January

With flow and efficiency as their plant design themes, along with what they like to call their, “best-in-class customer service,” Tide Dry Cleaners at 8452 Tuttle Avenue in Sarasota, Fla., is the winner of the Grand Prize in American Drycleaner’s 58th Annual Plant Design Awards. Also receiving awards are West Wendover, Nev.-based Rocket Cleaners for Outstanding Niche Operation, and Sierra Vista, Ariz.-based Flora’s Dry Cleaning & Alterations for Outstanding Plant-on-Premises.

Tim Burke, Editor

“We were looking for something fun and eye-catching,” says Ben Kohan, drycleaning owner of Encino, Calif.based Hilltop Cleaners. He’s describing his solution to how to reach out and attract potential customers coming and going from the parking lot of a high-end grocery store that was behind his drycleaning store. His answer to the dilemma was to install big banners on the back of his store. Find out how that worked out for him!

Tim Burke, Editor

Pre-Inspection

Wrinkle in Time 48 Jan. 1944: An Ex-Soldier Comes Back to His Plant

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

“I don’t have to rely on anybody for information. I can see immediately what I have for inventory, orders and accounts receivable.”

Welcome to 2019! Here we are at the starting line again, full of new dreams. ….Did I mention it’s a new year? Well it is.

But for just a sec, let’s go back a long time ago, to a galaxy far away... to a business conference I attended where people were asked to take a quick survey. Their answers were to help determine their business “personas.”

Phrases were made up to describe these personas, like: “climbing the ladder,” “building a bridge,” and “rising tide.”

This all came suddenly back to me today during the American Dycleaner 58th Annual Plant Design Awards. I realized the phrase “rising tide” is perfectly apropos for our 2019 Grand Prize winner, Tide Dry Cleaners, located in Sarasota, Fla.

Our front cover shows off the new Tide location at night, and the team of people who make it the big winner! You can read the feature article, Tide Rises starting on page 14. It’s all about flow and efficiency being keys to this Florida dry cleaner’s winning plant design. Becauee people are such a big factor in all you do in your drycleaning businesses, I felt adding the inset shot of all their people would be cool.

Also in this first issue of the new year, check out articles about the other winners: for Outstanding Niche Operation, Rocket Cleaners in West Wendover, Nev., and for Outstanding Plant-on-Premises, Flora’s Dry Cleaning in Sierra Vista, Ariz.

Another feature in this January issue is called Live Life Bold! ...In Banners! about the drycleaning owner of Hilltop Cleaners in Encino, Calif., Ben Kohan, who took a bold step to promote his operation by flying huge colorful banners on the back of his business to reach an audience at an upscale grocery store parking lot.

This issue there’s an article about Messe Frankfurt buying the Clean Show; our columnist Diana Vollmer writes about hot trends in Reaching Out (Part 1); and your other favorites: Around The Industry, Off The Cuff and Wrinkle In Time.

So here we are! New calendar on your wall. New coffee mug, perhaps. New perspective. A whole new year. Feels great doesn’t it?... I thought you’d say so! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 85, number 9. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2019. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, January 2019

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Tim Burke 312-361-1684 tburke@ATMags.com

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Roger Napiwocki

Advisory Board

Mike Bleier

Steven Dubinski

John-Claude Hallak Mike Nesbit Herron Rowland Fred Schwarzmann Beth Shader Ellen Tuchman Rothmann

Contributing Editors

Dan Miller

Diana Vollmer Martin Young

Office Information Main: 312-361-1700

Subscriptions 630-739-0900 x100 www.american drycleaner.com

One drycleaning owner in Encino, Calif., uses an entertainingly eye-catching series of amusing banners on the back of his building to create big customer interest.

By Tim Burke, EditorWhat do you do if a high-end grocery store stands behind your drycleaning location?

Your business, by the hand of fate, doesn’t happen to face the upscale store, which has a large parking lot full of potential customers coming and going all day.

You have seemingly no visibility for your storefront, as it’s pointed the opposite way.

All you have is the bare expanse of your operation’s back wall. So you’re sunk, right?... No!

For one clever drycleaning owner, there was an opportunity, but it needed a big, bold idea.

Enter Ben (Kamran) Kohan, owner of Hilltop Cleaners in Encino, Calif., who has advice for any cleaner with a big space to fill: “Be bold. Be creative. But, mainly, do something!”

Hilltop Cleaners is right around the corner from an upscale California supermarket, Gelson’s, notes freelance writer Larry Siegel, who first reported it for Hilltop.

For a long time, Siegel writes, Kohan had pondered how to get the market’s customers to drive half a block further to his cleaners, which happens to be open 24/7/365.

The answer, Siegel explains, that came to Ben, was to get right into the market’s customers’ faces. He commissioned four huge banners to hang on the back of the cleaner’s building adjacent to the Gelson’s parking lot!

“We use lots of posters and banners inside our plant to promote our services and some of them are up to five feet tall since we have high ceilings,” says Kohan.

“But filling a 95-foot-long wall is on a whole different scale…literally,” he adds.

Once customers came around to the front of Hilltop Cleaners, they found an equally bold and attractive looking business, impressive in this night shot!

American Drycleaner asks Kohan: What spurred you to develop the big colorful banners?

“We were looking for something fun and eye catching,” he replies. “Using bright colors is appealing to the eye. Also, we included ballerinas because we have the L.A. Ballet Academy as well, so we incorporated both businesses.”

Kohan started his business in 1985 as, “three brothers in a family-owned partnership. We specialize in laundry, dry cleaning, alterations and household items. In 1990, we expanded our services to open 24 hours a day,” he relates.

“We provide customers with the greatest services possible. Customers are ‘Number One’ in our store to us. We wanted to create a place for customers to not only feel like they get amazing service, but also to combined a family-friendly place along with a VIP upscale feel,” Kohan says.

“We provide free popcorn, candy, coffee, and delivery to all customers at no extra charge. We are also pet friendly,” he notes.

name recognition; environmentally-friendly; tailoring; and being open 24/7/365.

Siegel explains: “Ben said to add some ballet graphics, too, since the cleaners leases part of its building to the ballet studio,” and notes that what could have been a hurdle turned into a visual thread that tied the first banner to the last.

Anchoring the first 20-foot-by-18-foot banner with an illustration of a “retro” woman hanging clothes on a clothesline that Hilltop had used in promotions eight years ago, the banners had elements that linked them together, Siegel points out.

They provide free popcorn, candy, coffee, and delivery to all customers at no extra charge and are also pet friendly.

