SPOT Business Systems and CompassMax have come together

On behalf of the teams at SPOT Business Systems and CompassMax, we wanted to share some exciting news that will surely have a positive impact on you, our valued customers. After spending more than 25 years as competitors, our companies have joined forces!

We’ve both displayed leadership in innovation, solid customer focus and a willingness to find unique solutions to suit the individual needs of the businesses we serve. Coming together allows us to o in our ort ar inno ati t in ing and leverage our development spending on a single solution, rather than duplicate our individual efforts.

We are excited for what the future holds for the combined companies and for our customers!

SPOT Business Systems is the most comprehensive and complete system available.

Serving the industry since 1991 • 44 employees strong Hosting since 1999 (long before the “cloud”!)

Best feature set and support in the industry • Weekly feature and user webinars

Spray improved EasyGo onto soiled areas before drycleaning. Stains and soil disappear right in the wheel. For more difficult stains, use on the spotting board before or after cleaning. EasyGo is also an excellent leveling agent. EasyGo now flushes freely in all drycleaning solvents, including GreenEarth®, Perc, Hydrocarbon and K4.

And it's still eco-friendly...California compliant, chlorinated-solvent and NPE free, biodegradable and non-combustible. Drycleaning stain removal has never been so EASY!

September 2018 Vol. 85, No. 6

Pre-Inspection 4 Wrenchin’

Talk of the Trade 6 Counter Revolution

Tim Burke Management Strategies 20 The GM Diana Vollmer

Owner’s Office 27 Lazy: The New Power Look! Dan Miller

Spotting Tips 30 Good Old-Fashioned Spotting Martin Young Yarns Spun Here 32 Sunfade

Drycleaning owners are also do-it-yourselfers aka “wrenchers,” and that’s exactly what three owners share in this feature exploring the “tool-timer” in each of you. Some operators dig into the DIY, and some surround themselves with Mr. Fix-It friends and colleagues. Each of these three have learned how to be ready to fix their equipment themselves and share some of the handy tips they have learned. Get ready to wrench!

Tim Burke, EditorThree drycleaning operators share their thought process when preparing to buy drycleaning machines and wetcleaning machines. It’s all about piece counts and piece types and there’s a need for both types of machines to handle all the cleaning customers bring them. Get a glimpse into three owners’ personal decision-making when machine buying. As you read, ask yourself what’s your purchasing “throttle” set at when making a machine buy for your plant.

Tim Burke, EditorFabricare Show Wrap-Up 34 The Long View in Long Beach Special Feature 36 Smile, You’re Maine Clean Haley Jorgensen

Around the Industry 42 Classified Advertising 46

Advertiser Index 47

Wrinkle in Time 48 Cleaning for the Movies

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

“I don’t have to rely on anybody for information. I can see immediately what I have for inventory, orders and accounts receivable.”

Inside this September issue of American Drycleaner, check out a feature called We Are the Fixers about owners maintaining their own equipment, or getting key help. Is there a “wrencher” in you? Note: Some of those wrenchers I talked to for the article are on the front cover. In the center is Richard “Buddy” Gritz, owner, Presto Valet, between his business partner and manager.

Also, the feature Machine Mania spotlights three drycleaning owners discussing their own machine purchasing habits. Your favorite columnists are back this issue. There’s a wrapup of the recent Fabricare Show in Long Beach, Calif., and a new Talk of the Trade survey report called Counter Revolution about finding and keeping great counter personnel. There’s a new Yarns Spun Here: Sunfade, and more.

If I’ve heard one person say it, I’ve heard a dozen drycleaning owners talk about making their cleaning business look more like a bank than a dry cleaner. They want to change-up the old image. To my way of thinking, they are changing it, by discussing their hopes and by taking progressive action. Which is why I’m mentioning the following:

Is there a story waiting to be told about the history of fabricare, from the beginning through to today’s modern cleaners? This industry might want to think about developing its own unique Fabricare History Museum. It could be an exciting, interactive learning zone, so to speak, for the public, to address that whole image thing.

Many industries have these discovery zones. Shouldn’t you? Imagine an interactive tour through drycleaning’s history, an educational space, special exhibits, planned events, don’t forget a cafe, and a demo area to let the public get up close.

As just one example of this sort of thing, look at what the Computer History Museum (go to www.computerhistory.org) achieved for the computing industry when it opened its doors about a decade ago in Mountain View, Calif.

It’s good to put one’s best foot forward. Maybe fabricare’s time is here — to create a zone of its own. Not really a hard decision, I think. It’s your call. ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 85, number 6. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2018. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, September 2018

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor

Tim Burke 312-361-1684 tburke@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Roger Napiwocki

Advisory Board

Mike Bleier Steven Dubinski John-Claude Hallak Mike Nesbit Herron Rowland Fred Schwarzmann Beth Shader Ellen Tuchman Rothmann

Contributing Editors

Howard Scott Diana Vollmer Martin Young

Office Information

Main: 312-361-1700

Subscriptions 630-739-0900 x100 www.american drycleaner.com

When asked in this quarter’s American Drycleaner Your Views survey to tell us your secret: “How do you find, and keep, great counter personnel?”, we received responses like these:

• “I haven’t been able to find anyone in two or three years so I put up with all kinds of things I would have never put up with in the past.”

• “You have to be lucky and maybe go through three to 10 people.”

• “Family and friends.”

• “Treat them well, include them in decision-making, share the company vision and how they are a part of it, and clearly define the CSR position and expectations.”

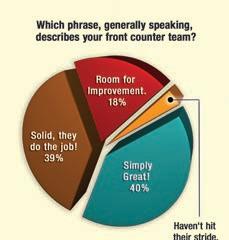

The survey also asked: “Which phrase, generally speaking, describes your front counter team?”

“Simply great!” says 40% of respondents, while 39% indicate, “Solid, they do the job.” Eighteen percent say, “Room for improvement.” (See graph for full results.)

Here are some of the comments survey respondents give in describing how much of their counter team is in place and how many positions they still need to fill:

• “Maybe a part-timer of only 10-12 hours.”

• “I would replace two of my seven counter people if I could.”

• “Always need one more.”

• “Have seven great people, only need to fill one more position.”

“Which factor do you think is the most important in your fabricare business?” the survey asked. “Counter Team” gets 58% of responses, while “Location” got 42%.

Here are some of the comments survey respondents give for describing their front counter team members who just have a knack for it:

• “One in particular has great enthusiasm. They just have a desire to do the work and enjoy it.”

• “Friendly and truthful.”

• “There’s no secret: training and training. Don’t stop.”

• “Friendly. Remembers names. Knows a lot of customers personally. Talks to customers about their

life. Knows how to resolve a problem. Trained well.”

• “Personable while professional.”

• “The gift of gab! Some people have it and some don’t. The vast majority of customers are seen when they park, and our staff knows them by name, so orders are pulled or being pulled when they walk in with a big welcome!”

• “They must like people; be a company person.”

• “One word: values.”

• “Self-starter, friendly, and attention to detail.”

• “Friendly, care, want to learn. They get it.”

• “Personality is everything!”

The quarterly Your Views survey offers a current snapshot of the trade audience’s views. Qualified subscribers to American Drycleaner e-mails are invited to participate anonymously in the unscientific poll. ADC

By Tim Burke, Editor

By Tim Burke, Editor

Is there a “fixer” inside you? Maybe you don’t even realize it yet. But drycleaning plant ownership might bring out the “wrencher” in you sooner or later. Or it already did.

Is there a DIY repair person in you waiting to get out? Who knows, you might even find out you like it. Hear from three drycleaning owners who do.

“Since I am not mechanically inclined, and I was taught to surround myself with people who are smarter and more skilled than I am, I went into partnership with Bill McClary, McClary Appliance Service, who had proven his competence at maintaining and repairing our drycleaning plants and Laundromats,” relates Buddy Gritz, owner of Presto Valet of Virginia Inc.

