Compassmax Cloud

Most

Compassmax Gateway

Compassmax

Most

Compassmax

Stain removal matters to your customers. But which stain removers perform best in today’s green environment? Wherever you live, California's environmental regs can guide you around future remediation nightmares – and to Wilson spotters. They’re VOC & Prop-65 compliant, chlorinated-solvent free, biodegradable and noncombustible, and they’ll deliver the stain free garments your customers desire!

Replace VDS with EasyGo® spray spotter. It quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing.

Replace traditional POGs with TarGo® EF. It removes tough oil based stains that remain behind.

Embrace your green future with these trusted Wilson stain removers. You'll build your reputation for quality – and keep your customers coming back.

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO. Become a STAIN WIZARD at ALWilson.com

For GreenEarth,® use ||G|| Go®

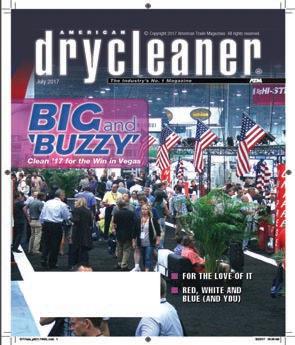

The products and equipment were plentiful and the educational sessions were charged with electricity across all four days of Clean ’17 in Las Vegas, but it was the people, like Kanak Raj, owner of Crown Cleaners in Sonoma, Calif., (front cover, left) who shined in the hot Vegas glare. They rolled into Nevada 12,500 strong and left a legendary show behind, to go down in lore as the “one to be at.”

Just like Woodstock, as history rolls along, everyone will say they were there — at the dazzler in the desert!

Tim Burke, Editor

It’s important for everyone to feel that their position is just as necessary as the next person, says Pilgrim Cleaners GM Lisa Goodmanson. Get tips on the best ways to coordinate staff between the counter and the plant so that both sides of your drycleaning “house” are in good order.

Tim Burke, Editor

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

“I don’t have to rely on anybody for information. I can see immediately what I have for inventory, orders and accounts receivable.”

Attendee walking past me at the Clean Show: “It really is the Year of the Clean!” Nice. Another: “Clean ’17 is the world’s largest fabricare classroom.” Indeed so. So many headlines call out. So many friendly faces and laughs shared at Clean. It was a hit for sure. That’s undeniable. Even Frank Sinatra couldn’t have said it better when he quipped, “swing baby,” to describe his 1960s Las Vegas Rat-Pack era. It could also describe Clean.

I was there and I was impressed and delighted at the upbeat mood. There was no better word than to say it was a “refreshed” business attitude across the big, airy convention hall. The aisles were full and noisy. The hallways, too! We were ... young, all over again! Nearly giddy.

I’ve said it already: Clean rocked the town! (Even a cabbie on the last day told me he was sad Clean was ending. “Real people. Great group. Please come back.” He meant it. I believed him.)

In total, the show felt a little like another Sinatra tune about the summer wind blowin’ in. In Vegas at Clean ’17, that wind carried the fresh scent of new ideas and approaches — and a renewed strength in the power of “us,” 12,500 strong, with our innovative ways and entrepreneurial drycleaning spirit!

This issue’s main feature, Smiling Faces of ‘Razzamatazz’: Clean ’17, starts on page 6. Check out the cool of it all, with plenty of photographs of your industry at work and at play.

Also this issue, our second feature, PowerHouse, looks at how two drycleaning operators manage employees at the front and back of their house. It starts on page 22.

Columnist Diana Vollmer looks at the emotional bond you have with your customers in Me, Me, Me. In Daunting Gizmodics, writer Howard Scott gives you “the works” about buying a going drycleaning business. Martin Young deploys his spotting tips for items beyond clothing in Window and Household.

There’s a new Yarns Spun Here about velvet, a new Off the Cuff, and more. It’s late summer. At my house, we go out for ice cream a lot come the evening. I wonder, is that maybe livin’ too large? ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 84, number 5. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2017. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

Publisher

Charles Thompson 312-361-1680 cthompson@ATMags.com

Associate Publisher/

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor

Tim Burke 312-361-1684 tburke@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Roger Napiwocki

Advisory Board

Mike Bleier Steven Dubinski John-Claude Hallak Mike Nesbit Herron Rowland Fred Schwarzmann Beth Shader Ellen Tuchman Rothmann

Contributing Editors

Howard Scott Diana Vollmer Martin Young Office Information

Main: 312-361-1700 Subscriptions 630-739-0900 x100 www.american drycleaner.com

Upbeat Fabricare! “Been coming to Clean Shows for 30 years,” says Kanak Raj, who owns Crown Cleaners & Formal Wear in Sonoma, Calif. He just celebrated 40 years in business last month, and says each Clean he’s attended has been special.

The odds were with the house on this one, even before “Clean version 2017” unveiled itself in mighty-brighty Las Vegas.

The sold-out exhibit of nearly a quartermillion net square feet of expansive double-wide floor space told anyone paying attention that weeks beforehand. The chatter from so many making plans to attend made the tea leaves easy to read.

But nothing could prepare anyone for the strong turnout of attendees, more than 12,500, and the high-energy, sheer “Coriolis effect,” palpable as a refreshing wave, at this fabricare industry tilt.

If Vegas lived up to its hype as the frenetic host of this “game,” then Clean ’17 was the bold roller who let it all ride, earned the winnings, cleared the table, and took home all the juice.

The faces of dry cleaning were apparent from all comers — and all corners of the United States. There was also a sizable, noticeable contingent of international drycleaning operators as well, intent on having a great time.

All seemed abuzz with the razzle-dazzle of Vegas and also caught up in the back-roar of an industry yearning to renew itself right before your eyes. Desert blooms outside, in striking red and yellow, weren’t

the only amazing things reaching up to be noticed in the hot Nevada sun in June!

It was no coincidence that many session speakers were youthful. Phrases such as “apps,” “web platforms” and others came rolling eloquently off their tongues at talks packed with attendees thirsty for ideas and ready to reimagine their operations with a fresh perspective.

Many drycleaning owners walked the busy aisles inside the vast exhibit hall with smiles on their faces.

“Love it,” says Kanak Raj, owner of Crown Cleaners & Formal Wear, Sonoma, Calif., who pauses at the American Drycleaner booth to explain he never misses the Clean Show. “This one is extra special. Great feel.”

He’s from wine country, and laughs about the clothing he cleans, often wine-stained.

Raj has been coming to Clean for 30 years and notes its impressive size and educational value. Holding a recent issue of the magazine, he mentions that he loves how it looks now. “It always keeps me in touch with what’s going on,” he says before heading down the aisle to see more booths.

Las Vegas is where the fabricare industry came to play, to see and learn about products and equipment and share ideas in dry cleaning. Many attendees came from beyond our borders.

“Just having a great time here at Clean, so much to see, and Vegas is great. We’ve been before,” says Bev Aitken with her “mum” Dot by her side. The two own Somerville

Drycleaners in Melbourne, Australia.

“Come down to Melbourne sometime and we’ll put you up,” Bev says with a wink, arms full of materials she’s collecting from booth to booth. They pause for a photo, then wade into the river of attendees, quickly disappearing down the blue-carpeted way.

“I’ve seen a lot of these shows, almost since the very beginning,” says Mark Witt Sr., a drycleaning owner from Phoenix, in Vegas with son Mark Jr.

In a hotel ballroom not far from the convention center, he’s chatting at an after-hours cocktail party thrown by two of Clean’s sponsors. and enjoying the double buffet of seafood choices and carved ham and roast beef.

“I’m glad to see some of the older, more dependable businesses having a strong presence at the show,” adds Witt Jr. “I took it as a positive sign for the industry as a whole.”

The large space is jammed full of attendees blowing off some Nevada steam.

