Since stain removal matters to your customers, each stain is an opportunity to impress them.

InkGo is the effective and safe way to remove ink stains from all types of fabric - including acetates. Use it to remove adhesives, too.

It's eco-friendly... California compliant, chlorinated-solvent and NPE free, biodegradable and non-combustible. And since InkGo is user-friendly and odor-free, it's pleasant to work with.

Use InkGo to deliver stain-free cleaning. You'll build your reputation for quality – and keep customers coming back.

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

January 2017 Vol. 83, No. 9

Classic Cleaners is Big ’N’ New on Knue Road in Indianapolis and the winner of the Grand Prize in American Drycleaner’s 56th Annual Plant Design Awards. But Classic isn’t the only one driving into the winner’s circle. Also recognized this year are Ziker Cleaners, also from Indiana, for Outstanding Central Plant; 24/7 Dry Cleaners from down Texas-way, winning for Outstanding Strip Location; and Caché Cleaners in Florida, named as Outstanding New Build.

Giving back to local communities is its own reward for dry cleaners from around the country. Operators share stories about their roles in charitable causes, provide tips on how to get involved, and describe how to promote good causes to their customers to get the word out. Whether supporting programs that help the homeless find shelter, or help children who have suffered a loss in the family, it’s all about giving.

Tim Burke, Editor

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

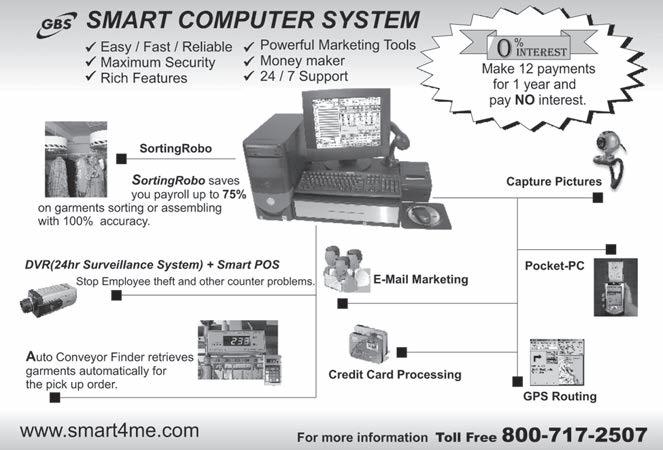

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

Since 2003, CBS has given me consistent updates and easy to understand tech support, all at a price that our industry can afford. I would recommend CBS, and I have, to anyone who is still wasting their time and money on those over priced POS systems.

It’s that time again ... to announce American Drycleaner’s 56th annual Plant Design Award winners.

The Grand Prize for Best New Plant Design this year goes to ... <big drum roll> ... Classic Cleaners of Indianapolis, Ind., for its new operation on Knue Road. Congratulations to Classic!

Check out the details and photos illustrating this prize-winning plant, and read about the other winners named in a trio of separate and distinct categories of plant design. Coverage begins on page 18.

Another feature looks at dry cleaners’ charitable works, and offers tips on how an operator can get involved in giving back to the local community. Good Deeds Well Done begins on page 6.

Our regular columnists you enjoy so much kick off the new year by covering topics such as becoming an information source for your clients, drycleaning detergents that eradicate the “big four” stains, and, as tax season approaches, the importance of honesty in calculating and paying your fair share.

So, welcome to a new year!

For this year, are you kicking off with a mantra? Something to help keep your employees’ proverbial “eye on the ball” all year long?

Maybe you created a sizzle sentence to identify your goals, such as: Bold, energetic drycleaning leader provides each and every one of its customers with the best quality and service, and unequaled professionalism.

(Sure, you can use that one if you want to.)

This year is full of potential. Clean ’17 in Las Vegas this June will certainly be a place to put your energies. (On top of — as usual — being busy taking the best care of your customers!)

So, are you geared up? Lookin’ sharp (as always)? Rested and ready? OK, then, let’s put our best foot forward. It’s 2017! Here ...we ... go! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 83, number 9. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2017. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, January 2017

Publisher

Charles Thompson 312-361-1680 cthompson@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com Editor

Tim Burke 312-361-1684 tburke@ATMags.com

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Roger Napiwocki

Advisory Board

Mike Bleier Steven Dubinski John-Claude Hallak Mike Nesbit Herron Rowland Fred Schwarzmann Beth Shader Ellen Tuchman Rothmann

Contributing Editors

Howard Scott Diana Vollmer Martin Young

Office Information Main: 312-361-1700 Subscriptions 630-739-0900 x100 www.american drycleaner.com

Good-Deed-Doers, we!

Dry cleaners get involved in their local communities and give back. That is undeniable. About charitable deeds, Tom Zengeler, president of Libertyville, Ill.-based Zengeler Cleaners, says, “These

By Tim Burke, Editor

(Image licensed by Ingram Publishing)

By Tim Burke, Editor

(Image licensed by Ingram Publishing)

efforts are driven by our shared belief that it’s important to support the communities we serve, not to get publicity or a ‘pat on the back’ because of the things we do.”

“Finding a charity that is locally relevant is important,” says Todd Ofsink, who has owned New York Citybased Todd Layne Cleaners since 2006.

“With homelessness increasing in recent years in New York City, we feel that it is important to keep the less fortunate clothed and clean to increase their employability,” says the certified business analyst and coach. His operation offers 100% eco-friendly dry cleaning, mainly to the millennial market through app, website, e-mail or text.

“Donating to charities that are locally important will also show customers that you care about the well-being of the community,” he notes.

His operation donates regularly to the Stephen Wise Freedom Synagogue Next Step Homeless Shelter, which helps homeless men who are in a

Sticker Awareness!

Charity Starts with a Smile! This smiling greeter works a sidewalk sale last summer in which OXXO Care Cleaners, headquartered in Hollywood, Fla., participated to raise money to benefit Tomorrow’s Rainbow, a charity that helps children who have suffered a loss in their family.

During October’s Breast Cancer Awareness Month, OXXO Care Cleaners placed stickers showing support for breast cancer awareness on all of its garment bags.

to helping local communities through charities; giving

transition period to get back onto their feet. The shelter provides them with food and a warm, safe environment.

Promoting the charity your drycleaning operation is involved in can effectively get the word out and give clients the opportunity to donate.

“There are many ways to get in contact with customers about charities,” Ofsink says. “Mentioning it on your website, e-mailing customers about it, creating in-store signs can all get the word out. Going into detail about what exactly the charity does will get people on board and encourage them to participate.”

Dave Beatty, current Drycleaning & Laundry Institute (DLI) president and the owner of Murrysville (Pa.) Cleaners for more than 30 years, also discusses how to spread the word about making contributions to good works.

“The best way to promote your charity program is by word of mouth by your counter staff, route drivers, and don’t forget to use all the social media sites they are on,” says Beatty.

