of making the sales promise a reality.

Because most plans for goal achievement have many components, project management software is a valuable tool for managing all of the underlying processes needed to move all aspects of the project forward on a disciplined and orchestrated pathway.

It helps the project manager and each of the participants plan and coordinate their efforts and see if all components are on track. There are many free and paid online systems to choose from, including from Microsoft and Google that will seem familiar to many.

Accountability tracking is key to goal achievement. The project manager must have the authority to hold everyone accountable for their required contribution.

When each step in the plan is spelled out with a specific date and responsibility, it becomes easy to ascertain if the action has been completed. It is also easy to measure the result.

Is the desired result being achieved by the implementation of the plan? If so, is the goal level appropriate or is the goal lower than it could be?

If the goal is not being achieved, where did the plan go wrong? Was the goal calculation inaccurate or was the plan inadequate?

What must be changed to reach the desired result? What did we learn from the attempts? How can we use those learnings to redirect our success?

This assessment phase is crucial because business plans are by nature dynamic and must be adjusted to meet company and market realities as well as outside influences.

Flexibility and adaptation to unforeseen circumstances are essential to entrepreneurial success.

With informed, realistic assessment of the planned efforts and results, future actions can be adjusted for alignment with higher level goals and more efficient execution of plans to achieve them.

This constant assessment, refinement and reassessment cycle will continue to develop the management skills of your team.

A goal-based management system will simplify your business life by keeping your team focused on what matters to the company.

Through clarity of thought and planning, showing them the path for optimum time and resource management and clarity of communication, this will result in your dream: a self-managed team. ADC

Diana Vollmer is a managing director for Methods for Manage ment, which has served dry cleaners and launderers with af fordable management expertise and improved profitability since 1953. For assistance with implementing your management systems, e-mail dvollmer@mfmi.com or call 415-577-6544.

It is essential that the sales team understands all of the underlying moving parts of making the sales promise a reality.

There is a technical side to fabricare.

My experience has been that many operators only come to recognize the validity of that statement shortly before the equipment auction.

I want cleaners to not only survive, but prosper. To do so, you must provide your customer with a perception of value. That perception of value is shattered each time the customer takes the stain you left behind and, feeling that there is nothing to lose, washes the garment after taking it home….and the stain comes out!

This month, the challenge is to add at least one more chemical tool to your arsenal: A neutral synthetic detergent, an enzyme digester, or a true wetcleaning detergent.

It is not hard to take that first step. Just ask a sales representative to recommend a neutral synthetic detergent for wet-side stain removal. There are many available. All of them are good, with slight variations in formulation.

A neutral synthetic detergent is formulated to precondition the stained area when doing supplemental stain removal at the board. It is a combination of surfactants (to solubilize the stain) and an effective penetrant to go deep into the stain. By also being pH-neutral, there is little risk of a color change caused by a sensitive dye.

When you flush the stain over the vacuum nose of the spotting board, you are taking several actions that are beneficial to stain removal.

Wetting the area will break down the surface tension of the fabric and allow for quicker penetration of all the chemical tools you use thereafter.

Using steam will warm the area, and we know that heat will accelerate chemical action.

The surfactant(s) in the neutral synthetic detergent will immediately begin to solubilize the stain and the penetrant will go deep into the stain to carry any specialized spotting agents through the stain.

From my experience, most of the “color loss” that is returned to the customer is caused by a sensitive dye reacting to the pH of a specific formulation of stain remover. Also, the addition of neutral synthetic detergent will remove

most “fresh” stains without the risk of a pH color change.

Try this: flush the area with steam and apply a few drops of neutral synthetic detergent. Set the garment aside while you deal with other garments that need spotting. Let the chemical do the job, while you do other things.

Come back to the garment(s) with neutral synthetic detergent after spotting all the others. Apply a little mechanical action with your bone/scraper or by tamping with your brush, then flush the area with steam over the vacuum nose.