“This is perhaps the best-attended, biggest show I can recall, maybe since back in the beginning,” Witt Sr. adds with a knowledgeable, wry grin.

The night, like other nights, will be full of events and parties all over town, many hosted by exhibitors such as Continental Girbau, GreenEarth and others.

On the show floor, many vendors indicated strong interest from the big crowds filling the aisles and checking out all the goods and products. Exhibitor after (continued)

exhibitor remarked that sales and/or leads were great.

“Wetcleaning interest is big here,” says Jeff Quail, who co-owns Poseidon Textile Care Systems with Michael “Stucky” Szczotka. “Every drycleaning store owner has wet cleaning, too. We’re introducing them to extra factors such as fast wash cycles.”

Poseidon rolled out its new Wet Cleaning Machines, shirt laundry plus washers and moisture-sensing and reversing dryers. The dryers were on display for all booth visitors, and Quail told onlookers: “Key features are its ability to create steps in the dry cycle similar to what we see in the wash cycle.”

Midway up another packed aisle, a group of drycleaning operators converged to pause and watch with fascination an LED information display above the conveyor rack of shirts in ScanQ’s booth. Company owner Evaz Fanaian was grinning.

They were looking at LARA, which stands for LEDAssisted Rapid Assembly. Fanaian says, “It’s a new system, used to decrease assembly time and eliminate operator error.”

Partnering with the firm Dark POS, Inc., which develops point-of-sale and customer relations management systems for dry cleaning, the LARA garment management system brings together cloud-connected devices, the Internet of Things (IoT) and distributed computing to the shop floor, allowing a staff to assemble hundreds of garments in a

fraction of the time, he says.

“The system,” Fanaian points out at his booth, “allows drycleaning staff to track garment pieces and automate assembly through simple visual cues provided by the LARA garment hangers.”

The system requires the latest Enlite version 10 for LARA garment hangers as well as a garment tagging system, he notes.

“Dirt is changing,” says Brian Hatt, North American wet cleaning segment manager with Alliance Laundry Systems, parent company since 2014 of Primus®. “Watersoluble is the challenge,” he notes, showing his all-in-one machine in another crowded, slammin’ intersection of aisles with attendees three-deep.

His firm introduced to North America what he calls “a highly effective and environmentally friendly alternative to drycleaning processes — Softwash®.”

Softwash delivers a total cleaning solution that is easier to work with than perc, he says, and achieves far superior results on a wider range of stains and fabrics.

The end results, Primus notes, are a cost-effective setup for any size of cleaning operation, and 20-30% cost reduction per 2.2 pounds of textiles cleaned, leading to overall improved profitability.

In addition, it can provide customers with a turnkey solution, one that is already delivering results for clients in more than 50 countries around the world.

“We’ve been focused on providing innovative solutions for more than a century,” Hatt says. “Founded in 1911, we got our start as a manufacturer of household washing and dishwashing machines.”

He also adds that Alliance Laundry Systems has a brand-new lab in the Czech Republic called the Star Center; there’s a YouTube-type video available online that shows off the modern, trés chic facility.

The grand hall outside is a great-carpeted-way full of Vegas memorabilia on the walls, that all attendees use, to go in and out of the exhibit space to coffee-up, find a session, grab a bite to eat, take a breather, or wander outside to experience a bit of the soul-sucking, firebaked thing they call daytime here.

Up in the high side of the exhibit canyon, in the 800 aisle, Foster-Stephens has added to its line of products with new wedding dress bridal storage and travel boxes. They are cleverly arranged in eye-catching stacks along the booth’s curtained back wall.

“Our new wedding dress bridal storage and travel box is

something totally new and different from Foster-Stephens,” says Nancy Jones, company president. “We are excited by this opportunity to help our customers with their travel needs as well as their preservation needs.”

The travel box is foldable for easy storage, or putting into a suitcase. It’s a solution for bringing a wedding dress or bridesmaid’s outfit on a plane.

“Lightweight and collapsible, our luggage is made from non-woven material and is water-resistant,” she notes. The boxes hold up to 10 pounds. The open dimensions are 22 by 14 by 8 inches; while folded, it is 1 inch high. The boxes come in pink, purple, or black.

Equipment speed and/or convenience were recurring features in many products at many booths.

Demos and crowded spaces at exhibitors — such as Dajisoft, ADC, SPOT Business Systems, Union, Fulton, Compassmax/Maineline, Itsumi, FH Bonn, Leonard, Fabricare Management Systems, Firbimatic and many more — were layers deep in booth visitors.

Over in the front by the wide aisle near the breezy entrance, A.L. Wilson Chemical Co. President Fred Schwarzmann talks not only about the terrific show traffic but also about some late-arriving attendees who, he guessed, were maybe out on the town the night before: “A few rolling in a little slowly this morning, but hey, they’re here. Strong, like all the days. Great!”

His booth had just been two-deep in drycleaning operators checking out his latest, The Laundry Two — a combo of spray spotters, Laundry TarGo and RiteGo, chlorinated solvent-free, California 2013 VOC and Prop-65 compliant.

At Trevil, company President Stuart Ilkowitz pointed to his new Presto FC shirt finishing machine at the far corner of his booth space as another demo of this single-buck, hot plate shirt finisher was under way.

Attendees plugged up the wide aisle, watching. “It’s been like this, non-stop,” he says.

Parker Boiler showcased a 9.5-HP, 150-psi, packaged steam boiler unit, in all-black (like something cool out of the flick Batman), new in 2016, called the Vertical Water Wall. After just a few words, National Sales Manager Mike Leeming was off to chat with drycleaning operators who were looking it over.

Elsewhere, there was a private demo of Garment Management System’s newly redesigned QuickSort automated assembly system with Rapid Movement Technology. Brett McLeod demonstrates how it works, feeding a shirt through the system and explaining the convenience is in “the way the system attaches the label before bagging up near the top of the hanger, then the invoice, and then into the power roller for bagging.”

The Sankosha booth early in the show was brimming with attendees chatting with Bill Odorizzi. Later, he presses a suit coat and is asked how he likes the show. “Love it. It’s great,” he says with a grin.

On the last day, a Sankosha employee demon-

They’re Tuned-In in Spokane! Drycleaning owners from Spokane, Wash., only had one comment to make absolutely clear to Editor Tim Burke at Clean ’17 when he asked how they were enjoying the show. They replied, with beaming faces, “We’re diggin’ it!”

strates a double-buck to finish two dress shirts at his company’s expansive booth. The employee is engaged with a drycleaning owner.

Nearby, Columbia/ILSA representatives were talking business with several customers. President Stephen Langiulli only had time to wink, as he looked to be closing a sale.

It was just that kind of atmosphere all four days. Fullthrottle exhilarating, squeezing lunch in, getting on to evening all too quickly.

An exhibitor passing by on the last morning says, “Never seen a show so consistently strong. Amazing.”

Representatives from Itsumi, Albatross, Renzacci and others echoed that sentiment. It became a message pleasantly rinsed and repeated, with grins. Often, “wow” was thrown in.

Adam Weber is president of Irving Weber Associates Inc. (IWA), which has been attending Clean Shows for more than 35 years: “I have to say that this year’s show, in Las Vegas, was one of the most successful Clean Shows we have attended.”

IWA introduced new Vice President of Business Development Steven Wright, who will be working directly with business owners nationally and discussing “insurance exposures.”

Maestrelli’s DreamClean ecological multi-solvent machine was eye-catching. Maybe it was the name. It might have been an undertone for the whole show. Owner Giacomo Fontana saunters over and says it is his first Clean Show. “Won’t be my last,” he adds. “Fabuloso!”

In the 1500 aisle, Union/Realstar’s Steve Henley grins amidst the companies’ gleaming, workhorse line of drycleaning machines in the 30-90-pound range. “Too busy to eat,” he mouths, shrugs and returns to a conversation with customers.