Beatty, who runs his operation with the help of his wife JoAnn, son Grant and daughter Melissa, says, “Include it in any advertising that you currently do. I would also send out press releases to your local papers with all the information on dates and times and what you are doing.

“The most recent charity event we did was to collect supplies for a local no-kill animal shelter. This was very successful and we collected hundreds of items, including beds, carriers, collars, leashes, and a large amount of pet foods and treats for the animals.”

Dry cleaners are a “very hardworking and generous group and we can probably always do a little more for our local areas if we can find the time to put these programs together,” Beatty says. “You won’t be sorry that you did!”

Buddy Gritz, owner of Presto Valet of Virginia Inc. in Alexandria, entered the business in 1967 and assumed ownership from father-in-law Harold L. Weisblut when Weisblut retired in 1974.

To advise a dry cleaner to get involved and pick a charity, Gritz says to: “Figure out what the needs are in their local community. Seek charities that spend a high percentage of their income on services that directly benefit the intended recipients rather than on fund-raising expenses or corporate salaries.”

His operation, which specializes in custom drycleaning and laundry services, alterations and shoe repair, and for more than 20 years has been processing costumes for prestigious theaters in the Washington, D.C., metro area, collects thousands of new toys annually for Toys for Tots.

Also, each year, his operation collects

and makes monetary donations to the Red Cross that specifically targets U.S. disaster areas. Donations have also been collected for the Montgomery County (Md.) Stroke Association and the Avon Walk for Breast Cancer.

Shoes collected from his store’s generous customers are given to the Alexandria Country Day School, which distributes them to the needy.

Suggestions from Gritz on getting the word out effectively about your charity work: “Distribute flyers in the store. Put up posters in the store. Encourage staff to inform your customers. Post notices on your website and announcements on your Facebook page.”

Salomon Mishaan, president of Hollywood, Fla.-based OXXO Care Cleaners, runs a drycleaning franchise that has a presence in more than 40 U.S. cities and is active in many charities.

“We do events for Tomorrow’s Rainbow (which provides grieving children, teens and their families an emotionally safe environment for hope and healing through guidance, education and support), “green” fairs, and yoga in the park,” says Mishaan.

“(We) raise funds for the local community where we help collect for the different charities. We have partnered with other local business as we did with NBC where we collected toys for needy kids on Christmas. We collected money for Haiti after their unfortunate natural disaster.

“We also work with schools to help them raise funds for their local sport teams. We are also big on promoting Earth Day and all the advantages of doing things to save the earth.”

Mishaan notes that there was a good turnout for the walk supporting Tomorrow’s Rainbow last summer. And during Breast Cancer Awareness month in October, OXXO personnel made stickers to place on all garment packaging so they would generate donations for the American Cancer Society.

“We have a very reachable audience just through our customer base,” he says. “When we have a charity event we are involved with, we send out mailings to the general public, but the most direct is attaching a small flyer with the information directly to our customers’ hangers.”

Dry cleaners are no doubt aware of their local and

American Drycleaner, January 2017

national charities, but for anyone looking to do more with their giving or are just starting out, how might they find a charity to get involved with?

“The way we go about it, is seeing the immediate needs in our community, and the easiest is donating the left-behind garments to organizations or churches that need them for the less fortunate,” Mishaan says.

Zengeler, who heads one of America’s oldest drycleaning companies, says, “The best way to find opportunities is to listen to your customers.

“For example, we learned about the Glass Slipper Project (helps young women enjoy the special occasion of prom, collecting donations from those who no longer need their dresses and prom night accessories) from one of their volunteers who also was one of our customers,” he notes. “She approached us with a request to provide some support. So many years on, this effort has blossomed into a huge event.”

The Glass Slipper Project in Chicago, since 1999, has collected used prom dresses, shoes and accessories. The program provides high school senior girls in the Chicagoland area who cannot afford a prom dress an opportunity to acquire prom apparel and attend their senior prom.

To get the word out and promote the worthy cause, Zengeler suggests placing marquee signs out front and in-store, posting information on the company website, and sending press releases to newspapers and radio stations.

“From time to time, we’ve also informed customers about the Glass Slipper Project through our regular e-mail campaigns,” he says.

“In speaking with other independent cleaners, most of us make significant contributions to the

community through donations, sponsorships, youth programs or efforts like our support for the Glass Slipper Project.”

Efforts in charitable deeds are made by individuals across the industry, and in so many ways.

Harry Kimmel, communications director for DLI since 2011, says, “DLI staff has participated in Toys for Tots every year since I joined the staff. We’re proud to share some joy with people in need during the holiday season.

“Though the giving is companywide, it’s mostly on the personal level, and we recognize that every contribution counts.”

Regarding the association’s members, he says, “On the community scale, our members do so much. When I read about just one member collecting, cleaning and distributing tens of thousands of coats for kids each year, it warms my heart.

“When we put it all together and see the sheer volume of projects our members undertake each year, it’s simply amazing.” Some cleaners were involved in 10 or more annual projects, he adds.

The way in which cleaners do good works for their communities can also be shared so that more cleaners learn how to reach out and give.

“Our member dry cleaners are extremely generous,” says Kimmel. “We wanted to take their creative energy and share it. We designed the DLI Cleaners Care project to spotlight member cleaner efforts to improve their communities by sharing success.”

DLI set up the Cleaners Care registry “to share the mix of ideas we were seeing,” he says. “If a cleaner is interested in charitable giving, I’d recommend they start by looking at what their fellow DLI members are doing first.”

Good works for the community means getting involved and getting others (friends, family, co-workers, clients) involved, too. Along the way comes good hearts and the strong feelings created by goodwill.

“In 2002, I wrote my first article about DLI members giving to charitable causes,” Kimmel says. “I am still taken by the creativity and ingenuity members bring to their giving. Our members are the friends and neighbors who provide these services to their communities, and that really stayed with me all these years.”

Ofsink would like to see more dry cleaners work together for a common cause, such as clothing drives, or for organizations that fight disease or poverty. “For customers, knowing that their patronage of our business is making a difference in the city helps create a strong community and builds loyalty,” he says.

Regarding helping out the no-kill animal shelter,

Drycleaner,

Beatty points out, “We were not expecting some of the people to come in and thank us for helping them deal with the loss of their pets.

“They had saved items after they passed away and were happy to see them going to such a good cause and help give them some closure. We got to see a lot of their pets’ pictures and it was really nice to know that people appreciated what we were doing. This will now be an annual event for us!”

“Mothers are happy when they see we help the sports team in their school with something as simple as washing their uniform or helping them buy them with money raised from our customers,” Salomon says.

“We do not do charitable deeds for the purpose of self-promotion,” Gritz indicates. “We prefer to generate community goodwill and let positive word of mouth reap its own rewards.”

