Laundry truck maker Fibertech expanding facilities

ELBERFIELD, Ind. —

Laundry/linen truck manufacturer Fibertech Inc. is adding 45,000 square feet to its facility here, the company reports.

The addition will give the company 125,000 square feet of space, which Fibertech says will help it meet its customers’ persistent growth and new market demand.

“We are always investing in our customers and our employees,” says Bill Scott, owner of Fibertech. “This expansion will add jobs and meet our goals of continuous improvement to our loyal customer base.”

According to the company, the new facilities will be equipped with state-of-the-art technology, equipment and warehousing. The investment offers customers enhanced ability with custom molding projects and offers shortened lead times in production, Fibertech says.

Fibertech serves the commercial laundry and linen industries with a line of laundry/linen trucks, including bulk storage trucks, commercial laundry carts, and internal usage options with utility carts.

The company also supports the hospitality and healthcare industries with laundry trucks, industrial utility carts, storage lockers and recycling carts. ALN

Next-generation launderers want to make leadership impact

BY MATT POE, EDITOR

BY MATT POE, EDITOR

CHICAGO — Brad Houchin has been in the laundry and linen industry for just three years, with the Chickasaw Laundry Service Uniform Distribution Center in Oklahoma.

However, in that brief time, he has enrolled in and completed his CLLM and RLLD certifications through the Association for Linen Management (ALM).

Also in that time, Houchin oversaw the expansion of the facility from a commercial laundry to an industrial laundry. The plan had been put into place before he arrived, and shortly after, the company purchased a tunnel washer, an additional ironer/finishing line and several other key pieces of equipment.

“We began operations in February of this year,” Houchin says. “As I like to say about opening a new industrial laundry, ‘It is one of the greatest learning experiences of my life that I hope to

never repeat.’”

Before becoming manager of the facility, Houchin was a customer of the facility. He managed the uniform department at a casino.

“When the opportunity presented itself, I jumped at the chance to be a part of a facility that had a proven track record of quality and service,” he says.

Joshua Briggs and Brandon Marsh have similar stories.

Briggs is director of linen services, mailroom and courier services at Charleston (W.Va.) Area Medical Center. He worked in safety for about six years, followed by time with a homebuilder, an aluminum manufacturer and Disney. He then transitioned into employee benefits for about a year and a half, and from there became an HR generalist. Briggs worked in that field a little more than a year before getting into linen services.

“I was told about the position

Is your laundry technology up-to-date?

BY MATT POE, EDITOR

HOUSTON — Dave Beavers has been in the laundry business for more than 40 years. He has worked in various types of laundry facilities, including industrial uniforms, hospitality, and healthcare. And he is always on the lookout for what’s new in the industry.

Today, he is employed by Crothall Healthcare as the chief engineer at Texas Medical Center Hospital Laundry, and if there’s a change in software or hardware, he wants to see it.

“What I’m looking for is

new or improved technology,” Beavers says. “Our industry is constantly changing, technology keeps emerging. I look for innovation and anything that improves or enhances safety. I look at the quality of the machinery, how well it’s built.”

At Clean 2015 in Atlanta, Beavers scouted out some of the most recent advances in technology and equipment. During the Textile Rental Services Association (TRSA) webinar Emerging Technology/Equipment, he shared some of the things he saw that he believes can help laundry managers and owners

improve operations within the facility.

IMPROVED FUNCTION, SAFETY

Beavers noted many innovations and improvements in equipment, from washers to finishing equipment. One was Braun’s Advantage Tilting Side Loader. The machine is a 900pound side loader with fourpocket configuration. He says it’s built pretty much like the company’s other washer-extractors, but with some advances.

“What’s nice about this machine is some of the ergonom-

ics, like the automated step so that operators no longer have to bend down to pull out or push in the step,” says Beavers.

He also noted the inner latch system and the closed detection system. In addition, the side loader has standard safety gating going around the machine, and compliance with standard arc flash panel control separating the high-voltage from the lowvoltage controls.

Another washer innovation Beavers noticed was Jensen’s QuickSoak feature on the compa-

JULY 2015 Late News

www.americanlaundrynews.com Volume 41, Number 7 INSIDE [12] [14] See

The Newspaper of Record for Laundry & Linen Management

NEXT GEN on Page 11

[4] See TECH on Page 6

Columnist at Large Eric Frederick examines sorting soil for operational efficiency.

SMALL-CAPACITY DRYERS PRODUCT

(Image licensed by Ingram Publishing)

SHOWCASE Panel of Experts Ergonomics aid in reducing employee strain and improving safety.

Survey: Most attendees satisfied

2015 in Atlanta

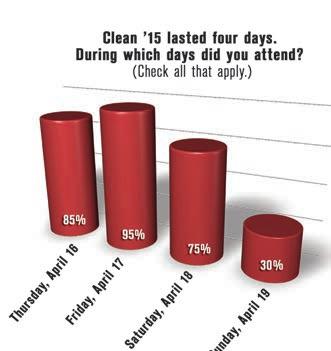

CHICAGO — It had been 28 years since the Clean Show had taken place in Atlanta, and before Clean 2015, some in the industry were unsure of how it would go.

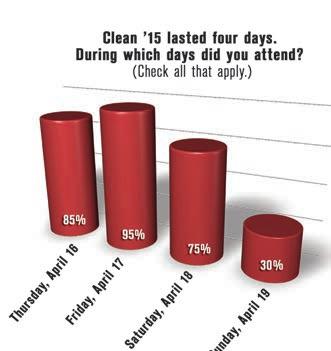

According to the results of June’s American Laundry News Your Views survey, respondents who attended the April show were quite pleased with the event.

“Atlanta was a good location and should become part of the regular show rotation, which also includes New Orleans and Las Vegas,” one respondent writes.

The majority of respondents (61.9%) were “fully satisfied” with their experience at Clean 2015. The remaining 38.1% were “somewhat satisfied.”

In fact, 90.9% of respondents who attended the show say they are more likely to do business with certain manufacturers, distributors and suppliers because of the information they received at Clean.

While at the show, survey respondents were on the lookout for certain types of exhibits. The most cited in the survey were:

• Textile products

• Chemicals

• Washers

• Finishing equipment

• Carts

Some respondents had specific products or services they were looking for. One respondent made a point to look for products new to the industry. Others looked for equipment. Systems—including productivity systems and water- and energy-management systems—were also a high priority for some who attended the show.

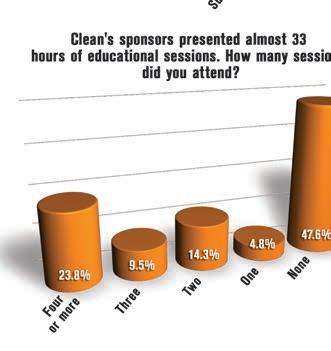

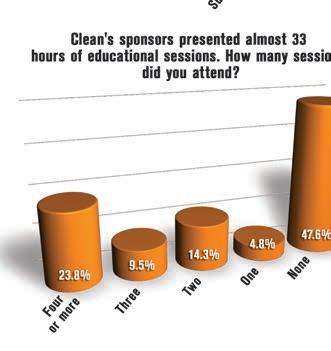

Besides the exhibits on the show floor, some 33 hours of educational sessions took place at Clean 2015. Nearly half of respondents who attended (47.6%) didn’t attend an educational session.

Roughly 24% made it to four or more educational sessions, and 14.3% went to two sessions.

One respondent writes, “I missed some educational sessions that I would have liked to attend, but they were scheduled at the same time. So, I had to make a choice.”

Among survey respondents who weren’t able to attend Clean 2015, they, too, had to make a choice. The most common obstacle—cited by equal

shares of 42.4%—was their “budget didn’t allow it” or they “couldn’t work it into the schedule.”

Other reasons for not attending were other staff members going instead (15.2%) and that “past show experience was sufficient” (3%).

One respondent writes, “I will be attending the IAHTM conference in Florida in October and had to make a choice.”

According to several respondents, only one thing marred Clean’s return to Atlanta: housing. There were reports of room reservations being lost.

“This needs to be fixed before the next one,” writes one respondent. “This was the only black mark on an otherwise excellent show.”

