® March 2019 © Copyright 2019 American Trade Magazines All rights reserved. ■ POSITIVELY TICKS ■ SMOOTH AS SILK

• Operates in our NEW web framework • Browser based route management offers: - Real-time view of driver location, including timestamps, counts for delivered orders, and bag pickup in summary and by stop - Advanced delivery zone editor - Map view of customer location by zone - View pictures and notes for each stop • Integrates all delivery processes and management with RouteTrac Mobile • Integrates all customer route interaction with the Mobile App and CustomerConnect • Route Model 2.0 enhancements include: - On demand, on-the-fly, static, and locker customer logic - Service plans support static, on demand, and locker customers - Service plans support multiple delivery zones on a single manifest - Powerful delivery schedule logic for Pick Up and Delivery windows - Customer Pick Up and Delivery service times - Day-of-the-week, time-of-day Pick Up and Delivery rules www.SPOTpos.com • (801) 208-2212 SPOT Business Systems is the most comprehensive and complete system available. Serving the industry since 1991 • 62 employees strong • Hosting since 1999 (long before the “cloud”!) Best feature set and support in the industry • Weekly “new feature” webinars powered by BUSINESS SYSTEMS TM Introducing Routes 2.0 BROWSER BASED ROUTE MANAGEMENT ANYTIME, ANYWHERE. MANAGE YOUR ROUTES

Become a STAIN WIZARD at ALWilson.com EasyGo is Eco-Friendly... California Compliant, Chlorinated-solvent and NPE Free, Biodegradeable and Non-combustible. To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO. • Spray it on and dryclean it out in any solvent... saving time and labor. EasyGo Drycleaning Spray Spotter & Leveling Agent: • Use it on the board to remove more difficult stains. • Keep customers coming back by delivering stain-free goods! You already know about RiteGo for laundry. Now Get To Know ®EasyGo ! ®

Guardians Of Their Galaxy

The two owners, the production manager, and the lead maintenance engineer at Martinizing Metro Milwaukee show off some of their dust and lint control equipment They, and other cleaners from around the U.S., discuss methods to clean their machines and plants with regularly-planned maintenance — because fire is that deadly and safety is that important. Read about their actions to guard against lint buildup to keep their own “galaxy” efficient and clean.

Tim Burke, Editor

Tim Burke, Editor

14 POSitively Ticks

Ian Noble, owner of Rick’s Cleaners in Austin, Texas, along with other cleaners and manufacturers, talks about all the uses for a Point-Of-Sale, or POS, system at a drycleaning operation. Helpful features, Noble points out, include tracking how much a customer has spent with you and if they are still in your “Top 50.” He also notes that the single most important thing about picking a POS provider is their support system.

Tim Burke, Editor

Tim Burke, Editor

2 American Drycleaner, March 2019 www.americandrycleaner.com

AMERICAN AMERICAN

No. 11 DEPARTMENTS Pre-Inspection 4 Thrive, Survive Management Strategies 27 Reaching Out (Further): Logistics Diana Vollmer Owner’s Office 30 Next Level Stuff Dan Miller Off the Cuff 32 Get to Know ... John Riddle Spotting Tips 34 Comforters Martin Young Special Feature 38 Smooth As Silk Jeff Quail Product Showcase 40 Drycleaning Machinery: Perc Around the Industry 44 Classified Advertising 46 Advertiser Index 47 Wrinkle in Time 48 Now A Major FEATURES

drycleaner

March 2019 Vol. 85,

NEED HELP FINDING THE HIDDEN HANGER? Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

) 6

(Photo: Martinizing Metro Milwaukee

“Business has never been better.”

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

Since 2003, CBS has given me consistent updates and easy to understand tech support, all at a price that our industry can afford. I would recommend CBS, and I have, to anyone who is still wasting their time and money on those over priced POS systems.

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

DanLoesher

better.” 800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

SunshineCleaners

BrentRamenofsky BostonCleaners

Thrive, Survive

Loop! <stomach jumps> Sharp turn! <neck strains> Drop! <gut check>

Our sometimes dizzying roller-coaster business environment today might have you a little restless at night, trying to calm down with, perhaps, a glass of warm milk, or a shot of booze. Both good! Hey, it’s understandable. You have a lot on your mind.

I asked a few of you to describe dry cleaning right now. Your answers: “Thriving,” “client-centric,” “business is up,” “could be worse,” “exciting and innovative,” “watch expenses,” “the fittest survive!”

This March issue hears you loud and clear, and will provide you with topics to keep you in the “fit survive” mode, so to speak. First, do not overlook the importance of dust control in your plant. The feature Guardians Of ‘Their’ Galaxy is about reminding you to always keep lint and dust in check.

Burke

In the next feature, POSitively Ticks, several drycleaning owners, and others from industry, tell why Point Of Sale can be a real game-changer.

There is a special feature called Smooth As Silk on programmable dryers to accompany wetcleaning washers. Also, we brought back the Product Showcase: Drycleaning Machinery: Perc from years past.

Your favorite writers are here: Diana Vollmer’s Reaching Out (Further) column concludes with hot trends in logistics. Dan Miller tells you, in this Clean Show year, about some Next Level Stuff to help you get the most out of conventions you attend. And Martin Young looks at caring for bedspreads in Comforters.

All that and more await the turn of the page. Also, here’s a heads-up for next issue: April is our Clean Show Go Guide where locals will tell us some of their favorite cool places to scope out while in hot, jazzy New Orleans, June 20-23, during Clean ’19. You may feel a little economic “gut check” this year, or not, but fabricare will thrive and survive — and boldly march forward like it always does! Happy St. Pats! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 85, number 11. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2019. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Tim Burke 312-361-1684 tburke@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Roger Napiwocki

Advisory Board

Mike Bleier Steven Dubinski John-Claude Hallak Mike Nesbit Herron Rowland Fred Schwarzmann Beth Shader Ellen Tuchman Rothmann

Contributing Editors

Dan Miller Diana Vollmer Martin Young

Office Information Main: 312-361-1700

Subscriptions 630-739-0900 x100 www.american drycleaner.com

4

March 2019 www.americandrycleaner.com

American Drycleaner,

Tim

PRE-INSPECTION

About Iowa Techniques Iowa Techniques is a manufacturer and distributor of unique products that work in a wide variety of industries and applications, and currently focuses on helping dry cleaners make smart choices that impact the bottom line in their plant operations. When your water heater dies, DON’T replace it! Get a DynaFluid 2000 from Iowa Techniques! Getting Steamed? the (800) 727+1592 | www.iowatechniques.com With steam from your boiler and a cold water source, this little valve makes an infinite supply of hot water. It outperforms water heaters by every measure, cutting costs and increasing productivity. Call Iowa Techniques today and learn how the DynaFluid Valve will help your business! (800) 727+1592

Keep lint and dust in check; because fire is that deadly, safety is that important

By Tim Burke, Editor

By Tim Burke, Editor

We work in a pretty dirt-filled environment. We are constantly bringing in dust and dirt with the exterior doors being open most of the day and by creating buckets full of lint from all of the depilling we do on coats and sweaters,” says Dave Cass, co-owner, along with his brother Brian, of Martinizing Metro Milwaukee, which specializes in convenience by offering same-day cleaning or free pickup and delivery route service.

“With that said,” Cass explains, “every day we need to clean-off our intake screens on all of our equipment. The best way is to use a vacuum and brush both. If a brush alone is used, then typically the employee cleans

the screen off and leaves the lint right there on the floor where it’s going to end up back on the screen the next morning when the machine gets turned on.”

Dust and lint, if left to build up, can cause serious safety problems and even lead to a fire in the plant. Drycleaning owners need to be vigilant in their dust control procedures. Cleaning isn’t just the name of your industry, it should be a way of life — for everyone’s safety.

But unexpected things can happen.