Zengeler sums up the feeling of the day: “Keep your eyes and ears open for opportunities throughout your community, then find something that is important to you and will resonate with your customers,” he notes. “There are plenty of worthy causes available in every community.”

There’s no limit on caring. Your big heart helps so many. Keep doing what you do.

Invariably, the most common question asked of me is: “How do I increase sales?”

This question is posed by those who are increasing sales at an enviable rate, as well as owners who are just main taining last year’s figures at a flat trend, and companies that are losing volume from a distant past sales peak.

This column focuses on the easiest way to add profitable sales, which is to train your entire team to provide timely information about your servic es to your existing customers so they spend more money with you.

“It costs 10 times as much to ac quire a new customer than it takes to upsell a current one,” notes an Aug. 18, 2014, Forbes.com article on customer-centric marketing lessons.

Many companies have proven the value of selling more to their existing customers by letting them know what the company can provide to make patrons’ lives easier.

The easiest way to get your team to sell is to train them to ask each and every customer a leading question. This is a proven strategy to grow sales.

Of course, the long-standing classic example is from McDonald’s: “Do you want fries with that?”

The company is still reaping the benefits of this question as well as increasing sales with their updated “question” versions.

Question: Relative to your employees, are McDonald’s employees smarter? Better paid? More motivated? More creative? More persuasive? Of course not!

If entry-level McDonald’s employees can be trained to succeed with this approach, so can yours.

Another example of a company utilizing “critical ques tions” to add sales: Apple’s “Would you like our ‘One to One’ instruction with your new computer?”

For those who are unaware, when purchasing an Apple computer at the Apple store, customers can enroll in One to One membership for $99, allowing them to receive person

alized individual instruction at the store for a full year.

Quoted in the Forbes.com article, Carmine Gallo, author, keynote speaker and executive coach, says: “The One To One program was created for one purpose: to build a cus tomer for life.”

Gallo continues: “It’s based on a simple premise – the more a customer understands and appreciates a product, the more likely they are to make a deeper emotional connec tion with that product.”

Never forget the importance of building a customer for life, and the outcome and the likelihood of recommending the service to a friend when explaining the customer ben efits of registering for your route service.

Another well-documented example comes from Amazon and its use of Amazon Prime to achieve the same goal of selling more to their existing customers and, as a result of marketing Prime to every customer, becoming top-of-mind for their customers’ every purchase.

“‘Prime’ members spend upwards of three times what they would without the service,” wrote

Being an information source for clients and engaging them with timely questions deepens their trust, grows your revenue(Image licensed by Ingram Publishing)

Fortune.com staff writer JP Mangalindan in quoting Wells Fargo analyst Matt Nemer in a Feb. 21, 2012, piece.

Amazon Prime is a loyalty program with a fee to join and has no point system, no requirement to sign up for a credit card, and no price discounts.

Prime aims to make life easy for Amazon customers by giving them easy access to a broad range of products and services for any occasion on a last-minute basis (if needed).

Their customers have responded to this appeal with increased purchases ever since Prime was introduced in 2005. Amazon still brings Prime to the attention of each and every customer.

Question: What could you do to make customers’ lives easier? Would they join your VIP club and pay a fee for:

• Platinum service?

• Double inspections?

• Faster turnaround guarantee?

• Express service (store, alterations, etc.)?

• Time-of-choice route delivery?

• Detailed preferences implemented every time?

• Personalized reminders?

Packaging a “free service” with a full-price product works for Zappos and Southwest Airlines. Why? Because they ask every customer if they want it!

Zappos lets every prospective customer know it offers free shipping and a 365-day return policy on its shoes and apparel.

Southwest is no longer the low-price airline, but it asks everyone if they know that “Bags Fly Free,” and this has resulted in continual growth for them.

It also always asks if you would like to add “priority boarding” to your reservation (for a nominal fee).

When a member of drycleaning business consultancy Methods for Management (MfM) Inc. implemented its “Timely Questions” program (shown in next column), sales immediately increased by more than 18%.

A key factor was to provide a physical reminder to the CSRs in the form of rotating laminated questions attached to the register with Velcro®.

Following is an example of a calendar of timely ques tions to ask every customer. (Be sure your list is adjusted for seasonality in your market. Always provide alternative service questions to ask the customers who already use the primary service being highlighted at the time.)

MfM’s Topical Timely Questions for CSRs to ask Cus tomers and Prospects© (Ask your clients at least one of

American Drycleaner, January 2017

these questions per visit – every customer):

January Did you know we will meet you at your car with your cleaning? (Call or text when you are on your way.)

Did you know we clean stuffed toys?

February Do you have ski/snowboarding gear that needs cleaning?

Did you know we clean pet beds and gear?

March Do you have any area rugs to clean? Did you know we clean car mats?

April Do you need any alterations on your summer wardrobe? Are your cottons and linens ready for spring?

May Did you know we can make your pillow like-new? Would you like to transfer your family laundry chore to us?

June Are your sports uniforms ready for the season? Did you know we can care for your delicate lingerie?

July Is your yoga gear in need of attention? Did you know we can extend the life of your swimsuit?

August Does your running gear need attention? Do your kids need pants/uniforms/skirts hemmed for school?

September Are your sweaters/jackets/leathers clean for the cooler weather? Did you know we can clean your patio cushions for storage?

October Have you had your comforters cleaned for the upcoming chilly nights?

Do you need any of your garments altered by our tailor?

November Are your Uggs ready for winter?

Are your table linens ready for the holidays?

December Are your party clothes ready for the celebrations? Does your Santa suit need cleaning?

A successful anytime default question: Do you need any repairs or alterations done?

For seasonal cleaning, ask before the season begins if the items are ready for the upcoming season; after the season, ask if they are ready for storing.

Train your staff to ask key questions that educate your customers. Your team will become a true sales force! ADC

Diana Vollmer is a managing director for Methods for Man agement, which has served dry cleaners and launderers with affordable management expertise and improved profitabil ity since 1953. For assistance in developing a winning sales strategy, e-mail dvollmer@mfmi.com or call 415-577-6544.

Developed to quickly and fully dry wetcleaned textiles without damage or wrinkling, the Poseidon Dryer eliminates air drying for catapulted productivity and unsurpassed results. Offering advanced programmability, it safely removes residual moisture from even the most delicate wetcleaned fabrics. Smart engineering not only ensures a quick dry, it brings superior efficiency, durability and a soft touch. The Poseidon Dryer works in concert with high-performance Poseidon Wetcleaning Machines and Flatwork Ironers for unrivaled results.

Professional fabricare operations rely on Poseidon to perfectly wetclean the most delicate items including tailored wool suits, cashmere sweaters, silk wedding dresses, camel hair sport coats, taffeta prom dresses, knit skirts and so much more. Poseidon offers innovative programmability for complete control over every conditional aspect of the wetcleaning, drying and ironing process.

