Alliance Laundry Systems completes $400M finance facility

RIPON, Wis. — Alliance Laundry Holdings LLC, the parent company of Alliance Laundry Systems, recently completed a new $400 million assetbacked finance facility to support its business operations in North America and select European markets.

Mike Schoeb, Alliance Laundry’s president and CEO, says, “Financing is a key component of maintaining and growing our leading market share, specifically within our vended laundry segment in North America. This new facility will allow us to expand those services to the European market.”

This is the sixth issuance completed by Alliance Laundry since 1998. The company says the new facility is backed by a pool of equipment loans, leases and trade receivables for the purchase of commercial laundry equipment.

Alliance Laundry says it has originated more than $2 billion in equipment loans since the inception of its captive finance business supporting its distributor and customer network.

“We have a long track record of success financing within the commercial laundry industry,” says Bruce Rounds, Alliance Laundry CFO. ALN

Changing textiles changes laundering practices

BY MATT POE, EDITOR

CHICAGO — They say that change is the only constant in the universe, and that’s certainly true when it comes to textiles. Textile manufacturers consistently work to find newer and better materials that make their products more effective for the end-user.

And that means changes in how the textiles are laundered.

Mark Mann, vice president of the USA Business Unit for MIP Inc., which manufactures reusable healthcare textiles, uses the simple cotton undershirt as an example.

“There was a day when we all wore cotton undershirts, and they took long to wash and even longer to dry,” says Mann. “And then, one day, Under Armour came out with this new high-tech material that was more comfortable. It was cooler in the summer and warmer in the winter. It wicked sweat away. It provided all these things, but it weighed about 10% of what your old cotton shirt weighed.”

He also points out that the new product is processed differently than the old cotton shirt. No bleach is used, and the dry time is shorter, and the shirt offers a better performance and useful life.

Changes are taking place across all sectors of the textile industry: hospitality, industrial, food and beverage, and healthcare. Launderers need to stay on top of these changes—and how those innovations will change the laundering process.

HOSPITALITY

What Steve Kallenbach, director of Market Solutions for ADI American Dawn, a manufacturer and supplier of a range of textiles and linens, sees happening in hospitality is an image upgrade.

He says that years ago, standard

bed linen was T-130 (the number reflects its thread count) and then T-180. The standard now is T-200 and leaning more toward the T-250 tone-on-tone product, and even T-300 in some cases. And

RFP equipment acquisition success in details

BY MATT POE, EDITOR

BY MATT POE, EDITOR

ATLANTA — When it’s time to purchase new laundry equipment, either to outfit a complete laundry system or as an upgrade, how do you go about it?

That’s an important question. Once you’ve identified your goals regarding the equipment purchase, you could talk with vendors to find the machines you need to do the job.

The problem with that is that verbal requests and instructions and specifications can be misunderstood or not remembered correctly later on.

By submitting a written request for pricing/proposal (RFP) to vendors, you are better assured that you will be purchasing the right equipment for your company—the equipment to meet your production and operational goals.

Gerard O’Neill, president and CEO of American Laundry Systems, a division of E&O Mechanical, discussed, in depth, equipment RFPs and their importance and value during his recent Clean Show seminar titled The 411 on Equipment Acquisition

The following advice comes from that presentation and can help you

put together a more effective RFP the next time you need to purchase equipment.

GET IT IN WRITING

While it may seem obvious, if you don’t go through the RFP process, you can’t reap the benefits. O’Neill stresses that verbal instructions and proposals are not adequate.

“This will come back to haunt you,” he says.

At every point along a verbal trail, there is the chance for someone—including you—to forget some detail. That can lead to problems later on.

According to O’Neill, when handled correctly, an RFP can clearly detail the parameters of the project in terms of finances, benchmarks, expected outcomes and results sought.

“The proposals provide a basis for choosing among seeming equals,” O’Neill says. “The RFP and subsequent analysis of the RFP results will quickly show that not all are created equal.”

Also, the information provided by vendors in a written proposal, including its organization and level of detail, can reveal the quality of a

Panel of Experts

Leadership, from the CEO to lead

can be

A UGUST 2015 Late News

www.americanlaundrynews.com Volume 41, Number 8 INSIDE [12] [14] See TRENDY on Page 6

The Newspaper of Record for Laundry & Linen Management

employees,

found and trained.

[4] See RFP on Page 4

Columnist at Large How does washroom chemistry factor into good laundering?

Industrial uniforms and chef apparel are becoming more colorful. (Image licensed by Ingram Publishing)

CHICAGO — When it comes to knowing how to do their job, laundry managers and operators are confident in their industry knowledge.

That’s what most respondents indicated in July’s American Laundry News Your Views survey.

In fact, 41.5% of respondents believe that they are “more knowledgeable than most managers and operators” in the industry. Only 14.7% say that they are “extremely knowledgeable,” while 26.8% of respondents believe that they are on equal footing as their peers when it comes to being in-theknow about the industry.

The survey revealed several sources of industry knowledge for managers and operators.

Nearly three-quarters of survey respondents (70%) have “attended or participated in an industry-related educational session.” These sessions have included webinars, service schools, and conference sessions and seminars.

Several respondents indicated that they prefer live events.

“I prefer educational sessions,” writes a respondent. “Webinars are fine for brushing up on current trends.”

Another agrees: “Live presentations where audience participation is active is most effective for me.”

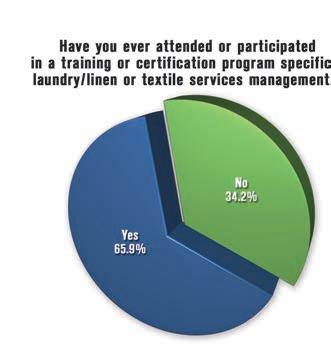

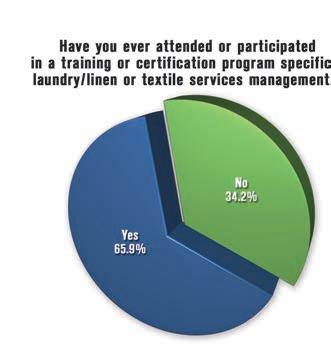

Roughly two-thirds of respondents (65.9%) have “attended or participated in a training or certification program specific to laundry/linen or textile services management.”

About 58.3% of those who took the survey have been certified. Among them are the Association for Linen Management’s (ALM) Registered Laundry and Linen Director (RLLD) and Certified Laundry and Linen Manager (CLLM) certifications, as well as the Textile Rental Services Association’s (TRSA) Maintenance Management Institute (MMI) certification.

For some respondents, their knowledge comes not only from education, but also from experience. “I have CLLM, RLLD and 24 years experience in the laundry industry,” writes a respondent.

Managers and operators who don’t take part in continuing education do a lot of reading, according to survey responses. Another popular option is networking with other managers and operators.

“I meet with a group of four to six operators,” writes a respondent. “We

meet monthly to discuss issues and concerns.”

However, some of those who took the survey aren’t too concerned about formal education. One respondent writes, “Self education to be the best works for me.”

Another writes, “The industry doesn’t change that much. There are products that are considered by their manufacturer to be innovative that never catch on.”

While the majority of managers and operators who took the survey are confident in their industry knowledge, 14.6% believe they need to “brush up on a few things.”

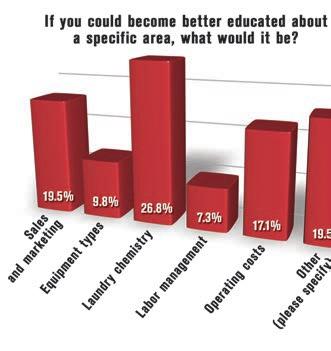

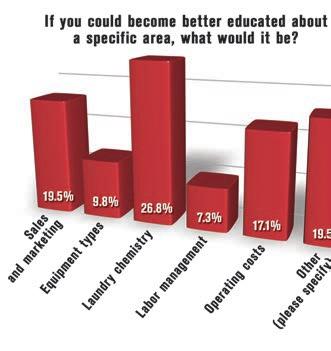

Laundry chemistry (chosen by 26.8%) is the leading area of which respondents believe they need to learn more. Sales and marketing education came in at 19.5%, while 17.1% of respondents want to learn more about operating costs.