Cass relates a lesson for all drycleaning operators: “My biggest surprise to date came recently after a motor burned up on one of our shirt units. I literally had just inspected the work done in this area about a

6 American Drycleaner, March 2019 www.americandrycleaner.com

(continued on page 10)

Guardians! Holding their dust control equipment (from left): Brian Cass (co-owner with his brother Dave of Martinizing Metro Milwaukee); Jose Cisneros, production manager; Josh Moore, lead maintenance engineer; and co-owner Dave Cass. About dust control maintenance, Dave Cass says: “We thoroughly clean a row of equipment every week.” (Photo: Martinizing Metro Milwaukee)

(949) 270.1609 | create@becreative360.com | BeCreative360.com Mobile-Friendly Design Web Hosting & Maintenance Google Analytics SSL Secure Site WordPress Design Fast Load Times Content & Creation SEO Services Available Additional Options Available WE MAKE WEBSITES BeCreative360 is a one stop shop for all your marketing needs.

week earlier and the cleaner had done what I thought was a great job. The cleaner removed a ton of lint and used a vacuum on all of the motors to get out what we thought was most of the lint.”

“What I thought,” is the key phrase here, drycleaning owners.

Cass continues: “What I didn’t realize was how much was still packed in that motor, causing it to overheat and catch fire. The electrician showed me afterwards how much lint was still left in there.”

Cass notes that: “We now use an air gun to try and blow out even more lint. Had we kept up with the lint early on it would not have been the problem that it became.”

Another key phrase to dwell on: “Kept up.”

If you don’t already have a dust control maintenance plan at your cleaning operation, start one now. And don’t assume what you think is being done. (See Cass’ lesson above.) Look over all your machines and motors inside and out to assess if they are being cleaned properly.

Even if you have a plan in place, ask yourself: Is it be ing followed properly and is it comprehensive? It’s never too late to update an existing plan, or create a new one.

Speaking of dust control maintenance, Cass points out that: “We have a plan in place to keep the lint in check. We thoroughly clean a row of equipment every week, cy cling back through in about five weeks.

“I say ‘plan’ because we have struggled with filling this position at times, so it does not get done as often as I would like. This is a position I offer more money for than just about anything in our building, but it’s still been dif ficult to keep filled. It’s part of a 10-15 hour job per week

cleaning our plant that can’t be done during the weekday. It has to be done after hours to do it right,” Cass says.

“We also try and clean all of the dryer duct-work twice a year, although I would have to admit it’s probably more like ‘annual’ the past few years, because of the struggle with keeping the cleaning position filled. We now have openings in all of our ductwork for easier access to clean the dryer vents. We need to retape these closed after we are done,” Cass says.

Critical to stopping lint and dust buildup at your opera tion is how well you stick to your cleaning routine.

Enter Bob Hilker, one of two co-owners, with twin brother Tom, of Raleigh, N.C.-based Brothers Cleaners.

“For dust control maintenance, we, on a quarterly basis, come in on a weekend and blow down the entire plant,” he relates.

His drycleaning operation was devastated by a cata strophic fire in 2015 but it was completely rebuilt and re opened two years later, and then was named 2018’s Grand Prize winner of the American Drycleaner Plant Design Award.

Hilker notes that to be ‘preventative,’ you must, simply put, keep your plant clean. Period. His straight-to-thepoint message, learned from experience, is a reminder to all drycleaning operators.

The turn of a phrase might go: In this business of clean, keep your business clean. And that means relying on your team members; consultants and partner companies; and following a plan.

HOUSEKEEPING

Annually you need to clean inside your vent pipes for the dryers and knock all the dust down from the rafters and walls using a duct cleaning company, points out Jan Barlow, owner of Jan’s Professional Dry Cleaners, Clio, Mich.

“It’s a little bit of work to move all the stuff out of their way to clean the ceiling and the walls but everything is brighter after the job is done,” she says.

Barlow’s business has one location, with five routes in the surrounding counties, and as she notes, cleans all gar ments and household goods; fire and water restoration; wedding and formal wear, alterations and repairs, vintage garment restoration, and more.

She says: “There are a machines that can be hung from the ceiling that you can run at night that will keep the dust from settling on all your equipment. I haven’t invested in one yet; for my operation it is more cost-effective to bring in the duct cleaner annually.”

According to Barlow, who is also chair of the National Fire Protection Association’s NFPA 32 Standard for Dry cleaning Facilities committee, housekeeping (continued)

10 American

March 2019 www.americandrycleaner.com

Drycleaner,

Dust Never Sleeps! Raleigh, N.C.-based Brothers Cleaners was rebuilt in 2017 after a devastating fire burned down the entire building two years earlier. Co-owner Bob Hilker says his entire team comes in on a weekend each quarter to, “blow down the entire plant,” of dust and lint. (Photo: Brothers Cleaners)

Toll Free (877) TREVIL 1 www.TrevilAmerica.com P.O. Box 127 - Mamaroneck, NY 10543 Telephone (973) 535-8305 E-Mail: info@trevilamerica.com PANTASTAR PRINCESS ULTRA NO MORE SHINE Princess Ultra 5037 Blouse/Shirt/Multi-Garment Tensioning Form Finisher • Sizes From 0 Petite To 3 XL and larger • Blouses, Shirts, Jackets, LabcoatsWet or Dry • Dual, Rotating Front Clamps (Patented System) No Need To Disconnect & Store Unused Clamp The Future Is Here! PRESTOFC Presto FC 5272 Hot Plates Shirt Finisher • Full Length, PTFE Coated Plates • No Shine Cuff Placket Presses • Rear Tensioning With Vacuum & Pull Down • Sleeve Angle Adjustment Panastar 5354 Finish the entire pair of pants INCLUDING THE CREASE with one operator. • For All Types Of Pants: - Creased Or Uncreased - Pleated Or Unpleated - Men’s Or Ladies’ • No Experienced Operator Needed • Requires Less Floor Space Than Conventional Equipment • Rotating Cuff Clamps For Creased/Uncreased/Flat Front Finish Trevistar 5257 Blown Air Shirt Finisher • High Quality “Hand Finished” Look • Includes Economizer Device - Saves Energy And Increases Production • Single Pedal Operation • Large Presses For Plackets And Cuff Pleats - PTFE Coated To Avoid Shine On Dark Colors TREVISTAR

is the number one way to stay on top of dust control: “Dai ly the lint screens need to be cleaned on all equipment, either brushed with a broom or vacuumed.

“It’s hard to get your staff to clean their work area at the end of every day but if each person takes care of their work space you never get into a really dirty state. It take discipline and teamwork,” she adds.

Barlow has some tips for drycleaning operators regard ing dust control in the plant: “Since we are in the garment business, an obvious byproduct of handing garments is lint which is dust and it goes everywhere! Daily maintenance with a vacuum, a cloth, and a broom with a dustpan are your best measures to stay ahead of the mess,” she says.

“Not only does the lint and dust lay on items it also be comes sticky from the moisture of the steam we produce,” Barlow points out.

“What are the obvious places to clean? Start with the drycleaning machine,” she reminds, “you need to clean the lint and button trap. I believe that this should be done after every load. It helps maintain quality and keep your machine clean.”

The presses should be covered at night so the dust that is floating in the air doesn’t settle on all the presses, Bar low mentions, adding that there are so many places that can get dirty, “We use regular full size sheets to cover all our presses every day at the end of the shift.”

In a worst-case, where dust and lint can lead to a fire, drycleaning owners need to have a fire drill and emergency escape plan in place. Both Martinizing Metro Milwaukee and Jan’s Dry Professional Dry Cleaners note they work regularly with on-site compliance firms such as Safety & Environmental Compliance Consultants, Inc. (S&ECC) who come in yearly and conduct a safety meeting.

“We have worked with S&ECC, Henry and Jan Parker since 1998,” relates Barlow. “They make sure we have a fire escape plan and document that all employees have signed-in on the safety training.”

She says that: “We also have several maps posted throughout the entire plant to list where all the fire extin guishers and exits are. Annually, we also have a company that checks all our extinguishers to make sure they are charged.”

Back to Cass on what tips he would give for dust control:

“Two things I would recommend,” Cass relates, “The first is to use a rotating ceiling fans for an hour or so every night especially over your shirt department. If you ever wonder if they work, just ask anyone who has one what happens when they don’t run it for a week or two. You’ll see all of the dust flying around like snow that you nor mally wouldn’t see if used daily.”

