Virginia VA medical center refreshes laundry services

RICHMOND, Va. — The U.S. Department of Veterans Affairs reports that it has contracted with Western State Design, Hayward, Calif., for new laundry equipment for the Hunter Holmes McGuire VA Medical Center (VAMC).

The $7.8 million contract will provide a steamless system—the latest in design and first of its kind for a VA medical center—resulting in a more efficient, and energysaving laundry, the VA says.

The OPL serves the medical center, Hampton VAMC, Ft. Lee, Fayetteville VAMC, Camp Perry, Ft. Eustis, and Langley Air Force Base. The new equipment will greatly enhance its capacity and offer the medical center and community partners the opportunity for additional services, the VA says.

More than 4 million pounds of laundry is processed annually through the Richmond facility. Equipment has been maintained but as newer technologies became available, renovations became necessary.

Sylvia Small, production leader, has for the last 25 years led a team of 40 employees responsible for washing, drying, folding and sorting linens and other items for the VAMC and other community partners.

She’s seen the increase in partners utilizing the laundry service over the years and says she is looking forward to the new equipment. The features are expected to be installed, tested and in use by this fall. ALN

Delivery fleets require constant attention

By Bruce Beggs, editorial director

CHICAGO — Route operations is an important function of any successful rental or commercial laundry and requires constant attention.

The Textile Rental Services Association (TRSA) says the textile services industry deploys a combined fleet of 25,000 trucks weekly to deliver goods to thousands of healthcare and hospitality facilities, and to businesses such as restaurants, auto repair shops, and others.

TRSA calculates that 1.8 million U.S. business locations are textile services customers generating roughly 15 billion pounds of laundry per year delivered by the third largest fleet of vehicles (behind only FedEx and UPS).

Efficient delivery of clean goods and pickup of soiled goods is what separates one textile service operation from the next.

ROUTE OPTIMIZATION

Route optimization can help companies eliminate routes and potentially reduce their costs by thousands of dollars per route.

Ask yourself: Do your drivers stop where it is most cost-effective for your organization, or do they stop where they want to stop and that’s

efficient for them?

Cyndi Brandt, Roadnet Technologies (formerly UPS Logistics), once addressed the value of logistics during a TRSA meeting presentation.

It isn’t enough to use index cards or pushpins and colored string to map out this week’s routes, she says. There’s a variety of routing software products on the market that can provide as much or as little planning help as is desired.

The traditional approach of focusing on daily, tactical route planning leads to what Brandt calls “reactive” planning, which can find a operator tweaking their routes due to volume fluctuations, making off-day deliveries and pickups, and even adding vehicles when capacity falls short, all of which create added costs and headaches.

She favors a more proactive approach, even using more than one route scheduling method to gain the greatest business advantage. Keys to best practices are to plan a transportation strategy, collect data in support of your strategy, analyze that data regularly and then implement changes based on your analysis, she says.

Restaurant association recognizes value of TRSA’s Clean Green certification

ALEXANDRIA, Va. — The Green Restaurant Association (GRA) has incorporated TRSA’s Clean Green certification for textile services operations into its Green Restaurant program, enabling restaurants to earn points toward the Green Restaurant designation by using a Clean Greencertified laundry.

“This recognition by the Green Restaurant Association reflects the relevance of the TRSA Clean Green program and the importance of supply chain partners’

green practices to restaurants’ sustainability,” says TRSA CEO & President Joseph Ricci.

The textile services industry provides restaurants and other foodservice operators with pickup/delivery service of laundered reusable products such as napkins, tablecloths, garments, towels, floor mats and other hygiene and reusable textile products. Clean Green certification differentiates launderers by verifying their adherence to a well-defined list of green management practices and compliance

with energy and water conservation standards.

Boston-based Green Restaurant Association provides environmental certification for restaurants, designating them as “Green” through a point system that assesses their sustainability. A restaurant must qualify initially by attaining 100 points from a variety of practices related to water, energy and waste. Each restaurant must then recertify annually, making an additional 10 points worth of improvements to maintain certification.

Any restaurant utilizing a Clean Green-certified laundry now can receive a total of four points toward Green Restaurant certification: two in the energy practices category and two in water practices. Verification of standards must be provided. In addition, utilizing reusable napkins adds six points.

Clean Green quantifiably validates the reusable textile industry’s positive environmental impact and will soon receive ASTM International approval, TRSA says.

J u N e 2013

Late News

www.americanlaundrynews.com Volume 39, Number 6

the Newspaper of record for laundry & linen Management

ALN

iNside [4] [6] [20] See ROUTE on Page 19 Clean Show Expectations Willingness to fully participate will decide event’s true value: Frederick

NOLA Know-How What to see and do while in New Orleans for Clean Show Panel of Experts Doing laundry in cramped quarters leads to sloppy work RunninG The RouTe:

(Photo: © iStockphoto/Eliza Snow)

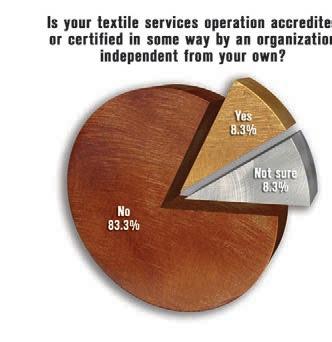

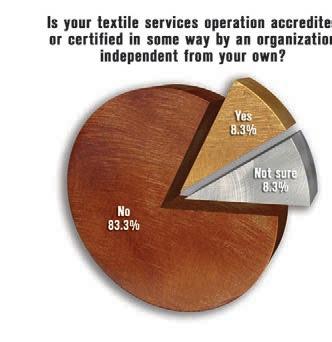

CHICAGO — The laundry administrators and managers who responded to May’s American Laundry News Wire survey expressed little interest in having their facilities independently accredited or certified by third-party organizations, according to the survey data.

Just 8.3% of respondents reported that their textile services operation is accredited or certified in some way by an organization independent from their own. Another 8.3% said they were “not sure.” The remaining 83.3% reported having no such accreditation or certification.

Organizations such as the Healthcare Laundry Accreditation Council (HLAC) and the Textile Rental Services Association (TRSA) can certify laundry facilities as being in compliance with industry standards and protocols. Respondents who reported their facilities as accredited/certified said this standing came from HLAC and the Occupational Safety and Health Administration’s (OSHA) Voluntary Protection Programs (VPP).

Roughly 42% of respondents said that they are “currently seeking” to receive accreditation/certification, or to renew accreditation/certification, within the next year. The remaining 58.3% are not.

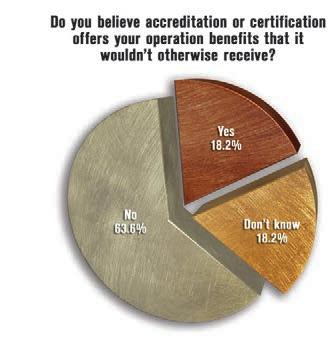

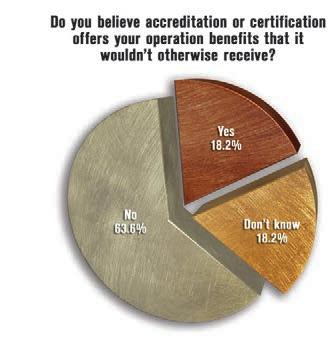

Approximately 18% of respondents believe that accreditation/certification offers their operation benefits that it would not otherwise receive, and another 18.2% are unsure. The remaining 63.6% don’t believe accreditation/certification offers benefits.

Do you think independent accreditation/certification of laundry facilities should be mandatory in the United States? Only 16.7% of respondents believe that it should, while 66.7% say no. The remaining 16.7% “don’t know” if accreditation/certification should be mandatory.

While the Wire survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific.

Subscribers to Wire e-mails are invited to take the industry survey anonymously online each month. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and industry trends.

Crown Health Care Laundry Services to open Miss. plant

COLUMBIA, Miss. — Mississippi Gov. Phil Bryant and officials from Crown Health Care Laundry Services announced recently that the company is locating laundry processing operations in Columbia’s Marion County Industrial Building. The project represents a company investment of $6 million and will create 150 jobs.

“I am grateful to the company for selecting Columbia as the home of its newest operation and creating so many jobs for the area’s residents,” Gov. Bryant says.

“Today marks another strategic milestone in the continued growth and expansion of Crown Health Care Laundry Services in the Southeast,” says company President Don Haferkamp.