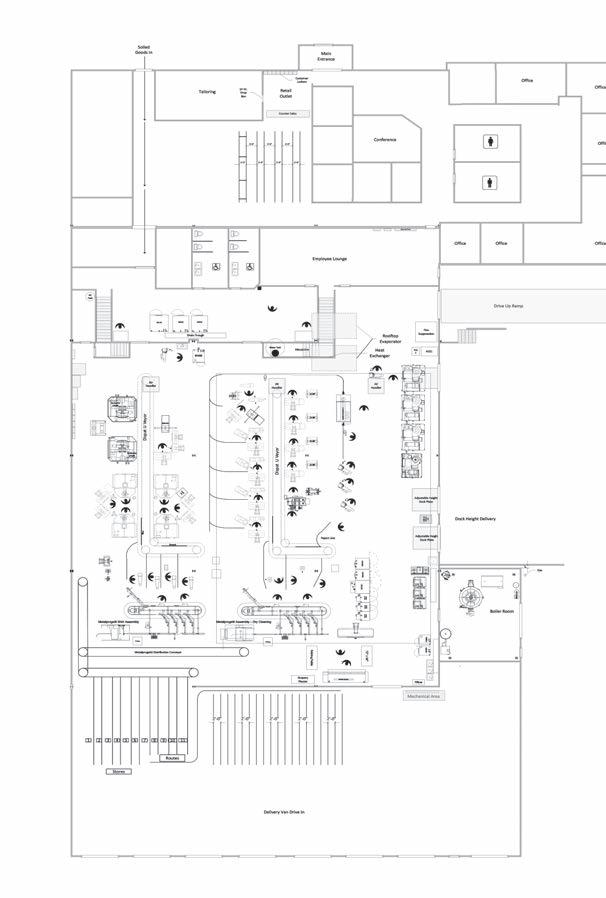

Twenty-five-thousand square feet is plenty big.

That’s the size of the new Classic Cleaners on Knue Road in Indianapolis.

Think of it this way: It’s the floor space equal to five large, sprawling homes combined.

Yet this is what was needed when Classic planned to move

its entire plant and offices from a location with one-third the square footage that felt, in the words of Operations Manager Tim Day, “Shoe-horned.”

“The lack of space to grow actually made us more efficient in the use of space,” Classic wrote in its Plant Design Awards entry application.

“It’s hard to imagine that 90% of the equipment that’s currently in the new 25,000-square-foot plant was in the old 8,000-square-foot plant,” says Day. “We just knew that if we were to meet our potential and maintain our growth curve, we needed more room.”

Besides the new plant location, the operation has

18 dry stores. The business notes that it is a quality-focused, fullservice retail dry cleaner serving the Indianapolis metropolitan market with services such as: dry cleaning,

laundry, restoration, delivery service, wedding gowns, and leather, among others.

Classic Cleaners traces its roots back to central Ohio where

the Arnold family began the business in Zanesville.

In January 1985, Carl Arnold and sons John and Steve, along with Jeff Stroman, opened their first two stores as Professional Cleaners in northeast Indianapolis. Shortly thereafter, they took on the name Classic Cleaners.

Throughout the 1990s, the cleaners opened more stores and gained additional capital when Leon Neal bought into the company as a fifth partner in 1990. Day joined the company as its sixth partner in 1993, the company reports.

Classic Cleaners increased locations to include five Carmel locations and a Westfield location. From 20062009, it remodeled its main cleaning facility, expanding its size to accommodate growth. With continued growth came the need for more space, Classic continues.

Finally, the operation purchased an existing structure on Knue Road in the Castleton area with the intention of expanding the plant and corporate office space.

When the cleaners finally settled on the location on Knue Road, Day put together a team to help them plan the big move and install the new equipment.

Day contacted Jeff Dunn of equipment distributor Machinex to assist with the layout, planning, installation and move.

“We spent many days of online CAD collaboration,

sharing the proposed layout on Jeff’s computer screen with Sandra Haralson, our drycleaning consultant; Jay Mills, our engineer; Metalprogetti and many other suppliers,” comments Day.

“We looked at this layout, tweaking and changing it over 100 times before we settled on the one we have.

“We tried to think of everything, but even when we started the install, we probably took more time analyzing the placement of every item in a workstation to maximize flow than we did on the actual installation,” Day points out.

With construction finished at the end of 2015 and the movein completed soon after, and at a project cost of just under $2 million, the resulting layout and installation maximized workflows and minimized labor wherever possible.

Separate laundry and drycleaning areas flow into their own finishing work aisles where finished goods are taken away by White conveyors, he says.

These conveyors deliver the finished garments to separate inspection stations designed to maintain workflow and production rates.

After inspection and touchup, garments are scanned onto the Metalprogetti assembly conveyor — the last time they’re touched until loaded onto trucks, Day notes.

Completed orders come to the assembly conveyors, go directly to be bagged and invoiced, and are carried on to the distribution conveyor. It separates the orders into 16 lines for drop stores and routes, writes Day. He adds that: “We can process approximately

(continued)

1,600 garments an hour.”

“Major new production equipment includes a 130-HP Fulton boiler, Hamilton Engineering steam water heater, and Metalprogetti distribution conveyor and second bagger,” he notes.

He also points out that the plant uses “a Kaeser air compressor, two new Sankosha double-buck shirt units with rotating quad collar and cuff, a second White distribution conveyor, a 70-ton KleenRite chiller system and a Sankosha

double-legger and topper.”

Existing equipment that was integrated from the old site includes Union HL890SSK K4 drycleaning machines, 130-pound and 90-pound Continental soft-mount washers, and Forenta utility and legger presses with puff irons and toppers. Their pads are made by FH Bonn.

Classic Cleaners has used a SPOT point-of-sale system since the late ’90s, “allowing for seamless integration,” Day writes. The Kleen-Rite spot-cooling system provides comfortable workstation environments.

Speaking for the entire Classic Cleaners operation, which includes 57 production employees, in regard to how the move went, Day says, “We are very pleased with the

implementation of the move. We can’t say enough about how well our staff performed during this transition.”

At first, he points out, the company approached the move with a great deal of anxiety because the task of moving the equipment while continuing operations appeared quite daunting.

“We decided to move as quickly as possible knowing we may face the challenges of weather, as well as doing the move during a busy time of year,” says Day. “So a tremendous amount of planning was put into the schedule and the process of how the move was to be made.”

Looking back on the move, he says, “It was a long year in preparing the plan, working the plan, and executing it. On reflection, we feel it was absolutely the right move and we are very proud of the finished result.”

And what are its clients saying about the new digs?

“Customers are amazed with the presentation of the new location,” notes Day. “They say the finished landscaping, the marble entry, and the 24/7 drop-off and pickup (locker) service project our ‘upscale image’ very well. They also say this is a much better location to get to.”

