IES changes

name to SonicAire

WINSTON-SALEM, N.C. — Integrated Environmental Solutions (IES) has changed its corporate name to SonicAire®, effective immediately, the company reports.

The name change is part of a rebranding initiative designed to clarify the company’s commitment to producing an engineered solution to fugitive combustible dust through its line of SonicAire fans, the company says.

“Our fans have strong reputations in the marketplace for keeping plants continually compliant with OSHA [Occupational Safety & Health Administration] standards by eliminating overhead fugitive combustible dust buildup,” says SonicAire President Brad Carr.

“Ensuring that SonicAire fans are at the core of our corporate identity is important to us as our company continues to expand. We like to keep it simple and let our SonicAire fans speak for themselves.”

The company says its fans offer a full range of cleaning capability: a 140-degree vertical oscillation radius with a full 360-degree rotation.

The comprehensive rebranding efforts reach across all aspects of the company and include a new logo, according to SonicAire. ALN

Do dollars spent on new equipment really pay off?

BY MATT POE, EDITOR

CHICAGO — Success in the laundry room for Judy McCollough, director of environmental services for Ramsey Village, a continuing care retirement community in Des Moines, Iowa, means keeping pace with all of the soiled underpads, diapers, sheets, blankets, comforters, table linens, towels and personal items that come through on any given day.

That’s a lot of textiles, which means a lot of wear and tear on the equipment.

Recently, the laundry retired an 18-year-old, 75-pound hardmount washer. Ramsey Village made an investment in smaller soft-mount replacements, rather than hard-mounts, for significant gains in extract speeds, dry times, efficiency and overall productivity.

“We went from a bigger machine to a smaller machine and we get more productivity out of the smaller machine,” says McCollough.

Every laundry operation reaches a point where it has to make the investment in new equipment and technology. Most, if not all, manufacturers today highlight the efficiency and savings their equipment will provide.

American Laundry News spoke with four laundries, including Ramsey Village, to find out how investing in new equipment and technology translated into better efficiency in relation to water, energy and overall production.

HIGH-SPEED SOFTMOUNT WASHERS BOOST PRODUCTIVITY, EFFICIENCY

Ramsey Village allows mature adults to “age in place” without ever having to move for health reasons, says McCollough. With multiple levels of care—from independent and assisted living to rehabilitative, memory and skilled nursing—Ramsey Village is a 150-bed facility generating up to 50,000 pounds of soiled laundry

per month.

McCollough works directly with Mike Ross of Ross Chemical Systems, Des Moines, for the laundry’s needs. A full-service provider of commercial laundry equipment, kitchen equipment and chemicals, Ross Chemical Systems monitors and ensures the facility’s laundry sanitation, productivity, efficiency, chemical mix and processes are the best they can be, according to Ross.

Ramsey Village has worked

closely with Ross Chemical Systems and relied on Continental Girbau laundry equipment for two decades.

The laundry’s Continental workhorses include a 50-pound-capacity L-Series hard-mount washer, a 55-pound-capacity Pro-Series softmount washer, a 55-pound-capacity E-Series soft-mount washer, two 80-pound-capacity D-Series

Oceanside to close doors in June after 40 years

employees and produces 40 million pounds of goods per year.

BY RICHARD MERLI

OCEANSIDE, N.Y. — Oceanside Institutional Industries, one of the two largest laundries on Long Island, will close its doors and shut down operations on June 15, according to company principals.

The second-generation members of the family who have been operating the business decided to sell its lucrative routes, its laundry machinery and its modern laundry building on Long Beach Road

in the south shore community of Nassau County.

There is no heir apparent in the third generation who would have an interest in operating the business, the owners say.

At its peak, Oceanside employed more than 450 workers and processed more than 60 million pounds of goods a year for approximately 125 institutional accounts, including hospitals and nursing homes, in New York, Long Island and the Tri-State Area. The plant still employs 150 full-time

American Laundry News was recently given the exclusive opportunity to meet with the current principals of the plant in its executive offices and to take a guided tour of the 76,000-square-foot plant, one of the most modern and efficient plants in the industry.

The second-generation principals include Dominick and Jack Ferrara, vice presidents, and Francine Boyle, the director of human resources, who are part of the family of Frank Ferrara, one of the two founders; and Randi Gertler, vice president, and Sherri Klipper, who are part of the fam-

ily of Walter Hermann, the other founder.

“We’re tired,” says Dominick Ferrara. “Forty years in business is long enough. We are ready to begin the next phase of our lives.”

The business owners would not disclose the terms of the sale of their laundry routes, the building or the equipment, because the transactions are still in progress, they say.

However, it is clear that the laundry routes, machinery and building will be sold in three separate transactions.

“It was one of the most well-

MAY 2016 Late News

www.americanlaundrynews.com Volume 42, Number 5 INSIDE [22]

The Newspaper of Record for Laundry & Linen Management

[4] See TECH $$$ on Page 10

[14]

Texcare

Preview What to expect at next month’s Texcare International in Frankfurt

OCEANSIDE on Page 6

Judy McCollough, director of environmental services for Ramsey Village, unloads a new soft-mount washer that has boosted productivity in her laundry room. (Photo: Ramsey Village)

See

Columnist at Large Eric Frederick focuses on the big three: labor, linen and energy

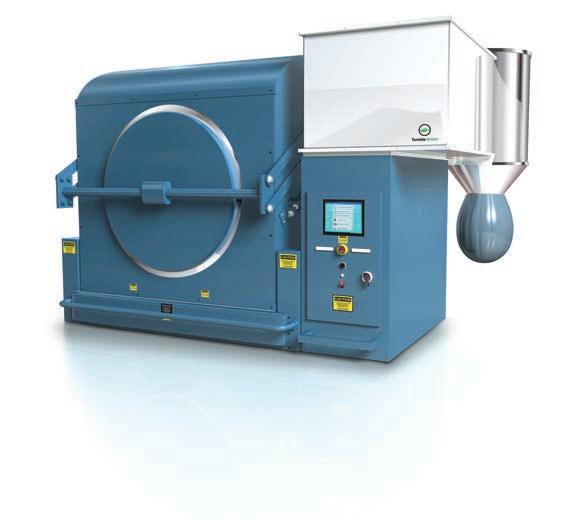

PRODUCT SHOWCASE Tunnel Washers Tunnel Washers

‘We’re tired,’ says second-generation principal of Long Island laundry company

Former laundry president pleads guilty to embezzlement of company he headed

Three others allegedly involved in fraudulent and inflated invoices submitted to Calif. company that netted more than $8 million

LOS ANGELES — An East Los Angeles man who oversaw a scheme that embezzled more than $8 million from an industrial launderer that provided finishing services for Citizens of Humanity, a manufacturer of high-end designer jeans, pleaded guilty on March 21 to federal charges, reports the U.S. Attorney’s Office, Central District of California.

Luis Mariano Rodriguez, 48, who was the president of the Gardenabased CM Laundry LLC, pleaded guilty to one count of mail fraud.

Rodriguez admitted in court that he and three other businessmen participated in a scheme that submitted fraudulent invoices to CM Laundry, which paid the bogus bills, with the proceeds being shared by the men.

According to court documents, the invoices sent to CM Laundry were fraudulent in at least two ways.

First, the invoices included fictitious and inflated charges. Second, the invoices were issued by companies operated by Rodriguez’s associates, which served to conceal Rodriguez’s role in the scheme.

Rodriguez admitted that he sent e-mails to two of his associates that gave them detailed instruction on what information to include on each of the fraudulent invoices that were submitted to CM Laundry.

At Rodriguez’s behest, the third associate established a fictitious business name (dba) for K&R Industrial

Supplies, and Rodriguez used this dba to submit other fictitious and inflated invoices to CM Laundry.

“This defendant victimized the very business that had entrusted him to lead it,” says U.S. Attorney Eileen M. Decker. “His fraud scheme, motivated by insatiable greed, threatened the viability of the victim company and the livelihood of its employees. Today’s guilty plea demonstrates the Department of Justice’s continued commitment to protecting American businesses from internal and external threats.”

Rodriguez admitted that an industrial supply company in Riverside, Calif., FI Products, billed CM Laundry for more than $3.6 million and transferred approximately $2.3 million of the proceeds to Rodriguez and a company he owned, Genesis Electronics Inc.

The Rancho Palos Verdes-based H&T Industrial Products, which was owned by another co-schemer, billed CM Laundry for more than $5.5 million and transferred approximately $3.6 million to Rodriguez and Genesis, according to court documents.

