Diamond Chemical acquires assets of Unichem

EAST RUTHERFORD, N.J. — Diamond Chemical Co. has acquired “certain assets” of Chicagobased specialty chemical manufacturer Unichem, the company reports. Through the acquisition, Diamond, a manufacturer of laundry, warewash, floor care, housekeeping, organic intermediates, industrial and consumer products, aims to serve additional customers.

Terms of the acquisition were not announced.

A representative at Diamond Chemical tells American Laundry News that the company bought Unichem’s name, customer list and supplies, and that salespeople formerly employed by Unichem now work for Diamond.

Representatives from Unichem did not immediately return calls for comment; the company’s main phone line now features a welcome message from Diamond Chemical.

For more than 40 years, Unichem has provided customers with specialty chemicals for the drycleaning, hospital, industrial and institutional laundry industries, Diamond reports. It expects Unichem’s transition to Diamond Chemical under the acquisition to be “seamless.”

“Current customers will continue to receive the same high-quality products and service from Diamond that Unichem previously supplied to them,” Diamond says in a statement. ALN

Boiler maintenance: Protecting the heart of a laundry/linen operation

Regular checks, inspections key to safe operation

BY THERESA BOEHL, EDITOR

CHICAGO — “It’s very easy not to think about a boiler until something goes wrong.”

This statement from Daniel Orr, general manager, National Combustion Co. (NATCO), is an unfortunate truth and a reminder to industry members that ignoring or overlooking this central piece of equipment can only have negative consequences for a laundry/linen plant.

Like much of the other technology that makes a plant run, boilers must be thoroughly monitored and maintained by any business that relies heavily on their safe and smooth operation.

American Laundry News consulted a number of boiler manufacturers that have advice for operators on how, when and why to give a boiler proper TLC, not only for safety reasons, but for overall plant efficiency.

BOILER SAFETY

No matter what kind of boiler a plant uses,

there are a number of steps that operators must take to be sure the equipment is in working order with no potentially dangerous problems.

For starters, most of the boiler experts agree that checking the low-water cutoff every day is an essential task for plant safety.

Polymer bead technology offers new approach to wash process at Crest Advanced Dry Cleaners

BY RICHARD MERLI

GERMANTOWN, Md. — A brand-new technology designed to drastically reduce the use of water and energy is being introduced for commercial, institutional and industrial laundry operations.

The new laundering system, manufactured by Xeros Inc., has recently been installed in several sites in the United States, including at Crest Advanced Dry Cleaners, a retail drycleaning and laundry operation with 10 plants in Virginia and four in Maryland.

The Xeros system uses a propri-

etary polymer bead technology to achieve mechanical action, and the manufacturer claims it has already reduced water consumption by 80% and virtually eliminated the use of energy in the wash process in these first U.S. installations.

The new technology is generating savings at three plants for Crest. Last month, a representative of American Laundry News toured the company’s new plant and laundering system here in Germantown, some 30 miles north of Washington, D.C.

The Xeros laundry system has also been installed in Choice

Hotels and in the Hyatt Regency in Reston, Va.

“Water and energy costs are three times higher in Maryland than they are in Virginia, so it was really a no-brainer for us to install the Xeros technology at our high-volume plants,” says David Slan, president and CEO of Crest Advanced Dry Cleaners. “Our new plant really revolves around the efficiencies of the new laundry system.”

HOW IT WORKS

The system can process table linen, uniforms, clothing and

other goods with municipal water at ambient temperatures of 60 to 70 F. Approximately 1.3 million polymer beads are introduced into a wash cycle—typically for less than an hour—along with the company’s proprietary detergent, “Pack 1.” The beads work to release and absorb soil from the goods.

When a wash cycle is finished, the beads exit through perforations in the drum of the washer and are stored in a bead sump. They can be reused up to 500

Panel of Experts Group offers tips for managing daily tasks and long to-do lists.

OPL 101: Proper Machine Maintenance

Keeping up with maintenance tasks can help operators avoid sudden problems and equipment downtime.

AUGUST 2014

“A low-water condition is one of the most unsafe situations you could have in a boiler if not properly addressed,” says Mike McLean, laundry/drycleaning sales manager at Fulton

Late News

www.americanlaundrynews.com Volume 40, Number 8

The Newspaper of Record for Laundry & Linen Management

INSIDE [12] [18] See BOILER on Page 6

See XEROS on Page 6

[8]

(Photo: ©iStockphoto/LSOphoto)

LARGECAPACITY DRYERS PRODUCT SHOWCASE

Survey: Operators ensure workers keep cool as summer

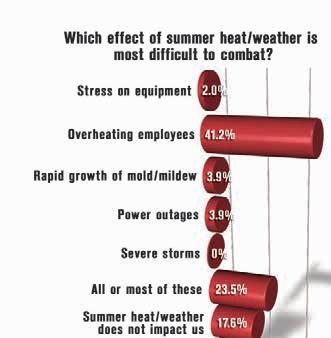

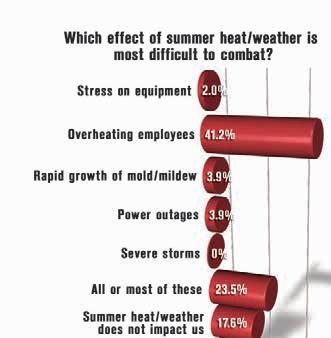

CHICAGO — “Overheating employees” is the most difficult challenge to combat during summer for the majority (41.2%) of laundry managers and administrators, according to results of July’s American Laundry News Your Views survey.

Equal shares of 3.9% say that “power outages” or “rapid growth of mold/mildew” are the most cumbersome effects of summer weather at their facility, with a small percentage (2.0%) citing “stress on equipment” as the most challenging.

While no one taking the survey found “severe storms” to be problematic, 23.5% say “all or most” of the listed effects of summer heat/weather are challenging overall. Though roughly 18% say summer heat/weather “does not impact [them],” 7.8% found “other” effects difficult to combat, with one operator facing a “lack of revenue as [his/her] customers close for three to four months.”

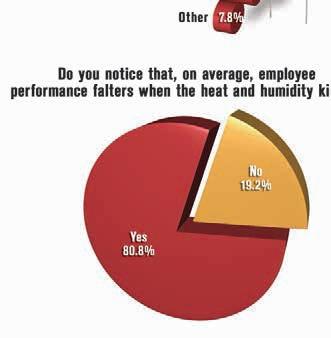

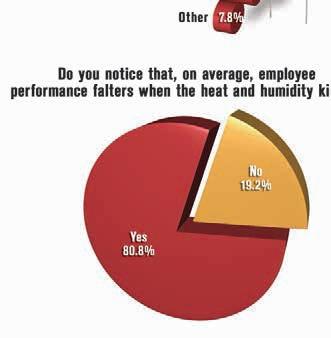

More than half of respondents (52.9%) say that summer heat/weather “slow operations,” while 47.1% say it has no effect at their facility. A resounding 80.8% say that, on average, employee performance “falters” when the heat and humidity kick in, while 19.2% say otherwise.

Frequent breaks and use of various cooling equipment, like air conditioning, fans and spot coolers, are among some strategies operators have implemented at their plant to help employees beat the heat.

“Each piece of equipment has an operator-controlled fan,” a respondent says. “Gatorade is offered at any time the employee requires, [and] cold towels are available to wrap around their necks.”

When it comes to keeping machinery running efficiently when temperatures rise, many operators (15.4%) perform “regular maintenance,” while equal shares of 9.6% “monitor equipment constantly” or direct employees to “note and report changes” in equipment performance. Roughly 2% “ensure air conditioning/cooling systems are working properly,” while the majority (63.5%) use “all of the above” tactics to keep machinery in working order in hot weather. No one who took the survey identified “other” alternatives.

The summer heat can also present challenges on the finishing side of the operation for some managers.

“Products may mildew quicker, [particularly] damp products,” one says.

“Humidity in [area] requires a slight adjustment to the drying cycles on certain linen items,” says another.

Whatever the challenges they face at work, operators are finding ways to wind down during summer vacation.

“[I am] forgetting about laundry and riding my Harley,” one says.

Some will be taking long breaks from work while another respondent says, “Summertime is when we have the most business coming in. Vacations are for December when business is at our lowest point.”

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online each month. Due to rounding, percentages may not add up to 100%.

All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and industry trends. ALN

Gurtler Industries acquires Hite Chemical Systems

SOUTH HOLLAND, Ill. — Gurtler Industries is reporting its acquisition of specialty laundry chemical company Hite Chemical Systems of North Canton, Ohio.

David Hite, principal of Hite Chemical Systems, will be joining Gurtler Industries as he continues to manage the primary customers his company served, Gurtler Industries reports.

“I am very pleased that Gurtler Industries and Hite Chemical Systems have joined together,” says David Hite. “Gurtler’s nationwide network of sales and service specialists will enable us to expand our unique offerings to a broader range of customers.”

Greg Gurtler, CEO of Gurtler Industries, says Hite Chemical Systems is a “great addition” for his company.

