White Conveyors’ OAS is the perfect solution to expand your existing business, improve customer service and increase profits. Order Assembly couldn’t be easier.

The OAS significantly increasing productivity with a single operator. That means a safer workplace, helping employees observe social distancing. What’s more, order accuracy is optimized, and employee morale is improved as fatigue is virtually eliminated.

And if that were not enough, labor savings combined with increased productivity typically results in a return on investment in less than one year.*

The system can be delivered and operational the same day. As an option, it can be mounted on wheels for mobility or storage. Isn’t it time to increase productivity with less labor while increasing workplace safety? White

Easy to Use clear and easy-to-read color touch screen, plus audible instructions

Increase Productivity with Reduced Labor Force capable of assembling over 2000 garments per shift with one operator

Fast Return on Investment typical ROI in less than 1 year*

More Capacity standard 5 slots per foot have 50-80% more hanger capacity than competitors, reducing the need to split large orders

Flexible software customization is available for specialized customer’s requirements

Highly Accurate and Reliable greatly reduces the chance for human errors

Reliable, Robust and Durable Construction with average operational lifespan of 25+ years

USA Based Manufacturer for over 75 Years remote diagnostics, setting adjustments and troubleshooting assistance reduces downtime, and minimizes the need for an on-site service technician

* ROI is based on the Bureau of Labor Statistics

October 2020 Vol. 87, No. 7

DEPARTMENTS

Pre-Inspection 4 Management Strategies 22 Analyze, Refine and Expand Marketing Through Results Tracking, Diana Vollmer

Spotting Tips 26 Tackling Stains That Customers Allowed to Set, Martin Young

Owner’s Office 28 Recharging the Battery, Dan Miller

Around the Industry 29 Classified Ads / Ad Index 30-31

Because machines can make or break a drycleaning business, finding the equipment that is best suited for an operation is key. In this feature, a handful of garment care professionals provide valuable insight and tips when it’s time to purchase a dry cleaner’s bread and butter.

Lisa White

What do you think of when you hear the term “employment law”? It can be a scary topic, one easy for a small-business owner to ignore, until a big problem arises, according to Sasha Ablitt, owner of Ablitt’s Cleaners. “We don’t know what we don’t know until it becomes an issue,” she warns. Ablitt and other cleaners discuss their approach to understanding employment law and creating a work environment that makes staff feel safe and cared for.

Lisa WhiteWrinkle in Time 32 Nighttime Panorama

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

I think it’s safe to say that 2020 has been a pretty rough year, for a variety of different reasons. The arrival of October means that we are beginning the last quarter of the year and nearing the transition to a new one.

It’s my hope that 2021 will be built on certainty and promise, because the uncertainty that accompanies the months-old coronavirus pandemic has been anything but positive for our economy and the business community.

It’s time for a change, and that’s what this month’s cover story is about, in part. Whether it’s because a machine is in need of regular repair or a newer model would provide much greater production, there comes a time when a dry cleaner has to purchase what writer Lisa White calls “their bread and butter.”

In The Ins and Outs of Machine Purchasing, a handful of dry cleaners offer insight on what to consider with these spends. The story looks at researching the possibilities and making the most of resources available to you to make the best decision for your customers and your business.

Manufacturers, distributors, and the equipment users themselves, the workers behind the controls several hours daily, all can offer valuable insights, say the cleaners interviewed. Check it out beginning on page 16.

The other primary feature this month is Understanding Employment Law, addressing a subject that should be top of mind for any dry cleaner. “My best tip is be proactive,” says Martinizing Dry Cleaners’ Grant Carson. “Don’t wait until you have done something wrong or have an unhappy employee to learn more about employment law.” Read the “legal briefs” starting on page 10.

And before I go, I want to remind you that American Drycleaner is accepting nominations for its Publisher’s Impact Award, introduced to spotlight drycleaning industry achievements. The details can be found on page 25. The late Dr. Manfred Wentz was the inaugural honoree. Who will be the next recipient?

ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 87, number 7. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2020. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, October 2020

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager Mathew Pawlak Advisory Board

Jan Barlow Mike Bleier John-Claude Hallak Wesley Nelson Kyle Nesbit Mike Nesbit Fred Schwarzmann Beth Shader Vic Williams

How would you describe your business’ social media presence?

CHICAGO — This quarter’s American Drycleaner Your Views survey asked the trade audience, “How would you describe your business’ social media presence?” Here is what respondents revealed:

The majority, or about 42%, say their use is above average, posting three to four times a week. Equal shares of 13.9% say they are average users that post weekly or infrequent users that post a couple times a month or less. Around 8% post daily, calling their business a strong social-media user. The remaining 22.2% of respondents don’t use social media for their business.

The survey also asked, “Have you made adjustments to your company’s use of social media recently? Why or why not?”

While approximately half of respondents indicated they have not made any changes, those who have offered details:

• “Starting to use it more frequently, it seems to be the best way to attract younger customers.”

• “Yes. We remind the community that we are open for business.”

• “Increase to try to recover from pandemic downturn.”

• “Yes, I hired pros to do that for me.”

• “Increased it. Need to acquire more customers and let them know our services are available in a contact-free transaction.”

• “Increased postings to keep customers aware.”

• Yes, posting more, pushing delivery and WDF.”

• “Yes, ensuring we aren’t tone-deaf to the current pandemic and BLM (Black Lives Matter) issues in relation to consumer messaging.”

• “Yes, we make adjustments and customize our messaging/branding periodically. Being a multi-channel service provider, our target audience changes based on how they preferred to be met. So we speak to them all by different social-branding communication styles.”

• “Yes, because it is cheaper than regular media.”

Dry cleaners were also asked, “What social media do you use for your business?” Respondents could select any or all among five choices.

Facebook is used by 78.8% of those surveyed, while

American Drycleaner, October 2020

Strong, we post on a daily basis

Above average, we post 3-4 times a week

Strong, we post on a daily basis

Above average, we post 3-4 times a week

Average, we post weekly Infrequent, we post a couple of times a month or less I don’t utilize social media for my business

Average, we post weekly Infrequent, we post a couple of times a month or less

I don’t utilize social media for my business

Sourcing client leads

8.3% 24.2%

How would you describe your business’ social media presence?

8.3%

Sourcing client leads

Relationship building Posting news on my business Posting relevant industry information Other

41.7% 69.7%

13.9% 69.7%

13.9% 30.3%

41.7% 13.9% 69.7%

22.2% 24.2%

13.9% 30.3%

12.5 17.5

37.5 52.5 Charts.indd

What do you use social media for professionally? (Select all that apply)

25 35

What do you use social media for professionally? (Select all that apply)

0 12.5 25 37.5 50 70

22.2% 24.2%

54.6% use Instagram. One-third (33.3%) use LinkedIn, and 21.2% use Twitter.

