Magnus Textile closes financing

CHELMSFORD, Mass. — Magnus Textile, a textile manufacturer, importer and distributor to the hospitality and healthcare industries, has closed a round of financing from LaunchCapital, the company reports.

LaunchCapital is the venture capital arm of the multibillion-dollar Pritzker/ Vlock family office. The round of financing will go to support product development and the company’s nationwide expansion, according to Magnus.

“The raise allows us to accelerate our product development efforts and to grow the team to reach more customers across the U.S.,” says Dev Ramasubbu, CEO and co-founder of Magnus Textile. “And with the capital investment and support of the Pritzker/Vlock family office, we are further enabled to redefine what is possible in commercial textiles.”

Edward Coady, an investment professional with LaunchCapital, will be joining Magnus Textile as chief marketing officer. Coady was previously an associate with the firm and was based in the Boston LaunchCapital office.

“We firmly believe that Magnus Textile is poised to transform the commercial textile industry,” says Cliff Sirlin, managing director of LaunchCapital. ALN

Laundry emergency procedure preparedness

BY MATT POE, EDITOR

BY MATT POE, EDITOR

CHICAGO — Parkland Health & Hospital System, also known as the Dallas County Hospital District, uses an on-premises laundry (OPL).

Richard Hoelscher, linen services production manager for Parkland, says the laundry has had emergencies over the years. Fortunately, these incidents have been minor.

“Parkland has had several small fires, but these only involved one piece of equipment each time, were promptly put out by staff with a hand fire extinguisher and verified out by the fire department,” Hoelscher says. “Parkland’s staff performed extremely well during the

Code Red, following the RACE (Rescue, Alert Security, Confine, Extinguish) procedure.”

The reason Parkland has performed so well during emergencies is that it has detailed emergency procedures in place, Hoelscher says. Also, staff undergo training to help ensure all know what to do in the event of a risky situation.

It is essential for laundry operations of all types and sizes to have emergency procedures and training in place for safety, and to ensure the business is able to keep processing linen.

PLAN DEVELOPMENT

For Laura Gracia, safety director for Admiral by Alsco in Houston, emergency procedures

are essential to minimize, if not prevent, injuries and damage to property, ensuring continuance of business.

ARCO/Murray expands two

operational facility and was carefully phased with dock and workflow transitions to eliminate production interruptions and allow for daily truck deliveries, according to the company.

DOWNERS GROVE, Ill. — ARCO/Murray, a design/build general contractor, recently completed laundry expansions for two uniform, linen and facility service companies, the company reports.

In Wichita Falls, Texas, ARCO/ Murray provided services to Alsco, completing a 10,500-square-foot laundry facility expansion. The construction took place in a fully

The project also included construction of a 4,760-square-foot mezzanine, new loading docks, and a 50,000-square-foot parking lot with truck court addition.

Along with upgraded LED lighting and improved building ventilation, the project scope included the expansion of existing electrical services, ARCO/Murray says.

Preconstruction services included architectural design, structural engineering, mechanical and electrical design, and permitting.

ARCO/Murray

“Each of our plants was assigned to develop a plan accord-

ny

In

A UGUST 2017

News

Record

Laundry & Linen Management www.americanlaundrynews.com Volume 43, Number 8 INSIDE [6] [28]

EMERGENCY on Page 24 [4]

Late

The Newspaper of

for

See

Columnist at Large Eric Frederick examines the future of automation and employee wages.

(Image licensed by Ingram Publishing)

says Justin Hearld was project manager and Mike Epperly served as project superintendent.

Ottawa, Ontario, the compa-

completed a 9,000-square-foot facility expansion for Canadian Linen and Uniform Service.

Both projects completed without service interruption to rental customers

laundry facilities

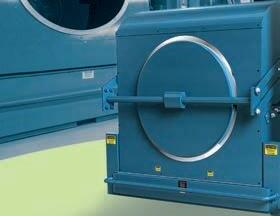

The Alsco Wichita Falls, Texas, expansion included a 50,000-square-foot parking lot and truck court. (Photo: ARCO/Murray)

See BUILDS on Page 4

Plans, training are keys to safety, business continuance

experts provide insight into keeping up with technology.

’17 Report Exhibitors in Las Vegas debuted their latest laundry advances.

Panel of Experts The

Clean

Angelica Corp. completes sale to KKR

B. Wood appointed president, chief executive officer

ALPHARETTA, Ga. — Angelica Corp., a provider of healthcare linen and medical laundry services, has completed the sale of substantially all of its and its subsidiaries’ assets as a going concern to KKR, the company reports.

Under KKR’s ownership, the business is moving forward with the Angelica name and will continue to provide linen services to the healthcare industry, serving more than 3,800 hospitals, clinics and long-term care facilities across the country, the company says.

In connection with the closing of the transaction, Cary B. Wood has been named Angelica’s president and chief executive officer.

Wood, who succeeds David A. Van Vliet, has more than 20 years

of experience improving operations, enhancing customer relationships and optimizing overall financial strength while prudently deploying capital to improve both topand bottom-line results, Angelica says.

“I am pleased to be part of the next chapter in Angelica’s storied 139-year history and look forward to working with the company’s dedicated employees to drive growth and success,” says Wood. “Partnering with KKR as our long-term investor, we will focus on quickly strengthening Angelica’s operations and finances while continuing to grow our customer base by providing our AngelTrak® RFID linen manage-

ment system to customers who elect to use this industry-leading technologically based approach that provides optimized and efficient linen services.

“Our top priority is ensuring we continue to deliver exceptional service to our customers. Looking ahead, we are focused on driving profitability, increasing operational efficiencies, implementing best practices and improving our organizational effectiveness.”

Rony Ma, principal on KKR’s credit team, says, “We are enthusiastic about Angelica’s future prospects and are excited to have Cary leading the company as president and CEO. With a stronger financial foundation and the full support of KKR, Angelica is poised to build on its position as an industry leader with a national footprint

and long-term partnerships with key customers. Cary’s significant experience and strong track record give us confidence that he is the right person to lead Angelica through its next phase of growth.

“We look forward to working closely with Cary and the Angelica team to leverage the company’s pioneering technology solutions and best-in-class service.”

Angelica says KKR is primarily making the investment through funds affiliated with its Direct Lending strategy.

Weil, Gotshal & Manges LLP served as legal counsel to Angelica, Alvarez & Marsal served as restructuring adviser, and Houlihan Lokey Inc. served as investment banker and financial adviser.

Paul, Weiss, Rifkind, Wharton & Garrison LLP served as legal counsel to KKR, along with Jones Day, which served as KKR’s counsel on labor and benefits matters. ALN

opens

industry speakers and panels, and live, interactive demos. Special feature areas for HX 2017 include:

NEW YORK — Attendee registration for HX: The Hotel Experience, slated for Nov. 12-13 at the Jacob K. Javits Convention Center here, is now open at the redesigned website, www.the hotelexperience.com, say show organizers.

“HX gives the hospitality professional an expansive, 360-degree look at the guest experience and how it will impact their property’s appeal, efficiency and profitability,” says Phil Robinson, HX show director.

Organizers say the show will feature more than 400 exhibitors,

• HX360° INNOVATION ZONES. New this year, three fully built-out areas designed by industry visionaries to engage attendees in the latest trends in the key hospitality areas of Lobby & Bar, Food & Beverage, and Spa & Wellness.

• HX: TECH. This ever-popular section is bigger than ever, organizers say, filled with the latest technology impacting the hospitality industry. From digital security and signage to drones and robotic service opportunities, attendees will be immersed in all the latest hospitality tech. Interactive

product demos and presentations round out this hightouch, high-energy area.

• HX: STAGES. The popular HX: Onstage Hotel and Onstage Restaurant returns with rich content, presenta-

of a five-module tunnel system noted on page 24 of the July issue were incorrect. The correct dimensions are 25 by 50 feet.

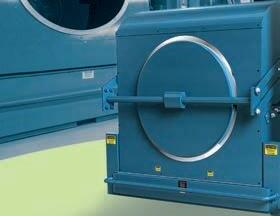

• In the same issue, the photo of the Jensen JTD tumbler/dryer on page 20 was incorrect. The correct image is shown at right.

