Since stain removal matters to your customers, each stain is an opportunity to impress them.

InkGo is the effective and safe way to remove ink stains from all types of fabric - including acetates. Use it to remove adhesives, too.

It's eco-friendly... California compliant, chlorinated-solvent and NPE free, biodegradable and non-combustible. And since InkGo is user-friendly and odor-free, it's pleasant to work with.

Use InkGo to deliver stain-free cleaning. You'll build your reputation for quality – and keep customers coming back.

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

June 2019

Vol. 86, No. 3

Pre-Inspection 4 Your 100% Smile Management Strategies 22 Summertime, Summertime Diana Vollmer

Special Feature 28 Sprout-Out: Site Remediation Tim Burke

100 Percent!

Employee relations is all about the relationship between you and your team and building a ‘workplace family’ feeling. It’s the give-and-take of a special environment of empowerment and trust for both owner and team. Todd Ofsick, owner of NYC’s Todd Layne Cleaners, shown in photo above on right, and on the front cover with his team, says, “With 100 percent certainty, I can say that my team holds the keys to the success of my business.” Hear his views, and those of two other drycleaning owners, about what it takes to make employee relations at your dry cleaners a success!

Tim Burke, Editor

Two drycleaning owners recall their first magical days in the drycleaning business in this, another in the How-To series, all about Starting Out. Hear stories and funny anecdotes shared by two owners about working in your industry! This answers the unspoken, tongue-in-cheek question: “So, you wanna be a dry cleaner?” Find out some of the lessons they learned!

Tim Burke, Editor

Special Feature 32 Dry Cleaner Retires; Dogs Sad Tim Burke Spotting Tips 36 Be Cool Martin Young Owner’s Office 38 Power to the Penny Dan Miller

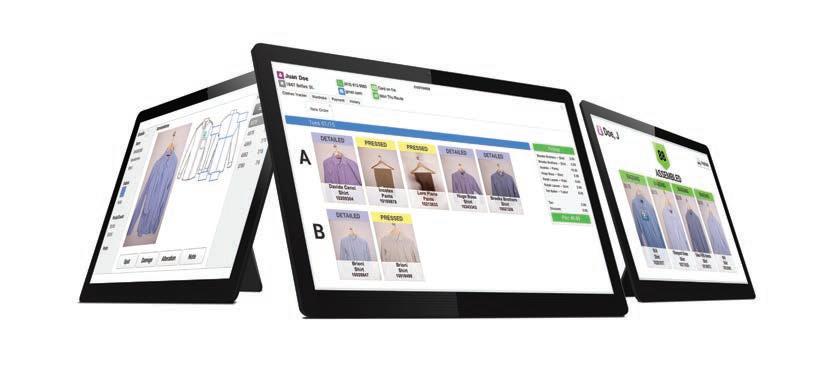

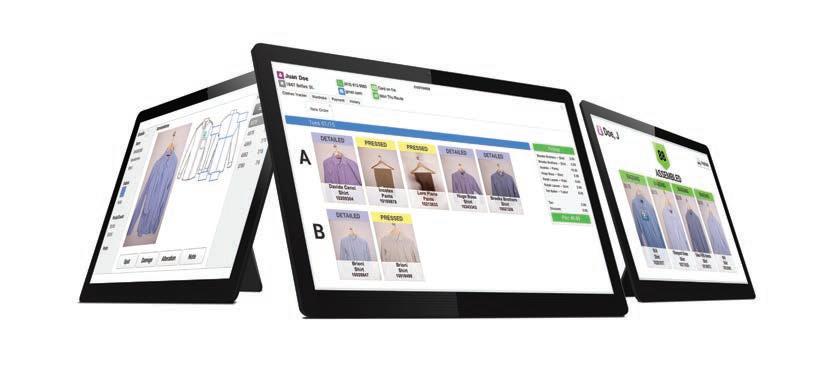

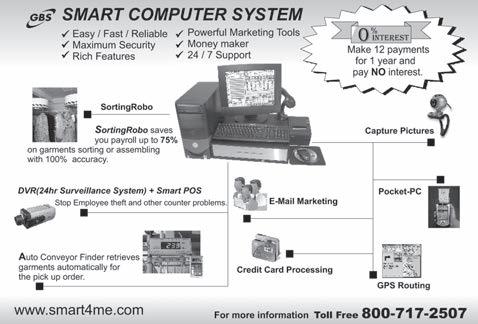

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

Since 2003, CBS has given me consistent updates and easy to understand tech support, all at a price that our industry can afford. I would recommend CBS, and I have, to anyone who is still wasting their time and money on those over priced POS systems.

You give 100 percent all the time to your drycleaning business — it’s your life. And you want your team to give their very best effort too.

How you treat them, fostering a family-like special feeling at your cleaner, and getting that pride and commitment back in return from them, creates a 100 percent winning environment.

And that’s what we’re talking about in this issue in the feature 100 Percent! — all about your employee relations.

Three drycleaning owners from across the U.S. share their experiences with their own teams at their businesses. Their team members give back to their communities and have strong bonds they’ve nurtured with customers.

BurkeOne owner, Todd Ofsick, CEO of NYC’s Todd Layne Cleaners, is on the front cover with some of his team members who he says, “selflessly help customers,” and that helps create a true family feeling.

Your other feature in this issue is another installment of our How-To series, this time called When We Started Out, bringing you anecdotes from two dry cleaners about how they first got started in the cleaning business, along with family history, and personal reflections from their past. Check out their humorous tales.

Your favorite three columnists are here. Diana Vollmer’s Summertime, Summertime asks you to recognize all the opportunities warm weather brings. Dan Miller’s Power to the Penny reminds us, while we’re busy hunting for new customers, to never forget our loyal, good ol’ customers! And in the heat of summer, Martin Young tells you that employees work better when plant conditions are cool, safe, and well lit, in his column Be Cool. There are also two special features this issue, and much more! Clean ’19 is here. Good times’ll roll. Smiles and laughter’ll reign! The fabricare industry will shine in Crescent City! So give us your 100% smile! See ya at Clean! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 86, number 3. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2019. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, June 2019

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor

Tim Burke 312-361-1684 tburke@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Roger Napiwocki

Advisory Board

Mike Bleier Steven Dubinski John-Claude Hallak Mike Nesbit Herron Rowland Fred Schwarzmann Beth Shader Ellen Tuchman Rothmann

Contributing Editors

Dan Miller

Diana Vollmer Martin Young

Office Information

Main: 312-361-1700

Subscriptions 630-739-0900 x100 www.american drycleaner.com

Employee relations is all about you and your team as a workplace family, one which proudly reaches out to customers and the community

By Tim Burke, EditorLet’s talk about employee relations. Your employee relations.

How key are your employees to the success of your business?

One dry cleaner we asked is Todd Ofsick, founder and CEO of Todd Layne Cleaners, in NYC, who relates: “With 100 percent certainty, I can say that my team holds the keys to the success of my business.”

He describes his cleaners as an eco-friendly drycleaning and specialized laundry company.

About his employees he says, “They know the major-

The team gives 100 percent, selflessly helping its customers, and giving back to the community. Those bonds create a true family feel at Todd Layne Cleaners, and founder Todd Ofsick, shown on right, is proud of his team.

(Photo: Todd Layne Cleaners)

ity of my customers by first name and are able to follow all of their individual instructions. We keep a profile for each customer with specific needs like best pickup/delivery times, laundry choices, etc. Without the right staff, the business wouldn’t survive more than a few days!”

