WASH acquires distributor Great Lakes Laundry

EL SEGUNDO, Calif. —

WASH Multifamily Laundry Systems, a laundry facilities management service company, has acquired Great Lakes Laundry, a distributor of commercial and coin-operated laundry equipment and accessories throughout the Midwest, the company reports.

According to WASH, the acquisition will expand the company’s footprint into the Carolinas and will add several new WASH branch offices throughout the Midwest.

“Our acquisition of Great Lakes Laundry is a significant step in our continued nationwide expansion. It will enable WASH to better serve our customers in the Midwest and to deliver our best-in-class services to new customers,” says Adam Coffey, president of WASH. “We are delighted that Great Lakes President Dan Naumann will be joining WASH to facilitate this transition and to oversee the growth of our commercial operations in the United States.”

WASH will acquire all divisions of the Great Lakes Laundry business, including its route laundry and distributorship, according to the company. In 2012, WASH partnered with the multi-family route division of Great Lakes Commercial Laundry Sales to expand its services.

Healthcare laundry equipment installed ‘cleanly’ at Institute

BY MATT POE, EDITOR

GRAND RAPIDS, Mich. — The Van Andel Institute (VAI) is an independent biomedical research and science education organization here.

VAI was established in 1996 and has grown into an elite research and educational institution that supports the work of more than 300 scientists, educators and staff.

With all that personnel on hand, there is plenty of laundry to be processed, from scrubs to mops. However, in early 2015, VAI had a problem.

The institute’s 15-year-old IPSO washer broke down—the only washer on hand.

Dave Marvin, maintenance technician at VAI, called Brookstone Laundry Equipment

Laundry equipment financing made easier

unrelated properties, etc.”

BY MATT POE, EDITOR

CHICAGO — In recent years, laundry operations in need of new equipment or upgrades have found it more difficult to obtain financing, according to some industry experts.

That has left some owners and managers in a bind to replace outdated or broken machinery, or to start up a new plant or an onpremises laundry (OPL).

And the owners and managers have had to find new, creative ways to finance capital purchases.

The method that has made

equipment purchases possible when commercial banks wouldn’t provide financing? Manufacturersponsored finance programs.

“The mere existence of today’s manufacturer-sponsored finance programs is the result of an unwillingness and lack of understanding by typical commercial banks 25 years ago,” says Kirk Stone, vice president-vendor group, U.S. Capital Corp. “Lenders like U.S. Capital and our competitors know the laundry business and spend the majority of our time and resources assisting owners and prospective owners with competitive financ-

ing solutions to help them get the equipment they need to operate their businesses efficiently.

Very few banks will offer startup financing unless they secure the loans with mortgages on other

“Equipment companies have developed relationships with thirdparty finance companies,” adds Keith Ware, vice president of sales with Lavatec Laundry Technology. “This allows laundries to deal with lenders that understand the equipment, its value and life cycle.”

Tina Gough, UniMac finance brand manager for Alliance Laundry Systems, says that for the laundry industry, it’s difficult to determine the value of the business and how much that equipment is worth.

“Manufacturers that specialize in the laundry industry, they know how to analyze that market and the value of the business, the

of Experts

to make the case for capital improvements to management.

FEBRUARY 2016 Late News

www.americanlaundrynews.com Volume 42, Number 2 INSIDE [20] See VAN ANDEL

Page 12

The Newspaper of Record for Laundry & Linen Management

on

Panel

How

[4] See FINANCING on Page 10

ALN

Columnist at Large Eric Frederick discusses the challenges of lint in a laundry.

[16]

Manufacturer-sponsored financing offers knowledge, experience and ease

Employees required to shower and wear scrub outfits, disinfect tools

“THE ... EXISTENCE OF TODAY’S MANUFACTURERSPONSORED FINANCE PROGRAMS IS A RESULT OF AN UNWILLINGNESS AND LACK OF UNDERSTANDING BY ... COMMERCIAL BANKS.” —KIRK STONE U.S. CAPITAL CORP. PRODUCT SHOWCASE

Having to pause drilling for a fundraiser wasn’t the oddest part of the installation at the Van Andel Institute, as evidenced by the outfit worn by Brookstone LLC employees. (Photos:

Brookstone

Laundry Equipment LLC)

Survey: Most laundry managers prepared to handle

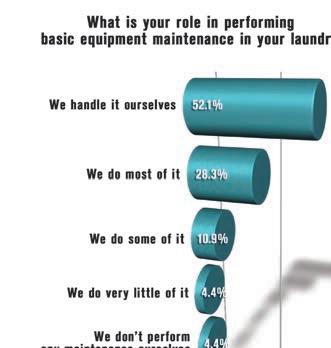

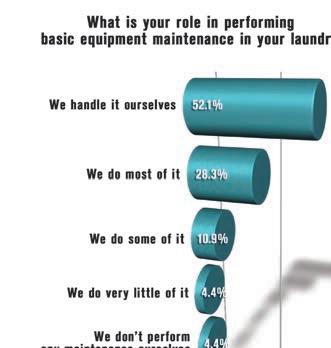

CHICAGO — When it comes to basic equipment maintenance, respondents to American Laundry News’ most recent Your Views survey indicate that they or someone on staff handle the job on their own.

More than 52% of those who took the survey say that they, or someone at the laundry, handle all of the company’s basic equipment maintenance. Almost 30% indicated that they take care of most of the maintenance.

Only 10.9% say that they handle “some” basic equipment needs, while just 4.4% say that they perform either little or none of their basic equipment tasks.

And it seems that managers or staff members are doing a good job on basic maintenance. Nearly 83% of those who took the survey answered “no” when asked, “Have any of your laundry’s equipment maintenance efforts ever backfired and ended up requiring repairs or even replacement?”

What happened to the remaining 17.8% who answered “yes”?

“A circuit board was installed wrong on one dryer, shorting out the entire bank of dryers,” one respondent writes.

“Equipment was down months for repair,” writes another.

One possible reason so many managers, or someone on staff, have a role in basic equipment maintenance for the company could be because of service school attendance. More than 60% of respondents say that they or a staff member have attended a service school offered by an equipment manufacturer or distributor.

The remaining respondents indicated that neither they nor a staff member have attended a service school.

Another possible reason that laundry staff perform basic maintenance could be because doing so is either the same or easier than it has been in the past.

When asked to finish the sentence, “Performing basic maintenance on our laundry equipment today is ______ than it has been in the past,” 43.5% answered “no different.” Nearly 24% indicated that basic maintenance is easier today, while 32.6% answered “harder.”

No matter how proficient managers or staff are at maintenance, most laundries, at one time or another, require attention from a maintenance or service technician. Most respondents have had solid experiences when a specialist had to be called in.

Almost 35% of those who took the survey indicated that the experi-

ence was “Good, they get the job done most of the time.” More than 28% answered, “Great, they always get the job done.”

Just 2.2% rated the experience as “poor,” and 6.5% answered that they “never call a repairman.”

No matter who is performing the maintenance, most managers who took the survey indicate that they have a formal schedule for basic maintenance tasks. Almost 83% have such a schedule, while 17.4% answered that their company does not have a maintenance schedule.

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and identify industry trends. ALN

Beck’s Classic Manufacturing to service Western Textile customers

BRENTWOOD, N.Y. — Beck’s Classic Manufacturing Inc. has come to an agreement to transition Western Textile Healthcare’s customers by the first quarter of 2016, the company reports.

Western Textile Healthcare is closing its manufacturing facility in Mexico, according to Beck’s Classic.

Beck’s Classic, in business since 1989, provides an array of incontinent textile products to the healthcare industry, the company says.

“This is an exciting time for both the industry and Beck’s Classic to bring even more products to the marketplace that will be ‘Made in the U.S.A.,’” says the company.

Terms of the agreement were not disclosed. ALN

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 231-740-2842

E-Mail: mpoe@ ATMags.com

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

Jim Buik • Richard Griffin

Greg Gurtler • Phil Hart

Janice Larson • Tom Marks

Gerard O’Neill

Richard Warren

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00.