The second thing Cass recommends: “Is to use filters or filter screens whenever possible. You don’t want to re

strict the airflow, but if you can stop the lint before it gets into the equipment that’s what you want to do; and make sure to clean them out on a regular basis.”

Remember the lesson from Cass about thinking all was great — it wasn’t. Check everything, inside and out, and make certain; because your lives and your business will depend on it.

Another tip from Hilker: “Insurance is Number One. Make sure your insurance adjuster has looked over every thing from A to Z. Be well-covered.”

Barlow relates that: “Fortunately, we have never had a fire. We really strive to lead by example, safety first.”

About dust and lint, and their dangers, she says, “The biggest problem I see is if someone is doing laundry for a restaurant and they accidentally don’t get all the grease out of the linens, they can spontaneously combust just sitting in a cart after drying.”

Barlow’s dust control tip: “Get a daily routine! If you’re not able to do it daily, then do it ever other day or once a week on your slowest day.”

Asking for a comment to describe why fire is that dead ly and safety that important, Barlow answers: “You don’t get a second chance at death!”

To recap, when it comes to dust control at your dry cleaning operation, remember these: daily maintenance; check all equipment and spaces yourself; get outside ex pert help; use your team members; don’t forget insurance coverages; and have an updated fire safety plan with prac ticed escape routes.

Be the guardians of your own ‘galaxy’ at your cleaning operation. Control dust and lint. Don’t let them control you, or your team, or your drycleaning business.

Now you’re all clear for dust off!

12

March 2019 www.americandrycleaner.com

American Drycleaner,

ADC

Clean Team! Owner Jan Barlow (front row in pink shirt) and her cleaning team at Jan’s Professional Dry Cleaners take daily dust and lint cleaning seriously at her plant. “It takes discipline and teamwork,” Barlow says. She is also chair of the National Fire Protection Association’s NFPA 32 Standard for Drycleaning Facilities committee. (Photo: Jan’s Professional Dry Cleaners)

Here’s how Point Of Sale becomes a game-changer for drycleaning owners

By Tim Burke, Editor

By Tim Burke, Editor

At the most fundamental level, we use our fabricare point of sale system, or POS for short, to make the operation tick,” says Ian Noble.

“I am the owner of Rick’s Cleaners in Austin, Texas. Rick’s has 16 locations with four plants and specializes in one-price dry cleaning and in providing a great value for our customer,” he notes.

“Your boiler is the heart of your plant; your POS should be the heart of your store transactions and data,” Noble says.

“We utilize a pre-pay model at our store and an automated assembly conveyer from GMS Conveyer to assemble items at our plant. Six of the 16 stores use bar-codes, and the other 10 use paper tags,” he says.

He plans on converting all his stores to bar-coding. “This allows for accurate mark-in, efficient tracking, and using customer data we never had before. It also reduces plant labor and allows for a smoother running plant.”

“POS should allow your company to be flexible and work ‘within’ your operation,” says Mark Jones, vice president of opertions at SPOT Business Systems based in Draper, Utah. “Software should not force your operation to work a specific way,” Jones notes. “If POS software is based on a single store and you attempt to scale you will run into issues such as reporting, time clock, production and other processes.”

Noble shares: “The two best things about using a POS are speed and data. I had converted from using paper tickets in 2011 and it was a game-changer.

“To help our staff know who they are dealing with, our POS currently places stars on the invoices of the top 50 customers in each store so our staff can always know who our VIP customers are. This changes as consumer spending increases or decreases,” he says.

A basic feature of all POS systems, Noble points out, is to be able to track how much a customer has spent with you.

“Beyond the dollar amount,” he relates, “you can easily dig deeper into their habits. We like to run reports of

our top customers who’ve ‘Dropped From The Top’ to compare their spending in the last 90 days to 90 days prior.

“The report will compare the totals of the two date ranges as well as the last visit date so you can determine whether or not you have lost a customer. If we know or even think they may have moved on we call them personally to ask about their experience, see how we can improve, and thank them for their patronage.”

Noble says this has helped them (continued)

14 American Drycleaner, March 2019 www.americandrycleaner.com

Ian Noble (on right), owner of Rick’s Cleaners, and his team. He says, “The single most important thing when interviewing a potential POS provider is their support system,” Noble relates. “Are they always available by phone? What are their hours? Can you get help fast? Do they provide solutions the first call or make you wait?”

(Photo: Rick’s Cleaners)

understand why people leave for a competitor.

The benefit, he says, is that: “It has helped us gain back customers who had an issue with us but never told us about it until we reached out to them in efforts to earn their business back.”

“Multiple price lists can be set if you want to price locations or customers differently,” Noble relates, adding that another, “Simple, yet powerful, feature is pop-up notifications alerting our staff of the customer’s history or preferences.”

“A POS system can allow dry cleaners to connect with their customers as never before,” says Brian Athens, senior systems engineer at Fabricare Systems located in Acworth, Ga., adding that, “Texting and emailing are the things customers like about their POS,” Athens relates. “Letting a customer know there is a problem or question with their garments or that the garments are ready, really makes the connection.”

Athens says: “We are always making changes to accommodate our customers. Requests are something we take seriously. Example, we have new customers that have requested merging customers and moving inventory between locations. That’s a game-changer for cleaners.”

Back to Noble’s customer preferences, he gives this example: “If you’ve double-creased a customers’ pants and he has written a negative Yelp review for it, then next time he comes in our staff will receive notifications to triple-check his pants before they get back to him to avoid further frustration for the customer.”

Noble notes: “Your POS can also be used to anticipate staffing for the next day in production by viewing piece counts, or view trends that allow you to reduce hours in your store.”

He adds: “If your employee says they stayed two hours late because they got slammed with customer drop-offs right before closing, there is a report for that. Nearly every step of the process can be tracked, data-mined, and verified, which is very powerful for an owner or operator.”

Noble describes himself as, “A hands-on owner who is extremely involved in day-to-day operations.” He also points out that, “Rick’s was awarded the 2018 Best Dry Cleaners in Austin. It’s our ninth time to win, and we are back-to-back winner.”

But Noble isn’t the only one talking about POS tech making a business tick today. Others weigh-in.

CHANNELS

POS is more than a revenue system. Think of it as communications channels for drycleaning operators.

Enter Jason Loeb, CEO, Sudsies, Miami, Fla., who says: “Software is an integral part of our business and our future. It is constantly changing.

“The software helps us mange production, communicate with our clients, communicate with each other, manage our systems, set expectations and because this all works together this will help us continue to grow,” he notes, adding that his POS system, “Speaks to our clients via text messaging and or e-mail.”

Loeb relates that he created Sudsies 21 years ago: “I am the current chief executive officer. We specialize in pickup and delivery services all over Dade, Broward and Palm Beach counties.” His business, he notes, has three boutiques and 30 pickup and delivery vehicles.

How is your POS?

“We are using fiber connections at our locations which gives us a consistent upload and download speed,” Loeb says. “Cloud-based also works much faster than even having a traditional server on location. And we are constantly being backed-up.”

Loeb also says that he and his team received on-site training, and notes: “We found training to be very simple. The software is intuitive and smart. The team was training other team members by the end of the day. When purchasing software take into account how you will be training your teams.”

Training in this tech means (continued)

Miami, Fla.-based Sudsies’ Jason Loeb, CEO, says: “Software is an integral part of our business and our future. It is constantly changing.” His business, he notes, has three boutiques and 30 pickup and delivery vehicles. (Photo: Sudsies)

16

March 2019 www.americandrycleaner.com

American Drycleaner,

investing in both the present and the future, and that seems to spell POS.

“Like all industries, technology is changing the way we can do business,” notes Joanna Creed, president of Toronto, Canada-based Pivot IO, a company which makes a POS system she describes as “built to streamline business operations at the point of purchase.”

She says: “POS software has changed significantly over the last decade from something that was only available as an on-premise solution for large enterprises with deep pockets.

“Nowadays, you have a host of POS systems that are pretty much plug-and-play right out of the proverbial box. For small businesses like dry cleaners, it doesn’t get much better than that.”

