® June 2017 DOUBLE DOWN COOLING TOWERS

FutureScoop Time Travel: Drycleaning Industry in 2022

© Copyright 2017 American Trade Magazines All rights reserved.

“The best of the best!” “Fantastic help, quick solutions and exceptionally polite.” “Professional, knowledgeable and excellent customer service.” “Outstanding service!” “Always great working with the Compassmax Support staff.” 98% of customers are reporting they are extremely satisfied with their experience using Compassmax technical support* Enjoy peace of mind with reliable, 24/7 technical support. *Actual quotes. 98% statistic based on sampling of 1,063 customer service calls surveyed from January 2016 through March 2017. Choose Your Direction Maineline Computer Systems 1-800-354-2525 www.compassmax.com sales@compassmax.com Connect with your customers in new ways with Compassmax Gateway and Digital platforms! Visit us at booth 511 at Clean 2017

Perc users – chlorinated solvent belongs in your machine, not on your board. Alternative solvent users – use stain removers that align with your chosen solvent. Replace traditional POG’s and VDS’s with TarGo® EF and EasyGo®, two of Wilson’s high-performance, cost-effective, California-compliant stain removers. You'll be taking steps to avoid future regulatory and remediation nightmares, while providing your customers with the garment quality they desire!

EasyGo spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to TarGo EF to remove any tough oil based stains that remain behind.

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

Time to Remove

From Your Board! Embrace Your Environmentally Friendly Future with Stain Removers from A.L. Wilson

It's

Chlorinated Solvents

STAIN

at ALWilson.com

use

GreenEarth is a trademark of GreenEarth Cleaning, LLC.

Become a

WIZARD

For GreenEarth,®

||G|| Go®

drycleaner

FEATURES

18

FutureScoop

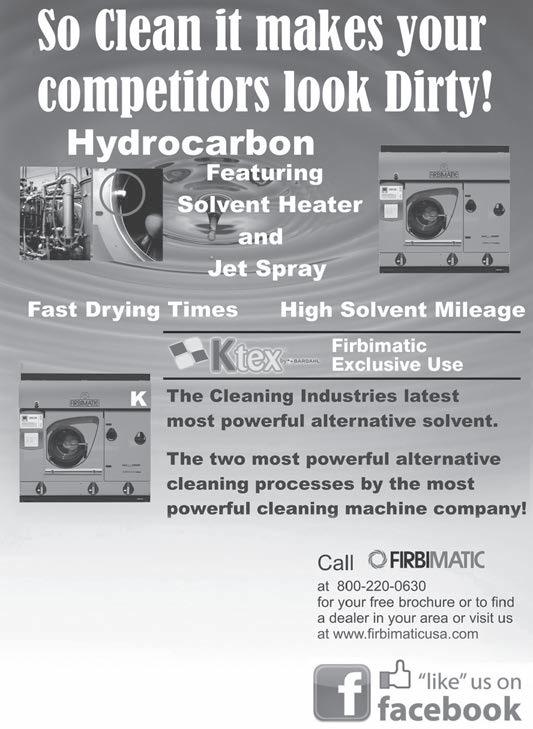

Ever wish you could time-travel a little into the future and see where your business will be? Now you can, as we get the help of your fabricare industry peers and take a trip to the summer of 2022 to check on the pulse of the field, five years down the road. Dry cleaners, manufacturers and association execs share their views of where we’ll be, how we’ll be, and, yes, why we’ll be enjoying continued success.

Tim Burke, Editor

Double Down

“If you have one, you have none,” it’s been said about equipment in this business, says one dry cleaner we talked to about the importance of equipment backup. Many believe in redundancy whenever possible, or at least having parts and the knowledge to fix, so that you don’t lose operating time when a piece of your equipment goes down.

Tim Burke, Editor

NEED HELP FINDING THE HIDDEN HANGER?

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

2 American Drycleaner, June 2017 www.americandrycleaner.com

AMERICAN AMERICAN

DEPARTMENTS Pre-Inspection 4 Tales from the Counter Clean

Exhibitor Additions 16 Management Strategies 26 A Swing and a Myth Diana Vollmer Industry Observations 34 Speedy

Smooth Howard Scott Cooling Towers, Part 1 38 Special feature by

Spotting Tips 46 The Times They Are

Off the Cuff 49 Get to Know:

Around the Industry 50 Advertiser Index 52 Classified Advertising 54 Wrinkle in Time 56 “Summer Cleaning!”

June 2017 Vol. 84, No. 3

’17

’n’

Mike Tatch

A-Changin’ Martin Young

Michael Leeming

6

(Image licensed by Ingram Publishing)

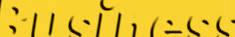

“Business has never been better.”

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

“We’re moving faster. We’re moving better. We’re moving more efficiently. That means profitability”

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

PhilLandauer, OwnerofPierceCleaners has never been better.”

BrentRamenofsky BostonCleaners

Tales from the Counter

We’re here behind the counter with you at your drycleaning store, waiting for your next customer.

Who will come in? What will be said? Will they leave satisfied and happy?

I chatted with a couple drycleaning owners a few days ago, and asked each to share a recent memorable experience from a customer who came in their store.

Lynn Albright, store manager, Pilgrim Cleaners, Apple Valley, Minn.: “A senior customer came in this morning to pick up his clothing and told me he and his wife have been coming to our store for about 20 years. They now live 90 minutes away and they still come here. He was very happy running errands while his wife had coffee with friends, before they headed home. I thanked him. He was terrific.”

Dan Miller, owner, Mulberrys, Minneapolis, Minn.: “At one of our stores, we have a customer who comes in a few times a week. One time, our store manager heard it was his birthday and went out and bought him a small birthday present. He was so grateful for the thought that he went out and bought flowers for everyone in the store a week later. It was just a great moment.”

I guess that’s the personal nature of the business. You’re so close to your customers. You’re trusted to make their clothes, and them, feel great. And you do! (We try to do the same for you in this magazine — give you info and a chuckle!)

In this issue, starting on page 6, enjoy the feature, FutureScoop, which takes you time-traveling five years into the future, courtesy of your peers, to see what your fabricare industry looks like in the summer of 2022.

A second feature, Double Down, on page 18, highlights backup equipment. Also, Part 1 of a special feature, Cooling Towers by Mike Tatch, on page 38, gives you the basics. Plus, read your favorite columnists, a new Off the Cuff, and much more. Turn the page and start reading while you await your next customer...oops, here they come already! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 84, number 3. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2017. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, June 2017

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor

Tim Burke 312-361-1684 tburke@ATMags.com

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Roger Napiwocki

4

www.americandrycleaner.com

Tim Burke

Advisory Board

Contributing Editors

Scott

Vollmer

Young Office Information

312-361-1700 Subscriptions

x100

drycleaner.com PRE-INSPECTION

Mike Bleier Steven Dubinski John-Claude Hallak Mike Nesbit Herron Rowland Fred Schwarzmann Beth Shader Ellen Tuchman Rothmann

Howard

Diana

Martin

Main:

630-739-0900

www.american

FutureScoop

2022: WHAT DRY CLEANING WILL LOOK LIKE

By Tim Burke, Editor

By Tim Burke, Editor

Where were you in the summer of ’22?

That’s 2022.

We’re talking in past tense about a point in time five years from today. But by that time, changes in the fabricare industry that are already forming on the horizon will come to pass. You’ll have evolved your business and adjusted with the market.

That’s not mere time-travel talk. It’s, in fact, what dry cleaners have been doing since cleaning began: adapting with their times. Changing. Creating new dynamics.

Suddenly you’re feeling wobbly...

You grab hold of whatever’s close as you morph into a dream-like state, just like the movies, spinning and dissolving, only this one is so real. You are losing touch with your world, being stretched through a psychedelic time-hole and then somehow, impossibly, you’ve reappeared, and you find it’s summer in the year 2022...

“With rents rising at a rapid pace — along with higher wages, strict environmental regulations and declining sales — the number of plants will drop significantly,” says Bobby Patel, owner of Orange, Calif.-based Kona Cleaners, the business he bought with his family in 1995 and has since expanded to 14 locations.

“I think we will see more of a hub-and-spoke model, central plants serving multiple drop stores and locker locations,” adds Patel, past president of the California Cleaners Association (CCA) and current Drycleaning & Laundry Institute (DLI) board member.