“Hite’s commitment to superior customer service aligns with the Gurtler philosophy. Plus, the Hite business unit that served Mexico will be a great addition to Gurtler’s existing operations there,” he says.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ americantrademagazines.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ americantrademagazines.com

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ americantrademagazines.com

Editor

Theresa Boehl

Phone: 708-280-1750

E-Mail: tboehl@ americantrademagazines.com

Production Manager

Roger Napiwocki

Contributing Editor Jean Teller

Editorial Assistant

Carlo Calma

Interns

Lauren Dixon, Charles Thompson II

National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ americantrademagazines.com

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies: U.S. $7.00; Foreign $14.00. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 40, number 8. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. No material appearing in American Laundry News may be reprinted without written permission. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2014. Printed in U.S.A

MEMBERSHIPS

2 AUGUST 2014 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Association for Linen Management

INSIDE: August 2014 • Vol. 40 | No. 8 [8] Panel of Experts: Keeping Up with Daily Tasks “How can busy laundry/linen managers keep track of all the tasks they have to accomplish in a day?” [11] Davidson College Full-Service Laundry to Close Students have enjoyed full-service laundry at the institution for more than 90 years, but that tradition will soon end [12] Product Showcase: Large-Capacity Dryers [17] Trade Ticker [18] OPL 101: Proper Machine Maintenance Regular preventive maintenance can help managers keep their operations efficient and effective

temps flare

ALN

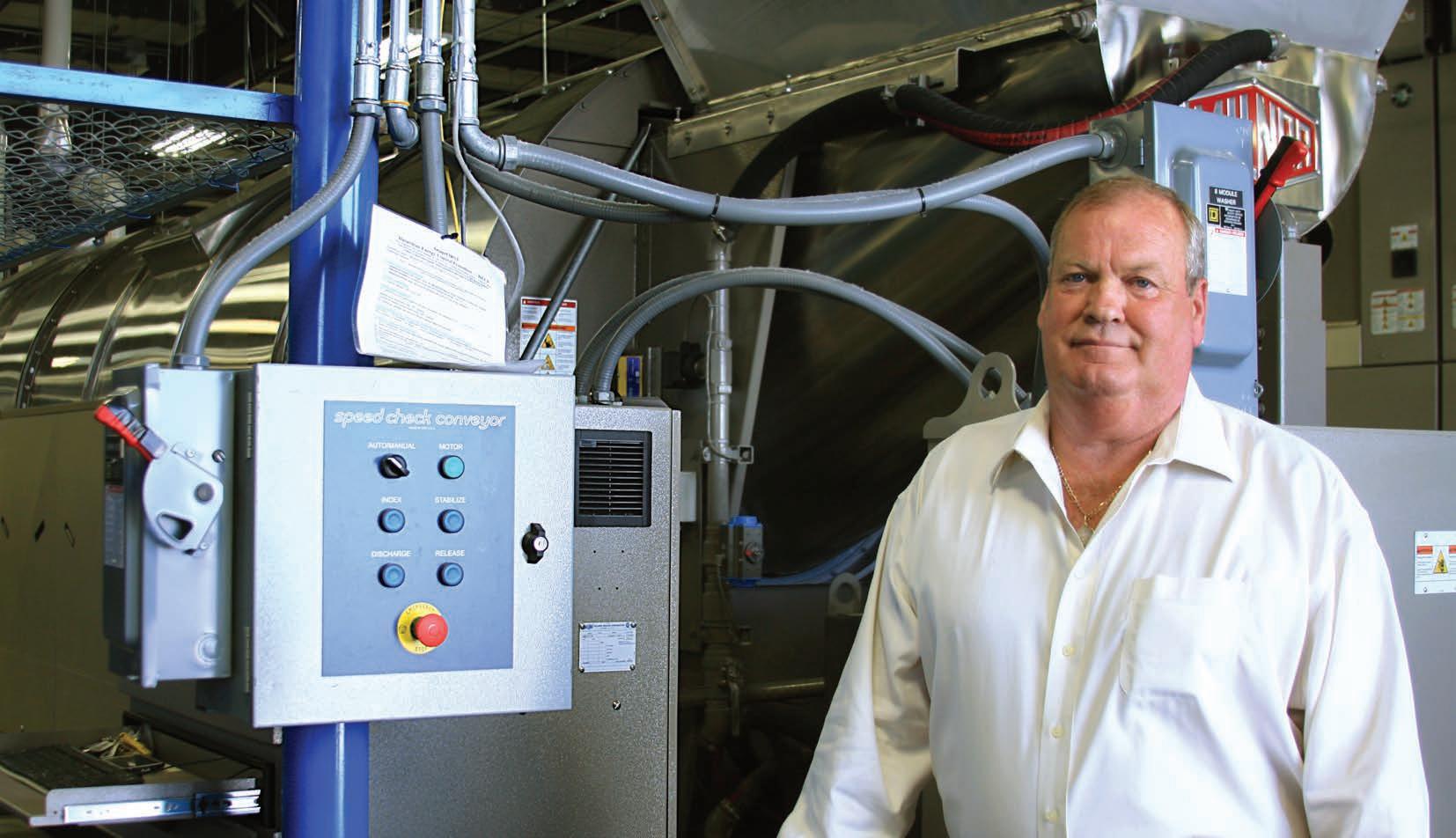

The PulseFlow changed my mind on tunnel washing.”

–

Tim King, Partner/General Manager at ImageFIRST, Clearwater, FL

Tim King admits he was a skeptic of tunnels, but understood that the production would benefit from a tunnel washer. “I saw firsthand how white the linen came out. PulseFlow is what changed my mind about tunnel washing. With a top-transfer tunnel, you get the lift-and-drop effect just as you do as in a washerextractor.” ImageFIRST Clearwater now runs as much linen as possible through the tunnel because of its inherent savings. Since the plant began using the PBW™ tunnel, the laundry’s water and sewer bills have been cut in half... even with the continued use of their aging two large open-pocket washer-extractors.

To find out how Milnor can cut your water bill in half, contact an authorized Milnor distributor or call 504-712-7656.

www.milnor.com/pulseflow_technology / pellerinmilnor

“

To see how PulseFlow CBW Tunnels work, scan this code.

Let’s keep on keeping on

As I leaf through this month’s issue of American Laundry News, I see that much of our editorial content touches on the concept of “maintaining.”

The lead story focuses on boiler maintenance and the importance of giving this integral laundry system the proper amount of tender loving care, not only for safety reasons but for overall plant efficiency.

On Page 2, our monthly survey touches on maintaining employee productivity and morale by keeping workers cool and comfortable, especially during the sweltering summer months.

The Panel of Experts article beginning on Page 8 discusses ways that time-challenged managers can maintain their sanity by

From The Director’s Chair BRUCE BEGGS

multi-tasking, delegating jobs when possible, and using a variety of planning and scheduling tools to help them make it through the day’s to-do list. We learn through our Page 11 story that Davidson College

has decided against maintaining its 90-year-old full-service laundry tradition. After the 2014-15 school year ends, so, too, will the college’s institutional laundry. Finally, the OPL 101 column on Page 18 describes how giving laundry production equipment the proper maintenance and care can decrease downtime.

The September issue will feature our annual Distributors Directory. Distributors, if you haven’t been contacted about updating your company’s listing (we solicit information for the free listings solely by e-mail now), e-mail Digital Media Director Nathan Frerichs at nfrerichs@ americantrademagazines.com immediately to remedy that. ALN

Annual AHE educational event focuses on strategies, tactics for environmental services

CHICAGO — Bringing together professionals involved in textile care, infection prevention, environmental services and other areas, the Association for the Healthcare Environment’s (AHE) annual educational event—EXCHANGE 2014—will be presented Sept. 21-24 in Tampa, Fla.

AHE expects this year’s event to attract more than 700 professionals, including those responsible for budgets related to laundry processing, linen/laundry contract management and distribution/textile processing.

“Each session is designed to include pragmatic ideas, strategies and tactics that will keep you abreast of changes as you look to the future,” says Mike Bailey, CHESP, 2014 AHE president, in a conference brochure.

AHE says more than 200 exhibitors will be present, including laundry equipment and supplies companies, uniform companies and textile care companies.

The four-day event will feature general sessions covering patient experience, effective communication, constructing purposeful leadership and new approaches to service and culture. Speakers in the “learning labs” will discuss topics such as textiles’ role

in preventing outbreaks; efforts to reduce patient linen loss; the role of the healthcare environment in transmission; and implementing and maintaining a hospital waste program, among others.

Social activities and opportunities to network include the AHE annual golf event, “brewed awakenings” breakfasts, an exhibitor summit and several receptions. Participants can also attend a review session for the Certified Healthcare Environmental Services Professional (CHESP) Examination before taking the exam on Tuesday, Sept. 23.

Among the honors to be presented at the conference are the AHE Innovation award, the Excellence in Safety and Quality Improvement in Environmental Services award, the Heart of Healthcare award, and the Phoenix award, the association’s highest honor.