Employees are often referred to as a team at drycleaning operations. Are your employees treated like a trusted team? Do you empower them to make decisions?

What can you say about that team feeling in business today, and what does it take specifically to create that special environment at a cleaners?

(continued on page 10)

(continued from page 6)

Ofsick weighs in on the topic: “Motivating a team of people at an investment bank is very easy because of the high compensation. Creating a team feeling with people at lower ends of the pay spectrum is quite challenging.

“People stay with me because I foster a family-style environment and get to know my staff on a personal and professional level. When they have issues, I often step in to help them, whether it’s a short-term loan or advice on a personal matter.

“I always try to stay positive and acknowledge and reward my team for tasks and assignments well done,” he says. He says he has five team members with an average tenure of six years.

Does your team run self-directed, as many owners describe, so you can be away at times and can trust their judgement and responsible attitude?

“To a large extent, my team can run in a self-directed manner and will generally exercise good judgment and a responsible attitude,” Ofsick notes.

“With the advent of technology like video surveillance, recorded phone calls, online scheduling of pickups/deliveries, texting, email, Google Sheets and other productivity tools, it is much easier for me to be away and only get involved when necessary,” he relates.

Team members treated like family may be the single most important trait for drycleaning business longevity. Ofsick indicates that drycleaning businesses rely on repeat customers and dry cleaners really are an integral part of the community.

“It is very different from the rest of the retail world,” he points out. “We know customers by their first names and get to know them and their families. We volunteer at local events, partner with other small businesses, and serve on the local block association.”

Sharing memorable thoughts that demonstrates how

much his team is like a family, Ofsick tells: “My team very much goes above and beyond in terms of assisting our customers. They have helped elderly customers go to their doctor’s appointments.

“They’ve also carried laundry/dry cleaning and sometimes groceries home, checked on a pet, made a call to make sure someone was feeling ok after surgery, and watered plants,” he relates.

“More recently,” he says, “there has been an uptick in our younger millennial customers asking one of my managers about the best way to tackle the online dating world of Tinder and Bumble.”

Ofsick gives some tips on how to help build this family feeling of mutual trust for the drycleaning operations: “Get to know your customers, support local charities, attend meetings of local block associations, create crossmarketing opportunities with other small businesses, and demonstrate to your team that you want to help them to grow within your company.”

Employee relations closely resembles a typical family dynamic.

In order to be successful, you have to get to know your team on a personal level and be there for them in times of need, he reminds.

“It is a delicate balance and they also have to respect you and know that if they get out of line, there will be consequences,” Ofsick says. “When done properly, it becomes a financial success for everyone involved.”

Taking responsibility for decisions, from both employer and employee, becomes the balance point sought at a successful drycleaning operation.

You strive for a healthy relationship in your drycleaning store’s employee relations. It benefits all: the owner, the team, the customers, and the business overall.

So what does it take to create that special team environment?

“When we hire an employee we stress the importance of attention to detail,” says Ray Kroner, president of Kroner Dry Cleaners in Cincinnati, Ohio, in business since 1939.

“We want to make the ‘extra step’ our routine. Clear communication of goals and respect of our employees input is crucial to our success. Monthly production meetings go a long way in creating the team atmosphere,” Kroner points out.

In these meetings, he relates, “we discuss the state of the industry, unsatisfied customers, what we’re doing right, and where we can improve. More importantly then meetings is daily interaction with our employees. This creates a rapport that instills confidence and loyalty.”

Kroner says: “For 80 years we’ve contin- (continued)

ued to provide our garment care service to western Cincinnati. I am the third generation of the business. We have 25 employees, many who have been with us over 16 years.”

He notes they just celebrated their 80th year in business with a customer appreciation party.

“We invited our employees, family, friends and customers to a Saturday afternoon open house and over 250 people attended,” Kroner says.

There are short and long term goals associated with this official celebration, he notes. “First, and most importantly, it’s good to recognize the hard work of our employees and family, and mark the occasion.

“Second, it shows appreciation to our customer base and they continue to have confidence in our service. Lastly, we received recognition from county officials and the local news ran a short segment on the event. It played well on social media as well,” Kroner says.

He relates that after his business has a good month or good season, buying lunch for the staff goes a long way in showing appreciation.

“We are a family-oriented industry, and also very close to our communities,” he notes. “These elements are highly important for your drycleaning business longevity.”

He indicates that through growing routes, “We have evolved from a neighborhood cleaners. Yet, it’s still extremely important for us to demonstrate how personal this business is. We believe that your wardrobe is a piece of your personality and it’s our professional mission to protect our customer’s investment.”

About family involvement in business Kroner points out: “My family has always been active in church and civic

groups. My father Lou Kroner Jr. started a program called the Outstanding Young Citizens Banquet.

“The event recognizes students from ten of our areas junior high schools for being good civic leaders in their classroom. It couples them with sponsors from the business community. Teachers are also invited so we can thank them for their efforts as well.

“The banquet concludes with a guest speaker. In all about 100 attend. Along with my daughters and our marketing director, I have taken over the event. This year will be our 55th annual banquet.”

Kroner also adds a final thought about balance in employee relations: “When we use the term family it creates a bit of a challenge because we are still running a business. It is important for the employees to know that while you are compassionate to life’s obstacles, business comes first.”

Business is business, and the bottom-line rules, yet the front line of a service business is the interaction between that customer walking in the door and the team member at the counter. That’s critical.

“The employees we have on the counters and drive-thrus at our retail stores are the face of our company. They are a new customer’s first impression of our brand, and this is something we take very seriously,” points out Robert Walker, III, president of Max I. Walker, a 102-year-old drycleaning and laundry business serving the Omaha, Neb. metro area.

“We diversified our services in 1974 to include uniform rental and facility services. Today, both sides of the company are quite successful,” Walker relates. “We have 22 drycleaning stores in the metro area, and service uniform rental for nearly all the automotive dealerships in town, amongst other well-known companies throughout central and eastern Nebraska and western Iowa.”

(continued)

In total, he notes, his team consists of more than 120 team members across both divisions of the company, some who have worked there for 35 or more years.

Based on customer feedback, he indicates, “We know that our customers become and remain loyal to Max I. Walker because of people and relationships. We of course have extremely high standards and strict quality control, and employ the best methods and technology available for garment care.

“But beyond cleaning, we know that customers follow employees around if they move to a different location, that customers go out of their way to keep coming to their same store if they move to a new home, and that they know they could go elsewhere and pay less but choose to remain loyal to their local neighborhood dry cleaner because of the excellent customer service they receive.”

Team is a special feeling that takes everyone: owners, managers and employees, working together.

Walker describes how they create an environment where employees feel comfortable asking for help or advice, “even if it’s not work related, and we do what we can to help people out in times of need.”

He notes that: “While this approach is not infallible, it has proven to be successful with our rising stars. We have many incredibly hardworking and dedicated people on our team who have overcome some tough situations, in part due to our support and coaching.

“We like to think of our team members as family, and we treat them as such,” says Walker.

Can a team run self-directed so an owner can be away?

“We have a group of trusted managers and veteran employees whose judgment we trust entirely,” Walker explains.

“If they are left to temporarily run things, we know we can count on them to not let us down. These team members have gained our trust by repeatedly showing us they

are reliable, hardworking, and willing to go above and beyond because they care about this business and its success as much as we do,” he adds.

What tips can we pass on to other owners to help build a family feeling of trust for their drycleaning operations?

“Owners and management need to get out into their stores and build relationships with employees,” says Walker.

