Late News

Clark family purchases supplier U.N.X. Inc.

GREENVILLE, N.C. — U.N.X. Inc., a chemical and services supplier to the laundry and institutional market, has been purchased by the Clark family, effective May 2019, the company reports.

Terms of the deal were not disclosed.

“We are excited and energized for the opportunity be a part of this great company,” says Josh Clark, CEO of U.N.X. “We are looking forward to providing the next generation of leadership, ideas, culture and resources needed to continue the U.N.X. tradition of being the premier supplier of products, service, and equipment to this wonderful industry.”

In addition, Clark and the U.N.X. board of directors named Douglas Story as president of sales and marketing effective May 20.

Story’s 32-year career in chemical services has involved him in leading a wide range of global and domestic diversified chemical services operations, the company says. ALN

Employees of ‘all abilities’ make laundry successful

BY MATT POE, EDITOR

BY MATT POE, EDITOR

KENT, Wash. — In 1965, three mothers who had children with developmental disabilities wanted to ensure their children were educated.

At the time, developmentally challenged children were usually placed in an institution.

In order to ensure that education, the Northwest Center was created here.

“[The mothers] demanded that every child deserves an education,” shares Tod Steward, communications specialist for Northwest Center. “So, in 1971, they got together with the governor and passed

House Bill 90 that in Washington state gives every child the right to an education.”

Steward says the movement went national, and in 1975, President Gerald Ford signed the Education for All Handicapped Children Act into law to give every child in

the United States the right to an education.

“So, in essence, Northwest Center has affected every single area of the country,” he adds.

Fine-tuning the overall drying process

TAKE ADVANTAGE OF, MAXIMIZE SENSING TECHNOLOGY USE

One factor most of the experts pointed to in fine-tuning the drying process is preventing over drying, and that means making use of moisture- and temperature-

sensing technology.

BY MATT POE, EDITOR

CHICAGO — Every step is important when it comes to processing linens.

But a weak drying process can impact and laundry/linen service in many ways, such as increased linen loss due to over drying, more employee handling and higher labor costs, a decrease in quality, and more.

How can an operation fine-tune its drying process?

American Laundry News contacted several equipment manufacturer representatives for their thoughts on how laundry/ linen services can make their drying processes more effective and efficient.

Panel of Experts

This time, the experts offer insights to help keep linens clean during transport, storage.

“Quite simply, over dry prevention technology is the most important feature in tumble dryers today,” says Bill Brooks, national sales manager for UniMac. “If on-premises laundry staff isn’t utilizing this technology, the operation likely is not running at peak efficiency.”

He says the first step in removing this inefficiency is selecting a tumbler that has an extremely accurate moisture-sensing system that has a large sensing area (not just one spot) and offers constant measuring.

“Accuracy means staff will trust that when the tumble dryer stops, it has achieved the desired dryness level,” points out Brooks.

“However, operations that want to ensure staff isn’t overriding the technology or performing their own ‘checks’ by opening the door frequently, will want a laundry

JULY 2019

Plant serves hotels, hospitals; processed 11 million pounds of goods last year

www.americanlaundrynews.com INSIDE [4]

The Newspaper of Record for Laundry & Linen Management

[16]

45, Number 7 [20]

Columnist at Large In this issue, Eric Frederick continues his look into doing research on stains.

Volume

(Image licensed by Ingram Publishing)

See CENTER on Page 6

6 tips to help maximize effectiveness, efficiency of drying technology

See DRYING on Page 10

Many of Puget Sound Laundry Services’ all-abilities employees consider coming to work the best part of their day, says plant management. (Photo: Puget Sound Laundry Services)

PRODUCT SHOWCASE

inclusive format

Boston event hosts top speakers, topics for breakouts, general sessions

ALEXANDRIA, Va. — The 106th Annual Conference of TRSA, the association for linen, uniform and facility services, will provide attendees with an expanded, more inclusive format Sept. 17-20 at the Hyatt Regency Boston Harbor.

The conference begins Sept. 17 with TRSA committee meetings. The association encourages industry professionals, from managers up through CEOs and owners, to participate in these meetings, which will include a 30-minute open discussion roundtable on industry-related issues.

Sept. 18 will feature the Management Development program, a new part of the Annual Conference, which will provide a day of breakouts and general sessions featuring subjects beneficial to leadership of all levels, TRSA says.

Next-generation executives, emerging leaders, general managers, and other plant-based management, graduates of EMI and PMI, owners and C-suite executives will be inspired by keynote speaker Steve DiFillippo, restaurateur and author of It’s All About the Guest. DiFillippo’s family has been deeply involved in the laundry business for a few generations, and he’ll bring that perspective as he shares the deliberate steps taken to transform his upscale restaurants into multiple locations during his presentation on Mastering Hospitality for Business

Six breakout sessions feature the “best-of-the-best” top-rated speakers and topics from TRSA’s range of programs, covering:

• Communications

• Management • Recruiting and Retention

• Safety and Skills Development Sept. 19’s opening keynote, Bill Taylor, founding editor, Fast Company, will rev up the audience with questions such as: What separates us from our rivals in the marketplace? And, what holds us together as colleagues in the workplace? Hear ideas, diagnostics and case studies, and be guided to a new world of work and a cutting-edge agenda for recruiting, evaluating, organizing and retaining talent.

Attendees will receive a complimentary copy of Taylor’s bestseller, Simply Brilliant: How Great Organizations Do Ordinary Things in Extraordinary Ways following his presentation.

Digital innovation is on the agenda with the presentation, Riding the Digital Wave, with Andrew Lippman, MIT Media Lab and co-director of Digital Life. This highly animated, engaging presentation will translate the latest digital technology trends into clear, businessready insights that are effective in any industry. Additional general sessions include:

• Government Relations Update, presented by Kevin Schwalb, vice president, government relations and certifications.

• Latest Trends in Labor and Employment Law with attorney Joseph Shelton, partner, Fisher & Phillips LLC.

• Textile Services Bottom-Line Performance presented by Andrew Wittmann, CFA,

director, senior research analyst, Robert W. Baird Facility and Industrial Research Services Team.

The conference’s closing keynote speaker, presidential historian and Pulitzer-prize winning author Doris Kearns Goodwin will discuss Leadership in Turbulent Times

Inspired by her current New York Times bestseller of the same name, Goodwin’s engaging and entertaining address will bring to life some of the actions of the

to all attendees and their guests/ partners. A special outing is also planned for guest/partners on Sept. 18.

The evening of Sept. 19 is the TRSA Annual Awards Dinner, a tradition that recognizes and celebrates the contributions of top industry leaders with the presentation of the Operator and Maglin-Biggie Associate Lifetime Achievement awards.

The Sept. 20 agenda includes the annual membership meeting and elections and presentations on the state of the association, as well as the industry, in addition to the closing keynote.

The Hyatt Regency Boston Harbor is close to the Logan International Airport and offers convenient free shuttles. The city of Boston is a 15-minute ride via water taxi, Uber or subway from the hotel.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Roger Napiwocki

Digital

Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

David Barbe • Jim Buik

most successful U.S. presidents to provide perspective for today’s leaders, and to underscore that the U.S. democracy has survived— and even thrived—through troubling times in the past. Attendees will also receive a complimentary copy of this book following the keynote.

Included social activities include a Secrets of Old Boston scavenger hunt, a competitive, yet fun small team activity that is open

The Annual Conference package is inclusive, covering all meals and receptions from noon Sept. 17 through breakfast on Sept. 20. However, TRSA says it is also offering stand-alone registrations for the Sept. 17 committee meetings and the Sept. 18 Management Development program. Registrations received on or before Aug. 9 will save $100 on registration. View the full brochure at www.trsa.org/annualconference ALN

ARCO/Murray begins build-out for Handcraft Services

HIGH POINT, N.C. — ARCO/Murray recently began construction on an 82,750-square-foot healthcare laundry build-out for Handcraft Services here.