Other areas mentioned include computerized management systems, leading from the CEO level, and safety. One respondent writes, “I want to know more about all of them. I have a thirst for knowledge. After 26 years in the industry, I am still learning new things.”

“All of it,” agrees another respondent, “but I think service is the big training need for all.”

Much of the service-oriented aspect of the laundry business is carried on by employees—those running the machinery and the delivery service. A large number of respondents (75.6%) believe that education and training for employees is “extremely valuable.”

And perhaps that’s a good thing for the 2.4% of managers and operators who say they’re “so busy running my operation that I don’t have time to learn about the industry.”

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online each month. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 231-740-2842

E-Mail: mpoe@ ATMags.com

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

Jim Buik • Richard Griffin

Greg Gurtler • Phil Hart

Janice Larson • Tom Marks

Gerard O’Neill

Richard Warren

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00.

Single copies: U.S. $7.00; Foreign $14.00. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 41, number 8. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2015. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

2 AUGUST 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Association for Linen Management

ALN INSIDE: August 2015 • Vol. 41 | No. 8 [4] Chapter 6: Changing Washroom Formulas Columnist at Large Eric Frederick continues his series with a look at washroom chemistry [8] Luxurious Linens at The ART In this month’s OPL 101 column, learn how a new hotel in Denver is preserving its high-quality linens [10] Berks Heim Finds Savings with Ozone Pennsylvania long-term healthcare facility installs system serving continuous batch washer, three washer-extractors [12] Panel of Experts: Who’s Taking the Lead? “How do you fill leadership roles, from the CEO to the floor supervisor? Employees who could become leaders?” [14] Product Showcase: Linen/Garment Transport Manufacturers provide a look at various equipment for moving linens, including carts, trucks, conveyors and monorails [19] Trade Ticker [20] Classified Advertising [21] Source Directory Survey: Laundry/linen managers confident in their industry knowledge

help to better define operator opinions and identify industry trends.

“

They have done everything they promised and more.”

– John Ambrose Magliocco, Arrow Linen, Garden City, NY

From

Arrow Linen first purchased their three Milnor CBW® tunnels two decades ago to replace conventional washer-extractors in their original laundry located in Brooklyn, NY. Since then, Arrow’s business grew to warrant a second laundry. In 2013, Arrow expanded operations–and raised their roof 11 feet! Arrow could have chosen any manufacturer to equip their new washroom, but they knew that would get longevity, durability, and accountability with Milnor.

Arrow’s customers’ restaurant linen requires frequent color and soil change formulas, but the quality is not compromised. Corporate Engineer Frank Park boasted the tunnels “have increased our workload over 40% without increasing energy, water, or labor costs we experienced when we converted the conventional washers to CBW® tunnels over 20 years ago. The major improvements from the CBW® to PBW™ are far superior washing capability with only 50% water consumption.”

To find out how PulseFlow® can cut your water bill in half, contact an authorized Milnor distributor or call 504-712-7656.

www.milnor.com / pellerinmilnor

Scan to read Arrow’s success story.

left to right: Frank Park, John Ambrose Magliocco, Ron Hirsch, and John Anthony Magliocco

Form, fashion meet function

I’m often impressed by the versatility that’s required of today’s laundry operation. The type of goods that a plant processes, or is going to process, affects its production efforts on the most basic level.

Traditional linen products such as tablecloths, napkins, sheets and pillowcases are handled much differently than industrial goods like uniforms, mats and shop towels, for example.

As textile manufacturers work to find newer and better materials to make their products more effective for end-users, Editor Matt Poe writes in this month’s cover story, that means changes in how the textiles are laundered.

RFP

vendor, according to O’Neill.

THE DETAILS

Vendors need as much detail as possible from you in order to put together a proposal. This can help prevent revisions and changes later on in the process.

“Not enough details equals not enough, or incorrect, information back from the vendors,” says O’Neill.

How far should you go when it comes to details? “Show [vendors] everything, he says.

His list of items to request includes many factors vendors need to make a RFP that is right for your company.

Vendors need to know how big the area is for the equipment. They need to know what your goals are for the equipment. They need to know if infrastructure connections are part of the RFP. They need to know the potential issues at the job/ delivery site. They need to know dates and schedules.

Another area that may seem obvious, but can be overlooked, is

The Director’s Chair BRUCE BEGGS

In hospitality, image upgrades are becoming the standard, with more and more properties offering high-thread-count bed linens. Following guidelines to process

these delicate, expensive goods is a must.

In serving the uniform market, textile makers are doing their best to create apparel that’s not only functional—it affords the wearer comfort and high visibility, for example—but is also stylish.

As Milliken’s Brenda BurrisDrake tells Poe, “Form and fashion must meet the functional requirements.”

And so our cover story examines the new trends seen by textile manufacturers, along with how these trends will impact laundry operations now and in the future.

New, high-performance textiles influence everything from chemistry to load sizes, it seems. ALN

mean, however, that you are creating the design when it comes to your new equipment.

“Do not pretend to be the expert,” O’Neill says. “Highlight your needs and let the vendors do the work. Sometimes, there are advances that you don’t know about.”

CHECKLIST

Changing washroom formulas

Washroom chemistry has always been an area I really enjoyed. Perhaps it is because my father, Kenneth Jacob Frederick, is the research scientist who first discovered dry bleach. He was assigned this project while working as a research chemist during World War II. I have always believed that the most effective way to wash linen is to do it right the first time (see Penny-wise and pound-foolish II, February issue).

There are four basic elements to washing: chemicals, time, temperature and mechanical action. When you decrease one of these items, you often have to increase one or more of the others to compensate. Trying to wash faster and at the lowest possible chemical cost will dramatically increase the amount of rewash in the laundry, labor costs and linen replacement costs. Since labor, linen and utilities are your three biggest costs, it makes sense to develop a wash formula and chemical usage pattern that protects your investment in linen and the efficiency of your labor force and makes appropriate use of your utility inputs.

who at your laundry is the vendor’s contact?

Contact information is important, says O’Neill, adding that you don’t want a vendor talking to several different people in the company and possibly receiving conflicting information. O’Neill suggests no more than two contacts from your company.

A practical piece of advice for submitting an RFP O’Neill shares is to provide vendors with a layout/ sketch of the area, or to put together a preliminary design to go with the RFP instructions. That doesn’t

O’Neill suggests providing a “classification list” in terms of equipment. That means providing the vendor with information such as the pounds or pieces you want to process, how many days of the week the equipment will be in operation and how many hours it will be in use, depending on the type of equipment you are purchasing.

For each piece of equipment you’re looking at, provide the vendors with an RFP checklist so that you both can be sure that the vendor is providing all of the information you need.

For example, O’Neill shares a checklist for material handling, washroom equipment, process water system, boiler system, water softener and finishing room equipment. Items for the vendor to provide include mini-

See RFP on Page 19

The first flush on a wash formula is probably the most important step. The temperature of the first flush should be 100-110 F. The reason for this is that blood and other bodily fluids are most soluble at this temperature. Contrary to the old wives’ tale that blood should always be rinsed out with cold water, blood’s solubility actually increases as the temperature warms. But once it reaches 120 F, it sets into a hard-to-get-rid-of stain. Adding a small amount of alkali to the first rinse will also prevent blood from becoming a stain.

The wide use of chlorhexadine gluconate in healthcare has made the first rinse the battleground for removing this potential stain. This hand/wound cleanser is an iodine-based product that in the presence of heat and chlorine will form a permanent brown to yellow stain on the linen. It is impossible to detect the presence of this product on linen before washing.

The good news is that it rinses out quickly and completely in the first flush that is below 120 F and does not contain chlorine. The bad news is that most municipal water supplies contain enough chlorine to activate the stain.