Fraudulent bills from K&R Industrial Supplies totaled approximately $639,939, of which approximately $493,617 was transferred to Rodriguez. As he admitted in court, Rodriguez generally kept approximately 75% of the proceeds generated by the false-invoice scheme.

Rodriguez pleaded guilty before U.S. District Judge Beverly Reid O’Connell, who is scheduled to sentence the defendant on June 20. As a result of the guilty plea, Rodriguez faces a statutory maximum sentence of 20 years in federal prison.

In related proceedings, Terry Jay Mink, 62, of Rancho Palos Verdes, the owner of H&T Industrial Products, pleaded guilty to conspiracy to commit mail fraud on Feb. 22. Mink faces a statutory maximum sentence of five years in prison when sentenced by O’Connell on May 16.

Rene Exequiel Bautista, 43, of Sylmar, the owner of the company used in the scheme under the dba “K&R Industrial Supplies,” has agreed to plead guilty to one count of conspiracy to commit mail fraud. Bautista was arraigned in the case and is expected to enter his guilty plea.

“Bautista admitted Rodriguez produced and submitted all of the K&R Industrial Supplies invoices that were submitted to CM Laundry and paid by Citizens,” according to the complaint affidavit. “Bautista stated [in a deposition related to a civil lawsuit] that he did not create any of the K&R Industrial Supplies invoices, did not know what any of

the invoiced items were and did not supply anything to CM Laundry.”

The fourth man allegedly involved in the scheme—Antonio Anguiano, 48, of Riverside, who was the owner of FI Products, which sold personal protective equipment—was indicted by a federal grand jury on March 4. The indictment charges Anguiano with five counts of mail fraud and two counts of aggravated identity theft.

Anguiano has pleaded not guilty, and his trial was, at press time, set for April 26. If convicted, Anguiano faces a statutory maximum sentence of 20 years on each of the mail fraud counts and a consecutive mandatory two years on each of the aggravated identity theft charges.

As a result of civil litigation brought by CM Laundry and Citizens of Humanity, a Los Angeles Superior Court judge in November ordered Rodriguez and several other defendants to pay a total of $9,563,786, according to court documents.

The investigation into the embezzlement scheme was conducted by the Federal Bureau of Investigation and the Los Angeles Police Department, Major Crimes Division, Criminal Investigations Section. ALN

Biloxi VA Medical Center facility story updated

In the March issue of American Laundry News, the article Biloxi VA Medical Center opens new textile processing facility should have noted the contributions of Western State Design (WSD) and the use of Parker Boiler components in the Biloxi, Miss., facility.

WSD designed the interior of the laundry. Per specifications for the bid, the government wanted a steamless boiler option, and WSD incorporated that. Two Parker Boiler T-6800 Direct Fired Hot Water Boilers were used in the system.

WSD partnered with R.W. Mar-

tin & Sons on the laundry build.

The overall project, which includes the laundry and dietetic services, was constructed by Roy Anderson Corp., Gulfport, Miss.

Roy Anderson reports that its project work earned a National Excellence in Construction Pyramid Award from Associated Builders and Contractors (ABC) in the Federal Government $10-$100 Million Category.

Roy Anderson representatives received the award March 2 during ABC’s 26th Annual Excellence in Construction Awards celebration in Ft. Lauderdale, Fla. ALN

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 231-740-2842

E-Mail: mpoe@ ATMags.com

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

Jim Buik • Richard Griffin

Greg Gurtler • Phil Hart

Janice Larson • Tom Marks

Gerard O’Neill

Richard Warren

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00.

Single copies: U.S. $9.00; Foreign $18.00. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 42, number 5. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2016. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

2 MAY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

INSIDE: May 2016 • Vol. 42 | No. 5 [6] Shift in Healthcare Mop Usage Traditional string mops and buckets are on the way out when it comes to floor cleaning in healthcare facilities [8] Tools of the Trade [12] Laundry Bottom Line and Technology In this month’s OPL 101, learn how advanced technologies aim to reduce operating costs and maximize throughput [15] ARTA Educational Conference Draws 130-plus Educational opportunities in Orlando focused on infection control issues as they relate to working with clients [18] Career Track [26] Trade Ticker [27] Calendar of Events [28] Classified Advertising [29] Source Directory

(Image licensed by Ingram Publishing)

“

They have done everything they promised and more.”

– John Ambrose Magliocco, Arrow Linen, Garden City, NY

From

Arrow Linen first purchased their three Milnor CBW® tunnels two decades ago to replace conventional washer-extractors in their original laundry located in Brooklyn, NY. Since then, Arrow’s business grew to warrant a second laundry. In 2013, Arrow expanded operations–and raised their roof 11 feet! Arrow could have chosen any manufacturer to equip their new washroom, but they knew that would get longevity, durability, and accountability with Milnor.

Arrow’s customers’ restaurant linen requires frequent color and soil change formulas, but the quality is not compromised. Corporate Engineer Frank Park boasted the tunnels “have increased our workload over 40% without increasing energy, water, or labor costs we experienced when we converted the conventional washers to CBW® tunnels over 20 years ago. The major improvements from the CBW® to PBW™ are far superior washing capability with only 50% water consumption.”

To find out how PulseFlow® can cut your water bill in half, contact an authorized Milnor distributor or call 504-712-7656.

www.milnor.com / pellerinmilnor

Scan to read Arrow’s success story.

left to right: Frank Park, John Ambrose Magliocco, Ron Hirsch, and John Anthony Magliocco

Equipment and infection

Equipment and infection.

That’s not a combination that occurs very often, but it does in this month’s issue of American Laundry News

We are featuring several articles that look at laundry equipment, in some facet.

Editor Matt Poe contacted managers and administrators at several laundries for his main cover story. In it, he asks the question, “Do dollars spent on new equipment really pay off?”

Poe found out what savings— cost and energy—those laundries experienced after buying new equipment.

In this month’s OPL 101, Bill Brooks also looks at new technology. He examines the topic from the angle of how advanced technology can help manage and improve laundry operations.

The Director’s Chair BRUCE BEGGS

Our Tools of the Trade department introduces a variety of new product ideas, while the Product Showcase examines tunnel washers.

Besides equipment, we have a couple of articles that look at the growing concern of infection control and how it relates to

laundry operations.

Our Panel of Experts tackles the issue, offering ideas on steps for laundry operations to take to ensure textiles are as clean as possible. The suggestions range from looking at the points of contact with linens to considering pursuing accreditation.

Poe also sat in on a Textile Rental Services Association webinar that explained why healthcare facilities are moving away from conventional string mops to microfiber flat-mop systems.

Finally, if you’re heading to Texcare International in Frankfurt next month, be sure to read the preview to see what’s in store and what companies will be exhibiting. For the first time, the show has expanded into a second hall, promising “big” things for attendees. ALN

New Hampshire laundry fined, given probation for hacking competitor’s computer

CONCORD, N.H. — A New Hampshire laundry that pleaded guilty to hacking a competitor’s computer has been sentenced to pay $18,900 in fines, penalties and restitution, plus two years probation, according to federal court records.

In December, General Linen Services LLC of Somersworth, N.H., formerly known as General Linen Service Co. Inc. (General Linen Somersworth), pleaded guilty in federal court to illegally accessing files of similarly named General Linen Services Co. Inc. of Newburyport, Mass. (General Linen Newburyport).

The Federal Bureau of Investigation reports that the facts to which the company agreed in its plea include that in September

2009, its former information technology director accessed, without authority, the computer server of General Linen Newburyport. The IT director then shared the login information with others at General Linen Somersworth, who then repeatedly accessed the competitor’s computer system, downloading approximately 1,100 of the competitor’s invoices for use in sales efforts directed at the competitor’s customers.

The FBI’s examination of the victim’s computer system proved that between September 2009 and April 8, 2010, there were 157 instances of unauthorized access to the victim company’s computer system, and that the majority of those intrusions originated at the office of the defendant, General

“Our company has been victimized by the deliberate and calculated actions of Shane and David Drolet, the owners and management of GL Somersworth, N.H.,” says Diane Whitney, owner of General Linen Newburyport. “We are the victims, yet we have paid thousands and thousands of dollars to law firms, accountants, and forensic experts. I shall be looking over my shoulder for the rest of my life, wondering who has our information and what awaits us. My family asks for two things: protection and justice.”

In response to American Laundry News’ request for comment on the matter, an attor-

See HACKING on Page 21

Keeping your eye on the goal

It is very easy to lose focus as we deal with the daily problems of running a laundry. These distractions can come in numerous shapes and sizes.

The important thing is to always focus on the big three: labor, linen and energy. These costs can make or break an operation. Every dollar you save in these areas goes directly to the bottom line.