The project includes 75,250 square feet of production space, including mechanical room, maintenance shop, and soil/clean docks, and 7,500 square feet of office, including an employee break room and production restrooms. Construction began in mid-March and will finish at the end of August.

This is the third time HandCraft Services has partnered with ARCO/Murray to build a new laundry facility, according to the company.

The shell building was under construction when ARCO/Murray started the project. By coordinating the laundry design with the building developer, ARCO says it was able to compress the project schedule and reduce overall construction costs.

Design changes include additional roof loading in lieu of floor supports for the rail system, coordinating floor trenches and pits with the floor slab design, natural gas and electrical upgrades, and improvements to lighting, spot cooling and plant ventilation.

ARCO/Murray is providing a complete design/build solution, including architectural and engineering design, permitting, and all construction work to convert the existing building into a new healthcare laundry. This includes equipment rigging, installation and final utility connections. Dylan Scarpato is serving as project manager, and Nate Smith is the project superintendent.

Tony Jackson • Janice Larson Tom Marks

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies: U.S. $9.00; Foreign $18.00.

Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661.

Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 45, number 7. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2019. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

2 JULY 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

INSIDE: July 2019 • Vol. 45 | No. 7 [8] Tools of the Trade [12] Protect Clean Goods with Proper Packaging Packaging types, from tying and strapping to wrapping, impact the “quality of your deliverable,” experts say [14] On-premises Laundry Planning, Layout Columnist says architects working with experienced laundry representatives key to productive, successful facility [24] Career Track [26] Classified Advertising [27] Source Directory [30] Trade Ticker [30] Calendar of Events

expanded, more

TRSA’s 106th Annual Conference to offer

ALN

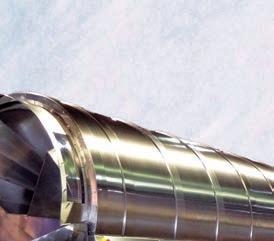

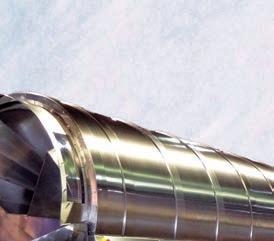

Milnor has a better solution through dilution.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®,

CBW® and RecircONE® are Pellerin Milnor’s registered trademarks.

Getting down ’n’ dirty

Frequently as I write, edit and assemble issues of American Laundry News, a major theme emerges.

I’ll realize that the features, columnists, maybe even the news, somehow tie together. In the past, these themes have included labor issues, healthcare laundry, maintenance and financing.

That’s not the case with this issue.

There’s not an overarching theme this time, rather, each article looks at various factors that go into running a successful operation.

For example, you probably saw the cover story on fine-tuning drying processes. In that piece, experts offer advice beyond overall drying equipment, digging into small, but vital ways the process can be more effective and efficient.

Or how about protecting goods

The Editor’s Desk MATT POE

once they’ve been cleaned and finished? Turn to page 12 and read about packaging options to protect goods while they’re being transported and when being stored.

You could say keeping goods clean is a “mini” theme in this issue, since the Panel of Experts (page 16) offer their advice on

Letter to the Editor

maintaining linen cleanliness during storage and transport.

But then the issue goes back to the plant floor with the Product Showcase on page 20. This time, equipment manufacturers highlight some of their small-capacity washer-extractors (under 100 pounds).

I suppose you could say that the theme of this issue is getting “down ’n’ dirty” in the details of laundry operations. Not a “grand” theme, per se, but absolutely necessary in successful day-to-day laundry/linen service operations.

Any time you’re curious about a laundry-related topic, or you have something to say about an article you read—whether positive or constructive—please get in touch with me. My contact information is on page 2.

We all have a part in the effort to help keep it clean, everybody. ALN

Healthcare laundry executive responds to minimum wage Your Views survey

I participated in your recent survey concerning minimum wage increases [June 2019, page 2]. I was, shall we say, a “reluctant” participant. I did not believe that your questioning around minimum wage increases was valid or even relevant to our industry.

Anyone running a laundry today cannot be paying minimum wage to his workforce. There is just no one willing to work as hard as laundry workers do for the national minimum wage of $7.25/ hr. This is because the most menial of jobs and the most abundant are now paying at least $10.00 per hour. The economy, which by all accounts is the most robust that I have seen in my lifetime, is driving wages at all levels higher and higher.

The concept of minimum wage, at least in today’s economy, is relevant for such positions as student part-time labor, fast food or other strictly entrylevel jobs. It is not meant to provide a household sustaining wage but merely a way to bring the raw-

est of the raw into the marketplace.

Asking if minimum wage increase or decrease would have any effect on a laundry that pays well above the minimum wage level for their area is completely irrelevant. The better questions would be for those that talk about artificially increasing minimum wage above what the market is willing to pay such as in California, Oregon, and New York. What effect would this have on long term employment? In the short term not much but if and when the economy cools off, these areas will experience the greatest unemployment. This is just how the laws of supply and demand work in a capitalistic society.

In short, minimum wage manipulations have little or no effect on companies that pay well above minimum wage.

Ed McCauley United Hospital Services Indianapolis

PART TWO:

Doing research on stains

L ast month’s article dealt with trying to narrow down the source of the stain, trying to understand the nature of the stain. This can be a very long and frustrating journey.

So, it is necessary to understand why this effort is so very important.

Many years ago, I ran across a stain that only appeared after the linen was washed. You could not detect it on the linen before washing, but it showed up as a yellow or brown stain after washing.

Test runs by various organizations could not determine the source of the stain or a way to remove it. It was a permanent stain that left the linen unusable.

My customer service representative spent a lot of time working with the hospitals to determine the source of the stain. Once we determined it was an active ingredient in one of the disinfectants, we set about trying to understand what caused the stain when the linen was washed. We determined that the stain was caused by a combination of heat and chlorine.

That information allowed us to develop a wash formula for our tunnel washers that had a cool rinse (under 100 F) with a little alkali and hydrogen peroxide in the first two compartments. The offending product could be rinsed out under these circumstances before it caused a stain.

The science of washroom chemistry and experience of laundry managers can be harnessed once we can determine the source of the stain. Until we have determined the source, we are like a blind man trying to find his way out of a room. If we try hard enough and long enough, we might accidentally stumble out the door, but we will have to endure the same process each time we are left in the room.

Stain management is an evolutionary process. What we learn treating one stain makes us better at treating the next.

Another example from my past is that we were getting large, oily looking stains on our reusable barrier surgeon gowns and isolation gowns. The stains would disappear after washing or reappear at another location. The normal laundry science says that in treating oil-based stains you should use high levels of alkali, but this process was not good for the garments.

Our research showed that these particular products did not need any softeners in the wash process because they were 100% polyester. We also discovered that the softeners were often responsible for the oil stains we were seeing on the gowns. Some of the stains came from oil used in certain procedures the gowns were used in. Since the products were 100% polyester, they loved oil.

We found the best way to remove the oil was with a solventbased detergent. To allow the detergent to work, we needed to wash at low temperatures. This worked extremely well and was very economical because the wash formula required very little alkali, no bleach, no softener and very little sour.

It is only by taking the time to research the nature of the items you are washing and the nature of the stains you are seeing that you are able to find solutions to many of the staining problems facing managers in today’s modern laundries.

