® April 2018 ■ BEING THERE ■ COLOR-SOLVER

Copyright 2018 American Trade Magazines All rights reserved.

©

www.compassmax.com

“Compassmax nailed it again! With the new CRM and Texting features interacting with customers has never been easier.”

-Tonny Walden, Walden Cleaners

“The online user portal has simplified the pickup and delivery process for our customers. It is simple to use and manage, and has become a profit center.”

“The new scanning at the point of delivery feature is a prime example of less is more. It is simple enough that everybody can use and provides all the data we need to provide over the top service to our clients.”

-Jordan Wood, Davis Imperial Cleaners

“The new route prepay process that Maineline developed and just rolled out is outstanding! This saves us so much time each day as we can now batch and charge out all the route deliveries due for the next day at once. It has also saved us on collections situations. ”

-Jon Simon, Parkway Custom Drycleaning

“Compassmax made our switch to cloud based Microsoft Azure a dream come true. The conversion was extremely well-supported and we no longer have to manage a primary server and back-up server.”

-Dave Coyle, In the Bag Cleaners

Maineline Computer Systems 1-800-354-2525 sales@compassmax.com

-Jason Loeb, Sudsies Dry Cleaners

“Our pressers are producing more pieces with better quality using the Compassmax Piece Tracking module. The integration with our assembly and dispatch conveyors is reliable, flexible and efficient.”

-David Gianfrancesco, Courtesy Cleaners

Same company. Same team. Better

Choose Your Direction Learn more about Compassmax Crescent 2018 at

Software.

our website

Drycleaning Stain Removal Has Never Been So

Spray improved EasyGo onto soiled areas before drycleaning. Stains and soil disappear right in the wheel. For more difficult stains, use on the spotting board before or after cleaning. EasyGo is also an excellent leveling agent. EasyGo now flushes freely in all drycleaning solvents, including GreenEarth®, Perc, Hydrocarbon and K4.

And it's still eco-friendly...California compliant, chlorinated-solvent and NPE free, biodegradable and non-combustible. Drycleaning stain removal has never been so EASY!

To learn more,

or

Become a STAIN WIZARD at ALWilson.com Easy! • More Effective • Use as Spray Spotter or On the Board • Excellent Leveling Agent • Flushes Freely in ALL Solvents

visit ALWilson.com

call 800-526-1188 A. L. WILSON CHEMICAL CO.

drycleaner

FEATURES

April 2018 Vol. 85, No. 1 DEPARTMENTS

Oh, That Finishing Smile

Mary Lou Hernandez, a presser for 20 years, the last nine at Culpepper Cleaners in San Antonio, Texas, “is able to press at any station we have,” says Jess Culpepper, president and general manager. She epitomizes finishers today who can move into different jobs to keep a business running smoothly. Hear from Culpepper about its new finishing equipment, and from some of the manufacturers that bring more modern, technologically advanced equipment to the finishing area of drycleaning operations today.

Tim Burke, Editor

Color-Solver

Dry cleaner: You just knocked the color out of the dress. It happens. You are focused on a mustard stain and following proper stain-removal protocol. You apply your tannin stain remover...and then the light blue color turns yellow where you applied your spotting agent. Now what?

Martin Young, Spotting Tips Columnist

NEED HELP FINDING THE HIDDEN HANGER?

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

2 American Drycleaner, April 2018 www.americandrycleaner.com

AMERICAN AMERICAN

Management Strategies 12 Treasure-Hunting

Industry Observations 28 Wear

Around the Industry 36 Classified Advertising 38 Advertiser Index 39 Wrinkle in Time 40

Pre-Inspection 4 What a Kick! Feature: Being There 6 Bust down conventional ‘walls’ of stereotypical business parameters and “partner-up” in new ways to be there for customers like never before Tim Burke

the Truth Diana Vollmer

the Dream Howard Scott

32

18

(Photo: Culpepper Cleaners)

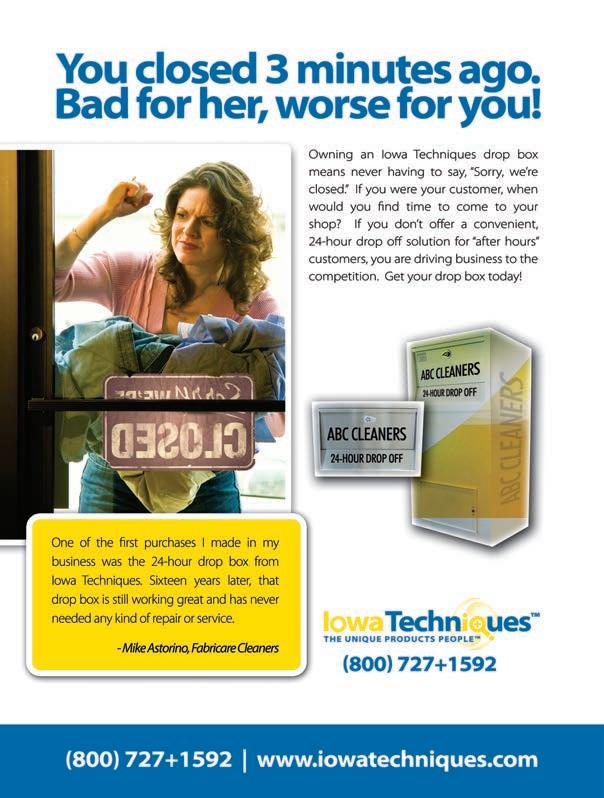

“Business has never been better.”

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

“We’re moving faster. We’re moving better. We’re moving more efficiently. That means profitability”

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

PhilLandauer, OwnerofPierceCleaners has never been better.”

BrentRamenofsky BostonCleaners

What a Kick!

“L

et me see that front cover. What a kick! That’s me!”

And some of my other favorite comments by some of you guys and gals: About being clean: “I’m a clean freak. I’m obsessed with a clean store. We clean every night.”

About new business: “I don’t actually have any idea where my new business comes from.”

About our podcasts: “Great! But you should be talking to me!”

About our annual Plant Design Awards: “Good to see it’s still going after all these years.”

About the drycleaning world: “Make your cleaner look like a bank, that’s the goal.”

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor

Burke

About the world in general: “Just golf as much as you can. That’s what I do.”

About vacation: “We make ourselves go away for a week or so every year to the Bahamas.”

About backup equipment: “If you have only one, then you really have none.”

About reading our magazine: “I read it cover to cover.”

About going to conferences: “Work in a little business between drinks!”

About being innovative in fabricare: “They amaze me with all their ways.”

About style: “The word in ladies fashion: athleisure; men: Duck Dynasty look.”

About our social media presence: “I read your Facebook page. What? ... You have a website?!”

About being quoted in this editor’s message: “Sure you can quote me, but I’ve said nothing.”

April’s issue features a story about what’s new in finishing equipment titled Oh, That Finishing Smile. It also has a feature, Being There, about breaking down the conventional “walls” of doing business. And your three favorite columnists return again, plus there are other goodies. What a kick! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 85, number 1. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2018. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, April 2018

Tim Burke 312-361-1684 tburke@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Roger Napiwocki

Advisory Board

Mike Bleier

Steven Dubinski

John-Claude Hallak Mike Nesbit Herron Rowland Fred Schwarzmann Beth Shader Ellen Tuchman Rothmann

Contributing Editors

Howard Scott Diana Vollmer Martin Young

Office Information

Main: 312-361-1700

Subscriptions 630-739-0900 x100 www.american drycleaner.com

4

www.americandrycleaner.com

PRE-INSPECTION

Tim

BEING THERE

Call it being a good neighbor. Call it a smart business arrangement. Whatever you call it, it’s where service meets opportunity. Three drycleaning owners show how they are breaking down the conventional “walls” of what are accepted as stereotypical business parameters to reach out and “partner-up” in new ways, serving new markets and, in the process, “be there” for customers like never before.

ll the deals are handshake deals,” he says.

The phone line crackles. The connection isn’t the best. And he is pressed for time so the answers are kept short.

“We’re known as a good, stable business.”

The voice is coming out of a “well” over the line. Then the echo goes away.

By Tim Burke, Editor (continued)

“The handwritten note on the front door of the drycleaning store that went out of business some time ago simply says: ‘Go to Hardware Store.’ Which is next door. It’s a smaller community. There wasn’t enough volume to run a full-time cleaners.”

So how does it work, exactly?

“We’ve set up ‘Convenience Centers,’ we call them, in stores in small towns. No staff.

No labor.

“For instance, we pick up three days a week from the hardware store manager, who accepts the drop-offs.”