To combat this problem, a number of smart launderers have started adding hydrogen peroxide or an antichlor to the first rinse. Both products will effectively eliminate the presence of chlorine and allow the chlorhexadine gluconate to rinse out of the fabric.

The better your control in the first flush, the fewer the stains that will be generated. You will know if you are making progress on the chlorhexadine gluconate by the color of the stain. The darker the color, the less effective you are. If the stains you are getting are progressively lighter in color (light yellow), then your procedures need just a little tweaking to eliminate the stain.

The rest of the wash formula needs to be determined by the type of fabric you are washing. I wash 100% cotton fabric and fabric blends differently than I do 100% polyester linen. Take care to understand the processing needs of each type of fabric and to make sure your soil-sort classifications take these differences into account.

When I started in the laundry business back in 1973, the majority of our linen items were 100% cotton and made in the USA. This 100% cotton linen washed with natural tallow-based soap, which was ideal for cleaning these fabrics. During my career, I have seen the rise of cotton/poly blends and some 100% polyester bedsheets. I have seen the rise of microfilament barrier surgical linen. Every innovation has required a change in the way we wash.

We managers needs to stay abreast of changes happening to the items that we are asked to wash, and we must be willing to change wash formulas as needed to properly process the textiles.

Next month, I will continue to explore this topic, writing specifically about reusable barrier surgical linen and incontinent pads. ALN

Eric Frederick is director of laundry services for Carilion Laundry Service, Roanoke, Va., and a past president and manager of the year of the Association for Linen Management. You can reach him by e-mail at efrederick@carilion.com.

4 AUGUST 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

From

COLUMNIST AT LARGE Eric L. Frederick, RLLD

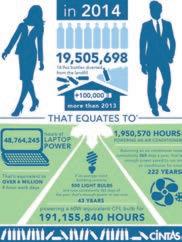

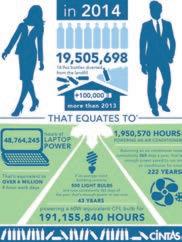

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending July 15 (WE) = WEB EXCLUSIVE NEWS • Cintas Converts Plastic Bottles into Apparel • Operations Camouflage Army Combat Uniforms Available (WE) • TRSA’s Annual Conference to Connect Generations • Laundry Plus Earns Continental Business Partner of the Year... (WE) • Huebsch Names Gulf States Laundry Machinery ... (WE) COLUMNISTS/FEATURES • Embracing Essence of Customer Service • Inner Workings of a Las Vegas Linen Company • Eric Frederick: Chapter 5: Soil Sorting for Greater Efficiency • Right Vehicle Can Boost Laundry Operation Effectiveness • OSHA Reality Check: Is Your Facility Safe? OUR SISTER WEBSITES From AmericanDrycleaner.com: • Anton’s Collects, Cleans ‘Belle of the Ball’ Prom Dresses (WE) • StatShot: Regions Split on May Drycleaning Sales (WE) From AmericanCoinOp.com: • Five Considerations When Acquiring a Laundromat • IPSO Names Steiner-Atlantic Its 2014 Distributor of Year (WE) (Image licensed by Ingram Publishing) Continued

Page 1

CHAPTER 6:

from

Villa Di Borghese™ hospitality products are fashioned from the finest materials; meticulously designed to capture an exquisite sense of Italian beauty, fashion and style.

collection

The gold standard in textiles; including towels, bath robes & slippers, sheets & blankets, basic bedding, table linen and apparel. Deep inventories. Immediate Shipping.

Made In USA Signature Plus™ fabric out performs all challengers in elegance, soft touch, color consistency and soil/ stain release. American Dawn and Milliken... setting the standard of table linen excellence.

®

SOLUTIONS

ADI - American Dawn manufactures, imports and distributes textiles for hospitality markets worldwide. ADI offers textile collections in bath, pool, kitchen, bedding, robes and table linens; as well as top of the bed accessories including duvet covers, bed scarves, matelassé and decorative pillows.

HOSPITALITY

hospitality@americandawn.com | 800 821 2221 | americandawn.com

Trendy

there’s a lot more in ring-spun special dobbys in the toweling.

“The reason for that is that Americans are not vacationing overseas like they used to. There’s a lot more of America vacationing in the U.S.,” he says. “Where it used to be it was just incidental travel or business travel, now you have vacation travel in the U.S., and when somebody goes from Iowa and stays in a Hampton Inn, they want to feel like they’ve gone on vacation.”

The cost of the T-250 tonal and the highend dobbys may be a little more for launderers in terms of processing because the heavier the towels, the less you can put in the wash wheel. However, these products are garnering more money, notes Kallenbach. How? More and more hotels are using the higher-end products.

The big change for launderers is greater separation of products. Kallenbach says the way for laundries to make these textiles profitable is to have enough to separate them in the wash.

INDUSTRIAL

Regarding the industrial textile market, Brenda Burris-Drake, vice president of Marketing Communications in the Specialty Fabrics Division of Milliken & Co., sees a move to deliver performance benefits to consumers in the uniform markets. These benefits require unique fibers, dyes and chemicals that are all part of textile engineering. She adds that Milliken builds its fabric constructions with the laundry market in mind.

“With more cellulosic-containing fibers used in our uniform markets, we are adding in performance features that improve textile’s ability to stay clean, release stains, resist abrasion, and other types of advanced engineered designs that will work with future washing technologies,” says Burris-Drake.

The way ADI American Dawn is seeing industrial textiles change, according to Kallenbach, is growth in the Hazard Analysis and Critical Points (HACCP) management system textile market for food manufacturing with spun-poly cover garments.

In particular, he says, spun-poly items like lab coats are being made with special cuffs that have grippers instead of buttons. Also, there are many specialty products being made for differentiation of departments within large HACCP manufacturing companies.

“For instance, you go into a Frito-Lay manufacturing plant, and they want five different colors for the five main departments,” Kallenbach says. “Maybe they want a white coat with a blue cuff and a blue collar. That type of market is becoming bigger and bigger to the point that, in our case, we’re actually stocking a HACCP line for the first time.”

In terms of processing, Kallenbach doesn’t see any difference in the methods used for the HACCP and spun-poly cover garments—just that they last longer.

“An example of that is a 65/35 lab coat or an 80/20 lab coat lasts about 50 washings,” he says. “A spun-poly version of the same thing lasts about 80-100 washings.”

FOOD AND BEVERAGE

Just like industrial textiles are becoming more differentiated, Burris-Drake and Milliken sees the food and beverage market moving toward unique patterns and color designs.

“But of course, in the laundry, consistency is key. Form and fashion must meet the functional requirements,” she says. “ColorSeal™ is one of our technologies that helps seal the color to the textile, which helps improve the fastness of the color through industrial laundry and bleaching. In fact, our Signature color consistency has been proven as some of the best color consistency in the market.”

Burris-Drake notes that even with a variety of designs and colors, the way the company engineers the products allows for mass customization without specialized processing.

Kallenbach and ADI American Dawn also see more colorful options when it comes to chef coats and cook shirts.

“In the past 50 years, that’s just been all white,” he says. “In the last 10 years, you’ve seen the introduction of black coats and trims and chef coats with black and white and some other trims, and you see a lot of the baggy pants with stripes and checks and such.”

Kallenbach says that laundries will have the same kind of separation as seen in industrial uniforms—light colors, dark colors and whites.

“What will happen in laundries as they get into color chef apparel, they’ll probably have to run it in a smaller machine,” says Kallenbach. “Will it cost a little more? It probably will at first. But as they get to critical mass, it won’t cost any more, because it will be at full load.”

Another change that Kallenbach notes over the last five to six years is the emergence of microfiber bar towels/mops. He estimates that 40% of the market is now microfiber, replacing cotton.

“They last much longer, they are bleachresistant, and they’re just a nicer presentation to the customer,” he says.

In terms of processing, Kallenbach says that the microfiber bar towels wash in about the same amount of time as a cotton bar towel; however, one can put about 40% more microfiber bar towels in the wash wheel. Even though some of the chemistry may cost a little bit more, because of the maximization of wash yield, the cost comes down significantly.