American Laundry News regrets these errors and apologizes for any inconvenience they may have caused. ALN

tions and interactive panel discussions.

Registration for HX 2017, including all conference sessions, is $50 through Oct. 16; cost will be $75 thereafter. ALN

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 231-740-2842

E-Mail: mpoe@ ATMags.com

Production Manager Roger Napiwocki

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

Jim Buik • Richard Griffin

Greg Gurtler • Phil Hart

Janice Larson • Tom Marks Gerard O’Neill Richard Warren

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies: U.S. $9.00; Foreign $18.00. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 43, number 8. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2017. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within.

Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

2 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com MEMBERSHIPS INSIDE: August 2017 • Vol. 43 | No. 8 [22] TRSA Conference Heads to Miami Beach Annual conference to feature textile services presentations and two keynote speakers from outside the industry [23] AHE Alters Conference to Focus on Solutions Healthcare environment association says it has analyzed and reinvented its EXCHANGE conference program [27] Two Laundry Facilities Re-accredited Plants in Springdale, Ark., and Burnaby, B.C., have passed the inspection process for HLAC re-accreditation [31] Career Track [32] Trade Ticker [34] Calendar of Events [36] Classified Advertising [37] Source Directory HX: The

Hotel Experience 2017 attendee registration

Due to an editor’s error, the possible dimensions

•

Show highlights three special feature areas

Cary

HX: The Hotel Experience is scheduled for Nov. 12-13 at the Jacob K. Javits Convention Center in New York City. (Photo: Richard Merli)

Wood

CORRECTIONS

Ultra and Nanofiltration: The Modern Solution for Ultra Clean Water.

It’s a whole new way to filter water. Using our exclusive hollow-fiber ceramic membrane, the PurePulseTM system operates in in the lower end of the ultrafiltration range into nanofiltration. Filter total dissolved solids and dyes as small as 5 nanometers – no need to cool water. This is innovative membrane technology for the modern age.

Recycle 70-80% of your facility’s water

Filter your water while it’s hot, saving energy

Self-cleaning ceramic membranes have 10 year warranty Reliable and long service life

Less expensive than RO technology

Affordable, low running costs and fast ROI

PurePulse system has a small footprint that won’t change as you expand with additional, stackable membranes.

Patent applied for system.

504-712-7700

www.PurePulseSystems.com

A ‘Clean’ sweep and wrap

It’s a little difficult to believe that it’s been almost two months since Clean ’17 wrapped in Las Vegas.

It seems like only yesterday that I was walking the floor of the Las Vegas Convention Center, visiting laundry and linen services vendor booths, enjoying evening events, taking photos and posting vital information (and a few fun things), talking with laundry operators like you … winning a fortune in the casino.

OK, that last part didn’t happen. I’m not a gambler, so the most I did was throw a few bucks in a slot machine, which I lost within minutes.

If you went to Clean, I know you’re not a gambler, either—

Builds

From The Editor’s Desk MATT POE

when it comes to your laundry operation. You went there to get solid information and ideas and make contacts to help your operation run as efficiently and effectively as possible. But with a sold-out show

(481 exhibitiors on the trade show floor), you couldn’t visit every vendor. Or maybe you couldn’t make it to Las Vegas this year.

That’s why on page 6, you’ll find the start of the Clean Show roundup. I was able to visit with quite a few exhibitors, and you’ll find some of the things I learned on those pages (through page 20).

If you couldn’t make it to Clean, I hope you can glean some ideas for your operation. If you were able to make it, maybe I visited some vendors you didn’t have time to meet.

The Clean Show is a high point in the industry. Now, it’s time to make that show work (and look ahead to Clean ’19!). ALN

Increased automation in the future

There have been a series of recent studies published about how the minimumwage increase in Seattle has negatively impacted the workers it was designed to help. The workers have experienced fewer hours per week, and employers have reduced the number of jobs through automation. Restaurants are moving to kiosks to place orders and accept payment.

So, what will happen in the laundry industry as this trend drives up the hourly rate?

There are many possible solutions that our industry can use to adapt to increasing wages. I am aware of laundry departments that are spun off as a separate company to allow them to reduce retirement benefits and possibly reduce the cost of health insurance. The parent company does not want to affect their executives or more skilled staff but has no concerns about reducing the benefits of lesser paid employees.

Continued from Page 1

Construction included a building addition, loading dock and parking lot expansion.

The project scope included the addition of a 1,000-square-foot mezzanine, new soil and clean loading docks, and upgrades to the building’s storm sewer, plant lighting, fire suppression and ventilation systems.

The site and building construction was completed while the existing plant remained at full capacity.

Alsco also added 10,500 square feet to its Wichita Falls laundry facility. (Photo: ARCO/Murray)

Preconstruction services included architectural design, engineering and permitting. ARCO/Murray says Rick Guth served as project manager. ALN

Crothall up to 13 Hygienically Clean

ALEXANDRIA, Va. — Crothall Laundry Services’ Wheeling, Ill., facility is the latest recipient of Hygienically Clean Healthcare certification, TRSA, the association for the linen, uniform and facility services industry, reports

The certification confirms a laundry’s dedication to compli-

ance and processing healthcare linens and garments using best management practices (BMPs) as described in its quality-assurance documentation, a focal point for inspectors’ evaluation of critical control points to minimize risk, TRSA says.

Crothall now has 13 TRSA Hygienically Clean Healthcare-

certified facilities. In addition to the newest designee, they are located in Mobile, Ala. (Coastal Laundry); Phoenix, Ariz.; La Mirada and Ontario, Calif.; Lakeland, Fla.; Augusta and Rome, Ga.; Madisonville, Ky.; Belcamp, Md.; Winston-Salem, N.C.; Johnson City, Tenn.; and Milwaukee, Wis. ALN

I have also seen hospital systems contract out the operation of the laundry to a contract company in hopes of finding better management and reducing the cost of labor. This hope often turns to disappointment because contract companies may have first-class marketing but no operational magic bullets. The cost of labor is dictated by the local labor market and not by the type of management.

“THE POSSIBLE EFFECTS OF THIS MOVEMENT WILL TOUCH ALL MINIMUM-WAGE INDUSTRIES. WE ARE IN THE EARLY STAGES AND NOW IS THE TIME FOR EACH MANAGER TO DEVELOP HIS OR HER GAME PLAN.”

I have also seen efforts made to reduce staff through a combination of automation and changes in the packaging of linen. What once was an unacceptable delivery style is now common practice.

When knitted fitted contour sheets first arrived on the scene, laundries tried to fold them like a regular woven contour sheet. The manufacturer attempted to increase the appeal of the product by suggesting that the sheets could be placed into bags and delivered to the nursing units in that manner.

Nursing naturally saw this as a decrease in quality or service, but over the years, more and more laundries switched to this delivery method. Now it is the most common form of delivery for that item. Bagging requires less staffing than folding the sheets.

We are in the early stages of bagging washcloths instead of flatstacking them. The bagging method is 300% faster than the stacking method.

As salaries continue to increase, the number of laundries moving to bagging washcloths versus flat-stacking will steadily increase. Additional labor-saving technologies will be implemented as the cost of labor increases, making the development of other systems more viable.

There will also be increased pressure to reduce other costs in the laundry. The second largest cost in the laundry is textile products. Emphasis will be on smarter purchasing and longer life. A manager may increase his or her washroom chemical cost per pound to increase linen life. Greater emphasis will be placed on machine maintenance to ensure maximum return on investment.

Employee productivity monitoring, especially real-time monitoring, will help to control costs. The possible effects of this movement will touch all minimum-wage industries. We are in the early stages and now is the time for each manager to develop his or her game plan.

Eric Frederick has retired from active laundry management after 44 years. He is available as a laundry operations consultant. He is a past president and two-time manager of the year of the Association for Linen Management. You can contact him by e-mail at elfrederick@cox.net or by phone at 540-520-6288.