Dennis Schmitt and wife Patti own Green Bay, Wis.based Lindeman’s Cleaning, a full-service dry cleaner, which they bought from the son of the original owner

(Photo:MichaelBrowning/UnSplash)

(Photo:MichaelBrowning/UnSplash)

6 American Drycleaner, April 2018 www.americandrycleaner.com

Steve Klinke, Klinke Cleaners Madison, WI www.SPOTpos.com • (801) 208-2212 SPOT Business Systems is the most comprehensive and complete system available. AT THE Innovating the Industry Since 1991 We were ‘In the Cloud” before there was a cloud Built for Hosted and Centralized Operations 39 Employees Strong 22 CustomerCare Agents 7 Full Time Developers 5 person Implementation Team Monthly New Feature and Software Release Cycle State of the Art Marketing Tools Weekly webinars and training MobileApp RouteTrac***Mobile *** AdvancedCashControl *** WeeklyWebinars andTraining *** ProductionAdvancedControl *** WebManager andConfiguration TOPOF OUR GAME

in 1998. It was first established in 1951.

Schmitt mentions how these opportunities came about: “Lindeman’s Cleaning partnered with some other businesses in the surrounding communities. We were asked by them to extend drycleaning services to their customers in such businesses like grocery stores, hardware stores, men’s and women’s clothing stores.”

Some are more successful than others, he explains: “The success of these partnerships comes down to the beliefs of the owners that the additional services are important to their customers. When that happens, the convenience center is viable.”

Store owners and managers like the arrangement, Schmitt notes, “because it’s another draw to their business.”

In another example, he points out, “at Gentleman’s Quarter, a clothing store in another town, we get new customers all the time. Again, there wasn’t enough volume for a full-time cleaners in that town so we have another convenience center set up. The owner handles the pickup and drop-off. The store gets a percentage of the revenue.”

He says the clothing store owner loves it. There’s a collection bag his cleaners provides that the customer uses after signing up. “It’s easy,” Schmitt relates. “All the knowledge is by phone call and credit card.”

Did anything surprise you, in a positive way or challenging way, during or after going into partnership?

“The biggest surprises were that the owners who embraced these partnerships have done well with consistent

“The biggest thing that needs to be done is understand the community in which you are located, from the type of business you are, the dollar values of the households, and the convenience and quality of other dry cleaners,” he says.

But this isn’t the only method to break down conventional walls and reach out in new ways.

PARTNER-UP, WALL-DOWN

Meet Stephen W. Moore, owner, Press Cleaners and PressBox Cleaners in Atlanta.

He started Press Cleaners in 2009 and PressBox Cleaners in 2012, to specialize in home pickup and delivery drycleaning and wash-and-fold laundry and locker valet service.

“I didn’t start offering wash-and-fold laundry right away,” he explains, saying that he held off because he “could never find a Laundromat that was truly willing to partner with me.”

Then he notes how he came across many Laundromats that needed to fill unproductive attendee hours but were unwilling to have staff handle increases in volume.

“I was encountering an antiquated mentality,” he relates. “I had several failing partnerships in the search for a wash-and-fold supplier — it turns out they weren’t really partnerships. Nothing really changed until

new customers into their store.”

American Drycleaner asked Schmitt to give a few helpful tips to readers thinking of partnering.

8 American

April 2018 www.americandrycleaner.com (continued)

Drycleaner,

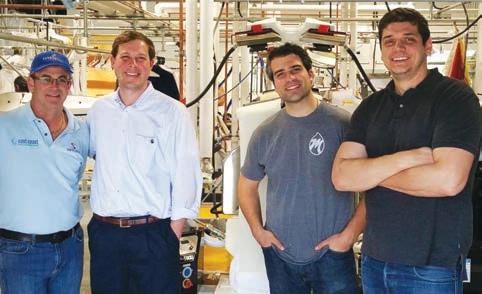

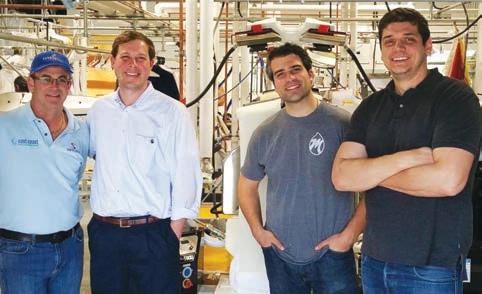

(From left) Steve Jennings, owner, East Coast Drycleaning Equipment; Stephen Moore, owner, Press Cleaners and PressBox Cleaners; Dino

Loles, owner, White Sail Linen (partner), and Stavros Simos, owner, White Sail Linen and HC Laundry (partner). (Photo: Press/PressBox Cleaners)

I modified my mentality and approach.”

He asked this key question one day: How could a sup plier increase their capacity to handle wholesale work that constitutes a larger percentage of their overall volume?

Moore notes that, “Ultimately, the trick was helping my partner get commercial work that I didn’t benefit directly from. I was always getting calls inquiring about com mercial work — mainly from gyms, salons, and massage therapists. I directed work to my partner.

“As my partner picked up this more profitable work, his ability to handle my work in a timely and professional man ner greatly improved. He was able to justify the infrastructure,” he says.

“The term ‘partnering’ is thrown around too much,” Moore indicates. “True partnerships have the mutual best interest in mind and take serious commitment. Though I maintain a sepa rate business from my wash-and-fold partner, our companies have become codependent.”

Companies can help each other break through old “walls,” but communities can play a part, too.

Enter Ed Longanecker, owner of Mt. Pleasant, Iowabased Iris City Cleaners, and District Five committee member with the Drycleaning & Laundry Institute (DLI).

His business is located in the center of a town of 8,500 in southeast Iowa. He reaches out into the rural communi ties all around his region for business. His “walls” are mile upon mile of emptiness, but he’s ventured out far beyond them to make connections—and money.

“We have to go out to where the business is, in a 30- to 50-mile radius.”

His firm handles wedding gown work and partners with local bridal shops in other towns. He also works with Overland Sheepskin Company in Fairfield, Iowa, which he says is “20 miles west of us. We do repair work on leather,

shoes, zippers.”

They sell sheepskin rugs, and coats, and they refer cus tomers to him, he explains. “We go out every Monday and pickup sheepskin jobs for maintenance and repair.”

He also runs a separate logo mat business, selling cus tom mats to his customers.

“We use graphic designers locally, and we partner with a mill in Georgia to make them,” Longanecker says. “We also do work with ServiceMaster on textile restoration.”

The cleaner started in 1949 and he took over in 1969, installing a plant in half his building. He expanded the business to cleaning linens, doing fire restoration, the logo mat business, and more. He joined the chamber of commerce in four commu nities to have a business presence, which helped his exposure.

“Not many cleaning services are in our rural area. We get our route person out on the road, do drop-offs, do home delivery.” He concludes with this: “Proximity is a value in these rural arrangements.”

Call them convenience centers, codependent businesses, or rural arrangements, this is how three individual dry cleaners reach out, in their own wall-breaking style, to gain new customers.

Schmitt relays a comment from a handyman who says his clothes get oily, describing the drycleaning conve nience center inside the hardware store: “Wow, this’ll work.”

Simply put, that’s the point. Make it work — for the customer, the partner and you.

Break down old stereotypes, go beyond the “wall” (so to speak) of your known business environs. Look around for new ways to partner and serve customers. Be opportunis tic. Bring your game out to them.

Are you ready to engage with a new player in a new way? Now you’re truly being there! ADC

10 American Drycleaner, April 2018 www.americandrycleaner.com ADC_HQuarter.indd 1 3/8/18 3:44 PM

“Are you ready to engage with a new player in a new way?”

Computer Systems (888) 325-4763 www.dajisoft.com

Treasure-Hunting the Truth

Surveys help drycleaning owners discover customer happiness

Getting to the truth is like a treasure hunt.

Do you ever wonder what your clients really think of your company, your customer service, your quality, your staff, your stores, vans or product range?

Cleaners who use surveys collect valuable information that helps them continually improve their business.

Most surveys elicit positive feedback, and most clean ers that use surveys report that they are “very happy” with the results. It is a confidence-builder to receive positive responses.

It is even more valuable to uncover weaknesses and receive suggestions that help you make corrections and direct your future growth.

Direct experiences include Brian and Dave Cass of Martinizing in Milwaukee, who were early adopters of surveys, currently use internet-based Constant Contact, which has provided strong direction for their business expansion and is integrated with their POS system.

