Since stain removal matters to your customers, each stain is an opportunity to impress them.

InkGo is the effective and safe way to remove ink stains from all types of fabric - including acetates. Use it to remove adhesives, too.

It's eco-friendly... California compliant, chlorinated-solvent and NPE free, biodegradable and non-combustible. And since InkGo is user-friendly and odor-free, it's pleasant to work with.

Use InkGo to deliver stain-free cleaning. You'll build your reputation for quality – and keep customers coming back.

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

July 2019 Vol. 86, No. 4 DEPARTMENTS

In the summer, your plant and store can get hot. Worker comfort and safety are vitally important to you — for both the health of the team and the efficiency of the business. Four drycleaning owners share their tips and strategies for keeping their teams cool in the summer sizzle. From Texas to Arkansas, back to Texas, then over to North Carolina, owners keep cool with icy headbands, air-conditioning, pre-dawn swing shifts and more. On the front cover is one of those owners, Charlie Jones, middle, from Frisco, Texas, and two of his team members at 24/7 Dry Cleaning, showing just how chill they can be!

Tim Burke, Editor

Three drycleaning owners with drive-thrus share some of the benefits and challenges they have encountered when getting out beyond the counter. Life in the drive-thru lane can be a worthwhile ‘meet-and-greet’ interaction for both the client behind the steering wheel and the team member, who provides quick, convenient curbside service, a boon in bad weather. Tim Burke, Editor

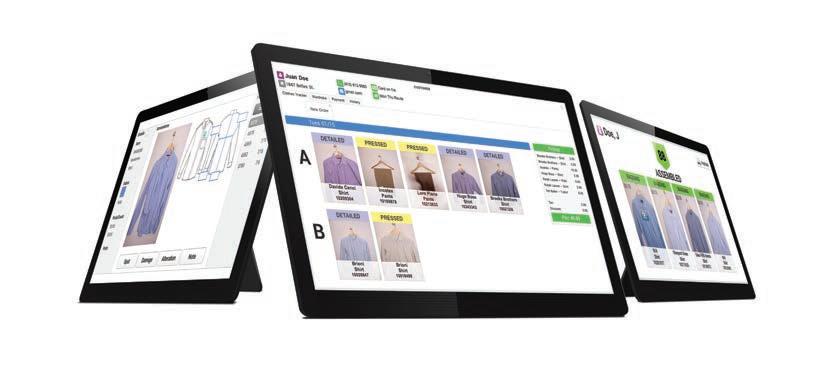

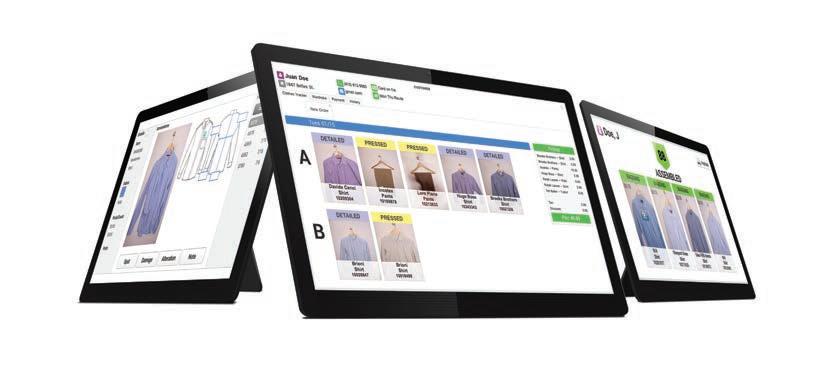

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

“I don’t have to rely on anybody for information. I can see immediately what I have for inventory, orders and accounts receivable.”

July rocks.... what with barbecues, fireworks, parades, family parties; and at night that warm summer wind blowin’ the stars around.

And so, did you hit your summer slowdown yet? (Maybe only in your mind.) But it is staff vacation time, and it is your own owner’s time too, a time to downshift.

We’re Chill! is our July front cover (that’s 24/7 Dry Cleaners Owner Charlie Jones in the middle with two of his team members), and it’s the feature story about keeping your drycleaning team cool in the heat of summer. It gets hot everywhere; but we have four owners across the states of Texas, Arkansas and North Carolina sharing their own ways to cool-out. Come with them, and chill!

You get to know your clients really well, especially when they drive up in the drive-thru, but hey, watch your toes as they pull forward! In this July feature, Drive-Thru Dynamic, three dry cleaners tell us their particular stories of “life in the drive-thru.”

Veterans and Service Personnel mean so much to all of us, especially at this time of year right around the Fourth of July. Red, White And Blue (And You) is your reader-favorite special feature where a few of you send in stories of a patriotic nature to represent some of the ways the fabricare industry recognizes our U.S. Veterans and Service Personnel — now and all year long!

Your popular columnists are here. Diana Vollmer, in Dream Brand, tells you how to take your business identity from dream to reality and asks you to take the brand challenge. (Don’t be scared!) Dan Miller describes how to turn your team members into long-term partners in Tightrope Walkers. Martin Young reminds you not to cut corners and Be True To Your System. And there’s much more in here as well.

Since it’s July and it’s warm, I’d like to crawl into my hammock now and rock to sleep. Can someone find me two trees close together?.... and also the hammock?!

PS Our big Clean ’19 Show Report will appear in the next issue (August). ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 86, number 4. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2019. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, July 2019

Publisher

Charles Thompson 312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Tim Burke 312-361-1684 tburke@ATMags.com

Digital Media Director

nfrerichs@ATMags.com

Chillin’ at 24/7 Dry Cleaners in Texas, with owner Charlie Jones in the middle, along with two team members on either side, having some fun showing just how cool they are in the heat of summer wearing their scarves and ear muffs. That’s so chill! (Photo by 24/7 Dry Cleaners)

By Tim Burke, Editor

By Tim Burke, Editor

Can you just chill a moment?”

How many times have you heard that saying uttered? Let’s put a new-old spin on chill by looking at cooling methods used at dry cleaners in Texas, Arkansas, and North Carolina. A dry cleaner in Texas fights the summer heat describ-

ing it as, “A beast that is difficult to tame.”

By chilling down the drycleaning work environment — and taming the beast — owners can increase worker efficiency, plant safety, and the overall comfort of all: team members, owners, managers, and clients coming in out of the hot day. (continued on page 10)

(continued from page 6)

“By providing a more pleasant work environment, I find that it is easier to hire, and retain, employees. I have found that myself and my employees have more energy, thus improving productivity during the intense Texas summers, a period which would typically drain us physically and mentally.”

This is Charlie Jones, the owner and operator of 24/7 Dry Cleaners in Frisco, Texas. Shortly after opening on Sept. 1, 2016, his cleaners was honored with an American Drycleaner award for Outstanding Plant Design in a Strip Center.

“Yes, adding air conditioning to your store adds to your energy consumption and costs. However, I find those costs smaller than you may think, especially when factoring employee morale and turnover into the equation,” Jones relates.

“I have yet to meet the person that has air-conditioned their facility and has regretted the decision. The typical refrain is ‘Why didn’t I do this sooner?’”

When Jones opened his first drycleaning plant in the summer of 1994, he says he knew very little about the business of dry cleaning.

Jones contracted with a local franchise to put in a store turnkey.