“Particularly in the dryer, cost comes down significantly,” he says. “Not only can you put more towels in the dryer, it just takes a lot less time to dry.”

Finally, in the food and beverage area, Kallenbach and ADI American Dawn see a big opportunity for 12-inch by 15-inch napkins, as opposed to a 21-inch by 21-inch dinner napkin. He sees more Americans becoming savvy to the environmental effects, and companies and restaurants are looking for other options, ways to upgrade themselves.

“We see that becoming the first opportunity for a rental laundry to rent a 5-cent napkin and actually make money,” he says. “We see that as a possible game changer in food and beverage, and that’s just entering the market right now.”

Launderers can put about 40% more lunch napkins in a wash wheel, so the cost is much less than processing a dinner napkin. They both last 80 to 100 cycles, but the cost of acquisition is much less.

“What it should do at that time is it should raise the amount of laundering they’re doing, because this is a new, virgin market they currently don’t have,” says Kallenbach.

HEALTHCARE

The textile market that is probably seeing the most change and innovation is the healthcare market. From bedding to scrubs, manufacturers are providing more high-performance, synthetic products for hospitals

and other healthcare facilities.

“The kind of things we’re focused on at MIP are products that have impact on patient outcome,” says Mann. “That would be bedding, patient wear—anything that’s on the bed, anything that comes in contact with the patient’s skin, including patient wear.”

The company has also made changes to caregiver textiles, and it’s been a long time since any improvement has been made in that area, he says.

“As you improve on one side of the house, you need to improve on the other side of the house, or the laundry is not going to pick up 100% of the efficiency,” he says.

The shift in all of these products, according to Mann, is toward high-performance, synthetic textiles. The change for launderers is that high-performance textiles are lighter.

“Laundries are going to have to make a shift,” he says. “Hospitals are going to demand it, and there will have to be some acceptance on the cost associated with that.”

Mann says that because the textiles weigh less, the laundries will be much more efficient in how many pieces they can push through the facility in a given day or shift. The associated costs in processing from an equipment side are not going to go down, he says, but what will go down for laundries is the amount of time they spend.

“Say you’re using reusable underpads. Old-technology reusable underpads could weigh as much as a pound and a half. Which means you take 110 pounds, divide it by a pound and a half, and that’s how many pieces are going to be in the chamber of that tunnel,” says Mann. “New-technology weighs less than a pound, so you’re gaining about 50% capacity just by moving to hightech product, which means you’re going to put more pieces through your system, at least in the wash system, than you would with the old-technology.”

He says the high-performance textiles will require fewer chemicals to process because less rewash will be necessary.

“They don’t stain like natural fibers do from all of the things you can imagine that come into contact with healthcare linens. It will wash out easier,” Mann says. “There will be far less rewash.”

Kallenbach and ADI American Dawn also see healthcare textiles trending away from blended scrubs and blended bed linens to 100% poly scrubs and bed linen. He says

that the laundering formula for the latter is basically the same except for some tweaking with regard to chemistry. The difference he sees is that the poly lasts longer.

“The cost of merchandise will go down for the launderers as a result of the conversion from blended scrubs and bed linens to poly scrubs and bed linens,” says Kallenbach.

Another product line gaining traction is microfiber room-cleaning products. It has become fairly standard that hospitals use microfibers to clean rooms because of the antimicrobial nature of the products.

“We believe that through self-policing, if you will, we actually think that the healthcare industry will be writing guidelines in the next five years that will pretty much dictate that room cleaning be done with microfiber of some sort,” Kallenbach says.

For on-premises laundries, especially in nursing homes and long-term healthcare facilities, ADI American Dawn sees an emerging market for knitted products, because most of the laundries in those facilities don’t have ironers.

“With the new knitted and fitted products for long-term care, the difference in that is really finishing,” Kallenbach says. “Right now, long-term care facilities have a small laundry facility and they wash them and dry them, they don’t press them, and they don’t look all that great. Knitted products really come out looking wonderful.”

He also sees knitted products for longterm care facilities becoming more attractive to laundries that don’t process healthcare goods.

“This is not acute care; it’s just long-term care,” says Kallenbach. “It doesn’t typically have the blood work. So, where you have a laundry not in healthcare, say, in food and beverage, and they can do some isolation in their soil area, they can get into this type of product without adding ironers because it’s just wash and dry.”

Change continues to take place in the textile industry, and Burris-Drake has some advice for laundries to help them be able to serve their customers: work with the suppliers.

“We would recommend that launderers understand the textile products they purchase by working closely with their suppliers,” she says. “It is good that launderers get process and product training offered in the industry and use resources available to them.”

6 AUGUST 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ALN Continued

Page

from

1

Healthcare facilities are moving toward high-performance, synthetic linens and garments for both patients and caregivers. (Image licensed by Ingram Publishing)

TWO ARE BETTER THAN ONE.

Happy with the productivity, efficiency and flexibility of his first Girbau Industrial (GI) tunnel system, Rick Rone of Laundry Plus maintains the decision to invest in a second identical system was a no-brainer. He likes the security they bring.

By adding a second GI tunnel system and moving equipment from two buildings into one, Rone enjoys streamlined production. The new plant – with its arsenal of high-performance equipment – opens the floodgates to new business, ensures backup in case of a mechanical failure, and allows Rone to launch a new linen rental program.

Since moving to the new plant and installing its second tunnel, another ironing line and additional open-pocket washers, Laundry Plus has boosted pounds of laundry per operator hour (PPOH) by 15-18 percent.

LAUNDRY SOLUTIONS FOR WET

ON-PREMISE

CONTACT GIRBAU INDUSTRIAL TO SEE HOW WE CAN INCREASE YOUR PPOH!

CLEANING,

& INDUSTRIAL LAUNDRIES

Rick Rone

www.girbauindustrial.com • (800) 256-1073 INDUSTRIAL

Laundry Plus, Bradenton, Florida

At Denver’s newest independent hotel, luxurious linens are key

BY DAVID BODETTE

BY DAVID BODETTE

DENVER — If you’ve ever spent the night—or simply ventured inside—a boutique or luxury hotel, the aesthetic touches and décor likely made an impression. From tablecloths in the restaurants to plush terry robes and the subtle pops of color on down comforters, each element is carefully selected to enliven the senses, while creating a first-class experience.

Lisa Litke knows better than anyone the impact thoughtfully procured elements can have in providing guests with a memorable stay. Litke is director of purchasing for Commonwealth Hotels Collection, a hotel management company that oversees hundreds of hotels nationally.

“Coordinated design elements provide that ‘wow’ factor from the time visitors and guests walk in the front door, all the way to their rooms,” she says. “They tell a story that translates throughout the entire hotel.”

Litke has helped with purchasing efforts for dozens of hotels during her career, but perhaps one of the most exciting has been one of Commonwealth’s newest properties, The ART: A Hotel, here in Denver. The independent hotel opened in mid-June, yet preparations to bring it to life began more than two and a half years ago. Architects, designers, buyers and managers were all responsible for ensuring The ART was built and outfitted with materials that would ensure a luxurious, unforgettable guest experience.

these premium materials.

“We have built a modern hotel filled with the best materials money can buy,” Snyder says. “There was no question we would equip the laundry room with dependable machines that will protect their life spans, while also allowing us to easily meet very specific processing guidelines.”

These guidelines include maximumtemperature recommendations during both washing and drying, specific wash formulas and desirable pH-level ranges. The recommendations are followed in order to maintain the integrity of the fabrics and the investment. For example, the hotel’s bath towels should be dried at no more than 160 F, while bedding should be heated to no more than 140 F. Thanks to the hotel’s advanced laundry equipment, meeting these requirements isn’t burdensome.

PRESERVING LUXURY

Equipped with three high-performance washer-extractors and three industrial tumble dryers, The ART’s on-premises laundry (OPL) has capacity to wash 325 pounds of laundry and dry 415 pounds at any given time. And, because these machines are networked to the equipment distributor, hotel managers have peace of mind that a laundry expert is clued in to the operation, even from many states away.