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online each month. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and identify industry trends. ALN

ARCO/Murray constructing new laundry for Crown Linen

FORT MYERS, Fla. — ARCO/ Murray, a national design and construction firm, is building a 36,800-square-foot, build-to-suit laundry facility here for Crown Linen, the company reports.

ARCO/Murray says it is providing a complete design/build solution, including architectural and engineering design, permitting,

and construction.

Crown Linen, which specializes in servicing hotels and resorts, is tentatively scheduled to begin operations in the new facility in the third quarter of this year.

ARCO/Murray says the facility will be able to process 25 million pounds of laundry annually and employ up to 135 people.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 231-740-2842

E-Mail: mpoe@ ATMags.com

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

Jim Buik • Richard Griffin

Greg Gurtler • Phil Hart

Janice Larson • Tom Marks

Gerard O’Neill

Richard Warren

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00.

Single copies: U.S. $7.00; Foreign $14.00. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 41, number 7. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2015. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within.

Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

2 JULY 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Association for Linen Management

INSIDE: July 2015 • Vol. 41 | No. 7 [4] Chapter 5: Soil Sorting for Greater Efficiency Columnist at Large Eric Frederick continues his series with a look at sorting soil for optimum operational efficiency [8] Tools of the Trade [10] On-Premises Laundry Technology Evolution In an OPL 101 Q&A column, three perspectives are offered on advancements making their way into laundry rooms [12] Panel of Experts: Is Your Plant Ergonomic? “What are some ways I can make my facility more ergonomic and reduce strain on my staff?” [14] Product Showcase: Small-Capacity Dryers Manufacturers provide a look at some of the singlepocket dryers offered in capacities under 100 pounds [18] Trade Ticker [19] Calendar [20] Classified Advertising [21] Source Directory

Clean

with

ALN

“ Only Milnor“

could offer the combined technology ”and support we expect.”

– Rick Hamlin, Crown Health Care, Columbia, MS

When Crown Health Care Laundry Services opened its fourth plant, it enlisted the help of longtime partner Pellerin Laundry Machinery Sales Company to design, equip, and install the most efficient laundry possible. The end result was a state-of-the-art laundry featuring two 76039 PulseFlow® Technology 10-module tunnels that creates a continuous workflow by integrating an E-Tech rail system to transport linen through the plant. Their Milnor 6464 dryer pod with GreenFlex™ Dryer Mode accepts new loads immediately after the discharge of the clean goods. This facility is designed to process over 25,000,000 lbs. of healthcare linen per year in a single shift operation, while consuming less than 0.5 gal/lb. Hamlin notes that “the project was seamless thanks to the combined efforts of Pellerin and Milnor.”

To find out how Milnor’s PulseFlow® Technology and GreenFlex™ Energy Mode can reduce your laundry’s utility consumption, contact an authorized Milnor distributor or call 504-712-7656.

To see how Crown Columbia’s state-of-the-art laundry works, scan this code.

www.milnor.com / pellerinmilnor

Technology at every turn

The act of “doing laundry” is, on its face, simple and straightforward.

It’s about collecting and cleaning soiled garments to return them to like-new condition. The laundry and linen industry dedicates itself to this pursuit daily. But the days of pounding a shirt with a rock at the river’s edge are long past.

Many of today’s laundries are run like manufacturing facilities, utilizing the latest technology to process and deliver load after load. It’s remarkable to see just

From The Director’s Chair BRUCE BEGGS

how far things have advanced. And so Editor Matt Poe takes

a look this month at technology and its role in laundry/linen services. He sat in on Dave Beavers’ Emerging Technology session at Clean and shares the 40-year veteran’s assessment of some of the new equipment now available.

Our OPL 101 column this month features three different perspectives on advancements making their way into laundry rooms.

And there’s much more to be discovered in the pursuit of learning how technology can make each of our jobs easier. ALN

Ecolab VP victim in Amtrak derailment

ST. PAUL, Minn. — Bob Gildersleeve Jr., a vice president at Ecolab, was one of the victims of the May 12 Amtrak train derailment in Philadelphia that left eight dead and more than 200 people injured.

Gildersleeve, 45, a resident of Elkridge, Md., was a graduate of Middletown H.S. South, the Culinary Institute of America and Florida International University. He had been with Ecolab for

more than 20 years. He most recently served as vice president of Corporate Accounts for Ecolab’s Institutional business in North America, the company shared in a press release.

Doug Baker, chairman and CEO of Ecolab, released this statement: “We are deeply saddened by the loss of our friend and colleague ...

our thoughts go out to his beloved family members and friends.”

Gildersleeve is survived by his wife, Deanna; a daughter, Ryan;and a son, Marc. Memorial donations can be made to The Bob Gildersleeve Memorial Scholarship c/o The Culinary Institute of America at www.youcaring.com/ bobgildersleeve ALN

CDC deputy director to speak at AHE’s annual EXCHANGE conference

CHICAGO — Michael Bell, M.D., deputy director of division of healthcare quality promotion at the Centers for Disease Control and Prevention, will be the general session speaker for the annual conference of the Association for the Healthcare Environment (AHE), of the American Hospital Association.

The conference, which is titled EXCHANGE, is scheduled for Sept. 21-23 in Grapevine, Texas.

Bell’s scheduled Sept. 23 lecture is titled A State of the State on HAIs from the CDC: An Environmental Perspective

A 20-year agency veteran and expert in drug-resistant pathogens and healthcare-associated infec-

tions, Bell has focused on investigating and preventing transmission of healthcare-associated illnesses for hospital patients and staff, as well as developing evidence-based infection control guidelines.

AHE’s EXCHANGE 2015 will cover issues in infection prevention, environmental hygiene, management and leadership. ALN

CHAPTER 5:

Soil sorting for greater efficiency

Agood friend of mine used to have a sign in his office that read, “Sorted Soiled Linen is Organized Grime.” As managers, we must deal with the soiled linen that comes to our laundry. There have been two schools of thought over my career as to whether the linen should be sorted before or after it has been washed.

The argument for sorting after washing is that it protects the workers from disease, needlesticks and other harmful items in the linen. The theory is based on the fact that the washer will decontaminate the linen and foreign items found in the linen. I personally have never been a proponent of this style of handling soiled linen. I feel it makes it harder to get a quality wash, increases by 30% the weight of the linen that must be sorted (moisture retention), and destroys medical instruments, cell phones and other items mixed in with the linen.

Regardless of when you sort, you will need to make several key decisions once you get around to sorting the linen. Many of these decisions will be based on what will work best in your laundry, not what your competitor is doing down the street. The number of different soil-sort classifications is determined based on the volume of linen you are processing and the type of finished product you are producing. By type of finished product, I mean whether you are ironing your sheets and pillowcases or not.

Your sorting process should be done in such a way that it increases the efficiency of your employees doing final finishing on the linen. If you are doing a lot of bath towels per day and folding them on a towel folder, it makes sense to have one sort for just bath towels. If your volume is less, you might want to consider mixing washcloths and bath towels together. This will give you a constant supply of both products.

To begin the process, make a list of every linen item that you will be responsible for processing. Then determine how each item is going to be finished: large-piece ironing, small-piece ironing, large dry-fold by machine, large dry-fold by hand, small dry-fold by machine, small dry-fold by hand, steam tunnel finish, and surgical pack inspection. (If I missed a finishing step used in your laundry, please add it to this list.) Group linen items by how they are going to be finished.

Using this grouping of items, and estimating the volume of each type of item, you will be able to group items together into a sorting classification.

The larger the operation, the fewer mixed categories you will have; the smaller the operation, the more mixed classifications you will have. A large-volume healthcare laundry might separate thermal spreads from bath blankets. A smaller-volume processor will combine these two items into a single sort category.

Every decision should be based on the answers to the following questions:

• How can I best maintain a good flow of product to my order fillers?

• How can my soil-sort classifications support or increase productivity?

• What soil-sort classifications promote a good, clean final product?

• What works best in the washers and dryers?