American Drycleaner asked Day to share some personal reflections about Classic Cleaners’ new plant.

“Our new location provides a great platform for future growth,” he says. “It also has a greatly improved work environment for the employees, with higher ceilings, proper ventilation and increased individual workspace enhanced by energy-efficient, brighter LED lighting.”

Day shares this parting thought: “The employees love their new facility!” ADC

Ziker Cleaners • Mishawaka, Ind.

Since the 1930s, Ziker Cleaners had operated in the same location close to downtown South Bend, Ind. But it was time for a change.

“Our leadership team put together a complex and sophisticated plan to successfully move the operation without any disruption to our customers,” explains John Mertes, general manager at Ziker.

Originally, Joe Ziker owned a building that housed a small, corner dry cleaner/tailor shop, with an apartment upstairs where he and his brother lived. As the business grew, so did the facility.

When the sale of its uniform division was complete in 2014, Mertes writes in Ziker’s Plant Design Awards entry form, it became obvious the facility was too big.

“So we began to look for a more

our central production facility for 10 stores, four routes, and a business office,” he notes.

As the operation explored a variety of locations, Ziker Cleaners kept coming back to a site found early in the search. It was a building with ample parking, a truck dock, high ceilings with skylights, plenty of utilities, and was close to “dead center” for distribution, the company writes.

(From left)

“We hired Forum Architects to design the offices, bathrooms and lunchroom,” he says. “The processing design and mechanical work would all be designed and managed by David Ziker and myself.

“Industrial engineers Frederic Veau and Don Desrosiers collaborated with us to design the production process and help decide what equipment to purchase and to move.” Equipment in the awardwinning plant comes from Union (with SYSTEMK4 solvent from Kreussler), Sankosha, Forenta, UniMac, Fulton, Hamilton, Speed Queen, Kaeser and Metalprogetti. Pads hail from Sankosha, FH

Bonn and Air World. Spotters are by R.R. Street and Adco. Ziker uses a SPOT Business Systems POS.

After many months of preparation and planning, there was still a great deal of anxiousness and stress, says Mertes. This type of change affects every employee, and Ziker was truly amazed that its employees responded in such a positive way, he adds.

“In my nearly 30 years in the drycleaning industry, this is perhaps the most difficult thing I have ever done,” Mertes says. “It is one of my proudest accomplishments here.

“It would not have been possible without the many dedicated managers and staff that went above and beyond the call of duty during a very challenging several months.” ADC

Charlie Jones’ 24/7 Dry Cleaners just opened in Texas, and it’s in a prime location, which is key.

But so is offering its clients amenities they demand along with keeping the plant cool for better worker productivity in the local heat.

“While dry cleaners today face a more demanding environment than ever, success can still be had in this industry if the operator understands and reacts to the changing customer demands and labor challenges present today,” says Jones, whose plant is the winner of American Drycleaner’s 2017 Outstanding Strip Location Award.

At his clean-looking, brick-andstone 2,400-square-foot store, Jones says, “We clean and press,

amenities such as a double-lane drive-thru for fast and easy pickup and drop-off.”

It’s Jones’ philosophy to “provide a good, clean and comfortable work environment.”

“In Texas, I feel that this must include a fully air-conditioned plant,” he says. “This helps the staff stay fresh and productive.”

Clients can utilize the drive-thru at the store’s convenient strip loca- tion. (Photos: 24/7 Dry Cleaners)

With a mix of amenities and cool zone, Jones launched his new store in a locale he says was the fastest-growing city in the U.S. between 2000 and 2014, according to U.S. Census.

“My store is just four miles away from the headquarters of the Dallas Cowboys, as well as the ‘5 billion dollar mile,’ as it’s known.

“My store is in the middle of the largest planned community in Frisco, Phillips Creek Ranch,” he notes.

Jones describes how he set his store apart from the competition by offering customers 24/7 access to their clothes. Using express bags, clients drop off thru the drop slot.

Equipment and

systems used in his store comes from Union (using K-TEX solvent), UniMac, Huebsch, Atlas Copco, Rinnai, Fulton, Unipress, Sankosha, Hi-Steam, Saratoga, and CompassMax. Pads and covers are by Covers Etc. and Sankosha.

Spotters are from A.L. Wilson, and wetcleaning detergents are produced by Adco and Laidlaw. The plant employs spot cooling air conditioning at all 15 workstations.

In today’s world of shrinking piece counts and added costs, the risk of opening a new plant is greater than ever, Jones says. To satisfy today’s discerning customers, one must do more than clean clothes and press well.

Amenities and retaining quality labor in a comfortable workplace are Jones’ “24/7” way. That’s cool!

It was more than three years in the making.

The Momins, Amir and Jamila, spent years planning, building and finishing the 16,000-square-foot building which they operate as owners of both the property and the business that is Caché Cleaners, Deerfield Beach, Fla.

At Amir Momin’s previous business, the writing was on the wall, so to speak.

“Once the production exceeded the capacity of the old plant,” says Momin, “we expressed interest in expanding and relocating. Then we received an ultimatum when the landlord wouldn’t renew the lease of our store with the plant.”

The Momins started in the drycleaning business in 1985 with three plants and three drop stores,

which they later consolidated into one plant.

“Designing the plant,” says Momin, “included a visit to Italy to design and finalize a full Metalprogetti layout, fitting the machines to the layout of the conveyors.

“We now have the capacity to finish more than 5,000 pieces in one shift at regular hours, with the ability to further expand.”

Caché Cleaners utilizes the most efficient methods of drycleaning production, Momin writes.

With the most advanced and complete conveyor system, garments are transported to and from each pressing station to the automated assembly conveyor and automated bagger, he continues.

tract and are bagged automatically.

Orders from the retail front of the plant also enter and leave in a similar loop, adds Momin.

In addition to Metalprogetti, Caché utilizes equipment made by Sankosha, Hi-Steam (tensioning), RealStar, UniMac, Milnor, Fulton and Kaeser.

bagged,

Once bagged, orders are stored automatically on the first storage conveyor. From this conveyor, orders are removed by store onto a rail which leads to an awaiting van to be loaded.

As garments arrive from the six drop stores, clothes are sorted by dry cleaning and laundry, and split to their respective areas. When orders are complete, they ex-

A.L. Wilson and Adco produce the spotters used, Momin notes, and pads are by Sankosha.

How’s it going for the new operation? Momin says that, the other day, he meant to catch up on correspondences. However, visitors from Europe came by to see the plant and that changed his plans.

“I got caught up,” Momin says.

Caché Cleaners employs 20 workers.

“Personally,” says Momin, “I’m very proud of my staff, family and friends.”

You will find yourself overwhelmed, trying to run the business and handle the legal case at the same time. Expense errors are generally less serious.

Taxes are upon us once again.