4 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

COLUMNIST AT LARGE Eric L. Frederick, RLLD

ALN

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending July 15 (WE) = WEB EXCLUSIVE NEWS • ARTA Presents Awards During Clean Show Breakfast • Huebsch Names Metropolitan Laundry Machinery Distributor ... • Pellerin Milnor Partners with HJ Weir for Distribution Across ... • HX: The Hotel Experience 2017 Attendee Registration Open • EnviroStar to Acquire Martin-Ray Laundry Systems COLUMNISTS/FEATURES • PPE Essential to Laundry Worker Safety • Kansas Hospital Goes OPL After 50-plus Years • New Kid on the Block • Mining ‘Diamond’ Employees Today • OPL 101: Right Equipment Mix in the Details OUR SISTER WEBSITES

AmericanDrycleaner.com: • Press Cleaners Calls for Drycleaning ‘Revolution’ • The Seabee, Two Wars, and a Navy Coat

AmericanCoinOp.com:

All Things Facebook

Survey: Summer

From

From

•

•

Doldrums Not Unusual in Self-Service ...

americandawn.com | imagine@americandawn.com HACCP IS ABOUT FOOD SAFETY In food processing plants, HACCP plans are about ensuring that critical control points are contaminant free. American Dawn offers a full line of HACCP Garments, as well as the knowledge and training to support your team. Give us a call to learn more about how we can open the door to this growing marketplace. CALL US: 800 821 2221 LET’S KEEP OUR FOOD SAFE

CLEAN SHOW REPORT

Leaving Las Vegas (with laundry news)

Convention Center.

BY MATT POE, EDITOR

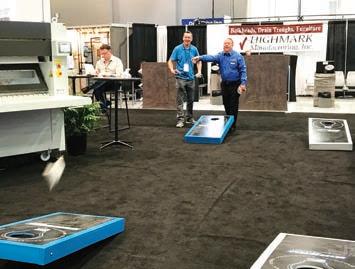

LAS VEGAS — Attendees of Clean ’17 left here with a grand haul.

Not a haul from the casinos (although some may have had a lucky streak), rather, a haul of information about products and services that the 481 vendors brought to the show.

“I’m impressed by the technology,” says first-time Clean attendee Brian Polatsek, CEO of EcoBrite Linen in Skokie, Ill. “I found that I’m interested in a steam tunnel. I didn’t think I would, but I’m impressed by the quality.”

Technology was the word on the floor, as vendors dazzled potential customers with virtualreality tours, equipment demonstrations and industry innovations.

“The best thing is the innovation,” says Randy Wendland,

corporate director of textile management services for ABM Healthcare Support Services in Royal Oak, Mich. “There are some game-changing products out here, from UV technology to high-tech software. It’s been phenomenal.”

Of course, not all of the 12,563 attendees were focused on the new and improved in the laundry and linen services industry.

“I came here because this is my chance to see the principals of my vendors, to have that contact,” says Bill Kartsonis, president of Superior Linen Supply in Kansas City, Mo.

And attendees were sure to find almost anything they were looking for on the show floor. Show organizer Riddle & Associates says Clean ’17 boasted the largest floor sales since the 2007 show in Las Vegas. Vendors covered 227,006 square feet of exhibit space in the Las Vegas

Sponsors for the Clean Show are the Association for Linen Management (ALM), the Coin Laundry Association (CLA), the Drycleaning and Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA) and TRSA, the association for the linen, uniform and facility services industry.

Many companies took advantage of Clean ’17 to introduce brand-new products, roll out newly improved products or exhibit well-established product lines. Still others exhibited at the biennial show for the first time.

American Laundry News presents this report describing just some of the companies and the products they exhibited in Las Vegas. With a sold-out show, this article isn’t intended to be allencompassing.

Readers are encouraged to follow American Laundry News in print and online (www.american laundrynews.com) during the coming months for product announcements from these companies and others.

Continental Girbau

Continental Girbau opened eyes at Clean with several new products. However, its new virtual-reality technology, GirbauMax, really turned heads. This allows users to access and design, via virtual reality, industrial, commercial and vended laundries. More than 150 booth visitors signed up and engaged in

the GirbauMax experience.

“The show was a huge success, with leads totaling over 800 and business opportunities more than doubling over the last Clean show in 2015,” says President Mike Floyd.

Girbau Industrial automation products were in constant

6 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Attendees crowded onto the Clean Show floor after the ribbon-cutting opening. (Photos: Bruce Beggs, Nathan Frerichs and Matt Poe)

What would Las Vegas be without showgirls, even on the trade show floor?

ALN_Tab_1-4_H.indd 1 7/10/17 2:47 PM See CLEAN on Page 8

Attendees at Clean ’17 learn about new products, reconnect with colleagues

Featuring a compact design and flexibility that allows Whistler Laundry to automatically feed, iron, fold and stack a variety of items, the Compact fits perfectly into its designated spot at the laundry. Configurable for one, two or four working lanes, with one lane for sheets, two for table linens and four for small items, including napkins and pillowcases, it executes up to three-lane primary folds and single- or two-lane cross folds. A bypass option allows goods to exit the front or rear of the machine, and the Compact offers left or right discharge and front or rear stacker orientation to meet specific needs. Finally, it automatically adjusts ironing speed and moisture removal — processing goods with no dryer preconditioning.

Contact Girbau Industrial for a FREE ESTIMATE and discover how production automation can boost productivity and profits in your laundry! (800) 256-1073 • www.girbauindustrial.com

INDUSTRIAL Our first ironer improved production and revenue 30 percent. The new Compact 5-in-One elevated it another 30 percent. The Compact has opened the floodgates to new business and bigger clients.

Steve Wheeler, Co-Owner, Whistler Laundry Inc., British Columbia, Canada

operation, as well, including the FT-Maxi towel folder, the new DRB Feeder and FRB Folder, the ST-1302 Dryer and the Compact 5-in-One—a machine that automatically feeds, irons, folds, stacks and accumulates.

Also on hand were Continental’s commercial/ on-premises laundry products, including soft-mount E-Series Washers, hard-mount G-Flex Washers, complementing dryers and Express Ironers.

The new 80-pound-capacity E-Series Washer debuted, as well. The freestanding machine, recently added to the E-Series line, offers a soft-mount design for simple installation, highextract speeds reaching 400 G-force, utilizing Inteli Control.

Positek RFID

With techology at the forefront of Clean, Positek RFID had success demonstrating its radiofrequency identification (RFID) system at its booth.

The company showed how its bundle readers, tunnels and portals will track thousands of pieces with lightning speed and guaranteed accuracy. Any tagged textile that is loaded onto conveyor belts

or into carts, containers, pallets or other bulk moving solutions can be scanned.

The company also showed how its state-of-the-art hardware and tags utilize the latest innovations in RFID technology to ensure that a laundry’s solution works accurately and reliably, is durable enough to withstand high-volume textile management workflows, and is flexible enough to grow as a company grows and evolves.

ADI American Dawn

ADI American Dawn reports it had a highly successful Clean Show engagement, having unveiled its new disposable paper product initiative.

This strategic alliance with VonDrehl is set to disrupt the current market distribution model—with no minimums on orders, according to the company.

Additionally, ADI reports high interest in its newly designed HACCP apparel program, complete with multi-colored stock selections of hidden-gripper, spun-poly cover garments.

Lavatec Laundry Technology

Lavatec Laundry Technology Inc. introduced a new Ride-On Shuttle, the LT50 110-pound continuous tunnel washer and the osLaundry software system at the 2017 Clean Show.

“We enjoyed many good conversations with customers and others about our new and existing equipment, including the TT-series Ecodry dryers,” says Keith Ware, Lavatec vice president of sales. “As expected, the Ride-On Shuttle was a hit with everyone. It was located along the main aisle and it stopped people in their tracks. That led to them coming into the booth to learn more about it.”

Ware says the Ride-On Shuttle gives an operator the ability to control washers, dryers and the rail system from the safety of a technology-driven cockpit. It has built-in sensors for the operator’s safety in case he needs to leave the shuttle.

Lavatec staff received positive feedback on its osLaundry software, says Ware, which can be integrated into all of the company’s new equipment.

Ware also says his staff answered many inquiries about the row of TT-series Ecodry dryers that took up residence along the back end of the booth. Ecodry dryers have undergone a few changes, such as large glass windows that allow a clear view of linens being dried, built-in smart technology, and a line burner that covers the entire drum.