AHE, a “personal membership group” of the American Hospital Association, represents more than 2,000 professionals involved in resident care environments in hospitals, continuing care retirement communities, ambulatory care and long-term care, among others.

To learn more about the upcoming event, visit the association’s website at www.ahe.org ALN

Why do managers tolerate difficult employees?

I have had the privilege of visiting many laundries during my 40-plus-year career in the laundry business. I have also been blessed to be able to use my talents in a variety of locations. Over the years, I have come across some individuals who were very hard to work with. They often fall into the category of “does not play well with others.” Yet these employees seem to stay on the payroll despite their faults.

In discussing some of the specific situations I have come across, I have found that the justification for keeping these individuals around often falls into one of several categories.

The first is the belief that these employees have essential information required for the proper operation of the laundry that is not possessed by the other employees. This is often a direct result of the fact that the employee in question will not share that information with anyone else. This type of employee is basically extremely insecure in his or her job and is afraid to share knowledge for fear that someone may take over his or her job.

I learned a long time ago that everyone can be replaced. There is no one employee who is essential to the operation of a laundry. There will be challenges in replacing a knowledge-hoarding employee, but after several months of turmoil, the end result should be better. You will have the opportunity to create a better work group that can fully utilize members’ talents and skills.

Knowledge-hoarding employees do their best to tamp down any idea that is not their own. They stifle creativity and cannot accept suggestions from other employees. In short, they are a real drag on employee morale.

The second reason that problem employees have been kept on board is because no one has ever had the fortitude to confront these employees and address their job performance.

I can remember one supervisor I worked with 25 years ago. I gave this person an average performance evaluation, accurate and fair based on his on-the-job performance. His response to the evaluation was to ask me what was wrong with me. He said he had always gotten top evaluations for the past 10 years and the only thing that had changed was me.

No manager had been willing to honestly evaluate this employee because they knew he would complain to administration. I stood by my evaluation and was able to show how the wording in past evaluations did not support the actual ratings.

The desire to avoid potential conflicts with employees can cause us to keep a problem employee. Sometimes we have employees who are really good at causing problems between other employees; I call them “pot-stirrers.” They just love to gossip and tell stories about other employees.

Sometimes they are physically intimidating and get what they desire by bullying other employees, but they are careful not to do so in front of other managers or supervisors. Employees do not want to file a report against them for fear of retaliation. We often pick up on the problem based on an unofficial conversation.

Coaching this employee into a better style of behavior is often impossible. Dealing with this type of performance issue is difficult but essential if you are to maintain good employee morale.

•

•

•

•

•

•

•

The truth is that in all these situations, we as managers accept less-than-ideal behavior or performance because it is easier to accept it than deal with the problem directly. In our failure to deal with these problems, we weaken our managerial performance and hurt our effectiveness as leaders.

Eric Frederick is director of laundry services for Carilion Laundry Service, Roanoke, Va., and a past president and manager of the year of the Association for Linen Management. You can reach him by e-mail at efrederick@carilion.com.

4 AUGUST 2014 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

COLUMNIST AT LARGE Eric L. Frederick, RLLD

ALN

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending July 15 (WE) = WEB EXCLUSIVE NEWS • Diamond Chemical Acquires Assets of Unichem • Cintas Partners with Cincinnati Non-Profit • ALM Annual Conference Highlights Industry Challenges, Opportunities • Georgia Linen Services Aims to Serve Hospitals, Local Community • Superior Linen and Apparel Services Earns TRSA...

Panel of Experts: Keeping Rising Laundry Service Costs Under Control

COLUMNISTS/FEATURES •

Eric Frederick: Cost-Reduction Ideas for Laundry/Linen Managers

Maximizing Linen Distribution Methods

Career Track: Companies Welcome New

Promote from Within

Hires,

Benchmarking Helps Laundry/Linen Managers Reach Goals... OUR SISTER

AmericanDrycleaner.com:

Handling Customer Claims

WEBSITES From

•

Lot of Little Things Contribute to Consistent Cleaning From AmericanCoinOp.com:

Do’s and Don’ts of Coin Laundry Preventative Maintenance

The Vitality of Vending

• • • • •

™

Boiler

Boiler Works. He explains that water added to an overheated vessel could cause the expansion of water as it flashes to steam and “create a blast or explosion which would potentially be fatal for anyone around.”

Orr reminds operators not to place chemicals or other materials on or near boilers. Lint, too, should be kept away from the area.

“Make sure there is an emergency switch outside of the boiler room,” he adds. “An emergency switch inside the boiler room isn’t all that useful in the case of a true emergency.”

drain are a real hazard,” Orr adds. “If they are not and one happens to open when a person is nearby, they could receive severe burns.”

And while manufacturers include as many safety switches as possible in their equipment—such as high- and low-gas-pressure switches, temperature sensors, etc.—there is always the potential for things to go wrong if those safety functions are dismissed.

“Operator error is typically the culprit on any boiler catastrophe,” says McLean.

MAINTENANCE TASKS

When it comes to regular boiler maintenance, sources we interviewed had suggestions for a few essential tasks that operators should make a point to perform.

“The very first, most important thing is always check the combustion heat exchanger by cleaning it and inspecting it,” Reasoner advises. “It’s a real critical point … to make sure everything is in line and everything is clean and not blocked.”

Leeming suggests a comprehensive water treatment program, including daily checks of the soft water and total dissolved solids (TDS), along with a monthly water analysis.

ent procedures for doing so.

And while there are many different kinds of boilers that operate in different ways, testing exhaust gases or using a combustion analyzer can quickly help determine whether maintenance is required, according to Orr. “The best start is to contact the boiler manufacturer for specific information,” he says.

INSPECTIONS

Regular inspections, of course, should be a key part of an operator’s boiler maintenance and safety schedule, the experts say.

Those interviewed agreed that an annual inspection is a good place to start, but that there are checks to be done in other time intervals, too.

and your business’ bottom line.

“If a boiler is undersized and can’t maintain pressure when the plant is running at full capacity, [that] will only hurt the efficiency of the workers as they have to wait for the proper pressure of steam, or [it] could even impact the quality of the product they are putting out,” says McLean.

A boiler with lower efficiency could end up consuming more utilities, too, driving up costs, Reasoner says. Orr suggests that operators with boilers that run on fuel oil as opposed to natural gas should make the switch as soon as possible “for financial reasons.”

cable. “If it’s a fire tube boiler, you can roll new tubes into it. And that could be 20-25% the cost of a new boiler,” he says.

NEW TECHNOLOGIES

For those interested in investing in a new boiler or in related technology, recent innovations are playing their part in improving boiler maintenance, safety and ease of operation.

And when a burner is out of tune, it can generate colorless, odorless carbon monoxide—a poisonous gas that can easily kill, says Michael Leeming, national sales manager, Parker Boiler Co. Another unsafe situation would involve operators bypassing safety controls when trying to figure out why a boiler is not working, he adds.

Birds, too, can be a problem, especially when they nest inside of exhaust stacks, plugging them up and causing a room to fill with exhaust, says Josh Reasoner, South regional sales manager at Hamilton Engineering. Relief valves can get plugged up as well, building up energy and potentially becoming dangerous.

“Relief or safety valves that are not piped down to the floor or a

“An operator may say, ‘Well, I’ve saved a lot of money not using any chemicals and it’s really maintenance-free,’ but what he doesn’t realize is his fuel bill is going up $50 a month,” says Leeming. “Proper water treatment will save you a lot of money.”

McLean agrees that keeping an eye on water chemistry is a major must-do. He says Fulton suggests to customers that they have their water tested prior to treatment and to take the results to their chemical suppliers, who can prescribe proper chemicals and dosages that take into consideration the boiler manufacturer’s guidelines.

Frequent blowdowns to remove mud and sediment from the bottom of the boiler are also important, Leeming says, though different manufacturers will have differ-

“Local codes dictate how often a boiler needs to be inspected,” says McLean. “As the manufacturer, we recommend a water-side inspection be done at least once a year.” This involves draining the boiler and removing all hand holes, and letting a local inspector verify the thickness of the vessel or the condition of the tubes. Checks for corrosion and the removal of any scale build-up should also be performed, and the inspector may ask to inspect the fire side of the boiler as well, according to McLean. Keep in mind while scheduling an inspection by a professional service technician that there is not a “one-size-fits-all” inspection checklist, Reasoner says, because much of the recommendations will be manufacturer-specific.

“If you start doing a few of [the maintenance tasks], they’re all kind of going to be the same, but you’ll notice one asks for a little bit different from what someone else asks for,” he says.

More inspections beyond the annual one might be warranted, according to Leeming, if poor conditions were an issue at any point.

BENEFITS OF MAINTENANCE

Keeping consistent watch on a boiler’s performance is not only smart, it also can have a positive impact on your daily operations

Xeros

times in wash cycles, according to Jonathan Benjamin, president of Xeros Inc. It is unusual to find more than one or two stray beads in the pockets of shirts at the end of a wash cycle, according to the company.