It is an annual ritual where we bring our figures to our accountant and the information is assembled. The fin ished forms are handed to you and you write out checks to the federal and state tax authorities.

It has come to my attention that not all dry cleaners are honest with their figures. Some pull money out of the register. Others bring false figures. Still others pester their accountants to doctor the figures.

I will argue, both from a personal and societal position, why this prac tice of dishonesty is wrong. Why this doesn’t help you or your business in the long run. And why this is not good for you, personally.

Cheating on one’s taxes is not a popular subject, but it needs to be faced. Avoiding taxes is a practice that has been in play since the begin ning of taxation.

Indeed, it could be said that the Revolutionary War was fought over unfair imposition of taxes for tea.

Small-business owners who operate largely in cash pocket some of that inflow. A few major corporations avoid U.S. taxes by creating their home base on a foreign land that has lower tax.

Individuals sometimes don’t report their under-the-table income. Accountants sometimes overstate inventory or other assets to reduce tax liability. But most companies are honest taxpayers.

Why should your business file its true taxes?

It is fraud to understate income. When you understate income, you reduce profit, and pay less taxes than you should. Fraud is an offense punishable by jail time and heavy fines.

Unless you admit guilt, there must be a trial. You must appear in court and hire a lawyer. The judge rules the out come. Time drags on.

If the Internal Revenue Service (IRS) finds that you have overstated some expenses, you could argue that your bookkeeper was incompetent or that your books got mixed up or that you misinterpreted tax rules.

The IRS might simply re-state the correct expense and recalculate taxes. You will pay the additional taxes due plus penalties plus interest. Since a few years expire be fore detection, these fees can be enormous.

On the other hand, if there is a systematic abuse of overstating expenses, then that too is fraud. You will be as severely punished as with understating revenue.

What are the odds of you being audited?

It happens, believe me. Over the course of 30 years, you probably have a 50-50 chance of being audited. Moreover, if you cheat, that increases your chances.

The IRS decides who they will audit by several different criteria. One method is simply random selection, but other criteria include changes from last year, divergent figures from industry standards, and a high audit score.

The IRS has a formula involving calculations that in clude low gross profit margin, high auto expense, high travel and entertainment, and little (or zero)

Honesty: It pays to be true to yourself, your business, and your country(Image licensed by Ingram Publishing)

profit to determine probable cheating.

The company that scores a high audit score is likely to be audited. These are the audit triggers.

As a former H&R Block tax preparer of 14 years, I have seen enough nail-biting, expensive audits to know that audits are the most miserable ordeals one could ever expe rience. Nothing in life is more nerve-racking, intimidating and dispiriting.

The auditor calls you to come into his/her office and to bring all your records, and grills you figure by figure. You could go yourself, but most bring an accountant.

If the auditor isn’t satisfied, you might be asked to come in again and again. I have been personally involved in a few of my clients’ audits and the best example that comes to mind is that it feels like an insect being stuck on flypaper.

You are totally at the mercy of the auditor, who could make you or break you. I’ve heard of three business own ers who were ruined by their audits.

One dry cleaner was so hounded by the IRS after it was discovered that he underreported his income that he closed up. He couldn’t take the nitpicking.

I know another business owner that reported minimal profit for many years and the IRS finally audited him, and assessed him $55,000.

When he wouldn’t or couldn’t pay that assessment, they began garnishing his wages. At that point, he killed himself, and his wife moved to Thailand so her wages wouldn’t be garnished. The business suddenly closed.

A third dry cleaner was found to be overstating expenses. The IRS revamped figures so that he owed several thousand dollars, including the penalty. He tried, but couldn’t catch up. Three years later, he was out of business.

Collected figures provide valuable information. They are used to pay taxes, yes, but they are also used to pro duce information.

They constitute your monthly profit and loss (P&L), your specific reports, and your ratios. If you don’t use your correct figures, the information will be corrupted.

Not only the altered figures, but all your figures become less than reliable. You will ultimately depend less on the information in front of you and more on gut, and that is where you will begin to make mistakes.

To use an example, if you pocket some cash volume ev ery day or don’t use authentic figures, you will lose track

of the proper margin you are operating on.

Your price-cost ratio will be incorrect and your labor ratio will be off. Your direct cost of goods sold will be incorrect. No one can make good decisions with skewed information.

You will lose focus and then your business becomes a vehicle for taking cash, not a legitimate enterprise.

You begin to look for other ways to cheat, rather than focus on the business. Your attention wanders. You are no longer focusing on business basics.

It’s no longer a going business, it’s a spigot for money.

When that respect vanishes, your business will never improve. Instead of a going, growing concern, it becomes a conduit for obtaining money. Without the challenge of building a business, you’ll become just another tired mer chant.

It is kind of like the youngster in school who cheats on tests to get better grades. He achieves his goal. But in the process, he’s lost site of the purpose of why he’s there: to learn.

A final reason you should pay your fair taxes is because you’re a person of integrity. You want to be able to look yourself in the mirror, as well as be comfortable talking to anybody about your business.

If you were cheating the government, you would be come reticent, afraid, less proud, less open. After all, you never know when you might say the wrong thing to some one.

So avoid that possibility and walk tall. Your attitude should be: I run my business so that it earns a profit. I pay my fair taxes, and I’m proud that I do my share to keep the economy (and country) going.

These are reasons why it is important to pay your taxes honestly. Let’s look at what your taxes pay for.

Over to the other side of the ledger.

Yes, it is our obligation as citizens to pay (continued)

Your attitude should be: I run my business so that it earns a profit. I pay my fair taxes...

taxes, but why? Because we receive benefits.

First, you are allowed to operate a business and to do as well as you can. That is our free enterprise system.

If you lived in China, for instance, you would be ex tremely limited to what you can do. Initial startup red tape would disillusion all but the bravest.

The greatness of our country is that the opportunity is there to do whatever you want. Anyone can open

a business.

Second, we are free. We can do what we want, go where we want, and say what we want, without fear of recrimination.

We can yell out in the middle of a crowded street that the government is full of criminals. If that were to be done in China, there would be quick punishment.

It’s easy to dismiss this as a benefit because it seems so natural. But if you were deprived of your freedom, you would know its value. Freedom costs, and we must pay for it.

We enjoy a safe society. Despite the occasional incident (rare con sidering we’re a country of 320 million people), we feel unafraid almost anywhere.

That goes a long way toward do ing business, not to mention living one’s life. Consider a country like Israel which has incidents regu larly. Israelis live with fear. There is palpable tension in the air.

We don’t have that. Our law en forcement organizations have done a good job keeping the country minimally affected by crime. The privilege of being able to walk any where and not fear for our safety is worth paying for.

Just look at television cover age of Iraq or Syria, bombed-out worlds almost beyond description. There is none of that in the United States.

Sure, we are lucky, with two oceans separating us from our ene mies, but still we have steered clear of war on our land.