Creed points out that: “As a former drycleaner myself, our mission as a company, is to make your cleaning business simpler and more productive.”

She indicates that POS systems, “Not only get you through your day-to-day operations but also help drive you into the future.”

Technology advancements, Creed notes, “Don’t only affect consumer experience, but also the operations of the company itself. Certain uses of a POS system are obvious, such as taking in customer orders; detailing gar ment mark-in; and accepting payment.

“However,” Creed adds, “there is a lot more to a POS system that makes it a worthwhile investment for a drycleaning business.”

For instance, she says, “POS collects customer data, sends invoices, tracks piece counts, manages corporate accounts, ensures consistent pricing, and keeps track of business performance. Without a POS system, owners are left guessing what’s going on in their business.

“A POS system,” Creed insists, “allows you to have access to information about your business so you can make informed decisions. It helps owners determine why customer habits are changing and how to market to your customers.”

Creed’s own business is a cloud-based POS system. She says: “Cloud-based systems are generally replacing traditional systems because of, among other things, the ease of remote access, seamless product updating, data security and recovery, and functionality across devices.”

There are certainly other companies serving the drycleaning industry and helping change the game with POS system advances.

One of those is Cleaner Business Systems in Burnsville, Minn. Tim Woodman, senior sales manager says this: “A point of sale system gives dry cleaning owners, whether they have one location or multiple locations, more control over their business in the areas of cash con-

trol, detailed reporting, and time savings,” “Also” he adds, “it provides the ability to manage multiple locations from almost anywhere.”

Another one of those firms helping to make this evolving POS tech continue ticking upward, is garment care software firm Starchup, based in Brooklyn, N.Y.

This company’s platform, notes Nick Chapleau, CEO and co-founder, “Includes: POS, customer relationship management (CRM), plus customer-facing mobile and web apps and an integrated marketing solution. We automate your garment care business so you can do more for less.”

What POS functions do drycleaning owners find particularly handy?

The answer from Chapleau comes simply and directly: “Variety.” Meaning all the different types of customercommunication options.

He says his firm, “Enables automated text messages and e-mails to inform customers about the order process, and to re-market services and promotions.”

Chapleau notes that, “Item tracking enables our customers to track down the last employee who handled a given garment to avoid misplaced pieces or match a found garment to an order.”

In general, does a POS system, ultimately, help make a drycleaning business more money?

Chapleau says: “A good software platform will increase annual margins by thousands of dollars per store.”

Chapleau points out that his firm’s integrated marketing platform — CRM, e-mail, digital marketing, and ordering apps — helps to acquire new customers using state of the art tools, noting his company’s, “Retention tools and customer communication features help to retain and increase revenue from existing customers.”

At CleanCloud, based in London, England, founder and CEO John Buni, describes his company as, “Cloudbased point of sale and delivery management solution, powering dry cleaners in over 55 countries worldwide.”

How does a POS system work in a drycleaning operation beyond revenue transactions?

Buni explains: “It works in a number of different ways. First, it allows drycleaning operators to have access to customer information in real-time and in multiple stores. This improves customer service across the board.

“If someone walks into store A or store B, the person serving that customer has the relevant information at hand and can give them more personalized service,” he notes.

If your POS system is cloud-based, Buni points out, “Then staff members at drycleaning operations have access to up-to-date order information as the piece of clothing gets moved on thru different departments.

“In other words, if someone comes (continued)

18

www.americandrycleaner.com

American Drycleaner, March 2019

“Poseidon allows us to wet clean challenging garments like wool suits and wedding gowns without worry. It allows me complete control over my equipment and my destiny.”

– Paul White, Lifestyle Garment Care

POSEIDON CATERS TO ALL YOUR WET CLEANING NEEDS.

Increase your percentage of wet cleaned garments while dramatically boosting plant production and reducing overhead costs. Thanks to Poseidon, you can safely wet clean, dry and finish even the most delicate fabrics at a fraction of the cost of dry cleaning.

POSEIDON — ECO-FRIENDLY, AFFORDABLE, PRODUCTIVE.

poseidonwetcleaning.com • 800-482-3400

POSEIDON TEXTILE CARE SYSTEM S ®

in and drops off clothes for dry cleaning and alterations at the same time, then a good cloud-based POS system will allow the business to know where those items of clothing are, and to keep the customer updated through e-mail,” Buni says.

What we’re hearing is that POS systems can help a drycleaning business: to be more efficient; to help an owner know more about their clients; to know things in an up-to-date way; and to help an owner be profitable.

What about when an owner looks into buying a POS system? What tips can we learn?

POS BUYING TIPS

You’re about to make a POS system purchase. But before you do, tick-off these buyer’s tips.

Creed wants you to think about this: “When it comes to choosing the right POS software for your small business, you just have to buy the one that works best for you.”

Additionally, Creed points out that: “You need to explore the best functionality for your business. Here are some general features you’ll want to look for: Accessible and free support for questions and technical problems; Cloud-based; supports multiple hardware options; and marketing features, such as customer loyalty programs

and customer communications, to name a few.”

Chapleau reminds you to, “Do your research and talk to existing users about the platform. How does the POS system’s payment processing affect their business? How is the customer support? Does the company go the extra mile for its customers, or are you just another number? How often is the software updated, and how open is the company to suggested improvements?”

Chapleau also says: “Think about the future. Do you want a POS that follows the crowd, or one that is ahead of the technology curve and thinking about what cleaners will need tomorrow? Skate to where the puck is going to be.”

Buni offers these tips: “Don’t just buy a system. Busi ness owners really have to imagine their staff using it. If the system isn’t intuitive, and if the training offered is poor, staff will inevitably become frustrated and the sys tem won’t have the desired impact.

“It’s important not to sign up for features that you don’t need, and business owners should be equally wary of hidden extras or unnecessary add-ons,” he advises.

“Look for a system that is transparent, and make sure those offering it are knowledgeable,” Buni reminds. “I think it’s also really important that potential buyers look for a system operator that offers reliable support.”

The tips from some of these software (continued)

20

www.americandrycleaner.com

American Drycleaner, March 2019

ADC_Hhalf.indd 1 8/14/18 3:16 PM

Many Coin Laundries Has Your Insurance Agent Handled? One or Two? Three? We’ve

handled insurance for

of coin laundries! We’ve

issue your

If you

coin laundries,

and

There’s more: We’re just three members of

team of experts. NIE has been handling fabricare insurance since 1915! Quote Request .............................................................. ............................................................ Coin Laundry Dryclean Plant Dryclean Drop Store Attended? Gross Sales Hours of Operation Coin Laundry Dryclean Plant Dryclean Drop Store Coin Laundry Dryclean Plant Dryclean Drop Store NIE Insurance • 6030 Bancroft Avenue, St. Louis, MO 63109 • 1-800-325-9522 • fax (314) 832-6775 • www.NIEinsurance.com “Insuring Small Businesses Since 1915” Ann Hawkins Vice President Hawkins@NIEinsurance.com Director of Korean Operations Kang@NIEinsurance.com 강 명순 입니다. 지금, 연락만 주십시요. Amy Russell Fabricare Specialist Russell@NIEinsurance.com Chuck Simpson Fabricare Specialist Simpson@NIEinsurance.com How Many Drycleaners Has Your Insurance Agent Handled? One or Two? Three? We’ve

handled insurance for thousands of drycleaners! We’ve

issue your

If you

insuring drycleaners, we can and

you

Call us

and

Long Term Storage Value Type of Solvent Location 1 ❑ Dryclean Plant Location 2 ❑ Dryclean Drop Store Location 1 ❑ Coin Laundry Location 1 ❑ Dryclean Plant Location 1 ❑ Dryclean Drop Store Location 1 ❑ Coin Laundry Location 1 ❑ Dryclean Plant Location 3 ❑ Dryclean Drop Store Location 1 ❑ Coin Laundry

How

personally

hundreds

already dealt with most any

business is likely to face.

have any questions about insuring

we can

will give you a prompt, clear answer. Skeptical? Call us with a question and find out for yourself.