“There will be a shrinkage of cleaners,” he soothsays. “Current owners are getting older and looking to retire. There are fewer buyers wanting to get into

6 American Drycleaner, June 2017 www.americandrycleaner.com (continued)

Come future-casting with us as we hear voices from all across fabricare sharing their views about the shape of our industry to come

(Image

Publishing)

licensed by Ingram

the business.”

And this: “With mil lennials flocking to urban areas, we will see more growth in dense urban areas.”

American Drycleaner reaches across fabricare for opinions to help us scoop our future.

“We will continue to see the bifurcation of the industry between the ‘discount cleaners’ and the ‘fullservice specialists’ as consumers select their preferences based on continually evolving demographic factors,” says Tim Maxwell, president of Kansas City, Mo.-based GreenEarth Cleaning.

“Fashion, income, age, societal trends toward urban ization and asset ownership will continue to play a role in shaping the demands of our customers toward profes sional garment care.”

Maxwell’s company was founded by three dry cleaners with the stated purpose of providing an alternative process to perchloroethylene — better known as perc — by offering a line of environmentally non-toxic, pure siloxane (silicone), drycleaning fluids.

“The market for ‘rental clothing’ has grown beyond traditional ‘formal wear’ such as tuxedos and designer gowns, and ‘work wear’ such as uniform rental, to include a variety of options that encompass the entire spectrum of clothing from casual wear through office and evening wear,” Maxwell says.

“While the requirement for professional care of consumer clothing will always exist, the potential for a portion of the consumer wardrobe to arrive through online subscription services appears to be a market of interest to a subset of consumers.”

Web-based platforms and apps leading to fingertip ordering, tracking, pickup and delivery, he means.

This flavoring of our industry services toward the apphappy youth of today gets to the heart of the matter. We need to serve the young leaders of tomorrow.

“I certainly agree with most pundits that the industry is shrinking but is becoming more specialized,” says Henry Parker, co-owner (with wife Jan) of Safety and Environmental Compliance Consultants Inc. (S&ECC), a Riverside, Calif., consulting firm started in 1993. “We do for the industry what OSHA and EPA require the business owner to do,” he adds.

“Personal laundry will bring new challenges as mil lennials come to need services but not in the traditional marketplace,” Parker says. “They will need more personal

American Drycleaner, June 2017

service. Some will begin to care how their clothes look on them as they progress within their work environment, and those individuals will become drycleaning customers.”

We all recognize a change happening. But is it fair to say it is “revolution” or merely “evolution” we face?

Enter Frank Dubasik, director of U.S. operations for Metalprogetti, situated in Phoenix. The company, which he’s been with since 1999, is owned by an Italian family, and the founder has 50 patents related to conveyors for garment-on-hanger applications.

“Like many of us in the business, I grew up in a family in which dry cleaning was the source of our living. This experience has proven so helpful,” he says.

“In my experience, there seems to be a consolidation occurring in the industry. It is becoming very difficult for the traditional small operator to remain profitable and, as a result, the larger companies are acquiring many of these smaller operations.”

Technology will continue to change the industry land scape, Dubasik says, and he believes that 24/7 kiosks will become more and more common.

“Self-service applications are growing in all different consumer markets. Our technology on the plant side will continue to allow operators to gain efficiencies and im prove their overall profitability,” he notes.

Here in the year 2022, we are seeing market consolida tion — but certain segments growing, too.

“I witness home pickup and delivery routes improving across the country for many of our customers,” asserts Dubasik. “In addition, I believe new, creative and innova tive ways to service customers are essential to keeping dry cleaners from losing market share.”

He indicates that providing consumers unattended pick up and drop-off of dry cleaning in parking lots of major retail developments is an example of progressive thinking. “Realizing customer habits are changing and evolving, it is essential operators are willing to think out of the box.”

FORWARDED

We’ve pulled you forward five years in time, and here you are.

8

www.americandrycleaner.com

(continued)

(Image licensed by Ingram Publishing)

This flavoring of our industry services toward the app-happy youth of today gets to the heart of the matter.

Let’s review what we’ve heard so far. Things you expected: consolidation; more self-service; expanding “personal laundry” convenience. Things you probably didn’t expect: growth in millennials in urban areas; need for even faster adaptation.

So what’s the real challenge of 2022?

“There are fewer pieces to clean, so, in turn, there are fewer companies. More of the individual, ‘mom and pop’ owners will struggle the most. The multi-chain cleaners will be the survivors,” indicates Tim Rees, CFO at Dependable Cleaners in Denver.

Casual care garments are an up-and-coming market due to millennials wearing more wash-and-wear clothing, he notes.

What about perc phase-out? In California, it goes into effect as 2022 comes to an end. Will it spread to other states?

“Yes,” Rees opines, “other states will follow, but slowly. It will happen over time.”

The challenges for the industry will be in finding pieces to clean, since people are not dry cleaning as often, declares Rees. He goes on to suggest that the opportunity for dry cleaners will be in finding more ways to be convenient and accessible to customers, whether that is via an app or through home delivery.

Evaz Fanaian is an electrical engineer with a master’s degree, an entrepreneur in the computer industry since the early 1980s, and owner of Alpharetta, Ga.’s, ScanQ, which delivers point-of-sale software to the drycleaning industry. He believes dry cleaners will need a strong method to engage their customers and create a sense of community to help “future-proof” themselves.

“People expect their phones to do a lot more than just five years ago. Going forward, the public will expect to interact more with their dry cleaners from a mobile device,” he says.

Fanaian thinks that as the marketplace gets more competitive, customer loyalty will play a large part in how dry cleaners engage their customers.

Also of importance is how the typical dry cleaner will adapt to the mobile era.

“There are dozens of new companies that have emerged globally that offer drycleaning services solely through a mobile application,” Fanaian notes. “There is no storefront, and many hardly have any human interaction.”

He alludes to the fact that these types of services are often compet ing directly with the typical dry cleaner. “The opportunity lies in this same change, he says. “Dry cleaners who have mobile apps and are engaging their customers are more likely to be able to thrive.”

Change means finding your way. Refreshing your business model. Again, that word: adaptability.

“For most cleaners, the days of waiting for business to come to them are fading,” relates David Cotter, CEO of the Textile Care Allied Trades Association (TCATA), based in Fairfield, N.J. The Association founded in 1920 represents the interests of manufacturers and distributors of drycleaning and laundry equipment and supplies, as well as related trades.

He notes that to capture business from the younger generation, cleaners will need to offer pickup and delivery services and apps for mobile devices. Also, “Cleaners will find ways to work jointly with coin-ops.”

Cotter says many industries remain concerned about labor costs, particularly with many states raising the mini mum wage. “This will likely accelerate the trend toward labor-saving automation and other technology such as bar codes or radio frequency identification technology (RFID).

“Dry cleaners will also find opportunities by branching out,” he adds, “to offer other services such as rug or blind cleaning, and storage services.”

Cotter believes we will likely see a continued decline in demand for professional dry cleaning.

“The Millennial Generation simply does not consume drycleaning services nearly as much,” he says. “Also, to day’s technology allows more people to work from home, with no need to dress up for an office environment.”

He says that the apparel industry is producing more items that can be laundered at home, such as wrinkleresistant shirts and machine-washable pants.

As a result, “We’ll see more cleaners close or consolidate their central plant, using other locations as drop stores. Drycleaning prices may increase as dry cleaners, with less pieces, will have to stay profitable in order to stay in business.”

However, he also notes that the better cleaners understand how drycleaning services in the last 25 years have changed from a necessity to a luxury.

10 American

June 2017 www.americandrycleaner.com

Drycleaner,

(continued)

(Image licensed by Ingram Publishing)

Signs of things to come are with us. If you’re progressive, you’re reading them and taking action.

Computer Systems Free cordless scanner with our Garment Verification System! SOFTWARE FAST EFFECTIVE AFFORDABLE!& POWERED BY DAJISOFT LET’S WORK TOGETHER: (888) 325-4763 www.dajisoft.com ❱❱ DryClean PRO Enterprise (DCPe) is even simpler to use than before SUPPORT LIKE NO OTHER Ask us about our DCPe Rental ❱❱ Built in marketing and e-mail functionality Designed for both small and large stores THAT IS Visitus atCleanShow Booth724

“A cleaner does not necessarily need to lose those items that can be washed at home, but, like many other services such as car washes and lawn care, the operator must show the consumer that they are saving both time and effort by bringing them to the dry cleaners.”