“I was so busy trying to learn as much as I could before we opened, that I paid very little attention to the build-out. They did a great job, but to my surprise there was no airconditioning anywhere, only swamp coolers,” he points out.

“As we opened in the summer, I quickly learned that swamp coolers were not very effective in a hot and humid environment.

“When I asked the franchise office: ‘Why didn’t we at least air-condition the call office,’ the response was, ‘A customer is only inside your store for two minutes.’

“I responded: ‘Yes, but I am here all day!’

“In short order, I became only the second operator in this franchise to air-condition the call office,” Jones says.

“For my second and third stores I took a much more active role in the design and layout, not only did that mean air-conditioning the call office, but also spot cooling the production area,” Jones notes.

“This was true dehumidified air and a tremendous improvement over the old swamp coolers,” he says.

“Finally, for my fourth store, we added 35 tons of cooling for the entire facility, achieving a very comfortable work environment for me, my employees, and my customers.”

They chilled at last. But they weren’t alone.

Let’s ride a ‘cool front’ up to Arkansas.

Charles Enderlin is the owner of Oak Forest Cleaners, located in Little Rock, Ark. The cleaners was started in 1951 by his father Al.

“I purchased the business from my father in 1973. During 1986, a new 8,000 sq. ft. facility was built. The original facility was converted to a pickup station,” Enderlin says.

“The new facility has 16-foot ceilings, and evaporative coolers are used to cool the facility. Originally the evaporative cooler pads were Aspen wood shavings. Two of the original Aspen wood-type coolers were replaced with coolers using corrugated rigid media,” he notes.

Enderlin says he was surprised at how cool the air from the rigid media coolers was when compared to the Aspen wood shavings.

“The original Aspen wood evaporative coolers are up for replacement,” he relates. “When that is done, my em ployees will once again be saying this is the coolest plant they have ever worked in!”

That’s chill for sure, but let’s do a 180-degree turn and go-with-the-cool-flow back down to South Texas to see what’s cookin’ at still another plant.

In San Antonio, Vicky Maisel, president and co-owner with sister Shannon of Cowboy Cleaners, says that the heat in the summer gets to over 100 degrees and dry or humid, it makes no difference, it’s hot!

“We worry about making sure all employees stay hy drated and that there is good air circulation in the plant,” Maisel says.

She explains their cooling strategies: “We have swamp coolers, exhaust fans in the roof to remove the heat, fans for each individual employee, and large overhead doors to keep the air circulating.”

Maisel says they also provide their employees with cooling headbands and scarves for each. “The employees wet their Arctic Skull headbands throughout the day and these really help keep them cool.”

Cowboy Cleaners was started over 60 years ago by their father, Don Maisel. “Today, Shannon and I have taken over the business. I am the president of the com pany. Both Shannon and I are basically chief cooks and bottle washers — we do whatever is necessary or needed to make sure we deliver a quality product and excellent service.”

Maisel relates a story of hot and cold: “One day some one forgot to turn on the exhaust fans! Needless to say, it was a sauna. Though that might be nice if we were trying to lose weight, it was awful to work in.

“We finally noticed and got all the fans on. It made all the difference and now we have assigned one person the job of making sure all the fans are on, and if they are absent or on vacation it’s the job of the chief cooks and bottle washers.”

In the summer Maisel relates, “We purchase bags of ice for the employees to keep their water cool. When its 100 degrees, your water gets warm pretty quickly, so we have a bag of ice in the freezer all summer long. We also have water coolers so that the water they drink is cold and not warm tap water.”

Maisel says, “In the hottest part of the summer our employees come to work earlier so they can be finished by the hottest part of the day. So if you see us in the summer we are here around four or five a.m., thankfully everyone here is a morning person!”

That’s both cooling and a chill way to operate. Now we’ll cruise ‘eastbound and up,’ taking

another ride to chill-town, this time in North Carolina.

“Since we live in North Carolina, we deal with heat and humidity from May to September. This is just part of being in the south. Our plant can reach temps of 100 plus. The daily challenge we have is to keep the air moving and keep hydrated.”

This is Lindsey Beane, owner, Fordham’s Cleaners in Greensboro, N.C., which first opened in 1947.

“My biggest concern for my staff is that they stay hydrated. We try to drink lots of water and keep things like popsicles on hand,” Beane says.

She explains: “We are your friendly neighborhood cleaners who work hard to take care of all your daily needs as well as your specialty items. I bought Fordham’s in 2015 and have been loving it ever since. I handle the dry cleaning and spotting for my operation. This means I enjoy the heat with my staff throughout the year.”

Her cleaners has five exhaust fan throughout their building. “We also use standing fans at each station and open the windows. We try to keep as much air moving

as possible,” Beane relates.

She’s says, “I have leaned a lot about how exhaust fans work and the required maintenance that should be done before the temperature gets really high.”

She also notes that, “Swamp coolers are wonderful things, when they work.”

Beane’s tip to stay chill and cool?

“Make sure your fans are working. I also find that frozen treats for your employees can help keep morale up on days when the heat is hard to handle.”

These four drycleaning owners shared how coolness can be achieved in the heat of summer. It’s certain you have your cooling ways as well at your plant and store. Remember to make sure your team stays hydrated. Keep ice on hand. Keep doors and windows open. Keep fans properly maintained and running, and, if possible, use air-conditioning.

The cost of keeping cool is relatively low when weighed with the benefits: efficiency, morale, and low turnover. These owners found ways to be cool in the summertime. So.... are you chill?

The drycleaning drive-thru is a dynamic place!

Owners offer their clients convenience and it’s a wonderful chance for their teams to interact. Let’s hear from three dry cleaners who each talk about their own particular drive-thru experiences.

Alex Yearout is the owner of Trussville, Ala.-based Complete Cleaners.

Yearout relates that: “John Patterson established this cleaners in 1994. He re-located in the year 2000 to a 5,000 sq. ft. building that he built, specifically customized, for an easily accessed drive-thru, lobby, and plant.

“A few years later he added a smaller dry store second

location with the same drive-thru and lobby layout.”

The owner says the drive-thru is the center focus of both properties.

“It is set up so that the customer pulls up to the building on the driver-side and never has to get out of their vehicle,” explains Yearout. “We can serve four cars at one time. The value for the customer is that their visits are quick and convenient.”

The owner and his team like several things about having a drive-thru.

“I like that we can accommodate many visitors in a short period of time. We are open 70 hours each week, but our peak moments in the day move quickly. (continued)

Get to know your clients in their cars really well, but watch your toes!Customers on the move hit the drive-thru at Trussville, Ala.-based Complete Cleaners to pickup their clean clothing. (Photo by Complete Cleaners)

Cars pull up in the drive-thru lane and it becomes a quick and convenient meet-and-greet where clients and team members interact. “Customers like and deserve it,” says

The team likes that it makes the customers happy to get good service; and the customer likes and deserves it!”

He notes that it’s surprising to see how many folks don’t use drive-thrus properly.

“There are many signs on our lot, but somehow folks still come in the wrong way sometimes. I ask the tellers at the bank and the servers at the fast food restaurants if they experience this, and they say ‘Yes!’ So, it’s not just us.”

About challenges with running a drive-thru at his cleaners, Yearout relates that, “It can be challenging to slow the customer down so that we are sure to serve them properly. Sometimes the speed of the drive-thru hinders our ability to communicate the details.”