•

•

•

•

•

OUR SISTER WEBSITES

From

•

•

•

•

From

There may be a product that comes along that represents a tremendous increase in patient care but will stain linen items. It is my experience that if the benefits are great enough, the staining problem in the laundry is considered an acceptable cost.

If this happens to you, being able to define the cost associated with this new product is important so that you can justify an increased budget or higher prices. It then becomes the healthcare provider’s choice as to whether the benefits outweigh the costs.

Eric Frederick served 44 years in laundry management before retiring and remains active in the industry as a laundry operations consultant. You can contact him by e-mail at elfrederick@cox.net, or by phone at 540-520-6288.

4 JULY 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

From

COLUMNIST AT LARGE Eric L. Frederick, RLLD

ALN

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending June 15 (WE) = WEB EXCLUSIVE NEWS • ImageFIRST Acquires Majority Stake in Faultless Linen • Prudential Overall Supply Announces End-of-year ... • In Memoriam: William ‘Bill’ Webb, Tingue, Brown & Co. • Clark Family Purchases U.N.X. Inc.

ALM Works to Define Quantifiable Measure ... WE

•

COLUMNISTS/FEATURES

Never Stop Learning About Your Industry

Avoiding Maintenance Mayhem in the Laundry

Clean Show Travel Guide: Let the Good Times Roll!

Textile Care Industry Ready for Clean ’19

Eric Frederick: Doing Research on Stains

AmericanDrycleaner.com:

University City Cleaners Goes Wet

Pains, Train(ee)s and Automobiles

AmericanCoinOp.com:

Multi-store Operator Performs Laundry CPR

24-7 Laundry Operations: Running Smoothly Round ...

americandawn.com | imagine@americandawn.com HACCP IS ABOUT FOOD SAFETY In food processing plants, HACCP plans are about ensuring that critical control points are contaminant free. American Dawn offers a full line of HACCP Garments, as well as the knowledge and training to support your team. Give us a call to learn more about how we can open the door to this growing marketplace. CALL US: 800 821 2221 LET’S KEEP OUR FOOD SAFE

The education at Northwest Center isn’t limited to classroom learning. It also owns eight businesses that offer people with disabilities jobs and job experience.

One of those businesses is Puget Sound Laundry Services, which started in 1994.

“It’s a viable business, and it’s a business that we can have people of all abilities work in,” says Tom Niemi, customer account manager for Puget Sound Laundry. “Not all of our employees are what we refer to as all-abilities employees, but somewhere in the neighborhood of, overall, about 50% of them are.”

LAUNDRY BUSINESS

Ofelia Almanza, operations manager, says Puget Sound Laundry’s plant is about 50,000 square feet, using one tunnel plus conventional washers.

“Our total capacity is 150 pounds per load,” she says.

On the drying/finishing side, Puget Sound Laundry uses conventional dryers, three ironers, six small-piece folders and a folding station.

“Last year, we processed 11 million pounds, and we’re expecting to process 13 million pounds this year,” Almanza shares.

She says that Puget Sound Laundry’s product mix is 82% hotel and 18% healthcare, serving hospitals, the military and medium to large hotels in the central Puget Sound region.

“We target medium to large hotels, and we focus on the geographic area, just because it makes sense as far as delivery because we do pick up and deliver the laundry,” shares Niemi. “So being in a relatively small area, a 25-mile radius is quite advantageous for us.”

He says the laundry uses a semitractor-trailer to deliver healthcare goods and three smaller vehicles, two around 28-feet and an 18-foot vehicle, for other goods. One of the laundry’s biggest challenges is retaining truck drivers, Niemi adds.

“We’re a seven-day operation laundry, and we have three shifts,” says Almanza. “We process the Madigan Hospital, and that’s our second shift to process all that. Then the hotel shift is morning, and they start soil at midnight.”

PEOPLE

The goods are processed by 113 employees, of which, as Niemi says, more than 50% are disabled.

“We’ve had people of all abilities work with us since the startup of the laundry, and we’ve been here for 24 years now,” Almanza shares. “Of course, they know a lot about the laundry, and they can work in practically every area

of the laundry.”

She says Puget Sound Laundry works hard at having its employees know how to work every position in the plant.

“It’s not always the case, all of the time,” shares Almanza. “Some people of all abilities can only learn certain stuff, but that is the goal.”

Niemi agrees that a major success for the laundry is “employing people of all abilities and having some of them work here for over 20 years and then being able to operate our tunnel system, which is not an easy system to operate.”

He shares that one employee of all abilities has been at Puget Sound Laundry 17 years, and she is able to work in every area of the building.

“We actually have a software system where we track their productivity, and we began giving out recognition to our people,” Niemi says. “She was recognized this past month of May because she produces more than everyone else.”

Almanza says that allabilities employees often come into the position with a coach, and the coach might stay as long as six months.

“Sometimes a coach stays here for only a couple of days,” she points out. “It depends on the need of the individual.”

Also, at least two supervisors are on the plant floor at all times. Every effort is made to be able to communicate with and educate all-abilities employees.

“We have a lot of visual cues,” Niemi says. “For example, our PPE; these are all visual. Every area has a board that tells you exactly what PPE you need based on a picture. We make everything as visual as possible and that has helped us a lot.”

Another example he offers is labeling. The hotels the laundry services are all labeled with the name of the hotel, a number and a color.

“One of the first things the Ofelia told me when I started here was that we always managed to be able to find a way to communicate no matter what the situation, and that certainly is true,” Niemi points out.

“We have folks who are deaf who never learned American Sign Language, and you find out how to be able to communicate with them just as effectively as with anyone else.”

And the effort Puget Sound Laundry makes is working. Almanza says employees are happy to come to work, shar-

ing that many of their all-abilities employees show up to work at least an hour before their shifts.

“We have a lot of them that maybe don’t speak but their parents will let us know whenever they can’t come to work, like a snow day or they’re sick, and they can’t physically come to work. They’re very sad because they’re not at work,” she says. “I always say that for many of our employees, coming to work is the best part of their day, which is certainly different than for many of us.”

QUALITY

The goal of Puget Sound Laundry is to provide the highest level of quality and service that it can to its customers.

“It’s no secret that we’re not the least expensive laundry out there, but we have many customers that stay with us all the time,” Niemi says. “They know that they can get a better price elsewhere, but they stay with us because level of quality and service.”

“In this area, we’re considered the best,” adds Steward. “There have been hotels that wanted to cut costs, and they came back to us saying ‘you know, you guys are just the best.’ They really appreciate the work that we do for them and how we do it.”

Niemi says Puget Sound Laundry maintains its level of quality and service through constant quality and productivity audits.

“We’re constantly auditing quality, looking at linen coming out, addressing concerns head-on really, dealing very directly with any problems that we find,” he shares.

Almanza adds that the laundry is “very forthright with our customers.”

“We return all the rag-out to them, and I know that with all laundries that might not be the case,” she says.

Of course, Almanza credits the laundry’s employees for maintaining a high level of quality and service.

“We have a strong group of employees that care,” she says. “For example, somebody came in today who’s worked here for about a month now and it was like, ‘You know, I can’t seem to memorize a difference between each hotel.’ Each hotel has something in particular, and she goes home and stresses about that because she’s only been here for a month. Our employees care very much.”

In addition, Puget Sound Laundry is a member of the Healthcare Laundry Accreditation Council (HLAC), processing all laundry to sanitary hospital standards. In addition, it is a member of the Association for Linen Management (ALM), and key management personnel have completed the ALM Certified Laundry & Linen Manager (CLLM) program.

Besides maintaining quality and service in regards to its customers and goods, Puget Sound Laundry is also looking to improve its operations.