Single copies: U.S. $7.00; Foreign $14.00. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 42, number 2. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2016. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within.

Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

2 FEBRUARY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

INSIDE: February 2016 • Vol. 42 | No. 2 [6] Texcare Asia 2015 Attendance Up 20% 153 exhibitors from 19 countries and regions showcased a full spectrum of textile care products in Shanghai [8] ‘Industry 4.0’ for Textile Services Texcare International to make clear what networked machines, systems will feel like in practice this June [14] Distributors Provide More than Equipment In this month’s OPL 101, find out how to partner with equipment distributors to operate a successful laundry [15] ALM 2016 Conference Set to Make ‘IMPACT’ The three-day conference will equip attendees with the latest methods and technology for improvement [23] Report: F&B, Healthcare Laundries Pay Better TRSA study produces salary/hourly rate and total compensation data on 14 laundry-related positions [25] Career Track [26] Trade Ticker [28] Classified Advertising [29] Source Directory

maintenance

basic

“

They have done everything they promised and more.”

– John Ambrose Magliocco, Arrow Linen, Garden City, NY

From

Arrow Linen first purchased their three Milnor CBW® tunnels two decades ago to replace conventional washer-extractors in their original laundry located in Brooklyn, NY. Since then, Arrow’s business grew to warrant a second laundry. In 2013, Arrow expanded operations–and raised their roof 11 feet! Arrow could have chosen any manufacturer to equip their new washroom, but they knew that would get longevity, durability, and accountability with Milnor.

Arrow’s customers’ restaurant linen requires frequent color and soil change formulas, but the quality is not compromised. Corporate Engineer Frank Park boasted the tunnels “have increased our workload over 40% without increasing energy, water, or labor costs we experienced when we converted the conventional washers to CBW® tunnels over 20 years ago. The major improvements from the CBW® to PBW™ are far superior washing capability with only 50% water consumption.”

To find out how PulseFlow® can cut your water bill in half, contact an authorized Milnor distributor or call 504-712-7656.

www.milnor.com / pellerinmilnor

Scan to read Arrow’s success story.

left to right: Frank Park, John Ambrose Magliocco, Ron Hirsch, and John Anthony Magliocco

Equipped to do the job

E

quipment is a common topic in American Laundry News It’s little wonder, since without equipment, no laundry could function. (Or, at least, function at the same level.)

In this issue, our Product Showcase focuses on largecapacity washer-extractors (those with capacities of more than 100 pounds). Fourteen manufacturers supplied updates on their latest models.

Maybe you aren’t sure what type of large-capacity washerextractor your organization needs. G.A. Braun’s Mark Zimmerman details four types of these machines and the basic usage for each.

Once you’ve decided what equipment you need, it’s time to

From The Director’s Chair

BR UC E BEGG S

purchase—after getting approval and financing.

This month, our Panel of Experts members share their thoughts on ways to improve your chances of gaining approval for capital improvements from

management and administration. After getting approval internally, it’s time to secure financing. Editor Matt Poe found out that banks today don’t make it easy to secure funding in the laundry industry. For the article, Poe spoke to equipment manufacturers and financing companies familiar with the industry in order to find out how laundries can get capital financing more easily.

Then, it’s time to install. But I’ll bet you’ve never had an installation quite like the one Brookstone Laundry Equipment encountered at the Van Andel Institute in Grand Rapids, Mich. Let’s just say the process involved showering, decontamination and special apparel. ALN

FOX TV personality to keynote TRSA’s Leadership & Legislative Conference

ALEXANDRIA, Va. — The keynote speaker for the Textile Rental Services Association’s (TRSA) Leadership and Legislative Conference March 16-17 in Washington will be Chris Stirewalt, digital politics editor for Fox News Channel (FNC), the association reports.

A key analyst for FNC in its coverage of the 2016 presidential campaign, having played the same role for the network in 2012, Stirewalt hosts Power Play on FoxNews.com and is seen on America Live with Megyn Kelly, Special Report with Bret Baier and Fox News Sunday with Chris Wallace, according to TRSA. Before joining FNC in 2010, he was political editor for the Washington Examiner , where

he wrote a twice-weekly column.

The association says Stirewalt’s late afternoon presentation on Wednesday, March 16, will precede conference attendees’ preparation for TRSA Hill Day activities the following morning. Hill Day activities include smallgroup visits to legislators’ offices.

TRSA says that participating in this members-only conference improves attendees’ insights into the current political and economic climate in which their businesses operate. Studying TRSA’s

policy agenda and advancing it face-to-face with members of Congress and their staffs provides you with valuable practice of your skills as a presenter and company representative as you portray your company’s economic and social contributions to your service area, the association says.

When Hill Day meetings are finished Thursday morning, the conference shifts back to the host hotel (Gaylord National Resort, National Harbor, Md.) for TRSA committee meetings, according to the association.

The conference concludes with a St. Patrick’s Day celebration, offering Irish delights in the early evening, providing all the benefits of a pub crawl in just one spot at the Gaylord. ALN

The need to control lint is manifold

L aundries are in the business of recycling soiled textiles into clean textiles. The major by-product that they create is lint. Lint creates a number of challenges for the laundry and the maintenance and housekeeping programs. It is a fire hazard, an insulator and a potential breeding ground for bugs and pathogenic organisms.

The first laundry I worked in had a two-shift, six-days-a-week operation. Housekeeping and maintenance had trouble finding time to clean the lint up on a regular basis. I had lots of practice handling lint fires in that laundry. The crew was well-trained in keeping the ironer and folders running during a lint fire in order to keep the aprons, belts and motors protected from the fast-burning fire. I often joked that a fire was our designated manner in which to clean the lint from under and within the equipment.

But lint fires are no joking matter. I have seen a lint fire start at the end of a beam when someone was welding and run down the horizontal beam to the other end of the laundry faster than my fastest employee could run the distance. In many ways, a light accumulation of lint burns like a trail of gunpowder.

A proper housekeeping program once involved using lifts and air hoses to clean the overhead area of the laundry at least twice a year. This cleaning frequency could increase based on the quality of the textiles purchased and their propensity to create lint. Generally, the less expensive a 100% cotton or cotton/polyester textile product is, the more it generates lint. The one advantage of 100% polyester textiles is that they lint less.

We recently installed three specialized fans in the ceiling of my laundry. We were skeptical as to their effectiveness, but we have been impressed with them and their ability to remove lint from high areas. The only drawback to the fans is the noise level associated with their use. For this reason, we have chosen to run them during non-production times.

We routinely cover all the linen in process and partially filled delivery carts at the end of the day’s production. A two-hour run on the fans will knock all the lint off the ceiling and overhead pipes and rafters. A quick sweep of the laundry at the start of the next shift is all that is required.

Lint also should be routinely cleaned from areas inside the ironers and the folders. Lint can act as a insulator and cause motors to burn out. It can also get into chains and gears, causing excessive wear. Cleaning of the equipment must be done on a regular basis.

Lint is also a great nesting material for certain types of bugs, and provides a warm, safe environment for rodents and airborne bacteria.

For all these reasons, it is important to take steps to lessen the amount of lint produced and to effectively clean it on a timely basis.

I recommend purchasing quality textiles and washing them in an effective wash formula designed to increase their service life. Many low-cost wash formulas use excessive amounts of chlorine bleach (because it is cheap) instead of more alkali or soap. The overdependence on chlorine bleach to clean textile products will create more lint. Turning out textile products from the washers with excessive chemical residue will also damage the fabric.

Drying your textile fibers at too high a temperature will also break more cotton fibers and encourage lint production.

I have seen thermal fluid ironers operate in excess of 375 F, and this will cause unlimited shrinkage of the textile product and the excess creation of lint.

A laundry manager has a number of steps he or she can take to limit and remove lint from the operation.

Eric Frederick is director of laundry services for Carilion Laundry Service, Roanoke, Va., and a past president and manager of the year of the Association for Linen Management. You can reach him by e-mail at efrederick@carilion.com.