“Let them know you appreciate what they do for you, and that you are invested in their success. Work to overcome the ‘us versus them’ mentality — you’re all on the same team, with the same goal.”

He passes on these ideas: “Invest some time and resources into showing employees that you value them — actions speak louder than words.

“We have an annual family picnic day at a water park. We give each employee a turkey at Thanksgiving and a ham at Christmas. We do a monthly pizza party with birthday cake. And we hold an annual service awards luncheon where we recognize milestone anniversaries and give each honoree a gift commensurate with their length of employment,” he says.

Walker adds: “We also give out ‘kudos’ cards whenever we notice someone doing an exceptionally good job or going above and beyond, which they can turn in for $10.

“But above all else, genuine attention from top to bottom in the organization is key. An attempt to spend a little time with everyone no matter what their position is, as often as you can, is the key to strong leadership and a culture of family that persists,” Walker concludes.

Do you want to grow your special team feeling and grow an even more special workplace family feeling? Take some of these tips to heart. Many of you do this now. It’s a unique and personal business you run and the service you provide your clients and your community shows you always give 100 percent!

By Tim Burke, Editor

By Tim Burke, Editor

What was it like on your first day as a drycleaning owner? Or your first day in the dry cleaning business?

Can you remember back?

Let’s jog your memory with a trip along “memory boulevard” to when we first started out.

Two drycleaning owners share their memories, thoughts, anecdotes and lessons learned... in their own words.

First let’s hear from Joe Gagliostro, owner of Muldoon Dry Cleaners located in Auburn, N.Y.

“Muldoon Dry Cleaners Inc. was founded in 1925. We are a full service drycleaning company with two locations that specialize in couture care, along with same day service. I am the owner along with my wife Diana, and my main responsibility is running the day-to-day operations.

“I am a third generation dry cleaner, so I have had industry background my entire life. My family warned me that this is a very demanding line of work, with long hours, and that if I so chose to run it, then it would run me.

“All true.

“I started working open to close daily right out of high school in 2003 mainly because of a passion to carry on my

family’s legacy that took hold of me,” Gagliostro says.

“One thing I’ll never forget was when I first started out I wanted to impress my grandfather and come in extra early. I even dressed up.

“On this day, I arrived a few minutes before 7 a.m. We opened at 7:30.

“I was feeling really good about myself for being there a half hour before opening. Upon entering he said that he’d like to give me a little bit of advice to help me start my days.

“He said it would be best if I tried to come into work earlier than this from now on to start prepping!

“You could imagine my shock as an 18 year old who thought he just woke up and started extra early! In hindsight it was kind of funny that I thought I was ahead of the day and the store ate me up and spit me out.

“Years later,” he relates, “I was coming in so early that I even changed our store hours to open at 7 a.m. because customers were used to seeing me inside on their way to work!”

One of his best “lessons learned” is not to sell himself short, he points out.

Gagliostro says: “Accounts definitely (continued)

come and go. I used to push really hard to pick up commercial accounts or out of town route stops. Its very easy to lose sight of the work that is already at hand when trying to focus on making gains.

“I wish a few of them I hadn’t given such deep discounts to gain their business, because it didn’t last for a very long time, and I lost out.

“We would have been far better off charging our standard commission rates or without them at all. It’s taught me to do a better job selling my product for its quality and consistency in those situations.”

If you weren’t a dry cleaner Joe, what would you be doing?

“Honestly, I cannot image in my life not being a dry cleaner. I have no idea where I would be, or what I would do.

“I would think that most newcomers drawn into the drycleaning business have a history or family background to help influence that decision like mine. Perhaps some have gained knowledge working through the ranks also,” he says.

The saying goes: doctors want to save the world. And, probably, realtors want to buy it; and philosophers want to explain it; do dry cleaners want to clean the world?

“Do dry cleaners want to clean the world?... Heck yeah! I do!”

What advice can you give to someone starting out in dry cleaning?

Gagliostro says: “My advice to anyone starting out new in the drycleaning business is to give 100% to everything you do everyday. It will make you a better person in general. This business can wear you down, so you need to find the best in yourself.

“Focus on your customer service, make customers feel valued as they should be — they keep the door open!

“Try to educate yourself on technology and techniques to give yourself a competitive edge. Reinvest in your business through yourself. If you’re just starting out, you should be doing as much as you possibly can on your own. It will help to teach you, and your employees will respect you, knowing you can hop on that press like them too.

“Finally, keep up your machinery, and upgrade when necessary. It’s always better in the long run, your product will show it, and your customers will notice the difference!”

Next let’s hear from Kevin Kell, co-owner of Twin Kell Cleaners in Ft. Worth, Texas.

“Twin Kell Cleaners was established in 1989 by twin brothers Kent and Kevin Kell. The third generation dry cleaners have deep roots in the fabricare industry.

“Grandparents Tom and Oleta Kell started the family business in east Fort Worth in 1932 with a five-dollar gold piece. Hats and fedoras were huge back then and even though it was during the depression era, it seemed as if everyone wore a suit, tie and hat,” Kell notes.

Specializing in delicate and fragile garment restoration, the twins split their tasks complimenting each ones specific gifts. Kevin is more production oriented while Kent is the analytical one.

Kevin says, “Drycleaning gurus Stan Caplan, Norman Oehlke and Dan Eisen are my mentors for stain removal.”

He relates: “I was always entertained by Caplan. I just could never tell if he was shooting straight with me, but I loved his humor. He once told a story of reverse psychology I was particularly amused with.

“After discovering an ink pen load, and identifying the garment the pen was found in, he asked the customer for her insurance information.

“He explained that there was potential claim because of the number of garments that have been damaged in the process of cleaning her coat which contained the ink pen(!)”

Kent and Kevin’s dad Jack was quite the prankster himself, he explains.

Jack apparently perpetrated a laugh at the expense of a crony, as Kell further relates: “Upon noticing a bikini clad woman exiting a hair salon and heading

OurFounder, Mitsuyuki Uchikoshi began as a Dry Cleaner. Running a cleaning store, his eyes always went toward one thing – the pressing machines. Eventually, he decided to become a finishing equipment press manufacturer. This was the beginning of Sankosha Manufacturing over 40 years ago.

TheSankosha Dry Cleaning Store provided the inspiration to create new and innovative pressing equipment for future generations of our Industry.

OurState-of-the-Art manufacturing facility incorporates the latest in manufacturing technology for making the most reliable

to the beach, Jack enticed the woman to take part in a joke the next day.

“Dad was always harassing his friend about his everchanging, and trendy, hair styles.

“During the meeting the next day, in front of a hundred or so, the woman showed up in a bikini along with all her accessories claiming she was here to do an urgent makeover. She set up up shop right behind his unsuspecting friend and began doing his hair. She presumed to insinuate that his style needed an update, to look more like his attractive friend Kell!”

In another instance, he relates, a fellow buddy and Shriner from Corpus Christi, was in on this joke:

Kevin relates: “After Jack introduced the man as mayor of the city, the friend proceeded to claim he had the ‘keys to the city’ and invited everyone to a special tour the next day. When he was a no-show, the joke was over and everyone had a good laugh.”

His brother Kent recalls accounts of his dad anony-

mously placing goats in the bathtub of a friend’s hotel room. “He is always up for a good prank,” claims Kent.

After Kent and Kevin graduated from TCU in 1984, they went to work for their father and immediately began to learn the customer service aspect of the business. Fresh off studying the principle’s of Sid Tuchman, Kevin notes, they focused on important questions to ask customers about their clothes.