Grand Rapids, Mich.-based Sheldon Cleaners believes in curbside care.

This cleaners talks about the concept of the drive-thru: “For most people, curbside service brings to mind an im age of wait staff zipping around on roller-skates delivering food to parked vehicles, but years later the theme is the same: delivering product with a personal touch for the cus tomer’s convenience.”

Sheldon Cleaners notes it was established in 1949 with one location. Over the last 70 years it has grown to 25 stores, 16 routes, and with a modern laundromat and café, all while employing 175 “outstanding staff,” the cleaners describes.

Why offer curbside service?

Well there are benefits to both clients and the team, as this cleaners explains:

“As a company, curbside service allows us another point of pickup and drop-off, and gives us a competitive edge for offering that convenience.

“On the customer side, they save time, skip the line, and have their items delivered all while in the comfort of their

own car. This can be a relief for the customer due to any number of reasons: children in car seats, a conference call, weather, or even a disability.”

The firm points out that curbside service does have its own challenges, which it says, “can range from the mundane to the insane.”

Sheldon Cleaners says that when their team member opens the door, they can experience anything including inclement weather, an aggressive pet, or a customer who is irate due to a perceived extended wait time.

“The biggest challenge is answering the question of, ‘Who do I help first?’

“The best approach is communication. Simply acknowl edging the customer in the drive-thru adds a professional touch to both the current customer as well as those wait ing. The reward is patience from both.”

The company relates that the biggest obstacle to a drivethru is often zoning restrictions.

“But,” the cleaners says, “we have found that a curbside permit is much easier to obtain, with the only requirement being that the product, ‘passes through a doorway.’ Armed with this knowledge we have been able to offer curbside service at 10 of our 25 locations.”

Karen Cooley is the manager at Oshkosh, Wis.-based Oshkosh Express Laundry Center

Cooley says: “One of our valuable features is our drive-thru. With the unpredictable Wisconsin weather, including our extremely cold winters, the drive-thru offers customers the wonderful option of not leaving the comfort of their vehicle.”

It is also ideal for elderly customers, “Who may have difficulty walking, to be able to use the services we provide with greater ease,” she indicates.

“We often have customers tell us they appreciate our drive-thru and come to our store, versus other locations, because of it,” Cooley says.

“It saves our Wash-Dry-Fold, or as we say, WDF customers time, as they can easily unload 50-plus pounds of laundry right into our work area and be on their way, instead of needing to take carts out into the parking lot to bring their laundry to us through our front door.”

She describes her company, saying, “Oshkosh Express Laundry Center, owned by Continental Girbau since 2011, is known in Oshkosh and the surrounding areas as the best laundromat in the area. We specialize in WDF and partner with a local dry cleaner as a drop-off/pickup site. As a working manager for the past three years, it is a delight to see growth in all our service areas.”

Cooley also says she appreciates the fact that their drive-thru provides customers with more

White Conveyors’ SUV-OAS is the perfect solution to boost your productivity, improve customer service and increase your profits while reducing your operating costs. The system is delivered fully assembled, and can be operational in less than two hours. As an option, it can be mounted on wheels for mobility or storage. Simply set it up on its supports, plug in the power, connect the computer, and link the system to an Internet connection. It’s time to begin realizing remarkable time and money savings.

Easy to use

Reduces labor costs

Increases productivity

Assembles over 2000 pieces per shift

Interfaces with all major POS systems

Can utilize a bar-code or RFID chip system

Easy-to-read computer touch screen

Highly accurate and reliable

Fast return on investment

Proudly made in the USA with fast support

ease in handling their drycleaning bundle.

“It is our desire to create an environment that makes our customers happy and desiring to return, and I believe the drive-thru assists in that regard,” she relates.

“The only real challenge with having a drive-thru that I have noticed, is when you open a door on a below zero day, the temperature in our work area has a tendency to drop.

“It’s always encouraging when customers who generally use the drive-thru come inside on the freezing cold days, telling us they didn’t want to freeze us out by using the drive-thru,” she says.

“It’s gestures of that nature that show me that valuing our customers by providing drop-off/pickup ease and good service, they in turn value us and the services we provide for them.”

Drive-thru interaction provides memorable team-client stories, as she shares:

“There are many memorable encounters I’ve had with drive-up customers. One is talking with a retired vet as he shared stories through his truck window and accepting the printed jokes and riddles he would share with our staff.

“Another is getting to pet one customer’s therapy dog as the customer picked up his order. Don’t we all need

an encounter with a therapy dog some days?

“Seeing the grateful look on our disabled customers faces,” who cannot easily come inside but make use of drive-thru convenience, “is very satisfying,” Cooley relates.

Owners provide some final thoughts on having a drycleaning drive-thru:

Cooley shares: “Having a drive-thru opens up possibili ties for reaching a wider demographic with the elderly, the persons with disabilities, and the families with young children and more. And a note to all those owners in the north, layer-up in the winter!”

Sheldon Cleaners says: “With the convenience this offers, we would suggest adding this service to any location you can.”

Yearout reminds: “Watch your toes and remember to shut the trunk. Use your imagination, if you can imagine it then I assure you that it has happened.”

Many of you have drive-thru service but for those who don’t give it a look. You might want to get in gear and add a drive-thru. These three owners shared the benefits of their curbside service.

The drive-thru! Pure client convenience! Great client interaction! Simply dynamic!

By Tim Burke, Editor

By Tim Burke, Editor

As we gather with family and friends this time of year, we also want to send a salute from fabricare to our service personnel and veterans for all they do, and have done, for us. Here are a few brief stories. Have a fun and safe 4th!

Amber Kraemer, office manager, Jones Cleaning Centers Inc., Fresno, Calif.: “If you pull up to our plant on any given patriotic holiday you will see dozens of American Flags lining our property, as well a flag pole with an American Flag displayed year-round. We are a veteran-owned company and we salute all veterans and active duty service people and families.

“One way we give back, and say Thank You is by

Robin Kraemer, president, Jones Cleaning Centers, Inc., Fresno, Calif., served in the U. S. Army, Private First Class E3. He’s shown standing in front of his cleaning center in his drive-thru lane with many American Flags displayed both large and small behind him. His daughter Amber Kraemer, office manager, says he is, “Wearing one of his many American Flag shirts he wears during patriotic holidays.”

cleaning American Flags for free all year long. Last year, we wanted to do more than clean flags for free, so we extended complimentary dry cleaning, and laundry to all veterans and active duty during the week of Veterans Day.

“Every year we try to do everything we can to give back to the people who have given us so much! Thank you to all veterans and active duty soldiers, we appreciate your service!”

At the heart of SMRT, we are a dry cleaner. It’s the reason we created our software in the first place: To solve the everyday problems we ran into at our own business.

We’ve stood in your shoes -- pressing, cleaning the button trap, filling in when the driver is sick, making payroll, and replacing equipment.

And with a dry cleaner’s perspective, we’ve built, from the ground up, the best dry cleaning software in the marketplace.

We understand that dry cleaners are dynamic, high-performing entrepreneurs. It’s no small feat to run both the factory and the dealership every damn day. You deserve a software partner that knows your business and is there for you 24/7. You deserve SMRT.

Next-level customer service to match their next-level technology. The SMRT team is passionate about solving problems and supporting their users.