The U.S. has about 800 military bases and 300 embassies in more than 190 countries, which has con tributed to our position.

All this costs, and we are happy to support those efforts to ensure continued peace.

Then there is infrastructure.

public transportation, communication networks and postal service all energize our society. We are better able to operate our businesses.

We can order an item from across the country, and it appears on our doorstep the next day. Not only that, we can check on its progress as the item makes its way across the country.

There is an amazing network of connections that make this possible. Without infrastructure, running a business efficiently would be impossible. Infrastructure is expen sive, and we must pay for it.

Our educational system delivers a competent work force. From this pool, we fill our ranks.

If help came to us uneducated, think how difficult it would be to train a counter staffer to process orders.

It would be hard to find a sharp-thinking manager. At minimum, a high school education is necessary for these positions.

Thanks to all sorts of educational opportunities, we have a ready-made workforce. Education is expensive and we pay for all the myriad choices through our taxes.

We have all sorts of bureaucratic organizations work

ing for us. For example, the Food and Drug Administra tion (FDA) ensures that any food we eat is safe. The Occupational Safety and Health Administration (OSHA) recommends practices to keep our workplaces safe. The Department of Education promotes student achievement.

All these are benefits to running our business. We can hire competent individuals who can perform tasks and work safely.

We have a safety net of welfare payments which ensure that our poorest citizens have food, enjoy shelter, and are able to live modestly.

The net result of these programs is that the population stays reasonably content. In other countries such as Brazil, there is such terrible poverty that it casts a pall over society.

We pay for our better society. Which is why you should be honest with your taxes. ADC

Howard Scott is a longtime industry writer and dry cleaning consultant. He welcomes questions and com ments, and can be reached by writing him at Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027, or via e-mail at dancinghill@gmail.com.

You can’t clean a white blouse by agitating it in a mudhole.

There are those “cleaners” who believe that proper pro cedures and technical knowledge are no longer necessary.

Far too many times, I will find a plant where the choice to cut corners has resulted in conditions that have reached a point of preventing even minimum production and quality.

I have a strong respect for this industry and want you to meet customer expectations.

Possibly you have overheard this: “I don’t use any detergent. It is just a waste of money.”

Martin Young

Drycleaning detergent is far from a waste of money. This chemical tool allows the immersion solution (sol vent) and the drycleaning machine to work together effectively.

There are two types of drycleaning detergents available to the garment care professional. The most popular is the injection detergent (cationic).

This type of de tergent is added to each run of garments, with the amount of detergent determined by the total weight of the garments in the run. By the end of the run, the detergent is absorbed by the gar ments in the run or by the filtration system.

The other type of drycleaning detergent (anionic) is used to charge the entire system to a predeter mined percentage. An example

(continued)

would be a ratio of 1 gallon of drycleaning detergent to a 100-gallon tank to equal a 1% charge.

The detergent greatly increases the ability of the solvent to “handle” moisture and use the moisture in the system to your advantage by breaking down any water-soluble stains, better and faster.

Also, controlling the amount of free water in a nonhalogen system will greatly reduce the chance of the solvent beginning to smell, as bacteria reproduce in the base tank and piping system.

Anything that reduces the chance of stinky solvent is good.

Further, the drycleaning detergent will add lubrication to the drycleaning system. Lubrication in the wheel will in crease the speed and efficiency of insoluble stain removal.

Finally, a drycleaning detergent will act as an additional stain remover. The drycleaning detergent will “hold” soil in suspension once it is removed in the wheel and, thus, not allow it to be redeposited on other garments in the wheel.

Note: Many experienced non-perc cleaners are still mix ing a favorite pre-spotter that is a variation on the formula of 4 parts solvent to 2 parts drycleaning detergent.

For the consumer, a spot is a spot. For the garment care professional, that spot must go.

If approached properly with knowledge gained through continuing education, successful stain removal is far supe rior in the eyes of your customer than a “Sorry” tag.

There are four broad categories of stains (solvent-soluble, chemically soluble, insoluble, and water-soluble) that are based upon the specific protocol used to remove each one.

1. Solvent-soluble stains are broken down in the immer sion solution in the drycleaning machine and resist water. These are often referred to as “dry-side” stains, since water has little or no effect upon their removal.

Solvent-soluble is represented by light oils and greases. These can move directly to the next appropriately classified run with little or no pre-spotting.

2. Chemically soluble stains usually consist of these dry-side stains that require a little extra help to break them down. Chemically soluble stains are represented by ink, glue and nail polish.

The first step in the protocol for chemically soluble stains is to apply a Paint, Oil and Grease (POG) remover or Oily

Type Paint Remover on the solid portion of the spotting board, along with light mechanical action.

This can be repeated a second time, often with the addi tion of amyl acetate as a co-solvent/catalyst, with additional mechanical action.

3. Insoluble stains are those stains that resist being bro ken down in solvent or water. These stains consist of small, solid particles that penetrate the upper layer of the fabric.

Insoluble stains are represented by sand, graphite and car bon; this is the car exhaust on the bottom of the pants legs after pushing a car in the snow. Since insoluble stains will not break down, they must be flushed away intact.

Insoluble stains are pre-spotted on the dry side with an Oily Type Paint Remover, receive mechanical action, then are dry-cleaned.

4. Water-soluble stains break down to a water-based procedure and resist solvent action and can be divided into three groups: sweet, protein and tannin. Sweet stains are sugar, and sugar left behind by food or beverage.

With the proper drycleaning detergent use, the immer sion solution in the drycleaning machine will be carrying/ handling enough moisture to rid the garments of the sweet

stains that appear as small, irregularly shaped areas. These can be removed with just a quick puff from the steam gun.

Protein stains are represented by blood, ice cream, and bodily fluids that originate with animals. These require an alkaline-based chemical tool as a helper to water/steam for proper, complete removal.

Tannin stains are represented by stains like beverages, vegetable, and fruit stains, and require an acid-based chemi cal tool as a helper to water/steam for removal.

As long as the solvent is maintained with proper filtration and clarification, your operation will be productive.

Garments will feel more natural and press more easily, with few if any “crow’s feet” in acetate linings. Never let the color of your solvent, in any tank, get darker than the amber color of a pilsner beer.

Using the proper drycleaning detergent in the proper pro portion is an asset, not a liability. ADC Martin L. Young Jr. has been an industry consultant and train er for 20-plus years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates to this day. Phone: 704-786-3011, e-mail: mayoung@ctc.net.

The Tuchman Advisory Group (TAG) recently toured Highland Cleaners in Louisville, Ky., reports TAG Presi dent Ellen Tuchman Rothmann. Highlights included see ing reclaimed wood floors from a barn, water-permeable pavers, flat rooftop solar screens, and rainwater harvesting.