In about half the cases, that is all you will need to do to remove the stain. That is an example of productivity.

An enzyme digester, for use in a bath or at the spotting board, can be found in both powder and liquid form. It is highly effective in removing protein stains, especially those that have become set through neglect.

If you choose to use the powder form, you will need to dilute the white powder in some warm water and then saturate the stain with the enzyme liquid.

Wet a small towel with steam, then lay the towel on the enzyme-soaked area. Keep the digester warm and moist, and it will do the job of breaking down the stain. You will be amazed at the results you will get.

I have noticed that blood stains grow progressively darker over time. Blood will go from red to

reddish-brown to brown, and finally appear to be black.

Using an enzyme digester in a bath is both simple and effective for large areas of blood.

Take a styrofoam-lined drink cooler and fill it with warm water. Dissolve the digester in the water and submerge the garment. Move the garment around to get it totally satu rated. Place the lid on the cooler to keep in the heat.

You can even leave the garment overnight. Retrieve the garment and inspect for any remaining stains. If stains re main, warm the water and submerge the garment. When all traces of the stains are gone, simply wash as usual.

The last of the chemical tools to consider is the group of wetcleaning detergent, conditioner, and sizing/texturizers.

Let’s keep this simple and focus on fragile and fine wash ables. A home-type top-loader will be the example.

Use cold tap water and fill the basket to its highest level. The high water level will cushion the agitation and reduce the mechanical action. Use the gentlest cycle (hand wash). Use a wetcleaning formulated detergent (a detergent that

has a pH at or below 7).

Alkali is one of four things that will contribute to shrink age and dye migration, therefore your “shirt detergent” is not suitable for this purpose.

In the case of fragile trim, you can run the garment in a pillowcase or cover the beaded bodice with a pillowcase, using a heavy cotton cord to hold in place at the waist.

Take the time to work with these chemical(s). Go to a second-hand store and purchase a few garments that have stains. Use these garments for practice by adding stains of your own.

You will find that with a minimum of practice, productiv ity will increase, a much higher percentage of stains will be removed, and garment risk will be reduced. ADC

Martin L. Young Jr. has been an industry consultant and train er for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates to this day. Phone: 704-786-3011, e-mail: mayoung@vnet.net.

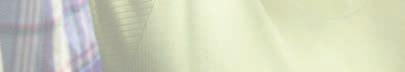

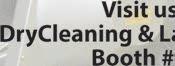

In this month’s Closer Look, which profiles manufacturers, distributors or other businesses that serve the drycleaning industry, American Drycleaner shines its spotlight on Firbimatic (www.firbimaticusa. com), Woodstock, Ill., a manufacturer of drycleaning machines.

Q: How long has your business been serving the drycleaning industry?

A: Our factory has been manufacturing machines since 1971. Our branch has been around since 1994.

Q: Tell our readers about your company’s current product and/or service offerings.

A: Firbimatic manufactures drycleaning machines that

are for use with alternative solvents and perc. They are available in a wide range of sizes, from 22 pounds to 176 pounds. There are various configurations from petite to tank versions, including wide body chassis with two or three tanks, with or without distillation, and filters or no filters.

Q: Where are your company’s products made, and how are they sold/distributed to end-users?

A: Firbimatic machines are made in Bologna, Italy, and are sold throughout the world and exported to more than 130 countries. Firbimatic SPA works through distributors and factory-owned importers around the world. In the USA, we have a dealer network for sales and service support.

Q: What is the biggest news at your business right now?

A: We have had many newsworthy items. Dave Aklinski has come on board as a sales representative covering all western states. We have had tremendous leaps in technology with our new IConnect, which allows remote access to the machines via the Internet. This system can give you real-time readouts of machine operation, programs, and temps, in addition to fault storage for better fault diagnosis.

Q: Why is your company successful?

A: Firbimatic is successful due to the high quality of the machines and the advanced features available on the different models. Firbimatic is always looking ahead to advance and test new designs to work with the newest alternative solvents.