50 70

One-third selected “Other,” pointing to online tools such as Google, Yelp and YouTube.

11 9/8/20 2:13 PM

American Drycleaner also asked the industry, “What do you use social media for professionally?” Again, respondents could choose any or all from a handful of responses. Equal shares of 69.7% say they use it for relationship building and for posting news about their business. Roughly 30% use it to post relevant industry information, and 24.2% find it helpful in sourcing client leads.

11 9/8/20 2:13 PM

Other responses to this question included:

• “It’s a way to reconnect with old friends.”

• “Job applicants.”

• “Services we offer.”

• “Just getting the brand out.”

The Your Views survey offers a current snapshot of the trade audience’s views. Qualified subscribers to American Drycleaner e-mails are invited to participate anonymously in the unscientific poll.

Find out why this subject should be top of mind for any dry cleaner

By Lisa White

By Lisa White

Several years ago, there was an incident at a Martinizing Dry Cleaners store in Alameda, California, that could have led to a potential sexual harassment claim. Because the business had documented training in this area, and the issue was covered in its personnel handbook, the actions to resolve the matter were quick, decisive and unchallenged.

“Liability and potential lawsuits are the first terms that come to mind, I think, because employment law is something most small-business owners [don’t] think about until they have broken the law,” says Grant Carson, owner of Martinizing Dry Cleaners.

Carson has owned Martinizing since 1999 and is currently operating one plant and one dry store. He educates

himself on employment law and meets with his management team to train all employees on its different aspects.

Because writing personnel procedures can be difficult, and hiring an attorney is costly, he finds what he needs through OSHA (the Occupational Safety & Health Administration), local or national associations, or human resources firms.

“My best tip is be proactive,” Carson says. “Don’t wait until you have done something wrong or have an unhappy employee to learn more about employment law. Working with family is tough, especially when working in a hot environment for long hours, however policies and procedures are in place to protect both the worker and the employer, so family should follow the same rules.”

Employment law can have negative connotations for business owners. Ian Noble, owner of Rick’s Cleaners in Austin, Texas, says most owners think of problems when it comes to this topic.

Noble is a second-generation dry cleaner. His father, Rick, was the first one-price dry cleaner in Central Texas. In 1987, he opened Rick’s Cleaners, which now has 16 locations throughout the city with about 60 employees. Noble also owns and operates a separate pickupand-delivery service called Ian’s Cleaners.

Noble believes although many drycleaning store owners have written procedures in place, a majority do not.

“If you don’t have them now, you need to create them,” he advises. “I have a fairly in-depth understanding of employment law due to first-hand experience with it. Our team is also small to where I am involved in writing the

policies our staff signs when they are on-boarded.”

When a new employee is hired at Rick’s, using an electronic signature and agreement cloud service, they sign basic hiring information as well as several pages of company policy and procedures that were built over years of document accumulation.

“We did not draft them with attorneys, as we try to avoid them when possible,” says Noble. “Most of the information can be found online, and you can structure your language around Workforce Commission or federal employment documents that are available for download on their websites.”

The rest of the documents, put together by the team in Rick’s Cleaners’ office, includes items such as a list of reasons why an employee can be terminated, and being subjected to random drug/alcohol testing.

“We have never used it, but it is better to have it and not need it than need it and not have it,” says Noble.

The biggest benefit of having a written policy in place within a company is protection from problems that can arise later on, he adds.

“For example, if you have your employees sign a list of possible causes/reasons for termination when they are hired, you can reference that document with the State Workforce Commission if they were to file a complaint against you,” says Noble.

“I can recall certain employees over the years that were terminated for cause but filed complaints with the state saying they were wrongfully terminated. Anytime you receive letters from the state, it is always nice to have written documentation supporting your decision for termination when you respond to an official letter.”

This can range from company policy documents, employee manuals or something as simple as write-up forms for staff being late to work or having drawer shortages, he says.

“Having policies in place prior to an incident will save you time and make it a stress-free memory of the past,” Noble says. “Most of us cringe at the sound of grasping employment law, but it is fairly simple most of the time. Prepare, implement and do the right thing as a company, and you should be just fine.”

Those in business with family are contending with a different set of circumstances. The key there is consistencies with work policies and procedures.

“I consult with my dad all of the time with things related to the industry but never actually worked with him, so I did not have to navigate this area,” says Noble. “At the end of the day, I would have everyone in your company sign the same documents and policy/new hire documents so you ... are ultimately covered regardless of the situation.

“If your family relations within the business get in the way of running the business as it needs to [be run], I would suggest asking yourself what needs to be done to change that.”

There are many great resources out there for smallbusiness owners that don’t involve HR companies, attorneys or outside consultants, Noble advises.

“One suggestion to get started is to check with your payroll provider if you don’t process payroll in-house,” he says. “They typically have generic documents and handbooks to get you started. If not, look to the internet. Everything can be found there.”

For a business owner, the backing of a team can pro-

Ablitt’s team members receive an employee handbook that ensures they are well-informed on company policies, including codes of conduct, break policies, vacation and sick time off, holiday and overtime. (Photo: Ablitt’s Cleaners)

vide added peace of mind in matters of employment law.

“When I think about employment law, I think about how important it is as a business owner to have a good team of lawyers, accountants, HR, etc.,” says Sasha Ablitt, owner of Ablitt’s Cleaners, located in Santa Barbara, California. “We don’t know what we don’t know until it becomes an issue.”

It’s always a good idea to get regular updates from competent and knowledgeable counsel, she says.

The Ablitt family has been providing drycleaning services for generations. Gordon Ablitt, Sasha’s grandfather, fell in love with the daughter of a dry cleaner in Washington state where he worked. In the 1940s, the couple moved to Santa Barbara and bought a large drycleaning plant. In 1984, their son, Neil Ablitt, Sasha’s father, reopened the family business and, for the first time, named it after the family. In 2002, Sasha moved back from a life working “in corporate” to take over the operations.

Regarding employment law, she points out that every state has different laws that are constantly changing and being updated, so she recommends talking to a lawyer before implementing any of her advice offered here.

The first requirement, she says, is that any dry cleaner needs a company handbook.

“A well-designed handbook needs to include a clear description of a working code of conduct; expectations for both employees and management; work and break policies; vacation and sick time policies; holiday and

GreenEarth Cleaners are cleaners who care – care about their communities, their customers, their associates, the fabrics they clean, and certainly our environment.

In the difficult times we have been through and that remain ahead, our GreenEarth Cleaners have found ways to help others in their communities while at the same time providing safe and effective environmentally non-toxic professional dry cleaning. One customer and one garment at a time. We salute you and thank you for caring enough to be the best! www.greenearthcleaning.com

overtime; safety communication, etc.,” she says. “There is just too much for any business owner to handle alone when it comes to government regulations.”