The Mississippi Development Authority (MDA) provided assistance in support of the project for modifications to the publicly owned building. The County provided assistance for building modifications and the City of Columbia provided utility infrastructure assistance.

“I am happy to welcome Crown Health Care Laundry Services to our state, and I am pleased MDA could provide assistance for the project,” says MDA Executive Director Brent Christensen.

Based in Pensacola, Fla., the company is an independent, full-service health care laundry processor and linen rental company. It has been a linen service provider throughout Alabama, Florida, Georgia, Louisiana, Mississippi and South Carolina for more than 50 years.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ americantrademagazines.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ americantrademagazines.com

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ americantrademagazines.com

Production Manager Roger Napiwocki

Contributing Editor Jean Teller

Editorial Assistant Carlo Calma

Advertising Sales

National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ americantrademagazines.com

Office Information

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions 630-739-0600 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. & possessions, 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies: U.S. & possessions $7.00; Foreign $14.00.

Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 39, number 6. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. No material appearing in American Laundry News may be reprinted without written permission. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2013. Printed in U.S.A.

MEMBERSHIPS

Association for Linen Management

interest

laundry

or certification 2 JUNE 2013 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com INSIDE: [6] Refining Your Company’s Safety Standards Former OSHA administrator Edwin G. Foulke Jr. offers suggestions for improving your safety program [8] Tools of the Trade [10] NOLA Know-How We’ve researched some of the things to see and do while you’re in New Orleans for the Clean Show [20] Panel of Experts “My laundry isn’t large. What general suggestions can you give me about how best to operate in cramped quarters?” [24] Career Track [26] Trade Ticker [27] Calendar [25] Technology Enables OPLs to ‘Go Green’ Recent advances in equipment and system design are enabling OPLs to sustain both environment and budget June 2013 • Vol. 39 | No. 6

ALN Survey: Respondents show lukewarm

in

accreditation

ALN

Come

There is a better way to save on laundry.

Take control of your conservation efforts instead of leaving them in the hands of your guests. Milnor has a new solution for mid-sized hotels and hotel compounds looking to save both time and money. Milnor’s five-module “short” tunnel washers can have a significant effect on your water and energy consumption, without compromising linen quality your guests deserve. We’re talking about using as little as 0.3 gallons of fresh water per pound of room linen instead of 2 or more gallons in a large washer-extractor.

No matter what level of soil or class of goods, facilities across the country have seen remarkable improvement in wash quality with a dramatic reduction in water usage and energy. All-told PulseFlow®* tunnels have saved more than 500,000,000 gallons of fresh water so far. And now, if your facility washes 1,000 pounds of linens an hour or more, you can take advantage of PulseFlow technology in a new, smaller tunnel.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more about getting big savings with a modest footprint.

www.milnor.com/pulseflow_technology / pellerinmilnor To see how a PBWTM works, scan this code. *Patent applied for

BOOtH #3443

see where Milnor machinery is made before CLEAN ’13! Register for the June 19th Open House at Milnor!

As the convention closes

here’s always so much to do to prepare for the Clean Show, which will convene this month in New Orleans

And I know that once I’m there, I’ll spend each day on the move. So it’s always enjoyable to take a break when the convention day has ended.

If you feel the same, then you’ll want to read Carlo Calma’s NOLA Know-How, beginning on page 10. He’s researched some of the Crescent City’s leading hot spots, including attractions, shopping and dining.

It’ll give you a good idea of just some of the diversions you can find beyond the convention center doors.

The Clean Show is, of course, about finding solutions to

From The Director’s Chair BrUcE BEggs

improve your operation. But if you’re not going to make it to New Orleans this year, this issue still has plenty of content aimed at boosting your bottom line.

Our Panel of Experts offers its thoughts on overcoming the restrictions of operating

in cramped confines. I’m sure none of you folks in on-premise laundries know anything about that, right? You can find Tips for making the most of tight quarters beginning on page 20.

If your laundry’s safety record has been a concern for you lately, you should read Refining your company’s safety standards, featuring insights from Edwin G. Foulke Jr., once administrator of the Occupational Safety & Health Administration (OSHA). That story starts on page 6.

Plus, we’ve got a slew of hiring announcements, product news, an updated events calendar ... yes, there’s still more in this issue, but like the Clean Show, you’ll need to get a move on to find it. Laissez les bons temps rouler! ALN

ARTA forms Cleanroom Committee to fund reusables life-cycle analysis

MISSION, Kan. — The American Reusable Textile Association (ARTA) has announced the formation of a Cleanroom Committee to undertake life cycle assessment (LCA) research on behalf of the reusable cleanroom garment industry.

The idea to form the committee and undertake LCA research came from textile manufacturer and ARTA member Precision Fabrics Group (PFG).

At the time, PFG’s John Smith was serving on the ARTA board of directors and shared his observations on the cleanroom marketplace (and the encroachment of disposable garments).

Smith has since retired, but his successor, Steve Glosson, and a

half-dozen other representatives from companies serving the market for reusable cleanroom garments, have answered the call to action.

Members of the ARTA Cleanroom Committee include fabric manufacturers, suppliers and operators.

Active members to date include:

• Mike Rataj, Aramark, Cleanroom Division

• Dianne Knitter, Prudential Overall Supply, Cleanroom Division

• Jan Eudy, Cintas, Cleanroom Division

• Steve Glosson, Precision Fabrics Group

• Dennis Moore, ITG/Burlington

• Scott Delin, Superior Uniform Group

• Doby Byers, Hi-Tech Garments

In addition, Dr. Mike Overcash and Dr. Evan Griffing of Environmental Clarity LLC will conduct the life-cycle analysis.

ARTA officers and directors serving on the committee include President Ed McCauley of United Hospital Laundry, Past President Steve Tinker of Gurtler Industries, and Director Don Pedder of Reino Linen.

The committee is working to gather data and define parameters of the research, which is to be completed by spring 2014.

ARTA intends to provide an update during its 2014 Education Conference, scheduled for Feb. 26-28, at the Orlando World Center Marriott.

ALN

clean show expectations

The Clean Show is just around the corner. Like so many other major events in our life, what we get out of attending Clean will be based on our expectations.

The Clean Show will provide all attendees a chance to see the latest laundry equipment on the market. It will provide hours of education and unparalleled opportunities to network with others in the industry. What key concerns will you bring with you to New Orleans?

The Clean Show will provide me with an opportunity to discuss with a number of textile suppliers the new, specialized healthcare linen being developed to help reduce bed sores. This linen is extremely expensive and can be a challenge to wash, process and package for delivery.

I hope to get guidance from the linen companies and other managers in attendance about the best wash formula and the easiest way to process the linen. Now seems like a poor time to enter into longterm fixed price contracts for linen rental. But this linen is being marketed to the nursing staff and skin care specialists, and it is up to us to figure out how best to handle it.

I will be looking for ways to reduce my operation’s energy consumption. Alternative fuel vehicles will be of great interest. I will explore ways to reduce energy at each stage of my operation, from the boiler room to delivery.

Going hand in hand with this will be attempts to make the operation more eco-friendly. How can I, as a trained environmentalist, reduce my impact? Part of this “section” will include how to make sure I get maximum life from my textiles without negatively impacting the environment.

I will be looking for ideas on how to create more flexible contracts that will allow me to partner with my customers to meet the challenges facing us in the world market. Many of us grow nervous when we see the rapid escalation of gas prices. How soon they will go up again is anyone’s guess, but it does appear to be far from a stable commodity.

I will look for labor-savings equipment, and network with other managers about labor-savings procedures. Wages continue to go up every year, and we must find ways to improve our workers’ productivity or lose our competitive edge.

I will revisit the real-time productivity monitoring system that was first shown at Clean 2011. The ability to give continuous feedback to employees about how they are performing minute to minute is appealing. And making such information available to my management staff should help improve their training and oversight of the workflow through the laundry.

Through networking, I will develop a list of employee recruitment techniques that really work. And I will enter into discussions about employee training and motivation. This show provides a unique opportunity to investigate what others are doing in other parts of the country and even around the world.

The Clean Show is that rare time when the entire laundry industry comes together in a special learning environment. We can come with our specific lists of equipment we want to see or vendors we like to visit, but the show is so much more. The value of attendance will be determined by your willingness to fully participate in the educational and networking opportunities available only at an allindustry show.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Make plans now to be there all three days, because the full value of the show cannot be realized without investing the proper time. Educational programs will be offered every day. Networking opportunities begin with breakfast and end when you return to your room at night. Make the most of your travel and registration by getting full value from this year’s show.