Q: What makes your business different from other businesses like it?

A: I feel our loyalty to our distributors sets us apart from other importers.

Q: Which is more important to your organization— mission, core values or vision—and why?

A: In Italy, it is vision: The ability to see future needs and changes in the industry and produce machines to ac commodate. In the USA, mission. Due to ever-increasing complexity of the drycleaning machines, it is more im portant than ever to support and train our distributors and customers.

Q: How does your company keep up with the industry to ensure it is offering the products and/or services that potential customers want or need?

A: Firbimatic employs a team of engineers that design and test drycleaning machines and are always looking to improve cleaning performance, drying performance, or overall machine quality.

Q: What is one thing that American Drycleaner readers would be surprised to learn about your company?

A: In addition to our standard drycleaning machines, we also manufacture large industrial machines and vapor

degreasing machines. Due to limited manufacturing in the USA, most of these models are sold overseas, though we do have two 350-pound tandem hydrocarbon models, which are the first-ever in the world, in San Antonio, Texas, which are used to clean sheepskins. Firbimatic also just produced our 100th 350-pound tandem industrial drycleaning machine.

Q: How would you characterize the current state of the drycleaning industry?

A: The industry is in a state of rebuild after the recession. As is usually the case, we see areas and neighborhoods grow and change, and old cleaners go and new neighbor hoods develop with new business opportunities. I feel this is the strongest market in 10 years for drycleaning machines.

Q: What do you think will change about the drycleaning industry in the next five years?

A: With the development of new cleaning solvents, I see a lot of trial and error to find the best cleaning available. And a great reduction of perc machines in operation.

Q: If there is one thing you could change about the dry cleaning industry, what would it be?

A: I would have to say consistency. I travel the country and am able to visit a wide array of cleaners, and the clean ing and spotting from one to the next can vary greatly. ADC

By Tim Burke, Editor

By Tim Burke, Editor

The characteristics and appearance of the burnt residue of a fiber will tell you what it’s made of.

The smell can tell you as well.

This from The Complete Spotting Guide And More, an informational map so to speak, to all things “garments,” written by Norman Oehlke and published by American Drycleaner:

“Take a garment that has a fiberidentification label and pull out a yarn from a seam allowance. Take an end of this yarn and place it over a flame. Blow out the flame, and let it cool a second. While this is happening, try to inhale some of the fumes and smoke that’s given off. What does it smell like?

“Now, observe the burnt end—is the ash larger than the unburned yarn? Does the bead or ember crush between your fingers, or is it hard?

“With some practice, these two procedures will give you a general idea of the type of fiber you’ve tested.”

The Spotting Guide explains that fabrics are often treated with various textile finishes at the mill, so the same kinds of fabric from different garments might have different odors

when burnt. However, the type of ember left will always be the same.

The burn test will never lie. Did you inhale? Was it convincing? Now check the embers.

Silk and wool are protein fibers and burn in short jumps. They will smell like burning hair, and their ember is a crushable black bead.

Cellulose fibers such as cotton, linen, ramie and rayon have yellow flames and smell of burning wood or paper. They all have the same gray, fluffy ash or, in the case of rayon, no ash. Rayon also burns quickly.

Synthetics such as nylon, polyester and spandex (and others) just melt over flame and have a smell of burning wax or a sweet or musty smell, and can be acrid like vinegar as well. Mostly, they form a hard, uncrushable bead; spandex

becomes a soft, sticky ember.

Glass and metallic do not burn, although metallic does glow. They give off no odor. The ember of glass will glow, and metallic retains its

shape. These are minerals. No ember, no worry, it’s metal!

The smell can often tell the tale but when in doubt, observe the ember.

Can you identify that fiber now? Did you burn it? Smell it? Observe the ash?

Remember, burnt protein fibers smell like hair; plant fibers, wood; synthetics, sweet or waxy; and minerals don’t have an odor. When in doubt, always check the ash.

