Taking control of what you can is a must in operating a successful business. However, how you react to forces outside your control is just as important.

One of the few positives many dry cleaners have taken from the past couple of years is that they have become more flexible. They were willing to set aside the status quo to explore new ways of doing business and serving their customers. By taking advantage of advancing technology, “the way we’ve always done it” became “what can we do next?”

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

DavisOur first feature in this issue, “Pivoting for Profit,” highlights some of the activities cleaners have taken over the past two years to protect their profitability as they steered their business through the months of the pandemic. By examining their businesses in a new light — and taking actions that they’d only once considered — many cleaners have found new roads to profits that they might not otherwise have taken.

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Dave Davis 312-361-1685 ddavis@ATMags.com

Digital Media Director

Our final feature, “Fuel Prices, Routes and Uncomfortable Decisions,” looks at another factor dry cleaners have no control over and how they’re dealing with it to maintain profitability. The surge in fuel prices has caused many cleaners operating extensive routes to recalculate how they charge for pickup and delivery services.

Stay flexible, control what you can, and maintain a mindset open to new possibilities! ADC

Our second feature, “Taking Advantage of Touchless Opportunities,” examines some of the options available to dry cleaners who want to offer their customers more options when it comes to dropping off and picking up their clothing.

Due to an editor’s error, there was a mistake in our 2022 Buyer’s Guide. Here is the corrected entry. We apologize for the error.

Messe Frankfurt Inc. 3200 Windy Hill Rd., Ste. 500 West Atlanta, GA 30339

Contact: Jewell Kowzan Phone: 678-732-2416 jewell.kowzan@usa.messefrankfurt.com www.usa.messefrankfurt.com www.cleanshow.com

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $50.00; 2 years $100.00. Foreign, 1 year $120.00; 2 years $240.00. Single copies $10.00 for U.S., $20.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 89, number 2. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2022. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, May 2022

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Mathew Pawlak

Jan Barlow

Mike Bleier

John-Claude Hallak

Wesley Nelson

Kyle Nesbit

Mike Nesbit

Fred Schwarzmann

Beth Shader

Vic Williams

Dan Miller

Diana Vollmer

Martin Young

Office Information

Main: 312-361-1700

Subscriptions 847-504-8175 ADC@Omeda.com www.american drycleaner.com

By Dave Davis, Editor

By Dave Davis, Editor

Business owners can often rely on past performance and habits to indicate future results when things are going well. For some, innovation — leaving their comfort zone — isn’t high on their list of things to do when they don’t see a particular need for it.

When that business model gets upended, however, as the pandemic did to the drycleaning industry in 2020, new business models and fresh streams of income can go from thoughts of “that would be nice” to red-alert status.

“They had to pivot,” Mary Scalco, CEO of the Drycleaning & Laundry Institute (DLI), says of dry clean-

ers. “They could not rely on doing things the same way they’ve always done them. When your business goes down by 80% overnight — and that’s what most people saw — they had to figure out a better way to do things.”

For Joe Gagliostro, president of Muldoon Dry Cleaners in Auburn, New York, this meant reexamining some fundamental beliefs and attitudes about his business.

“I was always anti-laundry,” he says. “We were way too busy and more equipped than we needed to be to spend my time doing people’s dirty socks and underwear. When COVID hit, and the volume dropped off, some people started inquiring about wash/dry/fold, including some of our top clients. So, we absolutely accommodated those customers.”

This led Gagliostro to examine other areas that could fill the gaps that the fall-off in drycleaning business had left.

“Another area where we did well with was (cleaning) outdoor furniture, and specifically patio cushions,” he says. “We did some for people, and those people told other people. Outdoor patio cushions ended up being the biggest thing that we’ve pivoted to.”

Casey Walker, vice president of retail operations for Max I. Walker, based in Omaha, Nebraska, says his company had a similar experience and found there was business to be done because of the pandemic.

“The pandemic really accelerated the push of wash and fold as a service for other businesses,” Walker says. “This service was somewhat of a niche for mostly residential customers prior to the pandemic. But as small businesses evaluated their practices, many realized they needed to improve their sanitation of a range of textiles that are used day to day. We have been able to fill that need.”

Max I. Walker also took the opportunity to assist its surrounding area in any way possible. This included partnering with hospitals to clean cloth face masks at no charge, laundering donated sleepers for premature babies in the NICU, and offering deep discounts to first responders.

“While this did not help profitability during the initial downturn, it sent a clear message to our community that we were doing everything we could to provide support and assistance,” Casey Walker says. “In turn, these gestures of goodwill led to increased profitability later, as things began to open back up.”

For Tim McCann, who owns Best Cleaners in the Albany, New York, area with his wife, Catherine, pivoting meant striking out in a totally new direction, using the tools that dry cleaning provided. They did this not by “adapting” the Amazon model that has changed consumer behaviors but rather by joining the Amazon model.

“In 2020, we started Best Logistics,” McCann says. With this business, McCann’s team works to complete “last-mile” deliveries for Amazon.

“We had been considering and working on that preCOVID and were actually awarded a contract from Amazon right before COVID. Catherine and I were not sure if we were going to do it, and then COVID hit, and that answered that question. And we absolutely decided that that was going to be something that we pivoted to.”

One element that made this choice attractive to the McCanns is that Best Cleaners and Best Logistics use the same infrastructure.

“We share the same back office, we share the same

physical space, and we share employees,” McCann says. “Many of our last-mile pickup and delivery team members had been working for the cleaners. When COVID hit, we went from 90 employees in the cleaning business to about seven in a week. Many of those team members pivoted over to work with us on the logistics side as we were building that up.”

This diversification might look like a massive departure from Best’s previous business model, but McCann doesn’t see it that way.

“For us, it was a good extension of what we were already good at on the retail drycleaning side,” he says. “We were good at attracting great people and great talent. Sometimes this is untrained talent, but they are great humans, and we provide a skill set, and then provide a career framework that allows them to grow with us.”

Making deliveries for Amazon didn’t require as much retooling as one might think, McCann says: “It’s really just a simplified service business. In a lot of ways, it’s much simpler than retail dry cleaning. I don’t have to be a great marketer to deliver packages to your door. I don’t have to deal with or understand chemistry or steam fitting, plumbing, HVAC, or the many disciplines that are required to be successful in garment care.”

