Late News

Caldwell & Gregory partners with Equipment Marketers

RICHMOND, Va. — Caldwell & Gregory, a provider of valuebased laundry service programs to the college and university market, reports it has partnered with Equipment Marketers, a laundry service provider headquartered in Cherry Hill, N.J.

The company says it will bring Equipment Marketer’s route and distribution divisions under its direction, allowing the owners to retire, adding that the partnership will ensure Equipment Marketers’ clients and employees continue to have an exceptional experience.

“When Equipment Marketers’ founders, Dick and Sue LaMaina, approached us about needing a partner that would care for their clients and their team members in the exceptional way they have for over 40 years, I was extremely excited,” says Caldwell & Gregory President and CEO Bob Dinnie.

“I have always admired the LaMainas’ commitment to excellence and for building a company of tremendous integrity.” ALN

Clean ’19 marches into the future

BY MATT POE, EDITOR

NEW ORLEANS — The classic spiritual, “When the Saints Go Marching In,” is the unofficial anthem of New Orleans.

And the 2019 edition of the Clean Show went marching into the past and the future here June 20-23 at the Ernest N. Morial Convention Center.

Clean ’19, the 42nd year of the show, marched into the past as the long history of John Riddle and his Atlanta-based company, Riddle & Associates, being the show manager came to a close.

Riddle & Associates has managed the show since 1992. John Riddle has been associated with Clean since 1981.

“I’m going to miss all of you,” Riddle says. “This show may not have reached the numbers of Las Vegas, but it was up there. The industry did some great business. It was a good last show.”

Both attendees and exhibitors agreed

that business was good in New Orleans. “Traffic in our booth may have been down, but the conversations were more meaningful,” says Steve Kallenbach, CMO, director of market solutions for ADI American Dawn in Los Angeles. “We’re

Laundry/linen services need to analyze branding

First impressions count, especially a logo, author says

BY GARY DEAN

CHARLOTTE, N.C. — “We help you have a better image” is a line that many textile rental companies tell prospective customers when asked why they should be hired for linen or uniform services.

But rarely do we in the industry take a step back to objectively analyze our own brands. We know it’s important, but in the changing routine of day-to-day priorities, it’s apt to fall way down the list.

When was the last time you stopped to analyze your logo, tagline, website, social media and marketing materials? Do they offer consistency across all platforms in appearance and message to your prospects and customers? Do they evoke an image that you are proud of, and one that is rel-

evant to your universe of potential customers? Is your brand current and relevant?

The first step in making improvements to your image is to organize a brand audit. Whether you do this internally or with a third-party consultant, you’ll want to

assemble all the materials that represent your company.

This laundry list of items includes, but is not necessarily limited to, your name,

Clean Roundup

Didn’t make it to New Orleans? Check out what some exhibitors highlighted at Clean.

Panel of Experts

In this issue, the experts talk strategies for Clean Show follow up that also works with new contacts.

Customer Migration

Three experts share how to gather information from and then transition new customers.

AUGUST 2019

Messe Frankfurt era of Clean starts with solid contacts made, business done

www.americanlaundrynews.com INSIDE [8]

The Newspaper of Record for Laundry & Linen Management

[26] Volume 45, Number 8 [30]

Publishing)

(Image licensed by Ingram

See CLEAN on Page 6

walking away with some good agreements.” Russ Arbuckle, president of Wholesale Commercial Laundry Equipment S.E. LLC in Southside, Ala., echoes Kallenbach’s

on Page 28

Leaders of the sponsoring associations and Messe Frankfurt cut the ribbon to open Clean 2019. (Photo: Nathan Frerichs)

See BRANDING

BY MATT POE, EDITOR

ALEXANDRIA, Va., and RICHMOND, Ky. — In May of this year, the American Journal of Infection Control (AJIC) published an article on the initial pilot research project completed by the Association for Linen Management (ALM). This project was undertaken following the guidelines essential for recipients of federal grants.

ALM says the primary aim of this observational study was to quantitatively identify what microbial levels are present on a sample of hygienically clean healthcare textiles in the United States, taking into consideration the handling, transport and storage following processing.

The Hygienically Clean Healthcare Advisory Board and Healthcare Committee of TRSA, the association for linen, uniform and facility services, responded by rejecting ALM’s assertion that it has taken “the first step to identify microbial levels present on healthcare textiles in the U.S. today” and its self-characterization as “the textile industry’s best resource.”

TRSA President and CEO Joseph Ricci, CAE, says that ALM’s plans to conduct research on microbial testing ignore wellestablished internationally developed and recognized standards and measurements.

“ALM appears to be highlighting and solving a problem that doesn’t exist, while committing resources to develop measurements that already exist,” Ricci says. “U.S. hospital patients’ risk

of obtaining HAIs from healthcare textiles over the past 43 years is less than 0.000007%, conservatively.”

TRSA points out that the study begins with nearly 800 words tying linen to healthcare-associated infections (HAIs), although noting there have only been 12 cases of HAIs indirectly linked to linens worldwide (including three in the United States) over the past 43 years.

ALM says it appreciates TRSA’s comments related to the recently published, vetted study in AJIC, adding that “they are an example of the discussions we could have as a collaborative organization.”

well as the more than $1 billion in linen loss created by mismanagement and misuse of linens and scrubs,” says Ricci.

The anticipated outcome of further research is unclear, according to TRSA. References in the AJIC research indicate there is no U.S. “standard,” when voluntary industry guidelines have been in effect for nearly a decade, which TRSA says implies that ALM intends to pursue government regulation and prescriptive processing formulas.

• An eight-question survey accompanied the textiles through the process, including information on location/ methods of storage, rotation of textiles, covering of the textiles, etc., to provide insight on the impact of storage methods within the hospital.

• Textiles remaining on these same carts after 24-28 hours were tested to measure the impact of textiles in use prior to delivery for patient use.

• Nowhere in this study was laundry processing in question or evaluated.

• Laundries both accredited and non-accredited were included in the research group.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Roger Napiwocki

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

TRSA points out that it has supplemented robust inspection protocols with a quantifiable healthcare textile (HCT) performance level through its Hygienically Clean Healthcare Certification program. In addition, it says its long-standing Healthcare Committee has developed dozens of resources to educate the linen, uniform and facility services industry and healthcare professionals.