“We certainly can add some capacity, probably, going forward, but really I think our challenge, or what we’re looking at now, is becoming more efficient,” says Niemi. “That’s where our growth will come, by becoming more efficient.”

He adds that Puget Sound Laundry is “basic” at this time and is exploring ways to go further with automation in the plant.

“The building is the building,” says Niemi. “We’re not going to take all this stuff out of here or add on to the building. So, we need to be more efficient and use our spaces as effectively as possible, along with our personnel.”

And for Puget Sound Laundry, it always comes back to the employees.

“I think the No. 1 thing is, regardless of who you are, whether you’re affiliated with Northwest Center or you’re not, there are distinct advantages to hiring folks of all abilities,” shares Steward. “They are the people who show up regularly and stick with us more than anyone else.

“There’s an entire population that can do great things for any organization.”

6 JULY 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ALN Center Continued from Page 1

Puget Sound Laundry is a seven-day-a-week, three-shift operation. (Photos: Puget Sound Laundry Services)

The goal of the laundry is for its all-abilities employees to be able to work anywhere in the plant, if possible.

Puget Sound Laundry’s equipment mix includes a tunnel and conventional washers, conventional dryers, three ironers, six small-piece folders and a folding station.

Cultivate your existing ironer’s production and quality by adding a Girbau Industrial spreader/feeder to your current ironing system. Our series of feeders improve product quality, enhance labor efficiencies and increase production in laundries. Keep pace and grow your laundry with Girbau Industrial. Nurture your growth – one piece at a time – with an investment sure to reap healthy dividends.

Discover how Girbau Industrial works seamlessly with your existing equipment. Call 800-256-1073. We have equipment in inventory and ready for installation.

INDUSTRIAL girbauindustrial.com INNOVATIVE LAUNDRY SOLUTIONS CULTIVATING YOUR IRONING LINE THROUGH SEAMLESS EQUIPMENT INTEGRATION Equipment Sizing | Laundry Design & Workflow | Installation & Commissioning | Training & Follow-up Care INCREASE PRODUCTION IMPROVE QUALITY PROMOTE GROWTH ENHANCE LABOR EFFICIENCIES

Tools f the Trade

Depletion wands, low-level alarm system introduced for laundry dispensers

Girbau Industrial recently introduced the Compact+ 5-in-One, a space-saving machine that automatically feeds, irons, folds, stacks and accumulates at speeds up to 49 feet per minute.

Engineered for mediumand high-volume laundries where space is at a premium, the Compact+ is available in 24- and 32-inch diameters with 130-inch finishing widths.

GI says the new machine offers multiple enhancements over its predecessor, the Compact 5-in-One, including a more robustly designed folder and stacker; an enhanced control that harnesses the same mechanics and logic as other GI products; and a standard, rather than optional, vacuumassisted feeding table.

The Compact+ offers a new cross-fold section that mimics the technology used in the GI FRB large-piece folder. It also features a new drop stacker, rather than a flip stacker, to mimic the high production and industrial design of the GI FRB Stacker.

Adding to ease of operation and cross-training, GI says the Compact+ touts the same PLC system as other GI products, including DRF Feeders, PC Ironers, FRB Folders and FT Folders. It harnesses a full-color Inteli Touch-Screen Control with 99 customizable programs, along with complete control over ironing parameters, faults, alarms and alterations in processing and diagnostics.

Like its predecessor, the Compact+ offers one, two or four working lanes, with one lane for sheets, two for table linens and four for small items, including napkins and pillowcases. Its standard, vacuum-assisted feeding table simplifies linen feeding, maximizes production and processing speeds, and ensures high-quality results.

Improving production and quality, GI says the Compact+ processes damp goods straight from the washer, without need for dryer preconditioning. As damp items are fed into the Compact+, the optional spreader/feeder straightens and spreads them.

The ironer then automatically adjusts ironing speed and temperature based on the moisture content of the item to ensure a high-quality finish.

Once linen is ironed, a built-in folder performs one to two primary folds and one, two or three cross folds to meet specific needs. Finally, an optional stacker collects folded items and delivers them back to the front via an incline conveyor. www.girbauindustrial.com 800-256-1073

ClearWater Tech LLC, manufacturer of smart, sustainable ozone water and air treatment systems since 1986, has launched its new AEROUSnx™ Oxygen Concentrator, which is engineered to create up to 95% dry oxygen at 15 SCFH.

The company says air preparation is critical for efficient ozone production, and AEROUSnx™ Oxygen Concentrator features include:

• Compact—Small footprint.

• Gas flow meter—Quick reference to check operation.

• External air filters—No need to remove any cov-

Davis Packaging has introduced a new line of affordable professional Laundry Wrappers and upgrade components for existing wrappers.

Working directly from customer feedback, Davis says it rebuilt its most popular wrappers from the ground up, integrating such highly desired features as height adjustability, advanced anti-burn safety protection, enhanced temperature control, improved film loading and component strength and durability. The results are the

ers to service filters.

• Easy to service—All components, including sieve beds, are serviceable and readily accessible.

• Produces -80 F dew point feed gas—Keeps equipment clean and dry for years, lowering maintenance and increasing efficiency.

• Built for outdoor conditions— Anodized aluminum base and stainless-steel enclosure.

• Generated on-site—Oxygen on demand.

• Engineered for high-humidity environments.

www.cwtozone.com 800-262-0203

Hydro Systems, an independent manufacturer of chemical proportioning and dispensing systems, introduced two new accessories to complement its EvoClean range of laundry dispensers: depletion wands and low-level alarm system. EvoClean is a venturi-based, water-powered laundry dispenser for on-premises laundry (OPL) applications with three to eight chemical products.

Depletion wands simplify laundry installations by allowing quick connections between a single chemical drum and three laundry dispensers, says Hydro Systems. In addition to limiting chemical spills and speeding drum change outs, the depletion wands come equipped with a float switch that can detect and alert users to costly out-of-product conditions. This reduces the risks of poor results and rewash.

Hydro’s Low Level Alarm

complements the depletion wand, allowing up to eight units to be connected to cover all chemicals in a typical OPL. The system minimizes rewash by detecting the signal from the depletion wands and immediately alerts users with an on-board buzzer.

The alarm is simple to install and flexible—it can be powered directly from select Hydro dispensers or from a wall outlet as a stand-alone system.

www.hydrosystemsco.com 513-271-8800

most affordable, dependable, easy to use, ergonomic, and safety-minded laundry wrappers available, according to the company.

For customers with existing Davis Packaging wrappers, easy to install add-on height adjustment and safety protection kits are also available, whether it’s a compact tabletop model or a deluxe multi-roll console www.davispackaging.net 800-622-3015

EDRO Corp. says its 80-pound capacity tumble dryer—available in gas, steam or electric heated versions—meets the needs of virtually every on-premises and commercial laundry facility. C-SERIES commercial tumble dryers dry fast and efficient thanks to the right combination of heat and air flow, delivering outstanding drying results, EDRO says.

The C80 tumble dryer is powered by a simple, time-proven DMP Microprocessor Control featuring five preset programs with time/ temperature display, on/off reversing, anti-wrinkle tumble, end-ofcycle buzzer and extra contacts. An industrial strength, compact drive

and gearbox design eliminates multiple belts and pulleys while providing a smooth, reversing action to prevent tangling and bundling.

The robust spiderand-basket assembly construction blends tough, tubular steel supports with a machined shaft and extruded basket perforations for a stronger basket and smoother surface that is comparable to a washer basket more than a typical dryer basket.