That’s the way it was, over and over, at this 40th anniversary of the Clean Show. Since 1977, it has brought the industry together to not only display equipment and services, but to put face to name. This is the industry’s “face,” and it is upbeat and youthful in expression.

“Clean 2017 was outstanding! There was so much energy and excitement on the floor, and it didn’t hurt that we sold out exhibition space and had a greater number of attendees,” says Mary Scalco, show chair and CEO of the Drycleaning and Laundry Institute (DLI).

“When there is a lot of activity, it makes standing on your feet for 10 hours a lot easier and, of course, robot ‘Press-ton’ kept everyone entertained.”

The sponsors’ booths acted as sort of a transition point from the lower hall area to the upper hall area, up a few wide stairs.

David Cotter, CEO of the Textile Care Allied Trades Association (TCATA), called Clean ’17 “a resounding success.”

He adds: “In speaking with many exhibitors both during

and after, it quickly became crystal clear how pleased they were to see so many customers and potential customers with real buying interest.”

Attendees flocked to the upper exhibit area near Cleaner’s Supply in the 800s, near CompassMax in the 500 aisle, and near Starchup in the 400 aisle, just to name a few hot spots.

While in Las Vegas, DLI also conducted some important association business. It appointed Mike Nesbit of MW Cleaners as its new president. Nesbit was on hand for the opening ceremony when Scalco sliced through the ribbon using oversized scissors.

“As Barnum and Bailey would say, ‘The greatest show on earth!’ That is also how I would describe Clean ’17,” says Nesbit.

“For those of you that got to attend this year’s show in Vegas, you were part of the largest Clean in the last 20 years. That was both attendance and size!”

Although the industry is facing some uncertainty, he points out, “what was certain is there’s still plenty of interest in the latest equipment, technology, and supplies.

“On behalf of DLI, the board of directors, and staff, we would like to send our appreciation to the vendors and attendees.”

The talking robot Press-ton would agree. He made many attendees laugh as he roamed the event, and not all were from the U.S. Scalco points out that 96 countries were represented at Clean ’17. About one of every five attendees were visiting from beyond our borders.

International flavor abounded at the Vegas show. Two drycleaning owners from Mexico were looking for ideas and, as one put it, “seeking out new business opportunities.” They held up their bags, chock-full of “information.”

A young couple, drycleaning owners from Spokane, Wash., had similarly heavy-looking bags full of goodies and spec sheets.

“Our first time,” the woman says, setting her bag by her feet and gesturing with both hands to show how overwhelming it all is. “Whew!”

They were hurriedly heading off to an educational session, one of many being offered throughout the show dates. They were hoping to get there early because talk on the floor was how the sessions were standing-room only, and deep at that.

Such was the high interest from attendees seeking to hear topics being presented.

On Clean’s first morning, the opening educational session, Business as Unusual, gave a glimpse of what this entire Clean Show would be: youthful energy, by fabricare industry professionals of all ages!

The room bulged to far over capacity, as young go-getter businessmen presented their views of business to a crowd hungry for ideas and to gain a better understanding of the new ways beginning to sweep into the field.

For instance, Nick Chapleau of Starchup tells the audience that dry cleaning is much more than suit-and-tie: “When partnering, make sure to partner with someone who will advance your brand.” Pens were jotting, cellphone cameras snapping. Ovation.

Then Kyle Nesbit, MW Cleaners, describes his business serving single-tenant office buildings, calling it the “most

Flow to the 800s! There were two segments to the cool, breezy, expansive exhibit space, both seemingly set on “full.” As shown here on the upper side, there was no ebb—only flow, flow, flow.

successful” of all the locker ventures he’s tried yet. More strong applause from the estimated audience of 400.

All educational sessions were open to all attendees no matter their background.

Drycleaning & Laundry Owners Partnering for Future Profits also involved a panel discussion, examining the “good working relationship,” says Stephen Moore, PressBox Cleaners.

Emcee Jeff Gardner, known as “The Laundry Doctor,” introduced Moore and fellow panelist Chris Balestracci, Super Wash Laundry.

Balestracci reminded everyone in the room to “resolve issues that come up as fast as possible, (and) make the customer happy,” later adding, “Making a ‘fix’ isn’t a ‘claim,’ it’s a marketing opportunity!”

Moore concluded with this remark: “We had a nice Ralph Lauren shirt, the cuff got ripped.” As the cleaner, they have responsibility and must own it, he says. “The dry cleaner said, ‘We washed it, we ripped it,” and took responsibility, gave their good customer a credit.”

One morning, Methods for Management (MfM) hosted an early breakfast talk at a nearby hotel. Tom Stites from Unipress, Bill Odorizzi of Sankosha, and a couple dozen drycleaning operators were among the audience who joined Diana Vollmer, one of the company’s principals as well as a columnist for American Drycleaner

Then back to the convention center and the session Five Considerations on Improving Employee Retention, presented by Brenda Stauffer, HR director at Balfurds Inc.

We Love Our Machinery! The machines ruled the show floor in all their shiny, drycleaning, glinting glory. You could describe the noise as a symphony of fabricare played in the key of Vegas-minor!

Developed to quickly and efficiently dry wetcleaned textiles without damage or wrinkling, the Poseidon Dryer eliminates air drying for catapulted productivity and unsurpassed results. Offering advanced programmability, it safely removes residual moisture from even the most delicate wetcleaned fabrics. Smart engineering not only ensures a quick dry, it brings superior efficiency, durability and a soft touch.

The Poseidon Dryer works in concert with high-performance Poseidon Wetcleaning Machines and Flatwork Ironers for unrivaled results.

Professional fabricare operations rely on Poseidon to perfectly wetclean the most delicate items including tailored wool suits, cashmere sweaters, silk wedding dresses, camel hair sport coats, taffeta prom dresses, knit skirts and so much more. Poseidon offers innovative programmability for complete control over every conditional aspect of the wetcleaning, drying and ironing process.

She encouraged drycleaning operators to engage with their employees and then asked if they would now, likewise, engage with the room and share stories.

Another full-to-the-brim room of attendees had a microphone at their convenience, which was passed up and down the rows of people.

One audience member says that Wednesdays is “sharing meals day” at their dry cleaner. “Where we bring in a snack.”

Another says they “love the middle-aged employees [cue laughter] who care so greatly!” Plenty of heads nod affirmatively. A third mentions giving “perfect performance awards.”

The presentation ended in loud applause, and many attendees lingered to talk to Stauffer as though they didn’t want it to end, even as the next session was setting up.

During a private moment out in the hallway, she shared that it’s about “treating employees as allies, thinking in terms of a ‘tour of duty.’” She adds that “a good fit is really the key.”

Late that afternoon, tired feet shuffled to a highcurtained area tucked just off the exhibit floor. It was the Show Floor Classroom: dark, cool, almost soothing to the senses, and a nice getaway from the high energy just steps away on the upper exhibit area.

In the amphitheater-like setting, a softly glowing neon blue-green Clean Show logo hung like a sleepy, incandescent moon over the dark-curtained stage.

DLI’s Brian Johnson leapt up there and soon was telling the audience what happens when an item like a felt fedora gets thrown into a dirty puddle. His session, Oops, Now What?, dealt with home remedies for cleaning items and whether they were legitimate.

Every single seat was filled, which is quite an achievement at 3:30 in the afternoon when one might expect people to be a little spent and maybe back soaking in their hotel bathroom

tub by now, or at the poolside bar, or the craps table!

Back to the dirty fedora: “We let it dry,” Johnson says, “Aged three days. Sprinkled baby powder on the stain, gently rubbed it.” This remedy sort of worked, he decides. “Then I used a brush. That worked better. So it passed the test.”