“Resources would be better spent focusing on real issues, such as the hygiene of washing healthcare textiles at home that endangers patients and others, as

TRSA says the AJIC report contends that further U.S. research is required to validate global protocols in the United States. International standards apply just as well to the United States as anywhere else in the world; essentially the same microbial tests and laundering techniques are used everywhere, observes Ricci.

ALM went on to clarify that as stated in the study, “Research shows that how healthcare laundry is processed, handled, transported and stored can impact the microbial level or contamination of the textiles, which, in turn, can lead to an increased risk of transmission to high-risk patients.”

The association says that the study, referenced in the AJIC article, first measured textiles as they arrived at the hospital. This was to establish a baseline measure of the hygienically clean textiles upon arrival. In addition, ALM says it is important to note that this study did not include any on-premises laundries since transportation by vehicle from the laundry to the hospital was required by all.

ALM adds that:

• A nine-question survey followed the textiles to provide insight as to the impact that methods and length of storage, road conditions and transportation might have on the textiles.

• Textiles were handled by the hospital following their standards of practice and placed in use on patient-care areas in three specific units (obstetrics, intensive care, medicalsurgical floor) within the hospital and stored according to the various methods utilized on each of those units.

All laundries participating in this study were ALM members processing textiles at commercial, cooperative and central laundry processing facilities. Commercial, cooperative and central laundries comprise 63% of ALM laundry processing members.

Given the limited resources available for the initial research project and the identified need for further research, ALM shares it has formed the Textile Research Council (TRC), a collaborative industry organization to continue with further textile care research efforts. The association announced the TRC at the recent Clean Show in New Orleans.

TRSA says it will not participate in ALM’s new research council and will encourage its association members not to participate.

“I’ve not spoken directly with anyone from their organization, but based on their comments, I don’t believe they understand the intent of the new organization,” says Linda Fairbanks, ALM’s executive director. “However, if they choose not to participate, that’s their prerogative and we will respect that decision.”

In lieu of the council’s formation, TRSA has proposed inviting Judy Reino, as the operator of a Hygienically Clean Healthcare Certified and HLAC Accredited laundry, and the president of ALM, to serve on the Hygienically Clean Advisory Board.

This would “foster ALM’s understanding of already established standards of hygienically clean linens as a starting point to research instead of starting from zero,” Ricci says.

“Our goal with the Textile Research Council is to unite those within the industry, not divide,” says TRC chairperson Cindy Molko, CLLM, RLLD. ALN

E-Mail: nfrerichs@ ATMags.com

Advisory Board

David Barbe • Jim Buik

Tony Jackson • Janice Larson Tom Marks

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies: U.S. $9.00; Foreign $18.00. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661.

Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 45, number 8. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2019. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

2 AUGUST 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

TRSA says research ‘solving a problem that doesn’t exist’; ALM’s goal is to unite, not divide

INSIDE: August 2019 • Vol. 45 | No. 8 [28] Associations Present Honors at Clean 2019 Both TCATA and ARTA presented honors and awards to members, show management in New Orleans [29] ITSA to Host World Textile Services Congress Event to take place prior to Texcare International; also launches new information-sharing, interactive website [33] Career Track [34] Classified Advertising [35] Source Directory [38] Trade Ticker [38] Calendar of Events ALM conducts healthcare laundry research, TRSA dismisses efforts

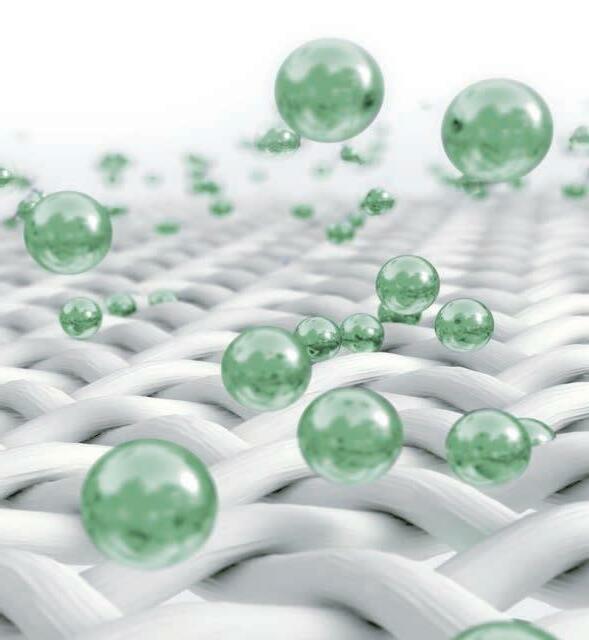

Milnor has a better solution through dilution.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®, CBW® and RecircONE® are Pellerin Milnor’s registered trademarks.

Coming down after Clean

It’s difficult to believe Clean 2019 has already come and gone.

Although I’m not sure my feet have recovered, yet.

Yes, like all attendees, I did a lot of walking up and down the aisles at the Ernest N. Morial Convention Center in New Orleans.

I’m always fascinated by the myriad ways laundry/linen service suppliers set up their booths on the trade show floor.

Some booths were huge, with massive, functioning laundry equipment. In many of these areas, employees or volunteers actually spent their days operating the equipment—especially feeders, folders and overhead rail systems.

Yes, the booths can get massive at Clean, but I found that every booth in New Orleans had its own special set up, a unique way to show off their products and services. From

The Editor’s Desk

MATT POE

monitors to laundry carts, from informational displays to fuzzy giveaways, each and every vendor made a distinct impression at Clean. But what if you couldn’t make it this year? Then this issue of American Laundry News is for you.

To start with, on page 1 you’ll find the beginning of an overall show report, complete with thoughts

from vendors and fellow laundry/ linen service operators.

Then on page 8, you’ll find the beginning of a “roundup” of information gathered from exhibitors in New Orleans. I visited with as many suppliers of products and services of interest to the industrial and OPL markets in order to share with you what they had at Clean. While not complete, I did follow up to get as much information as possible.

Speaking of following up, our Panel of Experts (page 26) offer their advice on following up with contacts after Clean, or whenever you make a new contact.

And that’s really the benefit of the Clean Show—making contacts, face-to-face.