Standard features on the C80 tumble dryer include fully insulated front, side and rear panels; a large door opening for easy loading; and a self-cleaning lint screen for ease of use.

www.edrocorp.com 860-828-0311

Manufacturers: Have you introduced a new product? Revamped your system? Released a new catalog? E-mail your product news, along with a high-resolution image, to mpoe@atmags.com and we’ll consider publishing your news free in Tools of the Trade.

8 JULY 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

line of laundry wrappers, upgrade components introduced

New

Small-capacity tumble dryer meets needs of on-premises, commercial laundry facilities with heat, air flow conbination

Oxygen concentrator

creates

up

to

95% dry oxygen

at

15

SCFH

Space-saving automatic feeding, ironing, folding, stacking, accumulating machine reaches speeds to 49 feet/minute

Results on whites are excellent. On colors, you have nothing more to lose and everything to gain by trying YellowGo. YellowGo may take out color you want to keep. But if it removes the unwanted dye without damaging the underlying color, you win! You won’t have to pay for the dye-stained garments and you won’t disappoint your customers.

So use YellowGo to keep your customers happy and keep them coming back.

information visit

or

or

YellowGo® removes unwanted dye from fabric. For more

AlWilson.com

call us at 800-526-1188

201-997-3300

Drying

management system.”

“By having employees manually open the dryer and feel the load to determine if it is dry, it often leads to over drying of the linen,” adds Keith Ware, vice president of sales for Lavatec Laundry Technology. “Most linen damage will occur in the last 10% of a dry cycle. If the linen is over dried, it leads to fiber damage, rough linen and the potential to scorch the product.”

Kevin Hietpas, director of sales for Dexter Laundry agrees that moisture detection is an underused technology, which can result in higher operating costs for a laundry service, beyond damaged goods. He says that with roughly 50% of the cost of running a laundry operation being of labor, the time saved with moisture-detecting dryers can add up to big savings in labor.

“For example, saving only eight minutes per load in dry time can save almost $5,000 a year in labor cost,” he says. “In just one year, that savings is many times the cost of upgrading from a non-moisture detecting dryer. In addition to the time savings, moisture-detecting dryers will also save wear and tear on linens, as well as save on utility costs.”

Most of today’s dryers include microprocessors that monitor multiple sensors and allow the user to adjust parameters such as temperature and dryness level, shares Joe Carrita, customer relations manager for ADC representing Whirlpool Corp. Commercial Laundry.

“Taking advantage of the offered computer technology may allow properties to effectively create cycles that are specific to the loads they are processing,” he says. “Doing so, may help prevent over drying, help prevent utility wastes and help against increased machine wear.”

TAKE ADVANTAGE OF DRYING PROGRAMS/FORMULAS

Gabriel Camacho, president of Consolidated Laundry Machinery (CLM), sees many operators not taking advantage of the different types of drying programs offered on dryers.

“The usual setup is drying by time and temperature, but many do not take advantage of which temperature the program uses to control, i.e., inlet or outlet,” he says. “Normal operators use outlet temperatures for the set point, which works for most cases, as it’s the temperature of the air after the goods.

“However, when maximum dry capacity (max load) is required or sensitive materials are being dried, inlet temperature set points should be used. This will limit the temperature before the goods, giving your max load or sensitive products time to reach temperature without being exposed to excessively high temperatures during ramp up.”

Steve Wilbur, director of engineering and product development for G. A. Braun Inc., says fine-tuning a dryer formula for each good’s type is the only way to ensure goods are not being over dried or under

dried.

“The use of differential temperature is the best way to dial-in each formula to leave just enough moisture so the goods do not become completely dried out as they travel through the remaining processes prior to being shipped to the customers,” he says. “If product is being conditioned prior to going to the ironers in finishing, the goods can be checked to ensure they have the proper moisture content left.”

Darrell Redler, marketing director-systems for Pellerin Milnor Corp., says drying formulas need to be evaluated for optimal performance—is the laundry getting as many loads per hour as it can without sacrificing quality?

“With the dryers in good working order, further refinements to the drying formulas may help improve performance,” he says.

“With few exceptions (such as timed formulas for conditioning only), dryers are usually programmed to leverage the particular technology used by the manufacturer to determine when drying is completed so that the cool-down step can begin.”

“It should be ensured that the dryer precisely stops the drying process at the optimum linen temperature, depending on the type of laundry, and automatically cools down to the optimum temperature for the laundry before the finishing process,” Thad Southwick, project manager for VEGA Systems USA, shares.

Redler goes on to says that it’s important to note that in dryer systems programming changes affect all dryers. Start with all dryers on a level playing field, and implement changes one step at a time.

Bob Fesmire, president of Ellis Corp., recommends experimenting with each dryer.

“For example, if your dryers are in a line, they will or can have slightly different airflow and/or slightly different pressure,” he shares. “Really analyze and experiment if you have the capability, such as changing basket speed, blower speed, inlet temperature if you can do it on your dryer. Some dryers have automatic algorithms that can help dial these in for you.”

It’s also important to have the right number of dryers, according to Ware.

“We often see customers wanting to purchase a large tunnel system but skimp on the number of dryers,” he says. “Accurately projecting your dryer capacity is important to a well-designed system.”

10 JULY 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

(Image licensed by Ingram Publishing)

Continued from Page 1

Redler says the ultimate goal is to understand what normal performance looks like in terms of loads per hour and moisture content requirements so that if something goes wrong, the laundry can, hopefully, eliminate programming as the culprit.

“Normalize, optimize, then set expectations for standard performance,” he says. Once the drying formulas are set, Redler suggests that they should be left alone, unless a situation arises that wasn’t initially considered, such as the best way to treat partial loads or unusually small loads or even seasonal differences in dryer performance.

“The best advice then is to be as familiar as possible with the troubleshooting technology in the dryer or system controls and to avoid programming changes to fix human error or some other mechanical issue with the dryer,” he shares.

LOAD MAKEUP

Load organization plays a key part in fine-tuning drying, according to Carrita. This means organizing loads so that they are like materials, which he says is the best way to achieve a consistent finished product.

“This allows you to create a cycle that specifically works with the material with regards to temperature and drying time,” he points out. “Additionally, the size of the material will determine whether a reversing feature should be enabled.”

This is important, says Carrita, because large material, such as sheets and duvets, will dry fast and efficiently with reversing enabled, whereas reversing with smaller items, such as hand towels, will produce the opposite effect.

“Then as we move to finishing, having like garments will allow us to adjust the dryness level or time to produce the water retention needed for that item,” he shares.

Carrita concludes that this concept also allows the ability to set a cool-down temperature that will work with the end-ofthe-line process.

Another load factor to consider is the size of the loads going into the dryer. Ware says it’s important to ensure load sizes are correct.

“Laundries often under load the dryer, thinking the load will dry faster,” he points out. “While there may be a slight improvement, a lot of the heat generated by the dryer does not pass through the linen. Instead, it flows out the exhaust duct. Heated air will take the path of least resistance.”

Gemma Colomer, communications manager for Domus, also observes that operators and staff working in an industrial laundry do not usually make complete loads.

“It affects and contributes to an extra use of energy and greater wearing of the linen,” she says. “As the linen and garments are overdried, the tissue is burnt and the garments have a much shorter lifetime.”

IMPORTANCE OF MAINTENANCE

Redler says there is validity to the saying, “An ounce of prevention is worth a pound of cure,” when it comes to drying

“Dryers can be long-lasting and reliable equipment as long as seals are maintained, bearings greased, baskets kept free of debris, lint controlled properly, etc.,” he says. “Use maintenance management software, if available, to help maintain and follow the maintenance schedule and document issues, repairs, etc. Also, watch for the first signs of trouble and address issues sooner than later.”