Clean Cycle Systems

Clean

Filters reports solid booth traffic during Clean ’17, along with increased interest in its economic models for OPL and coin laundries, the Lint Lasso Series and OPL Small Wonder Models.

“It’s always a very important show for us because we get to see our dealers,” says Michael Reilly, president. “Just to maintain the relationship is a primary reason, and then you pick up a lot more leads. Larger companies have sales reps that are calling on their customers, their dealers. Smaller companies, you don’t really have somebody covering the whole territory.”

The CCS Lint Lasso “inline” duct filter displayed in Las Vegas spotlighted new stainless models, custom capabilities and models for 4-inch to 18-inch ductwork.

The company says its Small Wonder OPL-200 and -300 models are available in more than 10 sizes, with capability ranging from 1,000 to 10,000 CFM, offered in a choice of fiberglass or stainless steel.

Pellerin Milnor Corp.

Milnor debuted two products in its booth at the Clean Show: MWT-Series rigid-mount washer-extractors and Premier Series dryers.

Premier Series dryers are available in gas, steam or electric heat. The dryers come in units up to 120 pounds of capacity.

Milnor showed more than just two new lines, though. The new MWF100J7 features 220 pounds of capacity, and the company says it’s the largest-capacity washer-extractor in the series.

Also on display was the 76039 8-module CBW tunnel, featuring PulseFlow technology.

Besides laundry equipment, the Milnor booth also featured a display that premiered PurePulse Water Recovery Systems, with its ceramic, hollow-fiber membranebased filtration technology filter in the lower end of the ultrafiltration and nanofiltration range. The company says this filtration delivers ultra-clean water, critical for commercial and industrial textile care operation.

Spartan Fleet Vehicles and Services

Spartan Fleet Vehicles and Services showcased its Utilimaster 20-foot Walk-in Van at the Clean Show.

Cycle Systems Lint

The company says its MWT Series features models up to 60 pounds of capacity, while

“At Spartan, across our Utilimaster and Spartan Upfit Services brands, we are dedicated to designing vehicles and supporting products that enhance the productivity and effectiveness of our fleet customers,” says Tom

8 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

The line for attendee registration was non-stop on Clean’s opening day.

Continued from Page 6

See CLEAN on Page 10

Booths were packed much of the time during the show.

Clean

Notice Anything?

InkGo® Is Now Odor Free!

InkGo has been reformulated to remove its odor… and to improve its performance.

InkGo is still the environmentally friendly,* safe way to remove ink stains from all types of fabric. It’s still great at removing autoclave tape and adhesives. And since it’s odor-free, InkGo is more pleasant to work with.

Does odor really matter? As more drycleaners position themselves as good environmental stewards, keeping chemical odors in the plant to a minimum can help them differentiate from their competition. And odor-free is a real plus if you’re working on ink for an extended period of time.

Now that’s worth noticing!

*InkGo is Biodegradable and is California Prop-65 and California VOC Compliant.

Become a STAIN WIZARD at ALWilson.com

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

Ninneman, Spartan Fleet Vehicles and Services president.

The Utilimaster 20-foot Walk-In Van, customized to serve the laundry and linen service market, has a multitude of features designed to make both soiled- and cleanproduct transportation safer and easier, the company says.

The van includes a 10.1-inch in-dash radio back-up monitor unit with a 360-degree camera vision system, 100% interior and exterior LED lighting, and curbside shutter door option for product staging and two-wheel hand cart storage. The van also features a number of Utilimaster-patented designs to keep cargo safely in place, including SafeLoad , locking cart and locking garment rail systems.

IPA

IPA (Innovation+Passion+Automation) manufactures automated surgical scrub and linen dispensing equipment for healthcare providers.

In Las Vegas, the company showed off its scrub- and linen-dispensing systems.

According to IPA, its ScrubEx surgical scrub dispenser has been proven to reduce replacement costs by up to 90% and laundering costs up to 40%.

Along the same lines, it says its AlEx linen distribution system typically reduces replacement costs by 25% and processing costs by 20%.

Throughout the show, IPA highlighted its ability to help hospitals to increase productivity, support infection control efforts and provide tangible cost savings by reducing replacement and processing costs for surgical scrubs and linens.

EDRO Corp.

EDRO Corp. put the spotlight on its C80 and C110 C-SERIES tumbler dryers.

The company says the units are assembled using high-quality and robust components to ensure a long and useful machine life for the laundry operator.

Available in gas, steam (C80, C110) and electric (C80 only) versions, EDRO says its commercial series dryer range is designed to meet the needs of virtually every on-premises and commercial laundry facility.

The company says standard features of the C-SERIES range include simple design; fully insulated front, side and rear pan-

els; large door opening for easy loading/ unloading; fewer moving parts; mounting holes for easy installation; and a self-cleaning lint screen for easy cleaning.

WSI Washing Systems Inc.

Clean Show attendees got an eyeful from WSI—an eyeful of optimization technology, that is.

The company highlighted its Wash-Eye system, which provides real-time, comprehensive information. WSI says the system can “transform any plant’s potential into reality” with its data-collection and -analysis capabilities.

Wash-Eye works in the plant, in the cloud and on a device, according to the company. In addition, WSI says its data professionals offer around-the-clock support and updates.

Tingue

Laundry product supplier Tingue demonstrated how its products work with Mato Lacing’s line of belting for feeders, folders, flatwork ironers and other laundry machinery.

Tingue became the exclusive North American distributor for Mato Lacing in 2016, and the product is now standard equipment included with every order.

The company says Mato Lacing firmly attaches belt sections together using an all-stainless steel, flat profile design with unibar fasteners to reduce contact between the linen and the lacing.

Also unveiled during Clean were new guide-tape spools for flatwork ironers from Tingue machined from durable, waterproof, PVC plastic to resist wear and offer extended service life versus the wooden guide spools commonly included with the laundry finishing machinery.

The company says the new spools are sized to OEM specifications, fit all flatwork ironer models from all manufacturers, and are available in custom shapes and sizes in quantity.

Davis Packaging

Representatives from Davis Packaging showed Clean Show attendees how its wrapping equipment could protect clean linens.

Systems shared included the Mini Bundler, the Deluxe Table Top and the Deluxe Dual Role Console. The company says its equipment wraps linens so that customers don’t have to worry about separation, spills or contamination.

A highlighted item, self-adhesive carry handles, allows customers to simply peel and stick a handle onto linen packages for easy carrying.

10 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued

Many exhibitors provided comfortable spaces for networking.

CLOTHS • 16”x16” professional microfiber cloths • Use for wet or dry cleaning • Wide variety of colors • 49, 45, 35, 30 Grams WET FLOOR CLEANING • Pocket, flat, scrubbing, heavy duty & tube mops • Designed to hold up to commercial laundry use • Charge with fewer chemicals • More ergonomic than cotton equivalents When you absolutely cannot fail, choose SmartChoice Microfiber by Monarch Brands. TRADITIONAL MOPS We now stock cotton-poly blended wet and dry mops for those who prefer traditional cleaning methods. DRY FLOOR CLEANING & DUST CONTROL • Popular sizes of Velcro® & Canvas backed dust mops • Fringed Dustmops to capture large and small particles • Dust wands and mitts for surface cleaning in hard places • Matching hardware available IMAGE: Canvas-Backed Dust Mop (215) 482-6100 monarchbrands.com

from Page 8 Clean

MICROFIBER

Royal Basket Trucks Inc.

Royal Basket Trucks displayed a variety of linen transportation carts in its booth.

Company representatives pointed out cart functions, such as collection, sorting and transportation.

Attendees were able to get up close to examine a variety of the company’s carts. On hand were poly trucks, liner basket trucks and wire basket carts.

Also on display was a tambour door truck with cover and shelves, which the company says is ideal for linen storage and transportation.

Whirlpool Corp. Commercial Laundry Whirlpool Corp. Commercial Laundry—a family of brands including Maytag Commercial Laundry, ADC™ and Whirlpool Commercial Laundry—showcased machines at this year’s Clean Show.

“We always look forward to being part of this spectacular event that brings the entire industry together,” says Trey Northrup, general manager of Whirlpool Corp. Commercial Laundry. “Long after the show, we will continue to build a network of support that allows our customers to harness the power behind the Whirlpool Corporation.”