I look forward to seeing you all again in 2021 (hopefully before), but until then, stay in touch and keep it clean, everybody! ALN

Reader says article should be ‘mandatory orientation’

Best “Employer drug, alcohol

policies” article I have ever seen in over 30 years [June 2019, pages 29-31].

Comprehensive, comparing the nationwide laws such as OSHA, ADA, EEOC, and FMLA. Yet succinct, for to-thepoint reading.

Definitely a keeper! This should be mandatory orientation for all new supervisors, managers and owners.

Chief Donald E. White Former Director of Safety and Security Northern Virginia Mental Health Institute Falls Church, Va.

T

he 2019 edition of the Clean Show is now in the books. Every time I have attended one of these shows I have come away amazed at the changes that were on display. New and better controls, improved database systems, improved chemicals, improved textile products.

The one consistent theme of the Clean Show has been to highlight changes in our various laundry industries.

When I was a young man back in the early ’60s studying chemistry in high school, I can remember going over the periodic table with my father, who was a research chemist. He said that when he took chemistry, the table was much smaller and the chemists of those days were sure they had every known element represented in the table.

Then came many discoveries and the table expanded by over 20 elements. Man’s understanding of the universe and his ability to understand the world around him continues to expand.

Back in 1972 when I first went to work in the laundry industry, my boss was an old-school laundry manager and still used tallowbased soap in this washroom. The fabrics in use in healthcare were just beginning to change from a 100% cotton to polyester/ cotton blends. The tallowbased soaps did not work as well on these products as they had on 100% cotton.

The industry needed to adapt to the new fabric and it did.

That laundry had a smallpiece folder on an ironer that worked with a mechanical timer. When properly maintained, it worked very well, but not as good as the computer-enhanced controls of today.

“W E NEED T O BE A L WAYS FL EXIB L E AS WE TRY T O ADA P T NEW TECHN OLOGIES AND PRO DUCTS INT O O UR EXISTING L AUNDRY. NO THING STAYS THE SAME; THERE IS N O P ERFECT WAY O F D O ING THINGS. T HE BEST TECHN OLOGY OF TO DAY WI LL BE EC LIP SED TOMO RR O W.”

I can remember cutting charts to program my washer and being very limited in what items I could control during the wash cycle. Today’s modern controls allow us to do so much more and be so much more precise than we could back in 1972.

All areas of the laundry industry continue to advance, and it has become a constant challenge to stay up with the various changes.

I recently went on a vacation to Thailand in January to spend time with my then fiancé (now wife) and spend time with her family. My oldest son and his wife joined me for part of the trip. I was worried because of my hectic schedule that I would not be able to spend as much time with them as I wanted. His answer to me was “Semper Gumby.” This caught me by surprise, and I asked what he meant by that. He simply said, “Always flexible.”

I have reflected on his saying often since January and feel that would be a good motto for most laundry mangers.

We need to be always flexible as we try to adapt new technologies and products into our existing laundry. Nothing stays the same; there is no perfect way of doing things. The best technology of today will be eclipsed tomorrow. We must be ready and willing to meet change.

The Clean Show provides a large showcase for those changes every two years. It provides attendees the chance to catch up on the latest and the best and to discuss how these changes might be incorporated into their laundries. As managers we must make do with what we have while looking for ways to incorporate the new and better into our system.

To be successful we must be “Semper Gumby.”

Eric Frederick served 44 years in laundry management before retiring and remains active in the industry as a laundry operations consultant. You can contact him by e-mail at elfrederick@cox.net, or by phone at 540-520-6288.

4 AUGUST 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

From

COLUMNIST AT LARGE Eric L. Frederick, RLLD

ALN

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending July 15 (WE) = WEB EXCLUSIVE NEWS • Alliance Laundry Systems to Acquire Texas-based ... • TRSA Dismisses ALM’s Healthcare Linen Research ... • Shaw Appointed President of VEGA Systems USA • WSI Receives 2019 Green Chemistry Challenge Award • ALM Introduces Laundry Industry Benchmarking Platform COLUMNISTS/FEATURES • Laundromat Owner Develops Commercial Laundry from Scratch • Clean ’19 Marches into the Future • Better Soil Sort, Less Stain/Rewash • Finding the Right Folder • Is Your Laundry Facility Tour Ready? • To Design, or to Redesign OUR SISTER

From AmericanDrycleaner.com: • Positive Attitude is All That, at Clean ’19 • Word-of-Mouth: Powerful Marketing

AmericanCoinOp.com: • Improving Vended Laundry Efficiency, Customer ...

Fine-Tuning Drop-Off Laundry Service

WEBSITES

From

•

It pays to be ‘Semper Gumby’ (always flexible)

testing

Letter to the Editor

(Image licensed by Ingram Publishing)

americandawn.com | imagine@americandawn.com HACCP IS ABOUT FOOD SAFETY In food processing plants, HACCP plans are about ensuring that critical control points are contaminant free. merican a n offers a full line of arments, as ell as the no ledge and training to support our team. ive us a call to learn more a out ho e can open the door to this growing marketplace. CALL US: 800 821 2221 LET’S KEEP OUR FOOD SAFE

sentiments.

“It’s been a worthwhile investment,” he says. “There have been quality people, decision makers—not just tire kickers.”

The 224,500-square-foot trade show floor was sold out, with more than 430 companies exhibiting. Officials say more than 11,000 professionals attended the show.

The Clean Show marched into the future in New Orleans under the new ownership of Germanybased Messe Frankfurt, an international trade fair, congress and event organizer—the largest in the textile care industry.

In December, Messe Frankfurt, purchased the Clean Show from the five sponsoring associations: Association for Linen Management (ALM), Coin Laundry Association (CLA), Drycleaning and Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA) and TRSA, the association for linen, uniform and facility services.

“It’s a milestone for all of us,” says Iris Jeglitza-Moshage, senior vice president-technology for Messe Frankfurt. “We at Messe Frankfurt are honored that you gave us your trust and will give us the chance to go on with this wonderful product, this extremely successful show.

“We will not only tell you that we will continue to improve and go on the best we can, but we will also show to everybody that we will do it in the future.”

Konstantin von Vieregge became president/CEO of Messe Frankfurt North America, based in Atlanta, about three months ago to lead the company’s efforts to run and grow shows like Clean.

“You need a strong team in the country to run these types of shows,” he says. “You can’t manage a show like Clean out of Frankfurt.”