“Bill and I opened and installed two additional drycleaning plants, a dry store, and a Laundromat. We designed the stores ourselves, purchased the equipment from the manufacturers ourselves, and installed the equipment ourselves,” Gritz says. (continued)

Owners share their DIY tips, like checking equipment every day

“Bill has an uncanny knack for figuring out what’s wrong and how to fix it when equipment breaks. Over the years, two additional team members have developed expertise at doing routine repair and preven tive maintenance on our equipment. ‘Chat’ Chatelain, my business part ner and vice president of production, and Frank Pannell, our production manager,” Gritz points out.

“They can handle most of the dayto-day maintenance. If we’re not sure what to do when the equipment breaks down or stops working, we can always rely on Bill to fix or replace it. Bill is now retired and in his 80s, but is always on call for us. We rarely need to call an outside service person to maintain, repair, or replace our equipment.”

Presto Valet was opened on April 7, 1951, by Harold J. Weisblut, Gritz’s father-in-law. Gritz notes it is a fullservice dry cleaner using GreenEarth products and spe cializing in providing “superb customer care, processing theatrical costumes, and solving our customers’ problems. I started working at Presto Valet on April 21, 1967, and took over the business in 1974.”

After his discharge from the U.S. Air Force as a special investigator, Gritz says he was planning to join the FBI and pursue a career in law enforcement. “However, my father-in-law informed me that I needed to support his daughter until the FBI school started, and told me that his manager had quit, and suggested that I work at Presto Valet for a while.”

After only a month, he notes, he was enjoying his in teractions with customers and crew so much that he aban doned those law enforcement plans.

“I completed the National Institute of Drycleaning (now DLI) 139th general course, which was a comprehen sive 10-week course that included basic repair and main tenance of drycleaning equipment,” he explains. Between his training and the expert maintenance knowledge of partners McClary and Chatelain and manager Pannell, he is able to handle almost all equipment fixes.

Here are some tips Gritz passes along about maintaining your drycleaning equipment:

“The key to maintaining the essential equipment in a drycleaning or laundry business,” he says, “is never be in the position of having to wait for the repair of a piece of equipment or for a small part. We check the working con dition of every piece of equipment daily to make sure that everything is functioning properly, so that we can continue operating the plant and pleasing our customers.”

Gritz also says: “We carry a very extensive supply of parts for every piece of equipment in our plant. We currently have two boilers, three air compressors, two drycleaning machines, two washing machines, seven presses, a shirt unit, plus other production equipment. When some thing breaks down, we make sure to order an extra part to have on hand in case that part breaks down again.

“Being knowledgeable about how the equipment works, doing routine maintenance regularly, and having extra parts on hand all help Presto Valet to continue to operate efficiently, even when a piece of equipment breaks down or needs repair,” he notes.

“It is also important to pay your equipment manufac turing and parts suppliers promptly,” Gritz reminds, “to ensure that they will respond immediately when you need their help to keep operating!”

Some drycleaning operators learn to maintain and repair their own equipment. One of those, Andrew Tirpok, owner of Tirpok Cleaners in Flemington, N.J., shares his own experiences and skills:

“When I first came into the family business in the early 1990s, I had zero mechanical ability. The television show Home Improvement was popular at the time, and the employees used to call me ‘Tim the Tool Man,’ because I was mechanically inept,” Tirpok recalls.

Unfortunately, he notes, his business is located in a rural area and it’s difficult to get a mechanic to come out and perform a minor repair on the equipment.

“Because of that,” he explains, “I had to learn to main tain it myself, or I could expect long delays without a pos sibly essential piece of equipment. Also, because we have been in business for so long, I had a lot of older equipment on hand and it required a lot of maintenance.”

Tirpok relates, “We had presses that my grandfather bought before I was born. Over the years, I’ve become pretty good at handling most of the maintenance and repair required for the machines we have. As a result of a devastating fire last year, I’m now in the position where I have all-new equipment, which requires a lot less atten tion than what we had before.”

His grandfather, Andy Tirpok Sr., founded Tirpok Cleaners in 1936. He started as a presser for a haberdash ery in Flemington. He started his own business with a shoeshine stand.

“Today, we’re a retail dry cleaner and (continued)

Drycleaning plant ownership might bring out the “wrencher” in you!

(Image licensed by Ingram Publishing)

shirt launderer,” Andrew Tirpok says, “with a small pick up and delivery business. I’m the third-generation owner of the company. I have a good staff comprised of many long-term employees. Mostly, I run the administrative end of the company and do the maintenance in our plant.”

Have you ever had to fix equipment and/or machines because your maintenance person couldn’t get there? How did that go for you?

“All the time,” Tirpok admits. “Because we had well water in the old plant, even with a softener, the refrigera tion cooling coils on the drycleaning machines required monthly acid washing. The first time I did it on my own, it took hours to get done, and I ended up covered in the acid solution because a hose popped off the coil.

“Fortunately, it’s a pretty dilute solution and no harm was done,” he continues. “It did get red stains all over my clothing. Another time, my father, daughter and I needed to change the bearing on a 75-pound washing machine. What we were hoping to get done in a weekend ended up taking almost a week.

“We couldn’t get the old bearing out, and broke two sledgehammers and bent a support column for the building, using it as a brace. We did eventually get it done, and the ma chine was like new after that.”

Are drycleaning owners and op erators surprised at how much re pair knowledge they pick up while owning their operation?

“Actually, I am surprised,” Tirpok shares. “I never thought I could actually enjoy working with my hands, but now I look forward to it. You get a sense of accomplish ment from fixing a machine — that nothing else compares to.”

Of course, he has tips for readers about what he’s learned while maintaining his own equipment, especially in a pinch:

“Keep your compressed air dry,” Tirpok insists. “If you don’t have an air dryer, get one. When I was first starting out, a mechanic that did work for me told me that auto mechanics know the importance of dry air, and dry clean ers have no clue. That is so true.

“I would say that 90% of the maintenance issues we used to have were due to extremely wet air running the machines. It makes a huge difference.”

Another tip: “Don’t keep broken parts laying around. This is such a ‘dry cleaner’ thing to do. When I first went to work for my uncle, we were fixing a press, and he asked me to grab a part from the tool room. I did, and he

told me the one I grabbed was broken.”

Don’t keep a broken part, he reminds. “Throw it out. You’ll have no use for that cracked air switch at any point in the future.”

Tirpok’s last tip for you maintenance DIYers: “Keep a stock of commonly used parts on hand. Sure, you can order that air cylinder when it breaks, but it might take a few days to get to you from wherever you ordered it from. Nothing beats having the part on hand. The lost produc tion will cost more in the end than the few dollars you spent on spare parts.”

Our last message about hands-on repair and mainte nance is from Zach Kinzer, the owner of Bridgestone Dry Cleaners, Brooklyn, N.Y.:

“We are a family-run business located in downtown Brooklyn. My dad, Ken Kinzer, started the business in 1983. We spe cialize in all types of garment care and tailoring. Last week, we cleaned and preserved a $16,000 Vera Wang gown. We kept our cool and got it done right.

“I would be lying if I said we are the mechanical type of owner/gen eral manager team. Sure, there was the time I had to remove the seized pump off of our drycleaning ma chine, or the time I had to rewire the spotting gun which went bad.

“Mechanical issues in a dryclean ing plant, like life, come at you fast. We have attempted over the years to limit the bleeding with weekly checklists to keep up with oil levels, clean filters and all the rest. This has helped a great deal.”

Kinzer notes that, most importantly, they have tried to keep a close relationship with their local mechanic, Dino, from Evangelos Repair Service in the Bronx: “He and his team are able to help us keep up to date on annual mainte nance while also jumping in when an emergency comes up.

“We are still learning to keep up to date on the little details with our machines in order to avoid the big hits of mechanical failure. I think we are getting better every day.”

Three stories out of so many from the drycleaning indus try about learning to do repairs on the job. Surprising your self and accomplishing more than you thought you could. And those tips: have an extra part in stock, keep your air dry, and make sure to pay your suppliers on time.