“I remember one incident,” Kevin recalls. “I was caught walking across the parking lot from the main office one day. I noticed a long Cadillac of which a woman rolled her window down and began to whistle at me. As I approached her she must have thought we offered a valet service.

“Since this was pre-computer age and I did not have an invoice handy, I realized she intended for me to grab the massive bundle in her back seat. Feeling the pressure of remembering basic information I asked her if she had any stains or repairs.

“She said ‘yes,’ pulling out the garment and placing it on the top of the pile under my nose. I asked her if she had any idea what the stain was. She paused, lifted her head back and said, ‘Why it’s menstrual, fool.’”

Kell also reminds that, “You have to have some common sense in this business. I would be leery of what I gave back to customers. Such as returning a tube of lipstick to the wife of a customer at pickup — when the husband dropped the clothes off — was obviously not a good choice. Of course the lipstick was not hers!”

Kevin says he loves the restoration part of the business.

“I tell our staff all the time there could be as many as seven or eight different processes involved with stain removal and this requires additional time. We will not press any garment, unless it is a rush, until we have exhausted all stain removal possibilities within reason. We may have to apologize for a garment being late but we will not apologize for poor quality. The times we have damaged garments are times we have moved hastily or been rushed,” he notes.

Kell is also involved with the environmental side of the business. He serves as a director of the Southwest Drycleaners Association (SDA) as well as the small business advisory committee of the Texas Commission on Environmental Quality.

With the influx of microfibers and the comfort of athletic wear, the casual look is trending. “Workout clothes are for working out,” says Kell. “I guess I long for the days of my grandparents. Bring back the suits and fedoras!”

There we have two drycleaning owners describing memories and sharing thoughts. Did that stir up stories of your own? We hope so. That’s what you get when strolling down drycleaning’s memory lane.

Recognize all the special opportunities warm weather brings

For most of you, summer represents a seasonal down turn in business. For those whose summer is a busy time, you may apply the following suggestions to your slowest period of the year. Either way, there are opportu nities in the entire range of business components.

Regardless of seasonal sales vol ume, the first thing on your calendar for this June should be the Clean Show 2019, for all the reasons that have been covered in detail in previ ous articles including: Networking, education, and rewarding your team for their accomplishments.

Keeping the plant and stores productive during seasonal downturns takes imagination, plus sales and marketing effort. Advance planning and implementation of that plan can keep your operation as busy as you want it to be.

Your slowest sales period is the best time to plan vaca tions for everyone in the company including you, for:

• The rejuvenation everybody needs to be top performers;

• Perspective on why customers find your service so valuable;

• A chance to experience new approaches to customer service, comfort and interaction;

• Time to think and dream about personal and business ideas.

It also avoids the need for paying overtime if vacations are taken during other busy stretches during the year.

Everyone in the company benefits from continual train ing that lifts their performance to a higher level. That benefit is directly passed through to the P&L. The higher level of performance afforded by training, and improved efficiency, provides a win to the employee, the company and the customer.

It is easier to schedule training and attain maximum par ticipation when traffic is lower.

In addition to obvious wardrobe care, your retail cus tomers have many textile items that need periodic cleaning like rugs (indoor and out), curtains and drapes, pillows, cushions, shades, heirloom garments, wall hangings, quilts, blankets, throws, door and car mats, patio umbrel las and shades, stuffed animals, pet beds, horse blankets, boots, slippers and shoes, and more. Summer is a good time to clean these and many more seasonal items.

Keeping a record of cleaning dates provides you a tick ler file to remind the customer when those items are next due for a cleaning. Your customer will appreciate this!

Seasonal cleaning projects provide a good way to intro duce your wide range of services to new customers that don’t automatically think you can do this work for them.

Reach out beyond your normal retail customer base. One common traditional outreach program that has filled summertime sales gaps has been school band and choir uniform cleaning. This can be further developed with more schools, churches, and other institutions, such as professional symphony orchestras, theater groups and performers.

Another seasonal occurrence that can provide volume business arises in the form of camps for both children and adults. Most of them are

At the heart of SMRT, we are a dry cleaner. It’s the reason we created our software in the first place: To solve the everyday problems we ran into at our own business.

We’ve stood in your shoes -- pressing, cleaning the button trap, filling in when the driver is sick, making payroll, and replacing equipment.

And with a dry cleaner’s perspective, we’ve built, from the ground up, the best dry cleaning software in the marketplace.

We understand that dry cleaners are dynamic, high-performing entrepreneurs. It’s no small feat to run both the factory and the dealership every damn day. You deserve a software partner that knows your business and is there for you 24/7. You deserve SMRT.

Next-level customer service to match their next-level technology. The SMRT team is passionate about solving problems and supporting their users.

Jason Yerby

Vice President: Crest Advanced Dry Cleaners

There’s more to SMRT than great software. They really know the business, bringing a new dimension to customer support.

Daniel Cha

Owner: Orchid Dry Cleaners

SMRT is light years ahead of the competition! We’ve never been so on top of our business and in tune with our customers.

Wayne Edelman

Owner: Meurice Garment Care

Robust

Richard Aviles

Owner: Bridge Cleaners & Tailors, King Garment Care

much more service-oriented than the “roughing it” envi ronment you may be imagining. They provide laundry and drycleaning to the participants via third party suppliers like you.

A further source of work is presented by business education conferences. Famous examples are college ad vanced management programs. The majority of colleges and universities sponsor extended executive education programs with a variety of themes, such as: leadership, management, finance for non-financial managers.

Other programs focus on adult learning of all types including great courses and academic pursuits, as well as skills development of all types. The list is endless!

Search your local college and university programs for the fabricare services needed by sponsors and participants.

Educational and other institutions are working to keep their facilities revenue-producing during breaks in their regular academic schedules. Visit most campuses dur ing “breaks” and you will be surprised at the number of people on campus participating in short-term programs like Rhodes Scholars.

Remember to ask about the linen needs (both residence and dining) as well as the apparel cleaning.

To appreciate the magnitude of this sales opportunity, review a list of all the event venues in your area.

You will be astounded at the number of sites that exist for general or special purpose usage. For example, Kansas City has 292 locations listed for “parties” alone.

There is a tremendous amount of work to be done for both repetitive use and for décor care. Ask if they have drapes, decorative pillows, that need periodic cleaning.

Schedule these projects whenever they can release them for the intermittent cleaning.

These opportunities can be greatly enhanced by involv ing the entire associate team. Paying a small commission on these projects will tempt your employees to approach their social and family contacts to let them know the unique and helpful services you can provide.

Off-season is a logical time to make desired changes in your plant and processes.

The temporary disruption caused by equipment move ment and efficiency layout changes can best be diminished when the workload is not overwhelming the plant and workforce.

Staff can become familiar with new systems when they

are under less immediate time pressure. Training classes can be scheduled away from the continuous customer interaction removing the anxiety customers and staff may feel as a result of visible front-line training.

Examples of process changes that can benefit from off-season timing include converting to a new or upgraded Point-of-Sale (POS) system, mark-in or barcoding up grades, and customer service and interaction upgrades.

Summer is a beneficial season to hold your planning retreat with key team members and to get them away from the daily challenges all at one time to focus on the ideal future of the company and how to achieve it.

An attractive outdoor venue and comfortable casual ap parel can inspire the willingness to open the discussion to more creativity and original thinking.

What changes should you make in your product line to better align it with the needs of your customers and their lifestyles?