So, to ID a fiber, go burn threads and smell what you fired up; crush the ember and look closely. Now you’re the fiber whisperer! ADC

To purchase your copy of The Complete Spotting Guide and More, visit the website at: https://americandrycleaner.com/ complete-spotting-guide-more.

How much is your drycleaning business worth?

Many of you debate this question endlessly. After all, you’ve put your heart and soul into your enterprise.

Yes, you’ve drawn a good living, but there must be something extra for your entrepreneurial skills. In this hard scrabble economy, it is a feat just to keep a business going. There is extra, but it may not be as much as you think.

First of all, these aren’t the grand old days, where you could, if lucky, get 100% of the sales dollar.

Thirty years ago, if you did a million dollars in volume for three steady years, you might have gotten a million or $800,000 for your business. Those days are gone.

For one thing, this is a tougher economy to do business in. Casualwear has sharply reduced demand.

Secondly, the U.S. is no longer the economic powerhouse it was in 1975.

Other economies—China, Germa ny, the EU—have gained ascendancy. One obvious cause is that the country has lost a portion of its manufacturing base.

With that in mind, I reviewed a dry cleaner who does $240,000 in revenue. The business has been going for 18 years. The operation incurs $130,000 in expenses. That leaves $110,000.

The husband and wife, who both work 50- to 55-hour weeks, take that money out as income. In addition, the company employs three part-time workers. Equipment is valued at $50,000 to $100,000. The business is situated in a higher-end neighborhood and has a loyal customer base.

How much is the business worth?

My formula is: worth equals value of assets plus value of goodwill as a going business.

The value of the assets is $50,000 to $100,000. The variation is understandable since the equipment is old and depreciated. On the other hand, the equipment is still usable.

Without seeing the equipment, let’s go on the lowish side of the range at $65,000. If we could see the equipment, we would examine each asset, but since we can’t be there, let’s simply make a lowball estimation. Moreover, having a small drycleaning shop using $65,000 assets is appropriate.

What’s our goodwill?

The business has been running for 18 years. The question is: What profit is achievable? That is the best determination of goodwill. The company revenues are $240,000, while expenses are $130,000, so that leaves $110,000 profit.

On the other hand, the owners pull out all the $110,000 as their wages, so arguably, that $110,000 is an expense. That means there’s no profit, and no goodwill. Now we’re between zero to $110,000 goodwill.

What we have to do is separate wages, which is an expense, from profit, which is the remaining sum after ex penses. The owners draw $110,000. What portion is wages for their effort?

Considering that two people work 50-hour workweeks, taking home $110,000 is not unreasonable wages. On the other hand, the drycleaning trade does not pay high wages.

Let’s say a new owner bought the business, and he worked a 50-hour workweek. Assume he drew a $40,000 salary. He would have to hire someone to take the seller’s wife’s place. Say he could pay this person $40,000.

That’s $80,000 expenses, against a profit of $110,000. Profit is now $30,000 ($110,000 - $80,000 = $30,000).

So, from this analysis, we will assume that the business is now earning at the rate of $30,000 profit a year. That’s 12.5%, which is more or less in order with existing small drycleaner figures.

The next question: Is this business sustainable?

If it has made $110,000 net for three of the last five years, that’s a good indication. If sales and net profit have been steadily increasing during the last five years, that’s an even better sign that the $30,000 figure is sustainable.

The principle of goodwill is that if the buyer can con tinue to make the same profit, then the price computation is a multiple of profit, most commonly three (3). So 3 x $30,000 = $90,000.

That’s the goodwill factor, for it is a reasonable assump tion that the buyers will reap this profit for the next three years. But if marginally situated, the multiple might be two.

If there is a strong chance that many of the machines will have to be upgraded soon, then that reduces the multiple. If

the machinery is less efficient, and there is more efficient equipment already on the market, then that puts pressure to reduce the multiple to two or less.