“From my computer in Kentucky, I can view information about each machine’s performance and cycle usage, to ensure staff are selecting the proper cycles that won’t damage the premium linens,” says Mark Moore, vice president of REM Company Inc., a distributor of UniMac® laundry equipment. “I also receive error codes, in the form of an e-mail or text message, should a machine detect improper usage.”

INSPIRED DESIGN

Located in the heart of the local museum and cultural district, the décor inside The ART complements its namesake and surroundings. In addition to the common areas that double as art galleries, each guestroom floor is inspired by a particular artist, whose style translates throughout each room and into the hallways. The room décor is curated to match the experience, with luxury touches and amenities that complement the artwork, playing off the artist’s color scheme and tone.

Multiple vendors were utilized to ensure each element of the hotel provides a oneof-a-kind, multi-sensory experience. This includes satin sheets and pillowcases, terry towels woven from the finest cotton, and even table runners and napkins imported from France.

According to Gordy Snyder, president of Commonwealth, it was critical to build and outfit a hotel laundry that would protect the investment in, and lifespan of,

For example, if a maximum-temperature guideline is exceeded, Moore or designated staff at the hotel immediately receive a notification. They can also view information such as machine utilization and operating expense and use the information to advise housekeeping supervisors on ways to improve efficiency.

“The ability to customize cycles and track machine usage, along with having an expert distributor to lean on for guidance, is invaluable,” says Snyder. “It allows us to be more efficient in the laundry room, leaving more time to focus on providing superior service and accommodations to our guests.”

Another critical feature to preserving the hotel’s investment in quality linens is over-dry prevention technology on tumble dryers.

This technology prevents the over-drying—and thus degradation—of linens. The dryer stops precisely at the desired dryness level, leaving just a small percentage of moisture. This keeps fabrics soft and plush rather than becoming rough and stiff from being excessively dried. This reportedly can result in 31% less fiber loss when compared to machines without the technology. Snyder says this technology also improves staff productivity, because it prevents staff

from making educated guesses about dryness level. They can process laundry and linens much more quickly when cycle times are exact.

CURATED EXPERIENCE

Whether you’re a weekday business traveler or Denver local stopping in to enjoy the hotel restaurant or lounge, it’s easy to see— and feel—the thoughtful touches that go into setting a luxury hotel apart from the rest.

“There is a substantial difference between the investment we make when purchasing items for a property in the luxury hotel segment, versus one in another,” says Litke.

“We’re attracting travelers looking for a specific experience and premier accommodations. In this case, the goal is to provide something to be admired at every turn.”

Another notable benefit relates to the hotel’s bottom line and level of guest satisfaction.

“You take tens of thousands of dollars worth of linens and destroy them in two months time, and you’re out of business,” Snyder explains. “Our laundry equipment maintains the luxury touch that will still impress guests a year or more from now.”

While guests might not understand the vital role the laundry room plays in maintaining this atmosphere day in and day out, those in the hospitality industry know it deserves admiration entirely of its own.

David Bodette is general manager of The ART: A Hotel, Denver. He has more than 30 years of experience in the hospitality industry.

For more information on UniMac, visit www. unimac.com/OPL101 or call 1-800-587-5458.

8 AUGUST 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

OPL 101

ALN

Linens used in guestrooms are processed in order to preserve the luxury of the items. (Photos: The ART: A Hotel)

“I CAN VIEW INFORMATION ... TO ENSURE STAFF ARE SELECTING THE PROPER CYCLES THAT WON’T DAMAGE THE PREMIUM LINEN.” —MARK MOORE, REM COMPANY

LAUNDRY EQUIPMENT MAINTAINS THE LUXURY TOUCH THAT WILL STILL IMPRESS GUESTS A YEAR OR MORE FROM NOW.” —GORDY SNYDER, COMMONWEALTH HOTELS

Every textile in The ART has been selected to provide a multi-sensory experience, hotel management says.

“OUR

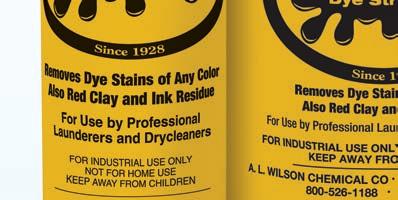

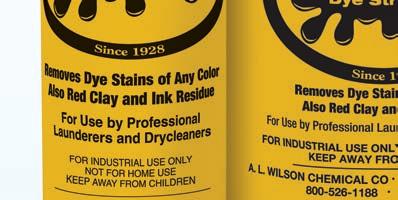

Results on whites are excellent. On colors, you have nothing more to lose and everything to gain by trying YellowGo. YellowGo may take out color you want to keep. But if it removes the unwanted dye without damaging the underlying color, you win! You won’t have to pay for the dye-stained garments and you won’t disappoint your customers.

So use YellowGo to keep your customers happy and keep them coming back.

information visit

or

or

YellowGo® removes unwanted dye from fabric. For more

AlWilson.com

call us at 800-526-1188

201-997-3300

READING, Pa. — The administration of Berks Heim Nursing and Rehabilitation, a long-term healthcare home here in Berks County, strives to provide the best available treatment and care at the most economical levels of service costs.

When Berks Heim investigated energy- and utility-cost savings as a long-term project for operations and cost reduction, it looked to an energy service company that also provided extra service for its inhouse laundry system.

The administration eventually contacted Wet-Tech, a Massachusetts company with a long-term affiliation with energy service companies, and it was decided that Wet-Tech would install an ozone system.

Berks Heim’s 420-bed facility is located in a stand-alone development surrounded by a parklike setting in the Pennsylvania countryside. The home takes an individualized approach to healthcare and quality of life, with the emphasis being on the social, emotional and physical well-being of its residents.

There are some major benefits that can be derived through the application of ozone in a laundry operation, especially when patient/ guest care is paramount, according to Wet-Tech.

“I was not a fan of ozone at first, but the cost savings is worth it,” says Steve Valk, who directs Berks Heim’s laundry and environmental services. Though owned by the local municipality, Berks Heim chose to outsource those services to Aramark, and Valk serves as on-site manager.

The laundry is equipped with a six-module tunnel washer, a 450-pound washer-extractor, plus 55-pound and 95-pound washerextractors for small, general loads.

In the summer of 2010, a total of four ozone generators were installed on the equipment. Although there were four generators involved, Wet-Tech was able to accommodate them in two

wall-hung cabinets thanks to their modular design.

The EnviroSaver II’s major thrust was to achieve maximum benefits through the continuous batch washer while producing high volumes of laundry. The application of ozone into the wash water works as a disinfectant comparable to chlorine bleach, according to Wet-Tech.

Wet-Tech uses ozone and chlorine to achieve a high level of “good-quality, clean, disinfected, odor-free linen” in the wash process, the company says. The ozone application in the final bath helps to reduce use of a sour and softener, saving on chemical costs while also providing “chemical-free” linen for patient/guest care.

“Our chemical costs have gone down,” Valk tells American Laundry News, although he didn’t specify to what extent.

By reducing chemical residue in the linen, the laundered goods provide a more comfortable “feel that does not irritate the skin when sleeping on it,” WetTech says. The approach of using chlorine bleach for stain removal and ozone as the antichlor gave Berks Heim the ability to extend linen and ironer pad life “by a significant amount,” the company adds. Further, the lack of chlorine reduced the exposure of goods to the potentially destructive qualities of heated chlorine during drying, thereby extending product life.

Wet-Tech says it worked with the facility’s chemical supplier, Ecolab, to affect changes to Berks Heim’s wash procedures.

The high oxidation power of the ozone enabled the facility to reduce wash temperatures in the continuous batch washer from 170 F to 110 F, Wet-Tech says. With a production level of 12 loads per hour or 90 loads per day (5-minute transfer cycle), that would relate to fuel savings of about 22,968 therms per year.

“I don’t have the statistics, but when you’re washing at 100 degrees instead of 160 degrees,

it makes a difference in energy costs,” says Valk.