A responsible business owner must have these documents written and regularly updated to account for changes. Sometimes circumstances require the handbook be updated more than once a year, such as when sick time off was mandated in California, Ablitt adds.

A common mistake is when people think because they operate in a fair and ethical way, they are not at risk of having labor law issues.

“While it is commendable to operate in such a way, it does not mean you can expect people to see things the way you do,” she explains. “I feel that a business needs to always be looking for how something can be misunderstood, and constantly striving to clarify and improve. Communication is key.”

Ablitt’s Cleaners has employed many members of the Ablitt family over the years, which Sasha believes has made it even more important to have a handbook outlining acceptable behavior and clear policies for communicating.

“In my experience, it’s always the things that never

occurred to me that become the biggest issues,” she says. “In this way, writing a company policy is not the end of the process, it is just the beginning. It amazes me how many times we revisit the policy every year and add small modifications and clarifications.”

Some chapters, such as workplace safety or sexual harassment prevention, become the focus of staff meetings, Ablitt explains. Having periodic meetings that discuss the handbook’s nuances helps to communicate the content to all staff members, highlight areas of potential misunderstanding and signal its importance to management. It can also bring up revisions that may not be so obvious.

Ablitt favors getting second and third legal opinions, if possible.

“I have the handbook reviewed by an HR firm that also performs HR audits, and I have a friend who is a lawyer review it for any omissions and general readability,” she says. “We also will ask questions of an HR lawyer we have access to via our employment liability policy. If you have that sort of coverage, you should look into what services are available to you.”

If this all seems like a lot, it is, she says.

“But we are a family business, and we want our staff to feel safe and taken care of,” explains Ablitt. “This framework in understanding the details of workplace policies must be addressed if we are going to create a successful business that is also a premier workplace.”

Employment law can be a scary topic, one easy for smallbusiness owners to ignore, until a big problem arises, she says. By then, it can be too late to easily rectify it.

ADC

“Mybest tip is be proactive,” says Grant Carson, owner of Martinizing Dry Cleaners, Anaheim, California.

“Don’t wait until you have done something wrong or have an unhappy employee to learn more about employment law.” (Photo:Martinizing Dry Cleaners) When Rick’s Cleaners hires new employees, it verifies basic hiring information and educates the newcomers on company policy and procedures. (Photo: Rick’s Cleaners)

poseidonwetcleaning.com

The Poseidon system offers innovative programmability for complete control over every conditional aspect of the wet cleaning, drying and ironing process. Customers are thrilled when even their most delicate garments including tailored wool suits, cashmere sweaters and silks come back with a cleaner smell, better odor removal and an overall superior clean.

Ready to GO GREEN?

“ We’re excited to be leaders in the industry by making the switch to wet cleaning and happy to do our part in minimizing our environmental footprint. ”

— Miriam Choi, daughter of Hyeon-Dong & Young-Sook Choi Owners, University Cleaners

cleaners offer insight on what to consider with these spends

By Lisa WhiteBecause machines can make or break a dry cleaning business, finding the equipment that is best suited for an operation is key. In this feature, a handful of garment care profes sionals provide valuable insight and tips when it’s time to purchase a dry cleaner’s bread and butter.

For Highland Cleaners, located in Louisville, Ken tucky, the decision to purchase new equipment generally falls into one of two categories, says owner Michael Jones.

“The first is when an existing piece of equip ment comes to the end of its useful life. Is the ongoing cost of repair and downtime greater than the cost of replacement?” he says. “The second … is deciding when an upgrade of equipment would dramatically improve quality or reduce costs, usually labor costs and utilities.”

Highland Cleaners, which opened in 1944, has 13 locations and just over 100 employees.

Jones says the decision to buy in the current business climate can be a tough one.

“In many cases, until the coronavirus shutdowns, the tight labor market made the purchase of labor-saving equipment very attractive,” he says. “Also, the lack of availability of service and parts for older equipment sometimes forced our hand in replacing old equipment.”

Now, when purchasing new machines, the guiding phi losophy for Highland has been choosing manufacturers it believes will be around in 10 years.

“For our last several purchases, we have chosen manu facturers that have a robust network of distributors that can help us service our new equipment,” says Jones. “We have also tended toward manufacturers that are industry leaders in sales, hoping that they will still be here for years to come.”

All the worry associated with a new machine purchase is typically not warranted in the end, according to Jones.

“Like all business owners, I have always sweated big purchases,” he says. “Invariably, a year later, our team always wonders, ‘How did we get by before we bought this?’ I have never regretted any new equipment purchase that made us more labor-efficient.”

Jones recommends calculating the payoff period for new equipment with regard to the cost savings.

“How much labor and other costs will your business save per year with this new equipment?” he asks. “If the payout is less than four years, it is a no-brainer.”

When considering a big machine purchase, Philip Cote, owner and president of French Cleaners, West Hartford, Connecticut, says his primary focus is on finding equip ment with unique ability and possibly the latest technol ogy in order to create the best outcome for customers.

French Cleaners is a 109-year-old family business that currently employs a staff of 28.

Equipment that takes a lot of maintenance, or breaks down frequently, is highly disruptive to Cote’s business and costly by cutting into production and adding repair expenses.

“I research as much as I can the items I look to purchase, asking for references (from) current users and reach out to my network of other cleaners and suppliers that I know across the country for input,” he says. “Making field trips to see the equipment running firsthand and talking to the actual users of the equipment are always useful. I also recip rocate with many cleaners who want to see my equipment.”

Highland Cleaners is most likely to purchase new machines when its current units are at the end of their service life or if an upgrade will dramatically improve quality or reduce costs, says owner Michael Jones. (Photo: Highland Cleaners)

He also looks at operating costs, as the consumption of steam, electricity and water can vary greatly, and any sav ings in those areas can have a huge impact on total cost. Purchase price is not a big factor in his machine purchas ing decisions.

“The largest tipping point for me is the maintenance factor,” says Cote.

It’s important to be specific about your expectations and to ask questions. A piece of equipment may satisfy one business owner’s needs but not another’s.

“For example, speed may be the most important item for one buyer where highest quality of a product may be the priority for another,” he says. “Think about exactly what problems you encountered with your previous equipment that caused you the most frustration and try to eliminate that with your next purchase.”

Before a recent machine purchase, Cote was struggling with solvent odors that lingered on some material.

“My new machine and chemistry allow me now to clean without distillation and without any smells ever,” he says. “It also saves me a lot of energy and, as most cleaners know, the distillation process is where most of the prob lems occur on a drycleaning machine.”

For new or used equipment, Cote recommends visiting a few different locations that have the machine and talk to the everyday users. Ask them specific questions to get a feel for their frustrations and their accolades.

Manufacturers can provide specifics on equipment op eration and capabilities, along with specs and volumes, counts, etc.—distributors also can be helpful in steering you in the right direction—but the users of the equipment are where you get the real insight, says Cote.