Jason Yerby

Vice President: Crest Advanced Dry Cleaners

There’s more to SMRT than great software. They really know the business, bringing a new dimension to customer support.

Daniel Cha

Owner: Orchid Dry Cleaners

SMRT is light years ahead of the competition! We’ve never been so on top of our business and in tune with our customers.

Wayne Edelman

Owner: Meurice Garment Care

Robust

Richard Aviles

Owner: Bridge Cleaners & Tailors, King Garment Care

Arthur “Otts” Garman, ran Glyndon Lord Baltimore Cleaners and was a WWII veteran. “He was also an active member of our community fire department and because of his patriotism and civic nature, we have always tried to show our appreciation for military personnel and first responders,” relates daughter-in-law Janet Garman, VP of sales and marketing. The current owners are his sons Mike on left and John on right shown here in this recent photo with their mom Diane Garman. (Photos by Glyndon Lord Baltimore Cleaners)

Janet Garman is VP of sales and marketing for Glyndon Lord Baltimore Cleaners: “My husband Mike and his brother John are third generation owners of Glyndon Lord Baltimore Cleaners outside of Baltimore, Md.

“Their dad, Arthur “Otts” Garman, ran the laundry before them and was a WWII veteran.

“Otts was assigned to the United States 33rd Army Division, 130 Infantry Regiment. He took part in the Battle of Luzon, fought January to August, 1945, in the WWII Pacific Theater of Operations by the Allied Forces of the U.S.” His family notes he started out in the Air Force, but ended his career in the Army.

“After that battle, the division was also engaged in

amphibious training in preparation for the invasion of Japan. However, the war ended while they were training in the Philippines.

“He was also an active member of our community fire department and because of his patriotism and civic nature, we have always tried to show our appreciation for military personnel and first responders.

“In addition to offering free American Flag cleaning, we give a 15% discount to all military and first responders that use our services.

“Here’s a photo of Otts in WWII. He has since passed, but we try to do what we can to recognize, remember, and honor him. I also included a current photo of Mike on left, their mom Diane Garman, and John on the right.”

Doug Johnson is the owner of Peerless Cleaners in Corpus Christi, Texas: “We clean uniforms for veterans’ funerals in the program The Final Salute. We take off all insignias, and clean and press the uniforms. My seamstress removes the insignias and my presser presses the uniforms. When the uniforms are finished and ready, Goodwill is in charge of handling delivery to the funeral home.”

About the Final Salute program, this taken from a recent spring 2019 article titled Uniform donations honor veterans during final salute written by Natalie Contreras for the Corpus Christi, Texas, Caller-Times: “Johnson, Army veteran and owner of Peerless Cleaners, said he and his staff have worked on about 35 Army, Marine Corps and Coast Guard uniforms during the past six months after ‘Uniforms for the Final Salute’ launched.

“Uniform donations are key to the program, a combined effort between Goodwill, Peerless Cleaners, the Nueces County Veterans Services, Coastal Bend State Veterans Cemetery and Treviño Funeral Home.

“‘Our brothers who will be buried, they need that respect,’ Johnson said. ‘This is just like taking care of our family. It makes me feel good and proud to be able to honor our brothers in this way.’”

Johnson says to American Drycleaner: “My father and I are both veterans and our community is very military- and veteran-supportive. I was asked to be a part of this program and immediately said yes before I knew the full extent of the mission. We have always supported our local military and veterans. This is an extension of our community that is very important to our company and we work everyday to make sure our military looks its best.”

Beth Shader is the co-owner, with husband Michael, of Milt & Edie’s Drycleaners & Tailoring Center in Burbank, Calif.: “We have year-round programs in place: All American Flags are cleaned free; and all uniformed clothing, such as for EMT, police, and sheriff, are dry cleaned at a 60% discount. We give 60% off on uniforms and then offer 20% off on all personal clothing for uniformed service individuals.”

Wet cleaning is better & faster than dry cleaning. We wet clean anything from wool suits to wedding gowns.

Poseidon offers innovative programmability for complete control over every conditional aspect of the wet cleaning, drying and ironing process. That’s why professional fabricare operations rely on Poseidon equipment to perfectly wet clean the most delicate items including tailored wool suits, cashmere sweaters, silk wedding dresses, and so much more! CALL 800-482-3400

“

”

— Gary Heflin, Owner, Perfect Cleaners

Consistency in branding is an ongoing challenge for all companies.

Even the best most iconic logos must be tweaked and updated periodically to remain current and appealing to the target market.

If there is any question in your mind about the veracity of these statements, search the logo history of your favor ite brand. The timely updates are often too subtle to even notice unless you see the versions side by side.

Since consistency of branding is a critical factor to make the most of your promotional budget, taking the Brand Challenge is a very productive effort for any management team.

Is your logo iconic and current or does the existing array of your company media look like the chaotic mess of the proverbial dog’s breakfast?

Perhaps your logo is used harmoniously throughout the company but looks like it is stuck in your grandparents’ era? Does that appeal to the current customers and the clientele you want to attract?

Every company should regularly take the Brand Challenge to ensure appropriate updates are being scheduled and implemented.

1. For your next management meeting, assign your team a preparation project. Have them scour the company for samples of all media seen inside and outside the com pany that might be construed as branding.

If the example is not easily portable to your meeting room, have them take a picture of it and print it for the meeting.

The list of possibilities is endless, so the number of samples to be reviewed should be huge. Prepare to plaster the table, walls, windows, easels, floors and projection screens with the collected images. Prepare to exhibit all of it at once.

The list should begin with and build from:

• Signage (be sure all versions from every location are represented)

• Letterhead and stationery

• Business cards

• Company vans, trucks, cars and any other vehicle

• Website (all pages)

• Social media presence (all variations)

• Published advertising (all publications, all variations) • Flyers

• Packaging (all variations)

• Hang tags

• Uniforms (all variations)

• Non-uniform attire of the entire team

• Store exteriors (all sides)

• Lobbies (photograph each one from all angles to show what customers see)

• Delivery people (both store and route)

• Customer service representatives

• Production staff

• Newsletters (hard copy as well as electronic)

• Staff headgear (sanctioned or not)

• Delivery carts

“Not only did I reduce my assembly sta from 2 people to 1, I also noticed signi cant reduction in mark in labor costs as well.The opportunity for human error has been vastly reduced. I should have switched years ago when Brett rst spoke with me!!”

“I can honestly say that the QuickSort is the single best item I’ve ever purchased. The direct labor saving payback was less than one year. The increased e ciency from barcoding at the mark-in counter coupled with the complete elimination of assembly mistakes makes this the smartest business decision I’ve ever made, and one that is paying daily nancial dividends. “

Allan R Cripe CED,CPD

Brian Robertson

Owner, Valet Cleaners and Coin Laundry

Allan R Cripe CED,CPD

Brian Robertson

Owner, Valet Cleaners and Coin Laundry

• Route promotional materials (consumer and business)

• Handouts of every description

• Promotional items provided for event participation of any kind

• Press releases

• Photo op announcements

• Anything and everything that is visual in around and about your company

2. Before the meeting begins, assign general category areas for the samples, such as table for stationery, wall for store exterior store photos, windows for van. Be sure to assign a miscellaneous locale for unique items. Provide plenty of non-permanent tape for attaching the samples.