Expanded wash and fold services have augmented the narrow traditional “dryclean only” image adapting to a more casual lifestyle that is so full that doing one’s own laundry seems like a waste of scarce valuable time.

Ultrasonic cleaning is another current example of adap tation in product line that extends your service.

Pricing deserves continual focused review to determine right-pricing based on covering costs, profit and consumer value.

Is your current physical and mobile footprint optimized or is it outdated and in need of realignment?

Whatever your key professional or personal goals, sum mer is a beneficial time to move them forward. ADC

Diana Vollmer is a managing director for Methods for Management, which has served dry cleaners and launder ers with affordable management expertise and improved profitability since 1953. For assistance brainstorming how to plan and leverage Summer 2019 for your maximum benefit, contact her at dvollmer@mfmi.com or call 415-577-6544.

Today — or soon — you’ll probably read in a newspaper or online about land that needs cleaning up. At times drycleaning operations are involved. Those headlines get your attention.

But do you really know enough about the topic of site remediation? What if it happened to your business? You should at least be armed with some info about this. Here’s a chance to let your knowledge bud. I’ve invited Jeff Carnahan, president of EnviroForensics, to a Q&A session about this topic, where we can hear new ideas sprouting.

Here we grow.... Welcome Jeff, let’s get started:

Tim: “First, tell readers about your company and yourself.”

Jeff: “EnviroForensics is a full-service environmental engineering and consulting firm. We take care of immediate exposure concerns, like vapor intrusion, cleanup contamination, and help our clients get out of the hot seat with the regulators. What makes us different is our in-house

insurance archeology division, PolicyFind which helps our clients find and assemble their old commercial general liability insurance policies to help them pay for the huge cost of these types of projects.

“I’m a geologist and a scientist and I’ve been an environmental consultant for over 20 years. For the last 10 years with EnviroForensics, I’ve been fortunate to have focused my efforts on assisting the drycleaning community.”

Tim: “Let’s familiarize everyone with the topic of site remediation. Briefly define it for drycleaning owners.” Jeff: “Environmental site remediation is the process of addressing and cleaning up subsurface contamination. Usually, this is performed with oversight by a state or federal regulatory agency, who will provide some level of case closure when the process is complete.

“In the drycleaning industry, most significant contamination issues are related to the past usage of perchloroethylene, or Perc. Accidental releases of Perc may have happened during machine filling, waste

White Conveyors’ SUV-OAS is the perfect solution to boost your productivity, improve customer service and increase your profits while reducing your operating costs. The system is delivered fully assembled, and can be operational in less than two hours. As an option, it can be mounted on wheels for mobility or storage. Simply set it up on its supports, plug in the power, connect the computer, and link the system to an Internet connection. It’s time to begin realizing remarkable time and money savings.

Easy to use

Reduces labor costs

Increases productivity

Assembles over 2000 pieces per shift

Interfaces with all major POS systems

Can utilize a bar-code or RFID chip system

Easy-to-read computer touch screen

Highly accurate and reliable

Fast return on investment

Proudly made in the USA with fast support

handling, or even from discharges of separator water down the sewer.

“Typically, we see three different types of subsurface contamination at Perc sites: 1. Soil contamination; 2. Groundwater contamination; and 3. Soil gas, or vapor contamination.”

Tim: “Please tell us more Jeff.”

Jeff: “Perc contamination can be quite serious and expen sive to clean up, and it may take years to complete. A common initial action is to perform some surgical excavation of contaminated soil from the most heavily impacted area. This slows down the continued migration of Perc from soil to groundwater, which then allows efforts to be turned to the vapor and groundwater issues.

“Since Perc is highly volatile, which is one reason why it’s such a good solvent, vapors in soil can be removed using spe cially designed vacuum blower systems. Groundwater contamination is com monly reduced using chemicals that are injected into the ground to either oxidize the Perc and break it down to harmless by-products, or to promote the break down of the Perc by naturally occurring microbes.”

Tim: “Who gets the ball rolling about an issue with a site? The drycleaning owner? The town?”

Jeff: “An environmental contamination issue is usually discovered as a result of some type of real estate or financial transaction. If the dry cleaner owner were to go to a bank to refinance a busi ness loan using the business or property as collateral, the bank would require an investigation.

“Similarly, if a potential buyer of the property were to go to a bank to finance the purchase, an investigation would also be required. Sometimes, a nearby property is undergo ing these types of financial transactions and as a result of an investigation on their own site, they may run across con tamination that originated from the drycleaning site.

“In these scenarios, the neighbor typically reports it to the state environmental agency, who in turn makes a demand on the dry cleaner to perform an investigation on their own property. In any of these scenarios, the state en vironmental agency would usually make a demand and has the authority to require that an investigation and cleanup be performed.”

Tim: “Can you tell us, generally speaking, about remediation efforts at dry cleaners?”

Jeff: “We have many drycleaning case studies that cover

a variety of scenarios. For example, here’s a few we have:

1. A dry cleaner’s operations caused vapor intrusion at a midwest high school. The historical insurance assets paid for both the investigation and remediation efforts.

2. An active dry cleaner on the west coast was able to stay open for business while we cleaned up their contamina tion, which was all funded by their historical insurance assets.

3. A prominent second-generation dry cleaner proactively prepared to sell their business. We conducted insur ance archeology which uncovered historical assets that insured the policyholder if contamination was found during due diligence/Phase I and II.

4. A bankrupt dry cleaner defaulted on its loan with the bank and the new property owners con tacted us to clean up the contaminated property. We were able to locate histori cal insurance assets to fund the cleanup. Additionally, we implemented a thermal remediation technology that cleaned up the property in 120 days.

5. A dry cleaner that was a part of the Wisconsin DERF enlisted our firm to conduct insurance archeology when their money ran out. We located histori cal insurance to pay for the cleanup. The dry cleaner was able to sell the property, which is now being redeveloped.”

(Editor’s Note about DERF: Its website says: “The Dry Cleaner Envi ronmental Response Fund, or DERF, reimburses the investigation and cleanup costs of contamination caused by dry cleaning chemical discharges.)

Tim: “As we wrap up our Q&A Jeff, let’s make sure we understand the phrase you used earlier, ‘insurance arche ology’ for everyone?”

Jeff: “Sure. We have a division in our company called PolicyFind and what we do is go back through any and all of our clients’ records to help them find old insurance policies, which can help pay for these environmental is sues, cleanups, and maybe even cover attorney fees for them. This is really the meat of what we do for dryclean ing owners.”

Tim: “I see, and are there any final words of wisdom for an owner?”

Jeff: “It’s always best when the drycleaning owner is proactive in these situations.”

Thank you very much Jeff for being with us today and digging into the topic of site remediation.

Wet cleaning is better & faster than dry cleaning. We wet clean anything from wool suits to wedding gowns.

—

—

Poseidon offers innovative programmability for complete control over every conditional aspect of the wet cleaning, drying and ironing process. That’s why professional fabricare operations rely on Poseidon equipment to perfectly wet clean the most delicate items including tailored wool suits, cashmere sweaters, silk wedding dresses, and so much more! CALL 800-482-3400

“

”

Gary Heflin, Owner, Perfect Cleaners

Phil gives a dog biscuit to little Canella. Her owner Angelina and her seem to have come in just to say their goodbyes. (Photos by Tim

By Tim BurkeDogs wag their tails to show they’re happy, we all know that.

Well, lots of tail-wagging went on at Phil’s place over here just northwest of downtown Chicago.

After a romp in the nearby park, neighbors brought their dogs over to make the ritual stop at Phil’s to get a dog biscuit.