Installing the ozone system also served to reduce the laundry’s washwater flow by about 25%, which saves roughly 12 gallons per minute, according to Wet-Tech. Using the same 90-loads-per-day throughput, that equates to 5,040 gallons per day or 1.3 million gallons per year.

But the greater benefit of the ozone application, according to Wet-Tech, is the disinfection qualities of the oxidation process.

This disinfection helps to remove the possibilities of cross infection while the linen is being processed. Ozone destroys MRSA as well as other bacteria such as cryptosporidium, E. coli, fecal coli, salmonella and other “challenge organisms,” Wet-Tech says.

The Environmental Protection Agency has determined specific CT values of a product’s disinfection concentration and the timeline for the effectiveness of the bacterial inactivation. As an example, chlorine dioxide at a CT value of 226 with one minute of contact time at 25 C would be required to inactivate cryptosporidium at 99.9%, Wet-Tech says.

To achieve the same inactivation of the same bacteria under the same conditions with ozone would require a CT value of 7.4, the company adds. This process of bacteria kill, along with the oxidizing power of attacking organic and inorganic materials, reduces wastewater contaminants.

Ozone works to eliminate some solids as well as reducing fats, oils and grease (FOG); biological oxygen demands (BOD); and chemical oxygen demands (COD) on the treatment system by reducing these items in the wash.

After five years of the ozone system’s continuous operation, Berks Heim has signed on for yearly service to maintain its performance level.

“Once a year, they come out and do preventative maintenance on it,” says Valk. “That’s it.” ALN

10 AUGUST 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ECWS Plug-N-Play Selling Customer Service FIRST! • OEM Distributor for RBI Water Heaters • 24/7 Technical Support • Laundry Consulting • Serving Commercial Laundries and Prisons across North America and the Caribbean We offer: • Hot Water Heaters 199-6 mil btu • ECWS Hot Water Storage Tanks • Water Softeners • Pre-plumb packages Call us for a quote using our SizeNet sizing program Phone: 1-866-513-7170 www.eastcoastwatersystems.com Fax: 843-225-6258 0415aln_ECWS ad.indd 1 4/13/15 2:33 PM Berks Heim finds energy and chemical cost savings Wash temperatures used by Berks Heim Nursing and Rehabilitation have been reduced thanks to the introduction of a Wet-Tech ozone system. (Photos: Berks Heim/Wet-Tech) Ozone generators were installed to serve a continuous batch washer and three washer-extractors. The greater benefit of an ozone system, says Wet-Tech, is its disinfection qualities.

XXL POWER. XS OPERATING COSTS.

Designed to stand up to the demands of your delivery business, the S2G LPG Commercial Truck is the only factory-installed 8.0L liquid propane system on the market. Backed by the nationwide service network and 24/7 Direct support only available from Freightliner Custom Chassis Corporation, it offers lower operational costs, lower emissions and powerful performance. All so you can upsize the savings of a real work truck.

A REAL WORK TRUCK. 1-800-FTL-HELP | S2Gtruck.com For ordering details, contact your

local Freightliner dealer.

There are many different things that make managers and supervisors successful. And, many different things are considered to choose employees to promote. But, I think a lot of these reasons are a distraction from the most critical considerations.

For example, I’ve seen many people at various businesses promoted because they were good employees. It seems logical to promote your best workers. To this concept, I say, “Maybe.” You might have someone who excels at their current tasks, but this doesn’t prove they can excel at management. They may or may not have the temperament and patience to deal with all the problems of leadership.

Many times, education is a big consideration for a position. That seems like a reasonable assumption. Again, that’s not always true. Just because someone has had the determination and intelligence to get more education doesn’t prove their leadership abilities. They may or may not have the vision to solve problems and improve processes or production situations.

Experience is another consideration. The supposition is that lots of experience teaches people things. Length of service to one’s

PANEL OF EXPERTS

Who’s taking the lead?

employer is important, and loyalty is certainly a consideration. And, while I’ve heard it said that good leaders are born, there are many training companies that run lots of classes trying to teach leadership.

So, how does one choose a good supervisor or manager? It does take someone with a lot of the described attributes to make a good leader. My advice is to certainly consider all these things, but I’m a big believer in character and attitude as being the most important factors.

Character and attitude are developed over one’s entire life. They are the hardest things to change about a person. You can teach them skills, explain procedures, set goals, etc., but you can’t change someone’s character or attitude easily.

Watch how candidates interact with their fellow employees. Are they industrious, consistent and conscientious? Do they get along well with everyone? Do they offer suggestions to improve things that are rational and reasoned toward improving things, not just making their job easier? Is this person honest, polite and kind to everyone? Are they organized and dependable? Do they understand the purpose of your company and what makes it successful?

Get to know all your employees well. Talk to them; observe their work and their interaction with others. Promoting a grouch, a bully, a cheat, or someone with any major character flaw will come back to haunt you. If you don’t have someone outstanding, look outside your company. Don’t

settle for someone you aren’t thrilled about promoting.

something different in the plant.

“I’m always interested in people taking on new roles at laundries, especially when it comes to leadership roles. That got me to wondering about hiring the right people to be in charge. How do you fill leadership roles, from the CEO to the floor supervisor? Employees who could become leaders?”

Employees who could become leaders do become leaders through training.

I have shared with others I have worked with over the years that hiring employees is one of the toughest jobs I experience. I would even go as far as to say, “There is nothing more important than the people you hire to do the work.”

The goal is to find people who you believe share the fire, drive or passion that you have. Many times, this happens while working with people inside your plant. Someone might say or do something that makes you realize they care, they are driven, and they are intelligent, with the potential to learn so much more. They may handle a situation with just the right balance of technical and practical savvy.

It is interesting to find out the experiences of current employees, from their educational backgrounds to their experiences in other organizations. From there, you can have conversations to determine their professional desires and goals. Sometimes, even knowing what current employees are doing in the community can be an insight to their readiness to do

I have experienced success hiring internally. After sharing my expectations, training them to develop the skill set needed for success is the next task. It is important that the trainee not get overwhelmed or be given more responsibility than they can bear or handle. I truly believe in creating a team of support. When an employee is promoted into a new leadership role, it is helpful that they already know the facility and have a functional understanding of the operations. The support structure for new leaders cannot be understated.

Regarding upper management, up to and including the CEO, it is important that education and progressive training is a part of your normal developmental methodology. It serves as your succession planning for the eventuality of someone leaving. The fundamental thing is that this development of staff should be ongoing. Preparing staff through ongoing development opportunities is worth the investment because it will pay off when you need someone to step in.

If you are in a fairly large organization, access to a broader pool of people can come through recommendations from others. This happens through networking, relationship building and professional connections. It is important to develop relationships of honesty such that both the employer and the candidate are helped or advantaged. There is a fit for everyone; it is about finding that best place.

Hiring externally is similar; it just typically requires more time.

Both processes are scientific and artistic. Whether internal or external, it comes down to a decision you have to make based on assessments and gut.

In the end, nothing ventured, nothing gained. The real gain stems from the concept that training is forever.

Hiring is not life or death, but it can be life-changing.

The correct combination of the proper people in the appropriate places is similar to a complicated chemistry formula. It is difficult to say that any one specific management position is more important than the rest. I am a staunch advocate of moving up from within whenever possible.

Most of us are probably familiar with a business theory referred to as the Peter Principle. If not, take a moment to look it up. There are quite a few good head-hunting firms, and the preponderance of both psychological as well as managerial testing programs that are available is exceptional.

That having been said, I am a firm believer in the fact that nobody knows your customers or your business ideologies better than the people who have some tenure with your firm. I have been

12 AUGUST 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com ALN_Tab_1-4_H.indd 1 7/2/15 3:15 PM

Textiles

Cecil B. Lee Standard Textile, Cincinnati, Ohio

Chemicals Supply

David Barbe U.N.X. Inc., Greenville, N.C.

Commercial Laundry Rick Rone Laundry Plus, Bradenton, Fla.

privileged in assisting quite a few of our plant’s hourly workers in their rise within the ranks of our company.