This logistics element is the third facet of McCann’s entire business, having become a restoration partner with CRDN in 2009.

“Dry cleaning is about 30% of our total top line, restoration is about 35% and logistics is 35%,” McCann says. While he expects dry cleaning to pick up as people return to the office, this diversification is valuable to McCann and uses tools his business already has available.

“Any successful garment care company has this crazy, broad set of skills,” he says. “I am looking to leverage and maximize the assets that we have. Over the years, we’ve invested in our plant and equipment, and built a great core set of team leaders and management. We think of ourselves as a training company, not as a drycleaning company or a logistics company. We onboard people, train them and get them excited about what we’re doing here. And then we hold them accountable to a standard.”

Having different types of positions open gives McCann much more flexibility when it comes to hiring and retaining employees.

“As everybody is struggling to find great team members,” he says, “we sometimes find that, for some of our delivery drivers on the logistics side, that type of activity is not the perfect fit for them. But they’re phenomenal people, and we have opportunities on the restoration team, or we have opportunities on the retail team. We’re able to give people across our team a different view of ▼

what their career could be — that there is movement and flexibility for them.”

While Kurt Lucero, owner of The Cleanery in Albuquerque, New Mexico, also added wash/dry/fold and household cleaning to his company’s services, he believes the biggest and most valuable pivot he made was to his own outlook on the business.

“I really got into the trenches with my people, especially in 2020 and a lot of 2021,” he says, “and I gained a new appreciation for my team. Of course, I valued them, but I came out with a completely different attitude about them. That was an important pivot for me.

“We looked at what we could do for them and how we could incentivize and appreciate them. We have Friday breakfasts now and make the atmosphere more fun and supportive. It’s not all about generating revenue, because if I don’t have any people to do the work, I’m really in trouble.”

Lucero also put a new value on his marketing efforts as the pandemic increased its grip on the industry: “I never had a huge plan or budget for marketing. It was more, ‘Let’s try this. Let’s throw some direct-mail pieces this way.’ It was never a targeted approach.”

He started marketing new services, including cushion cleaning, and using new mediums, such as text messaging.

“The pandemic showed me where I needed to pivot and evolve in my marketing protocols,” he says. “I had to look at my business in a whole new way, actually having a plan and implementing some of these ideas, rather than having these wonderful ideas in a notebook that never came to life.”

When shifting or expanding focus, it ultimately falls to the company’s team members to make changes successful. Casey Walker says that communication is vital for this to happen.

“Getting personnel up to speed is all about confidence,” he says. “In any new service you’re going to offer, or procedural change being made, making sure your team feels supported and confident in what they are doing is paramount. Proactive communication with detailed instructions, explanations and incentives for compliance will go a long way.”

Walker believes success hinges on the messages and attitudes coming from the top, so leaders need to be allin on new initiatives.

“Of course, there will always be resistance to change — that is human nature — but it’s management’s job to help the team see the value in that change,” he says. “When it comes to rolling out services, be sure you have an enthusiastic and trusted leader to champion it, who everyone knows is the authority on this new offering. And be consistent with your messaging.”

Gagliostro found that his team was, and continues to be, up to the challenge.

“Everything fell into place extremely smoothly,” he says. “Even today, we’re running a very limited staff compared to what we had three or four years ago — we’re not laying people off, but it’s just very difficult to hire at the moment. So, we’re still short-handed, but everything has fallen right into place.”

When starting a new venture, it can be difficult to know where to start or what to expect.

“The biggest risk is being vulnerable to the learning curve,” Gagliostro says. “You have to gain experience, and you’re going to make mistakes. You’re not going to know how to process something, or you’re not going to give an adequate amount of time to do it, so you’re not going to know your sweet spot for the profit margin. Finding that threshold of efficiency, I think, is actually the risk, so you have to educate yourself.”

▼

Fortunately, Scalco says, there are plenty of opportunities in this industry where dry cleaners can avail themselves of opportunities to network with other cleaners and learn from their experiences.

“We started these peer-to-peer calls we now have once a week, and what was amazing to me throughout this pandemic was how willing our members are to share information with one another,” she says. “We see this on online forums as well. People ask a question, and they get advice from those who know what they’re doing.”

McCann advises dry cleaners to ask honest — and potentially difficult — questions of themselves before taking the next steps.

“One way to minimize the risks, I think, is to do a selfskill assessment,” he says. “What did you learn about yourself through the pandemic? What did you learn your hidden strengths were through COVID? Lean toward those. Understand how deep the skill sets are that this industry forces upon successful operators and know that those are transferable and applicable into what I would say would be kind of any human-based service business.”

Lucero believes that going into new areas can mean leaving some old ideas behind.

“During an industry meeting, a cleaner said, ‘This is going to separate the dry cleaners from the entrepreneurs,’ and that really stuck with me,” he says. “I can’t just wait for customers to come in. I’ve got to take some action. I can’t control everything that’s happening, but I don’t have to sit there and wait, either. We need to have the mindset that we’re not just dry cleaners anymore. How can we solve problems that our customers are having? Maybe we don’t have that service line yet, but could we if we were open and curious enough?”

“Cleaners have to think of themselves differently,” Scalco agrees. “They need to think of themselves as a convenience, not just as dry cleaners. They have to think of themselves as textile cleaners. It becomes a mindset. And it took a crisis for people to come to terms with that. They’ve now had more than (two years) to come to terms with it.”

While business leaders need to adjust their offerings to better serve the ever-changing demands of their customer base, Walker believes that cleaners need to make sure they have the elements necessary to succeed.

“You can’t expand your business without pushing the boundary of your comfort zone. That being said, if you do not have the right person for the right job, then your core business will suffer. You could damage your brand’s reputation. If you have a great person for the new service, then give them the tools to succeed and go for it.”

American Drycleaner, May 2022

Scalco believes that trying something new doesn’t necessarily mean completely rewriting your business plan. With the exception of starting route services, she says, most new service ventures in dry cleaning don’t require a large capital investment: “It can’t hurt to try. In most cases, you can start out small and see what happens.”