4 FEBRUA RY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

COLUMNIST AT LARGE Eric L. Frederick, RLLD

ALN

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending January 15 (WE) = WEB EXCLUSIVE NEWS • Emerson Bearing Boston Creates Commercial Laundry Division • G&K Services Donates Cold Weather Gear to People ... • AmeriPride Services Acquires Mississippi’s First Class Linen • FOX TV Personality to Keynote TRSA’s Leadership ... • Beck’s Classic Mfg. to Service Western Textile Customers NEWS (CONTINUED) • MODRoto Names Ryan President, Chief Operating Officer COLUMNISTS/FEATURES • OPL 101: Finding Hidden Efficiencies to Improve Your Laundry Operation • Lean Laundries Create More Customer Value, Use Fewer ... • Eric Frederick: Set Hard-to-Reach Goals This Year OUR SISTER

From AmericanDrycleaner.com: • Magazine Ranks Dry Cleaners Among Top 500 Franchises • Ways to Make 2016 More Profitable From AmericanCoinOp.com: • Loomis Bros. Promotes Lamons to Sales and Marketing Manager • One HomeTowne Laundry Isn’t Enough in Newport

WEBSITES

Stirewalt

800 821 2221 | imagine@americandawn.com | americandawn.com

by TM The LunchkinTM is intended to extend the color o ering of The Greenie. Six additional colors to replace paper napkins in any lunch setting. Beyond the environmental benefits of The Greenie, The Lunchkin creates a fine dining experience -- at lunch. And the cost is about the same or less than paper napkins! Made in USA Fabric

Milliken. Made in USA Fabric By Milliken.

Replaces single use paper napkins at a lower cost

Creates a better dining experience and sets you apart in the marketplace

Lasts over 100 wash cycles

Never ironed, less energy use

Saves up to 5 billion pounds of trash per year Signature Plus is a registered trademark for Milliken & Company for fabrics. • Smaller 15” x 12” Lap Size

Your table linens touch every Customer at every event. Your linen needs to speak their language… fresh, clean, safe, consistent, reliable, and yes - elegant. They count on it. Together, ADI and Milliken have set the standard of linen excellence for decades. USA made Signature Plus fabric. Soft luxurious hand, consistent long-lasting color. Whites that stay white, and colors that stay bright. ADI American Dawn. The world’s leading supplier of Milliken Signature table linen products. Count on us. The Greenie® is America’s choice to replace paper napkins! At breakfast and lunch, if every American uses reusable linen napkins instead of paper, we can save 60,000,000 trees per year! That means cleaner air, less water use, less energy use, less waste in landfills, less toxic paper production chemicals. And the best part... Money raised through the sale of this product is given back - to educate our children on keeping the planet clean and safe. 84% of Americans prefer cloth vs paper at the table. The Greenie® Because it’s the right thing to do.

Lunchkin

By

•

•

•

•

•

Texcare Asia attendance up 20% from 2013 show

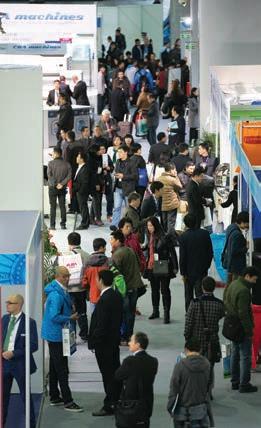

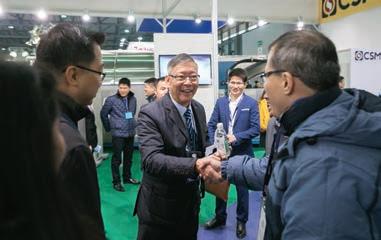

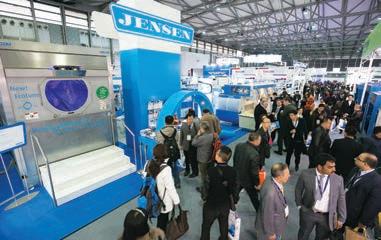

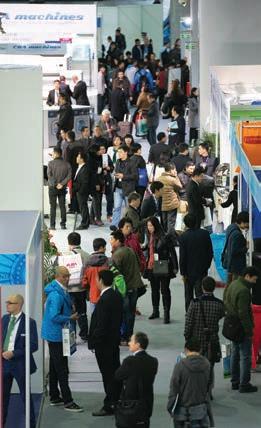

SHANGHAI, China — Texcare Asia, one of the region’s acclaimed trade exhibitions for the international textile care sector, ended its eighth edition on a bright note, say show organizers Messe Frankfurt (Shanghai) Co. Ltd. and the China Light Industry Machinery Association (CLIMA).

The biennial show returned to the Shanghai New International Expo Centre in late November. The three-day event—which fell during the Thanksgiving holiday celebrated in the United States—welcomed 10,267 visitors from 54 countries and regions, representing a 20% increase from the 2013 edition.

“Texcare Asia has unwavering support from the global industry, particularly from regional associations across continents. The impressive increase in visitor figures validates the show’s status as the firstchoice trade platform for textile care solutions in China and throughout the rest of Asia,” says Richard Li, general manager of Messe Frankfurt (Shanghai) Co. Ltd. “It also reflects the steady growth in demand for upgraded laundry machinery and innovative solutions with heightened concerns about energy efficiency and integrated automation.

“I am pleased with the show results and believe the fair has contributed to unlocking greater market opportunities for suppliers worldwide.”

Texcare Asia hosted 153 exhibitors from 19 countries and regions that showcased a full spectrum of products, solutions and advanced technologies related to laundry, drycleaning, dyeing, and ironing and textile management systems for industrial and commercial use, organizers say.

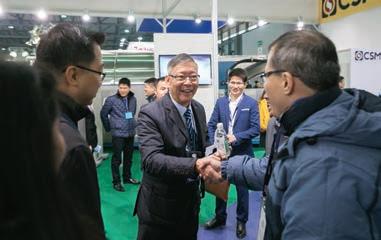

Alliance Laundry Systems en-

larged its booth for the 2015 show. On display was an array of machines from its family of renowned brands, including UniMac, Speed Queen, Huebsch and IPSO, with special focus given to the newly acquired brands of Deli and Primus.

“With Texcare Asia being held in Southeast Asia, every customer from our distributors comes to the show, making it an important platform for us to show them how unique we are in the industry,” says Christophe Sisternas, the company’s international marketing director.

“The Chinese market has great potential and is one of our biggest markets,” adds Michael Li, managing partner for the group’s Greater China business. “We will retain our focus here for at least the next 10 years.”

China’s own Shanghai Sailstar Machinery Group Co. Ltd. also returned to the 2015 show and successfully closed deals onsite. Says Mingjun Yang, vice president, “Texcare Asia is the most significant and popular industry trade fair for our customers. This year’s visitor flow was exceptionally high, and we have met many end-users, laundry plant owners and professionals from China and other countries across Asia.”

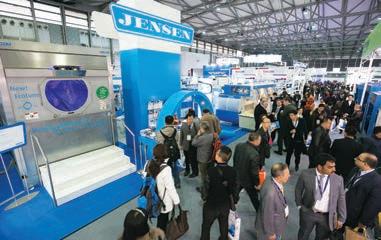

Another participating exhibitor, Jensen Group, displayed its resource-saving technologies and expertise in automation. Says Gerda Jank, head of marketing for the group, “The Chinese market is maturing quickly and paying greater attention to ecological protection, productivity and safety. We are happy to be at the fair and interact with Chinese customers to give them the right solutions. We are extremely satisfied with the quality and quantity of visitors, and engaged in in-depth discussions with both large companies and smaller laundry factories. I am very confident that we will join the show again in 2017.”

Visiting the show were buyers with different requirements and demands.

Edy Susanto, laundry manager at luxury hotel Raffles Jakarta, came with the Indonesian delegation.

“This is a very successful exhibition. I am delighted to see plenty of solution options that I can compare and choose from,” Susanto says. “My colleagues and I found some products, including tun-

nel washers and fabric-spreading machines from China, that we may place orders for. In recent years I have noticed a big improvement in Chinese products that are competing with European ones. We are very much satisfied by the products demonstrated here, and it is likely that we will place orders when we return to Indonesia.”