Turning to Siegel, his marketing consultant/graphic designer, who has helped the cleaner with branding since 2010, it was determined that “playful” illustrations would convey Hilltop’s core messaging:

He indicates that these elements include: the clothesline, which starts in the first banner and ends in the second; the running dogs and clouds, which appear in the second banner and continue into the third; and the ballet figures in the first banner, which are the focal point in the last.

A huge red directional arrow on the fourth banner leaves no doubt as to where Hilltop Cleaners is located and that it is open 24 hours a day.

The banner idea, Kohan explains, came together with the help of several people: “We have our marketing designer we work with, Larry Siegel, and he

helps us with most of our marketing designs.

“We expressed what we were looking for and we went from there. It was a lot of back and forth to get the right picture and message across. Once the design was ready, we went to our banner company to get the rest done,” Kohan says.

“We supplied the banner company with the artwork and size we needed and they handled the rest. Our inhouse marketing manager/general manager is Raquel Toledo, who makes sure it gets to the right people in order to bring it to life,” he points out.

The banners, installed last summer, are definitely having an impact, according to Toledo, who says: “Nearly every day, our customer service reps tell me about comments from customers relating how the banners are ‘attention-getting’ and ‘cute.’ Definitely the desired result!”

Kohan realized an opportunity to reach the upscale grocery store customers, saying: “We have always had the thought and attempted different options, this was the most ideal way to get it done.”

Once the banners were in place how long did it take to get customer response?

“Immediately,” Kohan relates. “We have a lot of our customers who shop at Gelson’s, and we were receiving compliments that day. It was pretty heart-warming to hear the good things people were saying. We love our customers.”

The team at Hilltop Cleaners poses for this group photo. They, and owner Kohan, noted an instant jump in customer activity after the big banners went up.

Many drycleaning owners make effective use of signage. But are you possibly thinking of adding banners to your own drycleaning operation? Attracting new customers might be just a banner away.

Kohan shares some of the more memorable customer comments he has received about his banner. He says the following are just, “some of the responses we got:

‘It was beautiful.’

‘The banner is so big and nice.’

‘Love everything about it.’

‘It is very nice to see up there, rather than just a plain wall.’

‘I am a loyal customer and to see the banner makes it special.’

‘Love the idea of mixing everything together.’

‘It’s so happy!’”

With the success of the banners, Kohan provides some advice for other drycleaning owners.

“Promoting is everything,” he says. “You consistently need to promote your business to get it out there. Having a great marketing crew and staff that love what they do, makes it all the better.”

Ribbon cut, new plant opens! The newest Tide Dry Cleaners in Sarasota, Florida, shown being opened at a ribbon-cutting ceremony in March 2018, has become the winner of the American Drycleaner

Best Plant Design, a contest now in its 58th year. The new Tide plant at 8452 Tuttle Ave., has 3,000 square feet and 17 employees, the company notes. Robert Lyons, president of Consolidated Cleaners Inc., which operates nine Tide stores, is in photo standing just to the right of woman holding scissors. Other team members include (from left) Brooks Ewing, VP of finance for Tide Dry Cleaners; Linda Cartwright, franchise business director for Tide Dry Cleaners; Donte Simmons, guest service representative; Mercede Davis, guest service manager; Tesla Gunderson, guest service representative; Jon Kassolis, CFO and general counsel for Consolidated Cleaners Inc.; Tara Carrol, general manager for Consolidated Cleaners, Inc.; Julann Harris, delivery manager; Blake Dillon, general manager for Consolidated Cleaners Inc.; Samantha Ranieri, franchise operations specialist for Tide Dry Cleaners; Amanda Fagan, operations support manager for Consolidated Cleaners Inc. (Photos: Tide Dry Cleaners)

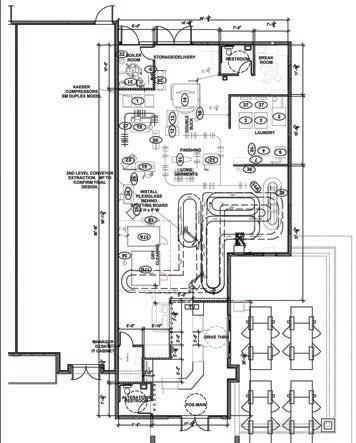

Flow and efficiency. Two words to describe the award-winning plant design layout at the new Tide Dry Cleaners store in Sarasota, Florida.

“From the outside to the inside,

Drycleaner,

it’s a beautiful building,” says Robert Lyons, president and CEO of Consolidated Cleaners Inc., the franchisee owner of nine Tide Dry Cleaners (TDC), in Florida, describing its newest plant at 8452

Tuttle Ave., Sarasota.

“The plant flow is efficient, it’s comfortably air-conditioned to benefit both customers and employees, and we provide our customers with the

Pano-flow! A panoramic view of the 2019 Grand Prize winner’s plant at Tide Dry Cleaners in Sarasota, Florida, emphasizing flow and efficiency. Union drycleaning machines, solvents by GreenEarth, spotting fluids by A.L. Wilson, Fulton boiler systems, Kaeser air compressors, and SPOT POS stations are just some of the many equipment and product highlights here. “We have fabulous teams of people with many years of drycleaning experience,” relates Robert Lyons, president and CEO of Consolidated Cleaners Inc. “The Tide team gives input on construction and design and brings templates for our franchise team to work with, all to develop the best and most efficient layout.”

best quality in dry cleaning,” Lyons says.

The Sarasota plant — which is all about workflow, plant efficiency, and the smiling faces of its employees and customers — is the winner of the 2019 Grand Prize in American Drycleaner’s 58th Annual Plant Design Award.

“Parent company Procter & Gamble, known as P&G, got into the services industry with one of its top brands, Tide, with a laser focus on using environmentally safe processes,” Consolidated notes.

It did this by “delivering best-inclass customer service through our carefully selected local franchise partners and through ‘PODs,’ what we call 24-hour service; utilizing access to P&G’s fabricare experts; and creating transparency to where garments are being cleaned.”

Consolidated describes itself as a “highly esteemed group of

individuals” that own and operate nine TDC units— seven on Florida’s west coast and two on the east coast— making them one of the top franchisees in the network.

“The group is a mix of family, family friends, and long-time co-workers,” Consolidated adds. “Together they have the ideal structure, with expertise in: site selection, development, accounting, operations, customer service, and the list goes on.”

The new 8452 Tuttle Ave. plant in Sarasota covers 3,000 square feet, accommodates 17 employees, the company notes.