The difference in the responses by age group gives them insight into capturing upcoming generations as their families and fabricare needs grow.

Brad Pickett of Modern Cleaners in Washington state has been surprised at the high response rates and the fact that “no one ever questioned our prices.”

Peter Kuchlik of American Cleaners on Long Island uses the survey development website SurveyMonkey and likes the immediacy of responses “within minutes” and that the results are aggregated and presented in a usable format.

Bob Guthery of Nichols Hills Cleaners in Oklahoma appreciates the kudos received but cautions that custom ers’ time constraints may limit the participation, possibly skewing results to customers with exceptions to report and less representation from the middle customers with average results.

It is worth noting: Average results present the most vul nerability.

PU R POSE

The purpose of a survey is to determine actionable in formation that you don’t currently have available and/or to confirm things that you believe to be true.

Information gained from a survey can provide valuable feedback on the issues that are important to your custom ers, your suppliers, bankers, employees or other stakeholders.

Surveys can be designed to find out how well your offerings meet customers’ needs and their likes, dislikes, satisfaction level and where you need to make improve ments that will advance your business goals and increase your competitive advantage in the market.

Examples of survey goals can include: Increasing cus tomer loyalty and retention; reducing employee turnover; and increasing favorable word-of-mouth buzz.

RESULT S

Clarity of your desired result is key to designing a useful survey.

“While any company can use data to

MANAGEMEN T S T RA T EGIES

12 American Drycleaner, April 2018 www.americandrycleaner.com

(continued)

Diana Vollmer

(Photo: Clem Onojeghuo/Unsplash)

Toll Free (877) TREVIL 1 www.TrevilAmerica.com P.O. Box 127 - Mamaroneck, NY 10543 Telephone (973) 535-8305 E-Mail: info@trevilamerica.com PANTASTAR PRINCESS ULTRA NO MORE SHINE Princess Ultra 5037 Blouse/Shirt/Multi-Garment Tensioning Form Finisher • Sizes From 0 Petite To 3 XL and larger • Blouses, Shirts, Jackets, Labcoats - Wet or Dry • Dual, Rotating Front Clamps (Patented System) • One Heated For Wet Shirts/Blouses • One Unheated For Drycleaned Shirts/Blouses • Front Clamps Pivot & Rotate No Need To Disconnect & Store Unused Clamp Finish the entire pair of pants INCLUDING THE CREASE with one operator. • For All Types Of Pants: - Creased Or Uncreased - Pleated Or Unpleated - Men’s Or Ladies’ • No Experienced Operator Needed • Requires Less Floor Space Than Conventional Equipment • Rotating Cuff Clamps For Creased/Uncreased/Flat Front Finish Presto FC 5272 Hot Plates Shirt Finisher • Full Length, PTFE Coated Plates • No Shine Cuff Placket Presses • Rear Tensioning With Vacuum & Pull Down • Sleeve Angle Adjustment • Top Hood Removes Heat From The Work Environment Trevistar 5257 Blown Air Shirt Finisher • High Quality “Hand Finished” Look • Includes Economizer Device - Saves Energy And Increases Production • Single Pedal Operation • Large Presses For Plackets And Cuff Pleats - PTFE Coated To Avoid Shine On Dark Colors • Hot Air Blowing Hood For Optimal Yoke Drying • Adjustable Arm Height Eliminates Wrinkles Under The Armhole • Can Be Operated At 80 PSI Steam Pressure The Future Is Here! PRESTOFC TREVISTAR

MANAGEMENT STRATEGIES

optimize costs or sell more products, real differentiation comes from understanding new information about custom ers and orienting that business around those insights. ... Businesses that integrated multiple customer and market ing data sources saw 2.6 times the sales growth over three years compared to peers.” (From google.com/analytics/ 360-suite.#quotation.)

In an example Harvard Business Review reported: “In 2015, 60% of companies said that organizational silos were the greatest barrier to improving customer experience. Successful companies are finding ways to organize around customer needs, creating nimble teams with the customer experience at the center.” (From google. com/analytics/resources/whitepaper-marketing-in-thedrivers-seat.)

Question: Do organizational silos exist between your front-line customer-serving facilities and your plant?

Surveys offer business owners significant feedback, can emphasize your value to your customers and employees, and get them to think about your business.

A DVANTAGES

Well-designed and executed surveys can consistently interact with your target audience to help build insights that can direct day-to-day business decisions.

“Day in and day out, your customer service team an swers the phone, handles email, and otherwise interacts with your customers. They’re a big part of your company and your success. In fact, our research suggests that 72% of customers are very or extremely likely to shop at a company with a reputation for excellent customer service.” (From a customer service survey at the SurveyMonkey website.)

Some things surveys can accomplish:

• Assess customer service training gaps by comparing actual performance with desired performance;

• Assist in determining customer engagement and value of touch points;

• Help understand which marketing is working and which is not, therefore determining where to budget effective marketing dollars;

• Create customer value by isolating where and how best to exceed customer wishes;

• Help assess business model vulnerability (do your customers want 24/7 access?);

• Cost-effectively gather large amounts of usable data.

D ISADVANTAGES

Survey question design is sensitive and must be well and thoughtfully planned or respondents may:

• Feel uncomfortable providing answers that present the company or the employees unfavorably;

• Not be clear on their reasons for any given answer due to lack of memory or disinterest, or if they believe the survey is too long;

• Not fully express themselves in closed-ended questions;

• Not respond to a survey question and their opinion may be different from those who do respond, creating bias;

• Interpret questions differently.

Example: Respondents may answer “no” if the option “only once” is not available.

FORMAT

You have the choice of several survey formats, and your choice depends on the type of results you’re seeking. Sur vey selection and design is critical, as well. Some survey methods are more reliable than others when targeting a spe cific demographic group. Several format options include:

Internet/Online or In-store Tablet

• Automatic ongoing response collection;

• Targeted single-date responses.

Phone

• Completed by internal staff;

• Using outsourced expertise.

In-Person/Exit Interviews/Focus Groups

• Implemented by informal internal staff interaction;

• Formalized by outsourced professionals.

Note: Live interviews and focus groups are most valu able when they are recorded to ensure thorough capture and analysis of the responses. Beware, sometimes participants say what they think you want to hear. Written mail-in sur veys are more thorough, but get lower response rates.

D ESIGN

There are many alternatives to meet your specific goals for the survey:

• Integrated into existing systems within the operation, i.e. your point-of-sale (POS);

• Stand-alone formats that have a specific focus;

• Sliding-scale overall rating;

• Multi-question detailed assessments;

• Trigger delivery (prompted by a specific (continued)

14

www.americandrycleaner.com

American Drycleaner, April 2018

RECOVERY CLEANERS BLENDS CARING CULTURE WITH POSEIDON WET CLEANING SYSTEM — REALIZES QUALITY RESULTS AND BOOSTED PROFITS

The female-driven Recovery Cleaners makes a business of helping others by carefully recovering and restoring garments damaged by fires and floods. President and founder Jacqui Schaefer, who started the business 24 years ago as a one-woman operation, has since grown Recovery Cleaners into a company with 29 employees and a 14,700-square-foot textile restoration facility. The Poseidon Textile Care System handles 70 percent of the collected items and restores them via wet cleaning only. The remaining items are processed via dry cleaning.

“We are almost all women here, with an average tenure of 17 years,” said Schaefer. “We go into homes that have been significantly damaged due to fires or floods, compassionately sort through the affected garments and linens, which are then brought back to our facility to restore. Our positive company culture enables us to go above and beyond on each and every claim. We truly have the greatest service team in the industry. That’s what sets us apart.”

“Here at Recovery Cleaners, we are always staying ahead with leading edge technology,” added Schaefer. “Our commitment to quality and earth-friendly processing is what brought us to the Poseidon Textile Care System. Wet cleaning is often more effective than dry cleaning when it comes to removing soot, odors and fire pollutants.”

Poseidon Textile Care System Boosts Productivity

Recovery Cleaners recently added new wet cleaning machines and dryers from

the Poseidon Textile Care System. “With these new machines we are able to increase productivity, cut utility costs and become more efficient. We estimate that we will add an additional 52,000 pounds of laundry in one year alone,” said Schaefer. Mike “Stucky” Szczotka, of Poseidon, in Troy, Mich., worked with Schaefer to retool her plant with appropriately sized Poseidon equipment. He recommended and installed one 90- and two 55-pound capacity soft-mount Poseidon Wetcleaning Machines and two 80-pound capacity Poseidon Dryers.