In the next test, dirt on suede, he used another home remedy: stale bread.

“Stale bread worked,” he notes as the projected video shows a woman using stale bread to rub out a stain. And it’s gone!

On a personal note, while a veteran of many trade shows in a long career, it was my first Clean Show. What impressed me the most, among the good people and happy faces, was a silly little comment from someone who has nothing to do with the show but everything to do with business in general.

As my cab to the airport left the hotel driveway, the driver asked, “Is Clean over?” I said, “Yes.” At the stop sign, he turned back to me and said, “Boy, we’re going to miss you guys. It’ll be boring next week. You gave us a lot of business but you know what? Just a great group of people. Nice, friendly and real. I sure hope you’re back.”

In a way, it seemed like he was talking about the fabricare industry — it is, indeed, coming back strong!

The Clean Show will return June 20-23, 2019, to New Orleans. It’ll take some kind of event down in The Big Easy to out-spin this one. Clean ’17 was special. The whole thing will be remembered in lore as full of razzamatazz

Was Sinatra right when, long ago, he sang, “the best is yet to come,” to a Vegas showroom? Only time will tell.

The faces at Clean ’17 were inquisitive, numerous, and smiling. Strong signs, all. Clean, like the fabricare industry, seems to be reinventing itself right before our eyes. Young again, and with a new breath of fresh air just now breezing in! ADC

t’s important for everyone to feel that their position is just as necessary as the next person, whether they are in a larger-volume store or a smaller one,” describes Lisa Goodmanson, GM and director of plant operations at Brooklyn Park, Minn.-based Pilgrim Dry Cleaners.

She is talking about the secret to Pilgrim’s success coordinating employees from both the front counter (front of house) and plant (back of house) so they work together as part of one team, making the business one unified house.

“Our community programs pull everyone together to coordinate and provide large-scale drives to give back to our community,” Goodmanson says.

The company gives back continually through its “Coats For Kids,” “Scouting For Uniforms” and “Costumes For Kids” drives, and other opportunities throughout the year.

Goodmanson has been in the drycleaning industry for over 30 years — with Pilgrim for 17 of those years, “so I bring a bit of experience to my position,” she says.

Pilgrim Dry Cleaners has been a family-owned business since 1940, servicing the Twin Cities metro area with 25 locations and free home and office pickup and delivery service. Goodmanson has daily communication with each one of Pilgrim’s stores.

“We give our employees the opportunity to provide us

with feedback about our business,” she says.

Pilgrim employees can apply for a yearly college scholarship. “This year we awarded scholarships to six of our senior high school graduates,” she says. “The scholarships help our employees feel appreciated and welcomed back during their college breaks.”

Her operation is currently investing in store renovations, new equipment and technology to attract new customers and new team members. Pilgrim takes pride in providing expert garment care, with professional staff, and new updated facilities and technology.

How important is it that all staff work together?

“Our front counter managers are an important key to our success,” Goodmanson says. “They are who our customers see and deal with daily, however, if we don’t put out a quality product, we don’t satisfy those customers. Our plant managers understand this and strive for the best cleaning and pressing out there.”

As with any business, having the right people in charge can be a challenge that eventually leads to success. As she puts it, “We have so much longevity with our employees that it keeps the challenges to a minimum. We want the right customer service representatives working one-on-one with the customers and the right plant personnel that can work together

pleasantly while putting out a great product.”

Ever heard the expression that you must “walk a mile in their shoes” before you know what another person’s job is like?

One of the many ways to coordinate your drycleaning employees to work together effectively is through cross-training.

“In our plants,” Goodmanson explains, “our front counter personnel may be trained to help the automated assembly, so the counter manager can help in production with pressing or whatever is needed. The pressers are hired for a primary position but know that they will be trained in all positions eventually.”

Everyone is responsible for keeping their department clean.

“We hold yearly meetings to go over safety issues and responsibilities, as well as twice-yearly manager meetings.

“Besides having summer cookouts for our plant personnel, there are plenty of lunch and dinner giveaways at the branch stores as a way of showing our appreciation for their hard work and going above and beyond to help out other stores in need,” she adds.

Your job is to make your customers look great in their freshly cleaned clothing.

The returning customer gives you their business because they expect a level of quality, speedy service, a friendly face and attitude, a connection that relates your personal service — and maybe all of those reasons put together!

You make people look good, and that can feel good! Keeping that feeling flowing takes special attention by operators to give that consistent service.

“Coordinating cleaning, and trucks, has become second nature,” Goodmanson points out, “sometimes servicing locations four to five times in order to accomplish this fast service our customers have grown to enjoy and expect.”

She adds, “Our plant managers do a great job, especially with the volume of items they see on a daily basis, but there are the periodic staffing issues or equipment issues that may come up.

“Quality is something we monitor at all times, so working with the pressers and cleaners, whether on the laundry side or drycleaning side, is important.”

That’s how one cleaner coordinates its “house” in Minnesota. How about another example?

“Probably communication between the two sides of the business is the most critical aspect of getting the entire company working seamlessly,” points out the Chicagoarea owner of Drive Cleaning, Mike Bleier.

American Drycleaner, August 2017

“If your CSRs aren’t doing what they’re supposed to be doing, such as unbuttoning all shirt buttons, separating problem garments, checking all pockets, using flag tags correctly, covering fragile buttons, then it makes it that much harder for the back-of-the-house team to do their jobs correctly,” he says.

For at least part of the time, he tries to personally work with each new hire at the counter for their first couple of weeks, “making sure that they understand all the finer points of working up front at our operation.”

One of the issues many drycleaning owners talk about is cross-training their employees to be as flexible as possible. American Drycleaner asked this owner, and he says, “To be honest, this is an area for improvement for me.

“What would help me sleep better at night would be complete crossover so that we would be able to be comfortable knowing that every single person in the plant could do any job. That’s my hope for the future.”

To keep the whole house feeling like one smooth team, he does other things for his employees. He has annual safety reviews, and works with a safety and compliance group to ensure “we’re following OSHA standards.”

Social events are important at this operation, too. “We do try to have two group outings per year — a family summer event and an employee holiday dinner party.”

Pilgrim’s Goodmanson says she speaks with each of her store’s counter managers every day. “If there is something I can help them with, whether it’s a customer service issue, a staffing issue, or a technical issue to do with the computer hardware or software, I try my best to do what I can for them.”

Both of these drycleaning operations, and no doubt many more, work diligently every day to make the front and back of their business act as one team — efficient, safe, sociable and healthy in the revenue column.

That recipe makes for one heckuva powerhouse ADC

In 2010, Oscar and Carmen Escalante seized an opportunity to change the way dry cleaning was being done in Mexico. Both had been part of a European company that used perchloroethylene exclusively in their franchise locations. Oscar’s first exposure to GreenEarth convinced him it was time to start his own franchising company built on GreenEarth. From their first Green Clean location in Monterrey, Mexico, they now have 43 locations across Latin America with more to come. Oscar and Carmen are making a difference, one customer, one location, one country at a time. And a continent is better for it!

In 2010, Oscar and Carmen Escalante seized an opportunity to change the way dry cleaning was being done in Mexico. Both had been part of a European company that used perchloroethylene exclusively in their franchise locations. Oscar’s first exposure to GreenEarth convinced him it was time to start his own franchising company built on GreenEarth. From their first Green Clean location in Monterrey, Mexico, they now have 43 locations across Latin America with more to come. Oscar and Carmen are making a difference, one customer, one location, one country at a time. And a continent is better for it!

In 2010, Oscar and Carmen Escalante seized an opportunity to change the way dry cleaning was being done in Mexico. Both had been part of a European company that used perchloroethylene exclusively in their franchise locations. Oscar’s first exposure to GreenEarth convinced him it was time to start his own franchising company built on GreenEarth. From their first Green Clean location in Monterrey, Mexico, they now have 43 locations across Latin America with more to come. Oscar and Carmen are making a difference, one customer, one location, one country at a time. And a continent is better for it!