Phil is Phil Luparello.

He and his wife Marie own Hollywood Cleaners, a business started by his father-in-law Nunzio “Bud” Raimondi, back in September 1947. But Phil is retiring, closing his business for good as of June 1.

American Drycleaner editor Tim Burke stopped by to chat with him on a spring morning recently.

“I’m going to miss my customers and their dogs,” Phil says with a twinge of ‘old country’ Italian in his voice and a little wistful twinkle in his eyes.

Where Milwaukee Ave. meets Evergreen Ave. is a friendly blue-collar neighborhood, a mix of old and new, where everyone knows everyone else by their first name it seems. It’s a little burg, sort of, inside a big metro city space.

And all the neighbors and their doggies know the cleaner who gives them a big smile, chats over coffees early in the morning long before opening, and gives out doggie treats to all their poochies.

Phil came to work in 1981. “Let’s see,” he scratches his chin, “it was, umm, March of ’81. Then I took over in 1982.”

He worked formerly at Brach’s candy co. “I was a candy machine operator,” he relates with a big grin.

“What was your favorite candy?” I ask.

“All of them!”

We laugh together and a customer who has just entered, hears us and

giggles. She’s carrying her pooch.

Phil is coming around the counter with a dog biscuit.

“This is Angelina,” he smiles and nods from me to the woman, who also has a big smile on her face.

“And this,” he says

Neighbors and their

are gonna really miss Phil

lovingly, “is Canella!” He pets the little chihuahua who seems eager to accept his touch, like an old friend, and then the doggie senses in anticipa tion what’s in Phil’s hand.

“Here you go,” he beams and holds out the treat to the pup. “Canella means Cinnamon you know,” he says to me with warm smiling eyes.

Phil has recently decided to close the cleaning business, sell the building he and Marie have owned, and enjoy a life of retirement.

“I’m 64 and I want to relax a bit. Retail is down a bit so why not. It feels like time. I’m not sure what I’ll do, but I have two grandsons on the way,” Phil laughs, “and I know I’ll be babysitting!”

His customers continue to stream in and out. With each opening of the door, he steps around the counter, calls out to greet his customer by first name, and then their dog by name, and gives the pooch a dog biscuit. The poochies all come in with tails wag

ging. They know Phil very well!

I take a moment to ask Angelina, who is paying for her freshly cleaned clothing, how she feels about Phil closing.

“I’ll miss him very much,” she pauses and nods down to her pooch, “we’ll miss him very much. The neighborhood will miss him very much.”

The customers come in smiling, and Phil beams at them all, but there is a tiny note of sadness in the air too be cause they all know he is closing.

His cleaners is a place of comfort. He loves dogs so much. He loved his own dog, his best buddy “Sammy” who came to work everyday with him for 13 years, “Seven days a week,” Phil says. He points to his beloved Sammy’s photo framed above and be hind the counter.

“Sammy lived here,” Phil relates, “I couldn’t even take him outside of the store at the end of the day, he would shake all over. Everyone knew

Sammy.”

Posters and signs above us reflect Chicago history, sports achievements, old movies, and special moments in his family’s cleaning history.

The high walls up above the big front counter area seem to be whisper ing from the past — old tales full of memories of the joys of neighborhood customers and their life stories.

Phil and Marie will enjoy retire ment. When Phil shuts the doors, they close a quality Wicker Park cleaning business that served their neighbors for 71 years, and gave out about a mil lion doggie treats.

Two customers picking up cleaning just now, with their playful puppy in tow, grab a treat from Phil as he says lovingly, “I’ve always treated all the dogs like they were my own.”

We shake hands and I thank Phil for his time. As I leave, I can’t help think ing I’ve visited a really special place, not only for all the people, but all the dogs! Happy retirement Phil! ADC

The production area of a drycleaning plant has never been a real hospitable location to work. Most are a concrete floor, surrounded by steam pipes; with equipment breaking down much of the air flow through the area.

I was once in a finishing area with a 6 ½ foot ceiling and a single 36-inch fan mounted in the back wall to draw air through the area. While locations that have been designed and built from the ground up for dry cleaning are much better; there are still a number of “converted” buildings that have their layout dictated by the space available.

If you are spotting garments in a back corner, behind the drycleaning machine, your work day can be a challenge.

There are several little things that require only thought and effort and very little financial investment but can improve the working environment.

Anything that improves working conditions is worth consideration. Productivity may be fine at 9 a.m., but if it has declined by a third at 2 p.m., that is a problem.

The production area of a drycleaning plant usually recalls heat and humidity. It is rare to talk with an operator that has solved this problem for employees.

It is common to find production areas that resemble a wind tunnel during the weeks between mid-June and midSeptember. I commend operators that have tried to minimize the heat and humidity of the working environment in their plant.

One of the better efforts I have encountered was in south Georgia, in August. Below a 12-foot ceiling was a slotted, drop ceiling, with A/C vents over each work station. A 24-inch fan was installed between the drop ceiling and the roof; one in the front wall and another in the back wall, to draw the warm air out of the building.

Swamp coolers are by far the most common choice to deal with the heat of the production area. The effective-

ness is determined by the variations in outside humidity. By forcing air into the area, warm air is forced to the ceiling and away from employees.

I have been told that hoods installed at a height of seven feet, on a central exhaust duct, are effective in removing rising steam and heat above finishing equipment.

Employees deserve the same consideration as machinery. That includes maintenance of the environment they work in each day.

Managing steam can make a world of difference in the work area.

When leaking valves are spewing steam into the air, they add both heat and moisture, which results in additional discomfort. It also increases burn time for your boiler, which means a higher than necessary fuel expense.

Most leaking valves, when caught early, can be quickly and inexpensively disassembled and inspected. Worn “seats” can be replaced and the valve is returned to service in about 30 minutes.

All steam and return pipes should be insulated, starting at the boiler and all the way back to the return tank. Worn insulation and uncovered steam pipes are a safety hazard and the exposed surfaces will add additional heat to the work area.

There is a good chance that a visit from the Occupational Safety and Health Administration (OSHA) will result in a citation and probably a fine. Do not put it off. It will save you money and make the production area a more comfortable place to work.

Almost all tasks performed in a drycleaning plant are done while standing or walking. The addition of anti-fatigue run-

Employees work better in better conditions aka cooling, flooring, lighting(Photo by Tim Burke)

„SENSENE continues to prove itself effective and efficient. This is an amazing product with a high cleaning power combined with excellent material compatibility. Finally, it‘s what we all have been waiting for.“

As Ben Franklin used to say, “A penny saved is a penny earned.” It’s a saying that guides many of us as owners in the drycleaning industry. Every day we monitor our labor costs, supply costs, and utility costs to make sure that we’re not wasting one penny that could be going to the bottom line.

Frequently, owners ask me questions about sales. How do I find new customers? How should I advertise to get new people in the door? How do I grow revenue?

I would argue that the best way to grow revenue is to make sure you save the revenue you’ve already got.

After all, just like pennies, revenue saved is revenue earned.

question is how do we keep it from leaking in the first place?

Here are four steps.

1. Execute

Research has consistently shown that the vast majority of drycleaning and laundry customers will stay with their current cleaner until there is a major problem like a lost item. Thus, deliver great service to your customers.

2. Monitor

Do you know how many of your customers haven’t visited you in the last month? Retaining customers is all about identifying signs from your customer.

3. Listen

Once you know which customers may be wavering, it’s critical to engage with them and listen. It never hurts to call or send an e-mail and connect.