NIE’s

personally

already dealt with most any

business is likely to face.

have any questions about

will give

a prompt, clear answer. Skeptical?

with a question

find out for yourself.

companies serving the drycleaning industry will help you formulate a plan when getting ready to make a POS system purchase. But the last word will come from the users — drycleaning owners and operators like you.

GAME-CHANGER

A POS system is a management tool for today’s world. If you’re setting out to buy, it’s best to first ask questions. Let’s listen to what owners Ian Noble and Jason Loeb say.

Loeb: “As technology is always changing, I wanted the most current up-to-date software. Look at the way the soft ware is communicating with your clients. Look at the secu rity. Also see how and when updates are deployed.”

Loeb recommends you ask: “What is the response time for technology questions? How easy will they make it for you to switch to another POS in the future by transferring your credit card data and your database? As long as my POS is delivering on its promises there is never a need to switch but the freedom to switch should be easy.”

Loeb concludes: “Make sure that your software provider will give you the information you request in the format you request and do it within an acceptable time period.”

Noble says this: “The upfront cost will be scary, but it is definitely worth it. We can now control costs by monitor ing employee activity and utilizing our reports to make better business decisions.

“If an order does not arrive or isn’t ready, it is easy to see, and we can call the customer immediately to let them know. This simple step could save you from a Yelp or Google review if you happened to save that customer a trip to your store that day.”

Noble also relates that: “The biggest savings, that the owners may not realize, is theft prevention. On paper tickets it was very easy to steal, but POS systems allow you to monitor every step of the transaction, and if there is unusual activity, suspicious voids, or any other activity, it can most likely be found in a report.”

“One major improvement to our business is implement ing heat-seal/bar-codes,” Noble points out. “It is more time-consuming the first time you apply them to a gar ment, but after that, the savings are great. It saves in time and labor for all future drop-offs on that item as well as increases tracking ability.”

Noble explains that if an item goes missing or the barcode comes off, “You know exactly what you are look ing for which can help you find the item or avoid costly claims. All of these things contribute to the bottom line.”

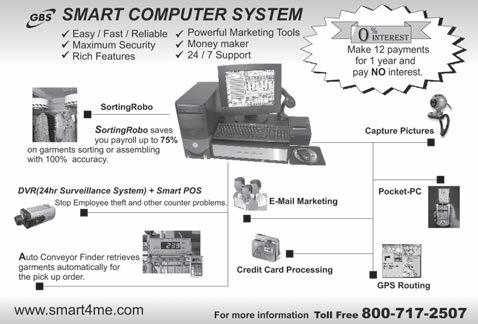

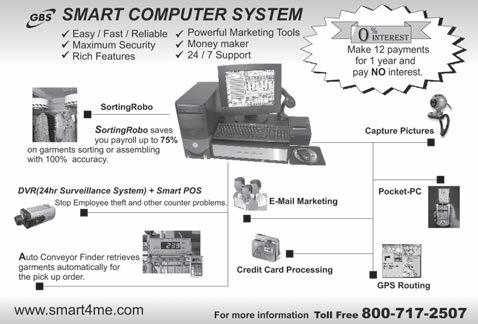

John Kim, owner of Wauconda,Ill.-based Global Business Systems says, “Coming generations will see automa tion as a key to succeed for drycleaning owners. Wages are up and manpower is harder, and not only POS but automated sorting and bar-coding will help in reducing

labor needs.”

Noble says: “Whether you are a one-price cleaners, stan dard, or a couture cleaners, every single penny counts.”

Noble’s POS purchasing tips? He has plenty, based on experience: “The first thing to analyze is where your busi ness is today and what can be improved by buying a POS. When you install one you immediately legitimize your business in the eyes of the consumer. It will help you run more efficiently and streamline your operation,” he says.

With a streamlined operation, POS can create, as Jones relates, “An efficient counter, plant and route operation, which will require less labor and help to maintain happy customers. A happy and engaged customer will visit your business more frequently.”

“The single most important thing when interviewing a potential POS provider is their support system,” Noble re lates. “Are they always available by phone? What are their hours? Can you get help fast? Do they provide solutions the first call or make you wait?”

Ali Khan, owner of Bellingham, Wash.-based DajiSoft says, “POS can actually change the life of a dry cleaner. Its record-keeping can prevent employee theft. And cus tomer history is a ‘gold mine’ because you can see where most of your customers are coming from.”

Khan indicates: “You can run reports to see if customer revenue or store visits have increased or decreased in the past month or so. Pricing mistakes are almost gone. So it has increased the bottom line for many clients.”

Khan advises: “For those who are looking to purchase a new POS, my biggest recommendation is to look more at the quality of service the POS provider is offering. Also look at the quality of the software and its marketing re ports especially.”

Woodman’s tips are: “Make sure the provider offers phone support and other mediums for their customers to communicate with them; and give those mediums a test to make sure that the company is responsive. You don’t want to be waiting on your POS provider for a response to an email, or a call-back, for hours, days, or even weeks.”

Noble says this regarding service: “Don’t entertain a POS company if their support isn’t fully equipped to take phone calls when you need them or they are not adequate ly staffed. The best thing to do is find out from friends or other cleaners how their technical support is, and make your decisions based off real operator experience.

“Don’t be afraid to make a change in your business,” Noble concludes.

“If you do things the way they have always been done you’ll ultimately suffer. Try new ways of utilizing your POS system to see if it enhances your consumer and employee experience. If your change does not work, change it back. This is the beauty of business.”

ADC 22 American Drycleaner, March 2019 www.americandrycleaner.com

24/7 Support YOU CALL, WE RESPOND We’re talking minutes, not hours SMRT SYSTEMS Problems Solved SMRT Systems • (415) 612-9885 • SMRTSystems.com • sales@smrtsystems.com • 1844 Belles St. San Francisco, CA 94129

At SMRT systems We Get it

At the heart of SMRT, we are a dry cleaner. It’s the reason we created our software in the first place: To solve the everyday problems we ran into at our own business.

We’ve stood in your shoes -- pressing, cleaning the button trap, filling in when the driver is sick, making payroll, and replacing equipment.

And with a dry cleaner’s perspective, we’ve built, from the ground up, the best dry cleaning software in the marketplace.

We understand that dry cleaners are dynamic, high-performing entrepreneurs. It’s no small feat to run both the factory and the dealership every damn day. You deserve a software partner that knows your business and is there for you 24/7. You deserve SMRT.

SMRT Systems • (415) 612-9885 • SMRTSystems.com • sales@smrtsystems.com • 1844 Belles St. San Francisco, CA 94129

There’s never been a better time to Get SMRT

ac a e. T e eo le, t e ro ct, t eir ri e an t eir oc s ma e my siness etter an my li e easier. - at y Ben

er, ner Ben

er s Cleaners

SMRT is t e com lete

in

in

Next-level customer service to match their next-level technology. The SMRT team is passionate about solving problems and supporting their users.

Jason Yerby

Vice President: Crest Advanced Dry Cleaners

There’s more to SMRT than great software. They really know the business, bringing a new dimension to customer support.

Daniel Cha

Owner: Orchid Dry Cleaners

SMRT is light years ahead of the competition! We’ve never been so on top of our business and in tune with our customers.

Wayne Edelman

Owner: Meurice Garment Care

Robust

Richard Aviles

Owner: Bridge Cleaners & Tailors, King Garment Care

SMRT Systems • (415) 612-9885 • SMRTSystems.com • sales@smrtsystems.com • 1844 Belles St. San Francisco, CA 94129 CALL SMRT Today AT 415•612•9885 AND LET’S EXPLORE THE POSSIBILITIES

KPI’s, easy customer access, instant Metalprogetti integration, text messaging... in one simple-to-use package. All I can say is, get SMRT!

MANAGEMENT STRATEGIES

R eaching Out (Further): Logistics

For the conclusion to my Reaching Out column, the focus will be on applying the same trends (that we saw in Part 1), to the areas of production and logistics, again with an emphasis on the impact on growing sales and profitability.