OSCAR ESCALANTE / GREEN CLEAN MEXICO PRESIDENT

OSCAR ESCALANTE / GREEN CLEAN MEXICO PRESIDENT

OSCAR ESCALANTE / GREEN CLEAN MEXICO PRESIDENT

OSCAR ESCALANTE / GREEN CLEAN MEXICO PRESIDENT

OSCAR ESCALANTE / GREEN CLEAN MEXICO PRESIDENT

OSCAR ESCALANTE / GREEN CLEAN MEXICO PRESIDENT

Self-esteem, confidence, achievement and respect are powerful motivators in driving clientele to hire you to polish their image.

Have you ever seen a drycleaning ad or website that did not profess to provide “quality” as a primary marketing point? In preparation for writing this, I actually tried hard to find one that didn’t cite quality as their key attribute. Twenty-three (that’s 23!) attempts proved futile.

No matter if the customer ratings were 1 or 5 on a 5-best scale, all claimed quality. How is a prospective customer to find the real difference that is meaningful to them?

If every company claims the exact same customer benefit(s), does any single cleaner stand out or have a true edge over the others?

When everyone asserts the same thing, is it a surprise consumers resort to the rating sites that most cleaners love to hate?

Is the provider more credible than the users of the product who are doing the rating? Not likely, hence the popularity of the evaluation websites, where unhappy experiences are five times more likely to be reported.

This math works exponentially against the cleaning pro fessional when combined with the statistic that “It takes 12 positive service incidents to make up for one negative incident.” (Source: South Carolina-based business consul tancy Lee Resource Inc.’s Bad Ratings Are Costly.)

So how do you market your business to stand out from the crowd? How do you keep your valued customers re turning regularly, and how do you woo your dream “highvolume, high-loyalty” prospects to give your service a try?

This has been a dilemma for decades, and the most common approach to marketing is to use discounts.

On the “pro” side, discounts are:

• Easy to promote;

• Easy to track;

The “con” side is more threatening:

• Giving the impression of “fake” pricing. Reduced pricing gives the consumer the idea that your “regular prices” are higher than they should be and that you are systematically overpriced.

• Discounting also attracts price shoppers, a uniquely fickle audience that will hop to whomever has the lowest price.

So what’s a professional cleaner to do?

Look at your whole value package from the perspective of your best customers. Why do they keep returning to enjoy the customer experience you provide? Understand ing what value means to them is key to retaining them and expanding your base to include more consumers like them.

This profiling step is critical to understanding customer motivation and value and to cultivating customers who are willing and able to pay what your service is worth.

Value is the sum of the entire experience and pricing is only one component of many that comprise value to consumers.

The exact combination of what consumers truly value is functionally and psychologically complicated. Remember your basic psychology class and Maslow’s Hierarchy of Needs?

Editor’s note: This “hierarchy,” developed in 1943 by American psychologist Abraham Maslow, is

(continued)

Emotional bond: Customers desire to look good, and you help that feelingDiana Vollmer (Image licensed by Ingram Publishing)

usually depicted as a pyramid-shaped model showing five “tiers” of human need (starting at the bottom and moving upward): Psychological (breathing, food, water); Safety (security, health); Love/Belonging (family, friendship, sexual intimacy); Esteem (self-esteem, confidence, respect); and, finally, Self-actualization (morality, creativity).

Also, the Harvard Business Review (HBR) describes a slightly different hierarchy beginning with “Functional” at the base, then moving upward to “Emotional,” “Life Changing,” and “Social” at the pinnacle, as explained in The Elements of Value by Eric Almquist, John Senior and Nicolas Bloch, published September 2016. The article is available on the HBR website (https://hbr.org).

Regardless of the titles applied, your service appeals to each of these levels to some degree. Choose your own specific advantages (from the many below or from alternative lists) and promote them in a relatable way that will appeal to your target customer:

Convenience — Contains components of delivery timing, location, hours of access, drop-offs, speed of service, in-car access, in-home/work access, breadth of product and service offerings, and proximity to other frequented businesses.

All of these are functional appeals that make life easier, once the customer has determined a need for your service.

Environment — Takes in ambiance, visual appeal, emotional appeal, staff appearance, friendliness and knowledge, store layout, graphics, displays, number, look and value of media messages, and provides emotional attraction.

All of your media should reflect the design theme and sophistication level of your niche.

Quality — This changes with the target market and is tied closely to the Esteem level of a customer’s confidence and self-respect (see pyramid graphic at right) and can even reach Self-Actualization shown in your customer’s creativity and style.

These are psychological points that allow fine and couture cleaners to prosper alongside mass-market, one-price and discount establishments, all of which can have healthy, profitable businesses.

The personalities and existing customer testimonials associated with your business are highly valuable at this level and are much more believable than what you say about your own quality.

Quality results from the combination of front-of-house

(store and route) experience and back-of-house (plant) skills, systems and logistics.

Safety — Is reinforced by your history, awards and longevity. You can be trusted to maintain their family’s wardrobe and protect their resources.

Customer testimonials and ratings are valuable here as well. In-car service can also speak to safety, since there is no need to bring a child, pet or other dependent in the store.

All levels of the hierarchy pyramid are significant, but the apex and the base are extremely powerful. The adage that “sex sells” is based in science as it is a reflex to basic survival instinct.

The dominant appeal for our service is at the very high level of esteem on Maslow’s chart. Confidence, achievement, self-esteem and respect are forceful traits in clients who want to look their best.

As you list your own distinctive advantages, assign each one to the psychological level described to achieve the most powerful motivational message possible.

Remember, consistency in customer experience and quality from both front and back of house, importantly supporting each other, is critical in customer messages.

And count on emotions speaking louder than facts. ADC

Diana Vollmer is a managing director for Methods for Management, which has served dry cleaners and launderers with affordable management expertise and improved profitability since 1953. For assistance profiling your best customers or planning your marketing message, call 415-577-6544 or e-mail dvollmer@mfmi.com.

Keeping light-weight, knit shirts from losing their shape can be easier said than done. Stretch the shirt onto the wrong hanger, and you end up with bumps on the shoulders known as “hanger dimples.” We created our line of Knit Hangers with a unique size and shape that prevents bumps in polo and knit shirts. Warm weather months mean it’s Knit Hanger season at M&B.

To learn more about our line of Knit Hangers, go to www.mbhangers.com to find your local distributor, or call 888-227-0436 to speak with one of our customer service representatives.

Taking over a sizable, going concern is daunting. You don’t exactly know what you’re buying.

Existing customers may not take to you. Key employees might not mesh with your personality. Vendors could take you for a ride.

Unless you’re a multimillionaire, paying off loans will erase much of your profit. Area competition will go on the offensive, knowing that a new presence doesn’t have the savvy that the departing owner did.

You’re a newcomer, and perceived as an outsider. Nobody emerges from the experience without having spent sleepless nights, wondering, “What did I get myself into?”

Tom Fay bought The Cleanist, in Plymouth, Mass., in December 2013. He had been a partner of Danny’s Cleaners, in Braintree, Mass., with his brother, and decided he wanted to go out on his own.

Ironically, two years after Fay took over The Cleanist, the brother decided he wanted out. So now Fay runs the two businesses. He has a lot on his plate.

The negotiation went smoothly, but slowly. Fay made the initial call because he heard the seller wanted out. They chatted. Fay did due diligence. He was impressed that it was a good brand and that the books were in good order.

There was a six-month interruption where negotiations stopped. But talks resumed, and the buyer and seller worked out a deal that included a fair price and a reason able exit strategy.