Ware has a few maintenance items that are key to optimal dryer performance. First is to check dryer basket cleanliness.

“Having toured many laundries, we often see dryer baskets blocked—some as much as 70%—with plastic,” he shares.

“This limits airflow within the dryer and prevents moisture from exiting the basket through the exhaust.”

Finding plastic in the dryers often starts with a poor sorting process, Ware says, but no laundry will remove 100% of the plastic from sorting, so a routine PM (preventative maintenance) schedule to clean dryer baskets is key.

Next to improve dryer performance is making sure the lint basket or screen is clean and that the lint removal system, whether automated or manual, is functioning.

Finally, Ware points out the importance of burner maintenance. Having the engineering crew clean and fine-tune the burners on a regular basis is key to energy efficiency and dryer throughput.

“Check the gas-to-air mixture, making sure the burner has a clean, ‘blue’ flame to get the most efficient use of the energy provided,” he concludes.

CHECK THE WASHERS

It may seem a bit odd to talk about washers when addressing dryer function, but a properly functioning washer can impact the drying process.

“Generally speaking, it is labor intensive to condition goods in the dryer prior to flatwork ironing,” says Adcock. “Although budget may not exist for replacement of the washer-extractors in the laundry, it is still an excellent exercise to understand exactly how double handling the goods impacts the productivity of the laundry.”

He says low-speed washers require the laundry operator to “condition” or remove some of the remaining moisture from the low-speed extract in the dryer prior to sending the goods onto the flatwork ironer. This extra operation takes time, requires manpower and floor space, and increases the amount of work in the laundry.

“Slightly lengthening the extraction time on a washer extractor can help in removing more moisture from the linen,” shares Ware. “With an extraction press, it is not only the pressure applied to the linen, but the time the linen is under maximum pressure.”

He goes on to say that increasing the final rinse temperature in a washer or tunnel will help improve extraction and reduce moisture retention, which helps to lower dryer times.

“A hotter load going into the dryer allows less energy to be utilized in the drying of the linen,” he says.

USE A TEAM APPROACH

Finally, Brooks says fine-tuning the drying process is a team approach between the manager, linen supplier and equipment distributor.

“They should work together to identify the perfect moisture level for finishing,” he points out. “From there, the system takes over and removes obstacles such as operator error.”

“By utilizing newer as well as widely available technologies, laundry facilities can improve their operating efficiencies and increase their bottom line,” shares Adcock. “On-premises laundries, as well as commercial laundries, can benefit and dramatically reduce overall costs and create a better laundry operation.” ALN

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | JULY 2019 11

Protect clean goods with proper packaging

and usage,” she says. “When clients discover that they can use the bag as a dispenser by pulling out one towel at a time, they buy into the concept and love the concept.”

BY MATT POE, EDITOR

CHICAGO — Packaging options vary widely across the laundry industry, with choices ranging from simple twine-bound stacks and poly bags to manual tabletop and console poly film wrappers and ultimately high-end automated poly film shrink tunnel systems, says Tim Davis of Davis Packaging, a provider of laundry packaging solutions.

“Historically, packaging has been an afterthought relative to the actual laundering processes, leaving many operations scrambling to meet customer requirements or failing to adequately protect newly cleaned product at delivery and incurring extra costs or low customer satisfaction,” he says.

Each of the popular wrapping options have a place in healthcare, hospitality and rental, whether on or off premises, Davis shares.

“Focusing on and prioritizing your customer needs, minimizing loss and contamination, and delivery presentation are the ultimate criteria for selecting the best packaging solution for you,” he adds.

TYING, STRAPPING, BAGGING

Tying and strapping machines or bulk bagging processes are very fast and cost effective for service and utility laundry items, such as shop towels, rags and bar mops requiring low amounts of finish work and visual presentation, Davis says.

“With these models, stacked or bunched items are simply banded together and/or dropped into bags for next use,” he shares. “Banding and bagging may be manually or automatically performed. The loose fill and exposed nature of this packaging however makes it less suitable for personal use linens and clothing items that would wrinkle or dirty easily.”

Neil Dowding, product marketing manager for packaging solutions company Felins, says bundling can be beneficial for in-house laundries for ease of handling and distribution throughout the facility. Tying provides a quick, low cost bundling solution for these products that remain on site.

Banding is a sustainable laundry bundling solution, says Dowding.

“Our banding machines and inline systems apply adhesive-free bands that can be printed with variable data such as company branding or track and trace information on either paper or plastic banding material,” he says. “This type of bundling is particularly beneficial for the uniform and garment segment.”

A more economical solution is tying or strapping, according to Dowding. These are very popular

and low-cost, bulk laundry bundling solutions that hold a tight bundle with minimal materials.

John Bunn, president of tying technology producer B.H. Bunn Co., recommends using a tying machine with twine for bundling all types of linen.

“The tying machine was invented in 1907 to bundle the mail,” he says. “In the mid 1920s, machine sales crossed over to other industries, including the textile industry. Today the tying machine is used to bundle bar mops, hand towels, bath towels, pool towels, bed sheets, blankets, hospital gowns, surgical gowns, aprons, rental rugs, overalls, pants, shirts, socks, roll towels, shop towels and surgical packs, to name a few.”

Bunn says that twine is the most economical and environmentally friendly medium for securing textile bundles. He adds that a machine-grade polyester/cotton blend twine is best to use, and specialty twines are also available, which can be used for color coding, inventory control and sterilization applications.

“When the proper tying machine model and the correct machinegrade twine is matched, a textile bundle customer will experience lower cost of materials and longevity of the tying machine,” he shares.

An additional benefit of twinebased packaging is a slip-proof-slipknot, which is tamper proof.

Marie King, communications manager for strapping systems solutions provider EAM-Mosca Corp., recommends the use of strapping to secure bundles of textiles—towels, bedding, scrubs for the healthcare industry, and table and kitchen linens for the food service industries.

“Banding textiles with one polypropylene strap leads to neat bundles that stay intact, leading to less re-work, easier counts and a better presentation to your customers,” she says.

King goes on to say that loading strapped bundles into wheeled totes makes for easier deliveries, too.

“Not all strapping machines are of equal value,” she says. “We recommend that potential strap users review the different offerings before making a purchasing decision based only on cost.”

Jeanne George, inside sales manager for Rennco, which specializes in vertical bagging, says an advantage with a bagging system is less handling, along with the ability to custom size the bag versus a large “garbage style” bag.

“Unless there is a specific need for items to be folded neatly (whereby they use either banding or stretch wrapping) most items are in a plastic bag for transport

The industry is quickly accepting the bagging of various linen such as bar wipes, shop towels, microfibers and washcloths, says George. New, larger bagging systems are available now to satisfy the needs for hospital fitted sheets and ISO gowns.

“At some point, linens need to be transported, to ‘move,’ so having them contained in a bag of some sort is always an advantage,” she points out. “It keeps the stacks, bundles, grouping together and easier to handle versus individual items.”

George adds that there are a variety of systems that can be configured to weigh items, inspect items and/or count items.

“This is a cost saving over manual labor to place ‘garbage style’ bags over a stand, toss the items into the premade bag, lift that bag, tie it closed and then lift back again to the transport cart,” she points out. “With an automated system once they are inspected, the rest is completed automatically, which is a win-win for the laundry facility. Less time and less money.”

Ross Sanders, CEO of Streamline Solutions, a provider of many types of laundry bagging products, says bags and other types of packaging products come in many different materials, sizes, thicknesses and colors.

“The key is to make sure that the bags fit perfectly,” he says. “Not too big and, of course, not too small. We want to make sure that the laundry has a product that fits well for them instead of using something that is not the right size, which in turn could cause issues with their customers which could cost them more money or even their business.”