The interactive booth experience offered solutions for the on-premises, multihousing and coin-op markets.

Products shown in the booth included the redesigned Maytag® Commercial Laundry Top-Load Washer, with a ½-horsepower PSC motor, traditional flexvane agitator and quad-gear transmission, and the Front-Load Washer.

ADC™ products included the EcoWash Washer Lineup, available in both rigidand soft-mount configurations, offering a solution for any OPL or coin laundry need. The company says the Heavy-Duty ADC™ i-Series Dryer Lineup offers versatility and customized solutions to help maximize staff efficiency, optimize dry time and increase throughput.

Finally, the new Whirlpool® Commercial Laundry Top-Load Laundry Pair is engineered with commercial-grade components to deliver optimal performance, the company says.

Datamars

Radio frequency identification (RFID) company Datamars released its LaundryChip 401 in Las Vegas.

The company says LaundryChip 401 is the culmination of its 30-year expertise in RFID technology, meeting the extremely demanding requirements that an industrial laundry expects from a transponder.

“In today’s market, industrial laundry

facilities, textile rental companies, hospitals and hospitality chains need transponders that both endure the harshest industrial laundry conditions and are as small as possible, allowing them to be easily embedded in flat linens and garments,” says Brian Zapach, president of Datamars U.S. “We have responded by introducing our slimmest UHF transponder ever.”

G.S. Manufacturing

G.S. Manufacturing produces laundry carts for the institutional, healthcare and hospitality laundry industry.

During Clean, the company debuted a simple feature on its enclosed carts to aid nursing staff in the distribution of linens.

The innovation is a magnetic latch on the doors. The purpose, say company representatives, is to make it easier for nurses to close cart doors and help maintain the cleanliness of linens.

Before, staff would have to keep a free hand to work a latch. Now, a simple nudge can close the doors so linens aren’t exposed.

Superior Uniform Group

Fashion Seal Healthcare®, a signature brand of Superior Uniform Group Inc., unveiled its new patient apparel catalog at the 2017 Clean Show in Las Vegas. The company says the patient apparel selections were designed to enhance patient comfort and include an assortment of exciting new styles, colors and patterns.

Featuring more than 140 styles, the 48-page, full-color glossy catalog is a complete guide to patient apparel for both acute and non-acute environments, according to the company.

“We are very excited about the roll-out of our new patient apparel catalog. The catalog features fashion-forward, modern styles intertwined with classic, timeless styles that patients have come to know,” says Peter Benstock, president of Fashion Seal Healthcare. “Our customer-first approach has allowed us to enhance the patient experience while providing the superior performance healthcare laundries demand.”

Chicago Dryer Co.

Chicago Dryer Co. launched seven new products in two booths on the Clean Show floor.

In its high-production booth, the company demonstrated the Edge Hi•Maxx cornerless, triple-input spreader-feeder; Skyfeed, a premium spreader-feeder with

NEW ITEM: T200 Institutional Sheets

The Lulworth collection features color-coded hem threads to easily identify the sheet sizes.

• Made in China for a softer feel than other imports

• Crease-resistant due to cotton/poly blend

• Tested for strength and performance

• Woven on airjet looms for a more precise weave

• Carton-Packed so they’re guest ready

• FOB Philadelphia, in stock, and ready to ship

• Consistency from box to box, month after month

Items available:

81”x115” Full Flat w/Red Hem Thread . . . . . . . . . . . . . $68.50/dz

54”x80”x12” Full Fitted w/Red Hem Thread . . . . . . . .$71.35/dz 90”x115” Queen Flat w/Blue Hem Thread . . . . . . . . .$75.50/dz

60”x80”x12” Queen Fitted w/Blue Hem Thread . . . $74.45/dz 108”x115” King Flat w/Green Hem Thread . . . . . . . . .$89.30/dz

78”x80”x12” King Fitted w/Green Hem Thread. . . . .$85.75/dz

Pillowcases also available in standard & king sizes

POPULAR LAUNDRY LINEN SUPPLIES

Route ready BAR Mops

Route Ready bar mops are optically white and packed in bags of 25 so you never have to pre-wash or recount them prior to use.

WHITE Institutional towels

Made with 100% ring spun cotton and a blended ground to provide a perfect balance of feel and durability.

These are optically bright white, soft to the touch, carton packed and ready for use.

TRUE COLOR towels

Ideal for colleges, country clubs, gyms, golf clubs, and hotels. These towels are made from soft, ring spun 100% cotton, with a dobby border.

(215) 482-6100

monarchbrands.com

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | A UGUST 2017 11

Even the aisles were full during the show. See CLEAN on Page 12

compact buffer for continuous linen flow; and the Air Chicago Elite towel and gown folder.

In addition, the booth featured the ATM2 fully automatic washcloth separator-stacker and CHI•Trac, a quality assurance linen inspection system.

In the OPL/specialty linen booth, Chicago Dryer spotlighted its tapeless deep chest ironer, called Powerhouse HI•Q, and Laser Plus, a mid-range ironer for specialty linen.

Parker Boiler Co.

Parker Boiler Co. brought its 9.5L-WW (low-NOx) water-wall design, 9.5 horsepower, 150 psi steam boiler for attendees to inspect in Las Vegas.

Parker says it conducted extensive testing on this new vertical water-wall design in 2015 and 2016.

The company says standard, heavy-duty 1-inch tubes are used that have 0.12-inch wall thickness. The tubes are bent around the flame, creating a water-wall furnace. A large half-inch-thick, seamless horizontal steam drum is used for a steady water line and clean, dry steam production.

Parker says that the sealed combustion design raises efficiency with lower excess air and minimizes heat loss to the room.

A low-NOx metal fiber burner is standard for 20 ppm and precertified to AQMD 1146.2. Units will be available from 9.6 to 24 horsepower.

It also has up to 4 inches of insulation, a 5:1 turn-down ratio, digital pressure control, reflex prismatic sight glass, and two sides that do not require access, which allows it to be placed in the corner of a room, saving floor space. Parker says the unit’s footprint is similar to a vertical tubeless boiler.

Jensen Group

The Jensen Group says that it

featured what was likely its largest booth ever in Las Vegas. The company says it increased its booth size by 33% compared to the Atlanta show to showcase its latest options in the automation of heavy-duty laundries.

One of the highlights at the show was the new Jenfeed Express Plus. The company says it’s the fastest feeder on the market, using cornerless feeding technology. Jensen says the result in the hospitality sector is increased poundage per operator hour, providing high speed at high quality.

Other laundry solutions the company displayed at its booth include the new Hybrid ironer, a high-speed roller for mats, the first robot for towel folders, and exciting new laundry process automation for the washroom section.

Beck’s Classic Manufacturing Inc.

Beck’s Classic representative at Clean, Jeff Bloom, really enjoyed the trade show in Las Vegas.

“The feeling I get is everyone is more relaxed, enjoying themselves,” he says. “It’s a great vibe on the floor.”

While things were relaxed and enjoyable, Bloom kept busy talking to attendees about his company’s products: reusable healthcare textiles.

One product line the company put in the spotlight was its Arid Collection of reusable underpads. Beck’s says the product is laundry-friendly and focuses on the dryness and comfort of patients.

The company also drew attention to its “Position-EAZE” Slider Drawsheets. The drawsheet is made of spun polyester for durability and stain resistance. Beck’s says it also sews surgicalgrade polyester to the drawsheet to make patient repositioning easier and less risky.

Hydro Systems

Hydro Systems, a manufacturer of chemical proportioning and dispensing systems, introduced its FM-800 Flush Manifold series for commercial laundry and

other similar applications during Clean. The company says the FM-800 minimizes leak points and is designed to optimize safety and reliability by completely flushing chemical products to the washer.

“Delivering incomplete chemical dosages due to leaks or inadequate water supply is a big concern for laundries. It can impact safety, waste chemical and produce poor cleaning results, all of which negatively affect the entire business,” says John Goetz, global product manager. “Our FM-800 series safely mixes and accurately delivers liquid laundry chemicals and water to the washer without leaks over the life of the install.”

The company says the FM-800 can accommodate between two and eight chemical products. The unit simplifies installation with straight and 90-degree hose barbs using a push-to-connect interface. The modularity of the FM-800 enhances flexibility with longer lead wires and allows for expansion over time as facilities grow.