Eric Frederick is director of laundry services for Carilion Laundry Service, Roanoke, Va., and a past president and manager of the year of the Association for Linen Management. You can reach him by e-mail at efrederick@carilion.com.

4 JUNE 2013 | AmEricAN LAUNdry NEws www.AmericanLaundryNews.com Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending May 15 (WE) = Web exclusive news

OSHA Fines New Jersey Laundry $219,000 for Reported Safety... (WE)

Lavatec Inc. Now Headquarters for Lapauw of America

Virginia VA Medical Center Refreshes Laundry Services

Clean Show Releases Free Mobile App for Smartphones

Prudential Overall Supply Celebrates 80-Plus Years...

Columnists/Features

Panel of Experts: Controlling Linen Loss is Key to ‘Saving Par’

Eric Frederick: The Fine Art of Fine-Tuning: Tunnel Washers

Consider Every Angle Before Building New Laundry

On the Trail of Textiles

Use SMART Goal Setting for Laundry Business Growth our sister websites From AmericanDrycleaner.com:

Deliver What Your Customers Want

JPB Capital Partners Buys Controlling Interest in ZIPS... From AmericanCoinOp.com:

Calvary

Attendants and Atmosphere Energize...

Laundromat:

Coin-Op 101: What to Look for in Coin Laundry Distributor

T

Columnist At lArge Eric L. Frederick, RLLD

ALN

Manufacturers, suppliers, operators join forces in support of reusable coveralls

Refining your company’s safety standards

By cArLo cALmA, EditoriAL AssistANt

By cArLo cALmA, EditoriAL AssistANt

CHICAGO — “Safety first” has become the mantra for many workplace environments, so it goes without saying that the safety and well-being of employees remains a top priority for many companies today. Is yours among them?

Edwin G. Foulke Jr., a partner in the Atlanta law firm of Fisher & Phillips LLP, in conjunction with the Textile Rental Services Association (TRSA), recently hosted a webinar covering how companies can improve their safety program.

Foulke’s experience speaks for itself. In addition to serving as co-chair of Fisher & Phillips’ Workplace Safety and Catastrophe Management Practice Group, he’s served as assistant secretary of labor for the Occupational Safety and Health Administration (OSHA), and was appointed by President George W. Bush to head OSHA from 2006 to 2008.

First Steps

The key to improving safety standards lies in first identifying why safety regulations are broken. Oftentimes, Foulke explains, many policies set in place are broken because they have become too hard to follow.

“We make sure our safety programs are such that we’re avoiding safety health hazards [but] we don’t want to have our program such that we’re so strict, or so cumbersome,” says Foulke. “We don’t want to get it to that point where we make it so difficult. We don’t want to make our safety program where it’s just so rigid that it doesn’t protect employees.”

Determining which OSHA safety and health standards are applicable to a company’s operations, and staying abreast of your company’s OSHA recordkeeping audits, should be your first steps

toward safety improvement.

While determining which safety standards apply to a company can be “self-evident,” Foulke advises business owners to look at their Standard Industrial Classification (SIC) or National Advisory Committee on Ergonomics (NACE) Code to know for sure.

“Make sure that OSHA properly classifies your establishment and you’re not classified wrongly because there are some things, like recordkeeping, [that] certain companies [or] certain industries are not required to do,” Foulke says.

He also recommended that business owners get themselves prepared for an OSHA inspection, and that they understand their legal rights.

“OSHA can’t just come in there and ask for every document you have. They’re not entitled to [them],” Foulke explains. “They just can’t walk around by themselves...[you’re] entitled to accompany them during an inspection.”

It’s critical that you assert your rights. If you give the inspectors every document you have, and you sign statements, neither of which you’re required to do, you’ll be hurting yourself. “And in the long run, the inspection is not going to go well for you, and you’re going to end up having a lot more penalties [and] a lot more citations.”

Low-Hanging Fruit

Regarding recordkeeping, Foulke advises owners to keep track of their company’s OSHA 300 Log. It can help an opera-

tor keep track of accidents in the workplace, plus possibly pinpoint patterns of where they maybe occurring.

“If 90% of the injuries in your 300 Log are occurring in Department A, you have a problem there that you need to address,” he says. “It could open up a whole array of OSHA standards that you may be violating, and if they see a pattern... the inspection starts to expand.”

To prevent inspections from expanding into other departments, Foulke advises company owners to audit their workplaces for “lowhanging fruit,” or common safety and health violations that could easily draw OSHA fines.

Standard (HCS).

The HCS has been “aligned with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS),” according to OSHA, meaning that the update will “provide a common and coherent approach to classifying chemicals and communicating hazard information on labels and safety data sheets.”

Under this revision, safety data sheets will be more standardized and detailed, and employers will have until Dec. 1 to train all employees on how to use them, according to Foulke.

Keep Track of Abatements, Citations

Foulke highlighted the abatement of past citations (correction of the safety or health hazard/violation that led to a citation) and keeping record of any such abatement.

Program. “If you have a fatality, if you’re a high-hazard industry, if you get OSHA citations and you get a bunch of egregious citations, then you’re going to be put in the Severe Violators program.”

Companies on the list receive not only follow-up inspections, but are placed on a “priority inspection list for wall-to-wall inspections” for all facilities owned, and also receive enhanced settlement provisions, among other penalties.

In addition to staying on top of its own citations, a company should pay heed to OSHA’s MultiEmployer Citation Policy, and how the company’s relationship with other contractors or companies they employ could affect them, Foulke says.

Blocked exits, extinguishers and electric panels; improper handling and racks; recordkeeping errors; and housekeeping problems are among the common violations that companies can easily avoid, according to Foulke.

One other precaution that applies specifically to textile care facilities is the handling of hazardous chemicals, under OSHA’s revised Hazard Communication

“We need to make sure that we’re reviewing all our past abatements and making sure that those abatements have stuck, and that we don’t have them anyplace else in our facilities, because that will be the basis for repeat [violation],” he advises.

Failing to abate past citations can be costly, he warns. “We’re talking about $7,000 for each day you didn’t abate it, so we’re talking about some serious money there.”

Not only can repeat citations hurt a company financially, it can also subject it to even stricter inspection visits under OSHA’s Severe Violators Enforcement

Not only can OSHA issue an open inspection on a contractor on a company’s site, it can also issue the same inspection on the hosting company because “[they’re] the controlling employer.”

“The part of that problem is OSHA gets a complaint from one of your contractors on site, by one of their employees [so] the contractor will get cited for that violation,” says Foulke. “But you could also get cited because maybe your employees are exposed.”

“[You] have to recognize how contractors, or vendors or suppliers, [can] create safety hazards that could potentially expose [your] employees, too, and [how you’re] going to be brought into that.”

To avoid this issue, Foulke

6 JUNE 2013 | AmEricAN LAUNdry NEws www.AmericanLaundryNews.com

See SAFETY on Page 18

electric panels;

All of the pieces are in place. The best just got even better. We have now strategically partnered with HBD Construction, who is committed to delivering quality and integrity on every construction project, from conception to completion and FV Consulting, Inc., the efficiency specialist for your lean process improvements. We are now the one and only laundry service company in North America to offer full services from building construction through to plantoperations and support. Building Smarter Laundries for Smarter Operators 978.373.1883 | www.eomech.com

(Photo © IStockphoto/NuStock) Blocked

exits, extinguishers and

recordkeeping errors and housekeeping problems are among common violations that companies can easily avoid.

David Mertens Sr. VP Operations ALS PUZZLE AD_Layout 1 5/15/13 3:20 PM Page 1 ALN_Tab_1-4_H.indd 1 5/15/13 2:40 PM

Gerard

O’Neill President/CEO

Tools f the Trade

New barrier washer-extractors built on

A new Secure Net design on the PolyTrux® 72N bulk laundry truck from Meese Orbitron Dunne Co. (MOD) allows durable cargo netting to crisscross the cart’s open, ergonomic front and secure linens inside for transport.

The optional Secure Net can be partially removed for quick, easy access to the linens and/or completely removed for cart washing and cart makeup. It can be replaced in seconds with no tools.

World Emblem International introduces its latest apparel decoration product: High-Visibility Striping.