The new laundering system also reduces labor costs because goods do not have to be bagged before they are thrown in the washer, says Jack Culotta, vice president of Crest Advanced Dry Cleaners.

“This type of change in technology is revolutionary, not evolutionary,” he adds. “It just blows the traditional wash process right out

of the water.”

The scrubbing action and polarizing properties of the polymer beads enable the plant to replace the method used for traditional laundering, according to Culotta. The beads in the Xeros system attract soils, which can be easily discharged.

Most clean items go directly from the Xeros laundry system to finishing. Shirts and other pressed items need to have some moisture in them to be pressed effectively. Heavier items, such as comforters, are dried traditionally.

“Old laundries have been doing laundry the same old way forever,” says Culotta. “What about doing something to improve the environment? What about processing goods more efficiently and profitably for your operation?”

INCORPORATING NEW TECHNOLOGY

Crest wants to be on “the bleeding edge of technology” in the race to remain ahead of its competitors, says Slan. However, the company prefers to take “educated, calculated risks.”

Its first Xeros system has been operating for a year at another company plant and yielding superior quality results, according to Slan.

“We tested the Xeros system in our first store for a long time before we embraced it,” he explains.

Xeros partnered closely with Crest to generate monthly reports demonstrating savings and efficiencies.

“It’s been a marriage of companies,” Slan says. “From the installa-

“A maintained, efficient boiler meets the heat demand more reliably and more quickly than a boiler that is inefficient or needs constant maintenance,” he says, adding that the reliability of a boiler is its most important feature.

REPLACING A BOILER

Everyone wants to avoid the unthinkable: a sudden boiler failure that wreaks havoc on operations. So how will operators know when is the best time to replace an old boiler?

“Typically, customers do not realize when the boiler needs to be replaced until they have a leak in the vessel or an inspector tells them the vessel is wearing thin, [which] forces them to replace the boiler,” says McLean. “By then, most customers are at the mercy of whoever has boilers in stock.”

Talk to an expert you trust, such as a licensed mechanical contractor, especially if you don’t have a strong mechanical background, Orr advises.

And while many boilers will last as long as 40 or 50 years, Reasoner says, newer technologies often need more maintenance, and a service tech might be able to help you plan for upgrades or even replacement.

Leeming comments that sometimes it’s more economical to simply re-tube a boiler, where appli-

“What people seem to want more is to be able to look at the boiler status from anywhere— either their computer or their phone, and there seems to be more of a request for that technology at the bigger industrial plants,” says Leeming.

Economizers for capturing heat from exhaust gases, especially in the case of steam boilers, are helping to increase efficiency, says Reasoner. He adds that monitoring and controls on modern equipment can help create a more integrated system.

“Boiler innovation has mostly been concerned with improving high-efficiency boilers, or condensing technology,” says Orr. “The other source of innovation has been on the controls front, by having boilers use controls that learn to anticipate demand loads and operating accordingly.”

Among recent innovations, McLean lists burners with low-NOx emissions, timer and conductivity controls for blowdown, and lead lag controls for multiple boilers. Owning and operating a boiler is a huge responsibility. But since the boiler is a driving force behind operations, it’s in operators’ best interest to invest the necessary time and energy for regular maintenance tasks, safety checks and parts upgrades and replacement.

“A lot of times, laundries only have one boiler, and if that’s the case, it’s really critical that they take care of that boiler, because if that boiler’s down, the whole plant is down,” Leeming says. ALN

6 AUGUST 2014 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

“OPERATOR ERROR IS TYPICALLY THE CULPRIT ON ANY BOILER CATASTROPHE.”

—MIKE MCLEAN, FULTON BOILER

WORKS

Continued from Page 1

Continued

from Page 1

See XEROS on Page 19

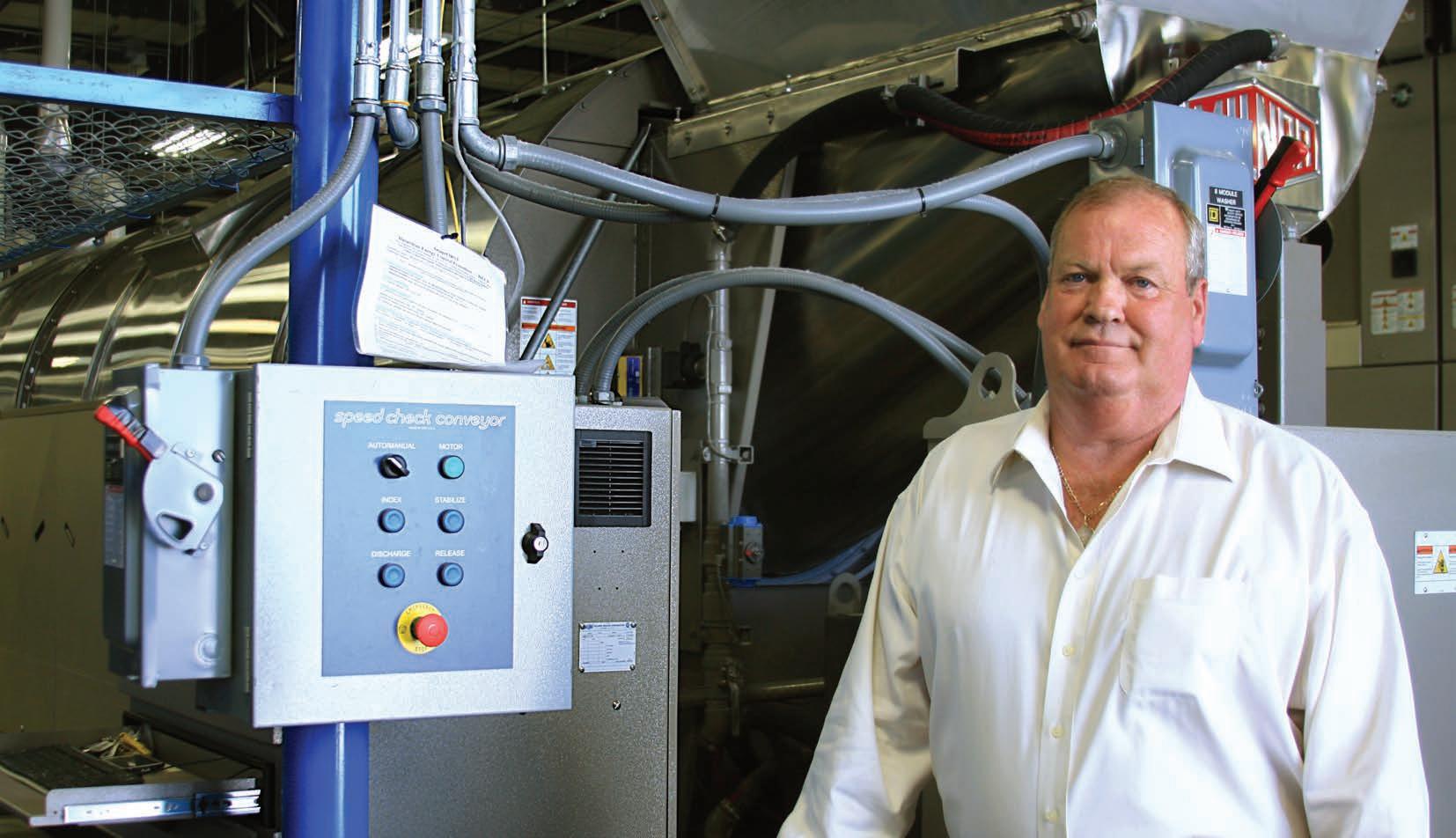

David Slan (right), president/CEO of Crest Advanced Dry Cleaners, stands in front of a Xeros laundry system installed at his company’s Germantown, Md., location. (Photo: Richard Merli)

Together, ADI and Milliken create best in class table linens for your Customers. Signature® Plus fabrics, with a soft and luxurious feel, have technology that releases stains and soils, for whites that stay white and colors that stay bright.

American Dawn & Milliken... Setting the standard in table linen excellence.

10 DISTRIBUTION CENTERS

ACROSS NORTH AMERICA

hospitality@americandawn.com 800 821 2221 americandawn.com

PANEL OF EXPERTS

Multi-tasking to get the job done

them upon your return to the office, you grab a paper napkin or even tear off a piece of the paper place mat and frantically start to write reminders, hoping and praying that you don’t lose the scrap notes later in a pile of papers on your desk!

pleted, I can check them off my electronic list. I have found that since I began using this app, I am more focused on the tasks at hand and getting more accomplished.

In today’s business environment, many companies are downsizing in an effort to become leaner. This has a direct correlation with the ever-growing “to-do” list we are faced with on a daily basis—a list that always seems to get longer rather than shorter.

Unfortunately, one of the reasons the infamous to-do list gets longer is because we as managers at times have more piled on our plates than we can handle on any given day, due to pop-up issues and unexpected tasks that are part of the daily life of a laundry/linen manager.