As a reminder, the trends list was generated by Ian Altman for Forbes Leadership because it exemplifies a consensus of last year’s trends lists. (For the entire article, go to: https://www.forbes.com/sites/ianaltman/2017/12/05/the-top-businesstrends-that-will-drive-success-in-2018/#23e807fb701a)

1. Artificial intelligence

Per Wikipedia, “artificial intelligence (AI) is the intelligence exhibited by machines or software. It is also the name of the academic field of study, which examines how to create computers and computer software that are capable of intelligent behavior.”

A familiar version of AI in the drycleaning area, is the computer-aided drycleaning machine that chooses the correct cycle based on the fabric and garment content in the specific load. Another is the moisture sensitive control for wet-cleaned garments.

Sorting conveyors help reduce human error and lost or misplaced garments.

The automated robotics of the newest finishing equipment makes the job of the operators much easier because of the “intelligent” features. The newer features have reduced training time, increased quality and consistency, improved pieces-per-operator-hour (PPOH), and improved overall throughput, reducing total labor and related production costs.

With the ever-increasing competition for competent labor, it is time to review and weigh the benefits of equipment investment against the cost and calculate the resulting return-on-investment (ROI).

The many available apps in the industry are designed to give you and your drivers an easier way to optimize

the routes while giving the customers more options for their convenience.

Robots could be adapted to deliver orders to the drivethru, lockers and beyond. Drone delivery is becoming a reality for some industries, so why not ours? Self-driving vehicles may also become reliable and cost-effective in the foreseeable future.

Apps and automation can be very beneficial to you, your company and your clients.

2. Communities embrace live interactions

Your local and remote teams benefit from electronic training and communication, but they also crave live interaction and events with their peers. Not only do they benefit from applying the training in a supportive environment, face-to-face encounters strengthen the bonds between team members and minimize the “them vs. us” silos that exist in most organizations.

3. Millennials welcome Generation Z

Millennials (now reaching their mid-30s) have been in their careers long enough that many of them are now managing their teams. They are now encountering the latest generation to enter the workforce. Born after 1998, Gen Z is the first generation born surrounded by personal electronic devices. They crave automation in all their tasks, and efficiency and constant access in their communications.

Are you ready to adapt to their preferred form of payment, such as auto deposit to their online bank, 24/7 interactive communication, flex work hours, re mote task completion, autonomy, and

(continued)

www.americandrycleaner.com American Drycleaner, March 2019 27

How does your production and logistics fit the 10 ‘success trends’

Diana Vollmer

(CONCLUSION)

(Image licensed by Ingram Publishing)

MANAGEMENT STRATEGIES

other preferences?

4.

Wages and more on the rise

Like the sales and service departments, the associates in production and logistics are considering the same compensation issues. Companies should factor in a Society for Human Resource Management (SHRM) prediction of an average 3% wage increase this year. Monetary compensation is only one component influencing jobholders and job-seekers. They are also weighing flexibility, benefits (including ever more expensive health care), and autonomy. The generation of the associate, influences the weight given to each component.

Offering job-sharing, remote work alternatives, flex hours, more self-management, and choice from a menu of benefits may be essential to attracting and retaining competent employees. You may need to be more creative to compete in the current job market.

5.

Social learning

Individual learning, regardless of the media, such as traditional learning or electronic, is beneficial and possibly essential to provide a baseline of knowledge about performing a given position. However, group learning outperforms individual learning when ranked on actual performance of the job. Seeing how someone else approaches the task or sharing perspectives during role playing can be very impactful once the initial reticence to participate is overcome.

Don’t forget to involve “lone wolf” drivers and remote workers, such as an outsourced billing department, so they feel connected to the company, their teammates and their counterparts.

6. Live-streaming video

Although different people prefer learning in different ways, live-streaming video has proven to be one of the most effective and efficient ways to share information. There are many resources available that have already been developed by suppliers, vendors and trainers.

Many of these resources are free, but if you need a personalized specific-use video, their production has become very affordable and can make your associates more efficient in both training and job performance.

7. Serve your community

Review the sources and commonalities of your associates. They and their communities (social and geographic) are an excellent way to attract their peers to join your workforce. Enumerate the ways to show off your company as a positive place to work. Reach out to them

through appropriate electronic media, physical media, and lifestyle events such as logo-canopy water-stations at children’s sports events. People like, and associate with, similar people in their communities.

8. Marketing focus on solving problems

When “marketing” to your employees and prospec tive employees, focus on the challenges they face and how to overcome them. A menu of benefits from which to choose is a good way to address a range of needs without providing everything to everyone whether they need it or not. Health insurance, child care, dental and eye care, carpools, flex hours, job sharing, discounted family laundry, and more, can all be attractive benefits and the flexibility to mix and match them provides wel come control.

9. Subject matter experts (SMEs)

You most likely have received the benefits of your suppliers’ SMEs throughout your fabricare career in the form of chemical specialists, equipment advice and plant layout suggestions. Your software vendor can also provide information and expert advice particularly in logistics and route apps.

Internally, you can develop SMEs for the benefit of your customers, as with the wedding specialist, and for your team in the form of expert team leaders or trainers. Your most discerning clients may appreciate meeting the “master dry cleaner,” “stain removal expert,” or “master tailor.”

10. Blockchain

You may wish to be on the cutting edge and offer Bitcoin as an optional form of compensation for your adventurous staff. Few, if any, would opt for that payment, but you would probably glean ample free publicity. Be sure it complies with all HR regulations in your jurisdiction.

Your company, your associates and your clientele can all benefit if you assess your status on each of the success trends coming out of last year and implement changes that move you through 2019. ADC

Diana Vollmer is a managing director for Methods for Management, which has served dry cleaners and launderers with affordable management expertise and improved profitability since 1953. For assistance imple menting success trends in your company, contact her at dvollmer@mfmi.com or call 415-577-6544.

28

www.americandrycleaner.com

American Drycleaner, March 2019

White Conveyors’ SUV-OAS is the perfect solution to boost your productivity, improve customer service and increase your profits while reducing your operating costs. The system is delivered fully assembled, and can be operational in less than two hours. As an option, it can be mounted on wheels for mobility or storage. Simply set it up on its supports, plug in the power, connect the computer, and link the system to an Internet connection. It’s time to begin realizing remarkable time and money savings.

Easy to use

Reduces labor costs

Increases productivity

Assembles over 2000 pieces per shift

Interfaces with all major POS systems

Can utilize a bar-code or RFID chip system

Easy-to-read computer touch screen

Highly accurate and reliable

Fast return on investment

Proudly made in the USA with fast support

White Conveyors, Inc 10 Boright Avenue • Kenilworth, NJ 07033 • (800) 524-0273 • +1 (908) 686-5700 www.whiteconveyors.com The

Automated Order Assembly System is designed to help make your business more competitive and profitable.

Assembly

Been Easieror

Affordable

SUV-OAS

Order

has Never

More

The World’s Most Trusted Conveyor

Next Level Stuff

In this Clean Show year, how to get the most out of conventions

Trade shows in the drycleaning industry can help take your business to the next level. Here’s how:

Way back last summer I attended the Fabricare Show in Long Beach, Calif., which was a terrific event full of good conversations and learning opportunities.

As I walked the floor of that convention center, I couldn’t help but think back to my first Clean Show and what a whirlwind that was. For a business owner, the sheer number of machines and displays on the floor at Clean can be overwhelming. Business owners can come away feeling as though they’ve seen everything and nothing, all at the same time.

Since this is a Clean Show year, it’s never too early to be thinking ahead.

With that in mind, I thought it would be helpful to discuss the three keys to getting the most out of our industry shows, and especially the Clean Show coming to New Orleans in June.

MAKE A PLAN

There are so many activities and displays going on at a fabricare show that you can spend days there and never see everything there is to see, so it’s absolutely critical that before you go you make a plan to make the best use of your time.

One of the best ways to plan for a show is to start with the major questions that you want answered.

Those may include the following: What can I do to reduce my supply costs? What type of pants machine should I get to replace my current one? What is the best way to improve my online presence?

Before the Long Beach show last year, I had a bunch of questions for my software vendor and got all of them answered in one hour-long meeting.

Listing the major questions that, if answered, will improve your business, will give you a road map for how to spend your time at the show.