But, mostly, it’s all about you, and discovering you might just have a “fixer” inside of you.

Is there a DIY repair person in you waiting to get out?!(Image licensed by Ingram Publishing)

By Tim Burke, Editor

By Tim Burke, Editor

Rise of the Machines!

That might make you envision Terminators. But machines, for purposes of this article, are drycleaning machines and wetcleaning machines working reliably and efficiently in your plants today.

You’re using both. But what goes into the decisionmaking process when drycleaning owners get ready to buy machines? We really wanted to know.

An unscientific Your Views survey by American Drycleaner polled subscribers back in February to ask: How many drycleaning and/or wetcleaning machines do you have? The results came back showing a nearly 50/50 relationship in machine types.

It’s telling that drycleaning and wetcleaning machines seem to be needed just about equally today.

Recently, three drycleaning owners spoke individually to American Drycleaner about what goes into their decision to use both wet and dry machines in their plants.

Bonnie Engler is president and owner of Pilgrim Dry Cleaners Inc., based in Minneapolis, Minn. She describes her business and the machines she uses.

“We are a three-generation family business that has been providing drycleaning and laundry services to the Twin Cities area since 1940. We have 26 locations with same-day service; provide home and office pickup and delivery; 24-hour drop boxes; 24-hour kiosk; and an ondemand app called PilgrimGO,” she relates.

“We have wetcleaning equipment in all plant locations. Our customers know: ‘Whatever the care label, we can clean it!’ Incorporating wetcleaning equipment has enabled us to provide the best cleaning capability for all fabrics, stains, and care labels,” Engler says.

Our “expert dry cleaners,” she explains, “can now decide if a garment should be dry-cleaned with our hydrocarbon machines, washed in our commercial laundry, or wet-cleaned for best results.”

She points out, “We have 65-pound wet- (continued)

White Conveyors’ SUV-OAS is the perfect solution to boost your productivity, improve customer service and increase your profits while reducing your operating costs. The system is delivered fully assembled, and can be operational in less than two hours. As an option, it can be mounted on wheels for mobility or storage. Simply set it up on its supports, plug in the power, connect the computer, and link the system to an Internet connection. It’s time to begin realizing remarkable time and money savings.

Easy to use

Reduces labor costs

Increases productivity

Assembles over 2000 pieces per shift

Interfaces with all major POS systems

Can utilize a bar-code or RFID chip system

Easy-to-read computer touch screen

Highly accurate and reliable

Fast return on investment

Proudly made in the USA with fast support

cleaning washers with stack dryers for the most flexibility. We have been happy with our choice in dryclean ing and wetcleaning equipment.

“We are able to suc cessfully wet-clean khakis, wool coats, and wedding dresses beau tifully! They work es pecially well to remove those Minnesota winter salt stains.”

Engler passes along a tip: “Training is imperative for an operator to feel confident in wet-cleaning the most items possible.”

That’s one owner’s view on machines. Let’s get another.

What is driving the purchase of the workhorse machines an owner and operator relies on?

Christopher White, executive director with America’s Best Cleaners (ABC) in Delmar, N.Y., has over 30 years of experience, from plant design, process and procedure development and technology integrations, to marketing strategy development, human resource development and executive coaching.

“ABC started in 2001 as the first independent quality certification mark for the drycleaning industry,” White notes. “Certified cleaners then take part in business development meetings, educational trips and in-house consulting and training services.”

Regarding making decisions about how many wet cleaning machines and how many drycleaning machines to own, American Drycleaner asks him to share his experiences:

“This is a question that has been on the forefront in plant design and general machinery upgrades for the last several years,” White opines.

“With the increase of ‘washable garments vs. dryclean only garments,’ there has been a definitive shift to the wet side.

“With a combination of government regulation, landlord requirements, consumer awareness, the increase in washable goods received, and advances in detergents,” he says, “operators are finally embracing this successful

technology.”

Then American Drycleaner asks him what he thinks is changing today in how owners look at wetcleaning machines and drycleaning machines.

White says, “Cost savings!” He finds that “the equipment is easy to install and maintain, there is no waste removal, the utility consumption is low, the machines are flexible and can be used for all of your laundry needs, too.

“Most operators have already invested in tensioning equipment, so the investment now is much lower than in the past to fully embrace wet cleaning. The transition is much easier than in the past,” he adds.

Is the buying decision harder today for owners?

In regard to buying drycleaning machines and wetcleaning machines, White says, “Yes, since there is only one thing that is predictable now,” pointing out, “the cost will be going up, especially on the labor side. Piece counts are reducing and the mix of dryclean pieces versus washables is constantly moving. This makes it hard to set a firm plan in place,” he notes.

White continues: “In regard to the choice on which wetcleaning machine you should purchase, it’s quite simple: Does the machine have a microprocessor that allows for complete control of wheel action and extrac tion speeds, water levels, water temperatures, detergent signals? If the answer is yes, then buy from the local machine distributor that services your plant when you need them.”

He adds that price should always be a consideration “but the cost of being down will hurt you more than a few hundred dollars on the machine sale price. Buy from those that take care of you.”

White shares personal tips taken from what he’s learned going through the buying process:

“There are a few brands on both the drycleaning side and wash machine side that stand out for their efficiencies and ease of use, but I

„SENSENE continues to prove itself effective and efficient. This is an amazing product with a high cleaning power combined with excellent material compatibility. Finally, it‘s what we all have been waiting for.“

There are reasons to consider hiring a general manager (GM) to run the daily operations of your company.

Would you like:

To spend more time on opportunities that will make your business thrive?

Fewer responsibilities demanding your immediate atten tion?

To expand into another market, business or career?

More time away from the business?

The freedom to develop your professional or personal capabilities through outside learning opportuni ties?

To take a sabbatical?

To spend more time with family and friends?

A trial or permanent retirement?

An alternative succession plan?

Peace of mind when an emergency leave of absence is necessary?

To continue to own the business, but not operate it?

If you already employ a general manager, are you tak ing advantage of what she or he can provide to you and your business? Do you trust them enough to let them do the job as it is designed to be done? Do you give them the responsibility and the authority to do what is in the best interest of the company?

Many of the GMs I meet are either owners’ assistants operating in a “gopher” role or line supervisors with an overblown title.

In both situations, the staff is well aware that the power lies elsewhere — strongly in the hands of the owner. These roles may serve a valid purpose, but they are not general manager responsibilities.

A fully functioning GM is a huge asset to a business that has the profit level sufficient to support the position. When the daily operations have a strong manager, the owner is freed to be a more effective entrepreneur who can build a more profitable business that fulfills a grander vision.

Or, on the opposite end of the spectrum, in the case of owner burnout, a GM can provide confidence to take

much needed time off. Between these two alternatives lie many benefits.

A typical general manager position description might be: Fabricare General Manager.

This position is responsible for managing and develop ing the company revenues, profits, processes, personnel, production, and physical and financial assets through his/ her personal efforts and the efforts of direct reports.

Always the focus is on the short- and long-term goals of the company as well as quality and service levels. The GM will be responsible for making necessary changes to the company’s current methods to optimize competitive advantage.

• Achieve annual sales and profit goals as recommended to and adopted by owner.

• Create and implement a plan to increase profitable sales volume by ___% in ___ months on same-store and route sales (excluding acquisition sales) as well as add ing an additional ___% through direct outside sales.

• Create, implement and manage adherence to a budget, making relevant dynamic adjustments as needed.

• Monitor monthly financial reports to make relevant ad justments to operations to achieve goal operating profit.

• Create, implement, and manage external sales and marketing to target businesses, institutions and com munity in conjunction with sales representatives to add ___% to current sales volume.