Are you that manager who, during lunch, all of a sudden remembers those few tasks you forgot to deal with earlier, or others that need to be completed by end of business that day? In a panic not to forget to deal with

Years ago, before the technology boom, we would print or write our tasks on a legal pad or in a document entitled our “to-do list,” or even on multiple paper scraps throughout the day like the example above.

Luckily for all of us, with the help of today’s technology, we are getting more organized and can reduce the stress level in our daily life as our to-do list can become smaller and condensed all in one place.

Thanks to smartphone and tablet technology, there are several free apps we can download on our devices that will make our to-do lists more manageable. One app I have found useful is called “Wunderlist.” With this app, I not only can list the tasks that need to be done, but I can also delegate or assign certain tasks to others who might be more qualified to handle them. Once these tasks are com-

For those who, like me, spend their days on the move, you might consider a recorder app. Many smartphones have this built in; a fancier version (not free, however) is “Smart Recorder.” These are voice-recorder apps that allow you to make voice memos to yourself of items on your to-do list.

If you want to make your life easier and your to-do lists easier to handle, forget about writing reminders on the back of business cards, or on paper napkins or place mats during your lunch hour.

Take advantage of today’s electronic technology and the apps that are offered, enjoy your lunch and get more accomplished during your day.

In many professions, a person’s job is done when he can see the final results of his labors. The carpenter’s building project has a final ending, and the finished results are obvious and apparent. The same goes with a painter, and so on.

In the commercial laundry or linen business, our jobs never stop. While order fill rates and serving excellent quality linens for a client can be accomplished, just like our so-called “to-do list,” the work itself is never-ending. This list represents goals rather than a finished product, as in the case of a carpenter or painter.

Managing a productive commercial laundry, OPL or linen operation takes good leadership skills. Communication, motivation and overall team-building make all the difference. This all starts with creating and promoting strong ethics within your operation.

Whether you manage a large commercial laundry, smaller OPL or linen operation, how you treat

A laundry/linen manager’s “to-do” list is seemingly never-ending. How can busy laundry/linen managers keep track of the tasks they have to accomplish in a day, and what tools can help them?

the people within your own organization seems to end up being the way you treat your customers.

Managing our to-do list is a constant. Keeping good records and using production or usage data is the key to a well-managed laundry or linen operation. No one man or woman can singlehandedly manage a commercial laundry or linen operation.

A good manager creates a team of responsible individuals who are each accountable for his or her specific operational function. With responsibility comes trust, and that trust must be earned.

Delegating various management duties to those we trust is a necessary aspect of managing our lengthy to-do list. Using laundry and linen management software, data collection devices and usage software helps us to manage our output, usage and customer satisfaction. Excellent communication and use of such industry management tools is essential.

While your laundry or linen management team may be responsible for supplying a separate page in your management portfolio, making sure that everyone on your team is on the same page is the key to managing that never-ending to-do list.

11. Nurse/key contact relationships and meetings

Let’s not forget to include the numerous interruptions to our day that can be difficult to quantify and that can extend what is already a very long workday.

There are numerous time management tools, programs and training opportunities available that are worth the expense and time to invest in. Finding what works for you is the key.

I developed a simple, and for me, effective tool—my daily calendar. I load it up with appointments and tasks and keep it with me throughout the day. It’s one document and one reference that guides me through a busy day.

Amanager’s duties are neverending, but there are ways to stay on track and keep things running smoothly.

One thing that I do is plan Without a plan, nothing can be accomplished in a unified way. Make a list of things to do for the next day before leaving the evening before, so you have an idea of what will transpire the following day.

Next, set the plan into motion, delegate what needs to be delegated and let your staff handle accordingly. If you surround yourself with successful teammates, then you will be successful. Have them check in periodically throughout the day and then you can plan for some other things on the fly and possibly take care of an additional task.

The last thing to do is follow up. How many times have we heard that one? It is highly important to follow up, whether it be with your associates, customers or vendors.

You can gather constructive feedback and plan again for following up on that as well.

To me, planning is one of the

8 AUGUST 2014 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

As I think about the daily activities I’ve faced during my experience as a manager of laundry/linen, I’ve come up with 11 tasks that need daily attention:

Managing supervisors

Ensuring supervisors are managing their staff

Linen purchasing budget control

Laundry equipment budget control

Linen

supply budget control

Linen

inventory compliance

Infection control compliance

Par level compliance

Linen reject/discard inspections

Linen utilization committee management

Hotel/Motel/ Resort Laundry James Brewster, RLLD

Long-Term Care Laundry Brian Barfoot St. Francis Health Center Topeka, Kan. See EXPERTS on Page 10

The Resort at Glade Springs Daniels, W.Va.

Uniforms/ Workwear Manufacturing

Healthcare Laundry Michael Kirsch, CLLM HCSC Laundry Allentown, Pa. (Image licensed by Ingram Publishing)

Scott Delin Fashion Seal Healthcare Seminole, Fla.

With over 50 years strong on the job, we know there are no small parts when it comes to delivering big dependability. In fact, we use all we’ve learned to build durable, longerlasting machines. Machines you can trust with the tough chore of keeping your operation up and running even as they handle the largest of loads. And no matter who’s operating the equipment, our user-friendly controls always keep it easy, shift after shift. Visit mclaundry.com for digital brochures, or for more information, visit our website at maytagcommerciallaundry.com or call 800-662-3587. *Visit maytagcommerciallaundry.com for warranty details.

We don’t overlook a single belt, bearing or bolt when it comes to reliably easier-to-do laundry.

® /™ ©2014 Maytag. All rights

reserved. *

most essential functions of any manager or supervisor.

You can use various tools to help keep track of your operation, such as sign-in and sign-out sheets for time clock purposes and drivers’ logs for their dropoff and pick-up points, as well as times they stop and go. Excel spreadsheets are one of my favorite tools—there is so much you can do with them, and they make information easier to read and understand.

For the production side, you can use forms that track pieces and input on a data sheet for tracking and trends. Your equipment manufacturer may have counters and scales that can track production and give you snapshots throughout the day to see how production is going.

Everyone has his or her own way of managing, but these are just a few that I use to make my life and duties easier.

things that fall through the cracks.

Of course, the to-do list is very important, and you probably need one for each of your different roles. But even that can become burdensome, since soon you will need a list of lists so you won’t miss checking one of them.

The best thing is having good people who support you in your work, provided you can delegate to them. Believe it or not, there are tasks that someone else should be doing, and spend more time

Equipment Manufacturing

and then a formal process of implementing an action plan to get the specific condition back on track.

As far as tools to help with these two items, I have found the Outlook e-mail program to be an indispensable tool in management of my tasks.

As a person who gets ribbed by colleagues and associates for still utilizing my trusty Day-Timer binder and pen in today’s world, this may be a “do as I say, not as I do” type of article, but let’s give it a whirl.

Maintain existing processes and programs. In my mind, this item is where many of us fall short. We put forth a great effort with our team to establish a viable program or process that benefits our operation, and then a year or two later, we are back where we started only because we failed to maintain the program.

From being able to schedule program/process meetings out as far in the future as I like, to giving myself daily reminders of tasks and obligations, Outlook has become something I use each and every day. My first statement acknowledged my use of a manual-type personal work calendar as well, and for me the two work well together.

Equipment/ Supply Distribution

Whether you are running a small business or running a laundry, the way you manage your day is critical to the overall success of the operation.

Focus is oftentimes hard to achieve. Managers will overbook their day and have trouble getting everything accomplished. The embarrassing thing is that you won’t remember what you forgot. All too often, it’s the small

on, who will probably do a better job than you. If that’s the case, you shouldn’t be trying to do it in the first place. You’re just messing it up. A manager should only do what others cannot do.

Managers are their own worst enemies. They will load themselves down with tasks that really aren’t important for them. Managers are not hired to fix equipment, drive trucks, run dryers, iron sheets, make reports, etc. Managers are hired to use their brains, and see that all those other things happen. That usually works better if the manager hires others to do that work.

Managers can easily become bogged down in the minutiae of trying to micro-manage. In reality, managers are the only ones who can fix their problems.

Whether in a safety, production, staff or management meeting, the objectives of such must be clear and the meetings held without fail. It is frustrating to have to take time to reestablish a program or process knowing that it would have been much easier and a greater benefit to one’s operation just to maintain it.

Measure everything and have a bar set for every measurement. Obviously, this data should be utilized in the maintenance of one’s programs and processes.

The “laundry list” is endless— fill rates, rewash percentages, pounds per operator hour, pieces per operator hour, equipment downtime, sick days, tardiness, employee injuries, etc.

The key thing is to have a process for reviewing all of one’s measurables—having the bar set to identify red-flag conditions

Years ago, the time and effort it took to collect the data for everything one wanted to measure in their operation was probably the biggest obstacle in actually doing so. Today, employee time management starts when team members swipe their fingerprints into work, and route management takes place proactively, as one can now monitor an entire fleet in real time.