When it is evident that there is an opening that cannot be filled from within, one great resource that is available to most of us is the comprehensive network of our suppliers. For instance, your laundry chemical supplier probably provides products to many other companies around the U.S. Most suppliers, as well as subcontractors, have a close relationship with their customers and therefore can be a valuable tool in your quest.

It is always important to handle your search in a professional manner. Remember that, “What goes around, comes around.” There are a number of good publications for our industry that offer a classified section for our job listings, as well as people looking to make a change.

Depending on the position, as well as your company size and budget, there are many good firms available to assist you in your talent search. This avenue may seem to be the most costly, but if you find the best candidate in an expedient fashion, this may ultimately prove to be the least expensive direction to take.

Lastly, I would like to stress that co-worker retention can be far more important and less costly in the long run than the hiring of a new person. I firmly believe in going the extra mile in an effort to keep the good people that have helped make the company what it has become.

Obviously, the ideal place to find our future leaders is within our own organizations. Promoting from within seems to build trust and respect among our workforce as they realize that they, too, can move up the ladder if given the opportunity to do so. Also, their peers have more respect and admiration for them, as they know firsthand that they not only talked the talk, but walked the walk.

As the job market is becoming tougher to fill, many high schools, technical schools and colleges are hosting job fairs for students looking for internships as an avenue to learn a craft and also to

decide their career path. This is a practical way for the overachiever to possibly land a position with an organization/laundry if they decide that this is indeed the career path they choose to travel. It is also an economical way to find the right person for the job while making a small monetary investment.

Ongoing education is key to the growth and success of our laundries and their management teams. Successful operators have to find a way to exploit their hidden talent from within while barring no expense in doing so. Trade associations offer educa-

tional courses for laundries to send their potential rising stars in an effort to maximize their skills and leadership capabilities and techniques.

The Textile Rental Services Association (TRSA) offers PMI (Production Management Institute), MMI (Maintenance Management Institute) and EMI (Executive Management Institute), for example. CSC Network offers various training sessions during its annual conference and also throughout the year for its members. The Association for Linen Management (ALM) offers a certification course for laundry and

linen managers.

These are just a few options out there to help uncover the possible leaders that will help our industry grow.

As everyone in our industry is looking for that one special person to lead in production, sales, engineering or maintenance, we need to pay attention to those who are already working for us. You never know, that next leader might just be the person who is working in soil sort, route makeup or even customer service. It is funny how the right person just might be in front of us but we’ve never taken the time to notice. ALN

Just last week, I received a phone call from a recruiter asking me if I knew of anybody looking for a position as a general manager for a regional laundry. Two weeks ago, another call came my way looking for a sales manager for a linen company. It seems to me that these calls are becoming more common than not, as everyone in our industry is looking for that one special person who can fill the voids left by the staff that was either dismissed or moved on to bigger and better positions.

Many companies today are looking within their own organizations for that one special person who is willing to step up to the plate and lead. However, when all else fails, we fall back to plan B— the recruiters (head hunters), vendors, trade associations, colleges and even technical schools—for the diamond in the rough who can bring some value and stability to their workforce, whether it be in production, sales, engineering or management.

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | AUG UST 2015 13

YOUR CHALLENGE PACESETTER CLM leads the way in dryer technology and provides an upgraded replacement for your old Challenge Pacesetter Our Model 165 fits the Challenge Pacesetter footprint perfectly and gives you technology that no one else o ers, including a fully integrated production management system. • Upgraded heat system with improved efficiency and lower emissions • Micro-Command III PLC upgrade with LAN and Blue Tooth communications • PLC now prepared for flow process management systems • 2-stage variable speed basket drive with 3-port load door. • Soft start to reduce component wear, lower utility use. • Heavy-gauge basket, includes removable steel basket panels • Long-lasting ceramic coating available on removable basket panels. • Configurable exhaust location • Configurable control/burner location Call CLM to replace your Challenge Pacesetter dryers, or for information on our broad range of industrial dryers. 323-232-2417 Model 165 shown with Tumble Green® configuration See Us at Booth 2560 at The Clean Show 211 Erie Street, Pomona, CA 91768 | T: (323) 232-2417 | www.clmco.com ALN_Jr Page.indd 1 11/18/14 2:36 PM 0515aln_CLM.indd 1 4/13/15 4:46 PM Uniforms/ Workwear Manufacturing Scott Delin Fashion Seal Healthcare Seminole, Fla.

UPGRADE

Linen/Garment Transport

for fast and easy emptying; the latter can also be turned into shelves on the 650-NX.

www.mcclureindustries.com 800-752-2821

MODROTO

MODRoto has unveiled its 2015 Buyer’s Guide to Laundry Carts product brochure.

The brochure features the company’s newest innovations—the 72ERgonomic, which is the first bulk linen truck with a springloaded platform that sinks and rises for proper work positioning, and the ComplianceCaddy, which is the first and only verifiable way to comply with both EPA and DOT rules for storing and transporting solvent-contaminated shop towels and wipes, according to the company.

JENSEN USA

Jensen USA says that complete laundry handling is available with its Futurail monorail systems, which can be used for either soiled- or clean-linen transporting.

With the size of processed loads continuing to increase, Jensen says its rail and trolleys are designed to perform under such strenuous conditions. The equipment is made of 100% coldrolled stainless steel for improved reliability and longer life, and is corrosion-resistant.

The company says its trolleys are made of quarter-inch pressed steel and feature a heavy-duty plastic wheel that is easily replaced (as well as the bearings), offers quiet operation, prolonged rail life, and reduced maintenance cost.

Also offered are vacuum transporting and sorting systems, clean-linen transport systems, and conveyor systems, as well as a patented Rail Cleaner, which is a fully automatic device that runs continuously to ensure that the running surfaces of the rail are kept clean, Jensen says.

www.jensen-group.com 850-271-5959

4 bushels to 60 bushels, the company reports.

Bayhead says it offers unique truck sizes and shapes to satisfy a wide variety of applications, and most of the line is available in a variety of colors for no extra cost. Also, optional lids are available for many sizes.

In terms of construction, Bayhead says the all-welded steel frames are secured through the bin for superior durability. Some of the largest sizes include a drop side to allow easy access.

The company also says it is able to make custom units to specifications.

www.bayheadproducts.com 1-800-BAYHEAD

LEONARD AUTOMATICS

Leonard Automatics says that its Transporter Conveyor chain is the only one offered to the laundry industry that is constructed of stainless steel. Stainless steel provides greater pull strength and lower stretch, and the corrosion resistance needed for operation in a garment finisher, the company says.

The Transporter Conveyor, designed for garment transportation applications, is an upright,

pendant-style conveyor featuring 31/8-inch and 6¼-inch pendant spacing.

It is available in the traditional upright style as well as its “Helping Hand” design. The design dramatically reduces drag on the conveyor system by carrying the hanger rather than dragging it as in traditional systems, Leonard Automatics says.

The Transporter chain can be used as a direct replacement for many existing systems. The company says its drive units are designed for ease of installation and superior performance.

Leonard Automatics also offers a full line of conveyor tubing and curves with all of the related parts to keep a system running smoothly. Most are in stock and ready for shipment, the company adds.

It offers a twist-style conveyor as well.

www.leonardautomatics.com 704-483-9316

G.S. MANUFACTURING

The G360-BD linen cart from G.S. Manufacturing is built with the same robust strength and durability that customers have come to depend on, while maintaining an ergonomic and fuelfriendly cart weight, according to the company.

The new cart allows staff to gain access to the soiled linen through the back. The 31-inch door swings a full 180 degrees to the open position and is held in place by a magnetic catch. Springloaded slide bolts secure the door when in the closed position.

work within their personal ergonomic safe zone, G.S. Manufacturing says.

With the addition of a garment bar, the cart can carry hanging garments, folded linens and soiled return, making it one of the most versatile carts on the market, the company adds.

www.gsm-cart.com 800-363-2278

MCCLURE INDUSTRIES

McClure Industries says that its Sanitrux carts, Saniwash cart washers, and cart-moving systems are “quality products that will last for decades.”