Von Vieregge goes on to say that the Clean Show in the future won’t be about Messe Frankfurt; it’s about doing business. He also says that the base of the Clean Show is stable and strong, and the company isn’t going to change that.

He adds that part of the continuation plan is to maintain the every-other-year schedule going forward. The 2021 show will take place in Atlanta, June 10-13. Following shows scheduled are May 18-21, 2023, in Orlando, and June 9-12, 2025, in Las Vegas.

“This is a company that understood what we’re trying to do from a quality standpoint, and a management standpoint, to be able to service the group that we have and not really change the

show dramatically,” says Joseph Ricci, president and CEO of TRSA and chairman of Clean ’19.

Ricci shares that as part of the sales agreement, the five associations will be part of the show for 10 years—five shows.

“We’re going to be a part of the show as long as we can,” he says. “We think the show is valuable to the industry as a whole here in North America.”

Besides new ownership, the Clean Show stepped into the future of laundry/linen services with the products and services attendees were able to experience from show exhibitors.

“It’s very positive on the floor,” says Doug Waldman, president of Superior Linen Service based in Tulsa, Okla. “I haven’t visited many booths because I’ve been seeing people I know and talking. I’ve noticed the commercial side of the show has been very busy.”

Products and services on the floor ranged from the latest advances in equipment to services like insurance.

“I’m looking to redo my plant from the ground up,” says Phil Jones, general manager for Hotelier Linen Services in Lakeland, Fla. “I’ve been looking at everything, and I have quite a few ideas to look into for the plant.”

Some of the “trending” items on the floor include remote equipment access and control, reporting technology, and virtual assistance for operators and maintenance technicians.

“I’ve seen some interesting technology on feeding and folding, and the new equipment,” says Paul Jewison, general manager for Textile Care Services in Rochester, Minn. “I’ve also seen what I think is one of the most amazing things—the artificial intelligence where people can put on a pair of goggles, and it can instruct them on how to do repairs on equipment, install equipment.

“It’s extremely interesting technology for our industry. You can train people and help them repair the equipment, so that is a very big innovation.”

Besides visiting exhibitor booths, attendees had the opportunity to gain knowledge with 30 hours of educational sessions. Some of the topics covered include customer migration and contracts, benchmarking, healthcare linen cleanliness, social media/websites, labor law compliance, and sexual harassment/ discrimination policies.

Once the trade show floor closed for the day, exhibitors and associations hosted social/ networking events around the Big Easy at locations such as the House of Blues, Generations Hall and The Jazz Playhouse at The Royal Sonesta. Some events even had themes, such as “Once Upon a Time” and “Boas & Beads on Bourbon.”

As Clean ’19 drew to a close,

sentiment from the floor indicates that both the laundry/linen services industry and the show are in good hands.

“This show is just going to keep going up,” says Riddle. ALN

6 AUGUST 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Clean Continued

Page 1

from

Once the ribbon was cut, attendees flooded the floor. (Photo: Matt Poe)

Exhibitors reported brisk business on the floor Thursday and Friday (Photo: Messe Frankfurt)

The education sessions offered at Clean 2019 were well attended. (Photo: Matt Poe)

The trade show floor definitely had a New Orleans flair. (Photo: Bruce Beggs)

At Girbau Industrial, we tout the industry’s most comprehensive offering of washing/ drying/ feeding/ironing/folding/stacking solutions! So no matter your laundry’s size, scope or claim to fame, we’ll deliver advanced equipment engineered to take you farther and make you better. We have equipment in inventory ready for installation!

INDUSTRIAL

INNOVATIVE LAUNDRY SOLUTIONS

girbauindustrial.com

GROWING AUTOMATION & QUALITY ONE PIECE AT A TIME Equipment Sizing | Laundry Design & Workflow | Installation & Commissioning | Training & Follow-up Care BOOST PRODUCTION TO IRON MORE PIECES PER MINUTE ENHANCE IRONING & FOLDING QUALITY STRENGTHEN POUNDS PER OPERATOR HOUR REDUCE UTILITIES & LABOR HOURS

to see how Girbau Industrial can help you add efficiency and profitability to your laundry.

Call 800-256-1073

Laundry is ‘Big Easy’ with Clean 2019

COMPILED BY MATT POE, EDITOR

NEW ORLEANS — One of New Orleans’ nicknames is “The Big Easy,” and laundry and linen service operators who attended Clean 2019 learned ways to make their operations easier, and better, on the trade show floor at the Ernest N. Morial Convention Center June 20-23.

Many companies took advantage of Clean ’19 to introduce brand-new products, roll out newly improved products or exhibit well-established product lines.

Still others exhibited at the biennial show for the first time.

New show owner company Messe Frankfurt reports that 60 new companies were part of the more than 430 exhibitors on the floor, which covered a sold-out 224,500 net square feet of exhibit space, surpassing the square footage of 195,140 that was previously recorded at the last New Orleans edition of the Clean Show in 2013.

American Laundry News presents this report describing just some of the companies and the products they exhibited in New Orleans. With a sold-out show, this article isn’t intended to be allencompassing.

Readers are encouraged to follow American Laundry News in print and online (www.americanlaundrynews.com) during the coming months for product announcements from these companies and others.

ADI American Dawn Representatives from American Dawn, a provider of reusable textile solutions to the industrial and commercial linen laundry market,

reports that while traffic was slow at Clean, the conversations that took place were in-depth.

ADI supplies towels, bed linens, table linens and other related products to laundry customers throughout the United States and Canada.

With company-owned distribution centers in Los Angeles, Chicago, Houston, Atlanta and Philadelphia, ADI says it is logistically positioned to serve more than 85% of the U.S. laundry market with same-day shipping and nextday delivery.

American Dawn says its products are manufactured in the United States, Pakistan, India, China, Mexico, Dominican Republic, Turkey, Italy, Portugal, to name a few countries. Additionally, ADI has partnerships with carefully evaluated sourcing mills, and the company says its partner mills are monitored closely by ADI management and have well-established quality systems, which are integrated with its own quality assurance (QA) systems.

Leonard Automatics

The theme for Leonard Automatics at this year’s Clean Show was “Take a Look at Leonard.” Although Leonard has been known as a steam tunnel finisher manufacturer for years, the company says its diversification into other markets since the recession of 2008-2009 warranted attendees taking a serious look at their product line.