Such striping is a standard uniform requirement for many low-lit and potentially hazardous working environments, World Emblem says, and can be applied to work shirts, pants, coveralls and vests.

World Emblem offers six different trims and 48 standard placement locations for the

Designed for textile rental companies, OPLs and others balancing efficiency, safety and linen security, the 72N handles payloads stuffed to 800 pounds in a rotationally molded plastic cart set atop a poly base and premium casters.

A choice of standard and optional custom colors and a range of custom accessories are offered.

modlaundry.com 800-829-4535

striping, and can create custom templates, the company says. A free quote and digital design proof is available within 24 hours, it adds.

Customers can drop-ship their garments from vendors to World Emblem’s Atlanta manufacturing plant. Once an order is complete, the company can even blind-ship it directly to the end-user. worldemblem.com 800-766-0448

Electrolux Professional’s Evolution range of barrier washer-extractors offers the healthcare industry, hospitals and nursing homes a laundry solution built on ergonomics and user-friendly technologies. The equipment is available in the United States via distributor Laundrylux. The Evolution range is designed

to meet the utmost hygiene standards.

It offers an optimal working height for loading/unloading, as well as newly designed reversible doors.

The Compass Pro® interface offers up to 55 programs and is available in 18 languages.

laundrylux.com/electrolux 800-645-2205

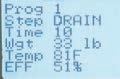

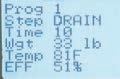

OPL dispensing system offers flexibility, ease in copying programs

The V-Line series of laundry dispensing systems from DEMA Engineering is specifically designed for OPL and small commercial applications.

Through a streamlined digital programming interface, an opera-

tor can easily create different user modes. Cut-and-paste programming means that copying programs between multiple dispensers is quick and easy, DEMA says. demaeng.com 800-325-3362

8 JUNE 2013 | AmEricAN LAUNdry NEws www.AmericanLaundryNews.com

Bulk laundry cart features new secure net design that keeps linens in place but removes easily for access

High-visibility striping enhances safety in low-lit and potentially hazardous work environments

ergonomics, user-friendly technologies

For over 50 years U.N.X. INCORPORATED has been involved in the development of products that not only solve quality problems that exist at the moment, but also provide long term benefits to the customer and the environment in which we live. U.N.X. was built on the foundation of improving the industry in which we participate. U.N.X. prides itself on being an industry leader with state-of-the-art products and dispensing equipment, and our plans for the future are extraordinary. With a Research and Development team second to none, U.N.X. is in a position to provide the industry with the most technologically advanced products and dispensers as possible. U.N.X. INCORPORATED 707EArlingtonBlvd Greenville,NC27858 (252)756 8616 www.unxinc.com ALN_Tab_half 10/9/12 2:40 PM Page 1 See us at the Clean Show • Booth #2502 0513aln_UNX.indd 1 4/26/13 10:48 AM

IF YOU DON’T HAVE OPTISPRAY

YOUR

An inefficient rinse is money down the drain. With a combination of bath and spray rinses, new OPTispray ™ Rinsing Technology utilizes unique spray hardware and exclusive software to minimize the water and time needed to rinse a load while also delivering far superior rinse results. OPTispray uses less water, saving up to $2,110 in yearly utility expenses compared to popular models with only bath rinses. To lower costs even further, industry-leading 400 G-Force extraction delivers maximum water removal and increased throughput. Innovative features like UniLinc ™ paired with OPTidry ™ offer complete laundry room control, minimize operating costs and optimize efficiency to save you even more time and money. It all combines to deliver the industry’s absolute lowest cost of ownership. SPECIAL FINANCING AVAILABLE. 4.50% finance rate on UniMac ® washers and dryers. Limited-time offer. Contact an authorized UniMac distributor today to run a laundry operating analysis and see how you can cut costs and save money. Visit UNIMAC.COM/OPTISPRAY or call 1-800-587-5458.

™

LINENS AREN’T THE ONLY ONES TAKING A BATH.

NOLA Know-How

BY CARLO CALMA, EDITORIAL ASSISTANT

NEW ORLEANS — The Clean Show—officially the World Educational Congress for Laundering and Drycleaning—will settle once again this month in the Crescent City for the fifth time in the show’s 36-year history.

At press time, more than 400 companies from the laundry and dry cleaning industry were registered to exhibit their products and services at this year’s event, encompassing approximately 200,000 net square feet of the Ernest N. Morial Convention Center.

Though the show schedule is shorter than years past—beginning Thursday, June 20, wrapping Saturday, June 22—plenty has been packed into the three days.

With all the hustle and bustle that the show can bring, however, New Orleans does have plenty to offer visitors for relaxation and ways for people to take it easy in the city known as the Big Easy.

With a world of culture right outside the Convention Center doors, visitors at the end of each convention day have every opportunity to do as the locals do: “Laissez les bons temps rouler,” or let the good times roll.

GETTING AROUND

Before taking to the streets of New Orleans, have a plan for navigation. Upon arrival, the cheapest way to get from Louis Armstrong International Airport to New Orleans’ Central Business District (CBD) is via the Jefferson Transit (JeT) bus line. The Airport-Downtown Express (E-2) Bus, which picks up passengers outside the airport’s upper level at Entrance 7, costs $2 and takes about 35 minutes to get to the city.

The E-2 bus then makes stops outside the CBD, circling Tulane Avenue, Elk Place, Pydras Street and Lasalle Street.

In terms of taxi service, a cab ride will cost up to two passengers about $33 to get to the CBD, according to Armstrong International Airport’s website. For those who want to arrive in style, Airport Limousine provides service at rates starting at $58.

Once in the city, the Clean Show will provide complimentary shuttle bus service to and from the Convention Center during show hours at all headquarter hotels, and within two blocks of all other Clean 2013 official hotels. Bus pick-up will be every 15 to 20 minutes. Three shuttle bus routes are planned to run from 7 a.m. to

11:30 a.m. and from 3:30 p.m. to 6 p.m. on Thursday, June 20. Buses will get started a little later, 7:30 a.m., on Friday and Saturday, June 21-22, but will otherwise follow the established schedule.

Cab fare around the CBD, according to Taxi Fare Finder, costs a flat $3.50 plus $2 for each additional mile.

But to get the authentic NOLA experience, hop on a Regional Transit Authority (RTA) streetcar, which provides service to various points of interest around the greater New Orleans area. The oldest

10 JUNE 2013 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com ALN_Tab_half 6/6/12 4:27 PM Page 1 Visit our Booth #2343 at CLEAN ’13 0613aln_B&C Tech.indd 1 5/6/13 10:18 AM

See NOLA on Page 12

(Photo: Alex Demyan and NewOrleansOnline.com)

What to see and do while in New Orleans for the

Clean Show

Electrolux smart washers will forever change the way you do laundry.

Imagine a washer smart enough to weigh the load size and add precisely the correct amount of water. Imagine a laundry chemical controller smart enough to adjust dosing for accurate water ratio each time.

Electrolux Professional washers do all that and more! Introducing AWS & SmartDosing.

Underloading washers is a common problem in many laundries, wasting water, chemicals, and energy. That’s why Electrolux developed AWSTM, a UNIQUE feature that automatically matches water consumption to load size. Combine that with SmartDosingTM which adjusts laundry chemicals to water ratio, and you will see immediate savings and superior wash results – every time, automatically.

Electrolux’s SmartDosingTM controller automatically dispenses the correct amount of chemicals for the weight load.

To learn more visit www.laundrylux.com

Experience the Electrolux difference – the #1 selling on-premise laundry brand in the world. Special financing available. Call to learn more. Laundrylux® (800)381-7222 info@laundrylux.com

Electrolux washers adjust water and chemicals to correctly match the weight of the load. Laundry Chemicals Dispenser Control FuLL Loa Load 60-65 LBS PLeaSe doSe detergent Load 30-33 LBS PLeaSe doSe detergent Attending the Clean Show? Visit us in Booth #3103!

NOLA

continued from Page 10

line, the St. Charles Streetcar, has been in operation since 1835.

Managing the streetcar lines is fairly simple. Head to Julia Station on Julia Street and Port of New Orleans Place, for example, and hop on the Riverfront Streetcar to the Jackson Park area and disembark at the world-famous French Market.

For those who prefer to travel on a more local route, the RTA also has 32 bus routes that operate throughout the city. Standard fare for both buses and streetcars are $1.25 one-way, but the RTA does offer day passes (“Jazzy Passes”) that start at $3 for a one-day pass, $9 for a three-day pass.