“Some salesmen are more knowledgeable than others, and the end-users are the most helpful when spending your hard-earned dollars.”

Joseph F. Hebeka owns The Belding Group, which has three Michigan locations: Belding Cleaners and Vintage Cleaners, both in Grosse Pointe Park, and City Cleaners in Detroit.

Belding Cleaners, which was founded in Detroit in 1918, relocated to Grosse Pointe in 1929. Over the past four years, Hebeka purchased two other competing clean ers in his area.

When contemplating a big machine purchase, Hebeka says it boils down to the dollars, research and planning.

“The fact that you’re even considering a new machine means there must be some sort of issue with your current machinery or production,” he says.

There are a number of tipping points that can be re placement indicators.

“Typically, a machine that is costing money in repeated repairs, potentially delaying the customer and/or mainly (causing) loss of productivity are all reasons to replace machinery,” he says. “In some cases, parts may not even be available or take weeks (to arrive), which means your operation is probably down, and you’re probably losing business.”

Hebeka purchased his last big machine when it was required to help handle growth in volume, and it was an easy decision to make.

“We noticed we were running behind almost daily, which meant we had the work, just not enough time in the day to do it,” he explains. “That’s where more automated finishing equipment comes in, saving time, energy and improving product quality.”

There is definitely planning involved in this process, which could take a couple months, Hebeka says. He esti mates having purchased nine to 10 new machines in the last five years.

“Shopping around for types of equipment, seeing or testing the equipment, layout in your plant, financing, and depending on how busy the main equipment installer is all play a factor in the timeline,” he says. “Sometimes you know exactly what you want, and you just order it, and it’s installed in a few weeks. Although that’s often not the case.”

It pays to do the legwork early on, be prepared for what’s to come, and give employees a head’s up with what the process will entail.

“Being down for a full day to have a machine installed can cause some issues with flow in your business but that can be lessened with proper planning,” says Hebeka.

He recommends preparing counter staff to get an extra day or two on returning items to customers, and communi cate with production staff, as well.

“Also, clean and press everything in sight just to be ahead of the game in case you run into any issues with installation,” Hebeka says. “Just know that hundreds of other dry cleaners in the industry are replacing or adding equipment all the time, and you’re not alone.”

Hebeka prefers Friday installations, which give him and his staff the weekend to reorganize and clean the plant after the disruption.

But not every installation goes exactly as planned. He beka recalls a time when a friend promised to send cement contractors to cut a bigger opening in his exterior brick wall to fit a drycleaning machine in the building.

“I wanted to be prepared, so I waited three or four days to have the wall cut open, and they kept saying they’d be there the next day. Finally, about 9 the night before the new machine was to be installed, they showed up and cut the hole in the wall for the machine to fit through, 11 hours before the installation!” he exclaims. “Everything was riding on these guys cutting the hole in the wall, so without them, all the other contractors and the entire proj ect was on hold. It all worked out in the end, but it was a really close call.”

He recommends sticking to machine brands that are well-respected and of high quality that have a good support system, as well as technical support, a war ranty and easily obtainable replacement parts.

Hebeka says your re lationships with other dry cleaners as well as distributors can be invalu able when considering a machine purchase.

“The absolute best way to test out a piece of equip ment, aside from the Clean Show every two years, is to see it actually working in a real plant setting with real machine operators and owners,” he says.

And there’s “no better, unbiased opinion of a machine” than the person who uses the machine six or seven hours a day.

Hebeka has assisted others with machine purchases through his local distributor: “I always let him drop in with prospective clients to see or use my new equipment, almost like a working showroom.”

Fostering good industry relationships will also help during installations, big or small.

“If there is any issue or delay with your install, you may need help from other cleaners to handle your workload for a day or two to avoid disruption to your operation or delaying customers.”

While a dry cleaner may look at new machine purchases as a negative, Hebeka recommends looking at the possible return on investment with reduced labor costs over time.

“Imagine shaving an hour or two per day off of payroll five or six days a week multiplied by four weeks; that can really add up,” he says. “That’s a potential savings of 20 to 30 hours a month in labor.”

Also, new machinery means better product, and bet ter product means one can charge higher prices, he says. Other benefits include more satisfied employees, better morale and an easier training curve.

“It’s much easier to train inexperienced operators on new finishing equipment than it was with older equipment, which saves you time and energy in the long run,” says Hebeka. “When a presser quits, you could have someone new pressing like a pro in just a few days with modern equipment, and that is a huge benefit.”

When purchasing big-ticket items, it helps to remember that they represent an investment in the business.

“We are most interested in understanding if the new ma chine will improve the client or team member experience and whether it will lead to increased bottom-line profits,” says Dave Coyle, owner of In the Bag Cleaners, which has 14 locations in the Wichita, Kansas, area. “We further analyze the return on investment to better understand how long it takes to pay for itself.”

Coyle opened In the Bag in 2000, and the company cur rently has 68 team members.

While some capital improvements are in reaction to a machine breakdown that can’t be repaired, there are other times when a purchase is planned, he explains.

In the Bag’s most recent purchase was a 20-ton chiller for six of its drycleaning machines. It replaced a 12-yearold 10-ton chiller that broke down.

“We decided, with some research, to purchase a larger unit and use the existing chiller as a backup if the new one ever goes down and needs service,” Coyle says.

“Prior to that, it was a set of 15 dryers for our washand-fold service,” says Coyle. “And prior to that was our largest ever equipment purchase—an assembly conveyor with three load stations, seven extract arms and integrated bagger, and a batching conveyor to automatically take it to the correct outgoing rail in our production workshop.”

Coyle’s first large equipment purchase was almost 18 years ago for his original plant.

“I waited as long as I could to replace it, but once I installed a new double buck, so much of my daily stress disappeared,” he recalls. “I learned that lesson early, that having good equipment is absolutely necessary if I am go ing to spend most of my time on growing the business.”

Once the purchasing decision has been made, it’s best to tap into distributors, manufacturers and other store own ers, whom Coyle says play a large part in most of his buy ing decisions.

“There is a wealth of knowledge out there, but the relationships with these other people have to be created, developed and nurtured just like we do with our team members and clients,” he says. “And finding a couple of individuals or companies that can install the equipment properly is critical.”

Coyle warns against getting stuck in “an endless cycle of analysis paralysis.”

In the Bag Cleaners, a Kansas-based drycleaning operation owned by Dave Coyle (inset), looks for ma chines that will improve the client and team member experience and be beneficial to the bottom line, Coyle says. (Photo: In the Bag Cleaners)

“You will be so glad once you make a decision,” he adds. “And you will be so happy once that new equipment is installed and working properly.”

Tracking results is critical to an effective and efficient marketing plan. Specific product promotions can be tracked by the sales boost in the targeted product or service. A goal of a boost in sales equal to 15 times advertising cost is realistic.