Heavier linen (also based on total weight) would mean a thicker bag or wrap, Sanders points out.

He goes on to say that a healthcare laundry may need to always use a cart liner for its customers, which is a plastic bag that is a protective barrier between the cart itself and the linen.

“Most hospitality laundries do not see that as a requirement,” shares Sanders. “If anything, they will use a cart cover, which in turn is a ‘dust cover,’ which in turn keeps the linen free of dust and dirt. Healthcare laundries do use the cart covers as well, of course.”

WRAPPING

Manual tabletop and console poly cling wrappers provide one of the most economical and easiest to use packaging solutions for any item requiring basic packaging up to the highest level of care, says Davis.

Manual wrappers range from compact tabletop units to freestand-

ing console models and utilize a transparent cling poly film, rather than shrink film, to custom fit and seal stacked bundles of laundry.

“The non-shrink cling film significantly reduces wrinkling and bunching associated with banding/ bagging and shrink films and prevents packages from sliding during transport or storage,” Davis points out. “The visually appealing clear packaging also allows easy identification of contents without opening packages.”

From a cost standpoint, he says the “use what you need” nature of cling film makes it more economical than single-sized, fixed-cost bags.

“Whether favorite jeans and shirts, table and bed linens, uniforms, or towels, neatly finished contents are securely wrapped in a fully sealed, transparent package, protecting contents from dirt, contamination, loss, and separation during delivery and storage,” says Davis. “Manual wrappers have a place in any sized operation across all industries.”

Semi- and fully automated shrink tunnel systems provide a similarlooking package as their manual counterparts but bring additional automation over the manual wrappers desired for high-volume standardized packaging needs, Davis shares.

Bundles of finished stacked laundry is generally fed down a conveyor system to a sealing station where poly shrink film is loosely sealed around the bundle. The sealed bundles continue by conveyor to a heated tunnel, which shrinks the film around the shape of the package.

“These advanced systems are highly configurable for manual sealing or fully automated processing,” he says. “While similar in look to manually sealed packages, most shrink-sealed bundles do require additional care during packaging setup to avoid bunching and wrinkling during the shrink phase and toppling if stacked during transport or storage due to the slippery quality of some shrink films.”

Shrink wrapping is the most

common form of bundling in the laundry industry, according to Dowding.

“Systems such as our TP300 wrapping system provides a tight, high-clarity plastic wrap around your linen bundles automatically,” he says. “This allows the product to travel from point A to point B with complete coverage and protection. For company branding or track and trace capabilities, you can also apply labels to the plastic with no residue on the linen.”

For hospitality applications where the linen must be covered/ wrapped, Bunn recommends using recycled paper for the wrapping process and then secure with twine.

“Typically when a laundry uses plastic wrap for bundling, the linen is not completely dry when wrapped,” he says. “When using the recycled paper and a tying machine to secure the paper and the bundle, it will allow the linens to breath while stored and therefore not retaining moisture creating a foul odor.”

MAKING THE CHOICE

Sanders recommends that laundry operations not rush to decide on packaging because there are many options available in the marketplace.

“Different materials, sizes and thicknesses need to be looked at and analyzed to see what works best for the laundry’s individual situation. Try different samples,” he recommends. “Like what we do with our customers, the laundries need to speak directly with their respective packaging vendor and discuss exactly what they are trying to accomplish for themselves and their own customers.”

“While cheap and easy may get the job done, it does little for growth and long-term customer satisfaction,” Davis points out. “The quality of your deliverable will be what you are remembered for, not the behind-the-scenes effort invested in the initial wash. It may be a single solution or a combination, just don’t ignore the significance of your packaging.”

12 JULY 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ALN

Packaging types impact the ‘quality of your deliverable,’ experts say

(Image licensed by Ingram Publishing)

Financing as low as 4.99% for up to 36 months.* CONTACT AN ADC™ DISTRIBUTOR TO LEARN MORE OR VISIT ADCLAUNDRY.COM Trust Your Linens With ADC™. Machines designed to help streamline your laundry facility’s throughput. ®/™ ©2019 ADC. All rights reserved. *This promotion is valid July 1, 2019 – September 30, 2019, and rate may vary depending upon individual credit profile. This promotion is valid for applications received by September 30, 2019, and funded by November 15, 2019.

On-premises laundry planning and layout best practices

key to success

BY THOMAS BELL

RIPON, Wis. — Architects responsible for the design of hospitals, hotels, long-term care facilities and other complex projects are expected to be experts on a wide range of subjects, including the layout and equipment selection of on-premises laundry (OPL) facilities.

To me, this seems like a pretty tall order.

So, if there’s any one best practice I can recommend, it’s for architects to consider engaging (at no charge) an experienced laundry representative to provide input and guidance. Following are just some simple considerations we cover with architects.

LAUNDRY ROOM LOCATION

When the project is new construction, we recommend locating the laundry room on a floor with a minimum 12-inch cement slab. Moreover, that slab needs to rest on compacted earth and aggregate (i.e., not over a parking structure or other sub-basement structure).

The reason is that this gives the building owner (or building management) the option of choosing the right hard-mount washer-extractors, which offer several benefits.

Hard-mount (or rigid-frame) machines contain fewer parts, because they are anchored to the floor. They don’t require the heavy duty shocks and springs that soft-mount units utilize. Mounting the washers on concrete reduces the number of vibration-control parts required. Typically, fewer parts means fewer things to maintain or repair.

Another advantage of hardmount machines is they can employ significant forces to extract water and thereby shorten drying time. Accordingly, there are labor efficiencies (enhanced throughput) and utility savings.

Finally, hard-mount machines are less expensive to operate over time and some manufacturers offer a more robust warranty, which can be as high as 48,000 cycles. Soft-mount machines often carry a 30,000-cycle warranty.

If the project is associated with existing infrastructure, or if other factors necessitate locating the laundry room on an upper floor, then we would suggest specifying soft-mount machines.

For example, building space

in New York City is expensive. It’s not always possible to put the laundry room on a cement structure that’s suitable. Again, this is where working with laundry experts can help navigate these types of structural and architectural challenges to arrive at the most efficient design.

LAUNDRY ROOM LAYOUT

The laundry room layout is important, especially during peak times, such as when a hotel is at full capacity. A laundry expert can provide guidance on the amount of labor required to work in peak conditions and, similarly, the open floor space required for them to work efficiently.

Moreover, the room needs to incorporate space for a variety of stationary and mobile equipment. These include sorting tables, folding tables, laundry carts, laundry chutes (if used), safety equipment and chemical storage.

Another consideration we point out is the actual location of washer-extractors relative to tumblers. It makes sense to minimize the distance between them, but not to the exclusion of staff comfort and efficiency.

If you place the machines such that they face one another, you must allow enough space for the doors of each to be open simultaneously, without contact, and

for employees to be able to pass by one another with armfuls of linens.

Finally, it’s not unusual during commercial building construction for machinery to be installed in its final location prior to the completion of framing and other construction tasks. Backup generators, for instance, are often placed on rooftop-based cradles, after which, a powerhouse is completed around it.

Similarly, laundry equipment such as washer-extractors, tumblers and ironers may be placed prior to the room being fully trimmed—and this can be problematic, as many standard door openings are 36-inches wide to accommodate ADA compliance, etc.

Yet, the frames of washer extractors and tumblers can be 38 inches wide, or wider. Thus, when they need to be replaced or repaired, removing them becomes complicated.

While some of this advice seems simplistic, quite often it’s little details that are overlooked.