On the other hand, if the neighborhood is becoming more upscale, where a higher percentage of residents wear suits to work, then that might shift the multiple upwards to four.

If there is reason to believe the area competition will be closing up soon, then that might increase the multiple. If the company has embarked on a new strategy to bring in more business, then that contributes to a higher multiple.

But if none of this is happening, and yet the business is a going concern, then three (3) is a proper multiple.

Putting this all together, we have $65,000 asset value and $90,000 goodwill, for a total value of $155,000 ($65,000 + $90,000).

In my opinion, sight unseen, this business is worth $155,000. Of course, if the sellers have taken on debt, that amount must be deducted from the value.

What this amount means is that the buyers can theoreti cally borrow $155,000 to pay the sellers, take over the busi ness, and make a living, even though they will be incurring a $7,750 interest expense ($155,000 x 5% = $7,750). Here’s how the new income statement will look:

Sales $240,000

Base expenses $130,000

Added employee $40,000 Owner draw $40,000 Interest $7,750 Total expenses $217,750 Profit $22,250

Hopefully, the new owners will invest this profit in more efficient equipment or in marketing efforts to further in crease business. But be clear: this is a turnkey venture.

The buyers can go in on day one and draw a salary.

They could take $20,000 profit a year and in seven and a half years, wipe out debt while still drawing a salary.

The question remains: Could the owners sell the business for its rightful value, $155,000?

It could be worth $155,000, but if no one would pay $155,000 for the business, then they don’t get their price. Selling an enterprise depends on using good brokers, and convincing the buyer of the concern’s value.

Every business sale negotiation is a matter of compro mise, negotiation and timing. If the sellers can’t sell their business at their asking price, they can wait and maybe consummate the sale next year.

Now you can determine your own business’s value. ADC

Howard Scott is a longtime industry writer and dryclean ing consultant. He welcomes questions and comments, and can be reached by writing Howard Scott, Dancing Hill, Pembroke, Mass. 02359, by calling 781-293-9027, or via e-mail at dancinghill@gmail.com.

also gives exhibitors longer exposure with a listing on the show’s website.

Clean Show 2017 exhibit sales are now open for the world’s premier exposition for the laundry, drycleaning and textile care industry that the Las Vegas Convention Center will host June 5-8, 2017.

“I think it is going to be a very good show with some new and exciting ideas and innovations being shown,” says John Riddle, president of Riddle & Associates, the show’s management company, speaking exclusively to American Drycleaner recently.

“I say that,” Riddle continues, “because of comments I am hearing from both our domestic and international exhibitors as to what they plan to bring.”

Companies interested in exhibiting are encouraged to sign up early for prime locations on the show floor because booth assignments are made on a first-come, first-served basis, his company notes.

A floor plan can be viewed on the show’s website: http://cleanshow.com/floor-plan.html. Contracting early

In addition, only exhibiting companies have the longterm marketing opportunity to advertise on the show’s website and in the Show Directory, he advises.

“As you can imagine, the exhibitor has to have a good idea as to what equipment they plan to bring, which has a huge bearing on how much booth space they need,” he indicates.

“While I can’t tell you at this point who is bringing new and improved equipment or services,” says Riddle, “we are hearing a lot of chatter about new things.”

Companies can expose their equipment, products and services to thousands of attendees from around the world. The Clean Show is unique in that prospective buyers can see actual working equipment, giving them the best opportunity to compare products, according to Riddle.

Clean 2015 in Atlanta featured over 430 exhibiting companies and more than 30 hours of classroom education. He indicates that it drew 11,264 people representing all 50 U.S. states and 88 foreign countries.

“The Clean Show is where the industry comes together and Las Vegas is always a popular destination,”

Early exhibitor chatter indicates lots of new ideas, innovations coming, says show manager Riddle(Image licensed by Ingram Publishing)

says Riddle.

What else does Las Vegas offer besides gaming, Ameri can Drycleaner asks Riddle?