WEBSITES

From AmericanDrycleaner.com:

• Promote the ‘Feel-Goodness’ of Dry Cleaning

• Whirlpool to Acquire American Dryer Corp. (ADC)

Your initial decision on soil-sort groups will need to be changed over time. Equipment and staff changes may result in different sort classifications. Too often, the laundry manager simply does what has always been done and never seeks to understand the logic in developing sorting classifications.

As a manager, you need to constantly look for ways to improve the workflow, process quality and productivity of your laundry.

•

•

From AmericanCoinOp.com:

• WashClub on ‘Trak’ with Company Rollout

• Whirlpool to Acquire American Dryer Corp. (ADC)

Eric Frederick is director of laundry services for Carilion Laundry Service, Roanoke, Va., and a past president and manager of the year of the Association for Linen Management. You can reach him by e-mail at efrederick@carilion.com.

4 JULY 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

COLUMNIST AT LARGE Eric L. Frederick, RLLD

ALN

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending June 15 (WE) = WEB EXCLUSIVE NEWS • Ecolab VP Dies in Amtrak Derailment • Whirlpool to Acquire American Dryer Corp. (ADC) • Equipment Marketers Now Authorized Electrolux ... (WE) • Cintas-Nashville Earns TRSA’s First Hygienically Clean ...

Stock Buyout Shifts Ownership of Distributor PWS COLUMNISTS/FEATURES • Laundry Plus Doubles Up to Deliver the Goods • Technology Helps Keep Watchful Eye on Laundry Room

•

Eric Frederick: Chapter 4: Take Time to Determine Where Things Stand

Learning to Benefit from Results-Focused Training OUR

SISTER

IN MEMORIAM:

Gildersleeve

SUSTAINABILITY GIVING BACK

• Made from recycled plastic bottles

• Replaces paper napkins to save up to 60 million trees per year

• Lasts over 100 wash cycles

• Never ironed, less energy use

• Natural look & feel

• Smaller size (12” x 15”) allows more napkins per wash load

• Adds up to 15 billion pounds of oxygen per year

• Saves up to 5 billion pounds of trash per year

The Greenie® Because it’s the right thing to do.

The Greenie® is America’s choice to replace paper napkins! At breakfast and lunch, if every American uses reusable linen napkins instead of paper, we can save 60,000,000 trees per year! That means cleaner air, less water use, less energy use, less waste in landfills, less toxic paper production chemicals. And the best part... Money raised through the sale of this product is given back - to educate our children on keeping the planet clean and safe. 84% of Americans prefer cloth vs paper at the table.

The Greenie® Because it’s the right thing to do.

Two cents for every napkin donated to environmental education!

• One cent to TRSA, Textile Rental Education & Research Trust Fund

• One cent to NEEF, National Environmental Education Fund

The Greenie® has its own color story:

• Green for our plant life

• Blue for our water and air

• Yellow for our sun and energy

The Greenie® Because it’s the right thing to do.

800 821 2221 americandawn.com

ny’s first module of the Senking Universal. As he describes the process, special beaters in compartment one are perforated. They take in water from the bottom of the drum, lifting it up during the reversing action of the drum. In the upper position, the water is released through perforations in both sides of the beaters and pours down on the linen to help saturate the load.

“The benefits are optimum penetration of the fabrics thanks to better and faster wet-out of the first compartment,” says Beavers. “There’s also the steaming effect from the scoops that the ribs create.”

The QuickSoak washer appears easy to maintain. It doesn’t use additional components valves, or anything that requires extra maintenance. The beaters have an inspection flange on the outside of the inner window for visual inspection of the inner drum.

Jensen claims to have the world’s fastest feeder, according to Beavers. The JenFeed Express has a three-lane feeder to process up to 1,800 single sheets per hour. It’s a high-volume feeder used primarily for hospital sheets, utilizing double feeding capacity by cornerless feeding with an optimum piece-per-operator-hour rating thanks to what he says are excellent ergonomic working conditions.

are very robust machines.”

For finishing equipment, Beavers points out advances from Chicago Dryer Co. It has standard equipment that would go behind an ironer line. Models like the King Edge give a high-quality spread and feed quality for hospitality, he says. The Skyline SP series is suited to small-piece folding of items such as pillowcases and napkins.

“All of this is being utilized now with the latest version of controls that help see what’s going on, help troubleshoot the machine,” says Beavers. “Technology is getting better and better on these all of the time.”

LINEN SEPARATORS

One part of the laundry process that Beavers describes as “a touchy subject” is linen separation.

“It’s very back-breaking work to take linen and try to pull sheets apart and prepare them for feeding. That’s been done that way for years,” he says. “But with the onset of faster feeders, ironers and folders, a lot of it has to be preconditioned work in order to get the numbers that they claim they are able to get from the machines.”

He notes that traditional methods have utilized tumbling in the dryer or some other means to break the cake apart so as to ease the separation and handling. But wet linen is still hard to separate. Beavers pointed out three manufacturers that make automated linen separators to help with the process.

Jensen’s Viking has a guillotine-type effect, according to Beavers, where it comes down to grab the linen out of the bin. The bin or cart is tilted to help move linen down to the edge of the container in order to be able to pick all of the goods within.

Kannegiesser’s separator has a conveyor unit in front that acts like a pre-sort, says Beavers. It breaks up the cake and loosens the linen so that it falls down into a hopper where the goods are separated.

laundry equipment operating faster, some quality-control aspects are going to get lost. To help address some of that in facilities that need to separate stains, tears, worn linen, things of that sort, he made note of two systems—Chicago Dryer’s CHI•Vision™ and Jensen’s JenScan NPS.

They are camera systems that picture linen that goes through the equipment quickly. They help detect stains and tears, and can be set to look at emblems, Beavers says. The systems can be userdefined to ignore things like the edges of the sheet where there may be thread markers or something like that.

pital linen, one thing that we have is linen control, and especially things that seem to grow legs and walk out, like scrubs, items like that,” he says. “This technology, sewing in RFID chips, is being used in a multiple-cabinet-type format.”

He describes using the system in this way. An employee at the facility will have a card reader that will open up and show their identification. They select what garments they want, then a particular bin opens and they take out the goods. Since each item is identified, the system knows what’s being taken out of the cabinet.

ing systems.

His facility uses E-Tech’s eVue software system, which has recently been upgraded and is operated through a touch screen. It offers modules for materialhandling control, production reports and maintenance reporting. Information can easily be accessed using an iPad or tablet.

Once an operator logs in at, say, the ironer, the system immediately starts tracking his or her production rate.

“It’s space-saving and energysaving. To watch this thing actually in operation is quite interesting,” he says. “It’s a very fast machine.”

Pellerin Milnor Corp.’s 72406 M5K washer-extractor is ideal for hard-to-balance loads, according to Beavers. He says the machine has more flexibility and features, along with an ample number of liquid supply ports.

Another Milnor line he noted was the V series washer-extractors, utilizing RinSave® water-saving technology and MilTouch™ controls. Every machine in the line has the capability to reach up to 400 G’s of extraction force for moisture removal.

“They’re all rigid mounts and still can fit through a standard 3-foot door,” Beavers says. “They

Beavers believes Chicago Dryer’s Cascade® has a unique way to do the work. It does the same sort of “pre-pulling” the cake apart, but it utilizes a large clamp that pulls the goods out over the belt and picks up a large amount to try to separate them. By doing that, it’s virtually breaking up the majority of the cake.

Those goods fall into the front hopper of the machine, an action which Beavers says makes it much easier for the separators to come down and pick up the sheets and transport them down to a conveyor belt.

“Designs for separators are changing,” says Beavers. “They are more robust and more heavyduty.”

CAMERA SYSTEMS

Beavers notes that with most

“It’s tied into the folder, and it allows the folder to do things like separate the items into various sections of the folder, whether it’s through the primary cross hole or the stackers,” says Beavers. “This allows you to separate stains, tears, things that are traditionally old-style, button-in-the-front of the feeder that we’ve been doing for years. It’s … very versatile.”

He says that the systems also have the capability of tracking all stains and tears. They provide a readout of the types, and can be tailored to certain counts, certain types of fabric, anything that is unique. The systems can record all of this and display it on the panel.