Most managers do not realize that these three are interconnected and changes in one area may have an effect in another area. My simple motto in dealing with labor, linen and energy can be stated, “Do it right the first time.”

If you want to keep your labor cost lower than your competitors, then make sure your processes and procedures are designed so that linen is handled as few times as possible as it moves from soiled to clean. A good production system will maximize the production per hour of each machine.

I have seen laundries that operate a small-piece ironer with a four-lane stacker on the back with only two feeders. When asked why, I was told, “I was short-staffed” or “I needed some contours for an order, so I took two employees and put them on a mini folder so I could get both items produced at the same time.” The laundry was designed to have two minis discharging to one area. Using two instead of three is running at 50% production on the equipment.

It would have been much more effective to run the smallpiece ironer fully staffed for 45 minutes to an hour and then run the minis fully staffed.

This can work well with effective product management. When you make the job more interesting and easier, the side benefit is that your employees stay longer and are more productive. Lower turnover results in better productivity.

Your second largest expense is normally linen purchases. Your laundry work procedures should be designed to extend the life of the linen and get it clean the first time it is washed. Rewash will eat away at your bottom line by increasing labor, linen and energy costs.

Once again, the best way to wash linen is to do it right the first time. Many managers will brag about how much money they save on washroom chemicals while failing to realize the negative effects on labor, linen replacement costs and energy.

A side benefit of extending the life of your linen is happier customers and a reputation for always producing quality linen.

To get the most out of your energy costs, make sure your equipment is well-maintained. We do not want to waste energy by having improperly operating steam traps, gas dryers with worn seals, washing machines with leaking drain valves.

We purchase energy to accomplish a specific task. It should never be wasted.

I realize that after being in the laundry business for almost 45 years now, I might be a bit of a dinosaur. Cold-water wash or low-temperature wash has been championed as a way to reduce energy costs. My question has always been how this temperature change affects the big three.

WEBSITES

•

•

•

•

•

•

•

•

When I took washroom chemistry at the American Laundry and Linen College, I remember that the higher the temperature, the greater the chemical activity. The greater the chemical activity, the less chemicals you need and the better the cleaning process. The fewer chemicals used and the better the cleaning process, the longer the linen life.

Good wash formulas should lower the amount of rewash. Often, spending more money in the original cleaning process saves money in labor, linen and energy.

We must keep our eye on the big three and understand how they are interrelated in order to properly manage our laundry.

Eric Frederick is director of laundry services for Carilion Laundry Service, Roanoke, Va., and a past president and manager of the year of the Association for Linen Management. You can reach him by e-mail at efrederick@carilion.com.

4 MAY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

From

COLUMNIST AT LARGE Eric L. Frederick, RLLD

ALN

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending April 15 (WE) = WEB EXCLUSIVE NEWS • Olympic Linen Files for Bankruptcy • Ecolab Ranked on Two ‘Global’ Lists (WE) • China Laundry Expo to Double Exhibit Space for 2016 • N.S. Farrington & Co. Acquires Fuller Supply Co. (WE) • Hawaii’s United Laundry Services Joins UMF’s Infection ... COLUMNISTS/FEATURES

Infection Control Will Change Healthcare Laundry

•

Rugged and Industrial: LargeCapacity Washer-Extractors

Eric Frederick: Textile Philosophies by Laundry Type

OPL 101: Providing More than Equipment—Distributor Service ...

Manage Linen Misuse, Loss— Save Money

SISTER

AmericanDrycleaner.com:

OUR

From

Kolar Comes Aboard The Huntington Company

Spotting Tips: Breaking Down Cosmetics Stains

AmericanCoinOp.com:

From

CLA Gears Up for Excellence in Laundry Conference 2016 (WE)

Laundry Industry Calendar Continues to Fill Up

Linen Somersworth.

Lowering patient health risk is the highest goal. Imaging procedures can present varying amounts of risk and anxiety to patients, by the awkward and untimely process of changing gowns for each test.

With the ONEGOWN by ADI, there is no longer the need to change gowns. Fitted with plastic snaps; guaranteed to withstand 700PSI extraction during institutional washing, the ONEGOWN will not interfere with imaging studies. Let us help you keep patients comfortable and safe!

HEALTHCARE SOLUTIONS 800 820 2221 | imagine@americandawn.com | americandawn.com

Oceanside

designed laundry operations in the industry,” says Ron Hirsch, president of Direct Machinery, a distributor of laundry machinery based in Hicksville, N.Y., which will be selling off the equipment. “It is a clean, well-run operation. The plant was always extremely well-maintained. That’s one of the major reasons why they were able to obtain the higher productivity from their laundry equipment.”

At its peak, the laundry produced some 15,000 pounds of clean goods per hour in its plant, a two-story building dating back to the early 1980s. Its fleet consists of eight tractor-trailers and six 24-foot-long trucks.

Soiled linen arrives on the plant’s loading docks and is loaded onto elevators and carted to the secondfloor sorting station. The goods are weighed to the 110-pound capacity of the modules of the tunnel systems on the first floor. Soil sorters toss the batches of linen into enclosures, which lead to the chutes of four 20-module Senking tunnel washers.

Senking extraction presses form the washed goods into 110-pound wash cakes, which are then loaded onto one of two two-tier Norman shuttles. The shuttles auto-

matically load the clean wash cakes into any of seven 450-pound-capacity Norman dryers or two 500-pound-capacity Milnor dryers. Each dryer accepts four wash cakes.

“The linen is not touched from the time it is loaded into the tunnels until the time it is fed into the finishing equipment,” says Hirsch, who accompanied American Laundry News on a tour of the plant.

Items such as resident clothing are processed separately through three 400-poundcapacity L-Tron washer-extractors and one 200-pound-capacity washer-extractor.

Clean sheets are fed directly into one of eight American Laundry Machinery ironers. In addition to the ironers, the plant’s finishing machinery includes nine smallpiece folders, manufactured by G.A. Braun; five Edge spreader-feeders and three Edge

Maxx spreader-feeders, made by Chicago Dryer Co. (Chicago®), which feed the ironers; and one Chicago® Blanket Blaster, which spreads and feeds blankets.

The plant’s owners take pride in the productivity of the company’s employees. Employees on the finishing end feed up to 1,100 clean sheets per hour into the ironing systems.

As of press time, it is not known how many of Oceanside’s 150 employees may be absorbed by other area laundries. There is only one other laundry of comparable size and scope on Long Island—FDR Services Corp. of Hempstead, N.Y., a major healthcare laundry. ALN

Healthcare facilities moving to microfiber flat-mop systems

BY MATT POE, EDITOR

BY MATT POE, EDITOR

ALEXANDRIA, Va. — Hospitalacquired infections (HAI) get a lot of press. That makes sense because when a patient enters a healthcare facility, they’re looking to get better, not become infected.

Because of HAIs, healthcare facilities are looking at effective surface disinfection, and this includes the floors and the mops used.

The changing policies on surface disinfection and types of mops used were discussed by David Shimp, vice president of sales and marketing, North America, for Pinnacle Textile Industries, and Marti Lawson, director of business development for Crothall Laundry Services in the mid-Atlantic region during the Textile Rental Services Association’s (TRSA) recent webinar, Healthcare Market Solutions— Greening of Hospitals: Cleaning of Surfaces in Patient Care Areas for Hospitals and Nursing Homes

“The number of HAIs is very high, and right now it’s a big topic as it relates to hospital reimbursements and big dollars,” Lawson says. “HAIs are unnecessary and can be eliminated and controlled. They continue to grow even with education.”

She goes on to say that there’s

been a movement from cleaning patient areas with a detergent plus a disinfectant to using a detergentfree cleaner plus bleach, which is far more effective.

In terms of effectiveness, Shimp says that hospitals are changing to microfiber cloths and mops that dislodge and remove particles from surface crevices where regular cotton products can’t reach.

“When you use microfiber products, it actually will reduce water and also the use of disposable products and use fewer harsh chemicals to get surfaces clean,” he says. “A microfiber cleaning system used in conjunction with green cleaners and specialized mopping techniques can have a positive health and environmental impact.”

According to Shimp, there are many reasons why hospitals are switching to microfiber, flat-mop systems. These include cost savings, environmental benefits, health and safety, labor and cross-contamination concerns.

Microfiber products are manufactured with polyester nylon fibers that have split edges capable of trapping and holding microbes, dust and debris a lot more effectively than conventional mop products, Shimp says.

“It increases the effective surface

area of your mop. It’s more effective in cleaning up small particles,” he says. “The fibers thoroughly clean surfaces. It’s like it grabs it, holds it and brings it in.”