“The one thing that Las Vegas has to offer is great hotel rates and hotels that have a lot of energy,” he says. “I think it is common knowledge that Las Vegas is a ‘nighttime’ town. It comes alive like nothing else at night.

“The number of lights in the city is in the hundreds of thousands, and probably exceeds a million if someone were to count them all.”

The food is world-class and the number of world-class chefs is mind-boggling, he notes.

“It appears to me that the old-style Vegas entertainment is slowly coming back. By that, I mean you have topnotch entertainers with their own showrooms today, like it used to be with Elvis and Sinatra,” Riddle points out.

“You can always spend time after the close of the show at some of the most unbelievable pools in the world. Las Vegas has brought pool design and construction to a new level. These pools are beyond amazing. After the Clean Show, they’re a great place to go and relax before dinner,” he suggests.

“Of course, during the day, you have many options,” Riddle says. “You can fly over the Grand Canyon; go to the Hoover Dam; visit Red Rock Canyon; or go to Mount Charleston and possibly play in the snow.

Yep, I did say snow. Check out the elevation change from Las Vegas to Mt. Charleston. You will be amazed.”

And last but not least, you can always go to downtown Las Vegas and enjoy the Fremont Street Experience. Las Vegas does offer lots to do, he says.

Prospective attendees will begin seeing Clean 2017 reg istration and hotel information this month. The registration fee includes entrance to the exhibit hall for the entire show and all educational sessions.

The biennial Clean Show—formally the World Edu cational Congress for Laundering and Drycleaning—is sponsored by five national industry associations: Associa tion for Linen Management, Coin Laundry Association, Drycleaning & Laundry Institute, Textile Care Allied Trades Association and Textile Rental Services Associa tion of America.

To obtain an Exhibitor Prospectus or get more in formation about Clean 2017, visit its website at www. cleanshow.com, or contact show management: Riddle & Associates, 2751 Buford Hwy., Ste. 100, Atlanta, GA 30324 USA; phone 404-876-1988; e-mail: info@ cleanshow.com.

“The best thing anyone can do in the day is spend that time on the trade show floor learning better ways to grow your business and then have fun in the evening,” Riddle concludes.

Drycleaner,

Bryan Steam LLC, originators of the “Flexible Water Tube” boiler design, reports it is celebrating its 100th year in business during 2016.

At press time, the company was planning an open house for its employees, North American representa tives, vendors, and local and state dignitaries.

Bryan Steam’s manufacturing facility in Peru, Ind., was to host the “family picnic” event to include food, tours, and more.

“The team here is proud to continue the tradition of Bryan Steam for the next 100 years,” says Bryan O’Toole, president of Bryan Steam.

Founded in 1916 as the Bryan Harvester Co. by George Bryan, the company began by producing cars and steam-powered tractors.

In 1922, the company stopped such production after the rise of the gasoline engine. Bryan Harvester then refined and marketed the bent water tube boiler that had powered the steam-powered vehicles and became Bryan Steam LLC, the company says.

Today, Bryan Steam offers a broad range of boil ers to meet custom ers’ needs, including gas-, oil- and gas/oilfired boilers, as well as electric, condensing, low-NOx and knock down boilers, the com pany adds.

The “Flexible Water Tube” design provides fast, natural internal circulation for maxi mum heat transfer and operating efficiency.

Bryan Steam also manufactures indirect water heaters, pool heaters, feed systems and related equipment and accessories.

Dr. Manfred Wentz, vice president of research & devel opment and environmental affairs at R.R. Street & Co. Inc. from 1988 to 1998, died June 12 at age 77 following a battle with metastatic cancer, the company reports.

After leaving Street’s, Wentz re turned to academia in North Caro lina. He later became director of Hohenstein Institutes (USA) and head of the Oeko-Tex certification body, USA, from 1999 until his re tirement in 2009.

Street’s says Wentz had a signifi cant impact on the company as well as the entire professional textile in dustry.