To illustrate the power of revenue saved, or “revenue retention,” as it is commonly called, I like to think of revenue in a bucket. Pretend your bucket contains all of your revenue from the previous year, say $500,000.

For example, let’s assume you followed Ben Franklin’s maxim to the letter and managed to retain all of your customers from the previous year. That means you would have $500,000 in revenue — a full bucket.

Now, let’s say your marketing attracts 100 new customers each month and they spend an average of $100 per year. You would have $120,000 in new revenue.

Sales is up $120,000! Your bucket is overflowing!

Of course we as drycleaning owners often get distracted by the chase for new customers and we forget about our current customers. As a result, our bucket starts leaking and we retain only 75% of the revenue.

That means even before you start getting new customers, you’ve lost $125,000 of revenue. So by year end sales are actually down to $495,000.

Now that we know the dangers of the leaky bucket, the

4. Inform

Retaining revenue isn’t just about saving customers who were about to leave, it’s also about informing current customers of all that you have to offer. I’m always astounded by customers of ours who have been with us for years and say, “I didn’t know you did comforters.”

Show your customers the range of services that you provide If you’re successful enough in this strategy, you can increase revenue without ever getting a new customer. Now that’s revenue saved!

If you’re skeptical of the power of saving revenue, I would issue a challenge to you. Try to retain 100% of revenue from last year. Execute on your core business, monitor, listen, and tell customers about all of your services.

I can promise you that, though you may not hit 100% retention, you will see a marked increase in sales and a whole lot more pennies in your bank account!

ADC

Dan Miller is the chief executive officer of Mulberrys Garment Care, a premium drycleaning and laundry business with 17 locations in Minneapolis, San Francisco, and Dallas. You may contact him at dmiller@mulberryscleaners.com or 866-473-0798.

For the past 20 years, GreenEarth Cleaning says, it has provided what it describes as, “An envi

ronmentally non-toxic technol ogy to thousands of dry cleaners around the world who in turn have

cleaned some 500 million pounds of clothes during that time.”

The firm says: “This sustain able technology has allowed GreenEarth cleaners to use less energy, less chemicals, a process that is proven to be environmen tally non-toxic, and is gentler for clothes and our planet.

“As a result, the technology has been embraced by the real estate, financial services, insurance, and garment manufacturing and retail ing industries as well,” it adds.

Twenty years later, GreenEarth relates, it is finding new ways to help “Mother Earth.”

“Our planet’s oceans are filled with plastics large and small,” the firm points out. “Efforts to remove macro-plastic waste have begun and are highly visible.

“However, millions of micro plastic fibers are released into the world’s wastewater treatment sys tems when garments containing polyester are laundered,” the com pany states. “This plastic poses an equal danger to our oceans’ eco systems as it enters the food chain at the micro level.”

Importantly, the company re lates, environmental focus has now caused it to address the mi cro plastic challenge posed by the laundering of polyester clothing.

“We are a member of the Sus tainable Apparel Coalition,” GreenEarth notes, “and we want to be a part of the solution to this problem.

“We are currently testing ways

By Tim Burke, Editor

By Tim Burke, Editor

There may not be another sight so memorable today as that which hits the unsuspecting driver, out tak ing a nice quiet-morning, summer drive, and coming unexpectedly upon that bike rider, you know the one, donning a Spandex outfit, trying, it would seem, to recreate Le Tour de France along his hometown roadway.

Spandex, as Norman Oehlke write’s in American Drycleaner’s Spotting Guide, “Is similar in appearance to rubber yarns, but it is superior in its resistance to solvents, flexing, age, sunlight and weather. Items containing Spandex are comfortable to wear, and the fiber contributes to the smooth appearance of the garment while worn. A small percentage of Spandex fibers is found in many fashion items.”

So there! <nyah nyah>

“Spandex is a fiber that has had an impact on fashion high and low, casual and formal, outer and under,” according to the Merriam-Webster dictionary. Spandex, it goes on to note, “is a generic term, coined in 1959 as an anagram of the word expands.”

Oehlke reminds that professional dry cleaners must learn to refrain from identifying any item contain ing elastic as “rubber elastic.” High heat usually doesn’t damage rubber, but high heat and the use of chlorine, on the other hand, damages Spandex. For dry clean ing use, “Slightly shorter cycles and a maximum temperature of 120 F. For finishing: Use light buck steam.”

Think of that smart choice in

fabric made, next time you see someone out riding Le Tour de Lycra!

“It flexes and ages well,” you quip to yourself, “even if we don’t so much!” ADCPhoto by Tim Burke

to filter the micro plastic fibers out of the discharge from washing machines used to launder (rather than dry clean) clothing so that the micro plastic fibers are never released in the first place,” says Ron Benjamin, co-founder and managing director of GreenEarth

Cleaning.

The company says its goal is to, “Make all garment care safe for our planet, whether using closed loop drycleaning machines or filtered washing machines, so that GreenEarth Cleaning becomes BlueSea Laun dry as well!”

One day, Alex Yearout decided to start upgrading his business, Complete Cleaners, located in Trussville, Ala., one step at a time.

“First I had to upgrade my computer system,” Yearout

His is a noticeably unhurried voice saying: “That led me to researching new technology and that led to

“done in stages,” and adds he went from manual assembly to automation: “We weaned off the old way.”

(Photo: Complete Cleaners)

automation,” he adds.

“One thing leads to another often enough,” he postu lates, saying, “When you go from manual assembly to au tomated assembly, that naturally just led to an overhaul.”

The Cleaners wanted to improve productivity.

“We did an overhaul in stages,” Yearout explains. “Mark-in, inspection, send-to-bagging, all done in bits and pieces, so we could get used to everything on our own pace.”

A customized SUV-OAS solution to address issues regarding space and the quantity of garments needing assembly, from White Conveyors, was part of this over haul.

Yearout says with a calm laugh: “Now we heat-seal our brains out!”

Before his upgrade decision, his plant didn’t have the room to manually assemble so they were using his dry store and making three to four trips a day, he points out. That was rushing. Not any more. The new system allows him to assemble in a 100 sq. ft. space.

What’s the upshot?

Yearout says: “We can identify garments better. So we have better personal relationships with customers and we can research their names and see how often a piece comes in.

“We are keeping a better inventory for our customers. Labor intensity has decreased in mark-in and inspection. We have more time to look at garments, and do it bet ter,” he remarks.

Alex Yearout is a drycleaning owner who sounds calm and collected over the phone.

“We weaned off the old way,” he yawns over the phone line. He sounds truly happy saying it.

“And for each other’s sake, we are smoother.” ADC

The following companies and organizations reserved exhibit space in the Ernest N. Morial Convention Center, New Orleans, for Clean 2019 during the 30-day period ending May 6, according to show manager Riddle & Associates.

At press time, the total number of exhibitors was approaching 440 (see our Clean 2019 Show Guide issue published in May for

❏

A.I. Care LLC 1109

Boutique organization focusing on providing healthcare solutions to healthcare facilities and individuals.

❏

❏

ClickHeat 4904 Reusable instant heat packs

Eagleby International 4920

Supplier of laundry and drycleaning consumables, including poly bags/film, hangers, paper products and pins.

❏

GoDaddy Social 4111

Social media networks management.

❏ Harmony Cleaning Systems 3765

Professional wetcleaning system.

❏ Highland Capital Corp. 4911 Equipment financing solutions.

❏ IPA 4901

Automated surgical scrub and linen dispensing equipment for healthcare providers.