THE FRENCH QUARTER

Ask anyone what comes to mind when they think of New Orleans, and its worldfamous French Quarter will likely be the answer.

The oldest neighborhood in the city, the French Quarter—or Vieux Carre as it was originally called—was established by the French colonists who settled in the area in

1718. Canal Street, Decatur Street, Esplanade Avenue and Rampart Street square off the Quarter, which showcases influences from the French, Spanish, Italian, Sicilian, African and Irish, amongst other cultures.

One street that many associate with the French Quarter is the colorful Bourbon Street, where many of the city’s street festivals, including Mardi Gras, take place.

Bourbon Street is turned into a pedestrian mall each evening, allowing visitors to walk freely. Every night, the “party” starts at the intersection of Canal Street and Bourbon, and stretches 13 blocks toward Esplanade Avenue.

Though Mardi Gras occurs only once a year, the party and events never stop in the French Quarter, where many of its bars, restaurants and music halls along other streets continue to celebrate life on a nightly basis. One such locale rests right in the heart of the Quarter off St. Peter Street, where true New Orleans jazz still plays on. Originally built as a residence in the 1750s, Preservation Hall touts itself as a “sanctuary to protect and honor New Orleans jazz.”

If the rhythm of the city still has you captivated, just hop over to Royal Street, where it not only presents some of New Orleans’ well-preserved architecture, but is also home

Food & dining

Cafe Du Monde. This NOLA staple has been located in the French Quarter since 1862. Enjoy its famous beignets, while sipping some chicory coffee au lait. Perfect for night owls, as it’s open 24 hours. 800 Decatur St., 504-5870833.

Brennan’s. Touted as the home of the decadent dessert Bananas Foster, Brennan’s also serves up a bevvy of classy breakfast options such as sauteed baby veal topped with poached eggs and Hollandaise sauce. 417 Royal St., 504525-9713.

Praline Connection. What started as a home delivery service in 1990 has become a local favorite for Cajun-Creole cuisine. Sample soul food favorites, as well as delicacies, such as fried alligator sausage. 542 Frenchmen St., 504-9433934.

Meltdown. This “artisinal ice pop” shop began as an ice cream truck in 2008. A year later, the owners opened their shop in the French Quarter, serving ice cream bars made of seasonal and locally sourced ingredients. 508 Dumaine St., 504-301-0905.

Acme Oyster House. Opened in 1910, Acme Oyster House is a New Orleans staple, serving chargrilled oysters and oyster shooters. 724 Iberville St., 504-522-5973.

Mr. B’s Bistro. Chef Michelle McRaney dishes up authentic Creole food at this restaurant top-rated amongst Yelp users. Menu items include fresh takes on Southern favorites such as signature barbequed shrimp and pasta jambalaya. 201 Royal St., 504-523-2078.

NOLA Restaurant. Owned by celebrity

NOLA is housed in a renovated warehouse and features Southern favorites that include gumbo, remoulade and po’boys, alongside rarities such as duck confit and fried egg pizza. 534 St. Louis St., 504-522-6652.

Cafe Amelie. If its menu items that include muffaletta, jumbo shrimp and grits, or chicken and andouille gumbo don’t draw you in, let its lush courtyard setting be the reason you stop by. 912 Royal St., 504-412-8965.

Commander’s Palace. Looking for an upscale experience? Chef Tory McPhail dishes up unique, sophisticated takes on Creole favorites, as well as delicacies such as grilled wild Texas antelope, worth dressing up for. 1403 Washington Ave., 504-899-8221.

Red Fish Grill. This eatery serves up a bevvy of surf ’n turf options from crispy Mississippi catfish to grilled filet mignon. Seafood enthusiasts unsure of what to eat can order the Seafood Sampler, featuring BBQ blue crab claws; chili pepper crusted oyster lettuce wraps; and Creole marinated gulf shrimp. 115 Bourbon St., 504-598-1200.

www.AmericanLaundryNews.com ALN_Tab_half_V.indd 1 4/10/13 11:32 AM

chef Emeril Lagasse,

See no LA on Page 14

(Photo: Joyce Bracey/New Orleans Convention & Visitors Bureau)

BIGGER JUST GOT A WHOLE LOT DEPENDABILITY MAYTAG® COMMERCIAL LAUNDRY INDUSTRIAL PRODUCTS

*Visit

for warranty details. ®/ TM ©2013 Maytag. All rights reserved. * Available in 180-lb., 230-lb. and 275-lb. capacities.

us at Clean Show 2013 Booth #3405, June 20–22.

With more than 50 years on the job, Maytag® Commercial Laundry has become synonymous with performance you can count on. And now we’re bringing that same lasting quality to our largest applications yet. Our industrial washer/ extractors are engineered to keep you up and running, and to make your operation as efficient as possible—today, and far down the line. See our industrial equipment at maytagcommerciallaundry.com.

maytagcommerciallaundry.com

Visit

to many street performers.

If Bourbon Street’s nighttime festivities are a bit too raucous for your liking, Royal Street’s daytime events may be up your alley. Like Bourbon, Royal is closed off to vehicular traffic for pedestrians.

From 11 a.m. to 4 p.m. each day, Dixieland jazz bands, puppeteers, magicians and vaudeville showmen overtake the street to provide live entertainment to passersby.

For those that feel that Lady Luck is on their side during Clean, venture over to Harrah’s New Orleans Casino on Canal Street.

Featuring more than 2,000 slots, 200 table games, comedy shows and a myriad of dining options under one roof, Harrah’s is just minutes away from the French Quarter area.

SEE THE SIGHTS

While the Big Easy has plenty of lively entertainment, those looking for a more relaxing experience can find solace in the myriad of tours the city has to offer. For an old world-style tour, try

Royal Carriages’ distinct muledrawn carriage rides, where tour guides highlight various landmarks around the city, including courtyards, iron-laced balconies, Bourbon Street and the Mississippi River, amongst others, according to its website.

Tours start at 8:30 a.m. through midnight daily, and embark at the corner of St. Louis and Royal Streets. A half-hour tour of the French Quarter for four people starts at $90.

With the Mississippi River running through the city, a different way to experience New Orleans is on tours aboard the Steamboat

Natchez, or the paddle-wheeler Creole Queen. Both offer a variety of daytime or dinner cruise options, while the Creole Queen also offers a unique 21/2-hour tour of the Chalmette Battlefield from the 1815 Battle of New Orleans.

Swamp boat tours offer a unique perspective of the sights and sounds of the Louisiana bayous. A 25-minute drive south to Marrero, La., for example, will give tourists a chance to see the Jean Laffitte National Historical Park and Preserve through the Jean Laffitte Swamp Airboat Tour.

Airboats accommodating up to 98 passengers travel along the park’s

meandering bayous filled with local wildlife, including alligators.

For those who want to venture out on their own, the city also has the Audubon Aquarium of the Americas; The Cabildo, the site of the signing of the Louisiana Purchase; and The Ogden Museum of Southern Art, according to travel advisor site Frommer’s.

SHOP AND DINE

Considering the eclectic aura that thrives here, this melting pot of cultures shines when it comes to food and dining.

A quick hop back on the Riverfront Streetcar to the French Market will lead hungry hounds to the Cafe du Monde, famous for its French-inspired beignets (square fried pieces of dough covered in powdered sugar) and chicory coffee au laits.

If you’re looking for a taste of savory Creole cuisine, The Praline Connection, located at 542 Frenchmen Street just off the French Quarter, serves up crawfish or shrimp etouffee, alligator sausage, barbecue oysters, as well as other favorites.

For those looking for a sweet fix, Brennan’s has the cure with its famous Bananas Foster, served since 1951. A marriage of butter, sugar, cinnamon, rum, banana liqueur and bananas is flambéed in a pan, creating a caramelized concoction, served with a side of vanilla ice cream.

If shopping is on your agenda, Magazine Street’s six miles of shops run the gamut from clothing boutiques to art galleries.

The lower part of the street was initially used as a commercial and industrial storage area. Centuries later, Magazine Street is now teeming with more than 150 stores, according to Frommer’s. Retail shops begin at the intersection of Magazine Street and Felicity street, or “Lower Magazine,” pick up at Washington Avenue, and again at Jefferson.

During your shopping excursion, set aside some time to veer off course and stroll around the Garden District around Washington Avenue. The city’s historic antebellum mansions can be found here, and up toward the intersection of Prytania Street and Washington Avenue lies another area for shopping enthusiasts.