Being open to new ideas is one of the best abilities a cleaner can have, Gagliostro says — a lesson he’s learned over the past two years.

“I went from saying, ‘I refuse to do laundry’ to, ‘Actually, that’s not a bad idea,’” he says. “We are 100% open-minded. One of my new service ideas is testing a subscription model, where the customer pays X amount of dollars for the month and gets their wash/dry/fold service. We’ll see how that goes.”

For the survivors of the pandemic’s economic fallout, Scalco believes that better days are ahead — if they’ve taken lessons from what has happened.

“People ask if we’re ever going to come back to 100%. I think they’re going to come back 110% because of what they learned in the past,” she says. “Cleaners added new diversifications. They added new ways of getting customers. I call it ‘COVID time’ — everybody was thinking about doing these things. Well, COVID didn’t allow you to think anymore. You had to put things into practice. And you had the luxury of screwing up because you had plenty of time to work on your business. You had nothing but time.”

Gagliostro believes that flexibility is key to future success: “Be as open-minded as possible. Listen to your clients and see what’s going on out there. Learn from others. As long as you can diversify and are able to shift with the needs and demands of the consumer, you should be fine.”

“I think the survivors realized that they’ve got to take action and cultivate relationships,” Lucero says. “We’re in the perfect business for that. We have great relationships with our clients, and I didn’t really realize that until I was in the trenches, working production and running routes. Our customers don’t just value sending dirty shirts and getting clean ones back. It’s more than that. We are saving them time. We’re taking care of their family. We’re part of the team that makes their lives better.”

Armed with his new attitude, Lucero is eager to see what happens next.

“I am excited about the industry and my business,” he says. “Sure, I’m a little guarded. It’s not the same as it was before, but I believe that, if you take some action and you appreciate your people and your clients, there’s room for growth.”

There’s more: We’re just two members of NIE’s team of experts. NIE has been handling fabricare insurance since 1915!

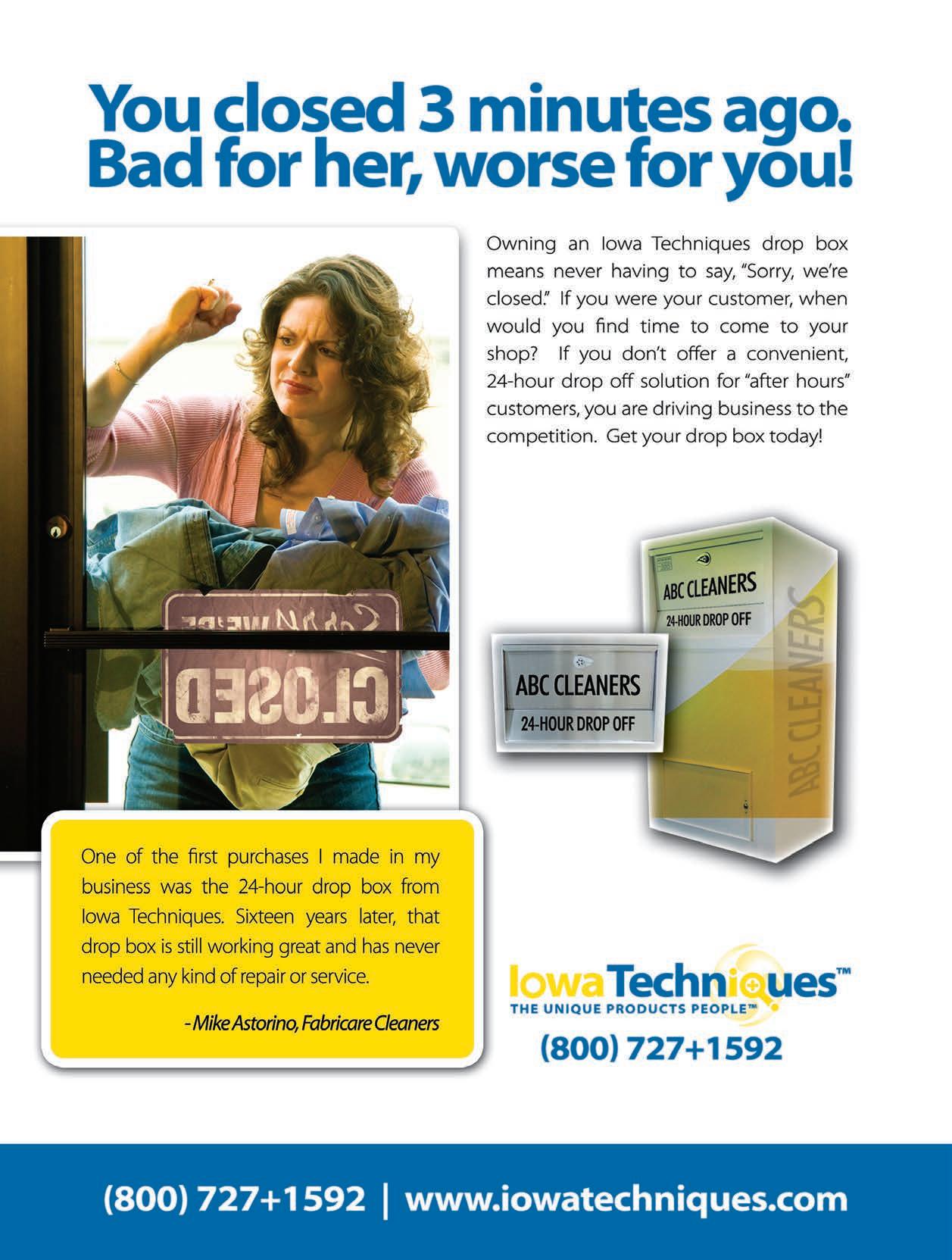

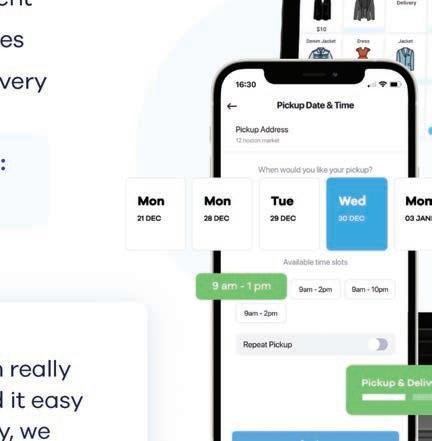

Convenience has always been a cornerstone of excellent customer service in the drycleaning industry, and, as the coronavirus pandemic gripped the country, the importance of contactless options skyrocketed.