• Create and implement a plan to develop professional community relationships and partnerships and to enhance company influence in the

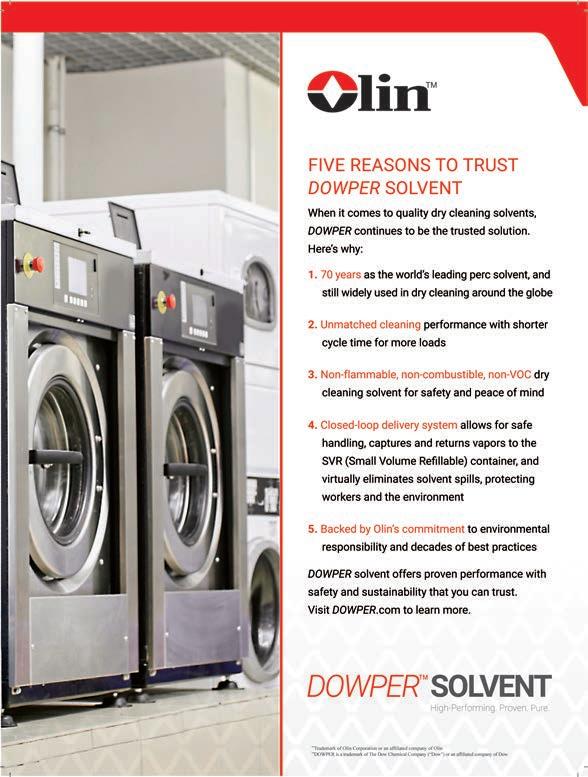

New technologies allow wet cleaning to significantly improve throughput production over traditional dry cleaning. This makes a strong case for the eco-friendly wet cleaning process. But what about the costs associated with wet cleaning versus dry cleaning? When compared — dollar for dollar — wet cleaning is thousands less.

First, let’s evaluate the initial cost of each system. This is the amount required to purchase new alternative-solvent dry cleaning machines versus similarly sized Poseidon wet cleaning systems. When the numbers are crunched, there’s a $67,000-$72,000 cost differential in favor of Poseidon wet cleaning. But that’s just the tip of the iceberg. Let’s dig deeper.

Often, there are additional costs associated with operating a new dry cleaning machine, including upgrading boilers, chillers, air compressors and electrical. If you have to upgrade any of these because of your new dry cleaning machine, you’ll fork out considerably more. Whereas, if you go with a wet cleaning system, you won’t.

For example, a customer is installing an 80-pound capacity dry cleaning machine at a cost north of $100,000 list price. It’s going into an existing facility. To operate correctly, the dry cleaning machine will require the purchase of another chiller ($16,000) and an 80 amp breaker. Additionally, the new chiller will require another 70 amp breaker. In the end, the new dry cleaning machine not only requires a new chiller, it demands a costly electrical upgrade. All this adds up.

By comparison, an 80-pound capacity Poseidon wet cleaning system, which operates on 15 amp breakers, doesn’t require anything extra. So, if you add a wet cleaning system, you’ll likely not have to purchase or upgrade anything else.

We know now that the minimal initial investment of a 60-pound capacity dry cleaning machine is at least $67,000 greater than that of a similarly sized wet cleaning system. We also know other capital expenditures and upgrades are also part of the installation and operational equation. Now, let’s compare labor, chemistry/solvent, regulatory/licensing fees and utility costs.

Chemistry — Initial start-up costs for chemistry for a 60-pound wet cleaning machine is around $2,000. It’s $6,000 for a 60-pound dry cleaning

machine. From there on, there is not a huge difference. Water — Water usage can vary. On the dry cleaning side, when a chiller is utilized to recycle water through a dry cleaning machine, very little water is used. But, a chiller costs between $15,000 and $30,000.

In general, a 60-pound wet cleaning machine uses 40 gallons of water per load, and over the course of a year, would go through as much water as a dry cleaning machine hooked to a water tower. A dry cleaning machine hooked to a chiller is the most water efficient. The only problem is that this scenario requires a costly initial investment.

Electricity — When it comes to electricity, wet cleaning comes out ahead. This is because a dry cleaning machine requires 60-90 amps to operate, whereas a wet cleaning system requires just 15.

Natural Gas — The boiler needed to operate a dry cleaning machine uses 670,000 BTUs, which dwarfs the wet cleaning requirement of 118,000 BTUs. Plus, a boiler will run until all plant production is completed for the day. A wet cleaning system dryer operates in 15-20 minute increments a dozen times a day. Again, wet cleaning wins.

Labor — When compared, labor costs are very similar in both dry cleaning and wet cleaning.

Finally, regulatory fees and waste disposal costs are not uniform across the country because each state has its own set of laws. Typically, it costs hundreds per drum for removal of dry cleaning still-bottom-solvent wastes. On the flip side, there are never disposal or regulatory costs for wet cleaning.

At the end of the day – when all factors are considered – wet cleaning costs are thousands less than those of dry cleaning. Plus, wet cleaning delivers 50 percent more throughput. That’s a one-two punch that’s hard to reckon with. Please contact Jeff Quail at jquail@poseidonwetcleaning.com with any questions.

COST OF INSTALLING A POSEIDON WET CLEANING SYSTEM VS. AN ALTERNATIVE SOLVENT DRY CLEANING MACHINE

target market.

• Identify and recommend potential acquisitions that will add profitable sales through consolidating expens es and taking advantage of economies of scale.

• Interact with and manage outside resources that aid in goal attainment, i.e. mystery shopping service, peer management groups, special focus consultants and marketing professionals.

• Conduct weekly sales meetings and status recap with outside sales team.

• Conduct weekly customer service status reviews for enhancement.

• Conduct weekly quality, maintenance, efficiency and staffing review with the production manager and/or staff.

• Hold biweekly meetings with all direct reports and entire staff quarterly.

• Create and manage the marketing plan.

• Present investment and growth opportunities to the owner with expected ROI.

• Make equipment purchase and/or upgrade recommen dations.

• Recommend new locations or reduction in locations supported by thorough strategic and financial analysis.

• Monitor claim management controls.

• Attend board of directors meetings as needed.

• Track key performance indicators and continually improve performance.

• Manage and approve payroll.

• Hire and fire with the assistance of HR and relevant manager.

• Maintain clear, current, updated documentation of all positions and training manuals.

• Maintain and share current processes and procedures documents and ensure compliance.

• Manage pricing and make appropriate adjustments.

• Oversee any acquisitions and facilities remodels.

• Manage accounts receivables for current collections.

• Complete annual performance reviews for all direct reports.

• Proven history of profitable sales increases.

• Demonstrated leadership skills.

• Proven business acumen.

• Communication proficiency.

• Customer/client focus.

• Organizational skills.

• Presentation skills.

• Problem analysis and solving ability.

• Goal achievement and results orientation.

• Technical proficiency in computer programs, includ ing at least Word, Excel and Outlook.

• Proven track record of profitable sales increases in a service business.

• Demonstrated leadership experience with at least ____ direct and/or indirect subordinates.

• Bachelor’s degree, preferably in a business field.

• Valid driver’s license with automobile insurance.

• Background check.

• One personal and three professional references. This description may sound overly complex, however, the general manager is exactly that — a manager over op erations. The GM is the owner’s substitute.

There is always an issue of whether an expenditure is judicious with an appropriate return on investment.

Take into consideration how effectively all the above duties are being handled currently. Do you have time to successfully manage every part of the business?

Do you have more than eight people reporting directly to you? If there was a more disciplined focus on profit, sales, productivity and customer outreach, how much could the financial result improve?

If you had time to think about opportunities for your business and to plan for the future, would your business respond favorably?

Conversely, would you be willing to trade a portion of your compensation for more freedom over your time and activities? Do you see value in having a skilled colleague to help you take the business to a higher level?

You may find that the answer to your questions and to your dreams could be a capable general manager.

ADC

Diana Vollmer is a managing director for Methods for Man agement, which has served dry cleaners and launderers with affordable management expertise and improved profitability since 1953. For assistance deciding if a GM is appropriate for your company, or recruiting, hiring, or developing a gen eral manager, contact her at dvollmer@mfmi.com or call 415-577-6544.

At the heart of SMRT, we are a dry cleaner. It’s the reason we created our software in the first place: To solve the everyday problems we ran into at our own business.