Roy Cheng, assistant sales manager, and Ir Roy Leung, assistant general manager, from E&M Contracting of The Jardine Engineering Corp. Ltd. from Hong Kong attended the show for the first time. They searched for laundry equipment that would provide optimized total solutions for their clients in Hong Kong and Macau.

“We decided to visit Texcare Asia because it was highly recommended by our work peers and customers,” says Cheng. “It was favorable that half of the exhibitors were from China and the other half were from overseas, because we look for products in different price ranges and with varied strengths to match the broad specifications of the many projects we work on.”

Leung adds, “The diversity of laundry machines is wide and basically everything along the supply chain can be found at the fair. The show is a good platform for us and anyone in the industry to keep pace with new products and market trends.”

Domestic distributors shared similar sentiments.

Richard Yang, representative of Pro-technic Engineering Co. Ltd., visited for the third time. “My company distributes domestic laundry machines and provides after-sales services. This year, I intended to learn more about large-scale machinery for centralized laundry plants which serve hotel chains and restaurants. Those plants are eager to upgrade existing equipment and favor locally made machines due to low maintenance costs and high performance. The show is highly industry-oriented, and I think it is the most professional trade fair in the region.”

Held alongside a portion of the show, the Texcare Forum Asia provided informative sessions that revealed the newest industry and product trends.

Prominent experts and market leaders from renowned research institutes presented on topics covering innovative smart laundry concepts, and cost-saving RFID and ICT technologies. They also covered specific fashion-care principles that help achieve high productivity, sustainability and maximum profits.

“The forum provides a good chance for participants to learn about what is happening in Asia’s textile market and to exchange ideas,” says one of the speakers, Sandra Constant, head of France’s Department for CTTN Research Institute for Textile Care and

Cleaning. “Besides big topics like dry cleaning and laundry, issues related to energy savings are also popular in Europe. Related costs are relatively lower in Asia, so this creates opportunities for brands. If brands want to develop their businesses in Asia, they have to adapt to the Asian market’s preferences for products, technologies

and chemicals.”

The next edition of Texcare Asia is scheduled for the fall of 2017 in Shanghai.

It is a sister event of Texcare International, the World Market for Modern Textile Care, staged every four years in Germany. The next edition of that major exhibition will be June 11-15 in Frankfurt. ALN

6 FEBRUARY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

More than 10,000 visitors from 54 countries and regions attended Texcare Asia 2015.

Texcare Asia, a biennial trade exhibition, returned to the Shanghai New International Expo Centre in late November. (Photos: Messe Frankfurt/Texcare Asia)

Alliance Laundry Systems and Jensen Group were among exhibitors with U.S. ties.

Participants at Texcare Forum Asia learned about the area’s textile market and exchanged ideas.

Attendees met new potential business associates and reconnected with current partners.

TWO ARE BETTER THAN ONE.

Happy with the productivity, efficiency and flexibility of his first Girbau Industrial (GI) tunnel system, Rick Rone of Laundry Plus maintains the decision to invest in a second identical system was a no-brainer. He likes the security they bring.

By adding a second GI tunnel system and moving equipment from two buildings into one, Rone enjoys streamlined production. The new plant – with its arsenal of high-performance equipment – opens the floodgates to new business, ensures backup in case of a mechanical failure, and allows Rone to launch a new linen rental program.

Since moving to the new plant and installing its second tunnel, another ironing line and additional open-pocket washers, Laundry Plus has boosted pounds of laundry per operator hour (PPOH) by 15-18 percent.

LAUNDRY SOLUTIONS FOR WET

ON-PREMISE

CONTACT GIRBAU INDUSTRIAL TO SEE HOW WE CAN INCREASE YOUR PPOH!

CLEANING,

& INDUSTRIAL LAUNDRIES

Rick Rone

www.girbauindustrial.com • (800) 256-1073 INDUSTRIAL

Laundry Plus, Bradenton, Florida

‘Industry 4.0’ tech for textile services

FRANKFURT AM MAIN, Germany — Digitalization is set to be the driver of the future in the textile care industry. The precondition for “Industry 4.0” is a comprehensively networked data communication system covering all the players involved in the production.

The technology will create a high density of information, which will allow companies to react to the wishes of their customers in the most personalized ways possible. At the same time, the processes involved in the factories will be smarter, more transparent and safer.

Texcare International 2016, slated for June 11-15 in Frankfurt, will be a guide to the latest developments for this key trend toward “Industry 4.0,” organizers say. Companies involved in plant construction; suppliers of identification, monitoring and control systems for goods; research institutions; and IT specialists will be showcasing their solutions for the “smart” automated laundries and drycleaning plants of the future.

A START HAS ALREADY BEEN MADE

Textile services these days have reached a considerable level of individualization and personalization. Protective workwear, delivered to a customer’s linen cupboard, matched to the staff who will use it and prepared with the specific job in mind, is now a standard service.

Care procedures that take into account the particular properties and/or requirements of residents’ personal laundry are seen as matter of course. Tailor-made patterns of supply for industry, healthcare services and the hotel trade are used across the board.

“We are just at the beginning of what we can do with the technology that is available to us at the moment,” says Friedrich Eberhard, president of the German Textile Cleaning Association in Bonn. “If we manage to link all the machines and systems completely and organize the data properly, then, in future, we shall be pretty well able to meet the needs and requirements of our customers in real time, as we are processing their laundry.”

The high density of information can, in his opinion, contribute massively to helping people meet the requirements of the job.

“If the laundry already comes with the information we need, then we can dispense with a huge number of the repetitive administrative tasks, which, in the past, have been necessary to pass the

their customers. “Industry 4.0” provides the basis; it makes it possible to link the reconditioning of apparel and laundry, which involves intensive manual handling with economic efficiency.

DATA COLLECTION AND USE BECOMES CORE COMPETENCE

Organizers of Texcare International 2016 say the trade exhibition will present numerous solutions for networked processes and procedures. An emphasis will be on contactless data collection, a process in which a data carrier (transponder) transmits its stored data to a reading device using an electromagnetic field (RFID, UHF).

manufacturers are introducing the next generation of the automated laundry service. Control and monitoring systems present all relevant data in a digestible form and provide the process chain with all essential and relevant consumer data in real time.

A link to intelligent systems for energy use, in turn, leads to direct optimization of the use of resources throughout the plant.

UNIFORM DATA FORMAT REQUIRED

In addition to this, intelligent monitoring sensors could provide further relevant information, such as, perhaps, about the relative degree of dirt of each individual item. Then it really would be possible to create fully automatic, “green” factory operations.

CREATION OF NEW CAREER PATTERN

The new smart systems impact the workplace in the sector in a number of ways.

customer’s wishes and requirements to the places in the textile service companies where the various tasks are performed. This applies to the administration, the production processes and the logistics.”

And the laundry services, too, will benefit from this and gain a new and closer relationship with

As a result of “smart” data collection and networked information, goods streams can be quantified across departments on the factory floor, linked to automatic distribution and return systems and subsequently taken over by the consumers’ goods management systems.

With the intelligent monitoring and storage of all parameters relevant to the factory plant and its processes, the machine

“The new ‘smart’ approach will have a positive impact on the efficiency of the laundry and drycleaning sector and hence on its competitiveness,” says Dr. Frank Ryll of the Fraunhofer Institute for Factory Operation and Automation in Magdeburg.

Moreover, it must be possible to connect all the players involved, from the machine control systems to the merchandise management systems, using a uniform data format. Systems that communicate with one another are the absolute prerequisite of the smart laundry plant with autonomous control, experts say.

“They offer engineering sciences an attractive area of activity and will lead, in [the] future, to the creation of the companies’ own powerful, high-performance IT departments in laundries and drycleaning establishments,” says Ryll.

At Texcare International 2016, training establishments, universities and professional associations will all be involved in designing a groundbreaking new career type in which information technology will play an ever more important role.