Couple these elements with the fact that many people are working on different schedules than they were pre-pandemic, and it’s easy to see why many cleaners are putting touchless technology into service at their stores.

These tools can take many forms in a drycleaning business, ranging from always-available drop boxes and lockers to complex 24/7 automated kiosk sys-

tems. Whatever form it takes, such a system has one primary purpose — to make the transaction easier for the customer. And, when a system is properly utilized, touchless technology can also benefit the cleaner’s bottom line.

“The biggest advantage to customers is that they can have access to their clothes, 24 hours a day, seven days a week,” says Steve Arnold, partner and general manager of Classic Cleaners, a 17-store chain in Indianapolis; an 18th location is opening in May.

Classic has offered locker service to customers since 2004, and it began using kiosks in four of its locations in 2018. The chain’s latest store, Arnold says, doesn’t include a counter; most items are processed through the kiosk or drop chute, even if a customer service representative is present.

“The other advantage to us is that we reduced our hours of being open and attended for the customers,” he says. “We used to be the traditional 7-to-7 dry cleaner Monday through Friday, and 8 to 6 on a Saturday. We’re now 9 to 5 on weekdays, and 9 to 2 on Sat-

to the(Photo: © sdecoret/Depositphotos)

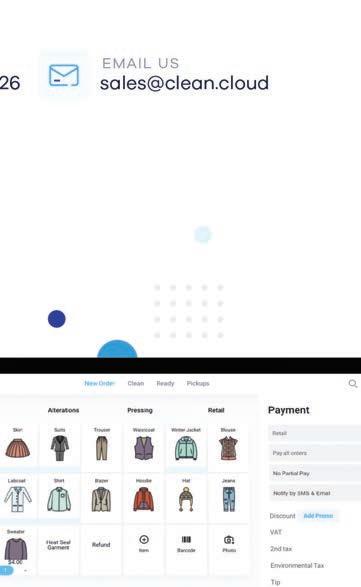

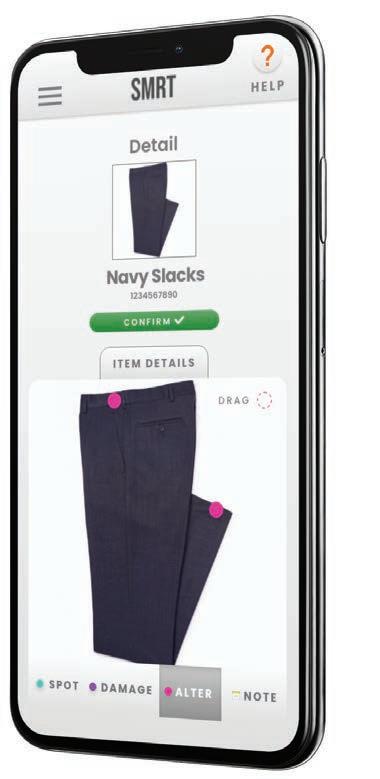

Upload pictures, track deliveries, and submit order status updates from anywhere, at any time.

Root out employee theft and increase accountability through machine learning and cash box security.

SMRT generates reports for every metric of your business. Access analytics 24/7.

Keep your data safe with industry-leading security encryption, threat monitoring, and detection.

Powerful communication tools and Interactive technology effortlessly combine innovation with quality customer service.

Upload pictures, track deliveries, and submit order status updates from anywhere, at any time.

urday, so we’ve been able to reduce our staffing. We were able to save at least 200 to 300 hours a week.”

Carlyn Parker, director of operations of Dependable Cleaners in Boston, also has a mixture of touchless technology throughout her 12 stores. This includes drop-off drop boxes and racks where customers who indicate via the company’s mobile app that they are on their way can pick up their clothing.

“We also have a 24-hour kiosk in one of our stores,” Parker says. “That’s very popular with people. It’s a commuter store — a lot of people go to the commuter boat that docks close by. So, when they get off the boat at 6 or 7 o’clock, they can still get their clothes after we’ve closed for the day.”

With work-from-home, hybrid-work and other models having upended the typical 9-to-5 schedule, the flexibility of touchless systems can open up whole new groups of consumers, says Matt Kool, owner and president of Iowa Techniques, a manufacturer of drop-box systems located in Hutto, Texas.

“You’re actually keeping time with the customer, instead of the customers keeping time with you,” he says. “We’ve always looked at the through-the-window or through-the-wall drop unit as an extension of cleaners’ business hours. And then, freestanding units, which can be located off-site, are an extension of their business footprint.”

In addition to offering better convenience to customers, cleaners can also streamline their operations and get more efficient work from their employees, says Brett McLeod, president of Garment Management Systems, a kiosk and automation producer based in Little Rock, Arkansas.

“Our systems are primarily used in drop stores, and drop stores are incredibly labor-inefficient,” McLeod says. “You’re staffing it 10 hours a day, and that person may be legitimately busy one hour out of those 10. That’s horrible utilization. If you take it from being staffed 10 hours a day to four hours, that person is more productive — they have some work to do, but just not 10 hours.”

McLeod believes that stores built around touchless systems also provide owners with more flexibility when it comes to staffing: “Everyone is having labor issues right now. If my drop store has a kiosk, and the employee calls in sick, I don’t have

to scramble around because I know the store can still function.”

The pandemic accelerated the process of adopting touchless technology, says Nathaniel Dubasik, sales and support manager at Metalprogetti USA, a kiosk and automated system provider headquartered in Phoenix.