Segregate the results on the specific product from the general increase in sales that results as a benefit of the marketing, and track both outcomes.

Service introduction promotions can serve dual purposes of increasing sales in the given service and increasing sales in general due to the added exposure.

We have often seen a general increase in sales when a competitor enters the market and the existing cleaner runs defensive promotions.

Branding campaigns can be measured by sales trend changes.

Kyle Matthews, director of sales and marketing for Janet Davis Cleaners, describes that business’ tracking process: “We choose our actual spending by doing our best to track each source to identify what works and what doesn’t. We ‘tag’ new customers that redeem coupons... Then we run reports later, utilizing these tags to see what sales were generated from each campaign each year.”

Since the most common approach to marketing in our industry is to use discounts, the analysis will start there.

Discounts are easy to analyze because they are:

• Easy to promote,

• Easy to track,

• Easy for your staff to talk about, and

• Potentially quick-cash generators.

The results can be easily obtained through your POS system by measuring:

1. The sales on the promoted item

2. The total sales increase over the comparable period

3. The number of customer touch points

4. Customer actions and feedback

Also, watch for and measure the negative impact of discounts, which can threaten your business.

Giving the Impression of “Fake” Pricing —

Reduced pricing gives the consumer the idea that your “regular prices” are higher than they should be and that you are systematically overpriced. This consumer impression that “regular” equates to “inflated” is so pervasive that the federal government and many states have passed strict laws about advertising that incorporates price comparisons.

Measurement: Does the service usage drop after the sale and only recover on the next sale?

Special Pricing to Select Customers — If special pricing is offered to attract new customers only, your existing customers feel poorly treated and may even leave to become a new customer elsewhere.

Measurement: How many regular customers comment or request the “new customer” pricing?

Full-Price Business — Full-price business will be

diverted to lower revenue per piece and result in lower profits.

Measurement: Calculate the total cost of the product, including fixed costs, variable costs, promotional expense, overtime, failure to meet standards on other product categories during the sale, and damage to quality reputation if plant or system is overwhelmed by increased volume on sale item. Weigh all the costs against the net sales increase.

Waiting for Sale — Your staff may encourage customers to “wait for the sale” thereby delaying current business.

Measurement: Are the sales results suppressed in the period immediately before the sale?

Discounting Regularly — A steady stream of discounts will cheapen your brand and may actually drive away your best customers who question your motives, financial health and future stability.

Measurement: Customer retention of top 20% of customers by revenue.

Attracting Price Shoppers — Discounting also attracts price shoppers, a uniquely fickle audience that will hop to whomever has the lowest price.

Measurement: Retention of customers that used the discount.

•

•

Brian Cass, co-owner of Martinizing Metro Milwaukee, shares some tips for keeping the drycleaning workplace safe and clean.

•

•

•

Listen as Joe Hebeka, owner of The Belding Group, talks about both sides of the equation: buying and leasing a garment care property. “It’s all about the cash flow,” Hebeka says, “look at every situation individually.”

Security begins with the garment care location. Alex Yearout, owner of Complete Cleaners, discusses leadership, the power of a smile, having lighting to reassure clients and staff, and using video to solve “the mysteries of missing pieces.”

The results can again be obtained through your POS system by measuring:

1. Sales on the promoted item

2. The total sales increase over the comparable period

3. The number of customer touch points

4. Customer actions and feedback

The results may be more subtle and require more nuanced analysis.

Again, your POS system will provide the primary measurement relying on:

1. The total sales increase over the comparable period

2. Future period sales trends

3. The number of customer touch points

4. Customer actions and feedback

5. Formalized surveys

6. Customer engagement

In all types of promotions, there are internet tools that can be utilized to aid in results measurement and effectiveness impact. Most media sites provide their own analysis tools. There are measurement tools that compare the results from various sites and campaigns via a set of master reports. SproutSocial.com and Hootsuite.com are examples of sites that provide this service.

The test is a chance to learn about responses but also to get feedback about tweaks that can improve the campaign. The results may show that the message was good but could have been better.

Don’t abandon it if all that is needed is a clarifying refinement such as:

• a timing shift

• a copy tweak

• an added entertainment component

• an attention-grabbing graphic

For example, if you tested “run of station” (a broadcast formula that spreads your announcements into all day parts), isolate results as much as possible by the times and shows when the ads ran and then duplicate only the successful spots. They will be more expensive, but fewer will be needed to reach your target audience. You might find that midway through the nightly news works well for one customer segment or that the intro to The Late Show with Stephen Colbert works best for another.

A successful playful approach on one product can translate to another product that uses a more sober approach.

Tone and timing that worked well on Facebook may need to shift for LinkedIn.

Both broadcast and social media analytics tools can help with refinements.

Once any enhancing refinements have been made as a result of the test marketing, place the campaign for the full rollout in the formats and channels that proved to be most effective.

You may find that your budget needs reallocation or adjustment (up or down) based on the impact of various media channels on the results.

Promotional efforts should be reviewed during and at the end of the effort and rated for success, no matter what initiative is tried. Hard data about results should be recorded as well as relevant observations, recommended refinements, and historical and anecdotal notes for use in future planning.

Remember: Marketing is an art that can always be enhanced with scientific analysis, tracking and refinement. Make it a planning and budgeting priority and your business will reap significant rewards by rising above your competition.

ADC

Diana Vollmer is a managing director and senior consultant for Ascend Consulting Group, which assists dry cleaners and laun derers in maximizing profitability, enterprise value and customer allegiance. For assistance with tracking results of your marketing efforts, contact her at dianavollmer@ascendconsult inggroup.net, 415-577-6544.

American Drycleaner welcomes entries for its Publisher’s Impact Award, introduced last year to spotlight drycleaning industry achievements.

The Publisher’s Impact Award shines a light on a person, company, innovation or event that has made an impact on the drycleaning industry, the magazine notes. The late Dr. Manfred Wentz, who gave much to fabricare during a long career as scientist, educator, speaker and visionary, was the inaugural recipient.

“The Publisher’s Impact Award gives us a chance to tell the drycleaning community great stories about people, innovations, companies and special events

that have made a lasting impact on the industry,” says Charles Thompson, publisher of American Drycleaner and president of parent company American Trade Magazines LLC.

If you would like to nominate a person, company, innovation or event you believe has impacted the drycleaning industry for award consideration this year, e-mail your nomination by November 1 to Editorial Director Bruce Beggs at bbeggs@atmags.com

A panel of judges review nominations annually. If selected, honorees will be contacted for a special feature story, with photos, which will appear in the magazine’s future print and digital formats.

There are some customers who will only use our service after home treatment—hair spray on ink, talcum powder on grease, peanut butter on mustard or seltzer water on wine—has failed. On rare occasions, one of these treatments will bring about a small level of positive results. But, in most cases, all the customer has done is make the professional’s job more difficult.