He was director of research at the International Fabri care Institute (now known as the Drycleaning & Laundry Institute) in Silver Spring, Md., from 1972 to 1974. Also, he was a professor at the University of Wisconsin-Madison from 1974 to 1985, and at North Carolina State University from 1985 to 1988. Other posts included Burlington Indus tries professor of textile science and Department Chair of Clothing & Textiles at the University of North Carolina at Greensboro from 1985 to 1988, Street’s indicates.

Wentz held many national and international leadership positions in the textile industry in addition to many profes sional associations, Street’s notes. In his later years, he fo cused on textile ecology and environmental responsibility/ sustainability.

He was widely published, with more than 100 articles appearing in both domestic and international trade journals, including American Drycleaner

He was a 19-year cancer survivor and in 2006 also sur vived Guillain-Barre Syndrome.

He is survived by his wife of 53 years, Gisela Wentz; daughter, Sabina Akins; son, Chris Wentz; three grandchil dren; and one great-granddaughter.

A private ceremony was held for family. Memorials in Wentz’s name may be made to the Cancer Research Insti

The Tuchman Advisory Group (T.A.G.), formerly known as Tuchman Training Systems, reported having a successful meeting hosted by Dave Coyle of In The Bag Cleaners, Wichita, Kan., in June.

Ellen Tuchman Rothmann, president of T.A.G., announced at the meeting the new name of the group. “We will continue our outstanding work and provide leadership in our industry,” she says.

“T.A.G. membership constitutes an industry-leading group,” says Rothmann. “We will continue to learn from each other as we work together to develop new systems and approaches that will strengthen our individual companies.”

During the June meeting, T.A.G. members toured In The Bag’s central production facility and two retail locations.

Frank Dubasik, director of U.S. operations for Metalprogetti, was on hand to answer any questions about his company’s recently installed equipment. Following the tour, T.A.G. members critiqued In The Bag operations.

Members of the Tuchman Advisory Group pose for a group photo during their June meeting at In The Bag Cleaners in Wichita, Kan.: (front row, kneeling, from left) Paul Billoni (Colvin Cleaners), Ellen Rothmann (Tuchman Advisory Group), Brett Allen (Medlin-Davis, South); (middle row, from left): Chris Billoni (Colvin Cleaners), Cyndee Billoni (Colvin Cleaners), Aram Coyle (In The Bag Cleaners), Anne Nash (Highland Cleaners); (back row, from left) Frank Dubasik (Metalprogetti), Dave Coyle (In The Bag Cleaners), Bruce Squires (Martinizing Green Earth Cleaners), Chuck Haddox (MW Cleaners), Rick Kirksey (Munro Cleaners), Mike Nesbit (MW Cleaners), Todd Watkins (Martinizing), and Gary Futterman (Flair Cleaners). (Photo: Tuchman Advisory Group) (continued)

Guest speakers at the meeting included Walt Smith, executive vice president and co-founder

tute, or in support of treatment of Guillain-Barre Syndrome.of Indy Hanger, who discussed his company. Members then gathered at the Coyle home for dinner.

footprint and reputation throughout the United States,” says Scott Pariser, president, Pariser Industries Inc.

Arthur Fatica, manager of the drycleaning and wetcleaning division for Pariser Industries, and the driving force of its marketing support systems, died July 31 at the age of 59, reports Pariser Industries.

He had been fighting cancer for the last number of years, the company notes.

Throughout that time, and as a 20-year employee of the firm, Fatica significantly contributed to the sustained growth and health of the company, which manufactures specialty cleaning chemicals.

“During his tenure with Pariser Industries, Art’s efforts were largely responsible for expanding the firm’s national

“Art’s energy, enthusiasm, and artistic talent helped es tablish Pariser. Art joined Pariser Industries in 1999 after a long stint managing a well-established, successful New Jersey drycleaning operation.”