Talking about your scope of services, how does the choice of equipment relate to design and layout?

Lyons says: “The Tide Dry Cleaners Sarasota plant design focuses on efficiency and productivity enabling the teams’ focus to remain on exceeding

A tall conveyor requires a tall store interior! Like what’s shown here at Tide’s newest Sarasota plant, opened in March 2018. Plant equipment includes installation of Metalprogetti automated conveyor systems. “The 20-foot ceilings allowed this to be three levels,” the firm points out.

our guests’ expectations with the quality of our cleaning and pressing, the convenience of same-day service with 24-hour access, duel-lane drive-thru valet service and unrivaled guest service with a smile, free bottle of water and P&G Samples.

“We are helping simplify our customers lives and the design of our plant enables us to deliver the convenience, quality

and guest service that consistently exceeds our guests’ expectations.”

What influences the decisionmaking process when placing your plant’s equipment?

“Most importantly for flow is efficiency, creating the fewest steps for our people between stations,” Lyons says. “We want the best plant workflow starting at the front, moving to the cleaning machines, then to finishing. It’s all about efficiency.”

Plant equipment includes installation of Metalprogetti automated conveyor systems. The 20-foot ceilings allowed this to be three levels, the firm points out.

Lyons relates that, “The threestory conveyor allows valuable floor space to be utilized for active production, increasing the efficiency of our space. Maximizing the vertical space is a key component to our plant design.”

Also in the plant are Union drycleaning machines, Unipress

pressing equipment, Alliance Laundry Systems (UniMac) laundry equipment, Fulton boiler systems, Kaeser air compressors, and SPOT POS stations.

The plant design and layout was done initially by TDC’s agency development team: “We have an ‘in-house’ designer on the Cushman & Wakefield team,” the company relates.

“We have fabulous teams of people with many years of drycleaning experience,” says Lyons. “The Tide team gives input on construction and design and brings templates for our franchise team to work with, all to develop the best and most efficient layout.”

The design starts from what the firm terms, “An ‘ideal template,’ that is adjusted for every location, given different dimensions and door placements. From there, it is reviewed and approved on a ‘design call’ where it receives input from the development, marketing, and operations teams before it is released to the architect of record, MHK in this case, for construction documents.”

MHK is used on

all of Consolidated Cleaners’ Tide stores, Consolidated says.

“The ‘design intent drawing’ was done in June 2016, and the store opened in March 2018,” it adds.

The building itself, which has two other attached retail spaces next door, “is owned by a couple of the principals,” Lyons relates, “and leased by Consolidated Cleaners. A nail spa business has recently moved into one space. We’re in the process of leasing the other space.”

Lyons says that since the building is owned by an affiliated company, they look for “‘Dailyuse’ types of co-tenants, that are ‘traffic-drivers’ for sure.”

About selecting the equipment in his new plant, Lyons says, “All of our stores start with the same basic idea and equipment package, and then modifications are made. For instance, in this new location, this is one of our largest plants, with two drycleaning machines.”

A.L. Wilson, pad covers from Unipress, and spot cooling by Unico. Tampa Bay Supply is the distributor.

Consolidated Cleaners has won several awards from the franchisor for operational excellence. Lyons points out, “You can see a list of achievements on the Consolidated website, including four Tide Dry Cleaners Franchisee of the Year Awards for the years: 2014, 2015, 2016 and 2017.”

Also on its website is this description of the group and its plans: “Consolidated Cleaners Inc. was founded in 2012 to merge its partners’ real estate and operational capabilities with the innovative concept of revolutionizing a basic service — dry cleaning.

“Consolidated Cleaners has

Other products used in this new Tide plant include GreenEarth solvents, spotting chemicals by

Other products used in this new Tide plant include GreenEarth solvents, spotting chemicals by

Since the installation of new Poseidon Textile Care System Wetcleaning Machines and Dryers, Perfect Cleaners, in Detroit, has tripled processing throughput, lowered utility costs, and realized an 8 percent increase in sales volume. Owner Gary Heflin, a dry cleaner of 28 years, has transformed his business from predominately dry cleaning to mostly wetcleaning. Wetcleaning, he maintains, is a more cost-effective, environmentally friendly and productive way to process garments of all types and fabrics.

“The Poseidon system allowed us to significantly improve productivity so I could seek out new accounts,” said Heflin. “Wetcleaning is so much better and faster than dry cleaning. It uses less water and natural gas and we can wetclean pretty much anything, including suits, uniforms, overcoats, wools, silks and wedding gowns.”

Perfect Cleaners worked with Jeff Quail and Mike “Stucky” Szczotka, of Eagle Star Equipment, in Troy, Mich., to select, install and program its new Poseidon wetcleaning equipment, including two 40- and four 90-pound capacity soft-mount wetcleaning machines, and four 85-pound capacity dryers. The highly programmable Poseidon system offers flexibility and ease-of-use. The wetcleaning machines are set up with 18 different programs for specific item types, including gowns, comforters, napkins, darks, spa sheets, chef coats, shirts, and more. “Soaps and conditioners are automatically injected,” said Heflin, “and one wetcleaning machine has steam injection for cleaning chef and lab coats. This eliminates prescrubbing labor and time,” he said. “The quality is excellent and my customers have

noticed a positive change.” Operators simply enter a program number, load the wetcleaning machine and press start. The machine automatically does the rest by combining the right chemicals, water temperatures, water levels, mechanical action, g-force, baths and cycle times.

The Poseidon Dryers, which are engineered to safely and quickly dry wetcleaned items with no shrinkage, according to Quail, offer moisturesensing technology, onthe-fly adjustments and a flexible control. “They program the dryers to fit the wetcleaning machines by item type,” said Heflin. “We have no problems with shrinkage, items come out slightly damp, and finish work takes less time. As soon as the dryer stops, we lay out the garments, which are finished and pressed in 15 percent less time. Before we had the Poseidon Dryers, we had to hangdry casino drapes. Now they are quickly dried in the Poseidon Dryer, which greatly improves our production,” said Heflin.

Wetcleaning is so much better and faster than dry cleaning. It uses less water and natural gas and we can wetclean pretty much anything,”

While it takes 60 minutes to dry clean one load, it takes just 35-40 minutes to wetclean and dry the same size load, according to Heflin. “This allows us to finish our work a couple of hours sooner in the day and turn off the boiler, which saves a ton of money on gas and labor.”