In New Orleans, Leonard says its booth was the largest in the company’s 50-year history. Leonard had to accommodate three new pieces of equipment designed specifically for feeding, folding and stacking of linen.

The LVF (Leonard Vacuum Feeder) is a small- or large-piece vacuum feeder that will increase operator production and accuracy. The LF Series large piece/small piece folder, crossfolder, draper, stacker provides great versatility for those ironer lines that are not dedicated to a single product. And the LFH “Hybrid” is a full-blown Stack-N-Store small-piece draping stacker for napkins, pillow slips and aprons that will also process large pieces in one or two lanes with up to two primary folds.

Leonard also showed its new LCS-UV cart sanitizer that does not use water or chemistry to clean carts, only ultraviolet light, sanitizing quickly and safely.

EzProducts International

EzPi put the spotlight on its EzBar™, an improved version of the 100-year-old Z-Bar that allows operators to quickly and easily slide up to 100 garments horizontally off one EzBar and onto another EzBar or onto the rails in a delivery van.

EZPi says EzBar is available in three configurations:

• EzBar-1, a direct replacement for conventional Z-Bars.

• EzBar-2 a customized EzBar designed to mount and hold the new EzSort garment sorting and Assembly System. (EzSort will be available 4th quarter.)

• EzBar-3 a customized EzBar designed to mount a pointof-sale computer system, including computer system, touch-screen monitor, barcode scanner and up to seven receipt printers.

UniMac

In New Orleans, UniMac, a manufacturer of on-premises commercial laundry machines, introduced attendees to what’s coming in its TotalVue 2.0. The upgraded monitoring

and management tool will give operators advanced reporting and analytics, real-time efficiency and error alerts (E 2 Alerts), remote programming capability, enhanced labor flex calculations and reporting, and Total Proof.

Bottom line, say representatives, is it becomes a far more active tool with real-time data to make on-the-fly adjustments to ensure quality and consistency.

UniMac also reminded attendees that the core of TotalVue is “Protect-Monitor-Elevate.”

Protect equipment, linen and reputation to deliver lowest cost of ownership. TotalVue gives maximum visibility to what’s happening in a laundry room, allowing unprecedented ability to precisely control laundry process.

Monitor operations (labor and utility costs) and performance to achieve maximum efficiency. With the real-time information TotalVue provides, the company says operators can more accurately predict demand and allocate labor to match needs. And, they have permanent records of all operational data for the life of the machine.

Finally, elevate laundry stan-

dards to perfection to ensure great guest experience. TotalVue allows operators to verify that the laundry is delivering superior wash quality every day, all day.

A.L. Wilson Chemical

A.L. Wilson Chemical demonstrated the effectiveness of its product lines in New Orleans.

The company says it continues to manufacture high-performance stain removers that contribute to the success of the cleaners and launderers who use them, valuable tools that let operators deliver the quality stain removal that their customers desire.

A.L. Wilson says its products pair high levels of effectiveness with equally high levels of safety for material color and tensile strength so that operators can remove more stains completely and safely. The company says its newly developed products are also designed to be safer for workers and the environment.

Norchem Corp.

Norchem highlighted its UltraPure® Wastewater Filtration

8 AUGUST 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

(Photo: Messe Frankfurt)

See CLEAN on Page 10

(Photo: Messe Frankfurt)

CLEAN SHOW ROUNDUP

Attendees at the 2019 Clean Show learn about new products, make face-to-face connections

Notice Anything?

InkGo® Is Now Odor Free!

InkGo has been reformulated to remove its odor… and to improve its performance.

InkGo is still the environmentally friendly,* safe way to remove ink stains from all types of fabric. It’s still great at removing autoclave tape and adhesives. And since it’s odor-free, InkGo is more pleasant to work with.

Does odor really matter? As more drycleaners position themselves as good environmental stewards, keeping chemical odors in the plant to a minimum can help them differentiate from their competition. And odor-free is a real plus if you’re working on ink for an extended period of time.

Now that’s worth noticing!

*InkGo is Biodegradable and is California Prop-65 and California VOC Compliant.

Become a STAIN WIZARD at ALWilson.com

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

Clean

and Recycling System at Clean 2019.

The company says UltraPure cross-flow ceramic water filtration and recycling systems are an effective solution for optimizing water heating efficiency, mitigating rising water and sewer costs, fluctuations in supply and demand, and exceeding POTW compli-

The ceramic membrane technology distinguishes itself by maintaining exceptional recycling percentages (up to 85%) while tolerating high FOG loading at all pH levels. The membrane’s 10-plus-year lifespan and anti-fouling composition keeps recycle flows

Norchem says UltraPure is a proven industry solution available to date with successful installations and integrations within all laundry types and wash floor configura-

Hamilton Engineering

Hamilton displayed its SOLSTREAM™ Direct Fired Water Heaters, a complete range of high efficiency, compact, all-stainless-steel water heaters, which it says are dependable, simple in design and operation, and suitable for a wide variety of hot water applications.

With standard operating capacities between 1 million and 15 million Btu per hour and customized systems up to 25 million Btu per hour, the company says SOLSTREAM™ water heaters often deliver fuel savings as high as 30-60% when compared to steam/water heating systems.

With a small footprint, 99.7% or greater heat transfer efficiencies, dependability, ease of maintenance, and the ability to operate well with poor water quality, Hamilton says SOLSTREAM™ Direct Fired Water Heaters are the product of choice for high-volume hot water users seeking to achieve Energy Conservation Measure (ECM) and Reduced Carbon Footprint objectives.

Positek RFID, a provider of complete RFID systems, solutions and integration for the textile maintenance industry, showcased its latest innovations in RFID at Clean Show

the company displayed

Hurricane RFID Portal—A smaller, costeffective portal that reads thousands of items in 10 seconds.

• Jet Stream Portal—An open portal with a pass-through design for fast, highly

accurate reading.

• Lightning RFID Portal—Available in multiple configurations, the Lightning RFID Portal provides the same fast and accurate reading as its larger models in a more compact design.

• Updraft RFID Portal—The Updraft Portal is designed to fit over existing floor scales and can be installed on ground level or recessed into the floor.

• UHF Tunnel—Built to mount on conveyors, the UHF Tunnel provides consistent and accurate reading.