OPTIONS: GOOD

Gazing into a crystal ball doesn’t just mean having wild visions full of unfounded highs and lows. Signs of things to come are with us. If you’re progressive, you’re reading them and taking action.

“We see the industry evolving into a more professional climate with entrepreneurs orchestrating larger organizations and utilizing technology to manage and reach a larger customer base,” says Poseidon Textile Care Systems co-owners Michael “Stucky” Szczotka and Jeff Quail, who together have more than 70 years of drycleaning and textile care experience.

“While there will be more alternative solvents, water and wet cleaning will lead the way. We also see more operators turning to advanced automation, including tensioning finishing equipment and matching systems,” the men indicate.

Their Troy, Mich., company works with drycleaning and professional fabricare operations to provide plant design services through their wet cleaning machines, shirt laundry plus washers, dryers and ironers.

“If we adapt to the buying habits and culture of the mil lennials, we should grow business,” both men say. “The millennials are looking for greener options, a more casual look and convenience. These things will drive much of their buying and determine with whom they do business.”

Quail and Szczotka add that they are already seeing it happening with home and office pickup and delivery ser vices, lockers, and on-demand services like DRYV.

About perc, they note, “The phasing out of perc will only increase due to new laws and regulations and the increase in solvent cost. In many states, the cost of perc alone has already begun to phase out its use without any new regulations.”

How well dry cleaners adapt to our new world will depend on if cleaners can reset their ways. That, along with the ability to be flexible, will tell all. You might just call it the survival instinct.

“With the shrinking number of pieces being processed on the traditional side of our industry, we as operators must become more efficient and open-minded,” Quail and Szczotka say.

“In return, opportunities will grow for operators willing to change by learning new techniques and adapting to the changing habits of the marketplace. Challenges are oppor tunities. Those that embrace the challenges will make the

most of those opportunities,” they add.

Part of the view of this future world seems to include not only outside forces but our willingness to change with the so-called “prevailing winds.” Youth will be served, it’s often said.

People are not going to suddenly start wearing suits and ties again, asserts Mary Scalco, president of the Laurel, Md.-based Drycleaning & Laundry Institute (DLI).

Her organization exists to help dry cleaners succeed, she says. The Institute was founded in 1883 by a group of cleaning business owners who decided to seek strength in numbers.

Even in church, she points out, “We see people in shorts and T-shirts. Convenience is the key to getting more casual items.”

The Millennial Generation continues to enter the workforce and even outnumber baby boomers, she notes. “They are at the beginning of their professional careers, they are always pressed for time, and they are prime potential customers for wash-dry-fold services.”

Scalco relays this message: “Routes have been growing for some time. The best thing we have to offer the customer is no longer ‘a perfect appearance.’ That worked well in the 1980s, but now the key message is, ‘We’ll do it for you.’”

Can the past teach us about how to go forward, and will we listen to those voices, learn those lessons?

“We have a lot of options today, something that we did not have years ago. Options allow us to tailor our business to today’s and future customers,” says Scalco.

“Styles change and that means we have to change as well. We have to adapt, and options allow us to do that,” she adds.

Steve Davis, the CEO of Jim’s Formal Wear located in Trenton, Ill., seems to concur with many of the industry voices you’ve already heard: “I foresee fewer small opera tors, with consolidation of plants to maximize efficiency.”

Davis believes that some delivery and pickup routes that offer consumers greater convenience seem to be the way of the future. And that operators should think in new ways about how to provide this to their customers: “Lockers, at workplaces or office buildings, is one example of this.”

He notes a theme we know to be true: “Casualization of our society and those lower-maintenance ‘performance fabrics’ are trending in the marketplace today and will likely decrease the need for traditional drycleaning services.”

Operators will need to adapt to remain relevant to today’s consumers.

“While they may have less need for dry cleaning, people are very busy today and look for services that offer conve nience to simplify their lives,” says Davis. (continued)

12

www.americandrycleaner.com

American Drycleaner, June 2017

adapt. These new times will demand it. 2022 isn’t so far off.

“Home delivery laundry service, for instance.”

Cleaners know only too well the actions before them: to be as ultra-convenient with the services as possible.

“Improve the quality of the customer service experi ence as a whole,” advises Richard Atack, vice president and general manager of Chicago-based Barry-Regent Dry Cleaners, a business “that provides quality dry cleaning since 1950.” He celebrates 25 years in industry next year.

“Dry cleaners should look to other industries that pro vide non-essential services for ideas on how to retain cus tomers and elevate the customer experience,” Atack says.

For example, movie theaters have responded to the competition of early release of movies on demand by offering a superior experience.

“Many theaters in Chicago now offer online reservations for plush reclining seats, with upscale food and beverage options, and show digital 3D movies on large screens with amazing sound systems,” Atack says.

The message resounds: Embrace the “new.” Let’s listen to fabricare voices tell us more about the way of the future.

LOOKIN’ AT YOU, IN 2022

Can owners really “future-proof” themselves and their businesses? Not really. That’s the truth. Someone wise said the future is promised to no one. But owners and op erators can prepare for what’s next and take action now.

“I see a lot of businesses making a mistake by milking the business to death and not putting anything back in the business,” Patel says. “I also see that most cleaners have no budget for marketing.”

But he says he sees a bright side to the future: “I see a huge opportunity for cleaners that want to expand by acquisitions. The cleaners are selling at a much lower multiplier.”

Maxwell sees this five years from now: “We have seen that if we focus on providing solutions for challenges the industry faces by including the needs of our constituent groups, such as landlords, garment manufacturers, regula tors, and the consumer, we can be viewed as a coopera tive and vital part of the garment life cycle.”

Challenges will be in manage ment decisions that affect the fu ture of each business, Parker says. “Changes that are occurring in the industry must be dealt with pro gressively. My observation of the younger owners and operators: they are thinking in new ways.”

Having been in the industry for nearly 20 years, Dubasik says, “I realize many dry cleaners are reluctant to change. Of course, aren’t we all. Routine provides us everyday comfort but at the same time, if we are not aware, it will hinder our growth and cause us to lose opportunities.”

Dubasik sees his work “as a calling versus a job,” add ing, “I believe (self-help author and speaker) Dr. Wayne Dyer said it perfectly: ‘If we change the way we look at things, the things we look at change.’ Progress demands we open our ‘real eyes’ and ‘realize’ the possibilities.”

The fact that the drycleaning industry is ever-changing means you have to change with it to stay competitive, notes Rees. Just being a brick-and-mortar business is not enough, he indicates.

“Equipment is becoming more technologically advanced and we have to stay on top of the technology changes to offer the best service,” he says.

Fanaian reminds of the need to embrace technology, which is always changing. “Those who are in the fore front have a better chance of surviving and thriving.”

Cotter says that cleaners must find and keep good and productive employees, as well as increase their customer service to differentiate themselves from their competitors.

“The cleaners who will survive will be financially astute — this means they understand their real cost of doing business,” he adds.

Ringing true now and certainly five years from now, Szczotka has a word to the wise: “Be certain of nothing and open to everything. The only thing that is for sure is change. So be willing to change.”

Quail implores that the greatest lesson he’s learned is “there are many different ways to get the job done. Our job is to provide the tools most needed by textile care pro fessionals in order to meet their customers’ expectations.”

“We have seen boom and bust in the industry since 1883,” Scalco reminds. “In our experience, best practices never really change. Learning best practices helps clean ers reduce costs and increase productivity.”

“I expect the traditional drycleaning side of the industry to further shift from being a necessity to being a luxury,” says Atack, yet notes, “Every challenge is an opportunity in disguise.”

14 American

June 2017 www.americandrycleaner.com

Drycleaner,

(continued)

(Image licensed by Ingram Publishing)

So you’ll

“The only thing constant is change,” adds Davis. “Instead of fighting and resisting, operators must learn to adapt, embrace change, and find new ways to profit from it.”

Profit. There’s the magic word to close the futurecasting session. Profit to stay in business. To do well. Operators continually relearn how to satisfy customers and meet new cleaning needs wherever they are and in so many ways.

You’re feeling wobbly once again — 2017 is pulling at you...

Hold on! You’re spinning and dissolving back through the time-hole as it draws you back home. Images float past: your dry cleaner morphs into an app and that app becomes your web platform and that web platform becomes your delivery service and...