To learn more about Texcare, visit the show’s website at www. texcare.com ALN

8 FEBRUARY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

International to make clear what networked machines, systems will feel like in practice

Texcare

Systems that communicate with one another are the absolute prerequisite of the “smart” laundry plant and will be highlighted at Texcare International 2016, show organizers say. (Photo: Messe Frankfurt/Petra Welzel)

“WE ARE JUST AT THE BEGINNING OF WHAT WE CAN DO WITH THE TECHNOLOGY THAT IS AVAILABLE TO US AT THE MOMENT.”

ALN_Tab_1-4_H.indd 1 1/12/16 11:59 AM

—FRIEDRICH EBERHARD, GERMAN TEXTILE CLEANING ASSOCIATION

Results on whites are excellent. On colors, you have nothing more to lose and everything to gain by trying YellowGo. YellowGo may take out color you want to keep. But if it removes the unwanted dye without damaging the underlying color, you win! You won’t have to pay for the dye-stained garments and you won’t disappoint your customers.

So use YellowGo to keep your customers happy and keep them coming back.

information visit

or

or

YellowGo® removes unwanted dye from fabric. For more

AlWilson.com

call us at 800-526-1188

201-997-3300

A HISTORY OF EXCELLENCE, A FUTURE OF POSSIBILITIES

A & B Wiper Supply is now Monarch Brands. We have changed our name to better reflect the full breadth of high quality and valuepriced textiles from manufacturers around the world. From global textile sourcing to private label programs, we have you covered, whatever your needs may be. Leverage our experience and purchasing power to find the perfect blend of quality and price point for your company.

Financing

equipment and all of that,” Gough says. “They know how to lend against that piece of collateral easier than a commercial bank does, or a financial institute or market does.”

“We understand the business and know what questions to ask,” adds Stone. “Our credit box tends to be a little wider than a bank. For experienced operators, it is possible to borrow 100% of the equipment order with very limited financial information required.”

Gough says that for the customer, a laundry owner or manager, this knowledge makes it easier during the financing process.

“[Customers] don’t have to jump through as many hoops and processes with manufacturers of the equipment,” she says.

Pamela Kuffel, international sales manager and consumer financing specialist with Continental Girbau, adds that manufacturersponsored financing is convenient because financing, service, support and warranty are all provided under one umbrella. Plus, she says that manufacturers have extremely competitive and flexible financing available.

“At Continental, we offer the full gamut of services. Financing is one component that makes the purchasing process more seamless. We have the relationship with the lender, distributor, and the customer. We can help bridge any gap between them,” says Kuffel. “This helps with the strength of each deal.”

For new investors, Stone says manufacturer-sponsored financing is the best solution to helping them get into the business. Manufacturers know how to evaluate new projects by using tools such as demographic reports, cash-flow projections based upon the demographic information for the proposed location as well as analysis of the competition surrounding the location, he says.

“You don’t have to make an appointment to go out and meet with a loan officer at an institution,” she says. “They can do it wherever they are. It can all be done with the click of a button.”

With U.S. Capital Corp., Stone says that for an existing owner who has been in business for a while, it is possible to borrow up to $100,000 with just a simple credit application and copy of three months of bank statements. For new investors and start-up laundry projects, he says the company will ask for more information than for simple equipment-replacement orders.

“We are fortunate to work with a number of high-quality and reputable commercial laundry distributors,” says Stone. “They play a big role in our new project review process by providing everything from help with site selection, lease negotiations, layout, analysis, pro formas and a project summary write-up that tells us about the competition, surrounding businesses and photos of the project to give us a feel for the location.”

How does a laundry owner or manager, or someone looking to start a laundry, go about securing manufacturer-sponsored financing? The process is not difficult.

“I would start with a phone call to the finance department, as your background in the industry helps determines the program that best fits your needs,” says Kuffel. “Then from there, the manufacturer can help you put together a complete finance package, which always starts with a credit app and financial package.”

Gough says the steps for her company differ a little bit, dependent upon the dollar amount of the transaction. If the loan is under $100,000, then it is the one-page application mentioned earlier. They run credit, and if the credit is acceptable, then the customer is approved. She says Alliance requires a signed sales proposal from the distributor or the customer.

After that, the company sends out a onepage approval with the terms and conditions of the loan, the rates, the term, to whom it’s made payable, to whose name the loan is going to be in and who’s going to be signing.

“Sometimes we’ll send the loan documents out with that approval to streamline it,” says Gough. “The customer will sign everything, send back the originals and once we get everything, the distributor will install the equipment at the location.”

Once the equipment is installed, Gough says Alliance calls the customer to make sure all is good to go, then funds the loan. At that point, the customer begins to pay on the loan.

“Your typical bank makes decisions on existing revenues of a business, which do not exist with a start-up project,” Stone adds.

Kuffel says, “I would argue that the financing through the manufacturer helps build a strong case for the financing, as we usually have visited the site, customer, business, etc.”

Even the process itself is simpler when it comes to financing through a manufacturer. Gough says with Alliance, it’s a simple onepage application for a loan under $100,000. If the applicant’s credit is above a certain parameter, then they’re approved, she adds.

“When we get an application, we are able to process it and get an answer within 24 hours,” says Gough. “[Banks] are not familiar with the industry or the business, so it causes them to have to look at and scrutinize the application more than what we do because this is all we specialize in. This is all we do.”

Another difference Gough notes between her company and banks is that everything can be done by fax or e-mail.

Gough says that if the transaction is over $100,000, then the company will need some additional information from them.

“We require [a] personal financial statement, tax returns, bank statements and then we start analyzing the location as well,” she says. “We do some internal analyzing of the location with the equipment mix.”

Even if the financing sought is over $100,000, Gough says it’s still just 48 to 72 hours for the customer to know whether or not they’ve been approved.

“The turnaround is really quick, because they are wanting to know if they’re approved—and we want to make sure they’re not going to go to the competition,” says Gough. “A lot of times, if they’re an OPL market, their equipment’s down. They don’t really have time to mess around. They need to get that approval and they need to get that equipment in so they can continue functioning their business behind the scenes.”

There are steps that a laundry can take

10 FEBRUARY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued

from Page 1

Call 800-333-7247 or visit monarchbrands.com to learn more. “SOMETIMES WE’LL SEND THE LOAN DOCUMENTS OUT WITH [A ONE-PAGE APPROVAL] TO STREAMLINE [THE PROCESS].” —TINA GOUGH UNIMAC/ALLIANCE LAUNDRY SYSTEMS

before working with a manufacturer that can make the approval process go more smoothly, say Gough and Stone. These include having a higher credit score, organized financial records, good pay histories on existing obligations and a positive bank balance.

“I would say cash flow is key when it comes to laundry owners and making sure that they’re able to handle the debt. I would direct them to really try to get their finances in order, both business and personal,” Gough says. “You want to be able to show that you’re operating within the income levels that you have, you’re showing that you have a positive cash flow and that you’re able to take on the debt that you’re wanting to keep the business up and operating and in good shape.”

Stone says it is also a good idea for a laundry owner to be prepared “and willing” to invest some of the business’ capital into the project.

“While it is possible to finance up to 100% of the equipment order, we expect the borrower to be able to invest their own capital to cover leasehold improvements including such things as electrical, plumbing, mechanical work, permitting, etc.,” he says.

In the end, laundry owners need to be aware of the requirements for financing, as well as make sure guidelines are understood and met, Kuffel says.

“Please be aware that the lender wants to get the full story, and any details you can provide other than the numbers is very helpful,” she adds. ALN

U.S. House, Senate members agree with TRSA legislative policy agenda

ALEXANDRIA, Va. — Leaders of the Textile Rental Services Association (TRSA) recently took the textile services industry’s legislative agenda to five members of Congress, who warmly received the contingent of launderers, the association reports.

Sen. Ron Johnson (R-Wis.) was particularly vocal in his support for the association’s stances on labor-related regulatory initiatives, says TRSA.

Johnson, a former manufacturing executive and user of TRSA member services, empathized with the TRSA group’s explanation of the likely negative impact on the industry of federal regulatory initiatives that:

• Limit the overtime pay exemption to higher-paid managers, enabling those who earn less than the increased threshold to receive such pay.