• Wave RFID Station—The Wave Station replaces manual sorting with higher accuracy at double the speed.

Hydro Systems

Hydro Systems,part of Dover, which delivers chemical dispensing and dosing solutions, introduced its Hydro Connect Real-Time Module at the 2019 Clean Show in New Orleans.

When paired with a Real-Time Module, Hydro Connect offers instant data streaming to further improve the laundry process, according to the company.

“The Real-Time Module helps laundries operate more efficiently, reduce costs and quickly address any abnormal conditions,” says John Goetz, global product manager.

“Previously, our customers could view historical reports on productivity, chemical usage, costs and alarms. Now, operational data is available as it occurs, allowing immediate action to drive continuous improvement.”

Hydro Connect is a cloud-based Internet of Things (IoT) platform that populates data generated from the company’s Dositec Central Dosing Systems that Hydro Systems says operate in laundries across the world. The platform offers chemical providers increased visibility into their operations while also optimizing production, reducing costs and increasing customer satisfaction.

The Real-Time Module can be retrofitted to existing Dositec installs, allowing ongoing data streaming to the Hydro Connect cloud. With a real-time dashboard, chemical providers and end-users can easily see what’s happening in every washer or in every module of tunnel washers. There is no guesswork about which formula is running, success of each chemical delivery or whether hygiene compliance is being met.

In addition to providing a clear view of measures like efficiency by shift, washer turn times and water and chemical usage, the company says its Real-Time Module enables users to set alarm thresholds and receive e-mails and SMS notifications if one or more is triggered. This allows laundries to reduce downtime, rewash rates and larger issues that

10 AUGUST 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued

8

from Page

(Photo: Nathan Frerichs)

can impact the bottom line. Hydro Systems also offers a monthly data analysis plan to provide insights and recommendations for busy laundry operators.

Odorcide

This was the first year for Odorcide to attend Clean, and representatives were very pleased with the show. The company shared its expertise on odor elimination and how its products can be help at all levels of the laundry industry.

The company’s product offers the same contact chemistry that is used in the veterinary products, is a non-enzymatic product that works instantly, has no dwell time after application, and is safe for use on any surface.

Pellerin Milnor Corp.

At the conclusion of the 2019 Clean Show in New Orleans, Pellerin Milnor’s vice president of sales and marketing, Rick Kelly, said he was pleased with the traffic in the Milnor booth.

This year’s Clean show highlighted the introduction of the MilRail™ sling system.

“As we continue to grow our footprint in the commercial and industrial laundry market space, a natural progression for us was to develop our own rail system,” explains Kelly.

In keeping with the idea of expanding its product offerings, Milnor introduced the MTF Series and MWF125 to grow its soft mount line. The introduction of the MWB Series barrier washers provided additional solutions for the healthcare and clean room markets.

Kemco Systems

Kemco Systems, a global water and energy technology company, introduced Clean attendees to CONSERVE, a program that delivers water recycling as a service to the laundry industry.

Built around the company’s understanding of the challenges of running a laundry, CONSERVE allows laundry operators to install systems that can recycle up to 90% of their water with zero capital investment.

Kemco says CONSERVE takes care of the burden of ownership of water recycling equipment. The company owns and maintains the equipment with limited support from the plant for system maintenance. This smooths plant operation and maximizes uptime.

The company says CONSERVE is allinclusive, including everything an operator needs to increase plant efficiencies: stateof-the-art equipment, turnkey installation, consumables, replacement parts, scheduled maintenance, remote monitoring, extended warranty, and full coverage of any and all

system failures.

CONSERVE produces many performance, environmental and financial benefits, such as, reduced utility costs and surcharges, exceptional water quality free of all viruses, bacteria, PFOA, PFOS and microplastics, improved product quality, increased longevity of wash aisle equipment, and reduced environmental footprint, according to Kemco.

Davis Packaging

Representatives from Davis Packaging report overwhelming response and positive feedback for its new Laundry Wrapper models and retro-fit upgrade kits released at the show.

The company says this is the biggest enhancement and design change in more than 20 years for manual wrappers.

Working directly from customer feedback, Davis Packaging says it rebuilt its most popular wrappers from the ground up, integrating such highly desired features as height adjustability, advanced anti-burn safety protection, enhanced temperature control, improved film loading, and component strength and durability.

Davis says the results are an affordable, dependable, easy-to-use, ergonomic and safety-minded laundry wrappers.

For those with existing Davis Packaging wrappers, the company says easy-to-install add-on height adjustment and safety protection kits are also available.

Girbau North America

Continental Girbau Inc. had a lot to share in New Orleans with a name change and new products.

Continental announced that it recently changed its name to Girbau North America (GNA), according to President Mike Floyd. Spearheaded by Girbau Global Laundry Solutions, the parent company of the North American subsidiary, the name change to Girbau North America provides a clearer representation of the company and its brands, says Floyd.

“As a company, GNA has grown significantly in terms of product offerings, distributor reach, markets and end users since first established in 1995 as Continental Girbau Inc.,” he says. “We feel as Girbau North America, the company better illustrates its broad scope in both product offerings and services area.”

He adds that the name change helps eliminate any brand/company name confusion.

Girbau North America’s brands, which remain unchanged, include Continental Girbau®, marketed to vended, commer-

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | A UGUST 2019 11

(Photo: Messe Frankfurt) See CLEAN on Page 12

cial and on-premises laundries; Express Laundry Center®, marketed to vended laundries; Girbau Industrial®, marketed to industrial laundries; Sports Laundry Systems®, marketed to athletic laundries and health clubs; OnePress® Ironers, marketed to commercial and on-premises laundries; and Poseidon Textile Care Systems®, marketed to fabricare and dry cleaning operations.

The name-changing initiative also impacts Girbau’s other 15 subsidiary companies across the globe, which are now named, simply, Girbau.

New products included the Compact+ 5-in-One Ironing System, a new all-in-one machine that automatically feeds, irons, folds, stacks and accumulates; the space-saving Compact+ Laundry Solution; the FR+ Folder; and 300and 160-pound capacity industrial dryers.

Foltex USA

Foltex USA, a provider of feeders, folders and stackers, took a unique approach to Clean 2019. Instead of enticing attendees with traditional trade show gifts, the company donated $5 per badge scanned to Second Harvest Food

Bank of South Louisiana.