You’re back. The trip wasn’t bad. In fact, you understand the goal, since voices from fabricare’s future helped you: Change with the market, they said, and thrive, like you always do.

So you’ll adapt. These new times will demand it. 2022 isn’t so far off. ADC

EXHIBITORS 2017

The following companies and orga nizations reserved exhibit space in the Las Vegas Convention Center for Clean ’17 during the 30 days ending May 12, according to show manager Riddle & Associates.

At press time, the total number of exhibitors exceeds 470 (see our May issue for the initial list); it’s possible that more exhibitors will be added leading up to the June 5-8 event.

Where available, the general descriptions of products and/or services are provided.

Listings subject to change. Check www.cleanshow.com for any updates.

Export management firm specializing in commercial laundry, drycleaning, boilers and related equipment.

❏ Expo Enterprise Inc. 560

F

❏ First Dry Clean, Inc. 3707 Laundry and dry cleaning app.

❏ G&I Innovation 3532

❏ Global Retail 1394

GH

❏ Movexx 625 Electronic tuggers; push/pull assists.

P

E❏ Press Cleaners 3384

App and pickup/delivery service for dry cleaning, laundry.

S

❏ Specialty Adhesive 662 Film Co. Heat-seal adhesives for laminating, coating/bonding.

❏ Sysmetic 1295 Software solutions.

❏ Air & Water Systems 3534 Industrial humidification and evaporative cooling equipment. B

❏ Brother International 561 Corp.

Sewing and embroidery equipment and supplies; labeling systems.

C

❏ Clenacorp 3577

Specialty lubricants; ironer tapes; surface cleaners.

❏

Conf Industries S.r.L. 3703 Hampers; cabinets; basket liners/covers.

D

A❏ Howfleet, trading as 461 Uniform Depo Inc. Apparel.

J

❏ JS Fiber Co. Inc. 247 Hospitality and healthcare bedding products.

K

❏ Kohinoor Mills LTD 255 Dyeing Div. Dyed fabrics.

M

❏ Main Street Hub 361

Online social media management services.

❏ Mazars USA LLP 446

T❏ Team Products 1398 Laundry detergents and chemicals.

❏

Thermaseal, Inc. 345 Labels.

U

❏

Ultra Soap International 3701 Laundry chemicals and cleaning products.

W

❏ Weifang Kangle 1697 Plastics Co., Ltd. Bags of various types.

X

❏

D.J. Giancola Exports Inc. 1620

Cost studies/profitability analyses for textile rental companies.

American Drycleaner, June 2017

❏

Xia Fang Hanger 3700 (Cambodia) Wire hangers, supplies.

16

www.americandrycleaner.com

ADC

DOWN Double

By Tim Burke, Editor

By Tim Burke, Editor

Zach Kinzer, general manager of Bridgestone Cleaners in Brooklyn, N.Y., remembers the day the man came in.

“A really slick guy came in trying to sell one thing or another and said something which stuck: ‘If you have one, you have none.’ In dry cleaning, I am not sure there is a better lesson to learn. If you don’t learn by actively implementing redundancy, the industry will teach you one way or another down the line.”

Since starting with his dad, Ken, in late 2008 (the father has been in the business since 1982), Kinzer

says they’ve experienced many situations in which plant redundancy, or lack thereof, has either been a godsend or a lesson learned.

“Traps, supplies, machines,” he points out, “if you have these things, you certainly can be helped by having two.

“Now it’s obvious not all operators have this luxury. A drycleaning machine is not something you go and buy at The Home Depot. For that situation, I would say you need to build redundancy through an active plan.”

If his machine goes down, Kinzer explains, he has a relationship with

“Mr. Smith” — what he calls a buddy in the business — who can help in a pinch.

“We currently operate with two drycleaning (machines) and two wetcleaning machines,” Kinzer says. “We once had to use only one drycleaning machine for over a year due to mechanical issues. We learned how to become more efficient and felt blessed once the other was back up and running.”

“Backup equipment seems like a waste of money until you need it,” says Gary Kite, who owns Kite’s Custom Cleaners in Fort Worth, Texas. “And when you (continued)

18 American Drycleaner, June 2017 www.americandrycleaner.com

Better Than None! Zach Kinzer and his dad, Ken Kinzer, at their Bridgestone Cleaners store in Brooklyn, N.Y., operate with two drycleaning machines and two wetcleaning machines. (Photo: Bridgestone Cleaners)

Backup equipment prevents lost operating time

US Machinery 5129 Powder Mill Road Beltsville, MD 20705 Phone: 301-345-8437 Email: usmachinery@gmail.com See us at Booth #1373

need it and don’t have it, you quickly find out that it’s not such a waste of money.”

Kite is a second-generation owner and operator. His dad, Sam Kite, started the business in 1958. Kite’s Custom Cleaners serves what he calls higher-net-worth households, offering, “the usual services in addition to a rug cleaning division, an Association of Wedding Gown [Specialists] affiliation, and delivery routes,” he says.

“We have had instances where our main air compressor has been down for some reason and we’ve had to rely on our old air compressor, which remains hooked up and ready to go at a moment’s notice. We do have a second shirt unit that is used every day, but we can get by with one in a pinch,” Kite adds.

His plant has multiple finishing stations for all drycleaning and laundry jobs so finishers are always able to move to an operable station. But it does not have a backup boiler: “The cost of another boiler, plus the room needed to house it, would be impractical at this time.”

Lack of backup equipment can present challenges, he says.

“Our point of sale (POS) system is totally hosted, which means when the Internet goes down, everything goes down. We used to have a second Internet protocol

If a key piece to your business — like your boiler — goes down, and your plant has no backup, you can find yourself dead in the water.

(IP) service as a backup, but lost it a couple of years ago.

“Also, we use auto-assembly,” he says. “When it goes down, our whole assembly is pretty much shut down. Trying to assemble with only bar codes and no auto-assembly can be very disruptive.”

Kite believes that having backups for key production equipment is vital to being able to provide on-time service that customers expect.

“Nearly all of our business is two-day turnaround,” he says. “Equipment breakdowns only back us up shortly. Most often, any machine can be repaired and put back into service within a day. It seems there is al ways some piece of machinery that needs some sort of maintenance.”

BACK IT UP

There will come a time when your backup equipment

American Drycleaner, June 2017

will prove to be essential.

Enter Andrew Tirpok III, owner and president of Tirpok Cleaners in western New Jersey. The company was founded in 1936 by his grandfather, Andrew Tirpok Sr. In 1976, his father, Andrew Tirpok Jr., bought the company, and then Andrew III purchased it from him in 2005.

“We are an operation that has had up to 15 locations in the past. My daughters are currently working with me and will be the fourth generation,” he explains. (Editor’s note: After Tirpok was interviewed for this story and shortly before this issue went to press, Tirpok Cleaners’ Flemington, N.J., plant was destroyed by fire. At press time, he had nothing to add when asked about future plans for the location.)

“I wasn’t planning on getting into the business, but life doesn’t always go where you expect. After I got my master’s degree, my wife and I had a baby on the way, and I started working for my uncle in the business with a five-year-plan to grow his three stores and get out. That was 1993, 24 years ago.

“We have two vacuums and three compressors. We have a rotary compressor and it takes both of the others to replace it when it’s down. We have two drycleaning machines; a third would be good. We have extra presses, two spotting boards, multiple washers and dryers. It’s good to have 9,000 square feet [of operation space].

“A few weeks ago, the rotary compressor went down and we had to run on the backups for three days waiting for the service mechanic to come out. Also, we recently had a bearing go on a washing machine. Fortunately, we have four other washers we can use.” (continued)

20

www.americandrycleaner.com

Be Prepared! A “boiler backup,” like this example the editor found at Mike Bleier’s Drive Cleaners in the Chicago area, stands ready in the foreground should the working boiler in the back go down. (Photo: Tim Burke)

See it at the Clean Show - Booth 1385 Toll Free (877) TREVIL 1 www.TrevilAmerica.com P.O. Box 127 - Mamaroneck, NY 10543 Telephone (973) 535-8305 E-Mail: info@trevilamerica.com INTRODUCING PRESTOFC PANTASTAR PRINCESS ULTRA NO MORE SHINE Tensioning Blouse/Shirt/Jacket Form Finisher • Sizes From 0 Petite To 3 XL and larger • Blouses, Shirts, Jackets, Labcoats - Wet or Dry • Dual, Rotating Front Clamps (Patented System) • One Heated For Wet Shirts/Blouses • One Unheated For Drycleaned Shirts/Blouses • Front Clamps Pivot & Rotate No Need To Disconnect & Store Unused Clamp The first machine that can finish the entire pair of pants INCLUDING THE CREASE with one operator at a level of quality superior to conventional equipment • For All Types Of Pants: - Creased Or Uncreased - Pleated Or Unpleated - Men’s Or Ladies’ • No Experienced Operator Needed • Requires Less Floor Space Than Conventional Equipment • Rotating Cuff Clamps For Creased/Uncreased/Flat Front Finish Single Buck Hot Plate Shirt Finisher • Full Length, PTFE Coated Plates • No Shine Cuff Placket Presses • Rear Tensioning With Vacuum & Pull Down • Sleeve Angle Adjustment • Top Hood Removes Heat From The Work Environment The Future Is Here!