RFID CHIPS

RFID—radio-frequency identification—chips aren’t really new, but Beavers sees them being used more and more in linens.

“In my particular field of hos-

When the employee returns the soiled goods to the cabinet, it “reads” the chips contained in what’s being returned. Their card tracks usage by what they take out and what they bring back.

“Another nice feature about this is that it will also inventory what’s in the cabinet and it will send that information and allow you to know what’s stocked in there, what’s getting low, what needs to be generated as far as refilling the cabinet,” Beavers says. “There are more and more of this type to help control linen losses being put into place. I thought this was a very nice system to have.”

REPORTING SYSTEMS

Beavers says his facility utilizes overhead rail systems, batch washers, finishing equipment, items of that nature. It’s important to stay up on the technology, he says, and that includes report-

“What’s nice about this system is it’s user-friendly,” Beavers says. “You can have displays in the plant showing the operator. You can have displays on the touch screen that you can pull up located throughout the system. You could also have this information sent to you by text.”

Softrol offers this type of technology through its new LOIS system, Beavers says. A mobile app allows a user to monitor plant production. One could utilize a total plant management program through the system with the same dashboard.

Another provider of reporting systems is Spindle, he says. Its SpindleLIVE system provides the same basic types of report information, and it’s smartphonecapable to remotely obtain this type of information from any location.

“More and more of this stuff is coming online, and it’s very nice, good technology, helps you keep better track and control of your operation and maximizing your pounds per operator hour,” he says.

6 JULY 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ALN Continued from Page 1 Tech

“MORE AND MORE OF THIS IS COMING ONLINE, AND IT’S VERY NICE, GOOD TECHNOLOGY, HELPS YOU KEEP BETTER TRACK AND CONTROL OF YOUR OPERATION...” —DAVE BEAVERS

(Image licensed by Ingram Publishing)

TWO ARE BETTER THAN ONE.

Happy with the productivity, efficiency and flexibility of his first Girbau Industrial (GI) tunnel system, Rick Rone of Laundry Plus maintains the decision to invest in a second identical system was a no-brainer. He likes the security they bring.

By adding a second GI tunnel system and moving equipment from two buildings into one, Rone enjoys streamlined production. The new plant – with its arsenal of high-performance equipment – opens the floodgates to new business, ensures backup in case of a mechanical failure, and allows Rone to launch a new linen rental program.

Since moving to the new plant and installing its second tunnel, another ironing line and additional open-pocket washers, Laundry Plus has boosted pounds of laundry per operator hour (PPOH) by 15-18 percent.

LAUNDRY SOLUTIONS FOR WET

ON-PREMISE

CONTACT GIRBAU INDUSTRIAL TO SEE HOW WE CAN INCREASE YOUR PPOH!

CLEANING,

& INDUSTRIAL LAUNDRIES

Rick Rone

www.girbauindustrial.com • (800) 256-1073 INDUSTRIAL

Laundry Plus, Bradenton, Florida

Tools f the Trade

Continental Girbau recently added the 70-pound-capacity G-Flex Washer to its line of hard-mount, flexible-speed washers. The line now includes 40-, 55and 70-pound-capacity models.

Like all G-Flex Washers, the 70-pound model generates extract speeds of up to 200 G-force, offers a highly programmable control and delivers superior results using less water and energy, the company says. It also has six programmable extract speeds, including 100, 140 and 200 G-force.

Because of the extract speeds the washer generates, G-Flex laundry loads take less time to dry, which improves laundry productivity and cuts natural gas usage and labor time, Continental says.

The programmability of the washer means laundries can properly clean a variety of fabrics, according to the company. Operators simply select a program number and press start. The Logi Pro Control offers 25 individually modifiable programs, each with up to 11 baths, including multiple pre-wash, wash and rinse cycles. Variables within each bath can be individually programmed for maximum efficiency.

The G-Flex operates on singlephase power and plugs into a standard appliance outlet, which the company says simplifies installation. www.continentalgirbau.com 800-256-1073

The Clean ’N Wax Cloth flatwork ironer cleaning and waxing cloth from Tingue, Brown & Co. features a choice of three flap styles to suit every flatwork ironer model from every manufacturer and every type of ironer wax, the company says.

Designed to help the wax melt evenly, and to disperse the wax onto the chests for lubrication without contaminating the ironer rolls, the three barrier flaps include the premium, siliconized barrier flap for extreme heat resistance and long-lasting, high performance; the

Teflon® flap for high heat resistance; and the standard duck flap for less intensive operations. Used in conjunction with the company’s Tingue Kleening Cloth, the Clean ’N Wax Cloth in all flap styles provides both lubrication and a preliminary cleaning step that supports proper waxing and sets the stage for easier, routine cleaning and removal of dirt and grime. The result is improved finish quality and a decline in the reject rate, the company says.

www.tinguebrownco.com 800-829-3864

IPSO has added SmartWAVe technology to its 20- to 70-pound capacity IY soft-mount washer-extractors. The company says the patented technology can significantly reduce an on-premises laundry’s (OPL) water and energy consumption by adjusting water levels based on linen material.

The water absorption verification technology automatically senses a load’s water absorption level and adjusts water use accordingly at each stage of the wash cycle, reducing water and utility use without compromising wash quality, IPSO says.

Instead of using standard linen weight to determine the amount of water used in a laundry cycle, SmartWAVe focuses on the actual absorption levels of each material, which, according to the manufacturer,

can result in water savings of up to 32%.

SmartWAVe works with the machine’s 99 programmable cycles, including efficient Eco washing programs, to optimize water, energy and detergent consumption. The Aries Elite control system also has a USB connection for flexible programming.

IY soft-mounts are built for dependability. The stainless inner and outer drum and tub deliver longlasting, worry-free performance. Plus, practical features, including a wide-set door hinge and front access to soap and parts, make loading/unloading and servicing the machine easy, IPSO says.

www.ipsona.com 800-872-4776

Ellis Corp. has introduced the SmartPRESS RP Extraction Press from Vega Systems. The company says the SmartPRESS RP can remove water at an energy cost savings that is 8.5 times greater than that of a dryer or ironer.

The SmartPRESS RP features a frame cut from one piece of Uniform Certified Steel (UCS) with only four main parts. This jointfree steel frame has no “operationcritical” elements and avoids weak points or fatigue associated with fretting or corrosion in conventional tie rods or posts, Ellis says.

The SmartPRESS RP is also equipped with high-speed hydraulics, which provide powerful, fast cycle times. In less than 48 seconds, it builds up the membrane pressure to 900 psi, ensuring low moisture retentions, even at fast cycle times.

With a 10-year structural warranty and quick, efficient cycling operations, the SmartPRESS RP is designed to withstand up to 1 million cycles, Ellis says.

The new EDRO side-loader washer-extractor range is available in loading capacities of up to 450 pounds (205 kilograms). The split two-pocket cylinder configuration has a full-width door opening for easy loading and unloading, the company says, and offers a 180-degree drop for good mechanical wash action.

Taking advantage of the large main door opening, the cylinder can be positioned at a variety of angles for gravityassisted loading and unloading. According to the company, the cylinder door features effortless operating hardware, securely fastened to the cylinder in machined pistons and bushings.

EDRO’s side-loader machine design incorporates the company’s DynaMount suspension

system for reduced vibration transmission, DynaTrol HMi touch-screen control for easy programming and operational accuracy, and inverter with single motor drive for energy efficiency. The washer-extractor also features EDRO’s exclusive variable step extract and high slip brake.

The compact machine design also includes EDRO’s side-mounted motor plate and enclosed cabinet guarding, which significantly lowers the machine profile. Dual fill piping and dual drains speed step times for fast, efficient cycle times, the company says.

www.edrocorp.com 800-628-6434

Manufacturers: Have you introduced a new product? Revamped your system? Released a new catalog? E-mail your product news, along with a high-resolution image, to mpoe@atmags.com and we’ll consider publishing your news free in Tools of the Trade.

Encompass Group offers a full line of synthetic underpads by MIP, all with the goal of providing enhanced protection for the patient, the company says.