Foltex representatives say the company’s mission was not only to give back to the community, but also to challenge others in the industry to consider doing the same.

The company also showed off new equipment options, including:

• RFID Technology. Foltex can equip its folders with a built-in antenna and a reader that will reject on item level.

• Lifting Stacker. The company now has a lifting stacker option on its FlexFold models that allow one stacker to meet items as they release from the stacker flaps, therefore creating neat, tidy stacks. This is a popular option for washcloths. This is also an excellent option for companies that want to process smaller items in mixed batches.

• Reversing Crossfold. This allows garments to stack with the collar up.

SMC Corp. of America

SMC Corp. of America used Clean to feature its wireless communication technology in EtherNet/IPTM protocol supporting solenoid valve manifolds, as well as the latest technologies supporting Internet of Things (IoT) in the industrial and processing space.

SMC products there were on

exhibit included:

EX600 Wireless Fieldbus Communication for EtherNet/ IPTM Protocol—Safe, secure wireless communication within a 10-meter radius and frequency hopping every five milliseconds.

Energy Saving Solenoid Valves, New SY Series—Versatile, side, top and bottom porting locations with built-in safety features such as back pressure check valve options. Long cycle life from 70 million up to 200 million cycles. Available in IP67 protection.

LEH Electric Grippers—Twoand three-finger electric grippers enable picking up and placing work pieces of varying diameters and widths without tool changes by simply changing the command programming. They are designed with robust dust seals to assure quality performance.

Two-way Solenoid Valves On/off solenoid valves for air, water and other fluids for controlling fluid flow and for piloting other larger valves are equipped with energy saving coils to extend service life.

AMG Water Removal Unit Removes condensate water that will be problematic to any industrial system risking premature corrosion, rust and pipe scale causing costly downtime and repair costs.

ABG Systems North America

ABG Systems North America displayed its latest innovations in

textile RFID tracking and dispensing.

The company shared that RFID tracking and process automation has become an essential tool that helps laundries, hospitals and supply chain managers oversee their entire linen operations in realtime. So, the company showed off the latest products, trends and strategies, including intelligent textile management demonstrations with its ONE software and WHITE line products.

ABG Systems North America is a new branch of the company that was established last year.

Select Risk Insurance Services

Most Cleanattendees were already familiar with Select Risk as an insurance, risk management and business consulting firm for industry, the company says.

However, it did share a secret, saying that Select Risk is well on its way to gaining similar recognition and status as being the vendor of choice for all textile care support companies.

Meese

Meese, a provider of rotomolded products for the laundry industry and also a division of Tingue, introduced Silva-Trux in New Orleans.

The company says the new plastic cart is the first proven antimicrobial laundry cart in the industry,

helping the laundry and healthcare industries maintain high standards of safety and cleanliness.

Meese says the carts help prevent the spread of infection by thwarting bacteria, mold, fungi and viruses, protecting anyone who comes into contact with the cart’s contents.

The company shares that the AATCC Method 147 Test was used to determine the cart’s antibacterial activity.

ABS Laundry Business Solutions

Over the past year, ABS says its development team has focused on making further improvements to the core functions and modules of ABSSolute, which were shared with attendees in New Orleans.

The company says it doesn’t just stop with improvements, with new apps that will enhance any industrial textile and/or garment laundry to work smarter, reduce administration time, and improve their customer service and support.

Gotli Labs

The team from Gotli Labs excited guests visiting the booth with its product GLOBE.

GLOBE consolidates the data management in heavy-duty laundries, saying it is the first and only solution to manage all laundry

12 AUGUST 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

(Photo: Nathan Frerichs)

ALN_Tab_1-4_H.indd 1 7/3/19 8:28 AM Continued from Page 11

See CLEAN on Page 14

(Photo: Messe Frankfurt)

Clean

© 2019 Maxon Lift Corp. Call (800) 227-4116 or visit maxonlift.com When your linen and laundry customers count on you to pick-up and deliver on time, you can rely on the DMD Generation 2.0 liftgate to deliver MAX performance. Maxon’s next-gen DMD 2.0 replaces the chain drive with our advanced dual-cylinder, direct-drive technology, which increases productivity, reduces maintenance costs and keeps your operation running smooth. Light, strong and easy to operate, the DMD 2.0 delivers reliable, cost-effective and hassle-free service. Increase productivity with the leader in liftgates since 1957. Keep them in the clean, we’ll keep you in the green

data, including staff scheduling, time and attendance, and a track and trace functionality.

Gotli Labs says it’s the most complete production information system in the entire laundry industry and an essential tool in the plan/do/check/plan cycle.

GLOBE helps laundries to know all details, facts and figures on the process flow with real-time data and gives an immediate feedback on the product status.

Gotli Labs is partnered with equipment manufacturer JENSEN.

Hydrofinity

Hydrofinity exhibited its new commercial XDrumTM at the Clean Show. XDrum is a simple, lowcost solution for original equipment manufacturers (OEM) to easily incorporate water saving XOrbTM polymer technology into their machine designs, the company says.

This means that for the first time, manufacturers will be able to bring the latest science and technology to their machines while still having the option of running existing cycles.

Reusable, recyclable and safe, XOrbs gently clean and protect clothes using less water and chemicals, Hydrofinity says. They mix into the XDrum at the start of the wash and gently remove dirt and stains while protecting clothing like tiny hands.

When the wash cycle is completed, the XOrbs automatically go back inside the XDrum and are ready to be used again for the next wash. If an operator would prefer to run a cycle without XOrbs, just simply select a non-XOrb program.

Sea-lion America Co.

In celebration of its 50 years in business and ever-expanding market presence, Jiangsu Sea-lion Machinery Co., Ltd. launched Sealion America Co., a joint venture designed to support Asia’s top pro-

ducer of high-end laundry equipment for the North American, Mexican and Caribbean markets.

Headed by laundry industry veterans Ed Kirejczyk and Caroline Wojcicki, the goal of Sea-lion America Co. is to provide unparalleled local sales and service support for the full range of automation, washing, and finishing technologies produced by Jiangsu Sea-lion, according to the company.