Ergonomically, both mopping systems use similar motor skills, says Shimp. There are unfavorable positions for both methods, but the

flat mopping system has reduced frequency and severity of risk factors. Also, there isn’t the weight of the water and the chemicals.

Shimp does point out that microfiber systems can’t be used in areas that have been contaminated with blood or bodily fluids.

“String mops absorb the fluids; flat mops push it and have to be thrown away,” he says. “It’s more of a disposal factor. If a flat mop was used, it would have to be disposed of immediately. Also, some products are ineffective in hightraffic areas and greasy and sticky floors. So, when using microfiber flat-mopping systems, they don’t necessarily work in every situation like a wet mop would.”

When it comes to laundering microfiber mops, the California Department of Health Care Services in its Licensing and Certification March 2014 memo says, according to Shimp, that it highly recommends using an industrial launderer to wash microfiber mops. The temperature has to be between 130 and 140 F. Also, the mops have to be separate from any other textiles, with no bleach or fabric softeners used.

“I have read other studies that bleaches are perfectly fine to use on microfiber mops,” Shimp says.

When it comes to purchasing a flat-mop system, Shimp cautions that “not all mopping systems are created equal; there is no governing body or industry definition of ‘microfiber.’”

Shimp recommends doing careful research to find a vendor with a good-quality flat mop. He adds that the density of fibers per square inch can affect pricing and cleaning ability.

In terms of performance of microfiber compare to conventional mop systems, Shimp says the flat mops last five to 10 times longer and increase production by 10%.

The microfiber system also uses 95% less chemicals and water compared to conventional mops, says Shimp.

“Overall, microfiber costs 5-10% less, not including workers’ comp savings,” he adds.

The take-home message points for microfiber mops, Shimp says, are that it is a practical, commonsense approach for patient care areas, but it will not meet all mopping needs.

There are immediate water and chemical savings, but most cost savings are a result of reduced labor. And there are improved ergonomics and cross-contamination infection control.

6 MAY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Richard Merli resides in New York and is a former editor of American Laundry News

Continued from Page 1

Perhaps some of Oceanside’s 150 employees will be absorbed by other area laundries after it closes. (Photos: Richard Merli)

Wash cakes are loaded onto a two-tier Norman shuttle at Oceanside. The facility’s equipment will be auctioned off.

A truck delivers linen to Oceanside Institutional Industries’ loading docks. The company will shut its doors June 15.

ALN

Flat, microfiber mops offer healthcare facilities cost savings and health and safety benefits. (Image licensed by Ingram Publishing)

LOOK BETTER. SPEND LESS.

Your clients expect the highest quality – and they should. Girbau Industrial washers and dryers provide a high-caliber clean while extending linen life. Add an Ironer to your equipment mix and linen is perfectly ironed straight from the washer. It feels soft and looks crisp, which is what your clients expect. Thanks to Girbau Industrial laundry equipment, you’ll heighten laundry productivity using less labor, while decreasing utility costs. Even better? Clients will thank you!

Contact Girbau Industrial for a FREE ESTIMATE to see how you can deliver more productivity to your laundry while increasing product quality! (800) 256-1073 • www.girbauindustrial.com INDUSTRIAL

Tools f the Trade

Utility truck line features spring-loaded platform for use

Plastic utility trucks in the 39 Series line from laundry product manufacturer MODRoto are offered with an optional, ergonomic, spring-loaded platform that automatically rises as goods are removed to help ensure work is properly positioned at a comfortable height for easy access and reduced bending and reaching, the company says.

Designed to support worker safety and minimize the potential for workers’ compensation claims, MODRoto says its spring-loaded platform sets a rotationally molded, waterproof, plastic platform atop a smooth, steel spring mechanism that can accommodate heavy loads of bagged laundry, loose linens and other goods. The entire spring platform unit is hidden

inside the cart bottom, away from contact with workers and linens, and may be easily removed.

The 39 Series line of utility trucks features rotationally molded, waterproof, plastic bins with safety, roll-top rims set atop durable bases on industrial-strength, non-marking casters, according to MODRoto.

In addition, the company says the 39 Series line is available in eight different models, offering a choice of sizes ranging from 7 to 24 bushels and a variety of standard colors. The 39 Series utility carts nest and stack one inside another when empty for efficient storage and transport.

www.modroto.com 800-829-4535

Scrubs catalog features new styles and colors, fabric options

Fashion Seal Healthcare®, a signature brand of Superior Uniform Group Inc., has released its new scrubs apparel catalog, the company reports.

Geared toward healthcare organizations, distributors and laundries, the catalog features lifestyle photography that provides a fresh, new look, the company says.

The catalog highlights traditional scrub shirts, pants and warmups, as well as several new styles and colors. A multitude of fabric options assure a perfect fit for acute and nonacute applications, as well as industrial and home laundering, says Fashion Seal Healthcare.

“Healthcare professionals truly represent the ‘heart of healthcare,’ from an operational and emotional perspective,” says David Schechter, vice president of marketing. “A well-designed uniform program helps them improve the overall healthcare experience for patients and their families.”

The company says the new catalog is easy to navigate, with expanded style and fit guides, as well as jewel-themed colorcoding to distinguish different product offerings.

www.fashionsealhealthcare.com 888-491-5818

Partnership offers innovations in reusable OR textiles

Encompass Group LLC is now offering innovations in reusable operating room (OR) gowns and drapes in the United States through a partnership with Canadian-based Lac-Mac, the company reports.

Encompass says Paragon Style Level 4 and Level 3 Surgical Gowns are uniquely designed and incorporate R-MOR-Tex® Liquid-Proof or LiquidResistant Barrier Fabric in critical zones and features a neckline that wicks away moisture and eliminates

chafing. Lac-Mac has an industrial design patent in both Canada and the United States for this gown.

Reusable drapes, which can be made to mimic single-use drape features, offer an opportunity for facilities currently using disposable drapes to easily transition into a more complex reusable product, according to Encompass.

www.encompassgroup.net 800-284-4540

Enzyme-fortified detergent offers benefits

Sunburst Chemicals has introduced Trifecta, a solid detergent for institutional laundering, the company reports.

Sunburst says Trifecta is specially formulated for effectively washing athletic (and other) uniforms without damaging fabric or transferring color, and is versatile for use on other linens.

Trifecta’s special enzyme-fortified

Digital

Xeros has launched Xeros Sbeadycare XTEND, a new commercial laundry linen management solution for hotels, the company reports.

According to Xeros, Sbeadycare XTEND is a first-of-its-kind product for the laundry industry, combining physical and digital technologies into a comprehensive “phygital” solution that utilizes smart, connected washing machines; responsive cleaning programs; and new polymers designed to offer the gentlest and most effective cleaning system available.

Xeros says Sbeadycare XTEND works in three ways:

Gentler Cleaning — Linens washed with XTEND are not subjected to excessive mechanical action, harsh chemicals and hot water found in traditional washing methods, Xeros says. XTEND leverages polymer bead cleaning that uses predominantly ambient water and proprietary soil-removal methods, leaving linens cleaner with less negative impact to the integrity of the linens.

Stained Linen Recovery —

formula is powerful enough to clean ground-in clay, grass, and blood stains and tough odors from uniforms—even at the low (90-110 F) temperatures recommended by uniform manufacturers, according to the company. Trifecta works effectively in soft- or hard-water conditions.

www.sunburstchemicals.com 800-899-7627

at a significantly higher success rate while still being gentle on the linens.

Cloud-Based Monitoring and Measuring — The Xeros Sbeadycare XTEND solution monitors and controls the entire laundry process to ensure each step is optimized to deliver superior yet gentle cleaning performance.

The company says customers can choose to seamlessly upgrade their current Xeros System with Sbeadycare XTEND.

www.xeroscleaning.com 844-207-1099

8 MAY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

and polymer technologies combined to maximize life of hotel linens

In recent tests, the Xeros reclaim program achieved more than 50% linen recovery rate when compared with traditional processes, the company says. XTEND removes tough stains more effectively and

ALN_Tab_1-4_H.indd 1 2/2/16 9:51 AM

Results on whites are excellent. On colors, you have nothing more to lose and everything to gain by trying YellowGo. YellowGo may take out color you want to keep. But if it removes the unwanted dye without damaging the underlying color, you win! You won’t have to pay for the dye-stained garments and you won’t disappoint your customers.

So use YellowGo to keep your customers happy and keep them coming back.

information visit

or

or

YellowGo® removes unwanted dye from fabric. For more

AlWilson.com

call us at 800-526-1188

201-997-3300

A HISTORY OF EXCELLENCE, A FUTURE OF POSSIBILITIES

A & B Wiper Supply is now Monarch Brands. We have changed our name to better reflect the full breadth of high quality and valuepriced textiles from manufacturers around the world. From global textile sourcing to private label programs, we have you covered, whatever your needs may be. Leverage our experience and purchasing power to find the perfect blend of quality and price point for your company.