Tirpok remembers a crisis a few years ago when a controller on his boiler failed New Year’s Eve morning.

“We couldn’t get anyone to come out and service it that day, so we lost production on a very busy day and couldn’t promise any same-day work. It was horrible,” he recalls.

“I had to drive an hour and a half to get a part from a distributor. We still lost the day, but at least we were able to start up again the next operating day. It totally ruined my New Year’s Eve. I definitely would like to get a second boiler at some point.”

The benefits of being prepared for these situations are clear, as he discovered.

“It’s important to me to have backup equipment for as many machines as possible,” Tirpok says. “If one breaks down, we can switch to the backup until it’s repaired. As the primary mechanic here, I like that I don’t have to worry about the pressure while I’m waiting for parts.

“Also, we do a lot of same-day work. If we had to wait for parts to make repairs, we wouldn’t be able to keep

our promise to our customers that their work will be done on time.”

Tirpok’s word to the wise?

“If you can’t have a backup, keep a well-stocked tool room with parts that commonly wear out or break, and learn how to maintain your own equipment.”

THE LIFE YOU SAVE

If a key piece to your business — like your boiler — goes down, and your plant has no backup, you can find yourself dead in the water, as this owner once found out. Dave Suber is the owner of Perfect Cleaners located in West Los Angeles, Calif. He is a third-generation dry cleaner from Michigan, and a 1983 graduate of the Drycleaning & Laundry Institute’s (DLI) three-week general course, who has been operating his cleaner in West L.A. since 1999.

“We have two full plants about four miles apart with a nice route business serving West Hollywood, Beverly Hills, Bel Air, Brentwood and

22 American Drycleaner, June 2017 www.americandrycleaner.com

Don’t Lose Service Time! Gary Kite owns Kite’s Cus tom Cleaners in Fort Worth, Texas. Kite says having

(continued)

backups for equipment is vital to provide customers with on-time service. (Photo: Kite’s Custom Cleaners)

a soft touch for the most delicate wetcleaned textiles

Developed to quickly and efficiently dry wetcleaned textiles without damage or wrinkling, the Poseidon Dryer eliminates air drying for catapulted productivity and unsurpassed results. Offering advanced programmability, it safely removes residual moisture from even the most delicate wetcleaned fabrics. Smart engineering not only ensures a quick dry, it brings superior efficiency, durability and a soft touch.

The Poseidon Dryer works in concert with high-performance Poseidon Wetcleaning Machines and Flatwork Ironers for unrivaled results.

Professional fabricare operations rely on Poseidon to perfectly wetclean the most delicate items including tailored wool suits, cashmere sweaters, silk wedding dresses, camel hair sport coats, taffeta prom dresses, knit skirts and so much more. Poseidon offers innovative programmability for complete control over every conditional aspect of the wetcleaning, drying and ironing process.

POSEIDON

www.poseidonwetcleaning.com 800-482-3400 • 248-457-1140

Santa Monica.”

Suber believes that whenever possible, one should have equipment redundancy to ensure that a plant will never be completely down.

“Years ago, the sight glasses broke on my boiler and sprayed water all over the boiler room, shorting out the electrical controls on the boiler as well as the motor on my vacuum. Since that incident, I have moved the vacuum out of the boiler room. But I was down for a couple days and had to ask a competitor to help out,” he says.

In another instance, Suber relates how backup equipment became a lifesaver.

“I had the piston heads go out on my air compressor and was able to switch to our alternate compressor. I recently had a pinhole in one of my steam coils. Thank

God I have two cleaning machines. We got behind, but were still able to get the work done.”

Suber has backups for his cleaning machine, air compressor, vacuum, washers, and presses.

“Do not put your vacuum or air compressor in the boiler room, and try and have two of everything,” he advises.

Tirpok offers some wisdom to consider: “You should always have a backup for as much equipment as possible. You never know when some $3 part is going to shut down production for a day.”

And Kinzer adds this cautionary tale: “There are too many times to count where a random part in our plant has broken and I did not have a backup.”

He sends a sound message to owners to take their backup equipment and parts seriously.

“I am currently the GM at my cleaners and I am proud to say that I just replaced a check valve on our spotting board, walked to the office, and ordered a backup. Lesson learned.”

24

www.americandrycleaner.com

American Drycleaner, June 2017

ADC

The Redundancy Reminder! Dave Suber is the owner of Perfect Cleaners located in West Los Angeles, Calif., and believes in redundancy on all equipment, when possible. (Photo: Perfect Cleaners)

Dave Suber

PM-470U Semi-Automatic PS-290U Automatic PS-290HU Industrial Automatic ~Jan Caon Barlow, CED, CPD, CPW Jan’s Professional Dry Cleaners W hat a blessing! e PS290U auto bagger from Sankosha is a dream come true! We started barcoding shirt laundry and dry cleaning with auto assembly before all the best places for barcodes were discovered.

labor savings

barcoding

We

labor savings we

and

“ •Increases Your Profits & Efficiency •Easy to Add to Your Production Line •Loads from Either Side Screw Conveyor Parts c ustomerfirst supremeQualit y THEhigher standard http://www.sankosha-inc.com 1901 Landmeier Rd., Elk Grove Village, IL 60007 TOLL FREE: (888) 427-9120 • TEL: (847) 427-9120 ... ALL IN PERFECT BALANCE Visit us at Booth #1347

As the economy changed, the

from

was wonderful.

didn’t realize the additional

would immediately realize with the PS290U. Adding the PS290U has made IAB Inspection - Assembly Bagging, a ONE person job! is addition has saved my company time, money

labor.”

A Swing and a Myth

Nine beliefs you thought were true, but they’re not

Industry myths can wreck your business.

It is human nature to repeat past behavior. Creatures of habit are less susceptible to day-to-day risk because they fall into safe habits that have proven to be sustaining in the past. But what about relying on these old habits and traditions in the future?

Can established behaviors and practices be relied upon indefinitely to keep you in the ranks of the survival of the fittest? If it isn’t broken, should you try to fix it?

Let’s ponder together a few established and widely accepted beliefs that have proven dangerous to operators who assumed them to be true and inviolate.

Several cleaners have demonstrated that these accepted beliefs are, in fact, actually myths that have impeded growth and profitability for many in the industry.

Myth #1 – All dry cleaners have diminishing piece counts

In fact, a large number of operations have proven that piece counts can grow significantly with proactive sales and marketing efforts that dramatically increase the number of items being processed.

These efforts are not relying on discounting, but rather on informing customers and prospects of the many services that the cleaner can provide to improve consumers’ quality of life.

Do your current customers all know that you can provide any or all of the following services in addition to keeping their

wardrobes beautifully maintained?

• Save them time with route service to their door;

• Save money and the planet (professional cleaning uses less water and utilities than home washing);

• Make household linens look fresh as new;

• Take drapes down, clean and re-hang them;

• Do the family laundry, to free up time to enjoy the family;

• Clean the muddy rugs inside and out;

• Clean the muddy Uggs that have hiked all about;

• Eliminate Fido’s hair and odor;

• Clean patio cushions for summer readiness;

• Eliminate the musty smell from the RV, cabin, boat or plane;

• Restore the disgusting floor mats to fresh and clean;

• Care for specialty garments from christenings to life celebrations;

• Preserve the memories of life’s highlights;

• Clean sports gear;

• Rejuvenate a favorite handbag or leather garment; and

• Repair or alter garments.

How do you convey this knowledge to your customers and prospects?