Of course, another shopping destination is the French Market, where you can buy local produce at the farmers market, and practice your bargaining skills at its flea market. Purveyors of various goods from all over the world flock here to sell crafts, fashions, New Orleans memorabilia and more. Hours vary by vendor, according to the French Market’s site, but vendors are usually open between 9 a.m. to 6 p.m.

Word to the wise for international visitors flying in for Clean—save your shopping receipts. Louisiana offers interna-

Jr. Page 14 JUNE 2013 | AmEricAN LAUNdry NEws www.AmericanLaundryNews.com

SYSTEMS Introducing Vega Systems USA. VISIT US AT THE CLEAN SHOW BOOTH #5043 Call today for more information; 630-250-9222 , or visit our website at www.vegasystemsusa.com For confidential distributor inquiries please contact us at: inquiries@vegasystemsusa.com ONE SOURCE – MANY SOLUTIONS. A new company has been formed to exclusively distribute Vega products: Highly engineered washing, extracting, finishing equipment with superior functionality, fit and finish and non proprietary parts. Our equipment is 2nd to none. Find out more at our booth … One source and many solutions. ALN_Jr Page.indd 1 5/9/13 10:23 AM continued from Page 12 NOLA See NOLA on Page 16

Gurtler has the solution.

Everyone in the Healthcare Laundry field has experienced the skin sanitizer stain that won’t go away. Now you can prevent those stains in one washing cycle with the new patent pending Magi-ClensTM chemical laundry product from Gurtler Industries. Plus you can eliminate the costly changes you made to avoid the dreaded permanent stains from Hibiclens® or similar Chlorhexidene Gluconate (CHG) products that your healthcare partners use.

And you will be able to address those infection control issues you have faced. We specialize in laundry chemical product technology...it’s our main focus. That’s why we have developed some of the most advanced and trusted laundry chemical products in use today. New Magi-Clens is only available from Gurtler Industries.

Contact your local Gurtler sales consultant today for a free magical demonstration!

Magi-Clens™...eliminates skin sanitizer stains like magic!

Gurtler...The Laundry Chemical Experts, Family Owned & Customer Driven! The

Call Gurtler today! 1.800.638.7300 or visit our website at www.gurtler.com Come see for yourself. Stop by booth #2210 ©2013, Gurtler Industries, Inc.

Pink Monster

Hibiclens is a registered trademark of Mölnlycke Healthcare US, LLC and is not affiliated with Gurtler Industries, Inc.

nOLA

from Page 14

tional visitors a sales tax refund at nearly 900 of its stores, including most of the major shopping centers in the city. Simply present an international passport or an official picture identification upon your purchase, and you’ll receive a voucher to obtain your refunds at the Refund Center at Armstrong International Airport, or the Downtown Refund Center in the Riverwalk Marketplace.

WEATHER THE WEATHER

In the words of the New Orleans Convention and Visitors Bureau, the city has a “subtropical climate with pleasant year-round temperatures.” It sees sunshine an average of 67% of the time in June, but with the rays comes the summer heat. Average June temperatures can top 90 F.

To stay up-to-date on local weather, many smartphone apps can deliver concise weather forecasts. But for those who truly want to dress according to the weather, Swackett provides fun, visual outfit recommendations for you to consider.

Frommer’s explains that

T-shirts and shorts are acceptable attire at most establishments (the exceptions being fine restaurants), so loose, light clothing is the way to go when sightseeing.

But for fashion-conscious travelers who don’t want to compro-

mise fashion for the extreme heat, lightweight fabrics such as cotton, linen or madras provide style not only during the day, but when dressing up for the nighttime. A linen blazer and linen dress pant can make up a perfect outfit for

a more formal dinner, without feeling too stuffy.

Those who are unable to bear the New Orleans humidity can take comfort in indoor activities, as many establishments are airconditioned. Those who absolute-

Shopping

Riverwalk Marketplace. Home to more than 100 shops, this marketplace combines the joys of retail therapy set along the Mississippi River. 500 Port of New Orleans Pl., 504-522-1555.

Lakeside Shopping Center. Featuring more than 120 retail shops, this center is perfect for those looking for a one-stop shopping destination. 3301 Veterans Memorial Blvd., 504-835-8000.

French Market’s Flea Market. Browse and bargain over clothing, jewelry, antiques and other wares from merchants from all over the world in this open-air market (pictured). 1008 N. Peters St., 504-522-2621.

Frenchmen Art Market. Night owls looking to spot a deal on handmade art and goods made by local and regional artists can flock here Thursday through Saturday night, from 7 p.m. to 1 a.m. 619 Frenchmen St., 504-941-1149.

NOLA Merchandise. Want to bring the celebratory culture of New Orleans back home? NOLA Merchandise’s stock of Mardi Gras beads, boas, Venetian masks and other souvenir items will help you relive your NOLA experience. 425 Decatur St., 985-236-9560.

Perlis. Considered uptown New Orleans’ “premier clothing store,” Perlis sells men’s, women’s and children’s clothing emblazoned

ly can’t stand the heat can wait to go out until the evening, as June lows average around 70 F.

ENJOY THE BIG EASY

Still undecided about what to do, or which sights to see? Trying

with the company’s trademark crawfish insignia. 6070 Magazine St., 504-8958661.

Louisiana Music Factory. Boasts a wide selection of New Orleans jazz, Zydeco and Cajun records. Bring the soundtrack of the city back home. 210 Decatur St., 504-586-1094.

Southern Candymakers. This family-owned candy store has a bevvy of chocolates and sweets to bring back home, including their award-winning pralines. 334 Decatur St., 800-344-9773.

Vintage 329. Featuring authentic autographed memorabilia, barware and other rare collectibles, it’s the perfect shop for those looking to snag a piece of history. 329 Royal St., 504-525-2262.

Fleur D’Orleans. Inspired by local architecture, it sells jewelry featuring historical designs, such as the iconic Fleur-de-lis. 3701A Magazine St., 504-899-5585.

16 June 2013 | AmericAn LAundry news www.AmericanLaundryNews.com Untitled-1 1

continued

(Photo: Chris Granger/New Orleans Convention & Visitors Bureau)

to fit some sightseeing into a threeday show schedule can be challenging, but online resources such as Frommer’s and TripAdvisor have multiple listings and ideas of attractions to visit on a limited schedule.

The New Orleans Metropolitan Convention and Visitors Bureau at 2020 St. Charles Ave. can also help you navigate your way, and even make trip recommendations around your specific interests, according to Frommer’s.

The Visitor Information Center at 529 St. Ann St. can also make recommendations. Open Tuesday through Saturday between 9 a.m. to 5 p.m., the center has walking and driving tour maps and booklets on local sights.

AttrActions & EntErtAinmEnt

One other resource: the locals. Don’t be shy to ask the grocer at the farmer’s market which restaurant he recommends for authentic Cajun cuisine, or the shopkeeper at the antique store which museums to check out. Not only can

they direct you to local attractions, they can also point you toward some hidden gems.

With many things to see and do in New Orleans, make sure you relish in the local flavor during Clean 2013. ALN

The National WWII Museum. In addition to its many exhibits memorializing the “war that changed the world,” The National WWII Museum (pictured) also hosts special performances in its Stage Door Canteen auditorium. Playing during Clean will be Two on Tap. 945 Magazine St., 504-528-1944.

The Ogden Museum of Southern Art. Settled in the campus of University of New Orleans, this museum boasts the “largest collection of Southern art in the world.” Be sure to check out its Ogden After Hours music series Thursday, June 20. 925 Camp St., 504-539-9600.

Royal Carriages. Tour the Big Easy aboard its signature mule-drawn carriage rides. Tour guides will escort visitors past NOLA landmarks, courtyards and famous eateries. 1824 North Rampart St., 504943-8820.

Jean Lafitte Swamp Tours. Venture out of the city to marvel at the unique

Louisiana bayous aboard the Jean Lafitte Airboat Tour. Airboats navigate through the Jean Lafitte National Historical Park and Preserve, where local wildlife, including alligators, lurk in its murky waters. 6604 Leo Kerner Lafitte Parkway, Marrero, LA. 504-689-4186.

The Steamboat Natchez. Touted as the “last authentic Steamboat” on

the Mississippi River, the Steamboat Natchez provides tours of the city on the Mississippi amid live jazz music and optional dinner and lunch packages. 400 N. Peters St., Ste. 203, 504586-8777.