3 Begin the meeting by having your managers post their samples in/on the general areas for each category.

4. Ask your management team to take 5-10 minutes to individually assess the examples and write notes of their personal initial observations.

5. Have each manager share their individual observations with the entire team.

6. Tally the observations by category on a white board (electronic or manual) or flip chart so they can be cap tured for future use and reference. The format should be visible for the duration of the meeting.

7. As a group, select items that you all feel proudly repre sent your company in their current version and group them together.

• List what makes them representative of your company identity.

• Note which categories are covered by the selected samples.

• List the categories that are not represented by the “proud” samples.

• Provide check marks by the ones that need to be tweaked to be timely or could use updating for any reason.

• Do they all use the same version of your logo?

• Do they all have a currently consistent look about them?

• If you saw one of the samples alone, would it be in stantly recognizable as being produced just for your company alone?

8. Choose the best of this selected group and discuss why they best represent your logo and brand. Note: While doing this exercise, keep in mind that:

• Everything Apple does has the current version of their logo prominently displayed.

• Amazon boxes always display their logo as the most visible thing you see, even from a distance.

• The Nike swoosh is always wherever Nike is.

• The McDonald’s arches can be seen for miles.

• Is there any way to avoid the Instagram, Twitter, Snapchat, Facebook or Google logo for longer than 5 minutes?

9. For the categories that are not represented in the “proud and current” group above:

• Determine which media groups are relevant and valuable.

• Select the remaining versions that are the “best” from the category group.

• Determine what necessary revisions would be required to meet your current branding ideal.

• Implement a plan to bring the critical media groups to your new standards level.

10. After completing the steps above, determine what categories of promotional media are missing in your current collection and that should be added to your materials.

11. Unless you or someone on your immediate team is a media/graphic professional, it is time to engage a pro to assist in taking the process from your initial assess ment and recommendations to a professional reality.

Your branding and logo can be as iconic in your market as the most recognizable and ubiquitous brands that surround all of us every day.

It just takes awareness and constant vigilance to ensure this is a reality instead of a dream. ADC

Diana Vollmer is a managing director for Methods for Management, which has served dry cleaners and launderers with affordable management expertise and improved profit ability since 1953. For assistance reviewing your branding for timely revisions, contact her at dvollmer@mfmi.com or call 415-577-6544.

To find past Management Strategies columns or share this month’s with your friends, visit AmericanDrycleaner.com.

One of the hardest things about being an owner in the drycleaning and laundry business is staffing.

All of us have had sleepless nights wondering how we’re going to fill a position or what we should do about a troubled employee. It’s a terrible experience filled with anxiety.

It feels like you’re wobbling along a tightrope and if you lose one more employee, you and your business are going to fall right off the wire.

Fortunately, it doesn’t have to be this way.

You can build your business so that instead of your staff being that tightrope ready to bring you down, they can serve as a platform for you and your company to grow.

But before that can happen you have to ask yourself some tough questions.

I can’t tell you how many times I’ve talked to owners who were exhausted because they had to fill in for an employee who called out sick or who quit abruptly. To me, this is akin to walking a high wire without a safety net.

Even the best high wire walkers know that there is always a chance that something unexpected could happen and cause them to fall.

Likewise, you as a business owner should know that no matter how good your employees are, there is always a significant chance that something will come up that causes them to leave or be absent. As they say, life happens.

Because you never know when your tightrope might wobble, it’s critical to have a safety net at your key positions. What does this mean on a practical level?

If you have multiple stores you should have a “float,” an extra store associate, who can slide over to another store in a pinch. In production, you should cross-train your staff, so that if the pants presser is out, a shirt presser can fill in. If you run a route, you

should have a production team member, route manager or route sales person who can cover if someone is out.

In short, your safety net should be structured so that on any given day a person from every major unit of your drycleaning business could quit and you could still get by with minimal disruption.

When I talk to other owners about the importance of a safety net, I often hear: “I can’t afford a safety net.” While, I understand this concern, I would argue that you can’t afford not to have a safety net.

First, you as the owner are the most expensive labor in the company so if you’re filling in for a store associate that is way more expensive than having a float.

Second, the cost of keeping poor-performing em-

ployees around because you’re afraid you’re going to have to fill-in, has a hugely negative impact on the business that far outweighs the cost of a float.

Lastly, if your cash flow is so tight that you genu inely can’t afford a float, either your pricing is wrong or your business just isn’t going to work in the long run.

No long-run, sustainable-growth business relies on the owner filling shifts.

Creating a safety net will go a long way in reducing the anxiety that we have all felt during times of staffing uncertainty. However, once you’ve estab lished your safety net, the next question you have to ask yourself is “why does it feel like I’m on a wire at all?”

The best companies view their employees not as unstable cogs to be plugged in to roles, but as partners in growth.

The catch is, for someone to feel like they are a partner in growth, they have to be paid a fair market wage and be invested in the company’s success.

To be clear, what I mean by a fair market wage is a wage where in the event that the employee leaves they can easily be replaced at that same wage.

At the most basic level it’s important because if you know that your employee is paid a fair market wage, then it empowers you to demand the best from them without living in fear that they will leave.

This accountability is absolutely vital to the success of your company. I know so many owners who feel like they can’t manage their people because they are afraid someone will leave.

Paying a fair market wage turns that tight-rope into a plank.

But if you want to build a platform for you and your company to grow, then making your employee part of the company ownership is the way to go. This can take many different forms, from profit-sharing to bo nus pools to company stock.

Whatever the method you choose, giving your employees long-run ownership of the future of the company transforms them and your company from a shaky high wire act to a rock-solid platform for success! ADC

Dan Miller is the chief executive officer of Mulberrys Garment Care, a premium drycleaning and laundry business with 17 locations in Minneapolis, San Fran cisco, and Dallas. You may contact him at dmiller@ mulberryscleaners.com or 866-473-0798.

Garment care is a system. And part of what I do is to help cleaners improve the cleaning technology in their operations. Marketing and social media are based on the foundation of an acceptable level of garment care quality.

My travels and e-mails indicate that there are some operations working hard at cheating the system. I am a firm believer in supplemental stain removal, with an emphasis on the word supplemental. But the heart of the cleaning operation is the drycleaning machine.

The popularity of spin-disk filtration is a product of convenience and reduction, or elimination, of the flow of hazardous waste.

Unfortunately, this convenience easily results in complacency, when spinning the disks becomes an afterthought. When you cheat the system, you open the door to a world of potential problems.

Production is slowed down due to re-cleans and the volume of the supplemental stain removal increases, unnecessarily.

If disks are not maintained properly there are several bad things that can happen. The longer an owner neglects to follow maintenance protocols, the more expensive the recovery.

The disks are intended to remove particulate matter from the solvent flow before the solvent is re-introduced to the cleaning wheel. If this particulate matter, such as lint and small soil particles, is allowed to build-up on the disks, the increased resistance to the solvent flow can easily warp the disks and allow the solvent to then “blowby” the disks.

When the solvent bypasses the disks, there is no filtration of the solvent before it enters the wheel. This results

in the garments acting as the only solvent filtration, when the particulate matter is redeposited on the garments.

These warped disks will have to be replaced to ensure a tight fit with the housing. That is unnecessary time and money.

In extreme cases operators have gone to spin the disks, only to find them bridged together and frozen in place. The motor used to spin the disks is then at risk of failure, then the motor will need to be replaced.