The company’s TC-35FL and 650-NX carts are made of fireretardant fiberglass to provide peace of mind against the threat of fire. Also, McClure products are ergonomically designed to help prevent injuries.

MODRoto says that an Ergonomic Showcase reveals, for the first time, the company’s signature, spring-platform design with cutaway imagery and shows its wide range of applications in bulk linen carts, utility carts and flare trucks that reduce bending, reaching and heavy lifting.

BAYHEAD PRODUCTS CORP.

Bayhead Products’ Poly-Box Truck line now has 22 sizes available, with capacities ranging from

According to the company, the back door offers a clear ergonomic advantage by allowing the staff unrestricted access to the soiled-linen bags. With greater access, the job is easier, and staff are allowed to

The carts have reinforced bottoms, a smooth interior surface for easy washing and sanitizing, and two removable front panels

Offering an in-depth overview of the extensive line of laundry carts, the brochure also features the company’s most requested bulk laundry trucks and shelf carts for clean-linen delivery and soiled-laundry return, as well as its utility carts that keep laundry plants and on-premises laundries moving smoothly and efficiently.

The brochure also offers a free flash drive loaded with specifications for 50 of MODRoto’s top products.

www.modlaundry.com 800-829-4535

FAIRFIELD LAUNDRY MACHINERY

Fairfield Laundry Machinery (FLM) has provided the laundry industry with a wide variety of material-handling solutions for almost 40 years, the company says.

According to FLM, its monorails are a fast, efficient method to move a large volume of linen (either soiled or clean) through a plant. FLM monorails also track linen so one can easily locate a specific customer’s goods. Multilevel storage racks conserve valuable floor space and eliminate costly fall protection as well.

Although FLM is in touch

14 AUGUST 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

COMPILED BY MATT POE, EDITOR

PRODUCT

USA]

[Bayhead Products Corp.]

SHOWCASE [Jensen

[Leonard Automatics]

[G.S.

Manufacturing] [McClure Industries]

[MODRoto]

with ever-changing materials and technology, some components on its monorail system are still made from steel, the company says. Its systems are known for years of continuous service and using steel rail components is a part of that success in longevity, it adds.

Also taken into consideration is the hostile environment in which electronics are used for laundry operations. Elements such as steam, water, heat and, at times, overzealous employees can create irreversible damage if a system’s structure is too delicate, FLM asserts. Thus, the company uses case-hardened human interface devices and industrial-rated PLCs.

The majority of its original systems are still in daily use with the same HMIs and PLCs that were first installed, FLM says.

www.flmcorp.com 973-575-4330

M.I.T. POLY-CART CORP.

The Model #1000-S Roll-Top Security Truck, designed by M.I.T. Poly-Cart Corp., remains the company’s most popular product because of its practical design and versatility.

The linen exchange cart has 48 cubic feet of storage space. The shelves are fully adjustable, so there is no limit to how many shelves can be used and where they can be positioned, according to the company.

The key feature the company points out is the lockable roll-top door, which provides sanitary containment and pilfer-proof protection when closed.

The durable, white tambour door is self-storing, so when it is open, it rests against the top and back of the cart: no hinges or doors that interfere with storage and transport. M.I.T. Poly-Cart Corp. says there is no need for cloth cart covers that rip, soil and require replacement.

The Roll-Top Security Truck rides on heavy-duty, 8-inch polyurethane casters that take the strain out of pushing even a fully loaded cart, the company says. As with its entire product line, every Model #1000-S is made to order and is available in 15 different colors.

www.mitpolycart.com 212-724-7290

FIBERTECH INC.

The Fibertech Solutions Team prides itself on its problemsolving ability and desire to create

an exceptional experience for the company’s customers, and cites the F-LT67 as a great example of this. The cart is made for business, whether the user serves hospitals, schools, hotels or prisons.

According to Fibertech, its

laundry carts feature the latest in durability design. The carts are rotationally molded with polyethylene, using a one-piece design and nominal .250 wall that resists dents, scratches, stains and rust. Featuring a combination of vertical and horizontal ribbing, the cart resists bowing and maintains its form, which translates to an increased cart life span. The plastic base is reinforced with metal for added strength and prevents warping, the company says.

www.fibertechinc.net 800-304-4600

AUTOMATION DYNAMICS

About the high-speed weigh sort system offered by Automation Dynamics, the company offers several reasons that laundry operators should consider using its product.

By sending high-volume sorts directly to the wash sling, an operation will reduce the soil load on its horizontal sorting belts, improving and speeding overall plant production, the company says.

The system will alarm or transfer roughly within four pounds of an operation’s ideal set wash load. The high-speed weigh ➢

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | AUG UST 2015 15

THE LEADER IN LAUNDRY TECHNOLOGY FA-X Folding Robots EFFICIENT - auto recognition of articles - reverse belt folding - articles are constantly guided - controlled stacking - 700-900 pcs/hr VERSATILE - adapts to varying thicknesses: thin patient gowns to heat resistant suits - automatic & manual feed available kannegiesser-usa.com 800.344.0403 ALN_Jr Page.indd 1 5/29/15 10:34 AM [Fairfield Laundry Machinery Corp.]

Inc.] [M.I.T. Poly-Cart Corp.]

[Fibertech

sort vacuum system removes or catches most of the paper, plastic or other items that might prove harmful to washers.

The company also claims that linen comes out cleaner thanks

to its system’s ability to remove debris from the incoming soil, enhancing the performance of detergents and other agents.

The system also helps to reduce reconditioning on darker colors, Automation Dynamics says.

Finally, the company says the system’s return on investment can be seen in just one to three years.

www.adllc.com 877-482-7200

CONSOLIDATED LAUNDRY MACHINERY (CLM)

Consolidated Laundry Machinery’s (CLM) shuttle conveyor systems combine the latest in plant material-handling technology with robust construction, according to the company. The conveyor traverses the wash room to unload multiple washer-extractors and load multiple dryers, thereby easing plant congestion and reducing worker injuries. For loose goods or a cake, CLM shuttle conveyors are available in a variety of capacities and are made for manual, semiautomated or fully automatic

dryer loading.

The company says that its shuttle conveyor has the ability to “communicate” with any washer system for effortless wash-aisle integration.

www.clmco.com 323-232-2417

ROYAL BASKET TRUCKS

Royal Basket Trucks says that its turnabouts and bulk transport trucks are designed for ease of use and durability. They have full

turnabout function for use with clean linen or are front-gated for bulk collection, the company says.

Shelves are designed with safety and ergonomics in mind so that staff doesn’t struggle or strain when putting carts back into service. Non-marking polyurethane casters glide easily, and a sloped bottom provides good drainage after cleaning. Nylon and vinyl covers are available.

Royal says it manufactures a full line of carts for the commercial laundry, drycleaning and coin-op industries.

www.royal-basket.com 800-426-6447

COLMACINDUSTRIES

Colmac’s Vacuum Transport System moves wet, dry, clean or soiled items to any area within a plant. Able to batch loads directly into slings, carts or equipment, the system works based on item count or weight and is able to classify with multi-tube workstations, saving floor space, the company says.

The variable-speed system reduces motor horsepower requirements by one-third and effectively controls lint and debris, according to Colmac. External venting reduces in-plant airborne pathogens. The company says the powerful vacuum is capable of moving items a few feet to hundreds of feet, allowing transport bins to be placed anywhere

CONGRATS! Lori Benson e Towel Guy LLC, Toms River, New Jersey to the winners of our iPad and Android tablet give away at the Clean Show. Join them in reading our digital edition on your tablet too! Heidle Baskin Baskin Laundry LLC, Canton, Texas 0815aln_tablet winner_Jr Page.indd 1 7/9/15 2:51 PM 16 AUGUST 2015 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Industries]

[Automation Dynamics] [Colmac

[Consolidated Laundry Machinery]

[Royal Basket Trucks]

within a plant.