Creole Queen Paddlewheeler. In addition to providing picturesque tours of the Mississippi River, this paddlewheeler also throws in a side trip to the Chalmette Battlefield, site of the 1815 Battle of New Orleans; the Malus-Beauregard House; and Chalmette Monument. #1 Poydras St., Riverwalk Marketplace, 504-529-4567.

Harrah’s New Orleans Hotel and Casino. Lady Luck on your side during Clean? Live up to the motto of the city and let the good times roll at Harrah’s casino, which features more than 2,000 slots and

200 table games. 8 Canal St., 504-5336000.

Preservation Hall. Visit this “sanctuary” where New Orleans jazz is protected and honored. Live New Orleans jazz emanates 8 to 11 p.m. nightly from this former art gallery. 726 St. Peter St., 504-5222841.

Audubon Zoo/Aquarium. Witness the Audubon Zoo’s exotic mix of animals set upon unique natural habitat exhibits, such as the Louisiana Swamp and Jaguar Jungle. Those looking for aquatic animals can find refuge at the Audubon Aquarium’s 400,000-gallon Gulf of Mexico Exhibit. 6500 Magazine St./1 Canal St., 504-5814629.

Southern Food & Beverage Museum. Food enthusiasts looking to learn more about the culinary heritage of the South will enjoy the museum’s exhibits, demonstrations and tastings. 500 Port of New Orleans Pl., 504-569-0405.

www.AmericanLaundryNews.com AmericAn LAundry news | June 2013 17 4/22/13 11:08 AM

(Photo: Richard Noritz/New Orleans Convention & Visitors Bureau)

safety

advises using teleconferences among other plants to share information on best practices, and how to apply them to similar situations they could face at their facility.

Ergonomic Standards

There are currently no ergonomics standards, Foulke says, and OSHA has proposed including musculoskeletal disorders in its

300 Logs. OSHA currently utilizes the General Duty clause to issue ergonomic citations, he explains, which can be more costly than other types of citations.

“They’re going to be asking for your audits, and if your audits identify ergonomics issues, then you now have knowledge of that and it makes it easier for them to establish a General Duty clause violation,” says Foulke. “And if you have knowledge and did nothing about it, then arguably, it’s a willful violation, so now you go from a maximum of $7,000 for [a serious violation] to $70,000 for [a willful violation].”

Metric for Safety

With these precautions in mind, Foulke identifies one metric that business owners can use to avoid repeating a violation. While many owners look to lagging indicators—including lost-time injury rates and worker’s compensation—as a tool to measure workplace safety improvement, Foulke explains that such indicators can actually exhibit weaknesses in a workplace safety program.

Instead, he recommends business owners look toward leading indicator tools, such as a job safety analysis, in which they can identify workplace hazards to increase

employee training and supervision. And although there are many leading indicator tests that business owners can look at, Foulke says that studying near-misses is one of the most important.

Other Avenues of Safety

Creating an emergency action/ response plan focusing on natural disasters, pandemics and manmade disasters, with an emphasis on evacuation plans and exit/ egress compliance, is one of the other requirements OSHA looks at during inspections, according to Foulke.

He also addressed the health

and well-being of employees, saying that workplace injuries can be the result of an employee’s health and fitness. He particularly highlighted the obesity problem among American teenagers.

Developing a safety program, which also focuses on health and wellness, is the solution, Foulke advises, and not having one in place can ultimately cost a company a lot of money in the long run.

“If you don’t develop a comprehensive wellness program for your facilities, and really address obesity...you’re going to go out of business,” Foulke warns. “Just imagine [what the] direct cost is going to be—healthcare costs and workers’ compensation costs, it’s going to be huge.”

The overall cost of an injury to an employee can be “very dramatic,” he says, but having a safety program in place can actually become a “profit center” for a company.

“If we have a comprehensive safety management system…we’re going to reduce our injuries and illnesses and fatalities, which in turn, is going to reduce our worker’s compensation costs,” Foulke says. “We’re going to be productive and more competitive because of the savings that we [have] there.”

Safety at Company Core

Ultimately, for Foulke, ensuring that safety is top priority in a company’s core values is the integral part of establishing or refining a workplace safety program.

“If you’re going to have safety as No. 1, it has to be core value,” he says. “And what that means as a core value is that we do not do the job, unless it’s done safely. If it cannot be done safely, you do not do the job.”

Not having safety at the core, according to Foulke, creates a domino effect in the workplace.

“In order to have great productivity, efficiency and quality, you have to have great safety. If you don’t have great safety, someone gets injured. If someone gets injured, they don’t show up for the job the next day. If they don’t show up for the job the next day, their productivity is zero.”

Creating or refining a workplace safety program should involve everyone in the company, Foulke says, from front-line employees to the corporate level. “When upper management makes it clear that safety is a priority, that it’s a core value, it drives all the way down.”

High performance and thru-put are paramount in the most demanding industrial laundries and the AD-464 provides the highest performance in its class. Utilizing a state-of-the-art power burner system and heat reclamation, the AD-464 ensures fast dry times while providing unsurpassed dependability. The industrial roller drive system and standard stainless steel tumbler means durability and the internal lint collection makes routine cleaning fast and simple. Pre-programmed cycles, and touch button operation allows for ease of use and multi-lingual display options. ADC’s AD-464 assures powerful, consistent, and reliable operation. For more information please visit: www.adclaundry.com or contact us directly at sales@adclaundry.com

Involving employees in the safety management process not only helps a company avoid facing other legal problems, it ultimately harmonizes the relationship between employer and employee.

“If you show employees that you care, then you may not get a union organizing drive against you, or you may not get someone filing a class-action age discrimination case, because they feel like you do care about them, and therefore you’re trying to treat them right,” Foulke says.

ALN

Innovative

Exceptionally Innovative

Exceptionally Engineered Proud of our Past...Excited for our Future www.adclaundry.com 508.678.9000 ALN_Jr Page.indd 1 4/2/13 3:02 PM 18 June 2013 | AmericAn LAundry news www.AmericanLaundryNews.com

continued from Page 6

Top

Top Performance

It’s critical for both drivers and your sales force to embrace your transportation strategy, because either can short-circuit attempts to get things headed in the right direction.

Global positioning system (GPS) technology can “follow” any vehicle that carries the GPS unit under the hood. During another TRSA event, attendees watched a large screen as icons representing buses moved from point to point along a map of Jersey City, N.J. Scrolling over one of the icons immediately popped up a smaller screen that identified the vehicle, the driver, the speed of the vehicle and its location.

Such data is useful in tracking a driver’s progress (is he on time or does he seem to be stalled?) as well as help prevent theft and misuse of company vehicles.

FLEET SAFETY

With so many textile service trucks and step vans on our nation’s highways every day, fleet safety has to be a priority.

For example, Cintas Corp. has used telematics to reduce the number of vehicle incidents that its drivers experience. The company initially installed inthinc’s telematics technology in 1,200 vehicles in its Uniform Rental division.

Cintas Corps. has used telematics technology to reduce the number of vehicle incidents that its uniform rental drivers experience.

“The system uses state-of-theart technology to influence driving behaviors and reduce risk in a real-time environment,” says Rick Gerlach, director of safety at Cintas. “But the most important benefit of the technology is that it not only allows us to identify drivers who could benefit from some additional safety training at the wheel, but also provides an opportunity for Cintas to recognize and reward our drivers who make safety a core value at all times.”

Cintas reduced its number of speeding events by 85% and increased seat belt use by 89% within one year of implementation, the company says. Overall, it translates to a 46% decrease in vehicle incidents.

ALTERNATIVE-FUEL

VEHICLES

It costs a great deal of money to keep their fleets on the road, so fuel efficiency is always on the mind of an operator managing a delivery fleet. G&K Services, Mission Linen Supply and Bates Troy Healthcare

Linen Services are among the textile services companies that have explored using alternative-fuel vehicles.

In California, G&K Services is testing diesel electric hybrid step vans to assess the potential of replacing standard diesel trucks, where feasible, to increase fuel efficiency. “G&K is focused both on maximizing the fuel economy of our delivery fleet and being good stewards of the environment,” says Dick Stutz, G&K’s senior vice president of operations.

After a successful pilot program in Santa Barbara, Calif., Mission Linen Supply has begun using six

CNG (compressed natural gas) trucks in Morro Bay, Calif., and Phoenix, Ariz., to deliver linens, uniforms and restroom supplies.