The seller would spend a few months introducing Fay to key clients, help smooth the employee-employer transition, and be available for phone consultation.

“If I’m having a problem, I can call, and Paul (the seller) and I chat,” Fay says. “It helps.”

The first rule of taking over a business is retaining your help. Fay has been pretty successful at this, but at a cost.

He has had to beef up salaries, put people on health in surance plans, and generally be proactive and accommodat ing. As a result, his labor costs are 40% or even higher.

Particularly onerous is ever-increasing healthcare insur

ance, which now is running $600 per employee. Even though the em ployee pays 50%, the burden is high. Especially so since healthcare costs have increased 50% in the four years he’s run his cleaners.

Taking over an already going business, much like trying to describe this “gizmo” sitting in The Cleanist owner Tom Fay’s office, can be a long, strange trip indeed.

(Photos by Howard Scott)

He also has instituted a 401K plan for eight key employees, to which he contrib utes. Finally, he offers disability and life insurance as a package of fering. Fay estimates that fringe benefits run 10-15% of payroll, a major concern.

The dry cleaner’s general manager, Kathy Cardon, now a 32-year staffer, is a big help. Moreover, all his key people are still employed. Keeping good employees is not easy, especially with a crew of 31.

Fay’s goal is to maintain a family atmosphere. For instance, when someone needs time off, with good rea son, he will try to accommodate.

The second rule of taking over a business is maintaining good customers. Fay has been quite successful in this area.

He has cultivated an air of reasonableness, which his low-key personality has helped. Of course, it helps that the operation is the premier dry cleaner in his region.

The third and final rule of taking over a business is to grow revenue. With debt management, profit is marginal. That’s the way it is when one makes the purchase.

So the key to profitability is to increase volume, so that more net drops into the bottom line, and reasonable profit is achieved. The firm operates the plant in North Plymouth, four drop stores — two in

Buying a going business not for ‘weak of heart’

Plymouth, one in Kingston, one in Duxbury — and a route.

Fay has increased drop store volume about 8%. His plant counter has been solid. The one area he hasn’t been able to increase is the delivery route. He is puzzled and frustrated at his inability to move it forward, but that is the reality. As a result, sales are around $1.5 million and he is in the rea sonable profit area.

One help was the relocation of the Kingston drop store to a much better location, which has nicely improved revenue. His strongest drop store is Pine Hills in Plymouth, which is a massive upscale development of retirees.

Fay talks about the next step: “I’m going to get out there and speak to offices, large commercial customers, and see if I can boost the pickup-and-delivery volume.”

As for prices, his operation has maintained and not raised prices. Fay believes that he took over a business that main tained pretty high prices, and he was able to operate within that framework. Perhaps there will soon be increases.

As for equipment, Fay has had to make investments in washers/dryers, wetcleaning equipment, and a tension col lar and cuff machine, and he has updated the computer. Fortunately, most of the equipment is in pretty good shape. Preventative maintenance is standard operating procedure.

The company maintains an active marketing campaign. The message is: We are the quality cleaner; we take the best care of your clothes; you should be using us.

This niche-focus is carried out in mailings, monthly e-mails, coupons via e-mails, and print ads. Altogether, he spends 1% of volume on marketing and promotions.

Fay is the face of his business. That includes putting his image on trucks, focusing on himself in ads and the like.

“This is not my nature, but it seemed important for the

brand,” he says.

Fay is happy that he’s the premier cleaner in his mar ket, but he frets that the smaller competition keeps nib bling away at the customer base.

For example, in Duxbury, an upscale community, there are five other dry cleaners. Placed throughout the town, each does some business, eroding his portion.

“I really think we need to see an exit of marginal operators. Unfortunately, some operators are hanging on when they should quit,” Fay says.

These days, his job is to handle customer issues.

He checks figures and follows the money. He fields many customer service issues and checks to make sure they have been resolved. He visits stores at least once a week.

Almost daily, he stops by Danny’s Cleaners in Braintree. Fortunately, he has a cadre of three key people who’ve been there for many years. He also will jump in the truck and make a delivery when needed.

Finally, Fay maintains an open phone line. Anyone, employee or customer, can call with an issue. All this means that his workweek is 60 to 65 hours.

Which brings us to his overall assessment of the industry.

“This casual workday trend has gotten to the point where profession als are losing self-respect,” Fay says. “As a result, I think that total industry volume has halved in the last dozen years. Only through price increases has revenue remained adequate.

“It’s harder and harder to make a decent living. Sure, the good operators do make nice profits, but not too many of us are getting wealthy. What would help is if some of the marginal operators would drop out.”

Besides running his operations, Fay has a busy family life with four kids. His oldest is just beginning college. And we know what that does to parents’ pocketbooks.

Still, Fay steers on, focused on making his purchase a success. ADC

Howard Scott is a longtime industry writer and drycleaning consultant. He welcomes questions and comments, and can be reached by writing him at Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027, or via e-mail at dancinghill@gmail.com.

your normal income stream. There are variations of construction that will impact the method of handling and therefore the price structure for your service.

Curtains are usually unlined and less than 60 inches long. If they have a water-based care instruction, you can easily treat them as fine-washable. This means water under 95 F, a mild- to neutral-pH detergent, and low me chanical action. They should be rinsed in a wet-side sizing to restore the hand (feel) and make them easier to finish.

Shears can be of most any length but are usually of synthetic material and a light color. They should be run in small loads of no more than half your washer capacity.

Drapes come in 1-foot increments of 72 inches, 84 inches, and 96 inches, with a price point based on length.

Cleaners are split in how they measure width. Some use the number of pleats while others use the linear feet along the bottom. Drapes may be unlined, lined, and even have a heavy thermal lining, and these variations influence how they are handled.

Thermal-lined drapes should be run at one-half the ma

chine’s rated capacity, as the thermal lining will absorb and hold solvent until extraction. This greatly increases the weight and thus creates added mechanical action.

When the drapes are extracted, there is tremendous pressure on the fiber, until most of the solvent is released. Draperies should always be sized to replace their hand and restore the original flow as they are hanging.

Time for some sad news: The sun will eventually kill window treatments. The nearer the window is to the south side of the house, the more extensive the damage to the fiber and the faster it will happen.

Many times, the slightest movement/mechanical action will cause razor-sharp vertical tears along the rolls/folds that were facing the window.

You and your customer service rep (CSR) must be aware of this potential hazard and inspect the drapes before accepting them, even with a release. Always get a release for all window treatments.

A quick story to help emphasize my point:

I have a long-time customer who has a breakfast room that has windows on three sides. The windows are 3 feet above the floor, but the window treatments go to the floor. The windows facing east have trees in front of them, and the windows facing west are protected by old-growth oaks. There is no blocking the midday sun from the south.

The royal blue window treatments were custom. After only two years, the east-facing treatments were slightly dis colored but retained their tensile strength, the west-facing treatments were in ideal shape, but you could hold up the south-facing treatments and see the outline of the window and measure discoloration at 34 inches from the bottom.

These southern-facing treatments had split in places just from the handling while taking them down. I ask my cus tomers where the sun comes up in relation to the window.

There is always a risk in garment care, and it must be minimized. You have been warned. You know what to look for when taking in window treatments.

Table treatments are another source of additional in come. To be done properly, one must have the ability to finish a tablecloth on a hothead press. The larger the sur face area of the press, the lower the number of “lays” it will

take to give the appropriately finished appearance.

Tablecloths are a flat surface under plates and bowls of food and in close proximity to people eating, so tablecloths catch every drip and dribble.

A limited amount of pre-spotting prior to cleaning will reduce the time spent post-spotting.

White and pastel tablecloths can be laundered using wa ter as hot as 140 F and perborate bleach. The darker colors should be treated as fine-washable and washed in water below 95 F with a mild alkaline detergent to protect color.