Hydro Systems has published the FM-800 maximum temperature (140 F) and pressure ratings (85 pounds per square inch) to ensure the unit is properly used and maintained.

Southwest Laundry Equipment

Southwest Laundry Equipment, a domestic and international supplier of commercial laundry parts and maintenance materials, highlighted an ironer pad in Las Vegas.

Representatives say the company’s Steel Master Pad is the most durable ironer pad on the market.

Given the design to retain a roll’s circumference, Southwest says Steel Master Pads provide true graduation, resulting in a superior finish on linen with fewer wrinkles.

Other advantages of the steel pad include reaching ironing temperatures more quickly and retaining heat longer than synthetic pads, thus requiring less boiler horsepower.

Another benefit, according to the company, is that because of the decreased resistance the pads yield to extract moisture from linen, ironer vacuums can be more efficient. Consequently, goods are drier and ironer covers last longer.

Leonard Automatics

Leonard Automatics says representatives spoke with key customers and made some new contacts at Clean 2017.

“I was very pleased with the reception we received at the Clean Show,” says CEO Jeff Frushtick. “It was a pleasure to say hello to friends and customers.”

The company demonstrated a variety of finishing equipment, including its new LF136

and LF136C large-piece folders, capable of high-speed folding, cross-folding and stacking.

Leonard also showed its VTP 32-XS steam tunnel finisher, its flagship tunnel with double the steam injection zone for even greater garment conditioning. The new model adds hot-air agitation in the steam zone, providing a more thorough relaxation and conditioning of the fabric.

Also demonstrated was the company’s IM series, small-footprint tunnel finisher, capable of superior garment finishing.

In addition, Leonard displayed its Stack N Store small-piece draping stacker and the LCW Cart Washer, showing its selfcontained design with no external tanks able to clean up to a 75-inch-tall cart.

Energenics Corp.

Energenics utilized its booth space to show off its filters and cleaning systems.

The company offers several products to help control dust and lint. These include lint filters for dryer exhaust, the In-Line Space Saver series, and an indoor air pollution filter series to remove lint and dust from work space called Lint Scrubber.

Besides its filter systems, Energenics also informed attendees about its sanitizing Kartwasher cart-washing systems for linen carts.

Dexter Laundry

At the 2017 Clean Show, Dexter Laundry says the “showstopper” in the booth was its new O-Series line of on-premises products, which gives customers “Total Control” over their businesses and laundries.

Dexter says O-Series controls offer technology and reporting systems to help limit downtime and keep the laundry running efficiently. Added features like moisture control, combustion sensing and specialty cycles set the O-Series line apart as the most advanced line of Dexter onpremises products ever offered.

The company says the new O-Series line is an addition to the current line of Dexter onpremises products and will available for sale later this year.

Dexter also showed that its

stack washer-dryer family grew with the addition of the T-350 SWD. Available in 20-, 30- and 50-pound capacities, the company says its stack washer-dryers deliver the same commercialgrade performance customers expect from a Dexter standalone washer and dryer in half the space. This makes them ideal for installations with limited space or in need of more capacity.

With a dry-to-dry time of less than one hour, they maximize laundry throughput while saving on utility expenses. The company says the T-350 SWD and the upgraded T-450 SWD will be available for sale later this fall.

OMNI Solutions

OMNI Solutions garnered attention on the show floor with SULAOS: Smart Ultraviolet Light Advanced Oxidation System, which dissolves organic materials from water through an enhanced oxidation process for tunnel washers.

Using a combination of methods involving ultraviolet light, the system produces potent oxidizers, including hydroxyl radicals, which react with contaminants, removing all traces of them from treated water.

The company says the system reduces bacteria in laundry water from more than 200 colonyforming units (CFU) to less than 1 CFU, without increasing total dissolved solids (TDS).

OMNI adds that reducing water and natural gas usage through SULAOS provides significant dollar savings and ensures linens and the laundry water are hygienically clean.

G.A. Braun

G.A. Braun announced four new laundry options in Las Vegas: a side loader, a tunnel washer press, a spreader-feeder and side-by-side dryers.

The company says the Braun Advantage® 900-pound Side Loader is available in a fourpocket configuration. The use of Braun’s proven and patented cylinder door-locking system, crush-hazard protection, an automated step, and the sleek, ergonomic design of

12 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued from Page 11 Clean

Equipment and products, ranging from tunnel washers to carts, were on display. See CLEAN on Page 14

Company representatives spent much of the show talking with interested attendees.

Does your laundry need a workhorse?

Our M-Series Washer-Extractors are built for optimum performance and easy service access. The simple design with single pivot two-way tilt and large door provide safe, fast and efficient loading and unloading. The open access allows for easy and simplified maintenance. Milnor’s unique and innovative SmoothCoil™ Suspension System means maintenance-free, superior vibration dampening with less wear and tear. Our intelligent bearing design provides three water seals and an excluder seal mounted on an easy-to-replace seal sleeve, along with a leak-off cavity to keep water and chemistry away from bearings. All of this and more, built to Milnor’s legendary ruggedness and durability.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

For more information, scan this code.

www.milnor.com

Optional integrated load chute door for automated washer-extractor systems. 275 lb., 400-500 lb. and 600-700 lb. capacities available.

this machine have answered the requests and needs of the market, according to the company.

The new SmoothFlow® Batch Tunnel Washer Press features a waterless membrane, inverter drive electric belt and high pressure, adjustable up to 50 bar, says Braun.

The company says its new Precision Series® Spreader/Feeder

serves a wide variety of flatwork laundry processing needs from hospitality, healthcare, commercial linen providers and general industrial laundries. Unique to the new spreader/feeder is a single-motor servo spread drive technology coupled with the company’s new spread detection and speed-synchronized spread belts.

Finally, Braun announced the expansion of its Side-By-Side (SBS) Dryers. The company says its SBS tunnel system dryers are now available in natural gas or steam, in a non-chute or

a patent-pending chute-loading system, in 300-pound processing capacities.

Braun says 500-pound SBS dryers will be available the fourth quarter of this year.

Monarch Brands

Linen and microfiber products provider Monarch Brands highlighted a new sheet collection and bundled bar mops in Las Vegas.

The company says its new Lulworth Sheet Collection represents its commitment to bolster its institutional lineup. Monarch says it has leveraged its Chinese

retail line partners to develop a softer sheet line that will hold up to the rigors of commercial use. The sheets come in either T-200 or T-180. The company says the T-200 sheets are creaseresistant because of the 60/40 cotton/poly blend, and are guestready out of the box. The T-180 sheets have a 55/45 cotton/poly blend, and Monarch says they are an economical institutional product.

Monarch’s other highlighted product, Qwick Wick Bar Mops, are pre-washed and bundled in packages of one dozen, packaged five dozen per carton.

The company says the bar mops are ideal for premium routes that demand virgin bar mops. Also, Monarch says the smaller product counts are preferred among smaller operations in industries which rarely need massive wiping inventory.

Consolidated Laundry Machinery

Consolidated Laundry Machinery (CLM) was all about its cutting-edge technology in its Clean Show booth, and it highlighted a new interface.

The company says the interface allows operators to monitor operations via mobile devices, such as an iPad.

During the show, the company also informed attendees about other technology found in its dryers, which results in fast drying times, contributing to increased output and tremendous energy savings over time.

Representatives say that customers continue to buy CLM equipment because CLM dryers are known as the workhorses of the industry that last for decades due to robust engineering and use of the highest-quality materials.

Chem-Tainer/Maxi-Movers Chem-Tainer Industries Inc. highlighted the poly cart, truck and transportation solutions that its Maxi-Movers division provides the laundry and linen industry.

Christopher Glen, vice president of sales and marketing for the company, noted the strength of the industry at the show.

14 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued from Page 12 Clean See CLEAN on Page 16

get

Now that another successful Clean Show has ended, we just want to say THANK YOU to those who visited our booth! We enjoyed spending time with you and helping to acquaint you with our products and services. For more information on all of the new products we demonstrated, please contact us at 800.432-7286 ext. 217 I gabraun.com ALN_Jr Page.indd 1 7/17/17 3:24 PM

It’s

easy to

swept up in all the excitement of the Clean Show...