- Gary Heflin Owner Perfect CleanersPerfect Cleaners, which did very little wetcleaning before, now wetcleans 60 percent of incoming items. Heflin expects that number to grow. “I really wish I had the machines years ago.

Poseidon gives you everything a drycleaner would want without the costs. Wetcleaning has enhanced our whole operation and allowed us to do a whole lot more in less time with great quality.”

poseidonwetcleaning.com 800-482-3400

partnered with Agile Pursuits Franchising Inc. (a wholly owned subsidiary of Procter & Gamble) to develop Tide Dry Cleaners in markets across South Florida.”

About Tide, it writes: “Tide has been a leader in innovation since its creation more than 65 years ago and now has expanded

beyond at-home laundry care by delivering the quality Tide is known for to the drycleaning industry. Tide Dry Cleaners’ purpose is to create a drycleaning experience with an unrivaled level of clean and care for customers’ garments.”

Consolidated Cleaners has

locations operating in Naples, Bonita Springs, Fort Myers, Boca Raton, Parkland, Wellington/ Royal Palm Beach and Sarasota, with additional locations under development.

The firm’s principals saw an opportunity “to build a business that would be a successful operation for family and friends to run for years to come.”

Those family and friends can no doubt look forward to a flow of customers to the attractive-looking new Sarasota plant. Walking in or driving through, night or day, the design catches the eye.

As 2019 begins, Tide rises up as the winner of the 58th annual Plant Design Award, an award originated by American Drycleaner in 1961 to call attention to the best in drycleaning plant innovation.

“The new plant is pleasing to the eye,” Lyons says, “but we’re all about efficiency, and all about providing the best-quality dry cleaning for our customers.” ADC

(continued on p.27)

At the heart of SMRT, we are a dry cleaner. It’s the reason we created our software in the first place: To solve the everyday problems we ran into at our own business.

We’ve stood in your shoes -- pressing, cleaning the button trap, filling in when the driver is sick, making payroll, and replacing equipment.

And with a dry cleaner’s perspective, we’ve built, from the ground up, the best dry cleaning software in the marketplace.

We understand that dry cleaners are dynamic, high-performing entrepreneurs. It’s no small feat to run both the factory and the dealership every damn day. You deserve a software partner that knows your business and is there for you 24/7. You deserve SMRT.

Next-level customer service to match their next-level technology. The SMRT team is passionate about solving problems and supporting their users.

Jason Yerby

Vice President: Crest Advanced Dry Cleaners

There’s more to SMRT than great software. They really know the business, bringing a new dimension to customer support.

Daniel Cha

Owner: Orchid Dry Cleaners

SMRT is light years ahead of the competition! We’ve never been so on top of our business and in tune with our customers.

Wayne Edelman

Owner: Meurice Garment Care

Robust

Richard Aviles

Owner: Bridge Cleaners & Tailors, King Garment Care

Four brothers came back home to start a dry cleaner.

Home is a small desert town just west of the Great Salt Lake, population about 4,000, where a towering neon cowboy sign known as “Wendover Will” has been famously greeting westward-bound visitors coming over the Nevada

state line since 1952.

Wanting to give back to their community, and using their mom’s nickname as added inspiration, the brothers opened their cleaners in this border town, described as “The Place Where the West Begins.”

“It’s kind of a long story as to why we decided to open a dry cleaner in

Wendover,” starts Robert Spillman, owner of West Wendover, Nevadabased Rocket Cleaners, which opened last summer.

He continues: “Wendover straddles the Utah and Nevada state line, and is my hometown. Several of us left here after our high school graduation in the

1960s and ’70s, and about three years ago, myself and three brothers started talking about doing something good for our hometown, and the people who live here.”

Wendover is a small community and never had its own dry cleaners, he explains, saying that the nearest one was a two-hour drive.

The Rocket Cleaners name came from a nickname his mother, Ruth, was given because her car “sounded like a rocket when she

gave it the gas,” Spillman relates. “She is 96 years old and was affectionately known throughout the town as ‘Grandma Rocket.’ She’s in a nursing home now.”

He points out that, “We went into this adventure having no experience with a laundry or dry cleaner,” but notes that they have received tremendous support from equipment and chemical suppliers, which has “really helped us move forward.”

What was the reason behind the location and design?

“We actually placed Rocket Cleaners in the location because it is the corner of the retail space we built here in Wendover,” Spillman explains. “We felt it gave us more back wall space we could use for venting, and the back piece was such an odd shape, it lent itself to back-of-the-house production and allowed us to use the rest of the building for our

White Conveyors’ SUV-OAS is the perfect solution to boost your productivity, improve customer service and increase your profits while reducing your operating costs. The system is delivered fully assembled, and can be operational in less than two hours. As an option, it can be mounted on wheels for mobility or storage. Simply set it up on its supports, plug in the power, connect the computer, and link the system to an Internet connection. It’s time to begin realizing remarkable time and money savings.

Easy to use

Reduces labor costs

Increases productivity

Assembles over 2000 pieces per shift

Interfaces with all major POS systems

Can utilize a bar-code or RFID chip system

Easy-to-read computer touch screen

Highly accurate and reliable

Fast return on investment

Proudly made in the USA with fast support

dollar store and restaurants.”

He continues: “Craig Riddle with Ally Equipment provided and installed all our equipment, and continues to provide us great support whenever we have a question or issue. Liz Davies came in and trained us prior to opening, and we continue to rely on her for expertise in cleaning different articles, procedures, and supplies.

“Bud Bakker with Sankosha, Jeff Schwarz with A.L. Wilson, and

Jeff Allen with Seitz have all been a great help to us and have made it feel like a community we became a member of.”

Other equipment and products in use by Rocket Cleaners come from Columbia/ILSA, Continental, Hi-Steam, Parker Boiler, Ingersoll Rand (compressor), QuickSeal (heat-seal press), White (conveyor), Kreussler (K4 solvent), and R&B Wire Products.

Side note: Wendover Will’s more

famous smaller twin “Vegas Vic” stands next to Fremont Street in Las Vegas.

The new drycleaning operation speaks directly to its “where the west begins” clientele. As this example tells, from a Rocket Cleaners’ Facebook post recently: “Did you know that our machines can wash your horse blankets? Drop by Rocket Cleaners for all your drycleaning needs.” ADC

“sounded

In 1999, three dry cleaners, Jim Douglas, Jim Barry, and Ron Benjamin, founded GreenEarth Cleaning to provide an alternative to perc. Now, after 20 years, GreenEarth has evolved into a process that is recognized by landlords, garment manufacturers, insurance companies, regulators, and consumers as the most sustainable way to care for fabric. Our sincere thanks go to our GreenEarth Members worldwide, who daily provide their customers with quality service and the planet, its people, and their business with the care they each deserve.