“COVID sped that up,” he says, “and I think you can see that in many different businesses. I was at CVS the other day, and they have a self-checkout. Costco has a self-checkout. It just used to be your grocery store, but now it’s at Home Depot, Lowe’s — it’s everywhere. People are getting used to it, so this technology is coming at the right time. The comfort level people have with touchless systems has been accelerated by the rest of the world coming to the same place.”

As with any new consumer-facing technology, there will be those who immediately adopt the new method and those who are more hesitant. Arnold has found that instructions need to be clear and available to clients.

“It’s an ongoing process to educate customers,” he says. “There’s signage within the stores that says, ‘Start here at the kiosk.’ The kiosk itself has signage, and we also created a video that plays in the lobby to help instruct people how to use a kiosk when we aren’t attended. And then, when a customer comes in and we know they’re new, and we’re attended, our person will go up and show them how to use it. On all this, we stress that it’s really simple to use.”

“I see touchless options similar to ATMs,” says Frank Dubasik, director of U.S. operations for Metalprogetti. “There’s nothing more personal than your money, and it took quite some time for consumers to accept using a machine to manage their money. I’m 61, and I specifically remember that I would not consider using an ATM for a long time. I see this the same way.”

“From my experience with affiliates who have put in touchless systems within the last 10 years, we’ve learned that you have to be prepared to commit,” says Christopher White, executive director of the consultancy group America’s Best Cleaners (ABC). “Prepare for anywhere from 60 to 90 days, or even longer — you’ll need to have an educational com- ▼

ponent to show your clients how to use it.”

Before teaching customers how to use the new machines, White says, it’s vital that the company’s management understands the technology, and then trains the client relations representatives who will interact with the customers.

“Perhaps allocate an additional person during those peak times to spend the time with people and let them really understand and feel comfortable with it,” he says. “Typically, once you do that, you gain a lot of traction. But there is a learning and educational component that you have to plan for, and it’s probably a lot longer than most dry cleaners would expect or want to commit to. But it’s necessary. There becomes a tipping point — this ‘aha’ moment when the critical mass gets it, and you don’t need to be so diligent about it.”

“The feedback from customers has been generally positive,” Arnold says, “and it’s mostly about the aspect that they can get their clothes any time. There have been a few negative comments, and most of them have been that they’re worried about their favorite customer service person and not being able to talk to that person. For our situation, we’re always going to be attended. I know that some other dry cleaners have talked about trying to set up a non-attended site, but we feel like we need to be attended to take care of customers’ questions.”

“I was in the store one day when it was closed, but I walked out and saw a customer,” Parker says. “I told him I could help him, and he said, ‘No, no, I like this better.’ And I said, ‘OK, great!’ Especially during the pandemic, people gravitated to the touchless system and learned it much faster than they would have pre-pandemic. They learned from the grocery stores and from Uber and Instacart. It made it so much easier for us to have our touchless systems at the same time.”

“One of the biggest misconceptions for cleaners is that they assume all their customers want the personal touch,” McLeod says. “I recently spoke with one of our clients in Atlanta, and her opinion is that, for customers under 50, their desire for the personal touch is minimal. I think cleaners have a history of assuming that what was important 10 years ago is still important today. They’re not very good at letting go of the past and changing the way they do business to be more profitable given the current climate.”

Parker agrees with White’s advice, seeing the results in her own store.

“For the kiosk, it was having a dedicated person in the store every day who believed in the kiosk and knew the system top to bottom — they taught everybody how to use it,” she says. “We still teach people today, and we’ve had it for almost four years. But people like technology.”

Many dry cleaners base part of their business model on providing their customers with personality and great customer service. While touchless systems might be more efficient, many cleaners believe that the personal touch might get lost in the transition.

“Most cleaners look at drop boxes as a way to keep better time with their customers,” Kool says. “They’re looking for any way that separates them from the guy next to them, so this is another tool they offer. A certain number of customers will take advantage of this, while other customers really want to spend time talking with the folks at the counter.”

“If you’re smart about how you manage it and look at when clients do come in, you could still have a human there,” White says, “but I think the loyalty aspect comes into play when you’ve made it so easy and convenient for them to get their work done by you. They’re saving their time, and that builds loyalty. You’re there for them 24/7. And then, when you complement that with route pickup/ delivery service, you’ve created an ideal scenario for the customer to have the most convenient and ▼

seamless opportunity to do business with you.”

Frank Dubasik also believes that touchless systems can help dry cleaners avoid pitfalls that they might not have considered.

“If you have a counterperson with a good personality, you have good sales,” he says. “What happens when that person leaves? You’re going to take a hit on your revenue. With a touchless system, your income is tied to technology, not personality. When you’ve taught your customers to use this type of system, a change of staff really has no effect on your revenue.”

Rather than eliminating jobs because of touchless systems, Parker says they’ve allowed her to make the most of her team’s efforts.

“Instead of cutting employees, we move employees to different spots where we need them,” she says. “We haven’t found huge labor savings, because we’ve been able to add on some extra services for customers and do extra things for them. We’ve upped our quality with those same employees, so we didn’t lose any people for it.”

When investing in new technology, business owners may think they know what to expect. Still, the experience often brings new things to light, and touchless technology is no different, Kool says.

“I think that the biggest surprise is going to be that the frequency of the interaction per customer dropping off clothes is going to be more regulated and consistent,” he says. “The time that the customer comes in to pick up their clothes is going to be shortened, as well, because they’re picking up clothes and not dropping off and picking up. The per-order size might decrease, but that’s only because you’re able to service the customer on a more frequent basis.”

Because a customer’s payment information is kept on file when using a kiosk, McLeod says, this can streamline a cleaner’s processes: “Getting their money upfront, instead of whenever the customer picks up, makes for a better cash flow. And cleaners have seen that customers are picking up their clothes quicker because they’ve already paid for it — another benefit to the cleaners.”

Touchless technology doesn’t allow for all things, but Parker believes there are ways to work around these issues.

“You can’t put folded shirts or wash/dry/fold in

the kiosk, so that’s one of the challenges,” she says, “but it seems to be a minimal problem. Our customers don’t seem to mind. They know when they bring in wash and fold, they’ll have to come into the store and get it. I’ve spoken to the store manager, and she says she doesn’t get any problems with it — customers just adapt to what is available.”