We’ve stood in your shoes -- pressing, cleaning the button trap, filling in when the driver is sick, making payroll, and replacing equipment.

And with a dry cleaner’s perspective, we’ve built, from the ground up, the best dry cleaning software in the marketplace.

We understand that dry cleaners are dynamic, high-performing entrepreneurs. It’s no small feat to run both the factory and the dealership every damn day. You deserve a software partner that knows your business and is there for you 24/7. You deserve SMRT.

Next-level customer service to match their next-level technology. The SMRT team is passionate about solving problems and supporting their users.

Jason Yerby

Vice President: Crest Advanced Dry Cleaners

There’s more to SMRT than great software. They really know the business, bringing a new dimension to customer support.

Daniel Cha

Owner: Orchid Dry Cleaners

SMRT is light years ahead of the competition! We’ve never been so on top of our business and in tune with our customers.

Wayne Edelman

Owner: Meurice Garment Care

Robust

Richard Aviles

Owner: Bridge Cleaners & Tailors, King Garment Care

Business owners in the drycleaning industry pride themselves on their work ethic.

Go to any drycleaning and laundry convention and you’ll hear amazing stories of hard-working drycleaning entrepreneurs who stayed up until midnight pressing shirts or came in at 3 a.m. to make sure that orders were ready the next day. Dry cleaners who aren’t willing to get up early, stay late or work the press are considered lazy and doomed to fail.

While it’s tempting to believe that the desire to avoid the hard work of drycleaning production is “lazy,” I would argue that it is absolutely critical to your long-term success as an owner.

In fact, thinking lazy is the only way that you will be able to realize your business’ full potential. You’re asking yourself: What does he mean?

Thinking lazy is constantly asking yourself, “Do I need to be doing this? Or can someone or something do it more efficiently?”

Most of the great innovations of our time came from someone who thought lazy. Cars were invented by someone who found the horse and carriage to be a hassle. Amazon was invented because we didn’t want to spend the time and gas driving to a retail store.

Heck, our industry wouldn’t exist if our customers didn’t think to themselves: “I’m tired of cleaning and ironing my clothes. Is there someone who can do this better and more efficiently?”

At its most elemental, thinking lazy is asking yourself the question, “How do I achieve my goals with as little work as possible?”

In order to start thinking lazy, the most important step you have to take is to define what your goal is as the

owner of a dry cleaner.

In talking with other owners, I’m always shocked at how many of them came into the business either because their parents were in it or they thought it would be a fun business to buy but aren’t quite sure of what their end game is.

As a result, they tend to get stuck in the day-to-day grind without moving forward toward any defined goal. This lack of a clear goal makes it difficult to differentiate between critical tasks and the fire drills that pop up in the life of a dry cleaner.

To think lazy, it is absolutely critical that you shut down the computer, turn off the phone,

take a day outside of the office, and think about your goals from both a personal and professional level.

What goal do you want your business to achieve?

Do you want your drycleaning operation to produce a set amount of income per year?

Do you want your drycleaning business to provide opportunities for your family members?

Do you want your drycleaning store to sell for a certain price?

Do you want your drycleaning operation to go public?

The next step you take in thinking lazy will be heavily determined based on your answers to those questions. A drycleaning owner who wants to go public will have very different answers to thinking lazy than someone who wants to make $100,000 per year in income, so it is critical to define those goals before moving forward.

To keep it simple, let’s assume that your goal is to make $100,000 per year in income. That’s a great goal and definitely achievable in our industry.

However, it’s one thing to be making $100,00 per year as an owner who presses shirts, works the counter and gets up at 3 a.m. to fix the boiler. It’s another to do it while playing golf four days a week.

Which leads to the next question you have to ask yourself: “How do I achieve my goal with the least amount of effort?”

Now that you know your goal, it’s critical to perform an audit of all the work you do in a day.

Do you spend most of your time in production? Are you dealing with customer issues? Whatever it is, make a full list of the work you do in a week and how much time you spend on it.

It doesn’t have to be anything fancy, just a simple Excel log will do the trick. The next step is to go through each of these tasks one by one asking four simple questions:

1. Can this work be prevented?

2. Can this work be outsourced?

3. Can this work be automated?

4. Can this work be trained?

If the answer to these questions is yes, then thinking

lazy requires that you shouldn’t be doing it.

To illustrate, let’s take the example of dealing with customer service issues. Many drycleaning owners spend a fair amount of time fielding calls, dealing with claims and other customer service issues.

However, if we apply the four questions to this customer service example, it becomes clear how easily this work could be eliminated from the drycleaning owner’s plate:

Can this work be prevented?

Some of it can, absolutely. If we minimize damaged and lost garments in production, we will eliminate claims calls. If we provide information more clearly on the website, the customer won’t need to call in the first place.

Can this work be outsourced?

Yes. There are a number of outsourced call centers now that can be found online and will field the majority of questions.

Can this work be automated?

Yes. There are phone services you can get that will provide answers to the most common questions, such as store hours, locations, turnaround time, and more.

Can this work be trained?

Yes. You can teach any friendly staff member to deal with customer service issues.

By applying the thinking lazy approach and asking these four questions regarding the major tasks you do on a daily basis, you can make your business run more efficiently and free up your life.

There’s an old saying: “Great managers makes themselves obsolete.” The same idea holds true for great business owners. By thinking lazy, you’ll be on your way! ADC

Dan Miller is the chief executive officer of Mulberrys Garment Care, a premium drycleaning and laundry business with 17 locations in Minneapolis, San Francisco and Dallas. You may contact him at dmiller@ mulberryscleaners.com or 866-473-0798.

To find previous Owner’s Office columns or share this month’s with your friends, visit AmericanDrycleaner.com.

American Drycleaner, September

It may be old-fashioned to you, but some consumers expect to receive their garments stain- and odor-free from a garment care professional.

Where do you rank supplemental stain removal? Think about it for a moment. Do you believe that your customers agree with your ranking of priorities?

Are you imitating the plant down the street? When is the last time you gave some thought to where your business is and where it is headed? It is my intent to motivate you to revisit those priorities.

Is making the effort to gain knowledge of fibers, construction, dyes and trim necessary? Does having a knowledgeable cleaner/spotter contribute to your long-term prosperity? Is the time spent on supplemental stain removal an advantage to protecting your investment?

Does your business model have room for more than “turning pieces?” Are you sure — really sure — that speed and price are more important than stain removal to the consumer?

Those are a lot of questions. But remember, you are betting your future on the answers.

It has become more common for some in the garment care industry to give priority to other areas of customer service and give a lower priority to removing stains that require even the slightest increase in time and effort.

The goal is to process all garments as quickly as possible, many times at the expense of stains like ink, coffee, wine, blood, and albumin.

The first priority, with a 9:30 a.m. cut-off, is to have “all pieces re-racked and delivered by 3:30 p.m.” If that involves travel to and from the dry store, that processing window shrinks even more.

With modern point-of-sale equipment, you can easily determine the percentage of garments that are not picked up after 36 hours. With that information in hand, you can use it to your advantage by considering adjusting your processing window by 12 to 24 hours.

“Same day/one day” can still be provided at a slight premium. The consumer is already used to paying extra for faster than standard delivery for packages and mail.

Employees will still be evaluated by pieces per operator hour. However, a small percentage of the workflow will be subject to additional attention in the cleaning department.

All this will be of little benefit if the cleaner/spotter lacks the knowledge, experience and tools to improve on the items that still need some form of detailed stain removal after being processed through the drycleaning system.

Every cleaning system needs help from time to time. Post-spotting is a necessary part of a modern cleaning operation. Pre-spotting is a time- and labor-saving process, as well as making post-spotting easier.

Having the appropriate chemical tool to treat the specific stain is a simple and economical way to drastically improve the quality of your finished product.

Sending your cleaner/spotter to one continuing education class per year is an investment that will give you a wonderful return. It will keep your employee aware of recent improvements in garment care tools and techniques.