In 1999, three dry cleaners, Jim Douglas, Jim Barry, and Ron Benjamin, founded GreenEarth Cleaning to provide an alternative to perc. Now, after 20 years, GreenEarth has evolved into a process that is recognized by landlords, garment manufacturers, insurance companies, regulators, and consumers as the most sustainable way to care for fabric. Our sincere thanks go to our GreenEarth Members worldwide, who daily provide their customers with quality service and the planet, its people, and their business with the care they each deserve.

Flor Castillo, owner of Sierra Vista, Ariz.-based Flora’s Dry Cleaning & Alterations, tells her story: “My journey began when I had a small taste of being a business owner. I worked for Lloyd’s Dry Cleaners for over eight years where I put my sweat, tears and hard work into the business.”

One day, she notes, “The owners saw how hard I worked and how I was dedicated to this industry so they offered me the opportunity to buy their business. Unfortunately, the deal fell through. I thought that all my hard work and dreams were gone. I cried myself to sleep every night thinking what could’ve been.

“While I was in this journey with

that cleaners, I came across an angel that would guide me to my next dream. His name is Edward Molina. He was a customer and later became my business consultant.

“He offered me the opportunity to become business partners. Sadly, to say, after a while he decided to walk away from my dream. Once again, I found myself lost and nowhere to go from there.”

Castillo relates how, as the days went by, a vision came to her: She saw herself surrounded by her family and her husband with their emotional and financial support. “I knew at that moment, I could accomplish my dream,” she says.

“But at that same time, and with a lot of fear, I knew I was no longer buying an existing business, but creating one from the ground up!”

She explains, “I took what I learned and began by looking for a building which ended up being a perfect location on our busiest street, 970 E. Fry Blvd.

“Along the same time, I looked for a general contractor which turned out to be another angel. He allowed my family and I to do most of the teardown because he knew I was starting on my own with a limited budget.

“The only knowledge I had about equipment was older than me,” Castillo relates. “So,

my search took me to Gulf States in Houston. Where yet another angel existed by the name of Harish Parmar. He gathered information about my plant and put a perfect package together for me.”

How did you decide on the layout and why is it designed that way?

Castillo answers over the phone recently from her busy plant, her noticeably hurried voice competing with loud drycleaning noises: “We are so busy working-working all the time but my answer is we needed to take advantage of every square inch of space available in our plant that we had to work with. It’s a small space as you can see, so we just tried to use all of it the best way we could. That’s it.”

She relates that her and her father Victor are excited at winning the Outstanding Plant-on-Premises award but also she can’t stay on the phone, “We’ve got work to do! But thank you so much!”

Flor knew from the outset she was going to need employees and she ended up at the unemployment center, Arizona@work, where she found some help. “It was hard to find the employees that I needed because we all know it’s a laborintensive job,” she notes.

“Finally the team came together, but with no knowledge in the drycleaning industry!” She exclaims. “So, I came up with a plan to train my employees. I made up a mock drycleaning store in the adjacent building to get them prepared for opening day.”

Castillo, in her own words: “We have a Unipress automatic legger, all-purpose utility presser, pant topper, Thunder series single buck body press, air bag sleever, collar and cuff press, and hot head jeans press.

“We have a Forenta form finisher, triple puff sleever, vacuum spotting board; and we have a Realstar 40-pound hydrocarbon drycleaning machine.

“We have a Fulton 20-hp stainless steel boiler with night switch; a REMA dry-vac system with stainless steel tank; an Ingersoll 10-hp air compressor; a Rheem water heater; and a Huebsch 70-pound soft-mount washer extractor, and 50-pound gas dryer,” she explains.

“Installer Chino Martinez from Sheen Equipment, was responsible for our equipment layout,” Castillo

points out.

“Our chemical distributor,” she says, “is Kurt Gnadt who represents Laundry & Cleaners Equipment out of Phoenix. Tom Newnreiter programmed our washer.

“M&M Diversified is our general contractor. George Lounsbury and Rincon Services is our engineer and plant designer. Joe Demaro from Streets programmed our drycleaning machine.

“Our solvent is Streets DF 2000 hydrocarbon. Our spotting fluid are by A.L. Wilson and Streets. The pad covers are from Air World, Covers, etc., and Buckeye.

“Our carts are by Steele Canvas Baskets. The POS is Liberty computer systems,” she adds.

“The space is small so I wanted to make sure we used it wisely. I have accomplished making it through this first year of business, and am looking forward to making it another 30 years,” Castillo says.

“Not only did I reduce my assembly sta from 2 people to 1, I also noticed signi cant reduction in mark in labor costs as well.The opportunity for human error has been vastly reduced. I should have switched years ago when Brett rst spoke with me!!”

“I can honestly say that the QuickSort is the single best item I’ve ever purchased. The direct labor saving payback was less than one year. The increased e ciency from barcoding at the mark-in counter coupled with the complete elimination of assembly mistakes makes this the smartest business decision I’ve ever made, and one that is paying daily nancial dividends. “

Allan R Cripe CED,CPD

Brian Robertson

Owner, Valet Cleaners and Coin Laundry

Allan R Cripe CED,CPD

Brian Robertson

Owner, Valet Cleaners and Coin Laundry

International trade fair organizer

Messe Frankfurt has recently acquired the Clean Show, it reports.

The former Clean Show owners — Drycleaning & Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA), Association for Linen Management (ALM), Coin Laundry Association (CLA), and TRSA, the association for linen, uniform and facility services — will “maintain their close involvement” with the show, Messe Frankfurt says.

Riddle & Associates, which has been managing Clean Shows under contract since 1993, will manage Clean ’19, to be held June 20-23, 2019, in New Orleans, on behalf of

Messe Frankfurt.

Clean Show attendees and exhibitors will see “no changes” in New Orleans from prior shows, according to Ann Howell, who handles public relations for Riddle & Associates.

“Based on its success organizing international events for the textile care sector, Messe Frankfurt has the expertise and experience, as well as relationships with key exhibiting partners, to ensure the continued growth and development of the Clean Show,” says Joseph Ricci, Clean 2019 chairman of the Clean Executive Committee (com-

By Tim Burkeprised of executives from the five sponsors) and president of TRSA.