Is your team really trained to share this information with your

MA NA GE M ENT S TR A TEGIE S

26 American Drycleaner, June 2017 www.americandrycleaner.com

Diana Vollmer (continued

on page 31)

(Image licensed by Ingram Publishing)

Get SMRT POS Perfected Use your hardware

Re orts are out o date the moment they’re run o MRT invented customiza le re orts or every decision ma er in your usiness The result: instant accounta ility and clarity e he n mbers yo an hene er yo an

F lly in e ra ed o r n yo r b siness sa e ime and ma e ban From ron door o ac o ce, and even on routes, MRT is here or yo no ser e ee and ro yo r s omers i h o er l beha io ral mar e in real ime s a s and seamlessly in e ra ed omm ni a ion ools ee yo r da a sa e i h ind s ry leadin se ri y en ry ion hrea moni orin and de e ion

Don’t worry MRT nows where everything is MRT will tell you i you’re ood o o or hen yo need o ran i Yo r s omers an ra orders s hed le i and deli eries see heir online ardrobe ma e aymen s da e ersonal in o and omm ni a e i h yo dire ly

od ie s ma hine learnin and ash bo se ri y roo o em loyee he and dri e a o n abili y

SMRT was the best investment I could have made. My only regret is that I didn’t do it sooner.

Kathy Benzinger

Owner: Benzinger’s Dry Cleaning

This is next generation stuff. When I saw it, I loved the way it looked. When I started using it, I knew it was a ten out of ten.

Jason Yerby

Vice President: Crest Advanced Dry Cleaners

MEURICE GARMENT CARE

SMRT is light years ahead of the competition! We’ve never been so on top of our business and in tune with our customers.

Wayne Edelman

Owner: Meurice Garment Care

I love SMRT more each day; it’s capabilities, and their support is awesome. There’s always a real person there to care for us.

Brian Fish COO: Pier Cleaners

Automation, robust KPI’s, easy customer access, instant Metalprogetti integration, text messaging... in one simple-touse package. All I can say is, get SMRT!

Richard Aviles

Owner: Bridge Cleaners & Tailors, King Garment Care

STRATEGIES

targeted market? Do they ask leading questions to identify the customer needs?

Are automatic periodic reminders sent to let consumers know that it is time to clean a specific item that hasn’t been cleaned since a specific date?

If these things are systematically being done, your team is the rare exception to the norm.

Myth #2 – Giving customers what they want, when they want it, can’t be profitable

The reality is that customers can get what they want when they want it from some provider. If you don’t supply the preferred alternatives, someone else will.

The rather famous entries and exits from the industry may not have found the perfect solutions for execution, but they have planted the seed of desire and possibility for instant gratification. Step out of the mindset of “This is how we do it.”

Expand your thinking beyond the past and test ways of doing things until it works for the customer and for you. Amazon is a constant “tester” and it continues to grow. One of its tests that was successful enough to expand is strategically and conveniently located “on-demand” lockers.

Competitors are emulating them as well, offering customers newfound convenience and access 24 hours a day.

Myth #3 – My staff will quit if we send them home when the day’s work is complete

Your staff wants to be successful and for that to hap pen long-term, the company must also be successful. Redesign your staffing schedules to meet production demand and customer traffic. Flex hours and job shar ing have been successful approaches to on-demand staffing.

Milking the clock is bad for productivity, bad for mo rale and bad for profitability. If your staff is too large for your workload, reduce it by eliminating the least productive employees to right-size the labor force.

Myth #4 – If I pay more, I will get what I want from my team

If the team is not properly trained, you will just pay more for the same mediocre results. Training is

essential to continued growth in sales, profit and expertise.

Consumers are a sophisticated lot, and the best drycleaning customers are especially discerning. They cannot be properly served by staff that has no knowledge of, or appreciation for, fine textile care. Attention to detail is the mantra for serving the luxury segment that we assist in our business.

Question: Do you spend at least 1% of your revenues on training? If not, it is time to budget for this necessity.

As an example, Rent the Runway, one of today’s fastest-growing fashion and service businesses, has one in-house full-time trainer for every 10 employees. What is your training ratio? Your training plan?

Do you rely on “on-the-job training” done by an em ployee with other primary duties and who probably also has bad habits you don’t want to perpetuate? Professional training is essential to a positive customer experience and a loyal clientele.

Myth #5 – Traditional presses provide the best finish

It is true that traditional, professional finishers can do a beautiful job with a standard press. It is also true that the traditional, professional finisher is becoming more and more scarce.

In the absence of a reliable and affordable pool of this rare person, industry suppliers have been innovating to create equipment that will supplement lack of skill with better finishing despite lack of expertise or proficiency.

Tensioning presses, up-air features, laser indicators, auto-timing, computerization, intelligent robotics, advanced steam tunnels and smart sensors are all helping to improve performance in the finishing arena and beyond. Be sure to explore the new alternatives available at the Clean Show.

Don’t let your past experience and historically pro fessional staff cloud your future acceptance of these advances.

Using the Rent the Runway experience

MANAGEMENT

www.americandrycleaner.com American Drycleaner, June 2017 31 (continued)

Examine your beliefs and test their current validity.

MANAGEMENT STRATEGIES

again, 97% of the garments shipped in their proprietary shipping pouches to customers for immediate wear are fin ished in a state-of-the-art steam tunnel only and are not touched with an iron or press.

Of course, these beautiful garments are carefully selected for fabric content and construction, but more importantly they are chosen for customer preference in design.

They are being shipped to your customers who are the most fashion-conscious consumers across the country, and the company is growing exponentially, so customers must be happy with the service.

Myth #6 – My main competition is the home washer

I contend that the main competition is backward think ing. Most people still wear clothes daily, most of them like their clothes to be clean and presentable (to fit their standard or definition), and most of them are busier than ever, even if the “busy” is caused by gaming, Snapchat, or hanging out with friends.

Laundry is not the favorite pastime of most. You can free your customers to pursue endeavors that are of higher value to them.

The generation that doesn’t own a car is not likely to be excited about owning a washer/dryer or an iron, and a needle and thread is a totally alien concept. They hire oth ers to do the things they don’t want to do and if you don’t believe they can afford it, research current income by con sumer segment.

Myth #7 – Fashion trends are working against the drycleaning business

The prevalence of active fashion adds to the myth that today’s consumer no longer needs or wants your services. In fact, that ultra-revealing athleticism, and egocentric outlook that drives it, requires even a better fit and mainte nance than traditional street wear.

For example, the majority of Lulu Lemon garments are altered professionally prior to wear. The return to cotton, linen and natural fabrics in general will drive even more business your way as consumers realize that quality fabrics need quality care that cannot be accom plished at home.

Growing incomes provide more so phisticated experiences and a greater appreciation for truly luxurious textiles and service.

Myth #8 – Word of mouth has always been, and will always be, enough to sustain my business

Historically, word of mouth has been the most effective promotion because an endorsement is more persuasive than an advertisement. However, in an ever more competitive and creative environment, organic recommendations are not enough of a competitive edge.

The good news is that personal endorsements and favorable ratings can be leveraged by amplifying and multiplying the impact many times over through social media and effective networking. Take the proven concept and expand it to your advantage.

Myth #9 – Cutting the marketing budget is the easiest way to decrease expenses and increase profits

Consumers need a continual, meaningful (to them) dialogue with their service providers. There is nothing more personal than one’s own wardrobe.

To communicate with your customers on a timely and appropriate basis is a full-time job in itself, and that is in addition to letting the general market know who you are and what you can do for them.

Your customer base includes a core that is generally reliable and loyal, but you must stay relevant to them and attract additional prospects as well to thrive as a company.

Whatever form your marketing mix takes, promotion is necessary to a dynamic, ongoing, profitable business.

Examine your beliefs and test their current validity. Owners that want to continue to improve sales and profits must focus attention on alternative operational improve ments that are proving successful, both inside and outside the industry and the traditional norm.

As with driving, looking only backward is dangerous.

Diana Vollmer is a managing director for Methods for Manage ment, which has served dry cleaners and launderers with af fordable management expertise and improved profitability since 1953. For assistance overcoming outdated industry myths, e-mail dvollmer@mfmi.com or call 415-577-6544.