Businesses are as unique as the people who run them and the customers who use their services, and touchless might not be the right fit for every dry cleaner. White believes cleaners should look at their entire operation before making the decision.

“No one is saying that this is a silver bullet to solve all ailments or problems,” he says. “Each business in each market has its own unique challenges and opportunities — what works in one market may not work for others. You need to ask if it’s right for you and your brand and your market. Give it a gut check and don’t just go for the shiny new thing. It’s a substantial investment — not just in the equipment, but in the shift of what you’re offering to your customers and what kind of messaging you’re putting out there with your brand.”

For cleaners who do decide to invest in a touchless system, Arnold advises them to get buy-in from their team before rolling it out to the customer.

“You have to get your employees to change their habits,” he says. “There is a difference between the stores whose employees have embraced it and those who don’t understand it. You have to have a training program that shows all the benefits, and make sure all the employees understand them so they can communicate those benefits to the customer.”

Parker believes this technology will find a permanent place in the drycleaning industry.

“People have gotten used to touchless,” she says. “I didn’t use Instacart at the beginning of the pandemic, and now I use it every week. It’s great because it’s one less thing I have to do. I believe that people will feel the same way about drycleaning and home-delivery kiosks. It just makes your life that much more convenient.

“I think touchless systems are here to stay. I think they’re going to grow, and I think there’ll be more players in the touchless industry that will change the market.”

Anew challenge was the last thing dry cleaners wanted to face as the industry continues to recover from the damage brought by the pandemic.

When Russia invaded Ukraine in February, however, ripple effects were soon felt throughout the world. Beyond the humanitarian disaster this action created in Ukraine, the global economy soon faced a crisis as international sanctions on Russia curtailed the amount of oil available on the international market, causing gasoline prices to rise dramatically.

Dry cleaners, already dealing with supply chain issues, labor shortages and shifting market demands, soon found their expenses were increasing again. This was especially true for those with large route operations.

So, why did gas prices increase so dramatically, and what should cleaners do to compensate for yet another spike in expenses?

“We have this obvious impact of the third-largest oil producer in the world being essentially frozen out of the market,” says Dr. Chris Kuehl, an economist and managing director of Armada Corporate Intelligence. “Seventy percent of Russia’s oil has no market right now because there’s no place to sell it.”

Still, on the surface, it can be difficult to see why prices in the United States were affected so quickly.

“When you look at the total amount of oil that we would get from Russia, it was on average, annually, less than 2%,” Kuehl says. “We never did do much

business with Russia because it was just easier to do busi ness with countries that were closer. To buy from Russia, you would have to put it in a tanker, then come through the Black Sea into the Mediterranean. Why would we go through all that? We just bought it from the Middle East, and they’d ship it around the Horn of Africa or through the Suez Canal, and we were good to go.”

However, Kuehl believes that the impact on the U.S. becomes apparent when we look beyond America’s borders. Because many European countries are major importers of Russian oil, forgoing that supply put more stress on the world’s markets as they looked elsewhere to meet their needs.

“That’s what hit us immediately,” Kuehl says. “Oil is a global commodity.”

So, why aren’t other petroleum producers, both foreign and domestic, increasing their production to make up for the shortfall? Kuehl believes it’s because they’re taking the long view of the situation.

“The more subtle thing that is slowing down the recovery is that the oil sector looks at this current crisis as something that is temporary, or at least could be,” he says. “They believe, however unlikely it is, that if there’s a quick end to this conflict — the negotiations start, there’s a cease-fire, there’s any kind of withdrawal

— the world will react pretty quickly and say, ‘OK, Russia’s responding, so let’s lower some of these sanctions and get some of this oil that we need.’ The oil industry is expecting that people will be unwilling to sacrifice if they’ve got any excuse to go back to their old ways.”

While the pandemic has receded, its impact on the American workforce is still being felt, and that’s also a factor in rising gas prices.

“(Petroleum producers) are looking at the one thing that really drives demand for them, and that is the daily commute,” Kuehl says. “They know that about 92% of our fuel consumption is going back and forth to work. So, as long as 60% of us are still working remotely, the commute is not back. They say, ‘Yeah, we see this shortterm demand, but the long-term demand isn’t there yet.’”

Kuehl believes producers just don’t see an economic up side to putting more oil on the market: “They’re not going to spend the money to radically increase production, since it’s going to be seven or eight months before those efforts come online anyway, only to discover that this immediate crisis has ended and we’re still working remotely.”

To maintain their profitability, dry cleaners must bal ance their own costs with what they charge their cus ▼

tomers. When dealing with rising gas prices, cleaners have the option of raising their overall prices to maintain their profit margin, or they can add a surcharge to their delivery fees.

Norman Way, vice president of Puritan Cleaners in Richmond, Virginia, wrestled with this decision when the price jumped at the pump.

“I was talking with some other cleaners about if should we put a surcharge on our deliveries, and that, as one of my friends puts it, is a ‘wholebottle-of-wine’ conversation,” he says.

Way examined the records for his 24-vehicle fleet. “I took a look at the month of February to see what my gasoline consumption was,” he says. “My gallons were very similar, and my costs, rounded up, were 0.5% of sales higher than the previous month.”

After weighing the pros and cons, Way made his decision: “Rather than creating any surcharges, we upped our prices plus the 0.5% to help compensate for that,” he says. “The surcharge thing just didn’t seem right with us, and when prices go down, we want that to remain as profit for us.”

Brian Butler, president of Dublin Cleaners in Columbus, Ohio, has six vehicles running 12 routes in his area. He faced the same decision as Way.

“I feel like I’ve got the devil on one shoulder and the angel on the other,” Butler says. “Dry cleaning is the last industry in our country that does not charge for delivery.”

Butler says that drycleaning delivery was structured around free service, a model most still use.

“We built these routes based on the promise that it’s the same price as if you come to the store,” he says, “and our product is not perishable. It’s not something you have to take out of the oven, run straight to one house and come back. You can load up a 200-stop route, and your time between stops is minimal. So why charge them?”

Increasing commercial real estate

prices also play a part in factoring expenses.