Initially developing local sales territories for Pariser drycleaning, laundry and wetcleaning products in the New York/New Jersey and Connecticut marketplace, Fatica was promoted to marketing manager while also focusing on national distributor development, helping the company to increase its national footprint to over 40 states and Canada.

The family requests memorials in his name be made to CarePartners Foundation, P.O. Box 25338, Asheville, NC 28813.

“Art dearly loved his company,” reflects Pariser on his friend, “and his devotion to it, along with his dedicated efforts and genuine collegial spirit, will always be remem bered and honored.”

■ Have you invested in renovations, equipment upgrades, or an entirely new drycleaning plant? Enter your project in the 56th Annual American Drycleaner Plant Design Awards!

Every year, our magazine honors the best new plants and renovation projects, recognizing them for appearance, efficiency, convenience and comfort. Your plant could be next! You can find our online entry form at: https://americandrycleaner.com/ 56th-annual-plant-design-awardsentry-form

■ Fill out the form completely and upload a layout (blueprint or sketch) and several photos (300 dpi digital files are preferred, but color photos will also suffice) that show off the features that make your drycleaning plant an excellent place to do business.

And include any information you believe is relevant to the way your plant’s design attracts customers and fulfills your production needs. The more detailed the entry, the better!

Perhaps you’ll join the likes of previous grand prize-winners Peerless Cleaners, Fort Wayne, Ind.; Wooven, Pompano Beach, Fla.; and Corona Del Mar (CDM) Cleaners, Newport Beach, Calif., at the pinnacle of the drycleaning industry. But you can’t win if you don’t enter!

■ Entries are subject to verification. Contact Editor Tim Burke, 312-361-1684, tburke@ ATMags.com, with any questions.

American Drycleaner is accepting entries until Friday, Oct. 14. Good luck!

10 YEARS AGO. The Fed’s Beige Book of current economic conditions says that high energy prices are keeping inflationary pressures up even as the economy slows. The Federal Reserve’s 12 districts reported economic growth for the last two weeks of June and the first two weeks of July, but there were “numerous individual reports pointing to evidence that the pace of growth has slowed.” … The “Market Basket” of goods and services represented by the Consumer Price Index (CPI) rose just 0.2% in June, down almost half from May’s increase. Prices are up an annualized 4.7% this year; core prices (excluding volatile food and energy costs) also grew 0.2% in June for the third time in three months.

25 YEARS AGO. The 1991 edition of the Neighborhood Cleaners Association’s Personal Guide To Drycleaning and Clothing Care is available, and it has been totally revised to add additional sections that have been requested by many members to help educate customers. In the pocket-sized booklet, the process of dry cleaning is explained so customers have a better understanding of all that happens to their garments from the time they are brought in until the time they are picked up. The booklet covers the areas of problem fabrics, trimmings and stains, as well as a good explanation of depreciation for when a garment gets lost or damaged. … On the beaches, at the mall, in school, clothing that changes color with body temperature is taking the junior sportswear scene by storm. Hypercolor™ is a color system that is affected by heat. When things heat up, the clothing changes color. Once the heat source is removed, the fabric reverts to its original color. The care instructions for Hypercolor™ garments recommended laundering in cold water, separately.

50 YEARS AGO. The coining of fancy titles for salesmen goes on. Such as “key account supervisor,” “executive representative,” “resident engineer,” or “communications consultant.” In fact, four out of 10 companies surveyed give their salesmen titles like these. Maybe a routeman

would have his ego inflated by being called “supervisor of domestic distribution.” Then the route supervisor would have to have a title to top that one. … On the ticket for some hair ribbons, a counter girl at a Chicago cleaner had written: “Prespot. Real tears.” The owner says he’d been urging the girls to put down any useful information. In that respect, he was pleased. He also thought he might have scented another story like the one about the dress that had been stained with “real tears” at a wedding. But he got a letdown when he learned that the 10-year-old girl had cried because her older brother wouldn’t let her watch TV.