“We went to Highland Cleaners’ central plant and main plant offices, and a drop store that is a LEED (Leadership in Energy and Environmental Design)-certified green building owned and developed by Michael Jones,” she says.

“The Tuchman Advisory Group meetings are always helpful and thought-provoking for Anne and myself, but there is nothing like hosting,” says Jones, who owns Highland Cleaners.

TAG members extended their visit in Louisville for some sightseeing.

People planning to attend Clean ’17 in Las Vegas June 5-8 can register for the show and make their hotel reservations through the website, www.cleanshow.com, or through the show’s only authorized housing service, Connections Housing, at 702-675-6584 or 844-216-0057 (toll free in the USA), notes show management firm Riddle & Associates.

Also, for the first time, members of the five national sponsoring associations can register for a discounted fee of $119 per person (membership must be active at registra tion). The pre-registration fee for non-members is $149.

Sponsoring associations are the Association for Linen Management (ALM), Coin Laundry Association (CLA), Drycleaning & Laundry Institute (DLI), Textile Care Al lied Trades Association (TCATA) and Textile Rental Ser vices Association of America (TRSA).

The deadline for preregistration is May 31. After that date, regis tration is on-site at the Las Vegas Convention Center only and the fee increases to $169.

Clean ’17 has con tracted with a number of Las Vegas hotels, many of which are new to the Clean Show package, Riddle notes. Hotel rates range from a low of $49 on a weeknight to a weekend high of $239.

Show sponsors have selected the following headquarter hotels for their organizations: ALM, Caesars Palace; CLA, Vdara; DLI, Cosmopolitan; TCATA, Renaissance and Westgate; TRSA, Signature at MGM and Westgate.

Front row, from left: David Makepeace, MedlinDavis Cleaners/North; Anne Nash, Highland Cleaners; Jana Janssen, Martinizing Green Earth Cleaners; Ellen Tuchman Rothmann, Tuchman Advisory Group; and Terry Quinn, MW Cleaners.

Back row, from left: Michael Jones, Highland Cleaners; Gary Futterman, Flair Cleaners; and Chuck Haddox, MW Cleaners.

Other hotels being offered to Clean Show attendees are Bally’s, Flamingo, MGM Grand, Paris, Tropicana and Wynn. Published rates do not include taxes, and most ho tels also add a mandatory resort fee of $15-$32 per night.

The Clean Show is the world’s largest exhibition of commercial laundry, drycleaning and textile services equipment and ancillary products, says Riddle. Attendees can see and compare working equipment. ADC

RATES: One- to five-time rate: $2.10 per word, boldface $2.20 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 12-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major

cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month. For example, for a June ad, the closing date is May 1st.

10 YEARS AGO. Employees at a cleaner and launderer in Sheboygan Falls, Wis., found a live bomb in a load of dirty clothing last month. A bomb squad from the Milwaukee County Sheriff’s Department successfully dismantled the apparently homemade device. Less than a foot long, with an explosive force similar to dynamite, police said, the bomb could have caused significant injuries if detonated. Police have no suspects in the case, but doubt the incident was a terrorist act. … American Drycleaner celebrated the New Year by unveiling its new website, www.americandrycleaner.com, Jan. 1. Incorporating the best features of the magazine’s print edition in a comprehensive, online industry resource, AmericanDrycleaner.com now offers the latest news, a directory of products and services, a distributors directory, classified ads, and a calendar of events in a searchable, user-friendly format. “We’re pleased to offer our industry what we believe is an extremely valuable management tool,” says Charles Thompson, publisher of American Drycleaner

25 YEARS AGO. Jack Brown Cleaners of Austin, Texas, was honored recently as winner of the 1991 Austin ReLeaf Business Award, presented in recognition of the company’s efforts in recycling, and outstanding contributions toward preserving Austin’s heritage of trees. Recycling efforts by Jack Brown Cleaners include a hangerrecycling program, in effect since April 1990, that has recycled more than 3 million hangers. For each hanger recycled, the cleaners donated one cent to Austin ReLeaf — for a total contribution of over $30,000. … At an open meeting recently, the Leather Apparel Association (LAA) introduced industry guidelines for manufacturing that ultimately should increase consumer confidence and satisfaction with leather clothing. The guidelines were developed specifically to address areas of tanning and manufacturing that can create problems when a leather garment needs to be cleaned.

50 YEARS AGO. An old-time duel — only this time was called a “shoot-out” — was recently fought by two

To read more of American Drycleaner’s chronicling of the industry over the years, visit www. americandrycleaner.com.

American Drycleaner, January

town officials in Fort Gibson, Okla. One man was wounded three times, and although the other wasn’t hit, he was taken to the hospital with a heart ailment. Both men were charged with dueling, and the mayor was charged with being “an accessory after the fact to dueling.” A well-known Oklahoma City dry cleaner, who spotted this news item, comments: “Now you see why I got out of politics.” … Credit buyers buy 33% more than cash buyers. That’s the conclusion reached by a cleaner in Fremont, Neb. Here are some of his other observations: Credit buyers do less shopping around for a better price. Credit customers are your customers, whereas cash customers are everybody’s customers. Credit customers more readily recommend you to their friends than cash customers.

75 YEARS AGO. Officials of the industry have fought hard to gain a priority rating for cleaners which would enable them to secure repair parts for their equipment. An A-10 rating was granted by the OPM under Preference Rating Order P-22, amended. This has since been changed to Preference Rating Order P-100, but the essential features are the same. It is not necessary to make application for the rating, but merely to include the statement on the original and all copies of the purchase order or contract: “Material for Maintenance, Repair, or Operating Supplies — Rating A-10 under Preference Rating Order P-100, but the essential features are the same.” … Details have not yet been announced, but officials are predicting “the best convention ever” for the coming “Little National.” The joint convention of the Nebraska, Iowa and Missouri Associations is to be held at the Rome Hotel in Omaha, January 19-21. Not only are large groups expected from the three member states, but announcements are being mailed to cleaners in Kansas, South Dakota and southern Minnesota — states which have previously been well-represented.

Since 1919 Parker boilers have been engineered for more effi cient operation (whether gas, oil, or combination gas/oil fired) for delivery of hot, dry steam in less than 10 minutes. And Parker boilers have a longer service life for a greater return on your investment.

Parker boilers are designed for ease of routine maintenance, annual inspections, and on site repairs, so there is less down time, more reliability. Parker boilers also have extra heavy, insulated, double-wall steel cabinet construction (Stainless steel cabi net lids and/or sides available).

All Parker boilers are delivered complete, ready to connect to utilities. What’s more, every boiler is test fired before it leaves the factory so you can count on getting up and running as soon as possible.

Kompact mounted return sys tems are available on 3 to 25 hp boilers to save on installation costs.

All of Parker’s superior quality boilers are available at com petitive prices and have been distributed through our region al representatives for over 60 years.

Steam Boilers