32

www.americandrycleaner.com

American Drycleaner, June 2017

ADC

Whatever form your marketing mix takes, promotion is necessary to a dynamic, profitable business.

garmentmanagement.com (501) 420-1682 Come see what’s NEW in Automated Assembly! FINALLY, the best AROUND-THE-CLOCK SERVICE for DRY CLEANING! See the redesigned QuickSort System with “RAPID MOVE TECHNOLOGY” ! Visit us at CLEAN ’17 - Booth 1321 INTRODUCING

Speedy ’n’ Smooth

Counter help’s speed is essential. What is the truly annoying aspect of your service? What drives a customer crazy?

What makes customers walk out of your shop with a bad taste in their mouth? ... Slow counter staff.

Let me repeat:

S-l-o-w C-o-u-n-t-e-r S-t-a-f-f.

With a slow counter staffer, most customers think, Why is this girl so slow? Doesn’t she know what she’s doing? Was she just hired yesterday? Doesn’t she realize that I have a lot of things to do? What’s wrong with that guy? Doesn’t he know that I’m a busy person?

If you have extremely fast, to tally experienced, highly competent counter staff, you do not need to read this column. But for the other 90% of you, read on.

Fortunately or unfortunately, we live in a fast-paced world. Everyone’s busy. Everyone has a lot of tasks. Even those who don’t work have all kinds of activities. So there is a potential rage factor when someone seems not to be working at full effort.

There is exasperation when someone is unsure of what they’re doing. There is dissatisfaction when a staffer interrupts the dealings with you and responds to another conversation going on.

There is annoyance when a counter staffer doesn’t sense that the customer is impatient and clearly wants to finish the encounter and leave the store.

There is anger when the counter staffer opens the cash register and has to tear open a roll of quarters. “Why didn’t the employee open the roll after the previous transaction?” the customer mutters.

An impatient customer experiences strong displeasure when a counter staffer starts off by babbling about what a nice day it is.

I know this feeling well. We winter in the Bahamas (we can’t take the Boston winter), and while we enjoy

ourselves tremendously, our blood pressure rises any time we have to deal with a store clerk.

Although they are fine people, they have no sense of time. They are glacially slow. They chat and dawdle as if there was all the time in the world. They have extra procedural steps, which are completely and entirely unnecessary.

When there is an issue, they stare and look as if it was something they had never seen before. It’s only then that they call over the manager. When they need help, they never say what’s going on.

Even though we don’t do anything constructive there, it’s annoying to see clerks so inefficient. With a shrug, we say, “It’s Bahamas time.”

To give an example of Bahamas time and wasted, unnecessary effort, most transactions are done with the clerk writing out a three-part receipt

34 American Drycleaner, June 2017 www.americandrycleaner.com

INDU S TRY OB S ERVATI ONS

Howard Scott

(continued)

Cool and in control at the counter is crucial

(Image licensed by Ingram Publishing)

INDUSTRY OBSERVATI O NS

after taking the money.

They often have to look underneath the cash register for the pad. They feel everything, including product numbers, must be included, and they turn the box around until a number is spotted. If they get in a tangential conversation, it might continue for several minutes.

If you say you don’t need a receipt, they insist that it is necessary. No en counter occurs without a lot of laughter and joking around. Indeed, it is the charm of Bahamas that time is at a standstill.

At the same time, it is a curse we must bear.

So beware. Make your counter staffers speedy. Make sure he/she has all the tools at arm’s length.

After you’ve trained them to move fast, make them super-fast. Every new employee who deals with the public must be made aware of the importance of being quick.

Any distraction while interacting with the customer (talking to a co-worker, kidding with a customer in another line, turning off a personal cell phone when called, and asking questions of another staffer) is forbidden.

Each encounter should be a seamless event. Eyes should be focused on the job at hand. Arm movements should be minimal. There can be no munching on an apple or chewing a cookie. There can be no looking away from the transaction. Hands must move fast.

Occasional eye contact is necessary. Perhaps the best way to say it is that a counter person should have the concentration of a person facing the firing squad.

That doesn’t mean a counter staffer can’t talk or even kid around. If the customer wants to engage in conversation, he or she can do so. But perhaps it is better to finish the transaction, and then the banter can take place.

This “getting business done first” also reduces the chance that an error is made. It also helps that the counter staffer gains time to gauge the customer’s mood.

SPEED THRILLS

After the transaction is completed is the time to chat.

This might mean that you will have to light a fire underneath some counter staffers. Many work at their own pace and that isn’t sufficient. Many have no sense of being slow.

Many don’t realize that they are annoying customers

with their relaxed movements. Many don’t even grasp the notion that time is important and that dawdling is bad.

Certainly, all new hires must be indoctrinated to the gospel of speed. Because they are not familiar with the procedures, they will tend to be slow.

When something unusual occurs (a customer complains about a stain that hasn’t been removed), they will not know how to respond.

This means that they must be told that speedy encoun ters are the No. 1 priority. You must also give staffers enough training so that they can handle common contin gencies.

To get your crew of counter staffers up to snuff, you must observe them in their customer dealings.

Watch to see if they are focused. Do they move fast enough? Perhaps you might establish time standards for different operations.

If your counter staffer is supposed to perform a pickup transaction in a minute and a half, see that they comply by using a stopwatch to time them. If they don’t comply, have them do the task again and again until they pass grade. Be a speed proselytizer.

Frankly, anyone can be taught to work faster. Some individuals might have a predisposition to working slowly, but if the slowness is pointed out and worked on, those people can greatly increase their speed.

Indeed, half the battle is pointing out that a counter staffer is slow and that this is annoying to customers.

At the same time, upping the speed doesn’t mean that the counter staffer is robotic, automaton-like, frenzied. That behavior will scare the customer away.

One can be fast and still comfortable. It’s a matter of focus and concentration. That is the gold standard you re quire of all your employees who interact with customers. Make sure your counter staffers are all up to your standards of speed, and eliminate/minimize customer annoyance at the counter. ADC

Howard Scott is a longtime industry writer and drycleaning consultant. He welcomes questions and comments, and can be reached by writing him at Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027, or via e-mail at dancinghill@gmail.com.

36 American

June 2017 www.americandrycleaner.com

Drycleaner,

One can be fast and still comfortable.

It’s a matter of focus and concentration.

IN THE SERVICE OF OTHERS A COMMUNITY CHAMPION

BY WAY of GREENEARTH CLEANING

Paul White represents all that is good in American business. For not only does his company, Roth Cleaners, provide environmentally non-toxic quality dry cleaning and jobs in Midland and Bay City, Michigan, but he helps others everyday. The Council on Domestic Violence and Sexual Assault, Rotary Club, Mobile Meals, Blessed Sacrament Parish and Midland Public Schools are just some of the organizations where Paul and his wife, Kim, serve as volunteers. “We are committed to building strong families and safe communiities where we live and work”, says Paul. On behalf of the GreenEarth Family, thank you, Paul, for all you do for others!

PAUL WHITE / ROTH CLEANERS PRESIDENT

PAUL WHITE / ROTH CLEANERS PRESIDENT

TOWERS COOLING

for Dry Cleaners

All the basics you need to know (first of a two-part series)

By Mike Tatch

By Mike Tatch

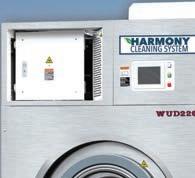

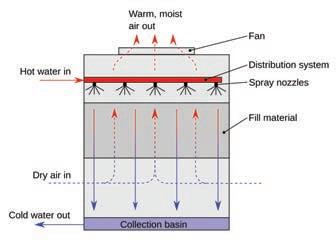

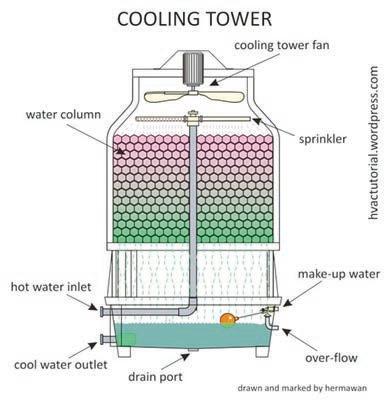

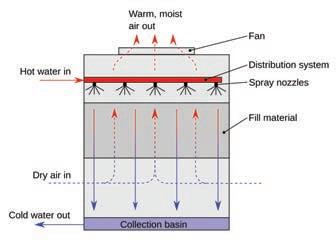

CDooling towers are a relatively inexpensive and dependable means of removing heat from drycleaning machines (DCM). There are other ways to cool your equipment, but if you are paying for electricity and water, a cooling tower is often the most economical.