You will experience a significant reduction in damage claims. It is an invalid assumption that the garment care industry is only about the machine and the immersion solution.

Once in place, a protocol of inspection after cleaning and before finishing will pay dividends. There is a point at which the priority for quick “throughput”

ceases to be of benefit. It only takes a moment to pre-treat a nail polish stain.

Studies have shown that it costs over five times as much to get a new customer than it does to keep an existing one. So keep your existing customer base and build on that foundation with a modest tweak in company attitude and employee work practices.

You can go even further by training anyone who has con tact with the consumer to sell your professionalism by rec ognizing stains by appearance, color, texture and location.

It comes down to a business decision. While others may choose to hire employees for low wages that usually leads to high turnover, you can invest an amount of less than 5% of your equipment budget in continuing education for your existing employees and really set yourself apart in the marketplace.

I hope I have caused you to think about where you place your business priorities. It is a fact that “Sorry” tags are a

S hade your face. If you’re getting tired of being in the sun too long, you’re experiencing sunfade.

Satellite sunfade happens twice a year, in spring and fall, when cable companies have brief outages.

Wikipedia calls it a sun outage, sun transit or sunfade. At these times, it describes, the apparent path of the sun across the sky takes it directly behind the line of sight between an earth station and a satellite. “The sun radiates across the entire spectrum, including microwave fre quencies used to communicate with satellites, so the sun swamps the signal from the satellite.”

Clothing sunfade, or light fade, as is described in author Norman Oehlke’s Complete Spotting Guide & More, published by American Drycleaner and available at https://americandrycleaner.com, is easily identifiable. “It’s only on one side of the fabric, and can only happen where light — natural or artificial — has altered color.”

Oehlke writes that, “Some dyes fade very rapidly. Deep blue and green dye on silk and wool can fade in a matter of hours. Go into a retail store where clothes have been

poor substitute for quality results.

Additionally: You may have read that the EPA has put its re-evaluation of TCE/trichloroethylene on hold for the time being. You can read about it at https://chemicalwatch. com. An article dated Dec. 21, 2017, notes, “The U.S. EPA has signaled it is shelving proposals to restrict the use of the solvents methylene chloride (dichloromethane), n-methylpyrrolidone (NMP) and trichloroethylene (TCE).”

I believe this is temporary. Do not stop searching for an adequate replacement. It has been a staple of the cleaning industry for many years and is highly effective on a limited range of chemically soluble stains. It has a serious image problem that is not going away. ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates today. Phone: 704-786-3011, e-mail: mayoung@ctc.net.

hanging on racks for weeks and you’ll see it.”

Re-dying, he notes, is the only possible restoration for sunfade, “and that is not always possible due to the type of dyes and pigments used in the original dyeing process.”

More sunfade tidbits from Wikipedia: “The British Island of Saint Helena in the South Atlantic Ocean suffers from island-wide loss of internet and telecommunications connections during sun outages because all telecommuni cations traffic to and from the island is carried on a single satellite link. As rural Alaska is served by satellite, Nome suffers from this as well.”

Sunfade is real. Clothing, satellites and people tired from the summer sun all get sunfade.

Could you hear it? That bold-busy-upbeat sound emanating from the West Coast?

That was the sound of your garment care industry at work — and play — in mid-August at Fabricare 2018, hosted by the California Cleaners Association at the breezy, bright Long Beach (Calif.) Convention Center.

There were four aisles full of exhibitors, hundreds of drycleaning owners and operators, and lots of chit-chat, deal-making (no doubt) and generally real good times right by the big, blue Pacific Ocean.

I walked a lot (my feet hurt), talked a lot (my voice was cracking by the end), grinned a lot, and listened to many drycleaning owners, and exhibitors, converse in those bustling aisles.

“I’m here for information, we both are, for products and equipment,” say two local drycleaning owners, pausing with me, midway down the crowded second aisle.

“This is my first show,” one owner adds, smiling, “and like it very much. I’m looking for finishing equipment. It’s here. I’ll find it for sure!”

Another drycleaning owner from Oregon stops me to tell me he reads American Drycleaner all the time. He’s down here at the show, he quickly explains before moving on, to learn all he can, soak up the California atmosphere, and interact with the industry.

Yet another drycleaning owner from Northern California sits a moment to tell me, “The show is great for information-finding, but it’s really all about...” He pauses and clears his throat. “Networking! Isn’t it really?”

There were several speakers across three days. Keynote Krista Clive-Smith kicked it all off with this

resounding message: “Create authenticity. Sell your persona,” she told three dozen in attendance at her speech. Then attendees and exhibitors seemed to go out and do just what she advised during the show.

Many exhibitors said the event was solid. “So good,” mentioned one veteran of industry shows.

A new drycleaning owner from Sierra Vista, Ariz., Flora Castillo, here with her father Manuel Romero, stopped and paused for a photo with me, arms full of show materials and big smiles. Then she summed up Fabricare in one happy breath: “It’s just so great, full of information I can use, and I can sorta feel the drycleaning industry’s heartbeat. I’m lovin’ it!” ADC

“Not only did I reduce my assembly sta from 2 people to 1, I also noticed signi cant reduction in mark in labor costs as well.The opportunity for human error has been vastly reduced. I should have switched years ago when Brett rst spoke with me!!”

“I can honestly say that the QuickSort is the single best item I’ve ever purchased. The direct labor saving payback was less than one year. The increased e ciency from barcoding at the mark-in counter coupled with the complete elimination of assembly mistakes makes this the smartest business decision I’ve ever made, and one that is paying daily nancial dividends. “

Allan R Cripe CED,CPD

Brian Robertson

Owner, Valet Cleaners and Coin Laundry

Allan R Cripe CED,CPD

Brian Robertson

Owner, Valet Cleaners and Coin Laundry

If you live in Maine, you might be a customer of Pratt Abbott Garment Care, the state’s largest pro vider of drycleaning, vended laundry and linen/ uniform rental services.

“One of the reasons we have all three business sectors is to provide volume to afford a management infrastruc ture which allows our employees growth opportunities,” says David Machesney, who, along with his father Jim, purchased the company in 1991.

The other, he maintains, is because providing “every thing clean” simplifies life for customers.

The firm umbrellas 12 drycleaning facilities, eight vended laundries, and a 50,000-square-foot linen and uniform rental plant. By design, multiple revenue streams feed the Pratt Abbott enterprise.

Always family-owned, the business was founded as a solitary drycleaning store in 1944, in Portland, Maine, according to Machesney. “Elliott Abbott led the business for 14 years, often waiting on customers and pressing shirts himself,” he relates.

“In the 1940s,” Machesney continues, “he combated un employment by hiring veterans through the GI Bill.” Among those hires was WWII veteran Roderick Lowell, who worked his way from the shirt presses to owner ship in 1958.

Lowell and his daughters staffed the counters,

while Lowell’s father repaired and maintained machinery, according to Machesney. During the 1960s, he opened ad ditional drycleaning locations and expanded into uniform rental.

Since acquiring the garment care firm, the Machesney family — children and grandchildren — have worked the counters as well. After Jim passed away in 2015, David took the lead.

He’s significantly grown each of its business segments: dry cleaning, vended laundry and linen/uniform rental, benefiting employees and customers alike.

Today, Pratt Abbott’s drycleaning business makes up 60-70% of Maine’s retail drycleaning market and gener ates 38% of total company revenue. Drycleaning facilities bring multiple services to customers, including dryclean ing, shirt laundry and household laundry services.

Other perks include free pickup and delivery, as well as off-season garment storage. Efficient equipment and pro cesses ensure high-quality, eco-friendly results.

The vended laundry sector sig nificantly contrib utes to the success of the company, contributing more profit than dry cleaning, according to Machesney.

In many ways, the two intertwine. This is partly because most of the company’s vended laundries and drycleaning stores are located side-by-side. This configuration

We’ve personally handled insurance for thousands of drycleaners! We’ve already dealt with most any issue your business is likely to face. If you have any questions about insuring drycleaners, we can and will give you a prompt, clear answer. Skeptical? Call us with a question and find out for yourself.