“Poseidon machines supply us with the tools to make the wet cleaning process quick, efficient and profitable,” said Schaefer. “There are many companies that cherry pick only the items they think they can salvage. We process it all and

are able to maintain a 95 percent salvage rate from wet cleaning and dry cleaning combined.”

“Prior to the company’s Poseidon Dryers, more items required air drying, which slowed production. Now, items are quickly dried with less wrinkling,” said Schaefer, “reducing the time needed to finish them.” “There are several companies in the textile restoration business,” added Schaefer. “While our Poseidon machines make it more profitable and efficient, it is our caring staff and amazing company culture that completes the circle.”

Read full story at poseidonwetcleaning.com

POSEIDON

poseidonwetcleaning.com 800-482-3400

Poseidon machines supply us with the tools to make the wet cleaning process quick, efficient and profitable.

- Jacqui Schaefer, Owner Recovery Cleaners

MANAGEMENT STRATEGIES

action, i.e. bringing in a large order might prompt the question, “Are you aware that we offer pickup and delivery to your home or office?”);

• Survey branching logic (triggers follow-up questions based on initial responses);

Example: If the customer was aware of your delivery service in the question above, the follow-up would be, “Would you like us to deliver this order for you?” Use sin gle-language/multi-language options for cultural variances.

TIMING

The responses will be more valuable if the survey is pre sented timely, so plan your survey calendar in advance.

Example: Customers are more likely to respond to ques tions about storage or drapery services during a change of season. They are more likely to appreciate the advantage of a mat service during the rainy season.

ASK THE RIG HT QU ESTI O NS

Question design is an art and a science with many varia tions that affect the responses. Many of the survey tools provide guidance, but if you are uncertain, hire an expert to draft your survey.

Quantitative questions ask respondents to specify their level of agreement or disagreement on a symmetric agreedisagree scale for a series of statements, such as a range of possible choices from “extremely likely” to “not at all likely” that they would recommend your service to a friend. Binary questions provide the target consumer only two answer options, usually yes or no. (You may want to offer a third option, i.e. “haven’t experienced.”)

Qualitative questions are open-ended questions that al low respondents to provide information that is important to them that you may not have thought about. This is especially valuable information for your business development planning.

Examples: “What can we do to improve your experience?” “Is there anything else you would like to share with us?”

NET P ROMO TER S CORE ( NPS)

NPS has been widely adopted with more than two-thirds of Fortune 1000 companies using the metric. It’s calculated based on responses to this: “How likely is it that you would recommend our company/product/service to a friend or col league? The scoring for this answer is most often based on a 0 to 10 scale.” (From Wikipedia/wiki/Net Promoter.)

B IASE D QU ESTI O NS

Question design has a huge impact on the answers, and especially biased questions will defeat the objectivity of your survey.

Example: Susan and Walter are getting ready for their big summer barbecue party. Susan agrees to be the barbe cue grill master if Walter buys all the ingredients. Not sure how many hamburgers to buy, Susan sends out a survey to all of the guests. When Walter checks the survey, he’s shocked that 0% of people want hamburgers. Then he reads Susan’s survey question:

Do you want to have someone kill a defenseless animal, skin it, grab some of it, add preservatives to it, and force me to inhale its death fumes while I cry silently because it reminds me of all my animal farm friends from when I was a child?

Walter shakes his head and sighs, “Do I have to do ev erything myself?” He writes a new survey question and sends it out to their friends:

Do you want to support local American farmers in these troubled economic times by grilling up a traditional Ameri can juicy burger?

Try to make people feel comfortable answering your questions truthfully. Remove unnecessary informa tion. Balance the question. Balance the survey. (From SurveyMonkey.com/curiosity/a-little-bias-is-a-bigproblem.)

Both forms of the survey are biased, so a more neutral attempt might be: How many hamburgers do you typically eat at a barbecue?

As you can see from the options, surveys have many advantages and present many options from which to choose when treasure-hunting for the truth about customer happi ness at your drycleaning store.

If you have never utilized surveys, the easiest option to implement is to simply ask, “What can we do to improve your experience with us?” Depending upon responses, that one question may aid you in directing your business. ADC

Diana Vollmer is a managing director for Methods for Management, which has served dry cleaners and launder ers with affordable management expertise and improved profitability since 1953. For assistance analyzing your opportunities and implementing plans to capture them, call 415-577-6544 or e-mail dvollmer@mfmi.com.

16

www.americandrycleaner.com

American Drycleaner, April 2018

Tells

25

A Story...

Years

All our customers are partners in our business. Because of their ideas and suggestions, they have provided us the ability to develop innovative equipment to help their businesses be successful and more profitable. We would just like to say for being a part of our family. http://www.sankosha-inc.com 1901 Landmeier Rd., Elk Grove Village, IL 60007 • TOLL FREE: (888) 427-9120 • TEL: (847) 427-9120 SANKOS H A U.S.A . YEAR ANNIVERSARY thank you

Oh, That Finishing Smile

By

Editor

eral manager, “which is atypical of most pressers we hire now. Having personnel such as Mary Lou, who we can move into different jobs, is a critical aspect of keeping a business running smoothly.” (Photo:

he new finishing equipment entering the market today is certainly making it easier for operators to finish garments, according to Jess Culpepper, president and general manager of Culpepper Cleaners in San Antonio, Texas.

“These improvements could not have come at a better time as it has become increasingly more difficult to find a finisher with experience,” he says.

His family has been in the drycleaning business since 1911.

“I entered in 1978 as the third generation to do so. At this time, we operated one plant and two drop stores. Our goal is and has been for 100-plus years to provide the best customer service, drycleaning and laundry service to the people of San Antonio.”

Culpepper relates that the new finishing equipment he installed is “very easy for the operator to learn to use properly with minimal training.”

He points out that, “We have installed a Unipress Versa Form 3, Unipress Tensioning Coat form, Sankosha Tensioning pants topper, and several Sankosha Leggers, one of which is the SDP-880U.”

All of the pieces replaced other older equipment, he adds.

“Most people don’t like change and that was true for some of (our) operators at first, but now they are all very happy with the new equipment and would absolutely put up a fight if they had to go back to the old equipment.”

On the drycleaning side, Culpepper notes, “We finish all of our cottons on hot-head presses. We have four employees that were operating four presses in that department and we were having a difficult time keeping up with our production demand. We purchased a Versa Form 3 and, to make way, we removed one of our hot-head presses.

“One operator now uses the Versa Form to steam finish all the cotton garments, which

18 American Drycleaner, April 2018 www.americandrycleaner.com

Tim Burke,

Today’s fi nishing equipment makes life easier and better for one Texas drycleaning owner and operator

Presser Mary Lou Hernandez is all smiles as she stands proudly by her finishing station at Culpepper Cleaners in San Antonio, Texas. She has been pressing clothes for 20 years, the past nine at Culpepper’s. “She is able to press at any station we have,” says Jess Culpepper, president and gen-

Culpepper Cleaners)

(continued on page 23)

BE th e Baddes t Get SM RT

yo a ay do at yo e a ay do e o a ay et at yo e a ay ot - e y o d

At SMRT, we never stop innovating to improve your business. We are fiercely committed to providing you the tools you need to be mobile, look forward, and get ahead. (And still get a good night’s sleep.)

e Ma a e

e

to

- -o e So t o

R T

Don’t worry – SMRT knows where everything is. SMRT will tell you if you’re good to go or when you need to crank it up.

Se ty

Keep your data safe with industry leading security encryption, threat monitoring and detection.

Ma et

Understand, serve, keep, and grow your customers with powerful behavioral marketing, real-time stats and seamlessly integrated communication tools.

Re o t a d

SMRT invented reports for every deciding factor in your business. Get the numbers you want, in real time, whenever you want!

ty

“God views,” machine learning and cash box security root out employee theft and drive accountability.

to e o e t

Your customers can track orders, schedule pickup and deliveries, see their online wardrobe, make payments, update personal info and communicate with you directly.

SMRT Sy te (415) 612-9885 SMRTSy te o a e t y te o 1846 e e St Sa a o 94129

Tired of High credit card rates? Get SMRT Get SMRT Today (415) 612-9885

are then touched up as needed on the three remaining hothead presses. Our production in that department has increased 15%, which certainly is a pleasant outcome from this move.”

The business also utilizes the Sankosha SDP-880U, a double-legger in which the middle press separating the two legs has a vacuum. “We have increased production by 20% at that position,” Culpepper says.

Upping productivity is always on the minds of drycleaning operators on the finishing side. But the need to find experienced operators has also become pressing. It’s put the focus on technologically advanced machines that are easier for team members to operate.