The tools available for today’s managers to accomplish tasks and objectives are immensely powerful.

This creates the condition we all now face: The ability to do more each day comes with an expectation that more will be done.

While the tools of today can allow us to accomplish more, my initial points become even more important.

Nothing hinders our ability to move forward more than having to go back to the start of something again. So the old adages of “measure twice, cut once,” or “change the oil now instead of the engine later” apply more now than ever.

For starters, making sure you have the right personnel in place will make your day much better. Knowing that you have a team that you can count on and that supports the way you run your business is important.

Creating a work environment where everyone feels good will not only increase the morale in your company, it will also increase your employees’ productivity.

Managing the inventory and supplies that you need to conduct your business is also critical to the overall success of running the laundry room. You can do your part by making sure your team never runs out of supplies or products, and this will ensure the ship keeps moving in the right direction.

Set up contingency plans should the unexpected happen. Cover your bases, whether it be with personnel, inventory or other necessities that help run your operation. Basically, always have options B and C just in case you need them.

Finally, keep your business well tuned and expect the unexpected. Proper planning will help you and your laundry quickly overcome any obstacles that come your way.

0513aln_Kemco.indd 1 7/9/13 3:28 PM

10 AUGUST 2014 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

8

ALN

Experts Continued from Page

Justin Oriel

Garment Machinery Co. Needham, Mass.

Gary Ostrum G.A. Braun Syracuse, N.Y.

Commercial Laundry

Richard Warren

Linen King Conway, Ark.

BEST

GOOD

YOUR WORK, PROVIDED YOU CAN DELEGATE TO

“THE

THING IS HAVING

PEOPLE WHO SUPPORT YOU IN

THEM.”

—RICHARD WARREN

Davidson College’s long-standing laundry tradition to end

BY THERESABOEH L,E DITOR

DAVIDSON, N.C. — When Davidson College students wrap up their studies in a little less than a year, they will also close the book on a unique chapter in the school’s history: “free” full-service laundry provided to all the students.

For more than 90 years, Davidson College students have had the option to have their laundry cleaned and folded by workers at the institution’s own laundry facility. The school did not charge students up-front for the drop-off service; it was included in their tuition and fees. But the college recently announced that after May 2015, the facility will close, ending the full-service laundry tradition that many students and alums held dear.

“I’m sure for any student who regularly used our service, there’s a sense of loss about that,” says Richard Terry, the college’s director of auxiliary services.

But closing the laundry will allow the college to save a significant amount of money—as much as $400,000 a year, according to Terry. The college says the closing will help the institution in “aligning its resources to meet educational priorities within the changing landscape of higher education.”

“Raising the tuition an additional amount to continue to provide this service just didn’t seem like the responsible thing to do,” says Terry. In absence of the fullservice laundry, students will have the option of using self-service machines in facilities across the campus which, like the full-service laundry, will have no up-front costs for students.

“The plan going forward is we will continue to not charge for the use of those self-service machines,”

Terry says, adding that many students prefer to use the selfservice machines anyway, even with the availability of the fullservice laundry.

THE FACILITY

The Lula Bell Houston laundry, named for an employee who worked there nearly 60 years, opened in 1920. The 6,800-squarefoot facility employs 14 full-time and part-time workers today; the college says it is trying to help those employees transition to other roles as the laundry service is discontinued.

About 430,000 pounds of laundry are processed there in a typical year, according to Terry.

Equipment in the facility includes three 125-pound washers and three 85-pound washers by UniMac; 10 stacked dryers and a 100-pound single-pocket dryer by Huebsch; an ironer by Continental Girbau; a Unipress double-buck shirt press, and an Ajax shirt press that has been used at the facility for

47 years. Most garments are handfolded, and some items are pressed and returned on hangers.

Terry says the college is still exploring options for how to use the facility once the laundry service has been discontinued, adding that school officials will be soliciting input from students. He says it is likely that the building will be used as a large, central Laundromat. No matter what’s in store in the future, it will still bear the name of Lula

Bell Houston, who retired from the laundry in 2004.

Houston, who worked in several capacities during her many years at the laundry, says she “wasn’t too surprised” to learn of the laundry’s impending closure, but that she’ll miss all the friends she made over the years.

“I got so close with the students,” she says, “I met so many of them—they would come to me for advice.” ALN

Workers at the Lula Bell Houston laundry process garments dropped off by Davidson College students. When the full-service laundry is discontinued next year, a tradition more than 90 years in the making will come to an end. (Photo: Davidson College)

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | AUG UST 2014 11

ALN_Jr Page.indd 1 5/30/14 10:57 AM

LAVATEC LAUNDRY TECHNOLOGY

The TT Ecodry series from Lavatec Laundry Technology offers best-in-transfer batch technology, safe ergonomics and sustainable processes for better operational performance, according to the company.

Developed for commercial and industrial laundries, the 140- to 450-pound capacity dryers provide state-of-the-art features, variable heating systems and intuitive program operation for increased production. Individual configured versions and options offer nearly 100 different adjustable programs to dry any textile type gently and efficiently, the company says.

www.lltusa.com 203-632-8777

CAPACITY PRODUCT SHOWCASE

LARGE-CAPACITY DRYERS

pound, single-pocket tumble dryer that’s suited to OPLs using 80- to 100-pound washerextractors.

The ST120 is available with easy-to-use Quantum® controls, which can help simplify employee training due to their use in both Speed Queen washer-extractors and tumble dryers.

The controls offer 30 programmable cycles, three cycle types and output for an external end-ofcycle signal.

With Quantum controls, Overdry Prevention Technology (OPT) is also available.

OPT offers a more precise drying performance with rotary transfer switch and sensors, which allows the machine to shut off when desired dryness levels have been reached. With OPT, over-drying is eliminated, linens likely will last longer, and businesses may experience savings on linen-replacement costs and energy expenses, according to Speed Queen.

WASCOMAT

Wascomat has a history of reliability and solid performance, and its 100-pound and 135-pound dryers deliver trusted results, according to the company.

Features and benefits include optimal combination of gas consumption (Btu/hr) and airflow (cubic feet per minute) for fast drying and low energy usage; large doors for easy loading and unloading; convenient access to parts; a large lint compartment for easy maintenance; and a reversing drum that minimizes tangling and wrinkling, improves dryer efficiency and makes flatwork finishing easier.

effectively. Benefits include longer linen life and significant labor and energy savings, the company says.

Wascomat equipment is distributed in North America by Laundrylux.

www.laundrylux.com 800-645-2205

CONTINENTAL GIRBAU

Continental Girbau Inc.’s (Continental)

Pro-Series II largecapacity dryers —available in 125- and 175pound capacities—are built to help with efficiency, production and safety concerns.

level from zero to 40%. To ensure accurate moisture readings, the LLE system provides a large loadto-surface contact area. When the dryer hits its preset target level of dryness, it shuts off automatically, helping to save energy, time and labor costs, the company says.

Pro-Series II dryers also feature an optional integrated sprinkler system, a sensing and extinguishing device designed to squelch dryer fires.

Speed Queen® offers on-premises laundries a line of tumble dryers that includes the ST120, a 120-

The machine features a highperformance heater box that helps to increase energy efficiency, reducing drying times and providing a more comfortable environment for operators. A large, easy-to-clean lint compartment simplifies cleanup.

www.speedqueen.com/info 800-590-8872

Residual Moisture Control (RMC) prevents damage to garments caused by over-drying and reduces lint and wrinkles by automatically stopping the dryer when the exact pre-set moisture level is reached. If the load is to be processed by an ironer, RMC will shut the dryer off while there is still sufficient moisture for the ironer to work

Designed for greater flexibility and easy operation, the company’s microprocessor control provides enhanced load management capabilities and cycle programmability, and it is equipped with Continental’s Linen Life Extension (LLE) system. The LLE system provides a moisture-sensing feature engineered to help prevent over-drying, to extend linen life and to increase energy efficiency.

Featuring 12 programmable levels, LLE can target any dryness

Additionally, the machines offer a modular electrical system for added reliability and easy servicing; balanced airflow and heat input to help reduce energy costs; and a multiple-burner heat system to help the machine reach desired temperatures.

www.continentalgirbau.com 800-256-1073

RAMCO LAUNDRY MACHINERY

RAMCO’s DS (steam), DG (gas) and DE (electric) industrial dryers are designed for large- capacity commercial loads. Its best-selling dryer is the 230-pound-capacity model, according to the company, although the line offers load capacities ranging from 60 to 350 pounds.

The user-friendly models fea-

• Consulting, Design, Plant Installation • Full Construction Services • Training & Maintenance Support • Operations Assistance

have now partnered with HBD

laundry service

in

America offering a wide range of services

support.

WE DO IT

ALS soup2nutsqthorz .pdf_Layout 1 1/8/14 8:47 AM Page 1 ALN_Tab_1-4_H.indd 1 2/4/14 3:28 PM

We

Construction. We are the one and only

company

North

including building construction, plant operations and

Building Smarter Laundries for Smarter Operators. www.eomech.com Or call 978.373.1883

ALL.