An even greater problem comes when the customer fails to inform the CSR that stain removal has been attempted at home. The residue of the alkali in the bleaching agent used on the coffee, for example, will greatly reduce the effectiveness of the tannin formula used to pre-spot the stain.

The best course of action after the customer fails is to flush the area with steam, apply neutral synthetic detergent (NSD) and flush again. It is always best to know what you are up against when trying to correct inadequate stain removal.

Unfortunately, your customer will put more trust in the hype of a television commercial than in the expertise of a well-trained cleaner/spotter.

No amount of bleach will remove acrylic nail polish. The chemically soluble portion must be removed. It is only then that the bleach can be used to treat any remaining pigment.

Stains can become “set” with the passage of time or by exposure to heat.

An oxidized oil stain has a similar appearance to a caramelized sugar stain; however, the time and technique needed to remove oxidized oil are much more involved than for caramelized sugar.

The customer drips hamburger grease on a white cotton sweater, and this stain is almost invisible. The sweater is stored without being cleaned. The grease that went on warm turns tan over time, and now the stain is noticeable

and makes the sweater unwearable. Removing oxidized oil is a time-consuming process, in most cases requiring prespotting, cleaning, post-spotting and re-cleaning.

The same customer drips a clear beverage on the white cotton sweater. The stain is almost invisible. The sweater is stored without being cleaned and turns tan over time. The stain is now noticeable and makes the sweater unwearable. A majority of cleaners do not take the time to learn the difference between these two yellow/tan/brown stains.

You will notice that one of the stains will have a distinct outline that usually appears as an irregular circle. The other stain will appear to be surrounded by small crosses, which are the result of the oil wicking along the threads in both directions. The oil travels through and along the threads, outward from the point of contact rather than over the fabric.

A tan stain with a distinct outline is most likely a beverage stain. It could be fresh coffee, or it could be old champagne. Just like an apple turning brown when set aside after a bite or two, any sugar in a clear beverage will turn brown over time. If this stain is a clear liquid containing sugar, the initial flush of steam over the vacuum nose of the board will remove much of the stain. Applying NSD and light mechanical action, followed by another flush of steam over the vacuum nose of the board, will remove the rest.

If the stain is a liquid other than sugar (like coffee), using the flush-NSD-flush protocol will spread the fibers and heat the area, and the penetration of the NSD will carry the tannin solution deeper into the stain. It is a winwin method for removing the stain.

If it is sugar, the steam will “melt” and flush away most of the stain; if it is another beverage, you have removed some of the stain and prepared the area for further stain removal.

When you fail to notice the “crosses” surrounding the stain, you will find out very quickly that the stain is oxidized oil. When the flush-NSD-flush protocol and the first application of tannin have little or no effect on the

stain, look again for the “crosses” surrounding the stain.

Oxidized oil and grease are tougher stains to remove. The stain has been in the garment for a period of time, probably was warm at the time of staining, and has penetrated the fibers. Stop wet-side stain removal, dry the area, then begin dry-side stain removal. (If you have kept a little volatile dry solvent [VDS] on hand, it’s time to pull it out of the back storage cabinet. Just substitute the VDS when I reference amyl acetate.)

Over the solid portion of the board, place a towel under the stain and apply amyl acetate. Now, remove the towel and tamp aggressively. Apply just enough amyl ac etate to flush away stain particles that have broken loose. Place the towel under the stain again and apply your oily type paint remover (OTPR). Remove the towel and tamp aggressively. Then, place the towel under the stain and flush the area with amyl acetate. Repeat the application of OTPR and amyl acetate until the stain is removed or no longer breaks down.

I would be remiss if I didn’t mention how to “push” the process. There is a method that has had success in the past. While not available pre-mixed, alcoholic potassium hydroxide (KOH) solution has shown great success in treating oxidized oil stains.

You must locate a source for potassium hydroxide

pellets (1/3 ounce) and a quart of normal butyl alcohol. Carefully mix the potassium hydroxide with normal butyl alcohol. Allow the mixture to stand overnight to fully dissolve the potassium hydroxide.

While many cleaners have avoided taking this step, it is an option. Never allow this solution to get wet or fog the area with steam. Also, do not allow this solution to dry on the fabric.

Apply the solution to the stain and allow it to soak in and solubilize the stain for a few minutes. Tamp the area lightly, then flush out the KOH solution with amyl acetate. Dry-clean the item. If a yellow tint appears after dry cleaning, apply acetic acid to neutralize the remaining alkali, allow the item to dry, then dry-clean again.

Having the proper chemical tools is an easy and inexpensive way to improve your quality and expand your customer base. Word-of-mouth is still the most effective form of advertising.

ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20-plus years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates today. Phone: 704-786-3011, email: mayoung@ctc.net.

As a small-business owner, you are asked to be a jack of all trades. In a given week, you may serve as production manager, accountant, marketing guru and customer service representative. Bouncing from one to the other so quickly creates a genuine strain. This is compounded by the fact that we are constantly inundated with emails, social media, phone calls and employee requests. I’ve spoken with numerous drycleaning owners who haven’t taken a vacation in years.

At the root of this problem is that we often forget to set the same standards and boundaries for ourselves that we set for employees. When you fail to do that for yourself, that is the job you’re signing up for, and it’s why so many drycleaning owners are completely drained. To keep our battery charged, we need to be mindful of what causes us to become drained, and the best methods to ensure we recharge.

The first step is to limit the stress and anxiety that leads to exhaustion. Treat your personal calendar with the same importance as your work calendar.

For example, studies have shown that regular exercise is critical to reducing stress and increasing happiness. I keep a standing meeting appointment in my calendar for exercise and treat it with the same seriousness as if I had a work meeting. If someone wants to meet with me during that time, I just say I have a meeting and can’t do it.

Similarly important in reducing stress and fatigue is mindfulness. Just 30 minutes a day of quiet reflection or meditation enables your brain to recharge and enhances the clarity and effectiveness of your thinking. However, this is nearly impossible to achieve if you don’t treat it with the same importance you would a staff meeting.

Finally, it’s critical that you define your working times both in your calendar and with your staff and vendors.

I tell my teams and vendors that I work from 8 a.m. to 5 p.m. Monday through Friday and that they shouldn’t contact me outside those hours unless it’s an emergency. That’s not to say I don’t work outside those hours, but no incoming requests gives me the time for deeper problemsolving on the evenings and weekends as I choose.

I use an app called Calendly and block out the hours outside 8-to-5 to ensure my schedule stays clear then. I also turn off email notifications during non-business hours.

All of us need an occasional vacation to recharge our battery. Here, planning and communicating with your team members is vital.

Set the standard with your teams that every so often, you will be taking a vacation. Then add those occasions to your teams’ calendars so they get used to the cadence of you being gone and can plan accordingly. And be sure to schedule vacations so that any regularly scheduled meetings/tasks do not fall during those times. If your vacation is interrupted by work, then it’s not really a vacation.