EASY RIDER

“Is it easy to learn?” That could very well be the mostasked question in the finishing area for drycleaning owners.

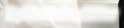

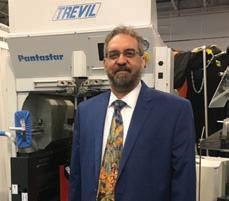

Enter Stuart Ilkowitz, president, Mamaroneck, N.Y.based Trevil America, in business since 1999 as the exclusive importer and distributor of Trevil equipment in the United States and Canada.

“Whereas a few years ago, the main question people asked about equipment pertained to productivity, as in, ‘How many can it produce in an hour?’” he says. “Now, the focus has changed to where they want the machines to be easy for anyone to operate while also productive and offering high quality.”

His company’s factory in Italy is one of the manufacturers of pressing and finishing equipment since the 1970s. He point out that it is difficult nowadays “to find workers who are reliable; show up for work every day; get along

with other employees; are able to produce high-quality, finished garments at a fast enough pace; and are willing to work in the conditions of a drycleaning shop, all for the salary that a drycleaning shop owner can afford to pay.”

As Ilkowitz sees it, finding, training and maintaining employees has become a larger challenge, particularly once you get away from the big cities.

“Shop owners are realizing now that they need to focus more on the capital investment on a piece of equipment that nearly anybody can be quickly trained to operate, rather than equipment that requires a particular set of skills that takes many months of experience to learn,” says Ilkowitz.

A customer of his in Omaha, Neb., was opening a second plant: “They wanted to find equip-

www.americandrycleaner.com

April 2018 23

American Drycleaner,

The team poses for a photo-op by the finishing area in their plant at Culpepper Cleaners: (from left) Rachel Trevino, Maria Martinez and Julie Alvarez. The women are in charge of pressing all cotton and linens on the drycleaning side.

Standing behind them is Jess Culpepper, president and general manager, who relates that the new finishing equipment he installed is “very easy for the operator to learn to use properly with minimal training.” (Photo: Culpepper Cleaners)

(continued)

Stuart Ilkowitz is president of Trevil America, an importer and distributor of finishing equipment. (Photo: Trevil America)

ment that would provide high-quality finishing but knew that they needed something modern that would be easy to operate, as finding experienced operators had become an issue for them.”

The cleaners purchased several pieces of equipment from his company, “including our Pantastar pants finish ing machine. The Pantastar can press the entire pair of pants, including the crease.”

He notes that the operator does not require the same level of skill that someone using a conventional topper and legger press would, so it is much easier to find someone to run this machine effectively.

“They are producing around 40 pair of pants per hour with consistent high quality,” Ilkowitz relates. “If the regu lar operator is out one day, another operator can step right in and produce nearly identical numbers.”

Michael “Stucky” Szczotka, co-owner, Troy, Mich.-based Poseidon Textile Care Systems, seems to agree when he notes that there have been many im provements and innovations in finishing equipment in recent years.

One of the most notable, he says, “is with flatwork ironers. More and more dry cleaners are installing them for quality ironing of sheets, pillowcases, tablecloths, napkins and more. This al lows dry cleaners to serve new revenue sources, such as hotels, restaurants and spas, for example.

“With improvement in ironers, opera tors can now go right from the wet wheel to the ironer without having to condition the goods in a dryer. This saves a lot of time!”

About her own drycleaning customers, Yuriko Tanabe, vice president, European Finishing Equipment Corp./HiSteam, based in Seacaucus, N.J., notes that her company’s most popular machine remains its SAM-451, a multigarment finisher for shirts, blouses, suit jackets and polo shirts, whether laundered or dry-cleaned.

Started in New York City in 1977, with gravity feed bottle iron and all steam iron, her firm around 1995 began offering Italian tensioning machines and vacuum boards, and later mini boilers.

What’s new today?

“Electric shirt finishing equipment, like the Turbo-Jr. (E), shirt finisher and CB-520 (E) collar and cuff press. We introduced them for those cleaners who do not have, do not want, or are not allowed to have an industrial boil er,” Tanabe explains.

“Our first customer was the laundry room at Lowes Regency Hotel in New York City, who removed their

troublesome boiler with frequent repairs and inspections.” She indicates that they are happy to find a new alternative to the traditional finishing processes.

“Dry cleaners ask for machines with a smaller footprint, cooler to operate, easier to train, and reasonably priced,” she adds.

Tom Stites, sales manager at Unipress, says whenever he is speaking with a customer, labor costs are always one of the major topics of the conversation: “They ask, ‘How can I increase my production?’ Or, ‘Will this save me labor?’”

Stites says his company’s name has been around for what seems like an eternity. “The company was actually reborn in 1982, with a new ownership group, new business model and a new manufacturing facility in Tampa, Fla. We manufacture a full line of shirt units, drycleaning finishing, wetcleaning finishing and laundry presses.”

Owners that successfully maximize their production are able to control their labor costs, Stites says.

“We strongly advocate that each pressing station should have produc tion standards. The operators should be held accountable to adhere to the standards.”

An example of this, he relates, is that recently, a Unipress customer in New Jersey replaced two traditionalstyle shirt units that were operated by four employees with two Hurricane double-buck shirt units run by three operators.

His customer is now “exceeding over 185 shirts, and with the previous equipment, he was averaging 180 shirts an hour with four employees.”

The Hurricane features a touch-screen PLC that tracks real-time production, Stites notes. The current hourly production, as well as the target rate, is displayed on the screen.

“Additionally, there is another highly visible display that monitors production with color-coded green, which means meeting the set standard; yellow, which indicates within 70% of the standard; and red, which is ‘unaccept able.’ This is used to motivate and remind the operator to keep on task.”

So what is Wesley Nelson, vice president of sales and the COO at Sankosha USA Inc., Elk Grove Village, Ill., seeing in drycleaner demand today?

“Customers are inquiring more and more about tension ing equipment such as form finishers, pants toppers and drycleaning presses. They are finding out

24 American Drycleaner, April 2018 www.americandrycleaner.com (continued)

Michael “Stucky” Szczotka, co-owner, Poseidon Textile Care Systems. (Photo: Poseidon Textile Care Systems)

that tensioning equipment benefits plants that are process ing garments by means of wet cleaning as well as dry cleaning,” Nelson says.

As an example, he says, “Recently, a Tensioning Form Finisher was installed at a plant in Sonoma, Calif. The equipment it replaced was an old Suzie. Both the plant owner as well as the presser noticed on the first garment, which was a men’s sport coat processed on the new Tensioning Form Finisher, that the garment was basically ready for assembly.

“Other than some light touch-up while the garment was already on the hanger, the sport coat never touched another press.”

Smart technology has come into everything in our lives and it’s in our drycleaning machines today.

As machines get smarter, where do you think this “smart tech” on the fin ishing side is leading?

Nelson explains that the goal of smart tech, “as far as Sankosha is concerned, is to provide equipment that requires fewer touches on each garment by the operator.

“Due to the difficulty in finding experienced pressers, the newer equipment requires less and less pressing expe rience, and shortens expensive training time.

“The smart tech is in the controls where the operator can tailor the type of press or time needed for each type of garment. It must be simple and quick and easy to maintain production.”

“Simple,” “quick,” and “easy” are words that come back more and more to describe today’s finishing needs. The machines are geared toward users understanding and oper ating on a general level. But are they understanding?

ARE WE THERE YET?

We see the flashing buttons. Hear the blast of air. But we want to know how it all really works, too.

So the question is: Do drycleaning owners and operators understand the technology in their finishing equipment?

Nelson says customers seem to have a very basic under standing of the new finishing technology: “Enough so that they can see the benefits of using tensioning equipment for garments that have not been wet-cleaned.

“We start up and train a large portion of our equipment in the field. The owner and operators become familiar with the machines very quickly with the operation, the controls, and maintenance. Our controls are similar across our line of machines, which helps in a major way.”

To that same question, Stites replies, “Good question — and sometimes the best way to answer that is to compare it to a smartphone. Some people only use a phone to com municate with friends and relatives. Then there are others that it becomes an integral part of their daily life. The more they use it, the more valuable it becomes.”

Ilkowitz thinks that most dryclean ing owners and operators understand the technology in their equipment fairly well, but often they do not fully consider the day-to-day costs of owning and op erating a machine.

“I recently spoke with someone who was certain that he did not want to buy a dedicated shirt-finishing machine be cause he didn’t want to invest that much money in equipment,” he points out as an example.