“With the cost of branches being as high as the commercial rates have gone,” Butler says, “there are many arguments for those of us who are large and efficient about delivery that we might be spending less under this free-delivery model.”

On the other hand, Butler often wonders if he’s leaving money on the table by not charging delivery fees.

“At the end of the day, if I can quietly grab another $2 per visit on my routes every day, and so few people would squirm, maybe I’m making a tremendous mistake and not realizing financial returns lying there in front of me.”

So far, he’s covered the rising expenses by raising his overall rates.

“We feel like that’s the most direct and honest way to handle it,” Butler says. “I think people know what’s going on in the world. For the most part, drycleaning customers are successful people. If they don’t own or run a business, they’re involved in leading a business to some degree, so they’re having the same discussions. We’ve had our prices go up three times in the last six months — never a huge jump, maybe a quarter on a shirt. If the customer notices, they know why I’m doing it.”

Mark Albrecht and James Peuster, who co-own the drycleaning consultancy firm The Route Pros, have been asked this question about surcharges for route delivery, and they agree with Way’s and Butler’s decisions.

“Yes, some people have added a surcharge as a line item on a receipt,” Albrecht says. “We don’t necessarily recommend it. We have been recommending raising prices accordingly so that it doesn’t list an additional line item on the receipt. Consumers are very frugal right now. They’re upset at high gas prices, they’re upset at politicians, they’re upset at

high meat prices, and so on. In our opinion, the last thing we want is for our clients to be upset with us, their trusted dry cleaner.”

“We had clients in the past who raised their prices and had no problem when gas went up,” Peuster says. “Those who added a fuel surcharge lost customers. What a dry cleaner needs to keep in mind is that the consumers are paying more for gas, too. But, by raising prices, you can hide the rising cost of everything.”

“It’s challenging enough to market our business and services to our clients and prospects,” Albrecht says. “We just don’t want to be looked at in a negative light like many other industries are right now.”

When gas prices spiked, the idea of electric vehicles (EV) became more attractive to many who want to control their fuel costs, Kuehl says, “if you don’t want to get caught in this ‘up and down’ that happens with fuel. The price of electricity tends to be fairly stable, and, of course, it’s cheaper.”

While EVs aren’t yet widely used, Kuehl believes it might be worth a dry cleaner’s time to investigate the technology.

“Electric vehicles only make up about 3% of all the vehicles in the U.S., so it’s still an infinitesimally tiny market,” he says, “but there are state and federal incentives, and everybody gets excited about the potential. It’s likely to be something fleets will deal with sooner than individuals.

“Going electric with a delivery fleet is more feasible because at least you can have a central place to charge. A lot of companies are looking at it, not only because it offers some protection from the vagaries of fuel prices, but there are so many government incentives out there now that it could be worth looking into.”

Based on his own experience with EVs, however, Butler isn’t convinced this is a technology whose time has come. His wife uses a Tesla for her work in medical sales and drives a lot of miles in the vehicle for her job.

“They promised a 340-mile range, and the range she actually gets on very cold or very hot days is heavily diminished by heating and cooling the car,” he says. “You’re combating temperature extremes, and in Columbus, Ohio, we have 90-degree summers and 15-degree winters.”

This passenger-car performance has made Butler question how an EV van would handle delivery operations.

“If you’re going to run a route van, you need to keep it heated or cooled, and it’s moving all day,” he says. “And if we’re getting just better than half the mileage Tesla promises, I can’t imagine a delivery van will get 30% of its promised range. Every time you open that door and a bunch of your heat or cool goes out into the atmosphere, it’s got to make that up.”

Butler says his wife experiences “range anxiety” when the end of the charge is coming up and there are no recharging stations handy — something that would also have to be considered in a delivery vehicle: “It’s not like gasoline, where you can immediately fill up. It can really cripple you and negatively impact your day.”

Kuehl believes that, barring unforeseen events, gas prices are about as high as they’re liable to go in the near future.

“They’re leveling off,” he says, “and what you’re seeing now are just market gyrations. If there’s a rumor of some kind of settlement in Ukraine, the price goes down. Then where there is the reality that there’s not going to be a settlement, the price goes up. We’ve seen prices ranging

from $90 to $140 a barrel within about two or three weeks’ time.”

While it’s difficult to predict what the oil market is going to do with so much still unsettled in the Ukrainian struggle, Kuehl believes the market has found some stability.

“The sense is that most of this wild gyration is probably settling down,” he says, “and prices may stay around the $100-a-barrel level — some-

times $10 lower or $10 higher. Gas at the pump is probably about close to peak, but again, that price is subject to rumors because what you’re seeing is all kinds of activity in the (crude oil) spot market. That’s generally what the refiners and distributors respond to when it comes to the price at the pump. And as we’ve learned, prices go up fast, but they don’t come down fast.” ADC

The Clean Show — the largest event in the U.S. for the drycleaning, laundering, textile care services, supplies, and equipment industry — will adjust the dates and locations for two upcoming editions. After The Clean Show 2022, being held in Atlanta from July 30 - August 2, 2022, Clean will shift back to the odd years in 2025.

The move comes in response to the unprecedented postponement and rescheduling of events and trade fairs across the industry.

“Our goal in shifting Clean back to an odd-year cycle is to help restore balance to the international trade fair calendar as the industry recovers post-COVID,” says Greg Jira, show director for The Clean Show. “We believe this decision is best for the global industry as a whole.”

After 2022, the next edition of The Clean Show will

take place in August 2025 at the Orange County Convention Center in Orlando, Florida for the first time since 2005. Clean will then return to the Las Vegas Convention Center in Las Vegas, Nevada in July 2027, which will be the event’s seventh edition in that location.

“We are looking forward to returning to these cities with a history of successful Clean Shows,” says Jira. “The venues are excited to have us back, and the industry is definitely ready for the return of our regularly scheduled in-person events.”

The Clean Show attracts industry professionals from around the globe to see the newest and most technologically advanced products the industry has to offer, and provides networking opportunities, live demonstrations for all segments of the industry, and more. In addition to exhibits, the show offers educational seminars on the latest technology, business management, sustainability, and more.