Tech $$$

Dryers, and two 50/60-pound-capacity ProSeries II Dryers.

The soft-mount washer Ramsey Village installed to replace the hard-mount washer reaches extract speeds of up to 387 G-force, according to Ross, compared with a hardmount washer’s max of around 75-150 G-force.

This made it possible for the laundry to continue operating with its existing 13- and 18-year-old dryers.

Because the soft-mount washers remove more water from every load, the dryers operate less often and consume less natural gas, according to Ross. Goods also experience less wear and last longer. In turn, Ramsey Village enjoys reduced linen-replacement and utility costs, along with bolstered laundry productivity.

The newest additions to Ramsey Village boosted productivity by six loads per day— around 330 laundry pounds—when compared to the laundry’s hard-mount washer, according to McCollough.

“I wish I could get another one,” she says.

Not only is Ramsey Village enjoying savings on costs, McCullough says saving cash on equipment installation was an added bonus. The soft-mount machine, unlike hard-mount washers, slid easily into place without reinforced concrete foundations and bolt-down.

Catering to the needs of Ramsey Village is important, according to Ross.

“We recommend advances in technology of newer machines to help the customer in total laundry operation costs,” he says. “We are interested in 100% of their laundry operating costs, not just in the 9% equipment replacement, or the 8 to 10% chemical operation. Everything goes hand-in-hand for us, so to speak, as we address a particular piece of equipment and how it will affect operational costs.”

In this vein, Ross says he has improved Ramsey Village’s laundry operation through the years while simultaneously keeping the older machines in prime working order.

NEW EQUIPMENT ENHANCES

PRODUCTION

Another laundry service that has had success with integrating new equipment with the old, and seeing savings, is Jackson Services Inc., a family business headquartered in Columbus, Neb.

The company was born in the home of Minnie Jackson in 1924 as a family laundry service, says Jesse Jackson, president. The business, originally named Jackson’s Pantorium, grew and evolved to include a multitude of retail and B2B services, including dry cleaning.

In the 1970s, the business dropped all retail and drycleaning services and began focusing solely on the uniform, dust control, and other B2B textile rental services.

Jackson says the laundry has relied on Horwath Laundry Equipment, the local authorized Pellerin Milnor Corp. distributor, to fill its commercial laundry equipment needs. Milnor’s business relationship with Jackson Services has spanned the last 50 years. Prior to that, the laundry had purchased wooden washers manufactured by Andrew Horwath, Horwath Laundry Equipment’s founder.

Today, the laundry employs 76 full-time employees and processes approximately 6 million pounds of uniforms, mats, mops and towels annually, according to Jesse Jackson.

Last December, Jackson Services installed four new 6464 pass-through dryers (in a pod layout), one 48040 M7K 275-pound-capacity tilting washer-extractor and a 68036 M5K 400-500-pound-capacity tilting washerextractor to enhance its washroom production.

Another major component to the recent washroom upgrades was the E-Tech rail system to expedite linen transport in the laundry. The new rail system enabled the dryer pod layout, which eliminates the need to wait for an available dryer.

One major piece of equipment the Jacksons chose not to upgrade was their 1996 G2 Milnor CBW® tunnel.

“Milnor equipment produces excellent product quality and lasts for a very long time. So long, in fact, that it creates challenges for their own people to integrate their old equipment with their new equipment,” Jesse Jackson says. “The 20-year-old Milnor equipment in our plant is still just working so well, that we couldn’t bring ourselves to replace it yet.”

Since the upgrade, dryer production is increasing steadily. The quicker dry times have made it necessary to turn off the dryers a couple times per day so the washers and post-dry portion of the laundry can catch up, according to Jackson.

“We choose to buy Milnor equipment, despite there being cheaper options out there, because we feel it is the best,” he says. “We believe in buying quality, and that is the same value proposition we present to our own customers. The Jackson Family is proud to have worked with all four generations of both the Pellerin and Horwath families for so long. We look forward to continuing to work together in the future.”

NEW TUNNEL WASHER SYSTEM, IMMEDIATE GAINS

Eastern Health, one of three regional Newfoundland health authorities, encompasses numerous locations throughout the area, many of which are small clinics and doctors’ offices.

The St. John’s laundry services 13 hospitals and long-term care facilities, the furthest being 110 miles away. About 85 employees process goods from 7 a.m. to 8:30 p.m.,

10 MAY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

or visit monarchbrands.com to learn more.

Call 800-333-7247

Continued from Page 1

Jackson Services’ new rail system expedites linen delivery. (Photo: Jackson Services Inc.)

Sunday through Friday, with a swing shift taking over from the morning crew at 4 p.m.

The 25,000-square-foot plant processes nearly 7 million pounds of linen annually. That rate has increased more than 1 million pounds a year since Greg Osborne took over as general manager of laundry and linen services for the facility.

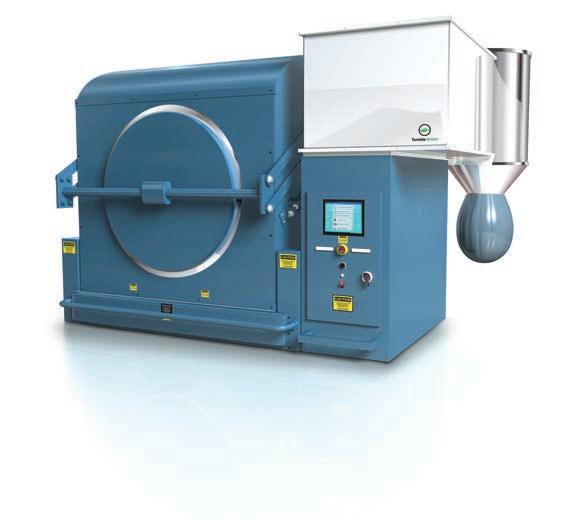

About five months ago, on Nov. 11, a new Lavatec Laundry Technology tunnel washer system, complete with extraction press and five drying units, arrived at the central laundry for Eastern Health, according to Osborne. The new 15-chamber tunnel replaced a likesized Lavatec unit that had logged more than 22 years of service for the regional health authority.

“The old Lavatec was still operating fine,” Osborne says. “But after two decades, it was reaching the point of needing a major overhaul. Replacement plans were under way when I became GM about two years ago.”

He says the 10-chamber Lavatec tunnel performed admirably throughout the transition, and the new 15-chamber tunnel picked up the pace without missing a beat.

“There are huge reliability advantages with a new system like this,” Osborne says.

Laser-guided drum manufacturing, for example, provides tighter tolerances, uniform welds and stronger, tighter, longerlasting seals. Osborne says this will help to ensure years of trouble-free performance. Double-drum construction ensures longterm strength and reliability. Maintenancefree friction drives are a definite plus, compared to chain drives in most competitive makes, he says.

In addition, Lavatec’s four-motor drive system keeps laundry moving when one or both motors suddenly require service.

More immediately noticeable for Osborne were the advanced tunnel software and controls.

“We have lots of new software to work with,” he says. These include simple, intuitive compartment-to-compartment monitoring.

Reduced water usage is a plus with the new unit, but not a major issue here, according to Osborne. “We don’t use meters like most operations in other areas. Water here is plentiful and, by comparison, relatively inexpensive.”

Savings and productivity advances elsewhere, however, are quickly proving to be significant. Like Eastern Health’s original tunnel washer, six previous dryers (three Lavatec and three Passat) had logged many years—some dating back to 1985.

“We were drying single loads,” says Osborne. “And a load would take about 25 minutes.”

The new system includes just five steamheated dryers, which more than match the

throughput of their predecessors.

“The new dryers handle double loads in as little as 17 minutes,” he says. This equates to nearly three times the total daily output per dryer, a ratio of more than 2.9 to 1 versus the older machines.

Granted, the new 40-bar LP 572 extraction press squeezes out more water than Eastern Health’s previous unit, before linen cakes go into the dryers. The biggest productivity difference, however, stems from the dryers themselves, Osborne says. Equipped with multiple-phase temperature controls and infrared sensors, they can precisely read each load’s progress and deliver the goods as desired.

“Infrared technology is already making a difference,” Osborne says. “There’s a whole lot more efficiency now.”

He also points out that no workers were displaced by going from six to five dryers. It has enabled the plant to effectively use more staff where needed.