It paid to be eye-catching on the packed trade-show floor.

knowledge is power

Control and Information When and Where You Need it

Introducing the new Dositec Electromagnetic Multi-Washer System from Hydro Systems. A complement to Hydro’s existing Dositec pneumatic systems, the electromagnetic unit is a more economical option that helps simplify and improve chemical delivery to your washers with a single, central dispensing system. It features a compact, wall-mounted design that saves space in a variety of on-premise laundries. Designed specifically for washers below 60 kg/132 pounds that may not have access to compressed air, the system can dispense up to eight chemicals to as many as six washing machines. The productivity, chemical usage, cost and alarm reporting will give you a better understanding of your laundry by allowing you to access to critical chemical data and make adjustments to formulas or settings from anywhere with an internet connection!

3798 Round Bottom Road Cincinnati, OH 45244, U.S.A. T 513-271-88OO F 513-271-O16O www.hydrosystemsco.com

Remote Monitoring

Remote Monitoring

“But, the industry is a little off, in my opinion,” he says. “However, that’s most likely because we’ve had two great years. Now it’s getting back to ‘normal.’”

The company says it continues to use the experience and knowledge gained from being the first and oldest poly cart manufacturer to improve and innovate.

Softrol

Softrol offers a complete line of solutions, including chemical, rail, management information, advanced sortation solutions and control systems.

In Las Vegas this year, the company highlighted its Total Plant Management system with LOIS.

The Total Plant Management system offers state-of-the-art rail systems for both soil- and cleangoods transfer, as well as material handling for the wash aisle, according to the company.

LOIS is a mobile app that lets

operators view plant operations from anywhere, Softrol says.

The company says LOIS features dashboards for each product line, so laundry managers can view production information at a glance. With drill-down capability for date ranges, more extensive reports can be viewed for comparisons and past production performance.

Lapauw USA

Lapauw USA says Clean ’17 was one of the busiest and most successful for the company because of the new products and

new initiatives unveiled.

“I’ve been coming to this show since 1983, and this was the most successful show I’ve ever had,” says David Bernstein, president.

The company says its new tunnel washing systems created a lot of buzz, bringing the attendees to its two booths to learn more about the announcement and to see new and existing products.

Announced at the show were the IronMAX, a gas-heated ironer with redesigned aspects to enable the largest ironing surface possible; the IronPRO, a chest-heated OPL ironer; and the TowelFold, a machine that can sort up to three different sizes of product, fold them accordingly and stack them in three separate piles, Lapauw says.

The company says it also saw a renewed interest in the Mediwave, a cleanroom washerextractor that is hygienic and ergonomic. In addition, the company says there was reinvigorated interest in the HotSTREAM, a tunnel finisher.

Spindle

Spindle, which provides operation management software, showed off a new product for smaller operations at Clean.

The Internet of Things (IoT) Kit has everything needed to connect a piece of equipment to the cloud, according to the company.

Once connected, data from the equipment is shown on SpindleLIVE, a visual workplace tool that helps to increase productivity, the company says.

Spindle says with the kit connected, management will begin to receive data on the piece of equipment to track time and efficiency.

U.N.X Inc.

U.N.X. Inc. provides laundry chemicals for all types of laundry markets it serves, and the company announced a new technical development at Clean—the MAXX series of laundry chemicals.

It says its new, super-concentrated detergents, along with the second generation of NPE-free detergents, are some of the best U.N.X. has ever formulated.

The company says these detergents will produce superior results on nearly every type

16 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued from Page 14 Clean ALN_Jr Page.indd 1 7/10/17 12:19 PM

With a sold-out floor, the Exhibitor Locator proved essential.

of soil a laundry operator may encounter.

U.N.X. adds that the formulation of these products allow for superior quality results achieved at a reasonable use cost.

Kannegiesser ETECH

Kannegiesser says this year’s Clean Show in Las Vegas was very exciting with an integrated booth. In April of this year, Kannegiesser acquired overhead rail systems provider E-Tech Inc., based in Minneapolis, and the newly formed North American company is Kannegiesser ETECH.

“We like the team, they are very complementary to each other,” says Martin Kannegiesser, president and CEO of parent company Kannegiesser GmbH.

The company says the booth was 11,700 square feet to highlight the combined company and products. Each day featured presentations on the company’s monorail and controls, explaining the eVue software package.

For the first time in a U.S. exhibition, Kannegiesser says it displayed a buffer feeding system designed for processing hotel sheets. The other highlight was a rollout of the ErgoFeed threestation, cornerless feeder for maximum throughput in a healthcare application.

On the small-piece folder front, the company showed off its upgraded XFM Speedline folder. Finally, the company displayed its Vectura Stack Management System, which collects and organizes folded stacks coming from ironer lines or dry folding machines.

Rennco

Rennco showcased two machines at Clean ’17: the Model VerticL-PP dual packaging system and the Texwrap L-bar sealer with shrink tunnel.

Rennco says the Model VerticL-PP dual packaging system uses generic center-folded rolls of readily available poly film, providing significant cost savings compared to pre-made bags. The company says bag sizes can be easily adjusted using a touch screen in a matter of seconds, without changing the roll.

The second machine displayed was a Texwrap (a Rennco sister company) Automated L-Bar Sealer with Shrink Tunnel set up to wrap folded and stacked linens. Polyolefin film will shrink up to 60%, allowing variance in stack height, width and length within the same production run.

Coupled with an ID Technology (a Rennco sister company) Print and Apply Labeler, linen bundles can be grouped and distributed by area code using RFID technology, to partially automate shipping.

McClure Industries

McClure caught the eyes of attendees with a burned cart in its booth.

The purpose? To show the fire-retardant capability of its Sanitrux line of carts.

The cart in the booth was scorched on the outside, but inside, it was untouched.

According to representatives, that shows that linens inside would be less likely to ignite in a fire.

The company points out that this is especially important for laundries that process linens soiled by grease and oil.

The DECC Co.

Clogged dryer panels reduce efficiency and increase dry times

and costs. DECC showed attendees at Clean how its product can help reduce plastic buildup.

The company’s dryer panel coating turns panels into nonstick surfaces. DECC says the coating reduces plastic buildup and decreases downtime due to maintenance and cleaning.

In addition, the company says the coating helps maintain “likenew” dryer efficiency and airflow for a longer time.

DECC says its product is also long-lasting, with customers having had panels perform well for more than four years.

WET-TECH, New Horizons in Ozone Solutions

WET-TECH took advantage of the Clean Show to share how ozone works in a laundry.

Representatives educated attendees on “cell lysing,” which is the destruction of bacteria cells with ozone. Simply put, ozone piped into the wash pokes a hole into bacteria cells, rupturing and destroying the bacteria.

“Using ozone reaches hygienically clean levels in industrial and commercial laundries,” says Jack Reiff, company president.

The company says its Enviro-

Saver II Ozone System can help laundries reduce water, electric and chemical usage.

MODRoto

Laundry product manufacturer MODRoto unveiled its new Linen Locker, which secures soiled laundry inside a durable, lockable, weatherproof plastic bin to guard against theft and eliminate risk of contact with the elements while providing easy, ergonomic access for removal. The company says the indoor-

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | AUG UST 2017 17

“Your products are long-lasting.” “CLM equipment has a good reputation: sturdy, reliable and e icient.” “I’m really happy with my CLMs; they’re more than 20 years old and they just keep running.” Since 1983, the CLM brand has delivered the most cost-e ective, most money-making shuttle conveyors, vacuum feeders, mat rollers, towel folders and its mighty line of 200-1200 lb. dryers. Come to the brand where long-lasting and low-maintenance equipment is standard. From the Pacific to the Atlantic, customers rely upon longevity of CLMs Pomona, CA | T: (323) 232-2417| clmco.com Robustly engineered long-lasting DRYERS Smartly productive and safe MAT ROLLERS Intelligently e icient SHUTTLE CONVEYORS Quick and easy-to-use VACUUM FEEDERS Clever and fast TOWEL FOLDERS All CLM equipment can seamlessly integrate into any laundry facility. Made in USA CLM ALN JR Ad July-Aug.qxp_Layout 1 5/8/17 12:11 PM Page 1 ALN_Jr Page.indd 1 5/9/17 9:45 AM See CLEAN on Page 18

outdoor Linen Locker is rotationally molded as a rugged, one-piece enclosure standing 80 inches tall with a convenient, non-removable, full-height, side-entry door that allows route truck drivers and/or housekeeping staff to quickly gather the laundry placed inside without significant bending, reaching or heavy lifting.