“After some conversation, I helped him to understand that it is not so much the cost of the equipment at the time of purchase that was the most important thing, but the cost of operating the ma chine every day that matters.

“When he realized how much money he was spending on labor to produce the quality and quantity of the shirts he needed to finish each week, it became clear that the shirt-finishing machine wasn’t going to cost him a lot of money. It was actually going to make him a lot of money.”

In some ways, it seems to be a matter of viewpoint on the owners’ long-term return in finishing.

“So it’s not so much an issue of them understanding the technology of the equipment,” Ilkowitz relates, “as much as the bigger picture of labor savings, consistency of quality, and ease of training that requires more of a conversation.”

Back to our dry cleaner Jess Culpepper in San Antonio, Texas, who as the president of his company, naturally, will have the final word about finishing.

Culpepper notes that the new finishing equipment enter ing the market is certainly making it easier for operators to finish garments.

“These improvements could not have come at a better time as it has become increasingly more difficult to find a finisher with experience.

“I am definitely a fan of making things easier and better, so I am hopeful the equipment manufacturers continue to improve their products, which in turn will help all of us in the drycleaning profession excel at providing our custom ers with impeccably finished garments.”

Can’t think of a better way to wrap up this article than to repeat his words: “impeccably finished garments.” And now we are finished!

ADC 26 American Drycleaner, April 2018 www.americandrycleaner.com

Wesley Nelson, vice president of sales and COO at Sankosha USA Inc. (Photo: Sankosha USA)

SHOPPING CENTER SUSTAINABILITY THE LEADER IN

BY WAY of GREENEARTH CLEANING

For property owners concerned about perc and other potentially hazardous dry cleaning chemicals, GreenEarth Cleaning doesn’t just solve the problem, it creates opportunities. Kimco Realty, one of North America’s largest publicly traded owners and operators of open-air shopping centers, is a leader in sustainable real estate practices. As part of their corporate responsibility and sustainability

program, Kimco educates its tenants on the advantages of GreenEarth cleaning, and several years ago chose to require that any tenant performing on site dry cleaning at its shopping centers use GreenEarth. Kimco’s decision helped to ensure the safety of its tenants, neighbors and shoppers.

SCOTT GERBER / VICE PRESIDENT RISK / KIMCO REALTY

SCOTT GERBER / VICE PRESIDENT RISK / KIMCO REALTY

Wear the Dream

Every dry cleaner should have a slogan to go alongside its name.

“With all the things I have to worry about, you want me to spend my precious minutes creating a silly tagline?” you ask.

“That’s the stupidest piece of advice I’ve ever heard,” you might declare. “What a waste,” you could add. “What good does a slogan do? Just adding more BS will not win me one more customer.”

The only thing is, slogans do work.

A slogan adds to identity. A slogan creates a mental dream in customers’ minds, which helps them identify and bond with your store. A slogan is a way in, emotionally, for a new prospect to try your store.

A slogan helps give your em ployees a rationale to motivate themselves. It focuses your thinking about your business, particularly when considering mar keting strategies. It unifies your promotional efforts.

A wonderful advertising aid in a sentence, a slogan helps breathe life into your whole enterprise.

John Deere is one of the most successful agricultural equipment manufacturing companies in America. Its slo gan, “Nothing runs like a Deere” is probably one of the best slogans used today. Moreover, it has been in use for 155 years. I am not saying the slogan is the reason why Deere is one of the preeminent names in its industry, but it helps.

Why is the John Deere slogan so good? Consider that customers above all else want their tractors and lawn mowers to run well, and be trouble-free. The slogan hits at that need.

First, one visualizes a deer bounding effortlessly through the dale, and then one connects this smooth effortless flow to the machine.

Second, the words make the viewer think and parse out its double meaning. On one hand, it’s talking about a Deere tractor. On the other hand, it’s talking about the fleet-footed animal, a deer. It’s a clever amalgamation of the two.

Third, it has a smooth-flowing cadence, almost like good song lyrics. It rolls liltingly in one’s mind, much like the Beatles lyric, “All you need is love.”

When I look around the marketplace, I see slogans such as “The quality cleaners,” “Serving customers for three decades,” “Your number one cleaner,” and the like. These are OK, but you can do better.

Make a memorable slogan that sticks in the customer’s mind long after their last visit. Think about what you’re selling.

You’re selling cleaning services — the processing to get clothes clean — that’s true. But so what? What do clean clothes mean? It means that the garments feel good to wear. But these garments not only feel good, they look good.

BEAUTY MATTERS

Customers see themselves as sharply dressed, self-confident, and feeling good about themselves. So in a sense, you’re not selling clothes processing, you’re selling attractiveness. Just as John Deere is not selling a machine but rather is selling smooth, reliable performance.

So your slogan should focus on the end result: appear ance. Here are some suggestions:

• Erickson Cleaners’ “For the sharper look.”

• Saffler’s “Lookin’ good, day after day.”

• Quality Drycleaners’ “The million-bucks look.”

• Town & Country Cleaners and Laundry’s “Always looking your best.”

• Reading Drycleaners’ “Look great, every day.”

• Seth Bros. Cleaners’ “Where your

28 American Drycleaner, April 2018 www.americandrycleaner.com

INDUSTRY O BSER V AT IONS

Howard Scott

A really unique slogan helps form a bond with your customers

(continued)

(Photo by Beth Solano/Unsplash

appearance is our business.”

Maybe you want to be clever with your words. Like the Deere slogan, you might want to make customers ponder over your slogan.

How about Fabric House’s “The image that can’t be fabricated”? The two similar words, fabric and fabricate, cause the customer to pause. What can’t be fabricated? So you patronize Fabric House.

Or Professional Drycleaners’ “Feel like you”? The cus tomer thinks, “What does it mean, ‘Feel like you?’ Wait a minute, I know what it means. It means feel totally your self in your clothes, feel like you belong in these clothes.”

The thinking makes you realize your true goal: to feel totally at ease in your clothes. So you patronize Profes sional.

And Goolby’s’ “Where beauty matters”?

This makes you think that dry cleaning is not really about beauty. “But, wait a minute. Yes, if truth be told, I am interested in being as beautiful, or attractive as I can,

and, yes, my dry cleaner, Goolby’s, helps.” Alternately, the slogan could be, “Where appearance matters.”

These are just a few suggestions to stimulate thought. Think about what you are all about and what you offer customers, and come up with your own unique slogan. Your slogan needs to suggest a real benefit. You want the words to sound poetic, so they reverberate in the person’s mind.

You need the slogan to stick out in the marketplace and to call attention to your unique offering. Finally, you want your slogan to be memorable.

Put your slogan to use. Over time, incorporate it in everything customers and prospects see. Go through the effort and create the perfect slogan for you. ADC

Howard Scott is a former business owner, longtime industry writer and drycleaning consultant. He can be reached by writing him at Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027, or via e-mail at dancinghill@gmail.com.

30

April 2018 www.americandrycleaner.com

American Drycleaner,

INDUSTRY OBSERVATI O NS

ADC_R_Hhalf.indd 1 11/3/14 2:27 PM

Color-Solver

You just knocked the color out of the dress.

It happens. You are focused on a mustard stain and following proper stain-removal protocol. You apply your tannin stain remover...and then the light blue color turns yellow where you applied your spotting agent.

There are times, with the best of intention, the spotter will “dig himself into a hole.” The choices are limited: pay the claim, deny responsibility, or find a course of action to restore the garment.

Here are some things you can do to help remedy the problem.

Many dyes are sensitive to the pH of the chemical tool being used. That is the science. It means that the color of the dye may not be gone, only altered. There is a solution, if you act quickly.

(Note: The term “pH” is a measurement of the hydrogen atom concentration, used to express the acidity or alkalinity of a solution on a scale of 0 to 14, where less than 7 represents acidity, 7 represents neutral, and more than 7 represents alkalinity.)

Pull the affected area over the vacuum nose of the board and flush the area with steam while at the same time applying an opposite-pH chemical tool.

If the color change happens when you applied the tannin formula (acid), steam and apply a protein formula (alkali). If the color change happens when you applied the protein formula (alkali), steam and apply a tannin formula (acid). It’s worth a try, and it will save your reputation and a potential claim.

When you “spot” an area with steam and rerun the garment without properly drying the area, dirt in the solvent will settle in the moist area, causing redeposition.

Redeposition remains the No. 1 drycleaner-caused problem in garment care. Uncontrolled moisture is the enemy in a drycleaning system. The moisture will attract the dirt removed from other garments in the drycleaning wheel. This dirt will appear as shades of brown or gray on the garment.