HIGH-OCCUPANCY HOTEL UPGRADES, SAVES ON UTILITIES

Best Western Plus JFK Inn & Suites in Houston is a 100-room hotel that was purchased with its original laundry equipment. For Sanjay Patel, general manager, looking at the utility bills showed that the old equipment used energy at too high a rate.

“We were looking to replace the old equipment, specifically so we could save on utilities—energy” says Patel.

He says that laundry usage is important for the hotel because it does all of its laundry in-house.

“On average, we reach 50-70% full occupancy, so laundry is a huge part of our business,” Patel says.

How much laundry does the hotel produce? According to Patel, each room has at least triple sheeting, pillowcases, two bath towels, two hand towels, one bath mat, shower curtain and more, which are all washed on a daily basis.

So, when it came to selecting new equipment, Patel looked hard at energy usage. He is a customer of Best Wash Inc., a dealer in Texas, and trusted the distributor’s input.

“James West from Maytag dealer Best Wash Inc., and his crew, are the best in the business,” he says. “We use them for all of our projects.”

For both washers and dryers, Best Western JFK chose Maytag equipment. There were several factors that led to this choice, such as the machines’ features, energy savings, little to no maintenance required, and experience with the brand, according to Patel.

And he says that he’s seen improvement in the laundry all around with the new equipment.

“With our new Maytag Commercial Laundry equipment, we’ve experienced time and energy savings, and our laundry comes out cleaner than before,” he says.

According to Patel, the hotel’s water and electric bills have decreased tremendously since the new equipment was installed. He estimates that the energy savings have averaged around 40-60%. In addition, the laundry loads from the washer are rinsed better, Patel says, which leads to faster dry times and the opportunity to complete more cycles.

“Most importantly, the machines work well so we don’t have to wait on parts or repairs, which we often experienced with our previous machines.”

For these four laundry operations, investment in new equipment and technology has paid off. Working with distributors and manufacturers, the laundries have seen increased savings and productivity—which will pay off in the long run.

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | MAY 2016 11 In addition to customer favorites, we now carry even more products to service your needs. Download our full catalog at monarchbrands.com. • Institutional Sheets

Cabana & Spa Towels

First Quality Collections

Eclipse Towel Lines

Route Ready Bar Mops

Performax Microfiber Lines

Microfiber Cloths & Mops

SmartChoice Wet Mops

Poly Spun Napkins

Personalized Product Lines NEW OFFERINGS INTRODUCTORY SPECIALS • Save up to 70¢/dozen when you eliminate pre-washing and counting these 32oz bar towels • Soft packed, optically white, and ready to use • Pre-packed bundles of 25 Promote your brand 24/7 with complimentary logo label embroidery! • Personalized microfiber products, terry towels, and bar mops • Ultimate control over inventory • Carry your own product line • Free advertising for your brand Call us to learn how you can carry your own lines for no additional cost!

SOLUTIONS • Wide variety of colors • Price breaks for bulk orders • 16”x16” microfiber cloths • Use for wet or dry cleaning 35¢ MICROFIBER CLOTHS • Commercial quality microfiber looped flat mops • 80% Polyester, 20% Polyamide • Cut your cleaning costs without sacrificing quality • 18” long with Velcro backing 95¢ SMARTCHOICE WET MOPS $3.25/doz ROUTE READY BAR MOPS Call 800-333-7247 or visit monarchbrands.com to learn more.

•

•

•

•

•

•

•

•

•

CUSTOM

ALN

Eastern Health recently installed a 15-chamber tunnel washer system and has seen immediate results. (Photo: Eastern Health)

Innovative tools help laundry room managers maximize throughput

advanced monitoring capabilities would have many positive impacts on our operation, and in less than one year, we have already seen a reduction in utilities and nearly doubled our throughput.”

BY BI LL BROOKS

With advanced controls, networking capabilities and green technologies, laundry equipment has undergone major improvements in recent years. While all of these cutting-edge advancements work in different ways, they have one thing in common: they aim to reduce the overall operating costs and maximize throughput for on-premises laundry (OPL) facilities.

These innovations allow you to stay constantly connected to your laundry operation through real-time and remote monitoring capabilities. They also help you set benchmarks and make immediate adjustments to simplify your laundry room management and minimize costs at every stage. Whether your current machines are equipped with the latest technology or you are considering replacing older equipment, read on to learn how embracing these advancements can have a significant impact on your laundry room.

REAL-TIME MONITORING

Research in early 2015 found that more than 90% of decision-makers in OPL facilities do not fully understand the cost of their laundry operation, but now this has never been easier. Advanced controls with real-time monitoring capabilities give OPL managers and executives complete visibility to all the major components of their laundry room. This technology can gather information on labor, utilities, equipment usage, types of cycles being programmed and efficiency, and compile the data for OPL managers in one comprehensive report.

“Before we replaced our laundry room equipment last year, I was determined to find the best machines to meet our needs,” says Sean Taylor, director of engineering, Loews Ventana Canyon, in Tucson, Ariz. “I knew that installing equipment with

Hotel executives who manage multiple facilities can use the monitoring reports to look at an individual machine or all machines across multiple locations. This technology can track everything from cycle times, number of fills, water temperature and idle time. Monitoring alerts can also be customized to be sent daily, weekly, monthly, quarterly and yearly so operators can see the immediate usage data, as well as the “big picture” over time. These reports can be accessed online and delivered directly to an e-mail inbox so a laundry manager doesn’t even need to be present to see how the equipment is operating.

“In addition to the reports, we also installed real-time monitors in the laundry room,” says Taylor. “Now, anyone in the laundry room can see the current status of each of our machines at all times and know how much time is left in a cycle, which has really helped our laundry room staff.”

THE IMPORTANCE OF SETTING BENCHMARKS

One of the best ways to ensure your laundry room is running as effectively as possible is by setting benchmarks. By taking time and investing in the appropriate resources to establish benchmark standards, an OPL manager can save time and money. With the ability to monitor all aspects of your laundry operation in real time, laundry room operators now have visibility that can help them make informed decisions on how to best manage labor resources based on the expected volume of laundry during a specific time period.

“Our hotel is very busy in the winter and slower in the summer due to the high Arizona temperatures,” says Taylor. “Establishing the right equipment mix to handle loads during busy and slower periods, along with the monitoring technology, made it possible for us to set more realistic benchmarks. We are now review-

ing machine usage data that we used to look at monthly on a daily basis, and it has improved our wash time dramatically.”

It’s estimated that labor costs represent up to 50% of a laundry’s operating budget and therefore establishing measures to optimize the labor process is critical. Reducing water consumption and energy usage also remain key concerns in the industry and are important factors to monitor by setting benchmarks.

If you are just starting to set benchmarks, your equipment distributor can help you determine what cycles are best for your industry and linen needs. Your distributor will also help you take a holistic look at your operation, including number of loads processed per shift, machine usage and types of cycles being used in order to set benchmarks that help increase efficiency.

WHEN TO MAKE ADJUSTMENTS

Visibility to your machine utilization will provide you with a strong understanding of how and when your machines

are running during a specific shift or day. This knowledge can help you identify bottlenecks in your laundry process. For example, if linens are sitting for an extended period of time between a wash and dry, you can determine the best way to fine-tune your labor and equipment to ensure they are all being used effectively. Additionally, advanced technology allows you to monitor and make adjustments anytime, from anywhere in the world, with cloud-based system access.

“The new monitoring capabilities have been really helpful for our day-to-day operation. When we look at the daily usage data and see we did not hit our goals, we can pinpoint the exact shift and identify inefficiencies and make modifications,” says Taylor. “It also helps us identify ways to improve our staff training, team member performance and overall processes.”

The technology can also help diagnose any equipment issues so that they can be handled immediately to reduce machine

12 MAY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com OPL 101

ALN_Tab_1-4_H.indd 1 3/31/16 10:23 AM See OPL 101 on Page 25

Managing and improving laundry operations through advanced technologies

Monitoring technology used at Loews Ventana Canyon made it possible for the hotel’s laundry room to set more realistic benchmarks. (Photo: Loews Ventana Canyon)

BECAUSE THERE’S NOTHING UNIFORM ABOUT FLEET REQUIREMENTS.

With Freightliner Custom Chassis, it’s all about delivering greater profits through increased productivity and proven fuel economy. Our commercial chassis feature heavy-duty components that are designed to surpass automotive-class vans for maximum uptime and unbeatable driver safety. FCCC chassis also provide the ultimate flexibility for box configurations to meet your needs. Most importantly, as an FCCC owner, you have access to 24/7 factory support and the largest nationwide service network.

FUEL EFFICIENCY

No matter which power you choose, you can count on the MT to lead the way in fuel efficiency that translates into enhanced profitability.