Tim Maxwell, president of GreenEarth Cleaning was asked by American Drycleaner for comment about the news and he says: “We’ve been happy with the professionalism shown by Messe Frankfurt and the European show, and we’re looking forward to working with them to provide innovation to the Clean Show.”

Maxwell adds: “Their expertise in managing other shows, we think, is a harbinger of good things to come with the Clean Show and we look forward to working with them.” ADC

Speed Check Conveyor, a member of the White Conveyors family of companies, recently completed an upgrade of Hospital Services, Inc.’s (HSI) soil monorail controls, it reports.

The firm’s Rail Management System (RMS) controls package was selected and its controls team worked tirelessly during changeover with little interruption to HSI production, Speed Check indicates.

“The RMS touchscreen interface, PLC, and inverter drive allow optimal interaction,” relates HSI.

The company has successfully installed RMS controls packages nationwide, both as upgrades to any existing industry monorail brands and as a key element in their own monorail system, it notes.

www.whiteconveyors.com | 800-524-0273

American Drycleaner, January 2019

Botkeeper offers what it calls a “breakthrough solution” to the problem of business owners spending many hours recording transactions oneat-a-time, by “automating bookkeeping tasks.”

The company says, “botkeeper marries the latest advanced learning methods — akin to the algorithms that fostered breakthroughs in our understanding of the human genome, the advent of self-driving cars, and Netflix movie recommendations — with robotic process automation and human oversight to redefine accounting best practices.”

The result, the firm relates, is round-the-clock and virtual accounting services. With botkeeper, it notes, dry cleaners have a virtual bookkeeper. www.botkeeper.com | 800-823-8064

Each year, extensive research is done to identify the 10 top business trends that are driving successful businesses forward to greater levels of achievement, profitability, sales, customer loyalty and client engage ment.

These lists may vary slightly, but generally they include common themes that cross industry boundaries. Also, what applies in 2018 can apply to the new year, now that 2019 is here.

Since fabricare has a distinct retail component and an equally distinct manufacturing component, we will explore various ways to incorporate the trends in each department starting here in Part 1 with sales, marketing and customer service. This two-part column will emphasize impact on growing sales and profitability.

For this discussion, the focus will be on the specific list generated by Ian Altman for Forbes Leadership because it exemplifies a consensus of the 2018 trends lists.

(For the entire article, go to: https://www.forbes.com/ sites/ianaltman/2017/12/05/the-top-business-trends-thatwill-drive-success-in-2018/#23e807fb701a)

To apply the trends, it is necessary to first understand what they are. Artificial intelligence (AI) is all over the media in many contexts. It’s so commonly highlighted that it is very often referred to only with the initials AI.

According to IBM, AI is, “the theory and development of computer systems able to perform tasks that normally require human intelligence, such as visual perception, speech recognition, decision-making, and translation between languages.”

A familiar version of artificial intelligence is Amazon’s Echo devices with Alexa. Hotel installations, like the Winn Resort in Las Vegas, allow guests to control the

climate, services and food ordering, and to ask a range of questions about amenities, sites of interest and entertain ment.

Drycleaners with 24/7 kiosks have been incorporating artificial intelligence for years. Also, there are many avail able apps for the industry designed to give customers more options than static software provides.

If you have not at least incorporated an app into your business, you have likely not captured the younger re placement generations of fabricare customers.

2. Communities embrace live interactions

With all the social media alternatives, why do people still spend their own money to travel to live events and meetings?

The interactions are different but augment and enhance each other. The initial social media contact creates a sense of community and the live contact enriches that feeling. A middle ground on this spectrum is interactive video.

The more options you provide for engagement to your customers, the greater will be their loyalty to your brand. Are you active on social media? Do you have a Vlog (preferable to a blog)? Do you sponsor live events with lifestyle partners?

3. Millennials welcome Generation Z

Just as business had to adapt to Millennials — now reaching their mid-30s — a new generation is moving into the workforce: Generation Z, or “Gen Z” for short.

Born after 1998, Gen Z is the first generation born sur rounded by personal electronic devices.

They present a whole new set of traits that are being furiously studied by behaviorists, managers and busi nesses that want to recruit them as associates and customers. Are you ready to adapt to their

phone), communication (24/7 inter active), and other preferences?

The combination of a growing economy and low unemployment is causing a Society for Human Re

tion of an average 3% wage increase this year.

Monetary compensation is only one of four components influencing job holders and seekers. They are also weighing: flexibility, benefits (including ever-more expensive health care), and autonomy.

The “generation of the associate” influences the weighting between the four mentioned components and oth ers that might be sought after.

Can you offer job-sharing, remote work location, flex hours, more self-management, and choice from a menu of benefits?

5.

This social learning—live inter action via social media— is group learning, and it outperforms individ ual learning when ranked on actual performance. This factor indicates a combination of reading or online training augmented with group inter active learning and role playing.

How are you training your sales and service team? Don’t forget to involve remote workers so they feel connected to their peers and the company.

According to Nick Losq, co-found er and creative director at StarBeast, a creative technology agency located in California: “Video is the most easily digestible form of media in a landscape now dominated by smart phones. And when a business starts adding a ‘live’ component, introduc ing real people, in real time, it has the power to connect with consumers in a personal and honest manner, allow ing businesses to separate themselves from their competitors. Live video has the ability to give many busi nesses a face and a soul.”

Livestream research shows that

80% of audiences would rather watch live video from a brand than read a blog, and 82% prefer live video from a brand to social posts. And 73% of B2B organizations report positive ROI from video marketing.

7. Serve your community Review the source of each of your recently acquired customers. Chances are, they were not on your radar before they decided to use your services.

Being visible in the many locales your customers and prospects frequent is essential to attracting new clients. Key locales: electronic media, physical locations and lifestyle events.

Consumers encounter so many challenges in their daily lives that they will pay you well if you can eliminate a pain point allowing them to focus on other problems or oppor tunities.

How many chores can you take off their To-Do list, such as: clean ing patio cushions, preparing table linens for guest dinners, washing and pressing bed linens. (And making the beds!)

9. Subject matter experts (SMEs)

SMEs educate, guide and advise. Whether you are targeting consumers or clients, the reason they should use your services often eludes them.

Many potentially great fabricare customers have no understanding of what you can do to address the needs they may not know they have. Think especially of the elusive younger generations of professionals who may never have encountered profes sional drycleaning and laundry, but they will love the service once they realize the benefits you offer.

That is why SME’s are necessary But... your team can only become SME’s with essential training. Re member that most of your team can not afford your service so they don’t

inherently know why the luxury of fabricare is valuable.