Maintaining skin integrity is a critical component in the care of the hospitalized patient. Understanding the impact of methods to maintain skin integrity is vital toward the prevention of pressure ulcers and skin breakdown.

The use of a new-technology synthetic reusable underpad is beneficial to the patient in the acute

www.ellislaundry.com 800-611-6806

care setting because of its ability to promote skin integrity—not just protect the bed linen, Encompass says. The Fusion underpad is in addition to the clinically proven DermaCare™ underpad.

www.encompassgroup.net 800-284-4540

8 JULY 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Extraction press designed to save energy while removing water

Lubricating cloth preps ironer for quality production

New side-loading washer-extractor available in models up to 450 pounds capacity

Synthetic underpads seek to maintain patient’s skin integrity

Patented water absorption verification technology added to soft-mount washer-extractors

Company expands hard-mount washer line by adding 70-pound-capacity model

When dealing with laundry stains, your reputation rides on getting the outstanding results The Laundry Two deliver. RiteGo® laundry spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to Laundry TarGo® to remove any tough oil based stains that remain behind.

Use The Laundry Two with confidence on shirts, wedding gowns... anything you're washing or wetcleaning.

Both Laundry TarGo and RiteGo are chlorinated-solvent free, biodegradable, noncombustible and California 2013 VOC and Prop-65 compliant.

Use them to deliver stain-free laundry and wetcleaning. You'll build your reputation for quality - which is what keeps customers coming back.

FROM COLLARSAND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... FROM COLLARSAND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

a STAIN WIZARD at ALWilson.com

Become

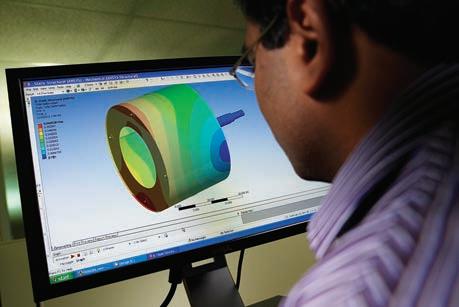

Q&A: Evolution of on-premises laundry technology

RIPON, Wis. — Compare an on-premises laundry from 20 years ago to today, and you’ll see that technology has the ability to make a laundry manager’s job easier rather than more complicated. With advancements continuously making their way from manufacturing plants to laundry rooms, you might ask yourself what’s in store for the next few decades. Here are three perspectives on the industry’s technological evolution, as well as predictions about what the future may hold.

to machines with advanced control systems, our customers can view vital performance information about their laundry operations from their smartphones or tablets.

Bob Baudhuin, vice president Engineering, Alliance Laundry Systems: You might have defined machines as “cookie cutter” a few decades ago. The more efficient and reliable, higher-quality machines available to OPL facilities today are a direct result of advancements in product development and design that didn’t exist even 10 years ago.

be sure the laundry room is operating as efficiently as possible at the lowest cost of ownership.

Bill Brooks, North American sales manager, UniMac®: Machines weren’t nearly as precise or as customizable 20 years ago as they are now. For example, water levels—low, medium, high—and temperature settings— cold, warm, hot—were basic, and machines didn’t offer features such as high G-force or moisture sensing. Innovation to engineering and manufacturing processes started ramping up in the early 2000s, resulting in more sophisticated equipment and control systems.

There are so many more models and lines available now, and we can build them quicker. Meanwhile, as a result of better quality control and manufacturing, the more advanced machine is built to last longer with fewer maintenance issues.

Jason Downey, regional sales manager, Southeastern Laundry Equipment: When I started at Southeastern five years ago, we used carbon copies on clipboards for every single transaction. Today, everything is electronic via a tablet, eliminating the need for paperwork while saving time and money, and meeting customer needs more quickly.

On the equipment side, thanks

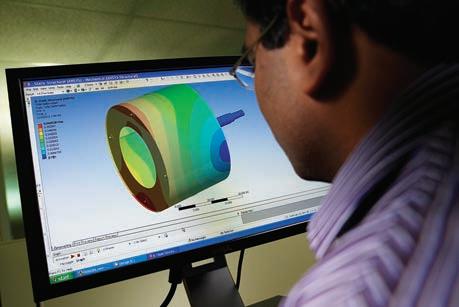

For example, today, our engineers can design a machine and perform test simulations entirely on a computer. This reduces the number of physical prototypes we must build, while ensuring the prototypes we do build are almost exactly what we intended them to be.

Q:How can technology benefit a laundry operator?

Brooks: A key challenge onpremises laundry operators have historically faced is the inability to measure efficiency, and therefore the inability to know if the laundry room is costing the business more than is necessary. Technology within a machine’s control system can solve this problem by collecting machine performance data, and displaying it for managers in easy-to-read, executive-level dashboards. This tool enables managers to set benchmarks and make adjustments to the operation that can conserve water and energy.

Reducing water consumption also remains a key concern in the laundry industry. With machines that include features like spray rinse technology and eco-friendly cycles, laundries can reduce their water usage without sacrificing wash quality. Combine these technologies with the ability to set benchmarks and improve upon them, and decision-makers can

Downey: With new monitoring and reporting technologies, our customers can more easily track the laundry room’s energy consumption and labor costs, and thus refine the operation’s efficiency. What was once a cumbersome task, or virtually impossible, is now easier.

Consider a hotel, where, every day, energy and resources are expended via the showers, lights, air conditioning, heat, etc. In order to save money and cut costs, hotel decision-makers want to be able to track every aspect of resource consumption. Today, a washerextractor can be connected to the Internet, where its performance can be tracked on a cellphone.

Baudhuin: Laundry operators are demanding equipment that is faster, more efficient and less expensive to run, while performing continuously day in and day out. They’re also demanding equipment that is more userfriendly and intuitive. As an engineer, it’s my job to make sure all of these concerns are met, and I wouldn’t be able to without technology.

Ironically, as technology becomes more advanced, we’re seeing that machines and control systems actually become easier to use, program and diagnose. I hope laundry managers who are hesitant to bring technology into their operations realize that the benefits far outweigh the learning curve.

Q:What does the future hold

ments in technology?

Brooks: We’re just getting started. From engineering to manufacturing to the final product, technology is going to take the OPL industry to the next level, and at a rapidly increasing rate.

Quality will continue to improve, and products will be much quicker to market. It used to take decades for a product to debut with the latest technology. Now, it can take as little as a year. This greatly benefits on-premises laundry facilities, because they can enjoy technologies that increase efficiency and enhance their operations sooner.

I also think cloud-based reporting and remote networking capabilities will continue to automate the process of identifying issues, because equipment will be able to do it for you with more precision.

Downey: Equipment with cloud reporting capabilities is the future of how people will acquire information about their laundry operations. I also predict control systems will become more advanced, yet simple to program, and may even start looking like your phone or tablet. As a result,

we salespeople will be able to provide our customers with the tools to do their jobs more effectively.

As machine diagnostics get even better, we’re able to counsel our customers without even stepping into the facility. People may shy away from the phrase “advanced technology,” believing it sounds intimidating. I encourage my customers to instead use the words “simple” and “smart.” Technology, when used to make life easier rather than more complicated, is a great thing.

Baudhuin: We already have a good idea of what the landscape will look like in five years. Features and functions that further reduce costs, enhance usability and improve productivity and efficiency for OPLs will be the norm. It’s the next 10 years that remain unknown, but I do believe capabilities that we haven’t even dreamed of yet will be available.

ALN

UniMac®, a brand of Alliance Laundry Systems, is a provider of on-premises laundry equipment. To learn more, visit www.UniMac. com/OPL101 or call 800-587-5458.

ALN_Tab_1-4_H.indd 1 6/3/15 9:05 AM 10 JULY 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com OPL

101

Q:What role did technology play when you first started in the industry, and what role does it play now?

when it comes to advance-

New monitoring and reporting technologies allow laundry facilities to refine and improve operational efficiency. (Photo: Alliance Laundry Systems)

and took the opportunity to get into management,” he says.

Marsh, who has been regional laundry and linen manager for Providence Health and Services in Portland, Ore., for the past two years, started in environmental services during school and had experience cleaning medical office buildings. After completing his education, he took a position in laundry and linen at Providence St. Vincent Medical Center.