SPEED QUEEN

12 AUGUST 2014 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

[Continental Girbau]

[Lavatec Laundry Technology]

[Speed Queen]

[Wascomat]

COMPILED BY JEAN TELLER, CONTRIBUTING EDITOR

ture microprocessor controls and are fully automatic. The machines offer convenient automatic control and timer drying, as well as an automaticreversal drum.

The large door glass allows the user to check on drying conditions, and the heavy-duty drive and door system keep the noise level down, according to the company. The 230- and 350-pound-capacity models also offer forward tilt and front rollers. The dimensions of the 230-pound unit are 60-by-69-by-95 inches, and safety switches throughout the dryer provide protection for the operator.

www.ramcolaundry.com 800-878-5578

ELLIS CORP.

Ellis Corp. recently added a third WhisperDryer model , the WD7664, to its product line. The dryer has a capacity range of 200 to 500 pounds with a 168-cubic-foot basket. It offers a variable frequency drive for both

the blower and the friction roller basket speed, which the company says allows drying formulas to be tailored to specific textiles needs, optimizing a dryer’s efficiency in energy and productivity.

The WhisperDryer oversized-blower design operates at 70 decibels. The burner modulates based on air flow and moisture content of the textiles to help optimize energy usage. The hinged swing-out blower allows for a simple and safe inspection of the blower wheel, motor and the lower dryer housing.

The dryer is available with single or pass-through doors with one-way or two-way tilting. The large 55-inch door opening is ideal for sling, shuttle or hand loading with opti-flow doors for airflow, Ellis says. Removable basket panels with optional Teflon coating are standard, with an optional stainless-steel, spacesaving lint filter. The control has the ability for remote monitoring for service assistance.

www.elliscorp.com 800-453-9222

IPSO

On-premises laundry managers can process more linen and reduce utility costs with the IT170 by IPSO, a 170-pound tumble dryer equipped with reversing technology and optional Over-dry Prevention Technology (OPT), according to the company.

A cylinder design allows for a drying process that helps keep utility usage low, and is built to help extend linen life. The IT170 is equipped with a large, self-cleaning lint screen and self-adjusting belts. The OPTimum control feature is available on the 170-pound tum-

bler and offers 30 programmable drying cycles with easy customization and three types of drying options—time dry, auto dry and moisture dry. Reverse technology, which allows the machine to stop, pause and then switch direction, is standard on the IT170. This helps reduce the tangling of large articles and offers a consistent and even dry of linens, IPSO says.

OPT is also available, helping to eliminate over-drying, increase productivity and reduce utility consumption. Using the technology, linens may be used 31% longer, further lowering operating costs, the company says.

www.ipso.com 800-USA-IPSO

GIRBAU INDUSTRIAL

Girbau Industrial’s ST-100 and ST-1300 dryers unbind, condition and dry up to 265 and 140 pounds of laundered goods, respectively, while using less energy, the company says. Both models are engineered with SpirotiltGirbau technology, which helps to optimize drying and simplifies unloading, and both models are available in steam, thermal fluid and natural gas.

Used in concert with the Girbau Industrial TBS-50 batch tunnel washer, or as a stand-alone tumbler dryer, the ST-100’s heating

ALN_Jr_half.indd 1 6/18/14 10:46 AM ALN_Jr_half.indd 1 7/8/14 11:36 AM www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | AUG UST 2014 13

[Ellis Corp.]

[RAMCO Laundry Machinery]

[IPSO]

➢

[Girbau Industrial]

system helps pass heated air directly through the load, removing moisture for a quicker dry.

Girbau Industrial says the standalone model can be paired with front-load washerextractors and an optional vacuumloading system for improved ergonomics, flexibility and production.

The ST-1300—a stand-alone unit— dries up to 140 pounds of damp goods in less than 15 minutes, according to the company. The ST-1300 is an efficient and userfriendly drying tumbler with a vacuum-loading system that allows operators to load items of all sizes into the dryer with minimal effort. Powerful suction pulls items inward, with no risk or hazard to the operator.

Both dryer models are engineered with Spirotilt, a system providing automated unloading without dryer tilting or air blasts, keeping more heat inside the cylinder for the next load.

Boasting highly flexible, color touch-screen controls, the ST-100 and ST-1300 offer multiple programs and easy-to-use graphic icons, the company says.

www.girbauindustrial.com 800-256-1073

HUEBSCH

Huebsch® offers on-premises laundry managers the opportunity to increase productivity and efficiency with the HT120, a 120pound tumble dryer with reversing technology and Galaxy™ controls, the company says.

The Galaxy-equipped HT120 features 30 programmable cycles, three cycle types and reversing technology for greater drying consistency. Reversing technology allows the machine to stop, pause, then switch direction, which helps reduce balling or roping of large articles, such as bedding and tablecloths. This technology helps

prolong the life of linens and produces evenly dried linens, according to the company.

Operators can further decrease costs while extending linen life by adding the optional Overdry Prevention Technology (OPT).

Baffles provide pinpoint moisture readings throughout the entire load, and once the tumble dryer senses the pre-set level of dryness, it automatically shuts off. Huebsch says that with OPT, linens experience 31% less fiber loss, which means laundry managers will likely spend less on linen replacement.

The HT120 offers improved efficiency with a high-performance heater box. Sealed cylinder rims and concentrated airflow pattern ensures no heat is wasted, and the self-cleaning lint screen makes for fast lint removal.

Huebsch offers a full range of commercial tumble dryers, including machines with extralarge capacities of 170 and 200 pounds.

www.huebsch.com/info 800-553-5120

MAYTAG COMMERCIAL LAUNDRY

The Maytag Commercial Laundry® large-capacity drying

tumblers offer on-premises operators the opportunity to dry more at once, saving time and energy costs, the company says. The reverse-tumble feature reduces dry times on large items, such as sheets, blankets and comforters. The dryer also comes with microprocessor controls, which allow operators to pre-program drying time, temperature and cool-down time on easy-to-use controls with a countdown display.

The 170-pound OPL dryer, available in white, is ergonomically designed for easy access to help with self-service and maintenance, and the waist-high door opening allows for easy loading and unloading, the company says.

www.maytagcommercial laundry.com | 800-662-3587

KANNEGIESSER USA

The PowerDry.II is the latest dryer from Kannegiesser offered for universal drying applications to process a variety of items, including towels, laminates, blended fabrics, micro fibers and other special articles. The product line is available in different loading capacities from 135 pounds up to 485 pounds.

The dryer technology employs a linear atmospheric gas burner, which evenly distributes the heated airflow across the entire width of the cylinder, ensuring even and consistent heat penetration, the company says. The drum incorporates removable

segments, which help to simplify cleaning and help to offer a consistent performance. The internal hot-air recirculation system offers a primary heating source and high drying capacity.

The PowerDry.II machines can be sited into tight spaces with an optional side-by-side mirrored control application. Standard items include a frequency controlled inverter drive, oversized loading and unloading doors, static lint filter screens and a redesigned drive system that thermally insulates the components against the hot environment of the drying chamber.

Optional features for the dryers include a touch-screen control panel, which offers all operational information together with a fault-finding display to improve machine availability. The optional InfraTouch Automatic program utilizes infrared technology and measures the actual surface temperature of the textiles to be processed. With the ECO2Power option, compilations of various parameters are processed in the

machine’s programmable logic controller and serve as a regulation value for the gas burner. www.kannegiesser.com 972-602-8766

CONSOLIDATED LAUNDRY MACHINERY

Consolidated Laundry Machinery (CLM) offers a wide array of single-door and two-door passthrough tumble dryers that are steam-heated and gas-fired with low NOx. CLM’s industrial designs are available in 250-, 350-, 450-, 600-, 800- and 1,200pound capacities. All sizes are available in the high-efficiency TumbleGreen™ version.

All models include the MicroCommand III color, touchscreen, programmable logic controller with diagnostics, which helps control fuel usage and other functions. The PLC is compatible with flow process systems and, as an option, can be upgraded with local area network and Bluetooth communications.

MicroCommand III comes equipped with CLM’s exclusive AutoDry feature that terminates the heat cycle when the appropriate condition and moisture levels have been reached. This feature, which uses the amount of energy required to dry a load to calculate the heat cycle finish point, is an advantage for laundries that require more energy savings and reduced cycle

ALN_Tab_1-4_H.indd 1 7/16/13 3:58 PM 14 AUGUST 2014 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

[Huebsch]

[Maytag Commercial Laundry]

[Kannegiesser USA]

[Consolidated Laundry Machinery]

times, according to CLM.

Industrial-grade materials are incorporated throughout CLM’s line, providing years of operation in any laundry environment.

www.clmco.com 323-232-2417

B&C TECHNOLOGIES

B&C Technologies’ dryer line stands up to the rigors of the most challenging laundry, the company says. All dryers feature a stainless steel basket, and they are easy to use, easy to maintain, and are available in gas or steam heat.