Once you’re gone, turn off all notifications and inform your staff that if they really need to talk to you, they should call. I’ve instructed my teams not to call “unless a building is burning down,” just to clarify what really constitutes an emergency. Lastly, be sure to delineate with your staff who should be contacted in your absence and update your out-of-office messages to reflect that.

If you’re like most of us, you became an entrepreneur so that you can create a great business and have the freedom to enjoy life. But if you don’t consciously take the time to manage your schedule and recharge your battery, you might as well be working for someone else. ADC

Dan Miller is the CEO of Mulberrys Garment Care, a premium drycleaning and laundry business with 17 locations in Minneapolis, San Francisco, and Dallas. You may contact him at dmiller@mulberryscleaners.com or 866-473-0798.

The America’s Best Cleaners Leadership Forum, a free online video forum, will be conducted via Zoom monthly through February. The next session will be Oct. 14.

It was created for thought leaders of the drycleaning and laundry industry to come together and share how they have reacted to and managed the current business environment, and what steps their businesses are taking to plan for the future, explains Christopher White, executive director of America’s Best Cleaners.

“In our calls with affiliates, I learned that manufacturers, vendors and suppliers are out there doing unique things to cope and manage with the crisis,” White says. “I wondered why no one knew about these things and decided to give back to the industry with a forum where anyone—dry cleaners or launderers—could come together for a stronger sense of community.”

The Oct. 14 session beginning at 4 p.m. Eastern will include Victor Williams, vice president, Union Dry Cleaning; Harry Caranza, president, Select Risk; Jeff Shapiro, president, Cleaner’s Supply; Ryan Luetzow, owner, Luetzow Industries; Dan Miller, CEO, Mulberrys Garment Care; and White.

Future sessions are scheduled for Nov. 11, Dec. 9, Jan. 13 and Feb. 10.

The forum’s agenda will be a free-flowing discussion, with the panelists receiving questions in advance to prepare. The goal is to create a smooth dialogue regarding participants’ leadership philosophies and principles, economic indicators and future outlooks, White says. An audience Q&A will conclude the forum.

Whether interested in attending or applying to participate as a panelist, more information is available by visiting https://americasbestcleaners.com/leadershipforum.

The Southwest Drycleaners Association has announced its board and membership meeting will take place in person October 30-31 at The Woodlands Waterway Marriott Hotel & Convention Center, The Woodlands, Texas.

Keeping attendees’ health front of mind, health protocols will be in place, including requiring that face masks be worn in public areas.

The only event on the agenda for Friday, Oct. 30, is an Executive Committee meeting in the afternoon.

On Saturday, Oct. 31, activities get started at 8:30 a.m. with a Board of Directors and spouses breakfast, followed immediately by the Board meeting. After lunch, an education session is scheduled for 2 p.m. After the meeting ends at 3:30, there will be an optional DCRP Texas Sunset Extension meeting.

Given the state of COVID-19, and government restrictions fluctuating, the meeting may be restricted in some way, SDA says. It recommends that attendees make reservations that can be easily canceled should circumstances prevent the in-person event from being held as scheduled.

Anyone seeking more information or wishing to register may visit the event webpage at https://www.sdadryclean.com/woodlandsmeeting.

In response to a Facebook request for baby sleepers from the Methodist Women’s Hospital neonatal intensive care unit (NICU), drycleaning and laundry business Max I. Walker, based in Omaha, Nebraska, teamed with Goodwill Omaha to fill the need.

The NICU is a 51-bed unit staffed by a highly specialized neonatal team. Since opening in 2010, it has cared for more than 6,600 babies.

“We teamed up with Goodwill in April to donate scrubs to the Creighton medical scrub drive, and it was a really positive experience,” says Casey Walker, director of retail operations at Max I. Walker.

Max I. Walker and Goodwill managed the sleepers donation project the same way they did the scrub drive donation: Goodwill’s retail operations team gathered all the sleepers in preemie and newborn sizes from its stores, Max I. Walker laundered and bundled them, and members of the two organizations delivered more than 60 freshly cleaned sleepers for the young patients.

2020 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 12-time rates. If box number is used,

Surface

SPECIAL SALE IN DIFFICULT TIME! $1000.00 > > > $750.00/Refurbished, $2000.00 > > > $1450.00/New System Includes Computer, Touch Monitor, Invoice Printer, Cash Drawer, All Name Brands & One Year Warranty! www.westerndccomputer.com 773-878-0150, westernk@msn.com

add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month.

For example, for a September ad, the closing date is August 1st.

PAYMENT FOR CLASSIFIED ADS: Must accompany order.

Ehrenreich & Associates, LLC

We have the unique experience of Drycleaning Hands-on Management, Business Brokerage & Management Consulting to HELP YOU!

Contact Richard at 301-924-9247 or Richard@EhrenAssoc.com

Complete Mailing Addresses of Publisher, Editor, and Managing Editor. Publisher: Charles Thompson, American Trade Magazines LLC, 650 West Lake St., Suite 320, Chicago, IL 60661-1036 Cook County. Editor: Bruce Beggs, American Trade Magazines LLC, 650 West Lake St., Suite 320, Chicago, IL 60661-1036 Cook County. Managing Editor: Bruce Beggs, American Trade Magazines LLC, 650 West Lake St., Suite 320, Chicago, IL 60661-1036 Cook County. 10. Owner: American Trade Magazines LLC, 650 West Lake St., Suite 320, Chicago, IL 60661-1036 Cook County. Charles Thompson, American Trade Magazines LLC, 650 West Lake St., Suite 320, Chicago, IL 60661-1036 Cook County. Bruce Beggs, American Trade Magazines LLC, 650 West Lake St., Suite 320, Chicago, IL 60661-1036 Cook County. Donald Feinstein, American Trade Magazines LLC, 650 West Lake St., Suite 320, Chicago, IL 60661-1036 Cook County. Nathan Frerichs, American Trade Magazines LLC, 650 West Lake St., Suite 320, Chicago, IL 606611036 Cook County. John S Suhler, 200 Long Neck Point Rd., Darien, CT 06820 Fairfield County. 13. Publication Title: AMERICAN DRYCLEANER 14. Issue Date for Circulation Data Below: September