For example, if you are looking for a new shirt machine you can look up what shirt machine

manufacturers will be at the show and where they will be located. You can also look to see if there are any productivity consultants who may have insight into what shirt machines work best for certain businesses.

I guarantee you that if you are looking for a shirt machine and visit those booths you will come away with substantially more knowledge than you went in with. You may come away with a discount as well, as many manufacturers offer significant “show” discounts.

ATTEND EDUCATIONAL SESSIONS

While the idea of sitting in windowless conference rooms all day learning about some arcane topic isn’t most people’s idea of a good time on the weekend, I can’t tell you how much I’ve learned from the educational sessions held at fabricare shows.

Whether it is software updates, business valuation, or social media strategy topics, there is a great deal of knowledge on how to improve your business at these shows.

Some of the most rewarding educational sessions that I’ve attended have been on topics that I thought were ancillary to my business, but ended up giving me new ideas and fresh perspectives that we leverage to this day.

30 American Drycleaner, March 2019 www.americandrycleaner.com

OWNER’S OFFICE

(continued)

Dan Miller

(Photo: Tim Burke)

- Kimberly Gerstner, Pressed Dry Cleaners

Starchup has been fantastic with supporting every aspect of our conversion to their point of sale software system. Starchup has developed a state of the art platform that is going to revolutionize the Dry Cleaning industry - and a team to guide us the whole way.

- Tonny Walden, Walden Cleaners

- Tonny Walden, Walden Cleaners

Starchup Point of Sale Superior Technology, Unrivaled Customer Care Flexible POS software accessible anywhere on a tablet, smartphone, or desktop Powerful garment tracking, assisted assembly, and conveyor integration with the leading systems Flat rate pricing - no up-front cost or 'per terminal' limits to your growth Fully integrated customer ordering apps, SMS & email automation, and delivery optimization Transparent integrated payment processing or use your own Dedicated training and customer support available 7 days a week via chat, email, or phone Join a community of garment care professionals and become a part of the future of dry cleaning! Loyalty & Marketing Customer Management Customer Engagement Delivery Management Reporting & Analytics Employee Management Customer Support Payment Processing Garment Tracking Assisted & Auto Assembly sales@starchup.com www.starchup.com Go to starchup.com or email us at sales@starchup.com to read case studies from other laundry professionals and schedule a demo today!

us

Starchup's team put

at ease from the very beginning. They worked with us every step of the way, transferring 10 years of customer and garment data seamlessly from our previous POS without interrupting our day-to-day operations. We could not be more thrilled with the training and support Starchup continues to provide!

WANDER AND LEARN

Once you’ve successfully had your planned questions answered and attended the educational sessions it’s critical to wander the floor and learn.

And I don’t just mean meandering the floor and walking by booths. I mean stopping at booths that offer something new and learning about what they do.

Much like the educational sessions I went to, many of the booths I stopped at, that I learned the most from, had nothing to do with my core business, but offered new insight into what was possible.

One booth I stopped by at last summer’s show made equipment that recycled water for laundry facilities to reduce water waste. I had heard of this before but assumed that it would only be viable for industrial laundries that used much more water than our facility.

Much to my surprise due to the high cost of water in California, our cleaning facility could still generate significant savings from this technology, and we are installing it this year. This never would have been possible had I not taken the time to wander and learn.

Drycleaning and laundry conventions are a great opportunity to get out of the office, clear your head, and open you mind to a world of new ideas.

If you follow these steps, you’ll emerge from the Clean Show in New Orleans with knowledge and innovative ideas that can take your business to that next level! ADC

Dan Miller is the chief executive officer of Mulberrys Garment Care, a premium drycleaning and laundry business with 17 locations in Minneapolis, San Francisco, and Dallas. You may contact him at dmiller@ mulberryscleaners.com or 866-473-0798.

Get to Know ... John Riddle

Former pro baseball player; and man behind the Clean Show

Tell us where you were born, grew up, and reside today?

“I was born in Kannapolis, N.C. and lived there until I went to college. After a six-year career in professional baseball, I moved to Atlanta and have lived here ever since.”

Hobbies (that you’ll admit to)?

“I love fly-fishing, fly-tying, golf, and team roping, think rodeo. I am an avid reader, particularly of history and other non-fiction. I am always trying to learn something new.”

What gets you excited at work?

“People! I love coming to work and being with the people who work here. I truly enjoy the show’s exhibitors and love the challenge of motivating attendees to come. I like working toward making the Clean Show appealing both visually and in content.”

Lastly, tell us a secret (keep it clean) nobody knows about you?

“Some remember this so it is not really a secret, but I had the first adoption center of the original Little People dolls, which are now called Cabbage Patch dolls, in my Terminus Gift Shop in downtown Atlanta. Another that some people don’t believe is that in golf I have had a holein-one from both sides of the ball, one right-handed and one left-handed. A true secret, what people always want to know, is when I wear my kilt, I am commando.” ADC (Do you want to take part in an Off the Cuff, or know someone who does? E-mail tburke@atmags.com.)

32

www.americandrycleaner.com

American Drycleaner, March 2019

OWNER’S OFFICE

OFF THE CUFF

John Riddle at his desk at Riddle & Associates in Atlanta. (Photo: John Riddle)

Comforters

Bedspreads and comforters come in all colors and textures. They are designed to be ornate yet functional. Many are so decorative that they should be removed at bedtime to extend their lifespan.

But, there are times when children and pets see only a flat surface to play or relax.

Dirty shoes and dirty paws can leave marks that only focused, knowledgeable care can remedy. That is where the professional has an opportunity to use experience and equipment to broaden the existing list of services.

Over the last 15 years, wet cleaning has come into its own, making watersoluble stain-removal on these large household items much safer and more efficient. Most modern commercial washers have inverter drive and micro-processor controls which allow for gentle mechanical action.

Combined with a large residual moisture-controlled dryer and the use of detergents that have neutral pH or are slightly acidic, any item with a water-based cleaning option on the care label can be cleaned as a fine washable. However, there are customers that want that special appearance of custom designed treatments for the entire bedroom.

The very first question that must be asked is; “Is this part of a set?” Custom room treatments can include a bedspread/comforter, pillow shams, a dust ruffle, drapes, valance, and shears.

When only one piece of the matching set is cleaned, there is often a variation in color and intensity between the item cleaned and the other items that were not cleaned. It is difficult to explain this after the fact, so it must be pointed out when receiving the item.

All items should be cleaned at the same time to ensure that all pieces match when placed side by side in the room. If one item requires dry cleaning, all items must be drycleaned.

Tip: It is far better to pass on a single item of a matching set than to face a claim because, “It doesn’t match anymore.”

Bedspreads and comforters often take a beating when left on the bed constantly. Many times, the customer will sit or even lay on the bed in dirty clothing.

The customer may treat a pet like a member of the family, allowing the pet to join them on the bed. You must not forget the underside of the item. There you are going to find soil and albumin stains.

Albumin stains are the result of the transfer of bodily fluids. These stains may go unnoticeable for an extended period, making them much harder to remove. These stains are for the most part water-soluble when fresh but may require a level of bleaching action by the time they are brought to the cleaners.

In extreme cases, the level of body oil and perspiration where the bedspread has been pulled up under the customer’s neck will be heavy. This will require additional effort to break down the discoloration, even with the best of the pre-spotting chemical tools.

In such extreme cases, the combination of perspiration and body oils may have to be addressed separately by breaking down the body oils to effectively remove the yellow/brown perspiration stain.

You may even be required, in other cases, to use sodium perborate or sodium percarbonate to completely remove the last of the stain.

Some comforters gain their appeal from being “stuffed.”

This partitioning of the surface provides only a minor adjustment in handling. In fact, I have found that more partitions contribute to an ease in handling, due to less chance of the filler shifting during cleaning and drying.

When the squares are larger than eighteen inches, I will run the item in a net bag to reduce shifting.