CNG was one of several alternative fuels that Mission Linen considered as it was seeking to increase its commitment to sustainability. It favored CNG’s reduced impact as compared to the threat caused by disposal of batteries used in hybrid applications, the company says.

CNG-powered engines are capable of reducing NOx (nitrogen oxide) emissions by as much as 98%, thereby reducing smog. They are also capable of reducing carcinogenic particulate matter by 99%.

The overall reduction in greenhouse gas emissions for Mission Linen will be 30% or greater.

carbon footprint,” says Don Bock, director of risk management. “We’re thrilled that we can have a positive impact on the environment and save money, making the case for other companies in our industry to follow suit.”

Bates Troy Healthcare Linen Services has used a test truck powered by a HybriDrive® parallel propulsion system in its healthcare linen service deliveries and pickups. The electric-hybrid propulsion system complements BAE Systems’ HybriDrive series system. It was designed to respond to the specific needs of the heavy-duty vocational truck market. ALN

www.AmericanLaundryNews.com AmericAn LAundry news | J une 2013 19

“Since we depend on trucks to conduct our business, we are committed to finding ways to increase fuel efficiency while reducing our

ALN_Jr Page.indd 1 4/5/13 3:28 PM continued

Braun ALN JR Page Ads_Braun JR Ads 4/2/13 3:24 PM Page 1

routefrom Page 1

Fuel efficiency is always on the mind of a textile services operator managing a delivery fleet.

PANEL of ExPErts

Tips for making the most of tight quarters

Irecently decided to tackle my garage and finally clean it out so we could use it for what it was intended: parking our cars. I was immediately faced with two dilemmas: 1) what to do with our excess belongings and 2) how to maximize storage and free up the area where our cars should be.

I realized that as my family continues to grow, we accumulate additional belongings with no solution as to where to store them all. Similar to many laundries today, as we add business and our volume increases, our physical storage capacity begins to choke us and bog things down. Lack of free space could directly impact daily production flow.

Then, I had an epiphany. I remembered what we had done in our laundry when faced with a sudden need for more storage and space. The only direction to go was up.

As laundries continue to grow, two tips to make the most out of existing production space and improve production flow involve going vertical. One could try adding an overhead rail system for garment storage and route makeup and/or adding a mezzanine.

By installing an overhead rail system, you free up valuable space to enhance production flow and allow for immediate growth. It is a good solution for storage of both soiled linen and garments, and also an excellent way to store and move clean garments prior to ship-out.

INDUSTRIAL BY

Adding a mezzanine is a perfect way to maximize the height of your building and, in some cases, possibly double and/or triple your storage capabilities. These systems allow you to gain more precious space by going up as opposed to going out.

The beauty of these two systems is that you can design them as needed to fit your specific facility but they can later be dismantled, moved and reinstalled if desired.

american laundry news jr page 7.75x10 For laundry done on time and on budget, there’s no better choice than IPSO ®. Forty years of European ingenuity, rugged industrial construction, and our intuitive Cygnus controls all add up to help you achieve your ultimate goal — maximum throughput at a minimized cost. Learn more about how IPSO helps you get the job done at IPSO.com/industrial VISIT US AT THE CLEAN SHOW, BOOTH 3621, JUNE 20-22

Work with your IPSO finance expert to learn about customized financial solutions for your business. IPSO USA 1.800.USA.IPSO IPSO.com/industrial

BY DESIGN. Optimal Efficiency. Maximized Throughput. 3929_IPSO OPL_jrPg amerlaundnew snipe v3a.indd 1 4/4/13 4:19 PM ALN_Jr Page.indd 1 4/5/13 10:10 AM

DESIGN

INDUSTRIAL

20 jUNE 2013 | AmErIcAN LAUNdry NEws www.AmericanLaundryNews.com

“My laundry isn’t all that large.

I am always looking for tips and advice to make the most of our production space. What general suggestions can you give me about how best to operate in cramped quarters?”

Uniforms/ workwear manufacturing Scott Delin

Superior Uniform Group Seminole, Fla.

It takes space to do laundry.

There are rules of thumb regarding how much space is required to do a given amount of linen. I have seen them range from .7 square feet to 1.7 square feet per pound processed per day. Check with an equipment distributor about this.

I would find out where the laundry stands within those parameters. Doing laundry in cramped circumstances leads to stress, fatigue, errors, sloppy work and lowered production. Increasing space is not the sole answer to those problems, but a lack of space certainly contributes to poor performance.

If there is clearance, you can go to overhead rails and slings, giving more storage space in the same floor space. Folders and other items not permanently anchored may be moved closer together to gain some room. If you have pony carts, go to fullsized carts. Any equipment that hasn’t been used in a while could be disposed of.

If possible, operate more hours with fewer people per shift. If you are using trucks to deliver the goods, you may wish to store linen in those trucks. If possible, change the collection/distribution schedule.

Another contributing factor may be unprocessed goods stored in the facility, consuming more space than necessary. If that is the case, increased production will get it out of the laundry facility.

Does new linen waiting for injection take up a lot of room? How about cart covers, wrap, and trash/laundry bags? Can these items be stored in an outside storage facility?

None of these ideas by themselves will solve the problem. By using some of them, and some that others will put forward, you will begin to evolve your operation into something that may be more manageable.

• • • • •

In the case of a hotel, designing a laundry facility is largely a matter of positioning equipment and tables to allow for easy movement by the housekeeping staff—regardless of the amount of space.

Maximizing equipment size is integral to the success of running a smaller, yet efficient laundry operation. Obviously, washers and dryers that handle bigger loads require a larger footprint, but typically, two larger-capacity washers will occupy less floor space than three smaller-capacity washers.

With a smaller laundry area, it may also be necessary to add

a shift or a half-shift to keep up with laundry demands. For example, instead of running a more typical 8-hour laundry operation, one may have to adjust to a 12- or 15-hour operation to process all linens.

Once the size and amount of equipment is determined, ensure that the washers and dryers are running at optimal efficiency. This typically means matching washer and dryer cycle times.

Historically, facilities experienced long dry times due to washers’ slow final spin speeds. This led to carts of wet linens occupying valuable floor space and slowing

down the laundering process.

For the highest level of performance, look for soft-mount washers with a G-force exceeding 300. A 350-G washer will leave up to 30% less water in the linens when compared to 100-G washers. This can significantly

reduce dry times, leading to a much more cost-efficient laundry operation.

Besides the overall efficiency in space and labor, this facility can also see reduced linen costs as shorter dry times help linens last longer, saving on replacement.

• • • • •

Operating within tight quarters can be challenging, but working with a well-organized, utilitarian space can also help optimize efficiency and profit.

Companies that utilize production space effectively can benefit from lower utility costs, rents, taxes, personnel benefits, etc. In

periods of growth, companies can analyze the profitability of existing accounts, looking at opportunities to apply price increases or to substitute some accounts with those that offer greater projected value.

www.AmericanLaundryNews.com AmerIcAn LAundry news | j une 2013 21

commercial Laundry

Richard Warren

Linen King Conway, Ark.

ALN_Jr Page.indd 1 4/5/13 3:31 PM

on Page 22

Braun ALN JR Page Ads_Braun JR Ads 4/2/13 3:25 PM Page 2

See EXPERTS

equipment manufacturing Steve Hietpas

Maytag® Commercial Laundry St. Joseph, Mich.

Textile/uniform rental

Tom Peplinski Golden West Oakland, Calif.

To help optimize your plant layout (large or small):

• Plan — Start with a diagram or layout of your plant and organize production flow. Once areas of improvement are identified, implementing the physical-plant change is a simple matter of time management. Creating a smooth workflow—soil to wash to dry to fold to load-out and, finally, to load-in—can greatly improve efficiency and safety.

• Analyze — Examine every foot of floor and wall space. Moving from horizontal storage to vertical overhead storage can free up valuable production space. Remember to brace and secure all storage for a safe environment.

• Identify — Identify those items in your plant that are not needed with present production and dispose of them or store them off-site.

• Explore — Think outside the box on your “who, what, where, when, why and how” approach to production. Explore the what-ifs and don’t be afraid to implement change. Adopt this credo: If I am not changing, I am not improving.

• Schedule — Can the hours of production be changed, split, etc.? Do the hours of operation take advantage of available low utility and operating costs?