2020 15. Extent and Nature of circulation: (average number of copies each issue during proceeding 12 months = “X”) (Number copies of single issue published nearest to filing date = “Y”) (a) Total Number of Copies (Net press run): X=18,201, Y=17,089. b. Legitimate Paid and/or Requested Distribution (By Mail and Outside the Mail). (1) Outside County Paid/Requested Mail Subscriptions stated on PS Form 3541. (Include direct written request from recipi ent, telemarketing and Internet requests from recipient, paid sub scriptions including nominal rate subscriptions, employer requests, advertiser’s proof copies, and exchange copies.) X=10,910, Y=9,921. (2) In-County Paid/Requested Mail Subscriptions stated on PS Form 3541. (Include direct written request from recipient, telemarketing and Internet requests from recipient, paid subscrip tions including nominal rate subscriptions, employer requests, advertiser’s proof copies, and exchange copies.) X=0, Y=0. (3) Sales Through Dealers and Carriers, Street Vendors, Counter Sales, and Other Paid or Requested Distribution Outside USPS®: X=0, Y=0. (4) Requested Copies Distributed by Other Mail Classes Through the USPS (e.g. First-Class Mail®): X=0, Y=0. (c) Total Paid and/or Requested Circulation (Sum of 15b (1), (2), (3), and (4)): X= 10,910, Y=9,921. (d) Nonrequested Distribution (By Mail and Outside the Mail). (1)Outside County Nonrequested Copies Stated on PS Form 3541 (include Sample copies, Requests Over 3 years old, Requests induced by a Premium, Bulk Sales and Requests including Association Requests, Names obtained from Business Directories, Lists, and other sources): X=6,799, Y=6,663. (2) In-County Nonrequested Copies Stated on PS Form 3541 (include Sample copies, Requests Over 3 years old, Requests induced by a Premium, Bulk Sales and Requests including Association Requests, Names obtained from Business Directories, Lists, and other sourc

www.withoutatrace.com.

es): X=0, Y=0. (3) Nonrequested Copies Distributed Through the USPS by Other Classes of Mail (e.g. First-Class Mail, Nonrequestor Copies mailed in excess of 10% Limit mailed at Standard Mail® or Package Services Rates): X=0, Y=0. (4) Nonrequested Copies Distributed Outside the Mail (Include Pickup Stands, Trade Shows, Showrooms and Other Sources): X=6, Y=5. (e) Total Nonrequested Distribution (Sum of 15d (1), (2), (3) and (4)): X=6,804, Y=6,668.

(f) Total Distribution (Sum of 15c and e): X=17,714, Y=16,589. (g) Copies not Distributed (See Instructions to Publishers #4, (page #3)): X=487, Y=500. (h) Total (Sum of 15f and g): X=18,201, Y=17,089. (i) Percent Paid and/or Requested Circulation (15c divided by f times 100): X=61.59%, Y=59.80%. 16. Electronic Copy Circulation: (a) Requested and Paid Electronic Copies: X=400, Y=1,392 (b) Total Requested and Paid Print Copies (Line 15c) + Requested/Paid Electronic Copies (Line 16a): X=11,309, Y=11,313.

(c) Total Requested Copy Distribution (Line 15f) + Requested/Paid Electronic Copies (Line 16a): X=18,108, Y=17,981. (d) Percent Paid and/or Requested Circulation (Both Print & Electronic Copies) (16b divided by 16c x 100): X=62.46%, Y=62.92%. I certify that 50% of all my distributed copies (electronic and print) are legitimate requests or paid copies. 17. Publication of Statement of Ownership for a Requester Publication is required and will be printed in the October 2020 issue of this publication. 18. Signature and Title of Editor, Publisher, Business Manager, or Owner: I certify that all information furnished on this form is true and complete. I under stand that anyone who furnishes false or misleading information on this form or who omits material or information requested on the form may be subject to criminal sanctions (including fines and imprisonment) and/or civil sanctions (including civil penalties): Charles Thompson, Date 9/15/2020

American Drycleaner, October 2020 www.americandrycleaner.com

2020 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 12-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month. For example, for a June ad, the closing date is May 1st.

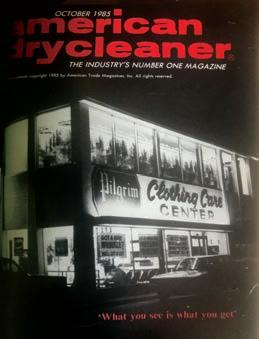

Day or night, Pilgrim Clothing Care Center in Richfield, Minn., attracted attention with a moving conveyor and eye-catching signs when featured in October 1985.

10 YEARS AGO. Held every two years by the California Cleaners Association (CCA), Fabricare 2010 benefited from unusually pleasant weather, even for Southern California. Despite there being fewer booths and fewer people than in years past, a standout among the seminars was a talk on marketing and customer service with Robert Shapiro, general manager of Milt and Edie’s Drycleaners in Burbank, Calif., and Barry Gershenson, executive coordinator of Leading Cleaners Internationale (LCI). Milt and Edit’s, of course, is the namesake of Milt Chortkoff, a longtime marketing and customer-service guru.

35 YEARS AGO. The new trademark of Pilgrim Clothing Care Center in Richfield, Minn., is a moving upand-down call conveyor, added when owner Jerry Fingerman remodeled in March 1984. The conveyor keeps the freshly cleaned, poly-wrapped garments in constant motion from first floor to second and back again. Fingerman has a 24-hour-a-day promotion going, and a spotlight turns it into a nighttime panorama.

50 YEARS AGO. A North Shore drycleaning and dyeing establishment, according to the Boston Evening

Globe, has this sign on the side of its delivery truck: Observe Caution … Dyeing Man Driving. … When a drycleaning plant manages to keep its sales on a constant level during an economically recessive period, it must be doing something right. Such a plant is Al-N-Way Cleaners in Minden, La. He think sales may average $2,000 a week for 1970. And that’s on a basic price of $1.40 for suits, 30 cents on shirts. Allen attributes the plant’s success to his new location, a drive-up window and customer parking facilities.

75 YEARS AGO. Four maimed veterans are operating the Veterans Cleaners, a group of four drycleaning agencies in Detroit, and hope to open their

own plant. Charles Orzell, who suffered a bout with rheumatic fever, tried working in a grocery store after his Air Force discharge but was hampered by the ailment’s effects. He learned two agencies were for sale and the resulting Veterans Cleaners prospered. The men say their plant will be operated by veterans and any profits will be used for welfare work among disabled veterans. … When Walter Roth saw he had a bottleneck in the spotting department at Davies Laundry, he didn’t look for more spotters. No, he devised a bonus system that rewards the spotters on staff for working harder. The result: better cleaning and sorting have spotters earning an extra 20%.

ADC —Bruce Beggs

The Parker Boiler tube bundle is extremely flexible and offers a long life with a 25 year warranty against thermal shock.

Each unit is Factory Assembled & Fire Tested. 4 years of Field Testing.

Extra heavy boiler tubes 1-5/16” OD. minimum 0.12” (11GA) heavy thickness steel, built for long term service life.

5:1 Burner Turndown Ratio. Digital Pressure Control. Boilers require access on two sides only. Reflex Prismatic Sight Glass. Up to 4” of insulation and 1/2” thick steam drum.