The air intake during the drying cycle is critical. Poor air circulation causes streaks and swales. Each and every air filter should be cleaned as routine. In high volume operations, this may require daily cleaning or even hourly.

Less air moving around the garments means slower and uneven drying. Re-running a streaked garment may well only move the streaks to another part of the garment.

To find past Spotting Tips columns or share this month’s with your colleagues, visit AmericanDrycleaner.com.

Reminder: Don’t cut corners, it will only cost you more in the end

Solvent maintenance is a challenge.

Solvent should be crystal clear in a system that injects detergent to each run and solvent should be no darker than a pilsner beer in a system that maintains a constant “charge” of detergent.

I have noticed that an increasing number of operators are choosing to run the drycleaning machine at a reduced capacity in the base tank. It is likely that the pump will pick up air instead of solvent, on occasion.

The risk of reduced solvent flow is high, reducing the number of solvent changes in the cleaning cycle, resulting in poor cleaning.

It is common to find a plant running a “dark tank” of solvent that appears to be the color of coffee. This contam ination is slowly transferred to the rinse tank over time.

Dirty solvent is dirty solvent, no matter the label it is given. All base tanks should be clean and at least 70% full.

Drycleaning detergent is necessary.

I have been in far too many plants where detergent is the first item eliminated in the name of cost savings. Dry cleaning detergents increase the cleaning range of the immersion solution, allowing it to remove a broader range of stains on the first time through the system.

Drycleaning detergents are formulated to help control free moisture in the cleaning system by putting it to work in removing water soluble stains. It also emulsifies excess free moisture to eliminate redeposition.

Drycleaning detergent helps to reduce linting on gar ments by reducing static in the system.

When detergent is eliminated, it removes the most effective additive in the system. Eliminating the dryclean ing detergent either makes more work or makes for poor quality.

Experience has led me to this conclusion: Reduce lint during the cleaning cycle, or have someone de-lint the dark wools before assembly, or send out garments con taining excessive lint.

Drycleaning detergent does not cost you, it pays you dividends.

Garment care is a system and is no more effective than the weakest part. Cheating the system is cheating yourself and may just cost you in the long run.

ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates today. Phone: 704-786-3011, e-mail: mayoung@ctc.net.

For owners of independent drycleaning stores, staying top of mind with consumers has never been more important as competition in the space remains fierce.

As the industry shifts its focus on new tactics to drive sales, strategic advertising campaigns and marketing materials can be the key to winning new business and turning them into loyal customers.

A mix of digital and print assets will guarantee the greatest reach, but only if you’re pushing out the right message to resonate with your target audience. Whether you’re creating a direct mail piece or a mobile ad, the following tips should be taken into consideration.

Before diving into a fresh marketing strategy, you should understand who your competition is and how they operate. Know where they’re advertising and what offers are being presented in your market, as this will help you devise a game plan that will stand out.

Once you have a firm understanding of your local com-

petitors, a unique, multi-level marketing and advertising strategy can give you the necessary edge to grow your customer base.

If you choose to include a direct mail component in your overall strategy, you’ll need to evaluate the number of households you are seeking to touch. Dry cleaners typically need to target a larger number of “zones” to effectively penetrate the market and garner the best response.

You should consider reaching the neighborhoods within a three- to five-mile radius of your location for a greater return on investment (ROI). Make sure to evaluate the average income for the surrounding areas, and target neighborhoods that fit your customer demographic.

Because not every customer is in need of your services at any specific point in time, it is important to have your message consistently in front of them. Send out a direct mail piece at minimum once a month in order to remain top of mind for consumers in your area.

For both print and digital advertisements, the strongest offers are those that are broad-based or tiered for different services. You want to make sure you appeal to multiple types of budgets so you have a better chance for redemp tion. Here are some examples of attractive offers to con sider:

• 30% Off All Dry Cleaning

• Laundered Shirts – Just 99 Cents Each

• Dry Cleaned Comforters - $20

Having the right reach and frequency is a must, however. If you don’t give consumers attractive offers that are designed to build trust and acquire new business, the result will be a small response rate and wasted advertising dollars.

Revamping your social media platforms is another way to appeal to new customers, especially younger millen nial professionals who have an increased need for your services.

To successfully manage your social media presence, post some engaging and personalized messages relevant to the customers you want. This includes a mix of promo tional and educational posts revolving around the services you offer, as well as interaction with your followers.

When planning your direct mail outreach, be sure to include your social media handles on the offer to drive traffic from younger customers.

The final, and most important, element for an effective ad is the graphics. Consumers are exposed to so many messages today that clear and concise communication of your offer is important.

Recipients should be able to quickly determine what you do, what you are offering and how they can access your services. Your illustration should be easily identifi able — within one or two seconds of looking at the ad.

For drycleaning services, images of clothes on hangers or crisp, clean shirts and pants will allow consumers to instantly recognize what you do.

Blues and greens have been known to be the most effec tive colors to use in your advertising materials, with red and yellow tones for the secondary or “highlight” colors.

These insights can help set the foundation for a re freshed and effective marketing approach that can provide you with the boost you need to increase both sales and customer retention.

ADC

Mike Tinz is the vice president of franchise sales at Money Mailer. Visit Moneymailer.com.

Charleston Prestige Cleaners of Charleston, S.C., recently hosted a three-day Methods for Management (MfM) mid-america bureau meeting for, “Prestigious dry cleaners from the U.S.,” MfM says, adding that the meeting promoted, “continual improvements in the industry where the members discussed the achievements and challenges of each company.”

“The group also enjoyed camaraderie and laughter over excellent food and wine in Charleston,” MfM adds.

During this meeting, MfM notes, its members exam

ined extensive financial and key performance analysis within their businesses, including group average perfor mances and benchmarks.

Best practices were shared, the firm relates, includ ing the latest marketing and advertising efforts of each company. Each member contributed a presentation of their 2019 corporate and personal goals and their road maps for achievement, MfM reports.

“The members conducted a thorough plant critique for Charleston Prestige Cleaners, with both praise and suggestions for improvement and innovation to con tinue to provide the highest quality service for their clients,” MfM says.

“Charleston Prestige Cleaners is the local leader in dry cleaning for Charleston, S.C.,” writes MfM. The host cleaners, it notes, specializes in dry cleaning, couture cleaning, bridal, express cleaning, and private lockers.

MfM, an international consulting group, facilitated by Kermit Engh, relates that it, “Provides membership to elite dry cleaners who wish to further their expertise and improve their business through shared industry knowledge, local community action, higher productivity and efficiency, and training for excellent quality in garment care and customer service.”

Kermit Engh has been an owner/operator in the dry cleaning industry for over 27 years, the firm relates, and is a member of MfM for over 23 years.