SAFETY

From heavy-duty braking to maneuverability, ergonomics and curbside access – driver safety is our top priority.

QUALITY

As part of the Daimler family, FCCC chassis are developed with legendary resources for design, engineering and manufacturing processes.

UPTIME

With 24/7 factory support and the largest nationwide service network, issues are quickly resolved to keep you on the road.

FUEL OPTIONS

Choose from gas, diesel, propane and CNG to best meet the needs of your delivery fleet.

REAL COST OF OWNERSHIP™ 1-800-545-8831 | freightlinerchassis.com For ordering details, contact your local dealer. Specifications are subject to change without notice. Freightliner Custom Chassis Corporation is registered to ISO 9001:2008 and ISO 14001:2004. Copyright ©2016 Daimler Trucks North America LLC. All rights reserved. Freightliner Custom Chassis Corporation is a subsidiary of Daimler Trucks North America LLC, a Daimler company.

Big is the word for Texcare International 2016

This year’s Texcare International event is packed full of exciting new areas of interest such as tech innovations and sustainability, show managers say. Because of so many more exhibitors and attendees, the show will expand to take over another entire exhibit hall to accommodate everyone journeying to Frankfurt for the June 11-15 spectacle.

BY TIM BURKE

FRANKFURT AM MAIN, Germany —

Big and growing bigger describes Texcare 2016. Not only in the number of people sojourning to this event, but also in the actual physical size of the exhibit space. You might say it’s bursting its seams.

More visitors than the 2012 show (16,000) are expected to step through the entrance to view hundreds of exhibitors. Growth does come with interesting learning experiences.

Topics brought together during this fiveday festival of all things textiles cover everything from fiber to machine.

For the first time, the international industry will be showcasing its innovations and new developments across the whole range of modern textile care, reports Messe Frankfurt, the managing host of the big show.

Wolfgang Marzin, president and CEO of Messe Frankfurt, says, “We are very glad to see the strong demand for Texcare 2016. In this way, the trade fair will be offering its visitors an even wider and more international range. Through this growth, Texcare is underlining its importance as a leading international trade fair for the industry.”

Going digital is also a hot topic this year, as well as buzz about the expected upturn in business prospects, particularly in Europe.

The megatrend at Texcare International is the digitalization of processes, Messe Frankfurt indicates in a recent show update. This development is also reflected in a growing range of information-technology products at the trade fair.

Thanks to modern identification technologies such as RFID, clothes and textiles today can be allocated to the customer problem-free in the laundry, notes Messe Frankfurt. In this way, goods flow automatically, and even the intelligent wardrobe on the customer’s premises can trigger an order.

That all processes, machinery and data are linked and optimally visualized is a prerequisite for the smart fabric of the future, the show organizer further notes.

Digital control is also one of the main topics at Texcare, which include sustainability, innovative textiles and their treatment, and changes to job profile.

The textile care industry is constantly reinventing itself, with ongoing development in mechanical engineering, washing and enviro-tech, reports Messe Frankfurt. A textile’s sustainability is determined above all by its usage. The industry is committed to improving the general ecological and ethical conditions under which they operate.

Efficiency of resources and sustainability will be central topics at Texcare. The latest developments in mechanical engineering and detergent chemistry will further encourage the proper use of resources.

“A successful concept of sustainability includes the optimum interplay of sustain-

EXHIBITOR LISTINGS

•

ability principles and collaboration by players who are pursuing the same goal,” explains Robert Long, secretary general of the Textile Services Association (ETSA), based in Brussels.

“Products and processes should have a minimum impact on the environment and still be efficient,” notes Long. “At the same time, they must enjoy a high level of functionality, which guarantees a business’ success. This, in turn, ensures jobs under good social conditions.”

The textile care sector and its supplier industry are pursuing a philosophy of sustainability and protection of resources, notes Messe Frankfurt.

A major step in implementing comprehensive sustainability is an effective network, the company reports. It bundles the industry’s requirements, encourages the exchange of ideas between all partners involved, and multiplies pioneering results,

Electrolux Professional S.p.a.

Emco Bau-und Klimatechnik GmbH & Co. KG

Everstrong Commercial Products

Expo Detergo S. R. L. F F3 Fumagalli S.r.l. • Fagor Industrial, S. Coop. • F.B. Italy di Fabio Bruno • Fimas Srl • Fintec Textilpflegesysteme GmbH • FIRBIMATIC S.p.A. • Flexco Europe GmbH

FLORINGO GmbH • Foltex B.V. • FriSatec GmbH • fuhlrottdatenverarbeitung ohg

G Richard Geiss GmbH • Gemme Italian Producers S.r.l. - LELIT • GestiClean Up • Ghidini Benvenuto S.r.l. • Giannoni Group S.R.L. • Girbau S.A. • GMP Commerciale Srl • Machinefabriek Goudkuil Apeldoorn BV • Grandimpianti I.L.E. Ali S.p.A. • GreenEarth Cleaning • Gütegemeinschaft sachgemäße Wäschepflege e.V. • Gulfraz Fabrics

H Hänel GmbH & Co. KG • Haghofer GmbH • Haosch Refrigeration Technology GmbH • hawo GmbH • Hayikama Makine Hali Yikame Ith. Ihr. San. Tic Ltd Sti • Healthcare Laundry Accreditation Council • HeBeTec Wäschereitechnik und Service GmbH

Kändler • Mobics B.V. • Mohan Spintex India Ltd. • Montanari Engineering Construction S.r.l. • Mountek GmbH • Mountville Mills • MS Group SRL a socio unico • Mujtaba Textiles • Multimatic Maschinen GmbH • Multimatic iLSA Deutschland GmbH & Co. KG • Multitex Maschinenbau GmbH N-O-P-Q

14 MAY 2016 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

A A13 S.r.l. • ABG Systems S.r.l. • ABS Laundry Business Solutions • ABZ Zierler GesmbH & Co KG • Adamjee Enterprises • AdvanTex Software GmbH & Co. KG • All Japan Laundry and Drycleaning Association • Alliance Laundry Systems • ALUX A. Wieckowski • Alvi S.R.L. • Angeline Group Ltd. • Anghinetti & Camptel srl • AquaRecycle LLC • Artmecc di Fornaro Renato • AS-Shop Ladeneinrichtungsund Messestände GmbH • ASA Horst Wieber GmbH • ATS-Tanner Banding Systems AG • Automated Packaging Systems Ltd. • Autovalet Systems • AVILON LTD • AVS FBI & Sept7.fr + US Lab B Bandall International • BARBANTI S.r.l. • Bartex SCRL • Battistella B.G. S.R.L. • beck packautomaten GmbH & Co. KG • Beepee Enterprise Pvt. Ltd. • Beirholms Vaeverier A/S • Bergparma S.r.l. • BG Energie Textil Elektro Medienerzeugnisse • Biar S.r.l. Ausiliari Biochimici • Bieffe S.r.l. Unipersonale • BIKO Engineering AG • BIMAP srl • BÖWE Textile Cleaning GmbH • BOLDODUC SAS • Borch Textile Group A/S • Brändl Textil GmbH • BRENTARENO S.r.l. • F. W. Brügelmann Söhne GmbH & Co. KG • BÜFA Reinigungssysteme GmbH & Co. KG Co. KG • BurnusHychem GmbH • Bussetti & Co. GmbH C CARBONELL Compania Anonima • Cargo Pak S.R.L. • Catinet S.L. • CBAmachines N.V. • Certuss Dampfautomaten GmbH & Co. KG • Chicago Dryer Co. • Christeyns N.V. • CHT R. Beitlich GmbH • C.I.N.E.T. - Comité International L’Entretien du Textile • Cizgi Tekstil Ithalat Ihracat San. Tic. Ltd. Sti. • Clayton of Belgium N.V. • Clean Show 2017 • Clinotest GmbH Die textile Company • Colmac Industries Inc. • Conf Industries S.r.l. • Consorzio Unimatic - Group Industrial Technology • CORDES Bügeltechnik GmbH • Creazioni Futura S.r.l. D Damino GmbH • DANTE BERTONI s.r.l. • Danube International • Datamars SA • deister electronic GmbH • Delta P.B. S.r.l. • Delta Umwelt-Technik GmbH • Deren et Cie SA • Dexter Laundry Inc. • Dibella GmbH • Karl Dieckhoff GmbH & Co. KG • Reiner DIEZ e.K. Verpackungsmaschinen • DOMUS LAUNDRY • Dositec Sistemas SL • Dragon Verkaufsgesellschaft mbH • DTV - Deutscher TextilreinigungsVerband • Düchting Software & Consulting GmbH • Dunnewolt & Rahe GmbH • Dyckhoff GmbH E EazyClean Technologies GmbH • Eco Impact Brüske GmbH • Ecolab Europe GmbH • econ solutions GmbH • Ecotex GmbH & Co. KG

•

•

•

•

•

HeboVandijk B.V. •

GmbH & Co.