❏ Jiangsu BE-SAFE Medical Technology Co. Ltd. 4921 Research, production and sales of protective medical textiles, including reusable surgical gowns, surgical drapes.

❏ Mat Master Technology LLC 4900 Mat processing system with RFID route building.

the initial list); it’s possible more exhibitors will be added in the final weeks leading up to the June 20-23 event.

Where available, the descriptions of products and/or services provided here are general in nature and should not be considered all-inclusive. Listings are subject to change without notice. Check www.cleanshow.com for any updates.

❏ Mayfield Group Advertising Bureau 1208 Advertising and marketing services for dry cleaners and laundries.

❏ My Shoe Hospital 4906 Shoe repair service.

❏ Newhouse Specialty Co. 4874

Maker of specialty products for the laundry, drycleaning and garment manufacturing industries.

❏ Ningbo Dasheng Daily-Products Co. Ltd. 4919 Manufactures plastic and wire laundry hangers.

❏ Suzhou Lingwei Textile Inc. 1210

❏ SWECO 4905 Vibratory separators for laundry applications.

❏ Tektem Makina San. Ve Dis Tic. Ltd. Sti. 4908

❏ TexTrax 4912 Software for laundry operations, linen management and route accounting.

❏ Vendors Exchange 1111 Vending equipment and parts. ADC

ners in the traffic areas, will reduce stress on joints.

Concrete is great as a building material, but as a shiftlong walking surface, it could use some help.

Foam anti-fatigue runner material can be purchased in a variety of thickness and cut to custom length, on site, with a good pair of scissors. Placed on the employee side of the counter, the length of any inspection area, in the route receiving area, the length of the finishing area, it will sig nificantly reduce discomfort and increase productivity.

In addition, there are mats available. Placing a mat at the work station where one is “dancing in one spot,” will enhance both productivity and quality.

Standing at the board on one foot while operating the pedals with your other foot can be uncomfortable.

I have been in plants where the customer, who is the final inspector, has found a spot in the light of the window at the counter. The operator has only to return to the spotting board and have the stain disappear in the available light.

You can’t do the job of supplemental stain removal in the dark. A 60-watt, incandescent bulb just isn’t going to get the job done. A single, un-reflected, T-12 cool white is not enough over the board.

Replace T-12 fixtures with T-8 fixtures instead of replacing T-12 tubes. At minimum, I recommend a double T-8 fixture with daylight/natural tubes.

To recap: The production area of a drycleaning plant can get uncomfortable. Remember these tips:

Be cool. Give top priority to moving heat and steam away from work stations and even dropping treated air into the work area. The employee will perform at a higher level for a longer period. This includes strict mainte nance to steam leaks and insulation of piping.

Walk tall. Add anti-fatigue foam in high traffic areas and anti-fatigue mats at work stations. You will be increasing the potential stamina of employees.

See me. The spotting board does not just need some light, the spotting board needs the right light — and plenty of it.

The Clean Show is coming in June to one of my favorite cities, New Orleans. If you are someone that has never been to the Clean Show, get your plans together. Let’s make 2019 the year of first-time attendees. You will not be disappointed.

ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates today. Phone: 704-786-3011, e-mail: mayoung@ctc.net.

three- and 12-time rates. If box number is used,

add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month.

For example, for a June ad, the closing date is May 1st.

PAYMENT FOR CLASSIFIED ADS: Must accompany order.

More than 60 years’ experience. We are the experts in silks, knits, French weaving and piece weaving. Reasonable prices. Send garments for estimate to: 3344 W. Bryn Mawr, Chicago, IL 60659; 800-475-4922; www.withoutatrace.com.

10 YEARS AGO. Consumer prices were flat last month after declining 0.1% in March. Drops in food and energy costs were offset by increases in medical care and automobiles. Excluding food and fuel, core prices grew 0.3%, partly due to an increase in excise taxes on cigarettes. The consumer price index (CPI) fell 0.7% in year-yo-year comparisons, the largest decline since 1955.

35 YEARS AGO. Explaining moth damage to customers: some tips. The U.S. Wool Bureau offers these tips on protecting garments from moths. IFI suggests that you pass them along to your customers. Make sure articles have been cleaned thoroughly before storing them away. Moths are drawn to soiled areas on garments. To get the most protection for hanging garments, hang your mothballs or crystals in a ventilated container on the hanger. The vapors from the balls or crystals are heavier than air and will fall, not rise. Don’t store garments with mothballs or crystals in flimsy plastic bags, the vapors will eat right through the plastic. Use airtight storage boxes, if possible. If you hate the smell of mothballs or crystals, use a nonresidual spray, applied directly to the garments. Sprays containing allethrin, pyrethrin, or resmethrin are safe.

50 YEARS AGO. How Lazy Can You Get? A motor-driven fishing rod

reel, made by a Japanese company, has a switch that automatically activates the reel when a fish nibbles the bait. … Can the Yakkity-Yak Chit-chat is blamed for workers’ irritability. A space-planning company surveyed 350 firms of all types and found that few workers were bothered by noise from equipment. The most bothersome noise is the human voice! Which reminds us of the cleaner in downstate Illinois who has a strict rule against talking among employees. Maybe he’s got a point! … Machine Banking. A check-cashing machine that operates 24 hours a day has been installed by some banks. It’s been tested in 10 branch banks in the Philadelphia area as well as two in Massachusetts. The machines dispense cash in pre-determined amounts when a bank customer inserts a special voucher and taps out a secret number on a keyboard. … Here’s the motto from a dry cleaner in Florida: “Let Us Be Your Press Agent.” Do you have a clever motto?

75 YEARS AGO. Good News! This news may, in time, mean the end of color-changes in dresses, especially blue one, for which cleaners get the blame but which are really caused by sulfur gas in the home: A new method of dyeing acetate rayon fabrics is reported to give them a high degree of resistance

June 1944 American Drycleaner front cover.

to atmospheric gas fading. … 25-Year Record. A cleaners in Hollywood, California, has a route man who hasn’t missed one day of work or had an accident in 25 years. Employers recently presented the man with an engraved gold watch. He has traveled over half a million miles, including his mileage in the early days by horse and wagon, and has over 100 customers who have been with him throughout his service. His customer list has included such film celebrities as Tom Mix, Theda Bara, Edward Everett Horton, George McManus, Louella Parsons, Jack Mulhall, and Lottie Pickford. ADC

— Compiled by Tim Burke, Editor

To read more of American Drycleaner’s chronicling of the industry over the years, visit www. americandrycleaner.com.

101-105 Series

We expect 15 to 25 years from our interchangeable tube bundles, and 30 to 40 years of life our more out the boiler.

209-211 Series

We normally expect 10-25 years out of the copper heat exchanger, 30 to 40 years out of the boiler.

207 Series

We expect 30 to 50 years out of our thermal fluid heater models

On all of the above units we have continued to build, and will continue to have available any part of the pressure vessel, burners, cabinet, and controls meaning that for as long as a customer wants, they will be able to infinitely repair their equipment rather than replace the equipment.

We are asked by many new and existing customers on what is our projected life expectancy of our products. We are not always the lowest initial price but know we have one of the lowest cost of ownership of any boiler manufactured in North America. These facts are based on our 90 plus years of boiler manufacturing, feedback and experiences from our end users, service departments, and all of our representatives and dealers worldwide. These life spans are based on our boilers being installed properly, and do receive our minimal recommended care, are applied to the correct application, and include the proper maintenance and water treatment programs.