10. Blockchain

Bitcoin is the most commonly recognized version of blockchain. (A complex technology beyond the scope of this article.)

You may wish to be on the cutting edge, incorporate it into your opera tion, and probably earn a lot of free publicity, by being the first cleaner in your market to accept Bitcoin.

Now that 2019 is rolling, take an objective look at your company and assess your status on each of those success trends. Participating in them can help you grow and prosper. ADC

Diana Vollmer is a managing director for Methods for Management, which has served dry cleaners and launder ers with affordable management ex pertise and improved profitability since 1953. For assistance implementing success trends in your company, con tact her at dvollmer@mfmi.com or call 415-577-6544.

Faye’s Laundry and Dry Cleaning celebrated its 50th year in business last fall with a party at its original store on Main street in Layton, Utah, it reports.

Owners Coral Petersen Arnold and Alex Arnold, wel comed 50 guests along with Faye’s past presidents, Cliff and Sharon Dutcher, and several grandchildren of the original own ers, Russ and Faye Cummings.

Peterson Arnold notes that she, “was just so grate ful to see so many ‘customer friends’ at the party.”

Mendenhall Equipment kindly provided drinks for all of our guests, Peterson Arnold points out, “and Craig Riddle from Ally Equipment and Richard Reese, our Unipress rep, dropped by to congratulate us.

“We feel truly blessed to have such wonderful support from our distributors and equipment reps,” she adds.

“The Lakesiders, they’re the Davis County Chamber of Commerce host committee, cut a ribbon to mark the anniversary and wish us success during the next 50 years,” says Dutcher, the previous owner (second gen eration) along with her husband Cliff.

Dutcher notes: “Seldon Young, a local business leader and originator of the Swan Princess videos and books, graciously spoke about the importance of family-owned businesses, and the long odds against having the third generation (and the fourth in training) leading the same business.”

During the party, owner Alex Arnold was pleased to announce the acquisition of Hoffman’s Cleaners of Og

den, making a total of eight stores under the Faye’s ban ner. “The acquisition of Hoffman’s has us all running in different directions,” he says.

Arnold was also thrilled to announce that Connor Pe tersen, fourth generation, will attend the Drycleaning & Laundry Institute (DLI) school of dry cleaning. “Here’s to the future,” he says.

About the original owners and why they started the business, Dutcher says: “It was started in the fall of 1968 by Russ and Faye Cummings. They bought it because they thought it wouldn’t be too much work!” Faye is her mother.

Dutcher continues: “Cliff and I bought Faye’s in 1989. We sold it to Alex and Coral in 2013. I still work here because,” she laughs, “well, where else would I go?

“Coral worked for me since she was 15, so I thought I’d return the favor and work for her,” she says.

“We’ve had a great 50 years and look forward to 50 more,” Dutcher concludes.

Recently, a fire destroyed completely the warehouse of the Garland Supply Company, located in Hialeah, Fla. The company sells supplies for both the drycleaning in dustry and the laundry industry.

“Everyone was safe, luckily, because the fire occurred in the middle of the night,” says Jeff Zaitz, one of the owners, along with his father Irwin, of Garland Supply.

“It was actually the second fire,” he points out, indi cating there was another fire a couple days earlier.

Zaitz, explains in his own words that the cause of the initial fire, “was undetermined however the fire marshal thought it might have started in a trash bin. That fire de stroyed about 15% of the warehouse so we started clean ing and discarding things.”

His business was in the process of cleaning up from that first blaze when, he says: “Thirty-six hours later it rekindled again during the middle of the night and burned the whole warehouse down.”

What are your plans going forward?

Zaitz relates: “We already rented a warehouse down the street and have all our vendors sending us emergency

After battling a fire at Garland Supply, Hialeah, Fla., fire personnel watch through smoke and haze as their relief crews work to contain the blaze which had consumed the entire warehouse. This was the second of two fires within 36 hours to happen at the same location. Company)

We were in that location that burned down for about 35 years,” Zaitz says.

“Ironically, the first warehouse we had in Miami burned down close to 40 years ago, in the McDuffie ri ots,” he relates, referring to the Arthur McDuffie riots in Miami in 1980.

He says: “Our vendors have worked around the clock getting stuff to us as rapidly as possible. Times like these you really see who your true friends are.”

Zaitz notes that his company plans to, “Stay in this

fire, food technologies, cleaning and cleanroom tech nologies, and environmental technologies.

Horaczek takes over from Ruth Lorenz, who retired after 27 years at Messe Frankfurt, 21 of which was in managerial positions, the events management firm notes.

A graduate in business management, Horaczek began her career at Messe Frankfurt in 2001 as part of a dual work and study program. Following this, she worked in the mergers and acquisitions and subsidiary manage ment divisions.

Kleerwite Chemical has reached an agreement with Rob ert Neuhaus and Patricia A. Joubert, previous owners of Neuhaus Chemical Products, Inc., (NCP) to purchase its

assets, including all formulas, trade names, and customer list, the company notes.

“Robert and Patti will provide continued support dur ing the transition,” says Bill Carli, owner, Kleerwite Chemical.

“NCP is a great fit with Kleerwite’s line of problemsolving chemicals. Jinx Ink® is a well known and re spected product that should be a great compliment to our existing products,” says Carli.

He points out that, “While we shared many of the same distributors, NCP will open the door for Kleerwite to a number of new distributors. I am confident that once these distributors become familiar with Kleerwite’s many fine products, there will be an opportunity to grow Kleerwite’s business.

“I look forward to the next chapter for Kleerwite and what the addition of Jinx Ink can mean for our growth prospects,” he relates.

Get to Know ...

Joe Gagliostro

Tell us where you were born, grew up, and reside today?

“I was born, raised and reside in Auburn, N.Y., located just west of Syracuse, which is where our company Muldoon Dry Cleaners, Inc. is located. My wife Diana and I operate as third generation owners and we have raised our daughter Sophia around the store as well.”

Hobbies (that you’ll admit to)?

“My favorite hobbies are spending

time traveling with my family and exercising after work.”

What gets you excited at work?

“I get excited at work when I start my first load of heated hydrocarbon every morning! I also most enjoy interacting with my clients.”

Lastly, tell us a secret (keep it clean) nobody knows about you?

painter. Those are two things that I love to do.” ADC (Do you want to take part in an Off the Cuff, or know someone who does? Email tburke@atmags.com.) OFF THE CUFF

10 YEARS AGO. U.S. retail vacancy rates jumped to 6.6% in the third quarter of 2008 from 6.1% a year earlier, according to CoStar Group, a provider of commercial real estate information. Shopping centers including strip malls fared the worst, with a vacancy rate of 9.4%. The trend is expected to accelerate as the financial crisis affects big-box retailers such as Circuit City.