34 American Drycleaner, March 2019 www.americandrycleaner.com

(continued)

Martin Young

SPOTTING TIPS

(Photo: Tim Burke)

Bedspreads often take a beating; Some comforters gain their appeal from being ‘stuffed’

Hoffman Body Press (used) $2,995* Easysec 50-lb. Dry Cleaning Machine $29,995* Huebsch 75-lb. Gas Dryer (used) $1,995* Miele 45-lb. Soft Mount Washer $11,700* Sankosha Triple Puff Iron $1,960* Ingersoll Rand 5 HP 120 Gal. Vertical Compressor (used) $995* Unipress Double Buck TD2 (used) $14,995* Forenta Utility Press (used) $3,150* Lattner 15 H.P. Boiler $11,495* Fagor 60-lb. Washer $7,695* Forenta 19VS Laundry Topper $4,595* Forenta Collar and Cuff (used) $3,600* Forenta 54VL (used) $3,400* Forenta 44SP Spotting Board $2,850* Hoffman Double Topper (used) $3,450* 86 6 - 73 4 - 364 4 Monthly Specials Online: MustangEnterprises.com New & Used Equipment for Drycleaning & Laundry Huge Selection of Parts for Most Brands of Equipment Prices valid until April 1, 2019 | *Freight Not Included

It is not the customer’s fault, but it is my responsibility.

It makes no difference if you choose to dry-clean or wet-clean a quilted item, you should always use something to shift and fluff the filler. This will ensure a like new appear

ance and during the drying time, it will shift the filler.

Shifting the filler will give “even” drying and a “fluffy” appearance. I have always used at least four clean tennis balls, since they are heavy enough to shift the filler upon impact.

The fuzzy cover prevents damage to the surface material.

Comforters that are filled with Down require extra attention. The Down may contain a small amount of lanolin that is released during clean ing. This is especially true in dry cleaning. This lanolin will appear as a darkened area on the surface.

This can be remedied by applying a mild POG to the stain, light mechani cal action, and then re-cleaning. The excess lanolin will be removed in the cleaning process. Be aware that manufacturers use “water fowl feath ers” as a cost cutting measure.

These feathers are larger and have longer, more brittle stems. These stems tend to poke through to the outside and ruin the appearance of the item. Water fowl feathers are listed on the content label and will feel like small twigs when the item is handled.

It is very important to use some thing like the tennis balls to move around the feathers during drying. I recommend that you increase your drying time by 20% with Down, and that you use additional tennis balls to increase the frequency of shifting.

Promoting bedspreads and com forters is a great way to expand/ diversify your service. These are usu ally items that are too large for home washers and dryers.

The customer can be easily overwhelmed when handling a comforter and will welcome the op portunity to have someone else take care of the item.

ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates today. Phone: 704786-3011, e-mail: mayoung@ctc.net.

36

March 2019 www.americandrycleaner.com

American Drycleaner,

SPOTTING TIPS Visit us at the Clean Show Booth 4427

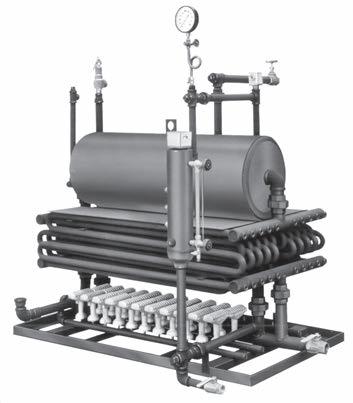

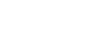

SMOOTH AS SILK: DRYER ADVANCES

Wet cleaning’s partner is a dryer that’s up to handling delicates

By Jeff Quail

While highly programmable wetcleaning washer-extractors have been on the market for years, their partner dryers have lacked the programmability needed to dry delicate fabrics — wools, silks, linens — without resulting damage.

Historically, garments were either wet-cleaned and air-dried overnight, which took a lot of time and space, or dry cleaned. Thankfully, emerging dryer technology is changing all that … revolutionizing the wetcleaning process and how textile care operators do business.

DRYER PROGRAMMED

Dryer programmability is finally catching up to the programmability level of a wetcleaning washer.

For the first time, there are dryers on the market offering several programmable phases/steps in the drying process, as well as sophisticated control over multiple variables within those phases, including oven temperature, drum temperature, drum rotation action and G-force, timed reversing, and moisture-sensing control technology.

Many of these drying variables have not been programmable. Yet, complete control over drying is critical to the success and speed of the wetcleaning process.

EFFICIENT

By controlling variables by phase/step, even the most delicate items can be dried to the proper moisture level that’s ideal for finishing.

This means textile care operations can wet clean gar-

ments more quickly and efficiently, provide improved customer turnaround times, become more environmentally friendly, and lower operational costs. Because the new dryers eliminate air drying, it takes wet cleaning to a whole new level of productivity.

Let’s take wool suits as an example. A load of wool suits takes just 15 minutes to wet clean, 15 minutes to dry and less than 10 minutes to finish. The new dryers make it possible to turnaround a suit — from drop off to pick up — in an hour.

CAPABILITIES

So, what are the key capabilities to look for?

Seek out dryers with programmability of multiple variables within each step/phase of the drying process. Programmable phases, beyond the typical dry and cooldown, allow for the control necessary to protect garments when they are at their most vulnerable — at the beginning of the dry cycle when they are saturated with water and at the end of the cycle when they are near dry. A minimum of five phases is essential:

1. Critical Programmable Features

To deliver great results, look for a dryer with the following programmable features within each phase.

2. Drum Rotation Speed (RPMs) and Interval

By controlling drum speed and interval, you can remove moisture quickly, without tumbling. This is important. When garments are wet, the drum should ideally spin with enough RPMs to cause garments to cling to the drum, rather than fall and tumble from top to bottom.

38 American Drycleaner, March 2019 www.americandrycleaner.com

(Image licensed by Ingram Publishing)

This prevents damage and shrinkage. Drum speed should be adjustable based on phase, item type, moisture content and fabric.

3. Moisture Level

Even the most delicate items can be dried to the proper moisture level that’s ideal for finishing.

It’s important for a dryer to have the ability to check and confirm the moisture content of a load before advancing to the next phase. Most dryers monitor for one moisture level throughout the entire dry cycle. Now, thanks to new technology, each phase has its own moisture level setting. This eliminates over drying, shrinking and damage at all phases of the drying process.

4. Timed Reversing

When the drum only turns in one direction, garments tangle and ball up, creating uneven drying. Look for a dryer with multiple different reversing options.

5. Input (Oven) and Output (Drum)Temperature

Most dryers allow control over the drum temperature for a set period of time. But it isn’t enough. A dryer with programmable oven temperature, from 104-392°F, allows total control over the dryer heat source/flame, which greatly reduces the risk of hot spots and heating inconsistencies that contribute to garment damage or

shrinkage. Typically, oven temperature is higher for thicker materials and lower for delicate garments. Additionally, new dryers can hit high drum temperatures of up to 195°F extremely quickly in order to evaporate moisture without as much tumbling. This precise control over temperature, rotation action and drum speed protects garments from damage while allowing the shortest dry times.

TIME LIMIT

It goes without saying that the duration of each phase is important. New technology allows cycles to advance to the next phase based on time limit or moisture level. A time limit is always programmed to prevent over drying due to a possible moisture sensing error. This redundancy is an additional safeguard against damaging garments.

ADC

Jeff Quail, co-owner of Poseidon Textile Care Systems®, has more than 30 years of hands-on industry operations experience in dry cleaning and wet cleaning. E-mail: jquail@poseidonwetcleaning.com.

March 2019 39

www.americandrycleaner.com American Drycleaner,

ADC_Hhalf.indd 1 2/13/19 2:40 PM

Renzacci SPA

Renzacci’s drycleaning machine Progress Extreme is available in models from 20- to 352-pound load capacity, and are both ETLand CSA-approved, the company says. This machine offers a wide range of innovations, the firm notes, among them, the new computer “i-Brain” equipped with the exclusive Sentinel-Friendly Touch (SFT), which uses the new communication system, V-SMS box. It can report in real-time, identifying invalid operations, and allows the customer to carry out actions regarding the steps to be taken.

The Progress Extreme can be equipped, on request, with the innovative app “My Brain,” that makes it possible to remotely monitor and control your drycleaning machine, the company describes, “as if you were right in front of it looking at the computer’s i-brain in action.”