Space equates to dollars, and there’s a lot of pressure on architects to minimize space while maximizing efficiency. It can lead to unforeseen situations.

MACHINE CHOICE AND PROPER CAPACITIES

While there are many experienced architects that can

determine laundry room and equipment capacity requirements for a facility, it can be helpful to get confirmation from a laundry expert.

For example, calculating laundry room space, equipment and staffing requirements for a 200bed hospital at full capacity can be bewildering. Laundry experts, however, can a bring a wealth of experience and knowledge to the task.

What we do is perform calculations that account for full occupancy (and less) such that all laundry needs can be addressed in an eight-hour shift.

TECHNOLOGY ENHANCES ARCHITECT ACCESS TO LAUNDRY EXPERTISE

One of the biggest changes I’ve seen in the last 20 years is how we work with architects. Demanding project timetables and tight budgets have made it advantageous for architects to rely more heavily on our expertise.

Further, electronics and technology (highspeed connectivity, the cloud, etc.) facilitate our interactions. We can quickly share and review documents, blueprints and pictures simultaneously, and remotely.

We are also finding that we are drawn into

the projects much earlier— which we prefer because it prevents mistakes and rework. Though we are brought into the process earlier, we still like to see the blueprints around the 80% completion mark. This helps ensure nothing has been overlooked.

SUMMARY

As you can see, there are a variety of details to consider when it comes to designing and equipping OPL facilities—I’ve only scratched the surface.

We realize architects are very busy. Yet, there are sometimes brief respites between projects or other occasions when they can “come up for air.” When this happens, we encourage them to attend a laundry lunch-and-learn event, where they can stay up to date on the changing needs of laundry facilities.

These events are usually hosted at a local distributorship or a convenient meeting space. Laundry experts and distributor personnel cover all the steps and considerations relevant to OPL operation planning. ALN

Thomas Bell is key accounts manager for UniMac national accounts. He can be reached at Thomas.bell@ alliancels.com. Bell

14 JULY 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Columnist says having architects work with experienced laundry representatives

Laundry experts can help architects create the most effective laundry room for an on-presmises laundry faciilty. (Image licensed by Ingram Publishing)

THE DEFINITION OF THE VEGA SMARTLINE BATCH WASHER MEISTERSTÜCK SUPERIOR DESIGN IS WHAT VEGA IS KNOWN FOR AND THE REASON VEGA SYSTEMS GROUP IS THE FASTEST GROWING MANUFACTURER IN THE INDUSTRIAL LAUNDRY INDUSTRY. CALL NOW FOR A FREE ANALYSIS WWW.VEGASYSTEMS-GROUP.COM 855-834-2797 ENGINEERING YOUR FUTURE THANKS FOR VISITING US AT THE CLEAN SHOW!

PANEL OF EXPERTS

Linen storage, transport—keepin’ it clean

that are already processed first. This can also lead to premature life loss due to the over-processed linens.

Linens must be handled after processing with the utmost care.

If the linens come into your facility shrink wrapped, make sure your employees do not rip off the plastic before storage. There is a reason why the laundry is sending shrink wrapped linens, and your facility agreed to pay extra to have them shipped in this manner.

Keep the linens wrapped in plastic so that they are not exposed to harmful dust and other contaminates, which can make people ill if they have open wounds; this is especially important when servicing the healthcare market.

If you outsource your linens, there are a number of companies now that are cleaning linen trucks by exposing the inside to UV light for a prescribed period of time. I would ask your linen provider if they are currently using this technology or another procedure to clean the inside of the trucks. Killing the bacteria from the walls of trucks will lead to safer storage of linens while in transport.

Carts need to be cleaned periodically, so the use of cart washers that use hypochlorous acid as a disinfectant in an industrial laundry helps keep linens clean after processing.

It might seem obvious but make sure the linen trucks are being cleaned and serviced periodically, otherwise the grime from the everyday use of the trucks can get on the linens. Furthermore, linens must be secured properly whether they are going to or away from the processing plant.

I have seen instances where linens are stored in a manner whereby the last linens are processed and stored on top of other linens that have been waiting to be employed throughout the facility. Do not let linens sit only to accumulate dust, use the linens

Make sure the area where you store the linens is cleaned periodically. Do not store the linens in an area where it is damp or close to food particles. Make sure your employees understand that keeping processed linens clean is important and make sure they are a part of a solution that keeps the linens clean.

As a manager, periodically you need to check on the linens to make sure they are being stored properly because after all, the buck stops with you. Not one but all employees need to feel responsible for the cleanliness of the linens post processing.

Make sure that you foster a culture inside your facility that allows an employee to say something if they feel proper protocol is not being used by an employee or by using a better general practice. You can do this holding quarterly meetings asking for better ideas from your employees and to review methods already in place and how to get better at these practices.

and all surfaces that touch textiles are clean.

• Make sure employee hands and other linen contact areas are clean.

• Make sure air that contacts clean textiles is devoid of lint or other contamination.

Entering the dryer:

• Make sure air that contacts clean textiles is devoid of lint or other contamination.

• Make sure all dryer surfaces are clean.

• Make sure dryer inlet air is clean.

Exiting the dryer:

• Make sure air that contacts clean textiles is devoid of lint or other contamination.

• Make sure all surfaces that linen contacts are clean.

• Make sure linen is dry.

• If manually unloading, make sure employee hands and garments are clean.

Entering the finish:

• Make sure clean carts are truly clean.

• Make sure conveyers are clean.

• Make sure linen is protected at all times along the journey.

• Make sure air that contacts clean textiles is devoid of lint or other contamination.

Finish surfaces:

• Make sure all finish surfaces are clean, including conveyers, feeders, ironers, folders, stackers, shelves and tables.

• Make sure linen does not dangle on a dirty floor.

proof, clean cart cover.

• Ensure finish carts with holes at the bottom are lined to prevent water from splashing up.

• Ensure all linen to be placed on finish carts is dried and cooled.

Trucks:

• Ensure truck linen areas are cleaned regularly.

• Ensure all linen carts are securely fastened to prevent goods from moving or falling during transport.

• Ensure clean linen carts are protected and physically separated from soiled linen carts.

It is best to have written policies for the above, supported with checklists and training records. Furthermore, it is a good idea to regularly monitor and measure your cleaning processes to ensure they are performing as designed.

Measure contamination levels of hard surfaces. Measure air cleanliness in critical clean linen areas. Measure employee hand cleanliness. Measure clean linen bioburden counts. There is a recently released HLAC process monitoring toolkit (see: www. PMTKnet.org) to help measure the effectiveness of laundry processes.

are protected from potentially fatal bacteria.

“Failing to plan is planning to fail” … this age-old wisdom coined by Benjamin Franklin holds true in virtually every situation. This adage is especially accurate in the laundry industry. Planning, communication, documentation, execution and consistent monitoring is critical to the needs and health of the recipients.

A typical hospital laundry scenario:

• Begins with reliable commercial laundry equipment and the proper detergent, chemicals and /or ozone, in order to be equipped to handle everything from light to heavily soiled textiles.

• After the linen has been processed, it is loaded onto the sterilized cart by the machine operators. The carts are built for fast turnover, ensuring the linen turns quickly for circulation purposes, with no extra time to accumulate airborne dust and harmful bacteria.

• The carts are sterilized daily. No cart is allowed from the soiled side unless it has been run through a “cart wash” and thoroughly disinfected.

• The carts are calibrated and maintained weekly by the chemical representative and the maintenance supervisors.

Effectively cleaning textiles in a laundry is a well understood process. We sort them by type, load them in the washer, add appropriate chemistry, temperature, water, mechanical action, and time. Presto! Clean textiles.