35 YEARS AGO. Cleaners Act as Block Parents. A Columbus, Ohio, cleaners saw a growing need for protection of children recently and volunteered its 35 stores as block parents. The business recognized that there were not enough homes available to serve as safety spots for lost, hurt, or frightened children. The block parent program was supposed to provide a designated place of refuge in every city block, but with so many mothers working, the number of block parents has dwindled and there were fewer mothers at home to respond to their children during school hours.

50 YEARS AGO. Send Cars to the Cleaners?!!? Are you ready for this? Suede cars and appliances may soon be with us. Two Michigan firms are trying to interest the auto manufacturers in new nylon fiber coatings for next year’s car tops, reports the Wall Street Journal. Several body shops already spray on the fuzzy material for about $80 a car. And it’s claimed that some manufacturers of refrigerators, boats, office equipment and other products have also expressed interest.

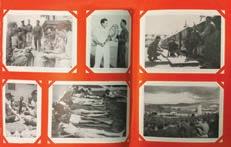

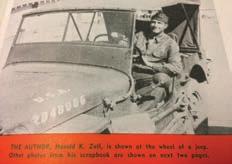

75 YEARS AGO. An Ex-Soldier Comes Back to His Plant!

In a feature in the January 1944 issue of American Drycleaner, World War II soldier Harold K. Zell, returning home, shares his thoughts on being in the service. The article’s sub-head is as follows: “The army life gave this soldier ideas, many of which he has already put to work in his plant. He tells of army days too—at our request.” Here is an excerpt of what Zell writes: “Yes, I made some very interesting observations (at least to me) while in camp

and since I came back to my plant. First, I want to tell you that we paid 60 cents to get our on-duty (OD) uniforms cleaned through the army, and they were just run through the solvent and came back with double creases, baggy knees and sweet spots still on them. We were required to get our OD’s cleaned every week whether they needed it or not. They were sent to an outside cleaner near the camp. Many a spot I removed from the uniform, after it came back from the cleaner, for the men in my outfit.” Zell continues: “It’s a funny thing, when the men in my outfit found out I was formerly in the cleaning business they elected me to do all of their button sewing and chevron sewing.” Later in the same article he goes on to relate to a fellow soldier that until he joined the army he had, “never sewed in my life!”

— Compiled by Tim Burke, Editor

101-105 Series

We expect 15 to 25 years from our interchangeable tube bundles, and 30 to 40 years of life our more out the boiler.

Indirect Fired Water Heaters

209-211 Series

We normally expect 10-25 years out of the copper heat exchanger, 30 to 40 years out of the boiler.

207 Series

We expect 30 to 50 years out of our thermal fluid heater models

On all of the above units we have continued to build, and will continue to have available any part of the pressure vessel, burners, cabinet, and controls meaning that for as long as a customer wants, they will be able to infinitely repair their equipment rather than replace the equipment.

We are asked by many new and existing customers on what is our projected life expectancy of our products. We are not always the lowest initial price but know we have one of the lowest cost of ownership of any boiler manufactured in North America. These facts are based on our 90 plus years of boiler manufacturing, feedback and experiences from our end users, service departments, and all of our representatives and dealers worldwide. These life spans are based on our boilers being installed properly, and do receive our minimal recommended care, are applied to the correct application, and include the proper maintenance and water treatment programs.

“

fter waiting several years to choose an alternative solvent and machine, I’m happy I waited. SENSENE™ and Columbia has replaced PERC in our cleaning plant without any increase in labor or decrease in quality of cleaning. I couldn't be happier with my choice.”

fter waiting several years to choose an alternative solvent and machine, I’m happy I waited. SENSENE™ and Columbia has replaced PERC in our cleaning plant without any increase in labor or decrease in quality of cleaning. I couldn't be happier with my choice.”

AAfter waiting several years to choose an alternative solvent and machine, I’m happy I waited. SENSENE™ and Columbia has replaced PERC in our cleaning plant without any increase in labor or decrease in quality of cleaning. I couldn't be happier with my choice.”

~Charles D’Angelo,

Oak Neck Cleaners West Islip, NY, USA~Charles D’Angelo, Oak Neck Cleaners West Islip, NY, USA

~Charles D’Angelo, Oak Neck Cleaners West Islip, NY, USA

“

“

e have been a perc plant for over 50 yrs. None of the alternative solvents out there made us want to switch. Although one in Europe was making its way to the States had us intrigued and that was SENSENE™. Stephen from Columbia Drycleaning Machines gave us the run down on all alternative solvents. We went with SENSENE™. It would clean better then Perc. No odor. We were the 1st Columbia SENSENE™ machine in the state of Ohio. The machine and solvent choice is the best choice for any former perc cleaner. Beads, leather are not a problem anymore, whites are white. The learning curve was minimal. We advise anybody looking for alternative solvents, SENSENE™ and Columbia are the right choice.”

e have been a perc plant for over 50 yrs. None of the alternative solvents out there made us want to switch. Although one in Europe was making its way to the States had us intrigued and that was SENSENE™. Stephen from Columbia Drycleaning Machines gave us the run down on all alternative solvents. We went with SENSENE™. It would clean better then Perc. No odor. We were the 1st Columbia SENSENE™ machine in the state of Ohio. The machine and solvent choice is the best choice for any former perc cleaner. Beads, leather are not a problem anymore, whites are white. The learning curve was minimal. We advise anybody looking for alternative solvents, SENSENE™ and Columbia are the right choice.”

WWWe have been a perc plant for over 50 yrs. None of the alternative solvents out there made us want to switch. Although one in Europe was making its way to the States had us intrigued and that was SENSENE™. Stephen from Columbia Drycleaning Machines gave us the run down on all alternative solvents. We went with SENSENE™. It would clean better then Perc. No odor. We were the 1st Columbia SENSENE™ machine in the state of Ohio. The machine and solvent choice is the best choice for any former perc cleaner. Beads, leather are not a problem anymore, whites are white. The learning curve was minimal. We advise anybody looking for alternative solvents, SENSENE™ and Columbia are the right choice.”

~Thayne Albrecht, Manager, Blue Ribbon Cleaners

~Thayne Albrecht, Manager, Blue Ribbon Cleaners

~Thayne Albrecht, Manager, Blue Ribbon Cleaners