Drycleaning

for Management (MFM) held a three-day MfM members mid-america meeting at host Charleston Prestige Cleaners in Charleston, S.C. The meeting attendees posed for this photo. First row, from left: Peter Kuchlik of American/NuClear Cleaners; Tripp Penninger of Tripp’s Fine Cleaners; David Feingold and Ben Feingold of Fabricare Center; and John Kim of CleanPression. Second row, from left: Lisa Sebastian of Ridge Cleaners; Monika Manter of Balfurd Cleaners; Kyle Matthews of Janet Davis Cleaners; Tom Prionas of Fabric Care Center. Third row, from left: Greg Gunderson of Gunderson Cleaners; hosts: Brian Meden and Jeanne Meden of Charleston Prestige Cleaners; Dave Matthews of Janet Davis Cleaners; Kermit Engh of Fashion Cleaners; Perry Bata of Pepper Square Cleaners; Bill Weidenaar of Paris Cleaners. Not Pictured: Dan Kuchlik, Doug Gunderson, Sarah Gunderson Hawkins, Bob Guthery, Dave Weidenaar, Amin Bata, and Bob Fogelsanger. (Photo: Methods for Management)

“He is also the president of the Association of Wed ding Gown Specialists for 12 years, a member of DLI and LCI, and winner of numerous industry awards including a 2016 CINET Internationale Sustainability Award,” MfM says.

Zengeler Cleaners, in a new partnership with Mothers Trust Foundation (MTF), recently hosted a two-day, no-cost prom donation event called the Pop-Up Prom Shoppe, which was open to any Lake County, Illinois, student with a high school ID, it notes.

According to Susan Suhling, executive director of MTF, “Our first Pop-Up Prom Shoppe weekend was a huge success. We were able to help approximately 500 students with prom apparel for this year.

Listen to the grooves your radio disc jockeys, or DJs, are laying down this summer. They rock!

Another type of ‘Jockeys’ are tighty whities. They’re still being worn out there. Or rather, under there. White clothing, like white briefs, white tees, white shorts, and white dress slacks and shirts are normal summer wear, enjoyed for their cool comfort.

They can get dingy, though. Not your DJs.... your white clothes!

In American Drycleaner’s Com plete Spotting Guide, author Norman Oehlke says: “White garments that come out dingy are probably being cleaned in dirty solvent. Various

types of soil loosened in dry clean ing are getting left in the garments, instead of being removed by a suf ficient cleaning cycle with proper filtration and distillation.”

He says that sometimes soaking the garment in warm water with detergent will brighten it.

Take some white or pastel items — you know, the light clothing of summer — that you’ve cleaned, and wet-out an area with a volatile dry solvent and tamp.

“If you get a clean area on the gar ment,” Oehlke says, “You need to clean the solvent with better filtration and probably more distillation and then reclean the item.”

About those tighty whities... A

brief Brief about, what else, briefs from Wikipedia; it says they were first sold in Chicago in 1935 and were known as, get ready, Jockeys!

But we were talking about DJs....

Since we’ve brought this back around to radio disc jockeys, this cool photo of a rockin’ DJ, makes total sense, totally! Rock on! ADC

from page 40)

“We are especially happy to see students from every high school in Lake County as well as home schooled students attend this year’s event.”

Suhling relates that, “Some students had special needs and our volunteers were so caring and helpful. Thanks to the amazing support of the College of Lake County and over 300 of our fabulous volunteers, we were able to provide all the students who attended a very special county-wide community pre-prom event.”

MTF is a Lake Forest, Ill.-based organization that has provided immediate assistance to children throughout Lake County since 1998.

Most of the dresses collected by Zengeler Cleaners come from high school students in Lake and northern Cook Counties in Ill., the cleaners notes, and others are donated by individuals who often purchase brand new dresses and donate them to the annual collection drive.

The result: Thousands of students for whom prom was out of reach because of the expense now have an opportunity to enjoy a lifetime of memories.

Suhling adds: “We have already begun making plans for 2020 and expect an even bigger turnout next year and increasing the number of dressing rooms to make room for more students.”

According to its website, MTF writes that it has, “Pro vided immediate assistance to children in Lake County

since 1998. Barbara Monsor founded the organization at a youthful 75 years of age following an 18-year career at Youth Guidance in Chicago, where she witnessed first hand how a seemingly small amount of assistance might change a challenging situation for a child.

“Hers was a simple idea — connect people in desperate situations with those who want to provide assistance where it will truly make a difference.”

“We’re excited to announce the promotion of Andy Lien to the position of GreenEarth’s technical director,” states Tim Maxwell, president, GreenEarth Cleaning.

“Andy has demonstrated terrific technical, communications, and managerial skills during his six year tenure with our team,” notes Maxwell.

Lien is the second technical director in the 20 year history of the company. Since helping to found the company, Jim Douglas has served in the role throughout its growth from a new start-up company to the largest environmental dry cleaning brand in the world.

Douglas adds: “Andy is tremendously capable, and I know he will provide great guidance and support to our Affiliated Members during the coming years. He’s an outstanding talent and we’re fortunate to have him on our team.”

After two stints as a manager in the service industry, he served as the general manager and director of opera tions for Camelot Cleaners in Fargo, N.D., from 2006 to 2013, the firm writes.

It was during this period that Lien became familiar with the firm’s sustainable drycleaning process, it re lates, and helped to convert the Camelot Cleaners opera tion from perchloroethylene to GreenEarth.

On the basis of that positive experience, Lien joined forces with GreenEarth in order to be a part of bringing its optimized sustainable perc alternative to the

drycleaning industry, the company says.

Lien graduated with a Bachelor of Science degree from Minnesota State University where he earned Magna Cum Laude honors.

America’s Best Cleaners’ (ABC) held its three-day national affiliates meeting in Santa Barbara, Calif., recently, and Ablitt’s Fine Cleaners and Tailors played host, it reports.

“Day one started bright and early with a tour of the facilities of host Ablitt’s,” ABC notes. “The tour provided an excellent example of how to run a drycleaning business now and in the future.”

The day was only beginning, it says, as the group toured Santa Barbara’s desalination facility.

“Water is a primary utility for dry cleaners, and understanding the need for a sustainable resource is critical to our short- and longterm future as humans and business owners,” the firm relates. “It was an eye-opening experience for all.”

Later that day, ABC writes, Bill Odorizzi and Wesley Nelson of Sankosha gave a timely presenta tion on sustainability.

The next day’s presenter, Harry Carranza of Select Risk Insurance, talked to the audience about Under standing Risk Within Your Sustain ability Plan.

Later Mark Jones and Toran Brown from SPOT Business Sys tems presented Technology of Today and the Future offering af filiates a first look at the future in terface of their company, it notes.

That night, ABC relates, “The Santa Barbara Fishouse was the perfect local venue to host the af

www.americandrycleaner.com

filiate dinner. Affiliates enjoyed a terrific selection of local Southern California wines paired with the fresh local seafood selections of fered.”

On the last day of the event, the firm notes, Dave Troemel of BeCreative360 presented Online Reviews, the Real Driver of Organ ic Growth. Then Toran Brown of Rytina Cleaners talked on Market

of background data and informa tion for forecasting industry trends. Catherine McCann, ABC partner, oversaw a workshop on sustain ability.

The meeting concluded with a three-part program: Country Club Cleaners spoke of their Solar Project; meeting host Ablitt’s outlined how using The Great Game of Business as their model

and last, affiliates went around the room presenting their business ideas, ABC notes.

Sasha Ablitt of the host cleaners reflects: “This group of cleaners is actively trying to improve their business and serve their clientele while reducing their environmental impact and make the world a better place. It was an inspiring gathering!”

“Connecticut is a great market,” says Dennis Cardona, store owner of the newest OXXO Care Cleaners ® to open, this one at 300 Oxford Rd. in Oxford, Conn., an upscale neighborhood called Quarry Walk, the firm notes.