“While in linen, I was fortunate to have a supervisor that mentored me and gave me the opportunity to learn all facets of the business. To expand my skill base, I was promoted to a supervisor position in environmental services,” Marsh says. “When the linen manager position became available, I jumped at the opportunity.”

Houchin, Briggs and Marsh are working to become the laundry leaders of the future. While all three are still learning and growing in their positions, they have ideas that they hope will impact the laundry and linen industry.

BUSINESS PRACTICES

When it comes to business practices in the industry, Houchin, Briggs and Marsh each have different areas that concern them.

Houchin believes there are inconsistencies in industry standards. And that, he says, makes it difficult for a next-generation laundry leader.

“As it is with many industries, there is a school standard, a vendor standard, an experienced laundry leader standard and probably a few other standards, none of which seem to fully agree with each other,” says Houchin. “Trying to determine what is the most reliable source or the most effective practice can be challenging. I would like to see an ‘industry standard’ that is more consistent throughout the industry.”

A positive for Houchin has been the partnerships he established almost immediately. He was introduced to other facility managers, and their approach to him was one of a mentor, a partner and a friend.

“Part of what drives me to learn more and to gain more experience is the possibility that I may one day be able to be for someone else what these industry veterans were to me,” Houchin says. “What they did, and are doing, for me went well beyond networking. I think it is something that is unique to this industry, and I believe that as long as that kind of environment exists, this industry will thrive.”

Briggs would like the industry to become even more automated. As much as possible, he would like to remove the human-error potential from the process.

However, he is realistic when it comes to how much the industry can change.

“Most of what is done is tried and true and will stay the same because it works,” says Briggs. “There is only so much you can do with the washing and drying process.”

For Marsh, the focus is on cost reduction. He says that in the healthcare industry, the most important practice that needs to change is educating the clinical staff on the value of linens.

“With the current state of healthcare, cost savings is essential to both the health system and the patient. Product standardization, proper utilization and conscious efforts will result in cost reduc-

tion,” says Marsh. “However, we have to be sensitive to changing the culture, because linen is very personal to nursing staff, and when we standardize or find a cost-savings product alternative, it often causes nursing dissatisfaction. This is an ongoing challenge for frontline staff, management and the co-op.”

One practice Marsh finds doesn’t work: exchange carts.

Marsh says the carts don’t work for the amount of linen his facility uses on a daily basis. Also, by using exchange carts, he sees the staff still use bulk items to fill the cart, which defeats the purpose.

TECHNOLOGICAL ADVANCEMENTS

It’s no surprise that these nextgeneration launderers are keen on using new technologies to improve laundry function. Houchin has already introduced some new technology at his facility.

“Things I had to track manually at my previous facility are now being tracked through automation and technology, and the benefit is immeasurable,” he says. “Whether it’s something as detailed as tracking production in real time, or something more simple like the benefit of having flatscreens at each sorting window that display

the product/customer/weight/production rate, the benefits are significant and are necessary in order to be competitive and streamline production to maximize quality and service.”

Even Briggs is amazed at how much technology is used in laundry and linens.

“I think the production software and the many new types of processing equipment have great potential to aid profitability,” he says. “You need to find the right blend of automation and manpower, but there is a lot out there

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | JULY 2015 11

YOUR CHALLENGE PACESETTER CLM leads the way in dryer technology and provides an upgraded replacement for your old Challenge Pacesetter Our Model 165 fits the Challenge Pacesetter footprint perfectly and gives you technology that no one else o ers, including a fully integrated production management system. • Upgraded heat system with improved efficiency and lower emissions • Micro-Command III PLC upgrade with LAN and Blue Tooth communications • PLC now prepared for flow process management systems • 2-stage variable speed basket drive with 3-port load door. • Soft start to reduce component wear, lower utility use. • Heavy-gauge basket, includes removable steel basket panels • Long-lasting ceramic coating available on removable basket panels. • Configurable exhaust location • Configurable control/burner location Call CLM to replace your Challenge Pacesetter dryers, or for information on our broad range of industrial dryers. 323-232-2417 Model 165 shown with Tumble Green® configuration See Us at Booth 2560 at The Clean Show 211 Erie Street, Pomona, CA 91768 | T: (323) 232-2417 | www.clmco.com ALN_Jr Page.indd 1 11/18/14 2:36 PM 0515aln_CLM.indd 1 4/13/15 4:46 PM Continued from Page 1 Next Gen See NEXT GEN on Page 18

UPGRADE

Is your facility ergonomically friendly?

Since leaving the daily routine of actively running a production commercial laundry, I have considered two additional pieces of equipment that I would add to a plant that would enhance the safety or ergonomics of the laundry.

The first piece of equipment is the automatic sheet sorter or separator (also known as pickers).

Automatic sorters separate and sort sheets so they are detangled from each other. They allow the operator to retrieve sheeting from a cart or table in a manner that allows them to be very productive with lowered potential for injury. This is accomplished through the reduction of stress on the body as machine function absorbs much of the normal human effort such as twisting, pulling and pushing. These features help reduce muscle pulls and strains.

While sorters have been around for years, I never had the opportunity to use one regularly. In the past when I would inquire about sorters, fellow managers generally talked about their limitations, their efficiency rating (how much better it made the operator) or the effort it took to keep them working properly.

Well, having recently viewed

laundry associates actively working with automatic sorters in several plants and at the Clean Show this year, it occurred to me that I currently have a positive view of them. First, anything we can do to affect the health and welfare of our employees positively is worth consideration. Second, sometimes the object that helps you the most requires the most effort to keep it running properly. Automatic sorters require fine-tuning to keep them working properly.

The second piece of equipment I recommend adding is protective safety netting or metal barriers for bags hanging from a monorail system. This netting serves to catch linen or bags falling from a monorail. In the past, I have been in plants that managed around the suspended bags. Many times this is accomplished by drawing safety lines on the floor. While this is acceptable, it requires people to make proper decisions to enhance their personal safety. Whether total or partial, eliminating safety decision points and opportunities for injury on a “permanent” basis is analogous to a solid foundation—once there, always there.

I have been in plants where all of the overhead bags are netted, and I have been in plants where a logical decision has been made to address the high-traffic areas, which would minimize potential accidents of dropped bags or linen. Sometimes you have to build plants so accidents just can’t happen because of safety redundancies.

In a previous article, I spoke

about how automated monorails have been one of the greatest productive and safety additions to the laundry for me over the past 10 years. The massive elimination of movable carts has reduced hand pinches, foot injuries, pushing/ pulling strains, and the elimination of the stopping and starting effort. It is truly amazing. It has been a pleasure to see the production and safety process grow hand in hand.

facility’s plant design, flow and/ or automation and how improved ergonomics positively affects the relationship between an operator and his/her production machine.

While laundry owners are focusing more than ever on providing a safe working environment, laundry equipment manufacturers have put more effort into their design and technology to supply ergonomically sound equipment. Employee concerns and production demands have led to manufacturers providing more automated and ergonomic options throughout an industrial laundry’s plant operations.

been developed for garment finishing as well, replacing the traditional manual processes of yesterday. With the evolution of garment fabric content over the years, it has allowed equipment manufacturers to develop more ergonomic options for processing wearable items. Ergonomic hanging stations, pass-through garment finishing tunnels, automatic sortation systems and automated garment-folding robots provide for high-volume processing with a completely automated and ergonomic process.

Ihave been involved in the laundry industry since the late ’80s. Back in those days, we heard very little concern regarding ergonomics. Today, it is a much different story, as evidenced by this month’s topic.

As I am working throughout my territory, now in the year 2015, the area of ergonomics and each of its core elements of body position, viewing sector, physical movement and repetitive motion are common discussion points when visiting with plant owners and operators.

Being in the capital equipment business, it is obvious that the majority of my plant visits involve discussions around upgrades of individual pieces of capital equipment and/or modernization of a

Many of today’s washrooms have moved away from the physically demanding manual washerextractor washroom to one that includes loading/unloading aids, all the way to operator-free washer-extractor systems. Automated tunnel washer systems are also common, given their added utility efficiencies, automated shuttle delivery systems, and dryers with automatic loading and unloading functions. Automated linen logistics systems, including monorail bags and integrated conveyor belts, are taking the place of manually moving linen carts around a production floor.