It has been said that “an ounce of prevention is worth a pound of cure.” This is certainly true when it comes to redeposition.

Be sure all moisture left from wet-side spotting is dried when you choose to put that garment in the drycleaning machine. It is a good idea to take the added precaution of applying a leveling agent to the area steamed to handle any moisture that you do not detect. Wool can hold about 33% of its dry weight in moisture and not feel wet to the touch.

However, if redeposition does occur, you must deal with the result. When redeposition is a small area, it can be treated as an insoluble stain.

Apply an oily-type paint remover to lubricate the stain, then tamp the area over the solid portion of the board to loosen and remove the stain. Then rerun the garment to finish flushing away the soil.

There should be a complete change of solvent in the wheel every minute. When that time extends past a minute and a half, you run the risk of general redeposition over the entire load.

With the increased number of plants switching to emerging solvent systems, some operators insist on running shortened cycles in the name of productivity. This leads to inefficient cleaning and loosened dirt being redeposited on the entire load rather than on the filter system.

Some operators might not use a good detergent in the wheel in the name of saving money. One of the many advantages of a drycleaning detergent is to help hold soil in suspension until it can be carried to the filter and not be left on the garments.

Proper filtration is the factor that allows the operator to constantly reuse the solvent. The convenience of modern filtration systems often leads

32 American Drycleaner, April 2018 www.americandrycleaner.com

Take steps to remedy your ‘altered-dye-color’ dilemma (continued)

Martin Young

SPOTTING TIPS

(Image by Pete Bellis /Unsplash)

“Not only did I reduce my assembly sta from 2 people to 1, I also noticed signi cant reduction in mark in labor costs as well.The opportunity for human error has been vastly reduced. I should have switched years ago when Brett rst spoke with me!!”

“I can honestly say that the QuickSort is the single best item I’ve ever purchased. The direct labor saving payback was less than one year. The increased e ciency from barcoding at the mark-in counter coupled with the complete elimination of assembly mistakes makes this the smartest business decision I’ve ever made, and one that is paying daily nancial dividends. “

Allan R Cripe CED,CPD

Brian Robertson

Owner, Valet Cleaners and Coin Laundry

Allan R Cripe CED,CPD

Brian Robertson

Owner, Valet Cleaners and Coin Laundry

(501) 420-1682 garmentmanagement.com

Owner, Comet Cleaners of Corinth

to the temptation of neglecting proper maintenance of filtration. You don’t wash laundry in a mud puddle, and you can’t dry-clean garments if the solvent is the color

of your morning coffee.

Overloading your drycleaning machine reduces solvent penetration and eliminates the necessary drop in the garments to give proper

mechanical action in the wheel. Reduced solvent flow and reduced mechanical action will result in sub-par cleaning; streaks and swales; and, in many cases, general redeposition of soils.

Dye transfer can be the result of many poor decisions and oversights. Proper classification of garments will reduce the chance of a navy garment transferring dye to a separate pastel garment in the load.

Proper detergent and proper run times will allow the dye that is loosened from garments to be carried to the filtration system or the still, as opposed to being transferred to another garment in the load.

When you do realize that you have dye transfer from a load, the proper protocol is to inspect each piece immediately, and rerun any piece that shows evidence of fugitive dye.

For those items that do not respond to the second cleaning cycle, a dye stripper may be necessary. In some cases you will be able to use a bath, but for small areas, a cotton swab or a wooden toothpick can be used for the pinpoint application of a reducing bleach/dye stripper.

Knowing various methods to prevent a problem and ways to correct a problem created by your staff can and will save your reputation and your pocketbook. ADC

Martin L. Young Jr. has been an industry consultant and train er for 20 years, and a mem ber of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates today. Phone: 704786-3011, e-mail: mayoung@ctc.net.

34

www.americandrycleaner.com

American Drycleaner, April 2018

SPOTTING TIPS Family owned since 1996 Plant built in 2006 2nd Satellite location (600SqFt) *2500 Sqft facility with additional 800sqft 2nd Floor o ce with Kitchenette & Bathroom 60#Frigosec DC 50# Unimac Washer/Cissell Dryer Two Parker Boilers Hi-Low Conveyor POS Computer System Delivery Van & Route (Est1996) Alterations

Exposure from major State Route Highway 3145 Maricopa Ave | 45 Capri Blvd, St B • Lake Havasu City, AZ 86406 Contact Sharon Lux @ 928.727.1320 Business For Sale

Dept.

Hoffman Double Topper (Used) $3,350* Milnor 45-lb Washer (Used) $2,995* Unimac 75-lb. Reversing Gas Dryer (used) $2,200* Easysec 40-lb. Hydrocarbon Machine $29,600* Unipress Sleever (used) $5,995* Ingersoll Rand 5 HP 120 Gal. Vertical Compressor (Used) $995* Wascomat 83-lb. Gas Dryer $3,525* Forenta Utility Press (Used) $2,950* Lattner 20 H.P. Boiler $12,995* Electrolux 62-lb. Washer $7,995* Forenta 19VS Laundry Topper $4,450* Unipress NT2 Double Buck (Used) $18,500* Forenta Single Legger $5,999* Forenta 44SP Spotting Board $2,750* Forenta Triple Puff Iron (used) $1,100* 1/2” Steam Traps $35 each, 5 trap minimum 86 6 - 73 4 - 364 4 Monthly Specials Online: MustangEnterprises.com New & Used Equipment for Drycleaning & Laundry Huge Selection of Parts for Most Brands of Equipment Prices valid until May 1, 2018 | *Freight Not Included

FabriClean Supply named ZIPS Supplier of the Year

FabriClean Supply, based in Little Rock, Ark., with warehouses in a dozen states in the central, southeastern and southern United States, was named ZIPS Supplier of the Year for 2017 at the annual ZIPS franchisee meeting last fall, FabriClean writes.

“This is a yearly confab of all 70 franchisees and ZIPS corporate management,” says Orville Johnson, vice president of sales for FabriClean Supply.

They award the top performers in their brand, he states, for customer service, number of pieces pro cessed, and other categories. They also award various vendors that have been a part of helping the brand grow over the past year, he explains.

Davis now VP of sales at White Conveyors

White Conveyors Inc. recently promoted Bob Davis to vice president of sales. “Bob will lead White and Speed Check Conveyor’s North American sales effort,” the garment-handling equipment firm reports.

“Bob is a 25-year veteran of the company,” it con tinues, “who has worked his way up the corporate ladder from engi neering design, project design and management, industrial sales and, most recently, as sales director for the commercial laundry market.”

Davis has represented both White and Speed Check at orga nization events, the firm notes, and looks forward to participating in future gatherings and meeting more people in the drycleaning industry: “I am excited to work with our talented market directors and region al sales managers to grow the White Conveyors and Speed Check Conveyor market share,” Davis says.

AROUN D THE INDUS TR Y 36 American Drycleaner, April 2018 www.americandrycleaner.com 800-323-0143 www.fhbonn.com customerservice@fhbonn.com Original equipment manufacturers insist on being...

At the annual ZIPS Cleaners franchisee meeting in Greenbelt, Md., FabriClean Supply was named Supplier of the Year for 2017. Accepting the award for FabriClean Supply is Dwayne Gwaltney (left), salesman, and Orville Johnson, vice president of sales. (Photo: FabriClean Supply)

Bob Davis

Minneapolis is ‘perc-free’

Earlier this year, Minneapolis, Minn., reports it became “the first city in the nation to go entirely perc-free as the last dry cleaner switched over to a safer process.”

With help from the City of Minneapolis, the Min nesota Pollution Control Agency, East Isles Resident Association and Lowry Hill East Neighborhood As sociation, Osman Cleaners switched its machines over from using perchloro ethylene — commonly known as “perc” — to a process using clean solvents safer for em ployees, neighbors and customers.

about the news: “I think it’s fantastic. As you know, Mulberrys was one of the first cleaners to be perc-free since our inception, and we’re proud of the fact that we can be a part of these positive changes in our industry.”

Alliance refreshes brand

Alliance Laundry Systems, which describes itself as the world leader in commercial laundry products and solu tions, has unveiled a new mission statement, logo and website, it reports.

CEO Michael Schoeb describes the brand direction as “refreshing our image to reflect the world-leading com pany we are.”

The Minneapolis skyline at night. The city says it became “perc-free,” with the last dry cleaner there switching over. (Image li censed by Ingram Publishing)

Dan Miller, CEO of Mulberrys Garment Care, a local dryclean ing operation in Min neapolis, with other locations in Minneso ta as well as the San Francisco Bay area, shares his thoughts

The company’s new mission statement reads: “We make the world cleaner as the premier provider of laun dry solutions. We deliver leading performance through our exceptional team, unmatched quality and our com mitment to innovation.”