The locker was developed for use at restaurants, hotels, catering halls and other foodservice facilities, and can hold 54 cubic feet of table linens, uniforms, aprons and other soiled linens.

The company also says it serves as an attractive collection bin for wet towels and other soiled linens at fitness centers, athletic facilities and aquatic facilities, and as a charitable donation collection bin suitable for indoor/outdoor installation.

Brim Laundry Machinery Co.

Brim Laundry Machinery Co.

showed off two products on the trade show floor: tumblerdryers and slim, tilting washerextractors.

The Pacesetter CPG-400 and CPG-600 tumbler-dryers can use less than 1,800 Btu to remove a pound of water, at the rate of 19 pounds a minute, the company says. Brim credits the low Btu usage to its Geyseric gas burner, axial airflow design and a fully modulating proportional gas train.

The units come in 400- and 700-pound capacities, with standard two-door, one-way tilt

pass-through design.

Brim focused on the “slim” part of its 66/40 Slim Tilting Washer-Extractor. Why slim? Because the unit has a footprint 10 inches narrower than previous units.

Railex Corp.

Railex showed off its garmentmoving systems in Las Vegas.

For industrial laundries, the company has overhead speed monorail and screw conveyor systems. Railex says these are designed to move garments, linens and uniforms.

For institutional settings, such as correctional facilities or food processing plants, the company highlighted its overhead garment and garment bag conveyors. Railex says the conveyors offer options for loading and unloading, as well as elevated sections to free up floor space.

Kemco Systems

Kemco Systems has provided systems with technologies to recover waste energy and recycle process wastewater for almost 50 years. The company highlighted these technologies at Clean, saying the highly efficient systems reduce energy consumption and costs, conserve freshwater resources and minimize laundries’ environmental impact.

The company says its wastewater heat recovery system recovers potentially lost thermal energy by capturing the heat from wastewater and using it to preheat incoming fresh water.

Also highlighted at Clean 2017 was the patent-pending Ceramic Microfiltration followed by Reverse Osmosis system. The company says this system will remove 100% of fats, oils and greases, and total suspended solids, while removing dissolved substances, such as total dissolved solids and surfactants. This allows for up to 95% recycle of treated wastewater.

Voltea

Voltea, which provides Membrane-Capacitive Deionization (CapDI©) for tunable, salt-free and chemical-free water softening and desalination, displayed the first-ever IS-24H (Industrial Series-Horizontal) to the market at Clean.

“I am delighted to introduce the world to Voltea’s IS-H series,” says CEO L. Bryan Brister. “Our engineering and design teams have made a big step forward in product performance while dramatically reducing capital equipment costs.”

The company says that engineering advances to its CapDI systems include improvements in electronic controls, redesigned piping significantly reducing interconnected dead volume, and the use of Voltea’s SingleBlock© technology for module connections.

Voltea says these advances required a repositioning of its modules to a horizontal orientation.

JP Equipment Inc.

In the JP Equipment booth, representatives showed off Inwatec’s garment-scanning and -sorting products from Denmark.

What really garnered attention was the X-ray garment scanner.

Using X-ray technology, the scanner detects foreign elements in laundry, such as pens, needles and scissors. The foreign objects are sorted out of the laundry and into a rejection bin.

18 AUGUST 2017 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued from Page 17 Clean LOW TEMPERATURE NON-CHLORINATED OXIDIZING WASH PROGRAM DESIGNED WITH INNOVATIVE, PATENT PENDING TECHNOLOGY TO CONSISTENTLY DELIVER EXCEPTIONAL WHITENESS AND UNPARALLELED SOFTNESS WHILE EXTENDING LINEN QUALITY AND LIFETIME. www.ecolab.com | 800.553.8683 | laundry@ecolab.com NEW LUXURY STARTS IN THE LAUNDRY Delight your customers and their guests by consistently providing the bright white she notices, the softness she feels and the quality that makes her experience luxurious. OxyGuard40 Preliminary Sell Sheet.pdf 1 3/10/2017 8:38:50 AM ALN_Jr Page.indd 1 3/10/17 8:48 AM

delivers benefits such as a sickle fan blade that increases performance and efficiency; a totally enclosed drive system that is patent-pending, called the iDrive, to allow for precise and consistent planning for cleaning ranges; and an extended, slim shroud that expands the effective cleaning area.

Penn Emblem

Penn Emblem displayed a variety of products at the show in Las Vegas. The booth featured a new product collection, including its new thermal ID labels

and printers.

Other items Penn presented to attendees included embroidered and woven emblems.

At the show, Penn Emblem continued its 70th anniversary with decoration solutions for companies and organizations all over the world.

Encompass Group LLC

At Clean 2017, Encompass Group announced its new UltraLinks Plus larger-size blanket in two new colors to appeal to a broader audience.

Aspen Green and Tan

UltraLinks Plus blankets are 74 inches by 102 inches to accommodate the more common use of 42-inch-wide mattresses in healthcare facilities, the company says.

The company says the soft, 100% synthetic fabric provides lasting patient comfort and warmth and carries color retention properties that ensure long-lasting, vibrant colors. The quick-drying fabric offers energy savings, while the tight weave minimizes the risk of snagging

The company says the machine can scan up to 2,800 pieces an hour.

JP’s sister company, JPE Inc., is the exclusive sales representative for Inwatec’s products in the United States.

EzProducts International Inc.

EzProducts International (EzPi) used the Clean Show floor to display its permanent tagless systems for textile labeling, heatsealing, decorating and mending options.

The company uses bar-coding, which it says saves time and money, and allows customers to maintain the history of each garment.

In addition, EzPi says its products eliminate the labor of applying and removing paper tags and the cost of paper tags.

The company says it uses heatseal presses for consistent pricing and finishing.

Spartan Chemical Co. Inc.

Spartan Chemical shared information about its complete line of laundry products with Clean attendees in Las Vegas.

One highlight was the Clothesline Fresh Laundry Care Program.

The company says the line of products is an “environmentally preferable approach” to cleaning laundry. This is because the line uses ingredients that have been designed to be environmentally friendly.

Spartan also says Clothesline Fresh Laundry products contain the latest in cleaning technology, providing high cleaning performance at a lower cost to laundry operations.

SonicAire

It was breezy over at the SonicAire booth. That’s because the company’s dust-control fans were on display and running.

In Las Vegas, the company highlighted its 1-horsepower fan.

Representatives says that just like the SonicAire 2.c, the smaller fan is an “acrobat,” with a size and maneuverability that allows it to clean spaces that are virtually impossible to reach otherwise.

In addition to being such a compact barrier fan, the company says the SonicAire 1.c

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | AUG UST 2017 19

kannegiesser-etech.com 612.722.1366 Kannegiesser USA and ETECH are now Kannegiesser ETECH

LAUNDRY seamlessly integrated equipment and systems

you

business.

industry. ALN_Jr Page.indd 1 5/26/17 2:07 PM See CLEAN on Page 20 Vendors went high-tech this year, even rolling out virtual-reality tours.

SMART

When

combine two companies, you transform a

When you combine two leaders, you transform an

and tearing.

Encompass also says the synthetic fabric has stain-resistant properties to help reduce costly relaundering. And the reversible blanket design allows healthcare staff to spend less time while making the bed.

The company also introduced the C2 Coverage+Comfort Collection of patient gowns. These new gowns are designed to increase patient modesty and comfort by offering more coverage across the back, a generous fit, and modern clinical features.

Felins USA Inc.

Felins USA, a packaging company, debuted its TPS L-Bar Sealer in Las Vegas.

The automatic shrink-wrapping system is made for single garments, like medical gowns. The company says garments can be hand-fed or can be processed via automatic inline operation. The machine automatically adjusts bag length to the fold of the garment.