The DE Series (120- and 170pound capacities) has as standard

a reversing cylinder and steam damper system, and is available with either a microprocessor or dual timer control. The DP Series (200- and 250-pound capacities) features standard reversing cylinder, steam damper system and microprocessor control, and a tilt option is available.

The industrial DI Series (225-, 325- and 475-pound capacities) has a standard microprocessor control, either vertical or horizontal opening doors, optional one- or two-way tilting and can be integrated into a tunnel system and customized to suit any installation. The humidity tracking system measures the actual humidity to prevent the over-drying of goods, which helps save time, money and wear on the goods, the company says.

www.bandctech.com 850-249-2222

ELECTROLUX

Electrolux provides laundry solutions designed to save operators time and money while increasing productivity, the company says.

Products feature “green” engineering, easy operation and years of low maintenance.

Electrolux Professional 100and 135-pound capacity dryers are equipped with features like

auto-stop, which prevents overdrying and wrinkling by automatically calculating the correct time to turn on and off the burner, resulting in longer linen life and energy savings, the company says. A reversing drum minimizes tangling and wrinkling and improves dryer efficiency. Sheets and towels dry faster, saving time and energy.

With Residual Moisture Control, damage to linens caused by over-drying is prevented, and it also reduces lint and wrinkles by automatically stopping the dryer when the exact pre-set moisture level is reached. Operators can experience longer linen life and significant labor and energy

savings, Electrolux says.

The company’s PLUS program allows customers to receive Electrolux Professional washers and dryers with no capital expense—they only pay for what they use.

Electrolux equipment is distributed in North America by Laundrylux. www.laundrylux.com 800-381-7222

PELLERIN MILNOR

Pellerin Milnor now offers the M202, a large, 200-pound-capacity dryer. It features radial airflow, a vertical steel door for easy loading/unloading, a reversing basket

and a stainless steel basket with removable panels. The M202’s optional features include a stainless steel front and cabinet and a fire suppression system. www.milnor.com 504-712-7656

[American Dryer Corp.]

AMERICAN DRYER CORP.

American Dryer Corp. continues its line with the introduction of the “I” Series dryers. The “Intelligent” dryers incorporate a transaxial airflow to help maximize efficiency and performance.

The machines feature a preburner chamber that intro- ➢

For laundry done on time and on budget, there’s no better choice than IPSO ® Forty years of European ingenuity, rugged industrial construction, flexible installation, superior G-Force extraction, and our intuitive Cygnus controls all add up to help you achieve your ultimate goal — maximum throughput at a minimized cost. Learn more about how IPSO helps you get the job done at IPSO.com/industrial.

Work with your IPSO finance expert to learn about customized financial solutions for your business.

IPSO USA 1.800.USA.IPSO

BY

. Optimal Efficiency. Maximized Throughput.

INDUSTRIAL

DESIGN

ALN_Tab_half.indd 1 2/3/14 11:00 AM www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | AUG UST 2014 15

INDUSTRIAL BY

DESIGN

[B&C Technologies]

[Electrolux]

[Pellerin Milnor]

duces warm, dry air to the burner. A variable speed drive (VSD) is calibrated with the Intuitive Micro Control and a patented auto-dry system. As items dry, they become lighter, and the VSD adjusts the speed of the drum to prevent centrifuging (when lighter items adhere to the drum away from the path of warm air). By keeping items in line with the warm airflow, dry times are reduced with maximum efficiency, according to the company.

The VSD offers less wear and tear on motors and rollers, and it allows for the elimination of an idler arm. Fewer moving parts equals less maintenance. The AD-120i, as well as all I Series dryers, features a heavy-duty trunnion and bearing assembly supported in front by hightemperature rubber rollers.

The I Series also features an Automatic Airflow Compensator (AAFC), which helps offset high static pressure caused by undersized exhaust work. AAFC senses, calculates and maintains proper airflow to maximize efficiency and performance, ADC says.

Reversing baskets are standard with all I Series dryers. The reversing tumbler action prevents the uneven drying due to balling or roping of larger items that can slow the drying process and add to utility use.

ADC’s patented Sensor Activated Fire Extinguishing (SAFE) system is standard. When connected to water, the SAFE system activates at

an abnormal rise in temperature to help avoid costly damage and expense due to spontaneous combustion. It is also the only such system to shut itself off to minimize cleanup, ADC says, and, in the event a fire re-ignites, it will reactivate. Stainless steel fronts and baskets are also standard on all I Series dryers.

www.adclaundry.com 508-678-9000

UNIMAC

UniMac® helps on-premises laundry managers improve throughput and experience utility and labor cost savings with the UT200, a 200-pound tumble dryer with the UniLinc™ control system, the company says.

Available in gas or steam, the UT200 is designed for highvolume operations such as cruise ships, hospitals and hotels. The extra-large capacity allows workers to dry more in less time for maximum throughput and utility savings, according to UniMac.

With the UniLinc control system, operators can monitor machine data and performance indicators, allowing managers to pinpoint opportunities for increased efficiency and lower operating costs associated with labor, linen replacement, utilities and maintenance.

For consistent and even drying, reversing technology comes standard. During the drying process, the machine stops, pauses and then switches direction

to reduce the balling or roping of large articles such as bedding.

An optional feature on the UT200 is OPTidry™ Over-dry Prevention Technology that UniMac says precisely monitors the level of linen dryness. When a pre-set level of dryness is achieved, the tumble dryer shuts off automatically, eliminating excess energy use and reducing processing time. Managers will spend less money on linen replacement, as linens processed with OPTidry experience 31% less fiber loss than those dried without the technology, according to the company.

www.unimac.com/info 800-587-5458

G.A. BRAUN

Braun’s 300 PBS side-by-side dryers feature a non-tilt design to help improve load and unload times. In a side-by-side configuration, no spacing is required between the dryers, providing a small footprint. All dryers can be installed together in multiples to help with space utilization, minimize the amount of spare parts needed and enhance productivity and efficiency within a tunnel system, the company says.

The side-by-side chute load dryer solution allows greater flexibility when it comes to the placement of dryers within a plant and is helpful for sites with multiple conveyor systems. The static chute on the front of the machine is designed for seamless integration with a rail system, and it improves turn times and eliminates the moving parts and maintenance costs inherent with the use of cross conveyors for dryer loading.

With client reports of a 40% increase in production, the company reports a 12% increase in energy efficiency when compared

to previous machines. Both chute load and non-chute load machines help to make the pull process more efficient and optimize dryer turns.

www.gabraun.com/ sidebysidedryers | 800-432-7286

JENSEN USA

Jensen offers a variety of largecapacity dryers ranging from its DT series batch system dryers in 130- to 520-pound capacities, to the DTX series stand-alone/ system dryers in 450- and 800pound capacities.

A popular machine is the DT140 batch system dryer with a capacity up to 300 pounds, and Jensen now manufactures this model in Panama City, Fla., along with the DTX Series.

The DT140 features directdrive technology, frequency-controlled basket speed, a modulating gas valve on the burner system, mirror image design, a high basket volume and a well-insulated and sealed basket housing. The combination results in optimal heat distribution in the basket and airflow through the linen, while maintaining low radiant heat and noise levels, the company says.

Possible loading methods are by shuttle conveyor, sling/bag

through stationary or shuttle conveyor, or by a Jensen VacuTrans system, which allows for efficient loading via a dryer’s loading or unloading door.

The dryer is maintenancefriendly with hatches in the fan housing for quick inspections and easy cleaning, Jensen says. To access the drum, the entire loading wall can be swung aside after loosening a few screws. The built-in lint filtration system is easily accessible for cleaning and maintenance.

www.jensen-group.com 850-271-5959 ALN

Ludell Manufacturing (800) 558-0800 sales@ludellmfg.com www.ludellmanufacturing.com Are you tired of... Paying High Fuel Bills? Replacing Boiler Heat Exchanger Coils? Waiting for Hot Water? Acid Cleaning & Rodding Out Boiler Tubes? Paying for Annual Boiler Inspections? High Maintenance Costs? Water Heating Equipment Corrosion? Replace your old, outdated, inefficient water heating system with a safe and efficient Ludell Direct Contact Water Heater! LUDELL WATER HEATING SYSTEMS (Nor woman either.) American Laundry News can now be viewed on tablets and other mobile devices – great ways to stay on top of the latest industry news and updates. www.americanlaundrynews.com Man does not live by print alone. The Newspaper of Record for Laundry & Linen Management “Print Alone“ Jr. 1/3 Page ad for American Laundry News Advertiser: American Trade Magazines Contact: Donald Feinstein 312-361-1682 Ad Trim size: 4.75” x 4.75” Art contact: Shelley Timm-Thompson, 708-771-9948 Insertion Date: Ongoing 16 AUGUST 2014 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

[UniMac]

[G.A. Braun]

[Jensen USA]

In Memoriam: Michael D. Levine, Kleerwite Chemical