Alliance also updated its brand logo with a cleaner, more modern design, it notes, and a new website.

“These enhancements position the company’s pre mium brands — Speed Queen ®, UniMac ®, Huebsch ® , IPSO ® and Primus ® — as global industry leaders,” it writes.

ADC

www.americandrycleaner.com American Drycleaner, April 2018 37

ADC_Hhalf.indd 1 3/6/18 1:31 PM

For example, for a June ad, the closing date is May 1st.

PAYMENT FOR CLASSIFIED ADS: Must accompany order.

POSITIONS AVAILABLE

Dry Cleaning POS company is seeking a motivated candidate to fill a position in the point of sale market. We are a national company that specializes in providing software solutions to dry cleaners.

Responsibilities will include: Understand the inner workings of the products and present this knowledge to customers in a professional manner. Prepare detailed proposals that include hardware, software and services in order to meet sales objectives. Develop and implement strategic sales plans to achieve sales goals. Accountable for meeting and exceeding revenue objectives through prospecting new business and growing existing accounts. Some traveling is required. Please contact: selldrycleaningsoftware@gmail.com

SPOT Business Systems the leading pro vider of Point of Sale systems is looking for qualified individuals with industry experience. We have openings in our Tech Support, Sales Support, Implementation and Training departments. We offer competitive pay with full benefits including 401k. Please send your resume to resume@SPOTpos.com

38 American Drycleaner, April 2018

BUSINESS OPPORTUNITIES COMPUTER SYSTEMS

www.americandrycleaner.com

Western Wonder Touch POS Systems $990 Refurbished, $1950 NEW All Commercial-grade Hardware Free New Cash Drawer & Free Shipping! Perfect for small to medium cleaners www.westerndccomputer.com 773-878-0150, westernk@msn.com 2018 RATES: One- to five-time rate: $2.15 per word, boldface $2.25 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 12-time rates. If box number is used,

rates are

credit cards

add cost of 5 words. Display classified

available on request. All major

are accepted. DEADLINE: Ads must be received by the 1st of the preceding month.

EQUIPMENT FOR SALE REWEAVING SERVICES WITHOUT-A-TRACE WEAVERS—More than 60 years’ experience. We are the experts in silks, knits, French weaving and piece weaving. Reasonable prices. Send garments for estimate to: 3344 W. Bryn Mawr, Chicago, IL

800-475-4922; www.withoutatrace.com. SELL OR BUY A DRYCLEANER. WE HAVE BUYERS!!! PATRIOT BUSINESS ADVISORS SPECIALIZES IN SELLING DRYCLEANERS IN NJ, PA, DE & MD. CALL LILIANE AT 267-391-7642. PLANTS FOR SALE D RYCLEANER FOR SALE Massachusetts grossing $980,000 Owner retiring. Selling or Buying a Drycleaner in MA, NH,& RI Leebrokers • Ming & Kyung Hae 508.962.2589 Drycleanersandlaundriesforsale.com BROKER SERVICES READY TO SELL YOUR BUSINESS? Our brokers have extensive experience in the industry as operators, equipment and chemical sales. Trust your business sale to a company that knows your industry inside and out. Buyer? Contact us for active listings National Coverage Marc Lazarus • ML@Tworld.com 201-370-9600 www.AmericanDrycleaner.com

60659;

www.americandrycleaner.com American Drycleaner, April 2018 39 SUPPLIES SUPPLIES 800-532-2645 www.comcoil.com Laundry/Dry Cleaning Coils Steam Or Water Replacements Large Inventory • FASTDelivery Improve Your Bottom Line Buy Direct and Save! Cut Your Overhead. Remove the Middle Man! Buy Direct and Save. Factory Direct gives you what your middle man never can. Cash Savings in Your Pocket! BUY DIRECT NO JOBBER MARK-UP WHOLESALE POLY 800-558-6055 Our Sparkling Clear Garment Bags Will Make your Dry Cleaning Look Better. GENUINE MBH ROPE-TIES from EzProducts International Inc. Toll Free 877.906.1818 www.ezpi.us Stop Shaking Out Shirts. Save time. Save money. Don’t be fooled by cheap inferior ones! SUEDE & LEATHER SERVICE LEATHER-RICH INC. • High quality cleaning, refinishing & repair Leather, Suede and Fur; • Free shipping in USA and rewards program FOR MORE INFORMATION: www.leatherrich.com E-mail: leatherrich@att.net Call 800-236-6996 Route Service in Upper Midwest A.L. Wilson Chemical Co. 1 Cleaner Business Systems 3 Cleaner’s Supply 39 Columbia/ILSA ................ BC Commercial Coils 39 Dajisoft 11 DeLux Cleaners 34 European Finishing Equipment 29 EzProducts International .......... 39 Fabricare Management Systems 9 FH Bonn ....................... 36 Garment Management Systems 33 Global Business Systems 30 GreenEarth Cleaning ............. 27 Iowa Techniques 5 In The Bag Cleaners.............. 10 Lang Innovations 38 Luetzow Industries ............... 39 Maineline Computer Systems ..... IFC Million Dollar Collar 38 Mustang Enterprises 35 Newhouse Specialty Co. 39 Parker Boiler Co. IBC Poseidon Textile Care Systems ..... 15 Realstar ....................... 31 Royal Basket Trucks 37 Sankosha USA 17 SMRT Systems 19-22 SPOT Business Systems 7 Transworld Business Advisors ..... 38 Trevil America .................. 13 Union Drycleaning Products 25 PLANTS FOR SALE When You Need HELP • Business Coaching & Consulting • By Hour, Day, Month or Project • Value or Ownership Sale Issues • Brokerage, Succession or Merger • Partnership or Management Buyouts • Business Evaluation/SWOT Analysis • Business Strategic Planning • Retiring Owner Exit Specialist Richard Ehrenreich, CED, SBA, F-CBI Ehrenreich & Associates, LLC Retiring Business Owners: Call to schedule a FREE initial telephone meeting. Review Richard’s credentials & references on Linkedin. (copy sent on request) Richard@Ehrenassoc.com 301-924-9247 www.AmericanDrycleaner.com

Cottontail Caper

10 YEARS AGO. An unexpected drop in retail sales in February is signaling recession to many market-watchers. Sales dropped 0.6%, the Commerce Department reports, a reversal of the 0.4% rise seen in January and far from the 0.2% increase analysts expected. Spending on automobiles led the decline, along with restaurant receipts, which saw a 0.4% drop. Excluding new cars, sales slipped 0.2%. Consumer spending is watched closely, since it accounts for roughly two-thirds of total U.S. economic activity.

35 YEARS AGO. This report just in from the Neighborhood Cleaners Association: “NCA tested two washable suits some time ago. One was a Haggar, the other was a Levi. The Levi suit performed poorly but the Haggar looked surprisingly good after six washings. The tester has continued to wear the Haggar suit periodically for the last year. The suit has been dry-cleaned only and professionally pressed. It has developed a severe pilling problem even with the gentler process of dry cleaning. It has required periodic shaving with a safety razor in order to look presentable. NCA stated originally that if the dry cleaner made sure he was doing a quality job, that the currently available washable men’s suit presented little threat to the dry cleaner. We believe that this evidence supports our statement.”

50 YEARS AGO. Cottontail Caper. Free advice to all cleaners in New York City and northern New Jersey: Brush up on your procedures for removing bunny fuzz from tuxedos. The senior class of Rutgers University has votes to hold its prom this spring in the New York Playboy Club. … Girl-watchers lament. Dame fashion bows to no man — not even the girl-watcher. Those delightful mini-skirts, alas, seem to be on the road to obsolescence. Newest thing on the fashion scene is the midi-skirt, which comes down to mid-calf. According to men, it is not flattering to any woman. But since when has mere male opinion been able to stop — or even impede — the march of fashion? And, after all,

where else could skirts go but down? … In an effort to combat the rising cost of producing free road maps, an oil company in Indiana is selling advertising space around the edges of its maps. Costs range from $150 per year for space bordering local maps to $2,000 annually for space on maps with statewide coverage. The idea of hitchhiking a promotional ride on an item that goes to potential customers is nothing new. We’ve had it on shirt-board advertising in the laundry industry. But have you ever thought of selling that valuable space on your cleaning orders for another business in your shopping area? Or, more to the point, making it work harder for you?

April 1968