On those occasions that you have napkins that match the tablecloth, it is best to bag the napkins and immerse all the items in the same load. Napkins are more likely to contain chemically soluble stains, such as lipstick. Napkins should be pre-treated with a laundry degreaser prior to cleaning.

Placemats must be returned like new. It is important to use wet-sizing to give them a crisp hand after pressing.

You need not fear household items but they require a plan before you begin your task of cleaning. ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates today. Phone: 704-786-3011, e-mail: mayoung@ctc.net.

Press Cleaners, founded in Austin, Texas, in 2015, offers a modern approach to the old-school laundry and dryclean ing business, it says, expanding to four more markets.

“Press is leading a technology-driven revolution in the laundry and drycleaning business,” says Ryan Harmon, co-founder and CEO. “Our goal is to shake up an indus try that truly needs a 21st century dose of innovation.”

The firm already has signed up what it calls “virtual franchisees” in Lubbock and Oklahoma City, and is ne gotiating with others to enter the Dallas-Fort Worth and San Antonio markets, the company reports.

In each market where the company operates, it enlists a local business to handle laundry and drycleaning ser vices as a “virtual franchisee,” while the firm manages billing, marketing and other back-end operations for that market.

The North American Restoration Dry Cleaners (NARD) board of directors recently appointed Frank Aucoin NARD’s national business develop ment officer, it reports.

“We are extremely excited to have brought Frank onboard,” says Manuel Vendelis, president of NARD. “Frank’s track record of success and unparalleled values align perfectly with ours.”

Aucoin, formerly of Rainbow In ternational, comes to NARD with more than 12 years of national ac count experience, and will be the leadership of the firm and pursue its vision and mission.

NARD says it provides responsible claims handling, constant innovation and out-of-the-box thinking to drive claims costs lower through member dry cleaners.

Members are experienced fabricare specialists, with locations throughout the United States, dedicated to the restoration of garments, textiles and soft goods that have been affected by loss, the organization says.

Compassmax/Maineline Computer Systems recent ly announced its first Certified Compassmax Expert, Wash Respess of Dry Cleaning Advisors, who has completed training and is available to conduct site visits to help maximize usage of the Compassmax system.

“He has been an active betatester for Compassmax at Southside Cleaners-Launderers, a four-store and six-home-delivery-van opera tion in Lakeland and Plant City, Fla., since 2002,” the company says.

As a certified expert, he will assess business tech nology, repair existing systems, recommend im provements, integrate technology into drycleaning operations, and communicate industry best practices.

Respess is a current board member and former president of the South Eastern Fabricare Association (SEFA), the firm reports.

OXXO Care Cleaners® has opened four new stores in the cities of Boca

Raton, Fla.; downtown Miami; West Palm Beach, Fla.; and Houston, the company reports.

Inspired by rapid growth, the brand’s new expansion goals en

vision 12 more new stores in the United States and five more abroad for 2017, OXXO says.

“OXXO continues to grow in 2017 with these openings and we are thrilled with the results. We also recently announced strategic multiunit growth plans throughout the United States,” says CEO Salomon Mishaan.

Two of the stores are owned by two of the firm’s multi-unit franchi sees, making them the first of mul tiple locations for the U.S. this year.

OXXO reports that it is awarding single- and multi-unit opportunities. Mishaan encourages those interest ed in pursuing an OXXO franchise to reach out directly to one of the brand’s franchisees.

There’s about 15 months to go be fore EXPOdetergo International re animates for another run in Milan, Italy, “Ottobre” 19-22, 2018. Al ready, 240 exhibitors have signed up, show management reports.

There is a rich variety of exhibi tors, EXPOdetergo adds, currently set to take up about 130,000 square feet, coming to this every-four-years event dedicated to machines (“mac chinari”) and technology (“tecnolo gia”) in textile care.

“Today, even if more than a year ahead, we can surely say that EXPOdetergo International will be an extremely important and appeal ing event for sector professionals from all over the world,” says Livio Bassan, its president.

The event will be at Fiera Milano in Halls 1 and 3, the nearest ones to the underground and railway station.

Bassan relates that the variety of exhibited products, the expertise brought in by world-leading companies, together with training sessions and informative seminars, will help to show where the market is going today.

Texcare Asia 2017 is coming to Shanghai, China, in September and expects a “strong interest from the glob al market,” according to one of two show organizers, Messe Frankfurt Shanghai Co. Ltd.

According to Messe, and co-host China Light Industry Machinery Association (CLIMA), the Sept. 27-29 show is drawing a: “Wave of elevated enthusiasm,” adding that “international industrial associations recommend the fair to players from around the world.”

(continued)

Shanghai’s Yu Yuang gardens, ancient teahouse, and shopping area lighted at night. Texcare Asia comes to the city Sept. 27-29. (Image licensed by Ingram Publishing)

‘Wave’ is a perfect word for the Shanghai event since the city name means “upon the sea.”

Located in the sprawling coastal city of 25 million that faces the Yellow Sea, the Shanghai New International Expo Centre will be the site for an expected 11,000 at tendees and more than 160 exhibitors to come together at Texcare Asia.

Organizers say confirmed participating companies include: Baiqiang, BÖWE, BÜFA, Castic-SMP, Chuan dao, Datamars, EazyClean, Ecolab, Electrolux, Girbau, Hohenstein, Jensen, Kannegiesser, Lapauw, Maxi-Press, Miele, Oasis, Sailstar, Sankosha, Sealion, Seitz, Stahl, TOTO, Vega, Veit, Voss, Weishi and Yamamoto.

“I am happy to learn the fair has received tremen dous feedback from many key industry players. It also reflected the unparalleled position of the fair in the fastdeveloping textile care industry in Asia,” says Richard Li, general manager of the fair.

Brooke Dubois, a Scituate (Mass.) high school student, collected 1,500 pounds of clothing as part of Lapels Dry Cleaning’s annual drive to benefit Big Brothers Big Sisters (BBBS), the company reports.

She had decided to use the company’s annual clothing drive to benefit BBBS for her community service work for school, just as her older brother Josh did the year before.

In the spring, the high school freshman began getting the word out to family, friends and acquaintances. She picked up items directly from donor households, the firm relates.

Her efforts added to the franchise’s Cohasset location to tal, which topped out at 2,990 pounds of clothing collected, the most of any of the company’s participating stores.

Also, it helped push the grand total for all participating stores to 16,093 pounds of clothes collected — the highest in the company’s 14 years of conducting the drive, it notes.

“I’m so happy we were able to get that many donations but what was really cool was how supportive friends and family were in helping this cause,” says Dubois. “In a way,

alone brought in 1,500 pounds of donated clothing for the charity drive.

(Photo: Lapels Dry Cleaning)

it almost made me forget that I was trying to beat Josh. Almost.”

She wanted to collect more clothes for the company’s clothing drive to benefit BBBS than Josh’s 1,398 pounds in 2016.

“There really are no losers when you have a rivalry of this nature,” says Kevin Dubois, father to Brooke and Josh, and CEO of the organization. “Of course, having seen what Josh did last year helped her get a bit of a head start.”

Participating franchise locations were represented from Arizona, Connecticut, Louisiana, Massachusetts, Michi gan, Missouri and New Jersey. ADC

In our first two Yarns Spun Here specials, we examined the terms “carding” and “combing” in textiles.

Now we turn our attention to another industry term: velvet.

Velvet — if you look it up on Wikipedia (and why shouldn’t you?) — is a type of woven, tufted fabric in which the cut threads are evenly distributed, with a short dense pile (that means raised surface) giving it a distinctive feel, the website says.

Pile fabrics consist of a base weave into which a third set of yarns is introduced. This from author Norman Oehlke’s Complete Spotting Guide: “The back is often composed of one fiber and the pile of another. In a method called the ‘V’ weave, the pile yarn passes through the fabric, around one yarn of the base weave and back again.”