• Remove an employer’s independent control of pay and benefits for its entire workforce when any employees are assigned on a daily basis to customer locations (joint employer).

• Prompt more individuals hired on a contract basis to be re-classified as employ-

ees, requiring their clients to become their employers.

The Wisconsin senator pledged to address these measures, according to the association, although this will be difficult in light of President Obama’s unwillingness to sign legislation that would curb them.

TRSA expressed great disappointment regarding expansion of overtime pay, which would drastically impair the industry’s ability to create jobs and cost-effectively serve customers.

Members of the House of Representatives with whom the TRSA contingent visited in December were similarly receptive to the association’s concerns.

Other issues discussed with the members of Congress included TRSA’s support for redefining full-time work at 40 hours a week under the Affordable Care Act (ACA) instead of 30, which would control business expenses and make it less costly to give parttimers more hours; and setting depreciation schedules for capital expenditures years ahead of time so businesses can better time these large purchases in light of their tax implications.

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | FEBRUARY 2016 11 In addition to customer favorites, we now carry even more products to service your needs. Download our full catalog at monarchbrands.com. • Institutional Sheets

Cabana & Spa Towels

First Quality Collections

Eclipse Towel Lines

Route Ready Bar Mops

Performax Microfiber Lines

Microfiber Cloths & Mops

SmartChoice Wet Mops

Poly Spun Napkins

Personalized Product Lines NEW OFFERINGS INTRODUCTORY SPECIALS • Save up to 70¢/dozen when you eliminate pre-washing and counting these 32oz bar towels • Soft packed, optically white, and ready to use • Pre-packed bundles of 25 Promote your brand 24/7 with complimentary logo label embroidery! • Personalized microfiber products, terry towels, and bar mops • Ultimate control over inventory • Carry your own product line • Free advertising for your brand Call us to learn how you can carry your own lines for no additional cost! CUSTOM SOLUTIONS • Wide variety of colors • Price breaks for bulk orders • 16”x16” microfiber cloths • Use for wet or dry cleaning 35¢ MICROFIBER CLOTHS • Commercial quality microfiber looped flat mops • 80% Polyester, 20% Polyamide • Cut your cleaning costs without sacrificing quality • 18” long with Velcro backing 95¢ SMARTCHOICE WET MOPS $3.25/doz ROUTE READY BAR MOPS Call 800-333-7247 or visit monarchbrands.com to learn more.

•

•

•

•

•

•

•

•

•

ALN

(Image licensed by Ingram Publishing)

Van Andel

LLC in Mt. Clemens, Mich., to order a new part for the machine.

Since the installation, Brookstone Laundry Equipment has since merged with p.b.gast Laundry Equipment. Gast has been in business since 1894 and in the commercial laundry equipment business since the mid 1940s.

“[Marvin] was extremely concerned about getting the part quickly, as extended downtime was not an option for them,” says Scott Burgess, owner and manager of Brookstone. “Upon working with him on the part he needed, I asked two telling questions: Are you sure you want to spend that amount of money on a machine of the age? Why in an environment like that would he have only one machine?”

Burgess says he explained how other laundries have redundancy, multiple machines to avoid situations in which operations are completely “down.” Marvin bought into the idea of replacing the old machine with a pair of new washers matched with a pair of appropriately sized new dryers.

“The old machine broke down, so we had to look at an alternative,” says Marvin. “I helped facilitate the installation.”

Burgess says Marvin presented the redundancy proposal to management in his division, which then called all involved in for a group meeting, and decided it was a good idea.

At the end of April 2015, Brookstone installed new IPSO equipment at VAI—two 35-pound soft-mount washers and two 50-pound dryers.

“They needed to go with softmount washers because the laundry is over their mechanical room and is not on grade,” Burgess says. “To do the testing environment, they cannot have vibration.”

But that’s only the beginning of the story.

INSTALLATION REQUIREMENTS

“I’ve gotten into some interesting places in this business but this one probably tops the cake in ‘different,’” says Burgess.

While installing two washers and two dryers isn’t usually that complicated, the process was bit more involved at VAI, says Burgess.

“Dave requested someone to come in and size up the facility to examine what the requirements would be to install new equipment,” he says. “I relayed this information to [Brookstone sales rep] Pete Gade, and he made arrangements with Dave for a site visit.”

At this point, says Burgess, no one at Brookstone had any idea what the laundry room environment was like. He explains that Gade arrived at VAI, had a brief meeting with Marvin in the non-clean room area and then they headed to the laundry area.

That, says Burgess, is where Marvin explained to Gade that he needed to disrobe, take a shower, wash with the soap provided, leave his clothes behind and dress with the scrubs, shoes and hair net provided.

“The showers are pass-through, so you enter from one side, the ‘soil side,’ and you exit on the ‘clean side’— two terms we know well in laundry circles,” says Burgess. “After the visit, Pete called, laughing, to explain to me the unique requirement for entering the laundry, stating he had never had to strip down and shower before making a sales call.”

During the installation, Brookstone employees had to strip, shower and dress just like Gade did. In addition, says Burgess, when the laundry was under clean-room requirements, the tools had to be exposed to

a disinfecting process involving chlorine gas.

“They brought into the laundry the emitting device that sort of looked like a medium-sized floor scrubber. They then put in test strips around the room. Our tools were exposed to the chlorine gas overnight,” Burgess says.

The test strips confirmed that the tools had received proper exposure to the gas. Additionally, he says, passing necessary items into the room required the tools to go through a pass-through portal, which again exposed them to the chlorine gas.

“If you wanted to bring your cell phone in, or smaller items, you could put them in the portal, which is a stainless steel box about 18 inches by 18 inches, and retrieve them, after your shower and hopping into your provided scrub outfit, from the other side,” Burgess says.

But showering and disinfecting tools wasn’t even the biggest challenge during the installation, according to Burgess. The biggest challenge was if an employee needed to leave the clean-room laundry, he would have to go through the cleansing process all over.

“Running out for additional tools or parts was not a good option,” says Burgess. “Keep in mind that the clean-room area was much bigger than just the laundry. Its primary function is a clean-room lab, with lots of staff running around doing their jobs, so clean-room bathrooms, water and most everyday amenities are available.

“We overcame this hurdle by carefully planning our needs so we did not need to leave the clean-room area until we were done for the day.”

WORTHWHILE EFFORT

Burgess says that his employees were extremely good-natured about the added restrictions during the VAI installation.

He says the workdays were fairly normal, except for the showering process and not being able to leave and easily come back in.

“One odd thing was that everybody looks a little odd dressed in scrubs, rubber clog shoes and hair nets on,” says Burgess. “It was pretty funny but definitely a little odd. You could feel a little reluctance from people who typically work in the non-clean areas of the

building when they need to shower and enter the clean-room area.”

Overall, the installation took two days. According to Burgess, day one was cut a bit short because some of the drilling in the floor was quite loud and the VAI was having an important fundraiser in the early evening that would have been disrupted by the noise.

Brookstone completed the installation, tested the equipment and conducted employee training on day two.

Marvin says that besides a few “normal” hiccups and adjustments, the IPSO equipment is running well throughout the day, every day.

“Everything is working good,” he says. “It’s up and running. Staff are running six to seven full loads a day.”

In the end, the installation effort was worthwhile for both VAI and Brookstone.

“The Van Andel name is well known and respected, particularly in West Michigan,” Burgess says. “To be associated with one of their projects, especially one this interesting, makes for good conversation at work and outside of work.”

12 FEBRUARY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com ALN_Tab_1-4_H.indd 1 4/28/15 3:25 PM

Continued from Page 1

ALN

Brookstone LLC installed two 35-pound soft-mount washers and two 50-pound dryers, all IPSO brand, at the Van Andel Institute.

THE

THEY SEEM TO

For over half a century, dependable Maytag® Commercial Laundry machines have stood up to daily use that would have lesser washers and dryers crying for a repairman. They’re also energy-efficient—increasing throughput, while lowering utility and labor costs. To learn more about our products and their comprehensive warranties, visit maytagcommerciallaundry.com

credit approval

individual’s credit

promotion is valid

LESS ATTENTION OUR MACHINES NEED, THE MORE

GET. Finance rates as low as 3.49%* Up to 36 months. Low fi xed fi nancing rates, terms up to 96 months available. Subject to

and

profile. This

through March 31, 2016.