• henning-Datentech-

•

•

AB •

Institute •

Systemhygiene GmbH •

&

•

CORPORATION I Imprimerie Pascal

• Ideal Manufacturing Ltd • IFL Industrie-

• ILSA

• Image Laundry Systems • Imesa Spa • INDEMAC S.r.l. • Indus Home Limited • Inwatec ApS • IPA, LLC • Italclean Srl. • Italia Service S.r.l. J-K Jensen-Group • JFC Manufacturing Co. Ltd. • JOBET GmbH • Jumag Dampferzeuger GmbH • Jyden Workwear A/S • Herbert Kannegiesser GmbH • KEMAS GmbH • Kentaur A/S • Kleen-Tex Industries GmbH • Krebe-Tippo d.o.o. • Chemische Fabrik Kreussler & Co. GmbH • Kurtenbach GmbH & Co. KG • Kurtz Software GmbH L LACO Machinery NV S.A. • Lamac Machinery nv • Lampe Technical Textiles B.V. • Langheinrich Vertriebs GmbH • Lapauw International NV. • Laundry Computer Technics BV • Laundry Dashboard B.V. • Lautratex B.V. • Lavatec Laundry Technology GmbH • LG Electronics, Inc. • LM CONTROL SAS M MACPI S.p.A. Pressing Divison • Maestrelli S.r.l. • MAGIELEK RFID • Malavasi - Mario Fonio S.r.l. • Malkan Makina San. ve Tic. Ltd. Sti. • MASA SPA - Industrie Tessili • Mascot International GmbH • Master Textile Mills Ltd. • MATO GmbH & Co. KG • Maxi Companies Inc. • MAXI-PRESS Elastomertechnik

• MBT Endüstriyel Tekstil Ürünleri San. ve Tic. A.S. • Medical Modular

S.A. • Metalprogetti S.p.A. •

GmbH • Micross Automation Systems • Miele &

KG •

Mats Ltd. • Milliken Industrials

• Pellerin Milnor

•

GmbH • MiRiCal

•

• MMB

See TEXCARE on Page 19

Gebr. Heinemann

KG

nik GmbH

HEPROTEX Maschinen GmbH

HIGEJA

Hohenstein

hollu

Holzmann Medien GmbH

Co. KG

HUQAS

Huyar

Leasing GmbH

S.p.A.

GmbH

System

MEVOMetzler

Cie.

Millenium

Ltd.

Corp.

MIP Europe

Emblems Ltd.

MKG

GmbH

Naseeb Fashions Clothing Pvt. Ltd. • Negin Pazirik Isatis • Nettuno A.S.G. sas di Moroni Maria Ippolita & Co. • Nordhäuser Palettenbau GmbH

WHAT: Texcare International, World Market for Modern Textile Care WHERE:

WHEN:

Messe

Exhibition GmbH/Petra

Frankfurt trade show grows, shows off industry advances, reinventions—and sheer seam-bursting size

Frankfurt am Main, Germany

June 11-15, 2016 (Photos:

Frankfurt

Welzel)

Marzin

Hammering Man leads the way to grounds of Messe Frankfurt, host of Texcare International.

ORLANDO, Fla. — The American Reusable Textile Association (ARTA) held its 2016 Education Conference in Orlando, March 9-11, at the JW Marriott Grande Lakes.

More than 130 industry representatives attended the conference, according to the association. The educational opportunities focused on infection control issues as they relate to working with clients, selecting client products, and processing issues in the plant.

“Our conferences offer an intense 1.5 days of education that help members stay competitive in marketing reusable textiles,” says Nancy Jenkins, executive director of ARTA.

According to the association, many attendees shared the sentiment that meetings like the one in Orlando are needed in the industry.

Infection control professionals in attendance particularly agreed.

“Hospital staff do not talk about these issues as they relate to laundry,” says Tiffany Silman of Chesapeake Regional Healthcare in Virginia. “This conference has opened my eyes, and I’m taking the information back to my teammates.”

The 130-plus attendees came from all over the country and as far away as Israel. Highlights of the meeting included a tour of Disney’s new plant, FLO, and two

receptions—a Welcome Reception hosted by MIP/Encompass and a Sponsor Reception hosted by ARTA’s Platinum and Gold Sponsors.

ARTA offers member in-person education on an annual basis. The next event is slated concurrently with Clean 2017 in Las Vegas.

ARTA will exhibit at Clean, host a member breakfast and offer education. Its next education conference is set for 2018. ALN

UPGRADE

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | MAY 2016 15

YOUR

PACESETTER CLM leads the way in dryer technology and provides an upgraded replacement for your old Challenge Pacesetter Our Model 165 fits the Challenge Pacesetter footprint perfectly and gives you technology that no one else o ers, including a fully integrated production management system.

Upgraded heat system with improved efficiency and lower emissions

Micro-Command III PLC upgrade with LAN and Blue Tooth communications • PLC now prepared for flow process management systems

2-stage variable speed basket drive with 3-port load door. • Soft start to reduce component wear, lower utility use. • Heavy-gauge

includes removable steel basket panels

available on removable basket panels. • Configurable exhaust location • Configurable control/burner location Call CLM to replace your Challenge Pacesetter dryers, or for information on our broad range of industrial dryers. 323-232-2417 Model 165 shown with Tumble Green® configuration See Us at Booth 2560 at The Clean Show 211 Erie Street, Pomona, CA 91768 | T: (323) 232-2417 | www.clmco.com ALN_Jr Page.indd 1 11/18/14 2:36 PM 0515aln_CLM.indd 1 4/13/15 Sixth association meeting focuses on infection control issues

draws 130-plus to Orlando

American

1.5

• Nuova Folati S.r.l. • NYBO Workwear A/S • Özdemir Kece San. Tic. Ltd. Sti. • Pallas Finish-Systeme GmbH • Pamilas Italia S.n.c. di Ancona Stefano e C. • M/S Paramount Textile Mills (P) Ltd. • Parotex Srl • Tessitura Perego s.r.l. • Picchi s.n.c. • Pir Inci A.S. • Polymark GB Ltd. • Polytex Technologies Ltd. • Pony S.P.A. • Premier Fine Linens Pvt Ltd • Prima Folder S.r.l. • Quadus GmbH R RAMPI PRODOTTI CHIMICI DI RAMPI FRANCESCO E FIGLIO • Ranyal Textiles • ratioplan GmbH Transportgeräte • ReaCoTec GmbH • Realstar S.R.L. • RE.MA. PLAST S.r.l. • Renzacci SpA Industria Lavatrici • Reverberi Arnaldo Srl • REWAKON GmbH • Rohrbach Elektrotechnik GmbH • Rotel GmbH • ROTONDI Group s.r.l. • rs-etiketten & embleme

• RTP - Radomskie Tekstylia

Sp. z o.o.

Europe

•

Industries, Inc. • Sankosha

Co. Ltd • Schmidmeier

GmbH • Hans-Joachim

GmbH • Schulthess

AG • SEALED AIR/

• Jiangsu Sea(continued on page 19)

CHALLENGE

•

•

•

basket,

• Long-lasting ceramic coating

ARTA

conference

Reusable Textile Association

members participated in

days

of education at the group’s conference. (Photo: ARTA)

GmbH

Przemyslowe

S SAFECHEM

GmbH

San-Ai

Manufacturing

NaturEnergie

Schneider

Maschinen

DiverseyCare

PANEL OF EXPERTS

Infection control and laundry operations

and more, I’m hearing about laundries and infection control. How concerned should I be about this? Are there steps I can take to, as much as possible, ensure my textiles are clean? Anything I can do with equipment? Chemicals? Working space?”

In our facility, we work very closely with our infection control nurse. Being aware that potentially all laundry we come in contact with should be considered infectious, we make sure we have safeguards in place. Our laundry is bagged at the point of use and placed into hampers that are lined with leakproof bags and have lids. The hampers are used to transport the soiled laundry to the linen chute on the unit. By doing this, we are able to contain any spores or microorganisms within.

Our facility takes steps to ensure that the routes that our soiled and clean laundry take do not cross paths at any point. We transport the clean and dirty laundry in their own separate carts, which have the sole purpose of transporting that type of laundry. Using covered carts to transport the clean clothing back to our patients helps to reduce possible contamination.