In the linen finishing department, the introduction of automated spreader-feeders back in the ’70s led to equipment manufacturers developing a full array of automated linen separators and linen-specific feeders and folders with stacking and even automatic sorting conveyors.

Many advancements have

To answer the question, when considering new capital equipment for your facility, many new automated and ergonomic options are available for consideration throughout the production floor.

As I get older, I am well aware of injuries, aches and pains, etc. Having accumulated a lot of wear and tear doing lots of dumb things, I would offer the following suggestions to minimize these issues.

Pay attention to your employees’ complaints. Talk to them. See what is physically hard for them. Look for tasks with repetitive movements involving

12 JULY 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com ECWS Plug-N-Play Selling Customer Service FIRST! • OEM Distributor for RBI Water Heaters • 24/7 Technical Support • Laundry Consulting • Serving Commercial Laundries and Prisons across North America and the Caribbean We offer: • Hot Water Heaters 199-6 mil btu • ECWS Hot Water Storage Tanks • Water Softeners • Pre-plumb packages Call us for a quote using our SizeNet sizing program Phone: 1-866-513-7170www.eastcoastwatersystems.com Fax: 843-225-6258 0415aln_ECWS ad.indd 1 4/13/15 2:33 PM

EXPERTS

PANEL OF

“I saw products at Clean that made tasks more ‘friendly’ on the body and would help prevent injuries. What are some ways I can make my facility more ergonomic and reduce strain on my staff?”

Textiles

Cecil B. Lee

Standard Textile, Cincinnati, Ohio

Equipment Manufacturing Kelly Outram

Kannegiesser USA, Grand Prairie, Texas

Chemicals Supply David Barbe

U.N.X. Inc., Greenville, N.C.

extreme motions, high effort and twisting motions.

No one should raise or lower something heavy while twisting; I’ve hurt myself doing things in that manner. If the task requires these movements, find a way to change the procedure, the tools used, the machine being serviced, etc. Something has to be changed.

Do the task yourself for a while and then think about how to make it easier. Perhaps a team approach will help. Perhaps a new machine with a better design can eliminate the problem. Maybe machines can be moved to a new arrangement that will work better.

Teach your employees proper ergonomics. People who haven’t hurt themselves yet will try to do things the quick and/or easy way, rather than the safe way. Learning the lessons of safety by having to visit the emergency room is a painful way to learn.

Training films, constant reminders and diligent enforcement of rules and procedures are a better way to get people to be safe. It’s hard to get people to understand that even minor injuries can have lasting effects for the rest of their lives. Be a nag! Someday they’ll appreciate you for it.

One of the heaviest things your employees have to move is a chemical drum. A 55-gallon drum of alkali will weigh more than 600 pounds. Don’t use a regular hand truck to move these; look for a drum truck.

It has a lever system and four wheels that will make tipping and moving drums much easier and safer. Remember to have all the caps on the drums while moving them, and also replace caps on the empties.

Rotate tasks regularly. Almost any task or movement done often enough can cause physical problems. Yes, one employee may be better at a particular job, but they should move to other jobs and do something else regularly. When people get bored, they get complacent. Besides, having fully cross-trained people on your staff is an advantage when employees are absent. It takes more time and may be slower in the beginning, but it’s worth the investment.

Consider inviting the Occupational Safety & Health Administration or your insurance company to come look around your facility. Yes, I know inviting OSHA in sounds like business suicide, but the agency will be much easier to deal with if it’s apparent that you are putting in a good-faith effort to be safe. Work with its suggestions.

Your insurance company has a vested interest in your safety and your financial well-being. It has many highly qualified people who can offer suggestions to minimize your risk and theirs.

As laundry operators today, we are mindful of several key factors: keeping our labor costs in check, improving our production flow and, of course, keeping our workforce safe and happy.

Both my father and father-inlaw taught me several key lessons

growing up in the textile and laundry business. First, if you want to maximize the effort from your workforce while getting the best from them on a consistent basis, always look for ways to improve their working conditions, and make their jobs more effortless while increasing their production.

Second, treat your employees like they are family, because they are the ones who are making sure a quality product is delivered on time on a consistent basis. Third, beware of those two nasty words that can bring you and your workforce down in a heartbeat:

workers’ compensation. Always be aware of new technology that can aid in removing these two nasty words from our laundries. Being a vendor at Clean, in the mornings prior to the doors opening to the masses, I was able to walk the empty hall and look at innovative equipment at my own pace. While walking, eerily at times, it was like I could hear some of the equipment talking to each other across the aisles as they prepared themselves to showcase their abilities to make the once tedious, non-ergonomic duties performed by our loyal employees more productive and

less strenuous.

Most of these conversations started as, “Remember when….” For instance, as I walked past one booth, I noticed robotic mechanisms untangling sheets from a huge bundle, making it easier for the operator to feed them into the flatwork ironer while increasing pieces per operator hour. That backbreaking task once required several operators to pull and tug the sheets apart for the feeders in front of the ironers.

Across the aisle was an automatic lift raising slings of goods

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | JULY 2015 13

800.611.6806 www.VegaSystemsUSA.com www.EllisCorp.com ATLAS FRAME STANDARD FRAME Solid rectangular steel frame for superior weight distribution Two-part construction reduces critical operational elements Pressure concentrates at the most vulnerable points - the posts Multiple structural components means multiple opportunities for failure OUTLASTS COLUMNS. Our unique ATLAS Frame eliminates the weak points from traditional four-column hydraulic press construction. Its joint-free design ensures maximum strength, integrity and operational reliability up to 62 bar pressure. Two solid rectangular frame elements are cut from 8” solid steel slabs along with the top and bottom platforms. Leave the columns to the Romans. Let Vega Systems and Ellis keep your laundry productive, year after year. ALN_Jr Page.indd 1 6/5/15 8:15 AM See EXPERTS on Page 19

Uniforms/ Workwear Manufacturing Scott Delin Fashion Seal Healthcare Seminole, Fla.

SMALL-CAPACITY DRYERS

with all “I” Series dryers. This means a property can upgrade dryers without having to spend on modifications to the electrical service, ADC says. Reversing tumbler action will prevent uneven drying due to balling or roping of larger items that can slow the drying process and expend unnecessary utilities.

All non-vended “I” Series models come standard with ADC’s patented SAFE (Sensor Activated Fire Extinguishing) system. When connected to water, the SAFE system will activate when sensing an abnormal rise in temperature to avoid costly damage and expense due to spontaneous combustion. It is also the only such system to shut itself off to minimize cleanup and, in the event a fire reignites, will reactivate, according to the company.

www.adclaundry.com 508-789-9000

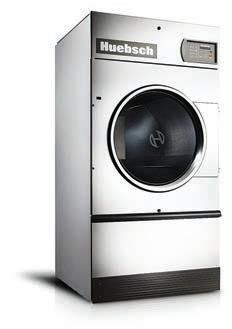

HUEBSCH

Huebsch offers the HT050, a 50-pound tumble dryer designed to meet the needs of medium- to large-scale on-premises laundry (OPL) applications.

A key feature of the HT050 is reversing technology, which allows the machine to stop, pause and then switch direction, Huebsch says. This helps reduce the balling or roping of large articles, such as sheets, comforters and tablecloths, during drying. Balling or roping causes the center of the linen to be less dry than the outside. The reversing feature provides consistent, even drying of the laundry.

The machine also features a large door opening for quick loading and unloading. This, coupled with a self-cleaning lint screen, will enable laundry staff to get more loads done and increase the overall throughput of the operation, Huebsch says.

Machines are available with

automatic anti-wrinkle extended tumble and time-remaining display.

www.huebsch.com 800-553-5120

RAMCO LAUNDRY MACHINERY

RAMCO’s DS-60 Industrial Dryer is designed for small commercial loads up to 60 pounds. It is the smallest model in the company’s line of dryers with load capacities ranging up to 230 pounds.