Cooling towers use the outside air to cool water that is circulated through the DCM’s refrigeration heat exchangers, still condensers and/or solvent coolers.

In an evaporative cooling tower, some of the water being cooled evaporates into a moving air stream. When water evaporates, it removes lots of heat from the rest of the water. Each one pound of water that is evaporated removes approximately 1,000 Btu from the system.

Water lost through evaporation is replaced by what is called “makeup” (city water). Removing heat by evaporation is highly efficient. That’s why you can cool a large

amount of water with only a small amount of evaporation.

COOLING TOWER SYSTEM

A “cooling tower system” might seem complicated, but it’s not.

An electric pump takes the water from the storage tank and pushes it through the coils in the DCM. The water picks up heat from the coils and then flows out of the DCM and up to the cooling tower.

It goes up to the top of the cooling tower and flows through the tower from top to bottom. The water is cooled. Cool water then drains out of the bottom of the tower through a large pipe to a storage tank where the pump starts the cycle over again. (See diagram on page 40.)

Depending on the size of the tower, this water flow can be 75-300 gallons per minute (GPM). Most of the water is reused at 93%.

38 American Drycleaner, June 2017 www.americandrycleaner.com

(continued)

SPECIAL FEATURE

professional cleaning solution that replaces traditional dry cleaning with one machine, one detergent and one process. Welcome to the future of dry cleaning! CLEAN SHOW - Las Vegas June 5-8, 2017 - Booth #1661 Live Demos - Special Pricing Our customers are telling us they are seeing 50% reduction in operating cost by using the Harmony Cleaning System! Reduced Cost of Ownership Eco-Friendly Green Technology Superior Cleaning Quality Steam Heat Dry-to-Dry Cycle Options Multi-Weight Loading 14-Minute Wash Cycles 55-Second Quick Extract Touch Screen Controls 100-Formula Capacity 10 Water Level Options Global Settings 8 Chemical Ports Heavy Duty Shocks and Springs Easy-to-Clean Drain and Filter No Hazardous Waste

The key to tower performance is rapid water flow. A cooling tower doesn’t drop the water temperature as much as a refrigeration unit, so the higher flow makes up the difference.

When the water flow is too low, the water does not flow through the tower evenly. When that happens, there is not enough evaporation. Without evaporation, the water is not cooled enough.

Now you have two problems: the water is not flowing through the coils in the DCM fast enough, and the tem perature of the water flowing into the DCM is too hot.

Both of these issues can cause the DCM to malfunc tion. Evaporative cooling towers are highly dependable. However, when there is a problem, it’s normally caused by reduced water flow.

To understand water flow, it’s important to understand the water pumps used in towers. Most of these pumps are “forward vane centrifugal pumps.”

Tower pumps are similar in function to the solvent pump in the DCM. When there is too much restriction to flow, these types of pumps simply pump less water. The pumps are still turning the same RPM and there is no buildup in pressure, but they pump less.

Water flow restrictions in cooling tower systems are the resistance to pumping water through the coils and the energy to pump the water up to where the tower is located (on the roof). This combined resistance is called “discharge head.”

When cooling tower systems are selected, the installer is trying to select a pump that will pump enough flow that allows the tower to cool the DCMs. Unfortunately, there are a lot of ways that can go wrong.

For example, a tower system might be sized to cool three DCMs. The pump can overcome the discharge head of the coils in the three machines as well as the vertical lift to the tower on the roof.

(continued) 40 American Drycleaner, June 2017 www.americandrycleaner.com

(Diagrams supplied by Mike Tatch)

www.renzacci-usa.com Contact Brent Padon: 561-644-5517 email: brentpadon@padonequipment.com Dry Cleaning Machines IS ALL YOU NEED EXCELLENCE 2.0 Huge range of machines hard & soft mounted with still and/or ltration unit from 20 up to 90 Lb. Washer ExtractorsTumbling Dryers High Spin Soft Mounted, Extra & Regular Spin Hard Mounted from 20 up to 264 Lb. Complete range from 20 up to 264 Lb., With exclusive range of closed circuitvent-less dryers COMPLETE PARTS INVENTORY TECHNICAL SUPPORT US SCHOOLING AND TRAINING CENTER ON DRYCLEANING AND WET CLEANING MACHINES Visit us booth # 1685 EXCELLENCE 2.0

But then let’s say, two of the machines get turned off. Now all of the water is trying to get through one set of coils.

The discharge head is too high for the pump, the water flow slows down, distribution in the tower is affected, the water temperature goes up, and the one operating DCM shuts down for lack of water.

The operator thinks, “How could the tower cool all three machines running at the same time, but can’t cool one machine running solo?” So, he switches to city water and curses the me chanic who sold him the cooling tower system.

Other things can cause the discharge head to change. Many modern DCMs have valves that limit or shut off the water flow through the coils when the coils are not in use, such as the refrigeration condenser during the wash cycle.

Another big user of water is the “still condenser,” which only needs water when the still is operating. These are all good devices to save water if you are using city water for cooling. Unfortunately, they work just the opposite when the cooling tower system is used.

The adjustment for this is the “bypass system.”

Properly installed cooling tower systems will have piping that connects the cooled water pumped from the storage tank (inlet header) to the warm water going back to the tower (outlet header), bypassing the DCMs.

A valve should be installed in this pipe. If the discharge head is too much for the pump, the operator slowly opens the bypass valve, which allows some of the cooled water to bypass the DCMs and go straight to the tower.

This increases the flow and improves the distribution in the tower, which lowers the water temperature—the dry cleaner is back in business.

Care should be used when opening the bypass valve. It should be opened just enough to improve tower operation.

If it is opened too much, the DCM will not get enough flow for cooling. This is especially helpful during hightemperature, high-humidity days.

HOW COOLING TOWERS WORK

For small applications such as dry cleaners, the most commonly used towers are mushroom-shaped assemblies housing evaporative cooling tower with distribution arms (also called “sprinkler arms”).

Warmed water is pumped to the tower inlet. The water flows through the inside of the standpipe and is distributed through the sprinkler arms and out the spray nozzles, lo cated above the fill (see the diagram above).

The bottoms of the sprinkler arms have a series of holes that are pointed on a slight angle. The water is sprayed out of the holes, and this reactive force causes the arms to rotate. In this way, the water is distributed evenly into a thick maze of corrugated plastic called “the fill.”

Many towers put sails or blades on top of the sprinkler arms to help rotate the arms using the airflow from the fan. At the same time, a large fan, located at the top of the tower, pulls large volumes of air (10k-20k cubic feet per minute) into the tower and out the top.

The air enters the tower through a screened cylinder that wraps around the circumference of the tower just up from the bottom (inlet louver). The dry air in (as shown above) goes through the fill from the bottom to the top. The heat is transferred to the air.

The water flows down the large surface area of the fill, evaporation takes place, the water is cooled and falls through the fill into the collection basin.

At the bottom of the tower, there is a cylindrical protru sion called the “tower sump.” One side of the sump has a large outlet (normally through a screen or filter) that is connected to a large-diameter pipe connected to the stor age tank, down below. In warm climates, the bottom of the tower may be used as the storage tank.

If the sprinkler arms are moving too slow or not turning at all (a very common occurrence), the water is not dis tributed evenly through the fill.

This means that only approximately

42 American Drycleaner, June 2017 www.americandrycleaner.com

(continued)

Forenta Dry Cleaning Sandwich Legger $7,175* Unimac 60-lb. High Speed Washer (Used) $5,800* Huebsch 50-lb. Gas Dryer (Used) $1,100* LG 35-lb. Commercial Washer $2,295* Hoffman Form Finisher $3,295* Fujistar Double Buck (Used) $14,000* Wascomat 83-lb. Gas Dryer $3,525* Hoffman Double Topper (Used) $3,599* Lattner 15hp Boiler $10,200* Electrolux 62-lb. Washer $7,500* Unipress Single Buck SB1 (Used) $10,500* Unipress NT2 Double Buck (Used) $18,500* Forenta Double Legger $7,400* Forenta 44SP Spotting Board $2,695* ADC 30-lb. Stack Dryer Coin-OP or OPL $3,995* 1/2” Steam Traps $35 each, 5 trap minimum 86 6 - 73 4 - 364 4 Monthly Specials Online: MustangEnterprises.com New & Used Equipment for Drycleaning & Laundry Huge Selection of Parts for Most Brands of Equipment Prices valid until July 1, 2017 | *Freight Not Included