“Quarry Walk was serious about ensuring they had the correct cleaners for the development,” Cardona relates, “seeking one with ideals that reflect those of Haynes Development. Once we showed them that we aren’t a ‘dry cleaners’ but a ‘care cleaners,’ it made all the difference.”

Cardona says: “They loved our 100% eco-friendly GreenEarth ® silicone cleaning process combined with our state of the art equipment that is 100% harmless to clothing, and the first and only 24/7 ATM style

machine in Connecticut.”

He adds: “Customers can pickup their clothing whenever convenient to their own schedule not ours.”

This location stands in the stylish, progressive Quarry Walk neighborhood, a 32-acre mixed-use development in the heart of Oxford, the company notes. Oxford entrepre neur Dennis Cardona will operate the OXXO franchise location.

OXXO CEO Salomon Mishaan notes, “Towns like Ox ford have a need for the sort of convenience, quality ser vice, and caring philosophy that OXXO brings into their communities.

“As we continue to expand and add locations across the South and Eastern seaboard, we’re going to keep finding these opportunities in places where people are ready to find a more compelling, forward-thinking way of tending to their drycleaning needs.”

The Michigan Institute of Launderers and Drycleaners (MILD), Kreussler, and R.R. Street & Co. Inc., present ed scholarships to five students attending Spring 2019 courses at the Drycleaning & Laundry Institute’s (DLI) School of Drycleaning Technology.

Scholarships are still available for the remaining 2019 courses, DLI notes, contact DLI’s Education dept.

MILD awarded scholarships to Adrienne Glover of Acme Cleaners in Muskegon, Mich., and Thomas Maurer of Maurer’s Sanitary Cleaners, Lansing, Mich., stated DLI.

Kreussler awarded a scholarship to Fabina Wilson of DSDJ Properties Inc – ZIPS Cleaners in Lanham, Md., to attend DLI’s Spring 2019 Introduction to Drycleaning.

Mary Scalco, on left, CEO of the Drycleaning & Laundry Institute (DLI) stands with Fabina Wilson of DSDJ Properties Inc – ZIPS Cleaners in Lanham, Md., who received a scholarship from Kreussler. (Photo: Drycleaning & Laundry Institute)

Also, the firm awarded a scholarship to Hana Van Straalen of Brio Cleaners in Bellingham, Wash., to at tend DLI’s Spring 2019 Introduction to Drycleaning Course, DLI reports.

R.R. Street and Co. Inc. awarded a scholarship to Lil lian McPhee with New Oriental Laundry & Cleaners in Nassau, Bahamas, for DLI’s Spring 2019 Introduction to Drycleaning Course, the Institute relates. ADC

C’mon and lend us an ear.... You should hear what you’re missing!

John Riddle, owner of Riddle & Associates, and the man behind the Clean Show for decades, is the special guest of host Bruce Beggs, editorial director of American Trade Magazines. Riddle discusses professional baseball, the Clean Show, and his retirement.

Kyle Nesbit, senior vice president of business development at Edit Texas LLC, a franchisee of Tide Dry Cleaners, tells you what it takes to “brand and expand” in today’s drycleaning market.

For example, for a June ad, the closing date is May 1st.

PAYMENT

Must accompany order.

GARY DEPRIEST 662-838-2211 or 901-604-3693

10 YEARS AGO. Consumer sentiment improved slightly, with the University of Michigan/Reuters index going from 68.7 in May to 69.0 in June. The index remains at relatively low levels, however; it averaged 88.2 during the last 10 years. The index of current conditions, reflecting American perceptions of their ability to buy big ticket items such as cars, rose to 74.5 — well above September’s 67.7.

35 YEARS AGO. Pennsylvania Landfills Scarce. It has been reported that solid waste landfills in Pennsylvania will be in short supply in the near future unless steps are taken to counteract the situation. A Pennsylvania Department of Environmental Resources (DER) representative has testified before the House Appropriations Committee that there will be less than 30 landfills available in 10 years unless municipal and county officials locate new sites or develop resources and recovery and recycling alternatives. The DER has closed approximately 800 of the state’s 1,110 landfills for failing to meet stricter environmental requirements.

50 YEARS AGO. An Amazing Statistic. A manufacturer of office furniture estimates that only 2% of some 1.5 trillion pieces of paper on file at U.S. companies will ever be referred to again! … Wearable Fringe Benefit. A fringe benefit in the form of year-round

‘career wardrobes’ for its 1,400 employees is reportedly planned by a midwest gas company. Among the purchases: several styles of jackets for men; boots, handbags, raincoats, jackets and skirts — and even some evening gowns for women employees. … What’s New? Plenty. Now you can sit on your jacket and wear your chair. Carter Thurk, American Drycleaner advertising editor, tells us that two Swedish designers have introduced a new concept in clothing comfort. Take off your jacket, blow it up, and it becomes a chair!

75 YEARS AGO. Cotton! This from a feature inside the July 1944 issue,

see photo, called Summer News!... Cotton is really king these days. We read of cotton dresses that cost $35, and designers are putting as much style into them as they used to put into silk. The conclusion seems obvious. The owners of these expensive, stylish dresses won’t want to entrust them to ordinary laundering methods. They may be perfectly safe, but knowing that cottons are scarce as well as expensive, their owners will probably prefer dry cleaning. If the cotton season had come in May, over-burdened cleaners might have said to laundries, “Take these cotton things and welcome to them!” But by July cleaners are likely to be looking for business again, and the peak of the cotton season fits right in with the slump in drycleaning volume.

To read more of American Drycleaner’s chronicling of the industry over the years, visit www. americandrycleaner.com.

American Drycleaner, July

ADC

— Compiled by Tim Burke, Editor

ADC

— Compiled by Tim Burke, Editor

101-105 Series

We expect 15 to 25 years from our interchangeable tube bundles, and 30 to 40 years of life our more out the boiler.

209-211 Series

We normally expect 10-25 years out of the copper heat exchanger, 30 to 40 years out of the boiler.

207 Series

We expect 30 to 50 years out of our thermal fluid heater models

On all of the above units we have continued to build, and will continue to have available any part of the pressure vessel, burners, cabinet, and controls meaning that for as long as a customer wants, they will be able to infinitely repair their equipment rather than replace the equipment.

We are asked by many new and existing customers on what is our projected life expectancy of our products. We are not always the lowest initial price but know we have one of the lowest cost of ownership of any boiler manufactured in North America. These facts are based on our 90 plus years of boiler manufacturing, feedback and experiences from our end users, service departments, and all of our representatives and dealers worldwide. These life spans are based on our boilers being installed properly, and do receive our minimal recommended care, are applied to the correct application, and include the proper maintenance and water treatment programs.

machine booth in New Orleans?

OMG and Holy Moly...they are awesome!

It was the only booth to visit! No need to look anywhere else.

Yeah, the booth was loaded with equipment and they were running live demo’s with full loads of garments with SENSENE solvent. That was amazing!

I was so impressed I bought 2 for my shop, I can’t wait to get them installed and running...So many Columbia users were there to talk about their experience with the machine and SENSENE solvent...and I just am so excited to get this system in my shop.

See I told you so...Columbia has always been the leader of change in the industry, and they continue to be the game Changer! You made the right choice...call me when your machines are installed...I’ll come by !

Send