All About Family and Community! David Machesney (left), company president, and Tom Gridley of Pratt Abbott. Earlier this year, the business received the U.S. Small Business Administration (SBA) 2018 Family-Owned Business of the Year Award for Maine.

Pratt Abbott serves 60-70% of Maine’s drycleaning market. The company has three main sectors: dry cleaning, vended laundry, and uniform and linen rental.

draws revenue from a broader demographic, creates shared operational savings and encourages consumer crossover.

“We look at it as a convenience to the customer and a way to serve more customers,” says Machesney.

“Co-mingling,” he adds, “also allows us to run fully attended laundries and offset some of the labor cost from drycleaning revenue.”

Thus, the vended laundries tend to make the drycleaning stores more profitable, and vice versa. Even better? The pairing creates “one-stop-shop” customer convenience. That’s important, according to Machesney, because Pratt Abbott “is in the business of selling time.”

Uniform and linen rental, the most profitable of the firm’s business sectors, began in the 1970s, but only re cently ballooned into super-performer status.

Making up a robust 58% of total company revenue, the uniform and linen service provides pickup and delivery of

cleaned and leased garments and linens. During the last 12 months, it has realized double-digit growth, according to Machesney. Thanks to the new plant’s size and equip ment mix, he expects that growth rate to continue for the next two to five years.

Committed to improvement, Machesney ensures his drycleaning locations, plants, and vended laun dries operate at peak performance. He reinvests for big returns.

“We continuously improve all our processes to provide innova tive services that increase satis faction, quality and value for our customers, and create profitable growth for our company,” he says.

During the last decade, for example, he’s renovated several vended laundries, which resulted in a per-store rev enue bump of 10-30% and utility cost savings of 50%.

“We like to diversify our assets and control our des tiny,” he notes, “so in addition to having the three different segments of garment care industry, we invest in commer cial real estate to control our locations and further diver sify our assets.

“We absolutely want to continue to grow and solidify our market,” Machesney says. “If you can do something you like and be profitable along the way, that’s the ticket.”

Machesney is ever on the hunt for new opportunities. His most recent development is new Express Laundry Centers in North Windham and Yarmouth, Maine.

It’s a journey, according to Machesney. “I didn’t look to get into the business to clean clothes. I wanted to run a business and I knew we needed enough size and infra structure to do it right. I have 160 employees and five di rect reports, and we try to make it a fun environment.”

Grateful for the company’s success, Machesney and his team make a point to give back. “We are active volunteers of Junior Achievement,” he points out.

Additionally, Pratt Abbott cleans 40,000 Coats for Kids each year and supports Camp Susan Curtis summer camp for underprivileged kids. “These kids are in tough situations and summer camp gives them a chance to breathe and plan for their future,” says Machesney. “It helps them break the cycle of poverty.” ADC

always suggest that you buy from the dealer or mechanic that is going to give you a great warranty and provide you continuous reliable service work,” he suggests.

“These machines should last you over 15 years if properly maintained.”

White notes to keep in mind: “Breakdowns will be unexpected and will cost you money in both repairs and

production downtime. So seriously consider this when making your purchasing decision.”

White’s last tip is this: “Know your numbers! Not just the amount of pieces but the class of your pieces — such as dry-clean, wet-clean, laundry — that are coming in.”

He says that most POS systems “allow you to track this information. Take that data and build your best trend line looking forward, and take into account where your

new business opportunities will be coming from.

“The trend, in general,” White continues, “is toward a lot more washables, and depending on your detergent technology, a majority of your ‘dryclean-only’ garments can be safely and effectively processed in a modern wetcleaning system.”

White concludes with this opinion: “Drycleaning machines are not going away but the capacity of the machines needed into the future is reducing.”

Jan Barlow, owner of Jan’s Cleaners in Clio, Mich., a suburb of Flint, started her business 36 years ago. She shares her experiences when deciding to buy machines.

“Over the past several years, while the industry was finding a perc replacement, we shifted our workflow from 80% dry cleaning and 20% wet cleaning to 30% dry cleaning and 70% wet cleaning. Until this past year, when a new modified alcohol came on the U.S. market, which cleans like perc, adds a new brightness to the cleaning process, and the hand of a hydrocarbon.

“We are changing our workflow back to 60% dry cleaning and 40% wet cleaning, with continued plans to move the ratio back to 80/20.”

She explains: “To protect our business from the shrink ing demographics of this industry, Jan’s specialized in bringing all our work to one plant through pickup and de livery, which includes personal, household items from the

client’s home, office, and fire and water damage.

“I have purchased both wet- and drycleaning machines. All the machines clean, some just clean better than others. Some cost more than others. Some require more maintenance than others.”

Barlow thinks that “It’s harder today to purchase than in the past because so much machinery gets out on the market before it’s adequately tested. So the innovative purchaser becomes the alpha or beta installation test site.”

What about sharing a tip when buying a machine?

“What I have learned over the years is everyone will take the plunge once or twice to try the new product, for the good of the industry.

“My measurements for a successful decision are in the cost to purchase, then the resulting labor and supply cost savings. I look for quality because once a decision is made, I don’t want to think about it again until depreciation of the equipment has passed for a few years and then some,” Barlow says.

These are three drycleaner owners’ opinions about buying machines. No doubt many of you reading rely on your own knowledge of what you’ve learned making machine purchases for your plants. One thing is for sure, all these machine choices, dry or wet, indicate a fabricare industry that is thriving. So rise, machines, rise!

For the fourth consecutive year, Leonard Automatics Inc. reports it has won the Gold Safety Award presented by the North Carolina Department of Labor.

“At Leonard we have a culture in which safety is our top priority,” says Scott Abernathy, Leonard’s general manager. “Our business operates more efficiently with an effective safety program, and I think it also shows our commitment to our employees’ overall health and well-being.”

Safety matters, it writes.

The goal at the company, Leonard relates, is to foster an injury-free workplace by making safety a part of its operational plan and including employees in that plan.

At Leonard, the people are the most important part of its success, the company says. Therefore, the firm takes their safety seriously.

Jay Desai was named Lapels Dry Cleaning franchise owner of the year, Lapels reports.

Desai is an owner of Lapels stores in Beverly Hills, Mich.; Rochester Hills, Mich.; and West Bloomfield Township, Mich.

“Jay is one of the most impressive individuals we have worked with over the course of Lapels Dry Cleaning’s 18-year history,” says Kevin Dubois, CEO of Lapels Dry Cleaning.

“Within a few years, he established a network of dry cleaning stores in the metro Detroit area and developed a system for expansion and growth.

“He’s coupled that effort with several community involvement endeavors,” Dubois further notes. “If that wasn’t enough, he’s also the owner of 19 Great Clips hair salons in the greater Detroit metro area.”

“I guess you could say I like to stay busy,” says Desai, who co-owns his cleaning locations with a partner from his company, Shambho LLC. Desai immigrated to the United States in the early 2000s.

“My partner and I have been very fortunate to have a great team led by our operations manager Tiffani Probst, whom I have worked with for 10 years,” Desai adds.

“As for the franchise owner of the year, it’s quite an honor and I do give credit to Tiffani for her amazing leadership and her team,” he indicates. “We’ve had a great relationship with Kevin and the Lapels team.”

(continued)

Miele’s patented honeycomb drum ensures a gentle wash to handle the most delicate garments while providing optimal cleaning results trust that your laundry is in great hands with Miele’s Benchmark Machines.

R.W. Martin Company, which de scribes itself as a leading provider of laundry and drycleaning equip ment, parts and support solutions, has hired Patrick Jovanovic in the role of parts specialist.

As a member of the firm’s PartsPLUS Team, Jovanovic will help manage the company’s large inventory of replacement parts for textile care equipment, it notes.

R.W. Martin, founded in 1968 by Robert W. Martin, celebrates 50 years in business and continues to flourish. “I’m excited to join R.W. Martin,” Jovanovic says.