®/ ™ ©2016 Maytag. All rights reserved.

Providing more than equipment— Distributor service and support

Partner with equipment distributors to operate successful laundry rooms

BY BILL BROOKS

When managing an on-premises laundry (OPL) operation, it’s important to find a distributor that will provide you with the right equipment to meet your business needs, as well as reduce operational costs and maximize efficiency. However, beyond providing equipment, your distributor should be a trusted partner who provides additional support and services to help you run a successful laundry operation.

Whether building a new laundry room or managing an existing laundry operation, your distributor is a laundry expert who can help you manage every aspect of your laundry room. Read on to learn more about how your distributor can help you determine the best equipment mix and laundry room design; improve efficiencies and lower utility costs; finance the operation; as well as provide service and maintenance to help machines run efficiently.

EQUIPMENT MIX AND LAUNDRY ROOM DESIGN

Distributors have extensive knowledge of laundry equipment and the industry. They know what it takes to run a successful OPL operation and will work with you to determine the best equipment mix to meet your laundry room needs. Whether your priorities are high efficiency levels, low utility usage, lowest cost per pound or lowest equipment price, your distributor will make a recommendation on the best equipment mix to meet these needs.

Your distributor will also help determine the right equipment size for your business. Based on the size of the facility, number of rooms and number of beds, your distributor will advise you on the best quantity and sizes for your washers and dryers. Additionally, an important factor to consider when making an equipment purchase decision is the type of linens you’ll be washing.

“To help customers make a decision on the type of equipment that will help achieve their desired efficiency levels, we need to know what type of linens they are washing,” says Mark Hubbard, president of Universal Laundry Machinery, Westland, Mich. “If they are washing a lot of towels, for example, the fabric will hold a lot of water and therefore the speed in high-extract equipment might be best because it can help cut down drying times by 30%, which has a large impact on a company’s utility savings over time.”

In addition to helping customers determine the mix of equipment, your distributor can also provide recommendations on the best layout for your laundry room. It is important to keep in mind how to design your laundry room to decrease the amount of steps that any worker may need to take to complete the laundry processing, as well as the proper workflow to clean soiled linens. If a new room is being built, a distributor will

work closely with the architect to develop professional drawings of the layout that can be used throughout construction.

UTILITY USAGE AND SAVINGS

A priority in the industry is equipment and technology that minimize gas, water and energy usage to help OPL managers reduce overall costs. To help determine which equipment is right for you, your distributor can help you better understand the utility usage and savings associated with different equipment models and your unique needs by providing an operating analysis estimate.

Laundry operating analysis reports provide an estimate on the cost per pound to process laundry. The analysis clearly identifies the impact of the equipment performance on labor and utility expenses, which can help a customer better understand the differences in equipment. If a customer is making a decision between equipment based on the purchase cost, analyzing the operating analysis may be beneficial in the decisionmaking process.

“Laundry equipment has advanced significantly in recent years, and there are many green technologies available to help reduce water and energy usage by preventing overdrying, minimizing water usage in rinse cycles and reducing overall cycle time,” says Hubbard. “Not only do these advancements help the environment, they also reduce costs for companies, and these savings have a large impact on the annual expenses associated with laundry room operation.”

TECHNICAL TRAINING ANDSUPPORT

Service-trained distributors are laundry experts who can educate you on varying equipment offerings. They will train the laundry room manager, chemical expert and employees on the equipment, including the operation, technology and cycle settings, as well as the maintenance and cleaning required to help the equipment maintain quality and efficiency.

“It is important that all employees who will use the machines undergo training so that they use the equipment correctly, from the proper loading techniques to customizing cycles,” Hubbard says. “With so many recent technological advancements, it’s even more important for employees to be trained on the equipment so that they know all of the benefits of their equipment and how it can help improve the overall laundry room operation and reduce their own time processing laundry.”

Additionally, training will differ depending on the type of OPL setting. For example, Hubbard says that for the healthcare industry, they spend time training employees on the health standards and requirements to ensure the proper workflow is followed to keep equipment used for processing soiled linens separate.

EQUIPMENT SERVICE ANDMAINTENANCE

Your distributor is your resource for any maintenance and service required for your equipment and will offer original equip-

ment manufacturer (OEM) parts, as well as trained service personnel to provide you with the support you need.

Whether it is a regularly scheduled service visit or a sudden issue that arises, your trained service personnel can offer assistance over the phone to diagnose the problem and help problem-solve, or they will provide in-person assistance to fix the machine as quickly as possible, so that business is affected as little as possible.

Distributors will also schedule preventative-maintenance visits, which can be on a monthly or quarterly basis. During these visits, service personnel will clean and lubricate equipment, adjust belts and much more to ensure that the equipment runs smoothly and efficiently. These preventative visits can ultimately help extend the life of the equipment.

“The service department has the most contact with our customers, as once a sale is made, it will be many years before the equipment needs to be replaced,” says Hubbard. “Because of this, we spend a lot of time training our service personnel, and it is critical to ensure that they are friendly and provide customers with the help they need during each visit.”

Your distributor can also provide recommendations on when it might be time to replace equipment. If older machines continually break down or have issues that require service, it may be more cost-effective to replace them with new and more efficient equipment. Your distributor can help break down the costs to show the difference of servicing versus purchasing a newer model.

FINANCING

There are many financing options to consider when investing in equipment, and your distributor can help you with this process. From deciding between a commercial bank, leasing company or financing through your equipment

manufacturer, your distributor can help connect you with the lending option that best suits your unique needs.

There are many benefits to choosing a lender in the laundry industry to finance your operation because they have an understanding of the industry and the needs of your laundry room. They may also be able to offer financing options that a bank could not.

It’s important to use your distributor as a resource when making this decision, as they can serve as the liaison with your financing lender to make sure you have all of the information you need throughout the process.

FINDING SUPPORT IN YOUR DISTRIBUTOR

When it comes to laundry room management, you are not alone. Your distributor can advise you on almost every aspect of your operation, and their support begins before an equipment purchase has even been made by working together to determine the best equipment mix and laundry room layout, and extends throughout the lifetime of your equipment.

“When working with a customer, I put myself in their shoes and think through their needs. This helps me better understand the customer—their questions, concerns and expectations—and helps my team exceed those expectations,” Hubbard says.

As equipment and technologies continue to evolve, it is even more critical to work with your distributor and turn to them for service and support to ensure you stay ahead of the latest innovations and understand how these advancements can improve your laundry room operation. ALN

Bill Brooks is North American sales manager for UniMac®, a provider of on-premises laundry equipment. To learn more about UniMac, visit www.unimac.com/opl101 or call 800587-5458.

14 FEBRUARY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com OPL 101

(Image licensed by Ingram Publishing)

Brooks

ALM 2016

RICHMOND, Ky. — The Association for Linen Management (ALM) has renamed its 2016 Education Conference to IMPACT, the association reports. The conference has been scheduled for Feb. 28-March 2 at Wild Horse Pass Hotel in Phoenix, Ariz.

“We named the conference IMPACT because we want our members to know how they can be IMPACTed, and how they can make an impact on their company and the industry, as well as understand the factors that are, and will be having an effect on their daily work lives,” says ALM President Randy Wendland, CLLM.

The three-day conference will feature top education programming, which will equip attendees with the latest methods and technology to improve quality, efficiency and consistency in their operations despite projected challenges in the industry, according to the association.

COMMUNITY IMPACT OPPORTUNITY

During IMPACT, ALM is teaming up with The Salvation Army Phoenix to provide much needed towels and sheets for the group’s

homeless shelter.

“We are encouraging conference attendees to partner with us and help us leave an IMPACT on the Phoenix community,” Wendland says. “We are fortunate and honored to be able to help address these needs, and giving

Conference

our support is ALM’s way to say ‘thank you’ for the support that the community will provide us during the conference.”