The model features microprocessor controls, is fully automatic and can dry a variety of fabrics. It also offers the convenience of automatic control and timer drying, as well as an automaticreversal drum, RAMCO says.

Its large window allows the user to check on drying conditions, and the lint drawer is easily accessible.

The dimensions of this unit are 50 inches long by 41 inches wide by 70 inches high.

Safety switches throughout the dryer also provide protection for the operator. The DS-60 is available for 208-240/60/3 or 480/60/3 electrical service.

www.ramcolaundry.com 800-878-5578

WASCOMAT

the Galaxy 600 control system, which allows laundry managers to reduce energy and labor costs with features including 30 programmable cycles and Over-dry Prevention Technology (OPT).

Additional user-friendly features include a one-touch cycle repeat,

Wascomat’s TD83 (83-poundcapacity) dryer for OPLs, distributed by Laundrylux, offers fast drying and has low energy consumption with an optimal combination of gas consumption and airflow, the company says.

It operates quietly, and the large doors make loading and unloading easy. In terms of maintenance, the dryer provides convenient access to parts, along with a large

lint compartment. The reversing drum minimizes tangling and wrinkling, improves dryer efficiency and makes flatwork finishing easier, the company says.

The model also has Wascomat’s Residual Moisture Control (RMC), which is said to prevent damage to garments caused by overdrying, and reduces lint and wrinkles by automatically stopping the dryer when the exact preset moisture level is reached. If the load is to be further processed by an ironer, RMC will shut the dryer off while there is still sufficient moisture for the ironer to work effectively. By not over-drying, operators benefit from longer linen life and significant labor and energy savings, the company says.

www.laundrylux.com 800-645-2205

AMERICAN DRYER CORP. (ADC)

American Dryer Corp.’s (ADC) “I” Series (Intelligent) dryers incorporate a trans-axial airflow that maximizes efficiency without sacrificing performance, the company says. They feature a pre-burner chamber that introduces warm, dry incoming air to the burner.

A variable speed drive (VSD) is calibrated with the micro control that also includes a patented auto-dry system. As items dry, they become lighter and the VSD adjusts the speed of the drum to prevent centrifuging (when lighter items adhere to the drum away from the path of warm air). By keeping the items in line with the warm airflow, drying times are reduced and efficiency maximized. The VSD also provides a soft-start, creating less wear and tear on motors and rollers and allows for the elimination of the idler arm, according to ADC.

In addition to utility savings, a number of standard features ensure minimal cost of ownership over the life of the unit, the company says. The small-capacity 35-, 50- and 80-pound dryers feature a heavy-duty trunnion and bearing assembly supported in front by high-temp rubber rollers.

A patented Automatic Airflow Compensator (AAFC) will compensate for high static pressure caused by undersized exhaust work. The optional AAFC will sense and calculate the airflow to maintain the proper amount, maximizing efficient performance.

Singlephase reversing baskets are standard

LAVATEC LAUNDRY TECHNOLOGY

The FL-series dryers from Lavatec Laundry Technology are durable, dependable machines that offer highly efficient production and many significant benefits, the company says. The front-loading dryers provide variable heating options. A 90-pound model is available with electric, steam, gas heating or oil.

Each machine is completely programmable with heat recirculation and forced air burners. The series is designed for optimal airflow, resulting in high evaporation performance and convenient handling and use, and requires low maintenance, Lavatec Laundry Technology says.

www.lltusa.com 203-632-8777

B&C TECHNOLOGIES

The B&C DE Series dryer line, available in small capacities of 30, 50 and 75 pounds, is designed to exceed the demands of continuous use and stands up to the rigors of the most challenging laundry, according to the company.

All dryers come standard with a stainless steel drying cylinder, fully enclosed fan-cooled motors, cast-iron pulleys and a heavyduty steel base. The DE line has

14 JULY 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

[Lavatec Laundry Technology]

[Wascomat]

COMPILED BY MATT POE, EDITOR

[Huebsch]

[RAMCO Laundry]

[American Dryer Corp.]

PRODUCT SHOWCASE

the option of either a standard manual timer controller or an easy-to-use microprocessor.

The large door allows for fast and easy loading and unloading, while the welded steel, fully enclosed cabinet offers energysaving insulation and quiet operation.

The exclusive humidity-sensing system directly measures the remaining moisture, preventing over-drying and saving time, money, and wear on the goods, the company says.

www.bandctech.com 850-249-2222

PELLERIN MILNOR CORP.

Milnor’s M78 dryer is rated at 75 pounds capacity, but it provides laundry operators with the same diameter cylinder (44.5 inches) as a 120-pound dryer, the company says. The large cylinder allows linens such as sheets, spreads, duvet covers and blankets “to open up” more fully than a standard 75-pound dryer with a 36/37-inch diameter cylinder, according to Milnor.

The dryer also has excellent airflow, the company says, typically 20% more than a standard unit (1,200 CFM vs. 1,000 CFM). This promotes quicker dry times, which also saves labor.

The M78 has other features. It fits through a 36-inch door opening. It has the Smart Lint Monitor, which prevents operation if the lint drawer is not cleaned out regularly (fieldprogrammable). Finally, it has a

user-friendly microprocessor control with an easy-to-read display.

www.milnor.com 504-712-7656

UNIMAC

UniMac offers the UT075 industrial tumble dryer. The 75-pound machine is equipped with advanced controls and OPTidryTM Over-dry Prevention Technology to reduce operating expenses associated with over-drying.

Over-drying occurs when tumble dryers run longer than needed and leads to the over-heating and scorching of linens. This

causes linens to deteriorate faster, decreases throughput and uses excessive energy.

According to a UniMac survey, 79% of respondents believe OPL laundries are overdrying linens by at least eight minutes per cycle.

For an OPL using a 75-pound tumble dryer, eliminating eight minutes of over-

drying from 10 loads a day could save hundreds of dollars in utility costs and thousands in labor a year, UniMac says. And linens experience 31% less fiber loss when over-drying is eliminated, the company adds.

OPTidry is an industryexclusive innovation available with UniMac’s

UniLincTM control system that accurately reads dryness levels throughout the entire load, the company explains. The UT075 contains moisture sensors that automatically shut the machine off when specified levels of dryness are reached, taking the guesswork out of properly drying linens.

www.unimac.com 800-587-5458

DEXTER

Dexter’s small-capacity, singlepocket dryers are available in capacities of 30, 50 and 80 pounds. These dryers are ➢

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | JULY 2015 15

THE LEADER IN LAUNDRY TECHNOLOGY kannegiesser-usa.com•800.344.0403 HIGH CAPACITY - 3+ loads per hour - Radial Air Flow - Continuous Heat Distribution PowerDry LOW ENERGY CONSUMPTION - Eco Air Re-Circulation - Infra-Touch Contolling - ECO2 Power PowerPress VERSATILE - 99 pressing processes ensure powerful yet gentle extraction - Optimum performance with range of articles EFFICIENT - Maximum extraction saves drying time - Optimized water drainage and recycling MOISTURE ELIMINATION U L T I M A T E ALN_Jr Page.indd 1 5/26/15 3:47 PM [B&C Technologies] [Pellerin Milnor] [UniMac]

designed to offer maximum speed and efficiency, which the company says helps smaller on-premises laundries optimize their laundry processing.

These dryers feature perforated tumblers, balanced radial airflow and the right amount of air recirculation to provide maximum efficiency, Dexter says. The dryers are built to last, with heavy-duty bearings in a cast-iron bearing housing and a fully welded and painted cabinet.

www.dexter.com 800-524-2954

simple customization using three different types of drying—timedry, auto-dry and moisture-dry. Over-dry Prevention Technology (OPT) is an add-on feature with OPTimum control, providing exact dryness readings within the entire load using advanced sensors. The cycle is then completed when the precise moisture level requested by the user is detected.

OPT helps eliminate over-drying to maintain linen quality and reduce unnecessary energy usage.

Available in two ranges, the ECO-line or Classic line, OPL managers can select the product that best suits their needs when it comes to energy consumption and throughput, IPSO says.

www.ipsona.com 800-872-4776

MAYTAG COMMERCIAL LAUNDRY