Registration is currently open for the next edition of The Clean Show, which will take place this summer in Atlanta, Georgia. For more information, please visit the show’s website (the-clean-show. us.messefrankfurt.com/us/en.html). Clean also still has exhibition opportunities available, but space is almost sold out. Companies interested in reserving a booth should contact Jewell Kowzan at Jewell. Kowzan@usa.messefrankfurt.com.

The Clean Show is organized in collaboration with five industry-leading associations: Association for Linen Management (ALM), Coin Laundry Association (CLA), Drycleaning & Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA), and Textile Rental Services Association of America (TRSA).

If you attend one industry event in 2022, The Clean Show should be it! Discover new products, exciting technology, and ground-breaking research in commercial laundering, dry-cleaning, and the textile service industry as exhibitors from around the world showcase their latest innovations. Registration is open! Start making your plans to attend.

REGISTER NOW!

www.cleanshow.com

2022 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 11-time rates. If box number is used,

add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month.

CHEMICALS GARMENT LABELING HEAT SEAL PRESSES from EzProducts International Inc. Toll Free 877.906.1818 www.ezpi.us

EQUIPMENT FOR SALE 40lb Columbia ilsa Perc DC machine that can be converted into a hydrocarbon. 3 1/2 yrs old. Ship anywhere US extra fee. Asking 13,000 firm. Email: Brickle1952@gmail.com To Place Your Ad Call Don Feinstein 312-361-1682

You Deserve the Best! The Ultimate Heat Seal Machine Proudly made in the U.S.A. Built to OSHA standards 2 YEAR WARRANTY

For example, for a September ad, the closing date is August 1st. PAYMENT FOR CLASSIFIED ADS: Must accompany order. Paying too much for spotters? Buy 3 Get 1 Free! Buy online and save. DryCleanerSoap.com CONSULTANT WANTED Drycleaner Biz Consultant & Broker Trainee Ehrnereich & Associates has an opening for a Retired Biz Owner with B to B Sales skills to join us for training in Business Brokerage & Consulting. Reply with your history, location, contact information & availability: Richard@Ehrenassoc.com

3 models, 7 different interchangeable lower platens and single or dual heated platens www.AmericanDrycleaner.com 000+ Annual Visitors Advertise Today Contact Don Feinstein • 312-361-1682

A.L.

CleanCloud-Tailor

Cleaner’s

. . . . . . .29

Cleantie . . . . . . . . . . . . . . . . . . . . . . .25

Cobblers Direct . . . . . . . . . . . . . . . . .21

EzProducts International . . . . . . . . . .30

Garment Management Systems. . . . . .9

Iowa Techniques . . . . . . . . . . . . . . . . .5

Luetzow Industries. . . . . . . . . . . . . . .31

Maverick Drycleaners . . . . . . . . . . . .10

Newhouse Specialty Co. . . . . . . . . . .31

NIE Insurance . . . . . . . . . . . . . . . . . .13

North American Bancard. . . . . . . . . .23

Parker Boiler Co.. . . . . . . . . . . . . . IBC

Patriot Business Advisors . . . . . . . . .31

Royal Basket Trucks . . . . . . . . . . . . .30

Sankosha USA. . . . . . . . . . . . . . . . .BC

SMRT Systems . . . . . . . . . . . . . .15-18

SPOT Business Systems . . . . . . . . IFC

Union Drycleaning Products . . . . . . . .7

2022 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 11-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted.

Ads must be received by the 1st of the preceding month. For example, for a June ad, the closing date is May 1st.

10 YEARS AGO. Business Casual Makes an Impact — More than three quarters (76.1%) of respondents to the American Drycleaner Wire survey said that the ongoing movement toward casual clothing in the workplace has had a major impact on the industry. Approximately 22% said the business casual dress code had a minor impact, and 2.2% said it had none. As for the overall impact casual clothing had an overall dry cleaning sales volume? About 43% said their sales had decreased substantially each year (more than 5%) and 31.8% said theirs had decreased slowly (0-5%).

25 YEARS

The Federal Trade Commission (FTC) allowed the American Society for Testing and Materials (ASTM) care symbols to be used by clothing manufacturers that instructed consumers on the proper care of their products. The symbols were found on labels of garments offered for sale after July 1, 1997. For the 18-month transition period from that date, the FTC mandated that written information explaining the symbols also be supplied — for example on a hangtag.

50 YEARS AGO. Sears Stamp of Approval — Dry cleaning, even for washable garments, was recommended by Sears Roebuck & Co. In

a mass-circulated pamphlet entitled “Easy-to-follow Washing and Drying Suggestions for Fashion Fabrics,” Sears said “Dry clean almost any fabric you wish.” The text went on to read: “Washable fabrics may be drycleaned, unless the catalog states ‘do not dryclean.’ All PermaLined fabrics (those bonded to tricut lining) may be drycleaned.”

75 YEARS AGO. Price Wars — As the

New Mexico Legislature entered its final week in March 1947, one of the bills which had been defeated during the session was one that proposed fixing set minimum prices for dry cleaning activities. The bill was introduced as a way to eliminate price wars between cleaners, but was defeated in the State House of Representatives.

Compiled by Dave Davis, EditorProductshaveproventolastupto10timeslongerthan similarproductioninthisindustryandapplications.

Wehavemanyinstallationswithsteamboilersthathave beeninserviceforover50-years,10hoursperday.

Thematerialsusedincurrentproductsarebetterthanthe materialsused50yearsago.Forexample,inthe80’s, steam drumwentfrom3/8”thickto1/2”thick.

Ourheatingsurfaceoramountofsteelabsorbingenergy has alwaysbeen2to3timesthatofotherunits(upto6sf ofheatingsurface per boilerhorsepower,whichsomeunits arecloserto2sfofsteel per hp,andsomeeven1sf).

Wehavethebestdistributedflameormostevensurface areaevenlydistributedundertheentirepressurevessel. It isalsoamodulardesign,so it canberepairedeasily.

Tube materials were upgraded from seamlessrated pipe to seamlessrated tubing. Material is not only thicker, ends up .133 wall, but is annealed which give the surface on both sides a mill scale coating that is more resistant to corrosion and is long lasting from testing.