Those making a contribution will have their name entered into a drawing to win a $300 gift card, according to the association. The

winner will be announced during a special presentation to The Salvation Army Phoenix at the Wild Horse Pass Hotel during the conference.

“This is the perfect opportunity to give back,” says ALM Executive Director Linda Fairbanks. ALN

Program highlights will include:

• Methods and innovations to improve efficiencies and lower cost.

• Expectations for the industry’s future.

• America’s Got Talent finalist Joe Castillo.

• Breakout session on linen utilization and linen distribution.

One general session features Dr. Lynne Sehulster, who will discuss the opportunities and challenges of healthcare laundries and the role textiles may play in the spread of infection.

In addition, attendees can expect intimate learning sessions, innovative technology advancements, social networking events, and “fabulous accommodations,” says ALM.

The association also notes that the conference will offer networking opportunities, including a special offsite Wild Wild West Party sponsored by MIP at

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | FEBRUARY 2016 15

Rawhide Wild West Town.

Education

UPGRADE YOUR CHALLENGE PACESETTER CLM leads the way in dryer technology and provides an upgraded replacement for your old Challenge Pacesetter Our Model 165 fits the Challenge Pacesetter footprint perfectly and gives you technology that no one else o ers, including a fully integrated production management system. • Upgraded heat system with improved efficiency and lower emissions • Micro-Command III PLC upgrade with LAN and Blue Tooth communications • PLC now prepared for flow process management systems • 2-stage variable speed basket drive with 3-port load door. • Soft start to reduce component wear, lower utility use. • Heavy-gauge basket, includes removable steel basket panels • Long-lasting ceramic coating available on removable basket panels. • Configurable exhaust location • Configurable control/burner location Call CLM to replace your Challenge Pacesetter dryers, or for information on our broad range of industrial dryers. 323-232-2417 Model 165 shown with Tumble Green® configuration See Us at Booth 2560 at The Clean Show 211 Erie Street, Pomona, CA 91768 | T: (323) 232-2417 | www.clmco.com ALN_Jr Page.indd 1 11/18/14 2:36 PM 0515aln_CLM.indd 1 4/13/15 4:46 PM

renamed, set to make ‘IMPACT’

PRODUCT SHOWCASE

B&C TECHNOLOGIES

B&C Technologies says that its line of large-capacity washer-extractors has been proven in the field to offer long life and dependability. Available in capacities that range from 110 pounds to 475 pounds, these machines utilize a simple design that the company says saves money by keeping repair costs and downtime to a minimum and allows for easy maintenance.

B&C washer-extractors also have the all-new, flexible FM7 control that’s Bluetooth-compatible for easy programming. The high extract speed of this soft-mount line ensures less dry time for goods, saving on utility costs and wear and tear on the goods, the company says.

All B&C washers feature a solid foundation, a large door opening for easier loading and unloading, and a strong door and hinge system made of 304 stainless steel, according to the company.

www.bandctech.com 850-249-2222

goods in the same space as the industry’s average 400-pound machine, and that the 450N2 fits in the same space as most 200pound machines.

According to Braun, its washer-extractors are designed in such a way that the load balances itself prior to moving into the extraction phase. By slowly ramping up to a programmable extraction speed, these machines evenly distribute the wet goods against the cylinder, eliminating the need for artificial counterbalances. This balance method results in consistent thickness of goods throughout the cylinder, delivering a uniformly extracted load, free of wet clusters that greatly hinder the efficiency of drying and finishing areas, according to the company.

Braun says its openpocket washers can be ordered for chute loading for fully automated wash rooms. This loading option removes the potential for serious injury from pushing bags into a moving washer cylinder.

www.gabraun.com 800-432-7286

JENSEN USA

The Jensen USA L-Tron series washer-extractors are available in 450- and 800-pound capacities, with loading capacities ranging from 300 to 1,200 pounds, depending upon soil level and/or product classification. They are designed for either stand-alone operation or to work as part of a semi-automated or fully automated wash aisle.

In stand-alone operation, the L-Tron can be manually slingloaded or hand-loaded. For a more ergonomic sling-loading process, add the optional Load Assist, says Jensen USA. In semiautomated or fully automated operation, the L-Tron can be loaded via monorail system, shuttle conveyor or stationary conveyor.

trols, a powerful single-motor variable frequency drive with extract speeds up to 300 Gs, hydraulic tilt (25-degree loading and 21-degree unloading), ratiometric washing, dual drain, air bag suspension, patented intelligent balancing system, and maintenance watchdogs, Jensen USA says.

The company suggests incorporating its Futurail monorail loading or an L-Tron Shuttle Conveyor and an L-Tron DTX Series tumbler dryer to maximize throughput.

www.jensen-group.com 850-271-5959

ELECTROLUX

Electrolux high-speed, 450-G-force extraction washers—distributed by Laundrylux—offer speed, performance, huge savings and easy installation, according to the company. Electrolux says its washer-extractors provide ultra-fast drying, “tremendous” energy savings and increased productivity.

Electrolux washer-extractors come in a full range of extraction speeds and sizes up to 265 pounds in capacity.

superior wash.

With Compass Pro, Electrolux says one knob does it all: program selection, diagnostics and custom programming. Compass Pro has 55 programs, more than 20 languages, and Smart Start for delayed start. There are also Voice Guidance and Sanitizing Rinse options.

G.A. BRAUN

G.A. Braun’s open-pocket washer-extractors are available in processing capacities of 250 to 300 pounds, 400 to 600 pounds, and 600 to 700 pounds in dryweight load sizes.

The company says that its 650N2 washer-extractor will process 675 pounds of soiled

Standard on all Braun open pockets, single-motor drive (SMD) is the latest advance in energy-efficient drive technology. Using only one motor, a Braun open pocket is economical to operate, easy to maintain and offers greater flexibility in program options, the company says.

The L-Tron can be outfitted with either a large door with an observation window or the AutoPro loading hopper. The AutoPro design allows for fast loading times—as fast as one minute, according to the company.

Standard design features of the L-Tron series washer-extractors include touchscreen PLC con-

The company also says that its washer-extractors come with Automatic Water Savings, Smart Dosing, Compass Pro and Power Balance.

Automatic Water Savings (AWS) helps save up to 50% on water with every load, says the company. With each wash cycle, AWS determines the weight of the load and adds precisely the right amount of water, resulting in reduced water consumption and energy costs.

Working with AWS, Smart Dosing automatically adjusts the ratio of laundry chemicals to water, resulting in lower chemical costs, longer linen life and a

Power Balance extends the lifetime of the washer, according to the company. The feature automatically calculates the unbalanced load in the drum and then adjusts distribution and extraction speeds. Electrolux says this results in lower maintenance, less vibration and maximum water extraction.

www.laundrylux.com 800-381-7222

EDRO CORP.

The EDRO Corp. DynaWash® DW300SM three-pocket endloader washer-extractor is built around a patented basket design

16 FEBRUARY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

COMPILED BY MATT POE, EDITOR

[EDRO] [B&C Technologies]

[Jensen USA]

[Electrolux]

[G.A. Braun]

that delivers a dynamic wash action for superior linen cleaning, the company says.

According to EDRO, the tough, battleship-quality machine is equipped with efficient and effective topquality components, which now include a new and improved DynaMount suspension system.

The DW300SM features a single-motor variable speed drive with exclusive variable step-extract timing for improved load balancing and water extraction. An optional DynOzoneDynaWash® Ozone System— which reduces hot water requirements and overall water consumption—is also available, says EDRO.

A state-of-the-art HMi Touch Screen Controller allows for the most specific wash programming, simple operator interface, and full array of owner/supervisor productivity reporting, according to the company. With a 50-program memory, the controller features fully programmable field programming, manual overrides with password-protected security and operation reports on productivity, including wash program reports and alarm history/logs and pop-up service reminders for maintenance.

The controller’s integrated ozone control also provides maximum safety and ease of use of the powerful DynOzone cleaning feature, the company says.

www.edrocorp.com 800-628-6434

GIRBAU INDUSTRIAL