Employees from four affiliates of America’s Best Clean ers (ABC) will pursue a new level of the drycleaning craft by accepting educational scholarships from its part ner Kreussler Chemical, a professional textile care busi ness, ABC reports.

The four chosen scholarship recipients will be head ing to Drycleaning and Laundry Institute (DLI) classes to continue their education in environmentally friendly

(ABC),

the help of its partner Kreussler Chemical,

provided four of its affiliates with scholarships to attend DLI classes. (Photo: America’s Best Cleaners)

dry cleaning in addition to perfecting the comprehensive skill sets mandated to be certified by ABC, the firm re lates.

“We are so proud of our affiliates that continually in vest in the people maintaining the highest standards of quality garment care and services in our industry,” says ABC Executive Director Christopher White.

The four scholarship recipients are Graystone Hill (seen in photo above), Blue Sky Cleaners, Seattle; Jason Pardi, Best Cleaners, Albany, N.Y.; Veronica Moeai, Henries

Dry Cleaners, Salt Lake City, Utah; and Courtney Kraemer, Jones Clean ing Center, Fresno, Calif.

“I’m very excited for all of the award winners and hope that this is just the beginning of a long, fruitful career in our industry for the scholar ship winners,” says Kreussler Presi dent Richard Fitzpatrick.

Hamilton Engineering, a manufac turer of custom-engineered, prepackaged hot water solutions for commercial and industrial applica tions, announces a new sales team lineup and introduces Tyler Segur as regional sales manager serving customers in expanding eastern U.S. markets, it reports.

“We have the most knowledge able and responsive sales profes sionals in the business,” says Jeff Deal, director of sales.

The Hamilton sales team includes Deal, along with Andrew Hyde, re gional manager, central states, and Josh Reasoner, regional manager, western states.

Ken Novak is sales manager of U.S. laundry distributors, and covers all laundry distributors nationally.

Clearent Software Holdings, a whol ly owned subsidiary of St. Louisbased payments solutions provider Clearent, reports it has purchased Falmouth, Maine-based Compass max, a developer of comprehensive drycleaning point-of-sale software, the firm reports.

The deal marks the company’s second acquisition in the dryclean

www.americandrycleaner.com

ing space, following Clearant’s purchase of Draper, Utah-based SPOT Business Systems earlier this year.

“With Compassmax, we saw an opportunity to bring together two software leaders in the drycleaning industry,” says Dan Geraty, CEO of Clearent.

Compassmax joins SPOT Busi ness Systems as a company un der Clearent Software Holdings.

Clearent plans to combine the com panies’ operations over time, fo cusing all software development and innovation on the SPOT plat form, the company writes.

“Compassmax and SPOT have the knowledge, experience and technical expertise to ensure cus tomer needs are exceeded in the complex and competitive world of dry cleaning,” notes Geraty. “We couldn’t ask for a better fit.”

Own Your Own Drycleaners—Managers, Spotters, Tailors, Pressers! 100% Financing. Plant or Drop, location of your choice. Call 1-561-302-5031 or 1-888-275-6637.

• Business Coaching & Consulting

•

Richard Ehrenreich, CED, SBA, F-CBI Ehrenreich & Associates, LLC Retiring Business Owners: Call to schedule a FREE initial telephone meeting. Review Richard’s credentials & references on Linkedin. (copy sent on request) Richard@Ehrenassoc.com 301-924-9247

Great opportunity to purchase fully equipped plant in Paterson NJ. Almost new Hydrocarbon 80 pound machine. Perfect for multiple drop store operations.

For full list of Equipment email: bobsaeed@gmail.com

Laundry Pro of Florida is the 2016 Dexter Distributor of the year. We are looking for new prospects to join our team. Come work where people vacation, in sunny Florida. We are seeking:

• Proven Laundry Equipment Salesman

Great work environment, highly competitive compensation, paid relocation expenses. Please respond in confidence to: Rjansen@laundryequipment.com

Dry Cleaning POS company is seeking a motivated candidate to fill a position in the point of sale market. We are a national company that specializes in providing software solutions to dry cleaners.

Responsibilities will include: Understand the inner workings of the products and present this knowledge to customers in a professional manner. Prepare detailed proposals that include hardware, software and services in order to meet sales objectives. Develop and implement strategic sales plans to achieve sales goals. Accountable for meeting and exceeding revenue objectives through prospecting new business and growing existing accounts. Some traveling is required.

Please contact: selldrycleaningsoftware@gmail.com

Experienced plant manager for established Drycleaner in South Carolina, close to Charlotte. Responsible for the dayto-day operations of a Perc plant grossing $900,000 per year. 5 days a week and some Saturdays for cleaning and mainte nance. Salary & Sign-On Bonus negotiable. Possible equity position. Send resume to: sstaples@comporium.net

Director of Operations – Lapels

Join the Future of Dry Cleaning. Lapels Dry Cleaning is looking for a Director of Operations to assist in Franchise Operations. With this position you will be responsible to train and assist our Franchisee to become more profitable.

Duties include:

• Manage the overall operations of our 4 Corporate Locations

• Training of Lapels Standards of Operations

• Assisting Franchisee in start-up includ ing on-sight training

• Follow up training of Franchisee owners

• Train Franchises on overall plant per formance tracking Pieces Per Operator Hour (PPOH)

• Maintain relationships with local vendors and suppliers

• Quality Assurance Visitations

As the Director of Operations, you must have overall Plant operations with the ability to train others.

This position also requires monthly travel and the ability to work from our Corporate Office located in Hanover, MA.

Please contact Dave Grippi, VP of Operations. dgrippi@lapelsdrycleaning. com or 781-829-9935

WITHOUT-A-TRACE WEAVERS—More than 60 years’ experience. We are the experts in silks, knits, French weaving and piece weaving. Reasonable prices. Send garments for estimate to: 3344 W. Bryn Mawr, Chicago, IL 60659; 800-475-4922; www.withoutatrace.com. www.AmericanDrycleaner.com

10 YEARS AGO. Vacationers may soon be able to visit Europe after all — E.U. member nations are beginning to feel the recession, and the dollar is rising against the Euro and the British pound. German, French and Italian economies contracted sharply in the second quarter, and British housing prices fell after its even bigger “bubble” burst.

35 YEARS AGO. Norman Oehlke, the International Fabricare Institute’s garment analysis expert, will be on the air with Ruth Dinwiddie of the Sugar and Spice show during its broadcast over 32 radio stations from Alaska to Florida on Sept. 23. The interview was taped in Chicago during Clean ’83. Oehlke presented lots of commonsense advice on cleaning care.

50 YEARS AGO.” Battle of the Sexes. Newspaper want ads that are placed under separate “Male” and “Female” headlines will be illegal after Dec. 1, unless sex is a “bona fide occupational qualification.” The Federal Equal Employment Opportunity Commission has ruled that the separation of want ads by sex for convenience of job seekers “has a discriminatory effect by indicating employer preference” in filling job openings. …. Our friends in Texas have long had the reputation of making an extra effort to “out-do” the rest of us, and it just may be well-deserved. We have an ad run by a cleaners in Plainview with the headline, “59½-Minute Cleaning Service.”

75 YEARS AGO. Cleaning for the Movies! Dyeing pants for penguins, cleaning wooden legs, laundering shirts to a tattletale gray, or throwing mud on freshly cleaned garments are services few cleaners offer. But they are all in a day’s work for the movie studio cleaners in Hollywood. The plant, after 15 years of serving the motion picture studios, can take the Believe-It-Or-Not orders of the movies in its stride — and give express service besides. Operating 24 hours a day, the cleaners give speedy, efficient service the filmmakers need to keep production on schedule. Costumes worn on a set during the day are picked up by the plant’s three-truck delivery system, processed, and returned in the small hours of the morn-

In same issue, caption for above photo: These are the tricky costumes you have to handle in cleaning for the movies. Men matching a dye job.