He adds: “In another method, the ‘W’ type, the pile yarn passes under one or more yarns, over the next, under again, and up. The latter weave tends to lock the pile more firmly in place than the ‘V’ weave.”

By extension, Wiki adds, the word velvety means “smooth like velvet.” Just think royalty.

An entry from the Encyclopedia Britannica Eleventh Edition (1911) notes: “The peculiar properties of velvet, the splendid yet softened depth of dye-color it exhibited, at once marked it out as a fit material for ecclesiastical vestments, royal and state robes, and sumptuous hangings; and the most magnificent textures of medieval times were Italian velvets.”

There are other usages of the word velvet. This from the Merriam-Webster dictionary: “It is the winnings of a player in a gambling game. A profit or gain beyond ordinary expectation.”

This definition relates to fabricare, too, in a sense.

For if one excels in the drycleaning business – for example, the cleaning of fine clothing such as velvet – then one’s profits are likely going to be velvety! ADC

We talk with a different person from fabricare each time, so you can meet someone new. Tell us where you were born, grew up, and reside today.

“I was born and raised in Hartland, Wis., and still reside there today. My parents, myself and my brothers, and both of my kids, all went to the same high school.”

Hobbies (that you’ll admit to)?

“I am an avid golfer and musician.”

What gets you excited at work?

“Trying a new marketing campaign/idea when it works. Sending out an e-mail for some type of special and seeing people respond and bring those items into our stores.”

Lastly, tell us a secret (keep it clean) nobody knows about you.

“I like putting ketchup on my potato chips.” ADC

(Readers: Do you want to take part in Off the Cuff, or know someone who does? E-mail tburke@atmags.com.)

■ Have you invested in renovations, equipment upgrades, or an entirely new drycleaning plant? Enter your project in the 57th Annual American Drycleaner Plant Design Awards!

Every year, our magazine honors the best new plants and renovation projects, recognizing them for appearance, efficiency, convenience and comfort.

Your plant could be next! You can find our online entry form at: https://americandrycleaner.com/ 57th-annual-plant-design-awardsentry-form

■ Fill out the form completely and upload a layout (blueprint or sketch) and several photos (300 dpi digital files are preferred, but color photos will also suffice) that show off the features that make your drycleaning plant an excellent place to do business.

And include any information you believe is relevant to the way your plant’s design attracts customers and fulfills your production needs. The more detailed the entry, the better!

Perhaps you’ll join the likes of previous grand prize-winners, Classic Cleaners, Indianapolis, Ind.; Peerless Cleaners, Fort Wayne, Ind.; and Wooven, Pompano Beach, Fla., at the pinnacle of the drycleaning industry.

But you can’t win if you don’t enter!

■ Entries are subject to verification. Contact Editor Tim Burke, 312-361-1684, tburke@ATMags.com, with any questions.

American Drycleaner is accepting entries until Thursday, Oct. 5. Good luck!

Own Your Own Drycleaners—Managers, Spotters, Tailors, Pressers! 100% Financing. Plant or Drop, location of your choice. Call 1-561-302-5031 or 1-888-275-6637.

For example, for a June ad, the closing date is May 1st. $350 SHIPS SAME DAY

Must accompany order.

street,

il 60545 WWW.Dltelectric.coM

10 YEARS AGO. A judge denied a request last month for reconsideration of her verdict from the plaintiff in the lost-pants lawsuit against a Washington, D.C., cleaner. The judge refuted the plaintiff’s $54 million claim and also charged him with the defendants’ legal fees. …

Seven out of 10 (70.4%) dry cleaners don’t think that the bans against smoking indoors will have any effect on the industry, by eliminating an unpleasant odor that consumers want dry cleaners to remove.

35 YEARS AGO. The Federal Trade Commission recently refused to go ahead with the plan it “approved in substance” in 1980 that would have extended the care labeling rule to upholstered furniture, carpeting, draperies, curtains, household linens, and suede and leather products. The Republican commissioner who earlier voted for the extension joined the conservative economist chairman to block the extension this time on the grounds that — except perhaps in special cases — there is insufficient evidence that labels are needed on household and leather goods. … “Cleaning items top list” reads the headline of a recent news report in Advertising Age that states: “Special laundry problems are gaining the attention of household products marketers, who are designing new products to meet the apparent needs.”

50 YEARS AGO. Mini-Skirt Merry-Go-Round! A drycleaning and tailoring shop in New York City says it has so much business shortening skirts (at $3 each) that customers must wait as long as two weeks, reports The Wall Street Journal. But mini-skirts may be on the way out, trendsetters warn. Fashion experts expect an invasion of the “maxi-skirt,” which, we’re told, will fall to milady’s mid-calf. So the process may go something like this: Lady brings skirt to her cleaner to be shortened. She picks up shortened mini-skirt two weeks later. But by that time, mini-skirts are “out,” and maxi-skirts are “in.” So, two days later, she brings back the same skirt to be lengthened. We wouldn’t

go so far as to say women are “nuts,” but honestly — aren’t men much more sensible? … More on Minis! Dry cleaners in Great Britain are going mad for mod business by charging mini-prices for mini-skirts —2 cents per inch for cleaning a plain skirt. … What’s In A Name? A busy counter girl in a Chicago suburban call office recently reported an experience she described as “spooky.” Seems she waited on a customer named Oswald, and her next customer calling for cleaning was named Ruby! Should we tell the Warren Commission about this?

75 YEARS AGO. News from the Delivery Front (about the front cover)! Good news keeps rolling in from the delivery front. Cleaners are slashing their mileage figures in a way that once would have seemed impossible. The plans, the early accomplishments of cleaners in various states, should be known to the Office of Defense Transportation (ODT). They are. The latest developments and the details of some newsworthy plans should be made known to cleaners everywhere, so that they can profit by an exchange of ideas. That is the purpose of this (cover story) article. By the time we write this, the general story of cleaners’ efforts to cut their mileage has been told to ODT officials in Washington. … Another report on mileage reduction should be added. From Richmond, Va., on July 21, a cleaner wrote about the results of a plan by 40 cleaners and laundries. Early in February, the group acted to reduce deliveries. Large newspaper ads were run. Plant owners reported mileage savings of 30% to 50%.

— Compiled by Tim Burke, EditorTo read more of American Drycleaner’s chronicling of the industry over the years, visit www. americandrycleaner.com.

When you’re looking for a boiler to fill your steam or hot water needs watch out for a “Big Foot.”That’s right! Big Foot is lurking out there, but not at Parker Boiler. Parker Boil er makes a line of small watertube boilers designed specifically for reduced floor space Even though the square footage that a “Big Foot”boiler may occupy is sometimes less; when consideration is given to manufacturer’s required clearance for maintenance and service, the Parker Boiler footprint will consume significantly less floor space. When a power burner is installed on the top of a vertical boiler, at least 11 feet of clearance may be required for removal and service of the burner and pressure vessel. We don’t know how many buildings have 11 feet of clear space above the boiler, but we do know that Parker Boilers require much less space than the “Big Foot” recommended clearance*. That adds plenty of room for your feed system, air compressor, chemical feeder, water softener, and air vacuum. So if you need a dependable, quality boiler, foruse in smaller spaces, just call your local Parker Boiler representative today.

For Parker Boiler and a Typical “Big Foot” boiler in a standard 9’x10’ boiler room. Boiler, Blow-Off Tank, Chemical Feeder, Floor Sink, Water Heater, Air Compressor, Air Vacuum, Boiler Feed System & Water Softener

5930 Bandini Blvd. Los Angeles, CA 90040 Tel: 323-727-9800 www.parkerboiler.com sales@parkerboiler.com