These disciplines include automation technologies, such as loading and sorting conveyors; overhead monorails; shuttles, elevators and material movers; and the SCADA network control center

Washing technologies include tunnel washers with press and extractor; pass-through, automated tumble dryers integrated with tunnel washer; stand-alone, openpocket, high-speed washer-extractors; barrier-type, Pullman-style washer-extractors for hospitals and clean rooms; and stand-alone electric, gas and steam tumble dryers

Finishing technologies offered include spreader feeders; flatwork folders; flatwork, double chest and multi-roll ironers; towel and uniform folders; and tunnel finishers.

Rennco

Attendees were introduced to Rennco’s VerticL-PP weigh bagging system on the show floor in New Orleans.

At up to four bags per minute (or up to 24,000 wash clothes per hour at approximately 100 per bag), the new VerticL-PP weigh bagging system from Rennco, a product brand of ProMach, provides the perfect solution for bagging of hospital fitted sheets, ISO gowns, wash clothes, bar wipes, micro fibers and more, the company says.

An operator simply loads the weigh bin with singles or batches of linens (dependent on required inspection). Once the target weight is achieved, the operator simply presses the cycle switch to drop the batch onto a conveyor. The batch then travels up the incline conveyor and is automatically bagged on the wide mouth bagger.

Rennco says the system uses

generic center-folded Poly film, (LDPE); therefore, it is available from many sources, at significant savings compared to pre-made bags on a roll. Bag sizes up to 24 by 27 inches can be changed on the touch screen in seconds, without having to change the roll. Therefore, only one supply item is ever needed.

Reigel Linen

The main attraction for attendees visiting Riegel Linen’s booth in New Orleans included the company’s Craft Collection and its Premier spun polyester line. Both feature new colorGUARD™ technology that extends the lifecycle of the textile and ensures a color rich product from the first wash to the last.

“We are excited to come to Clean 2019 with a new look and some really cool products,” says Vice President Chris Gowdy. “For the first time we are bringing the Craft Collection of aprons and coordinating napkins to the Clean Show. This collection was designed by listening to our customers. The color pallet is just as artsy as the collection’s name, and the spunpolyester, denim-inspired fabric is ideal for venues with an earthy, local farm-to-table flair.

“We are also bringing our popular Premier line back to the show, but this time we will be sporting new colors that stand the test of time, wash after wash, now that they are manufactured with colorGUARD™ technology.”

Consolidated Laundry Machinery

CLM showed Clean attendees how they could dry more goods, faster and for less money. CLM manufactures and rebuilds highquality, 200-1,200-pound, durable industrial dryers.

Known for customizable, heavyduty, high-efficiency and highproductivity equipment, CLM says its new technologies and innovations have brought these high-performers to a new level.

A sophisticated MicroCommand Ill PLC (MC-Ill) utilizes an easy-to-read color touchscreen display with the ability to create 96 unique formulas.

The company’s newest dryer control platform is the ConsoliDry SmarTouch 4.0. The platform features a high-definition touch display, is compatible with Smart Sensors, offers remote technician troubleshooting/maintenance, has next-generation burner controls, and delivers dryer data reports remotely accessed via cloud.

With worldwide customers, CLM says it cements its high-quality reputation by providing ongoing parts and dependable responsive service and support.

Whirlpool Corp.

Decision-makers in the commercial laundry industry discovered new business solutions, product innovations, technology advancements and an overall new

perspective within the Whirlpool Corp. booth at Clean 2019.

The company says it continues to invest in the commercial laundry industry and strengthen its portfolio of brands, including Maytag® Commercial Laundry, ADC™ Laundry and Whirlpool® Commercial Laundry.

During Clean 2019, attendees viewed the results of those investments as the three brands demonstrate quality equipment and innovative thinking that help address the various challenges within the different industry segments.

“We understand that our customers don’t simply buy machines, they buy solutions,” says Trey Northrup, general manager, JennAir and commercial laundry for Whirlpool Corporation. “Maytag® Commercial Laundry, ADC™ Laundry and Whirlpool® Commercial Laundry command confidence in facilities around the world due to their history of performance and reliability.

“Each brand focuses on a unique industry segment, because we recognize the needs of a four-chair salon are different from a 200-bed hotel, a bustling Laundromat, or an industrial facility.”

During Clean 2019, Maytag® Commercial Laundry demonstrated key components of its full solution line up, offering attendees a front-row view to equipment and business decisions that can help impact their bottom line.

Included in this line up is the brand’s newest solution for the vended and on-premises laundry markets, the Maytag® Multi-Load Washer. Designed to handle heavy loads of laundry turn after turn, the Multi-Load Washers are available in rigid-mount construction in 20-65-pound capacities, with a phased rollout of additional configurations continuing through 2019.

Clean 2019 attendees also had the chance to see how ADC™ dryers can meet unique business needs, from equipment that provides fast drying to helping improve throughput and optimize productivity. The innovations on display included the AAFC (Automatic Air Flow Compensator), which is optional on the i-Series, and the engineer-driven AD Series, which is a popular choice by laundry operators. The brand also

showcased stack multi-load dryers designed for space-savings and the large capacity AD-170 available in electric, gas and steam heat options.

Whirlpool® Commercial Laundry provides commercial laundry washers and dryers for small businesses and multi-housing markets that are seeking quality, reliable machines to serve a specific need within their business. The brand aims to deliver the simplicity that end-users demand, while still providing the technology to elevate experiences, such as the new stacked products that help save space.

EcoKnit

EcoKnit® introduced its snagfree, quick-drying products into the United States during Clean 2019.

“It’s been a long time coming, we have sharpened our teeth on other international markets and supplying top international fivestar hotels like the Okada Manila hotel,” says Paul Balladon, director of the company. “Now with proof and ample testing of the product, we can show with confidence how EcoKnit can save money.”

The company says testing shows, on average, 40% reduced drying times. Further is the 15% reduction in water consumption, which leads to reduction in chemicals and heating water.

As a result of reducing energy comes the reduction in CO2 emissions, and reducing water and chemicals means lower impact on the environment.

The product has been designed for heavy commercial use, and its unique construction means it is snag free and it will not fall to pieces like traditional cotton towels, extending the life of the product and saving on replacement costs, according to the company.

MAXI-PRESS

MAXI-PRESS presented membranes and spare parts at the Clean Show in New Orleans, with fast delivery service for water extraction membranes and spare parts

To avoid long and thus costly downtimes, MAXI-PRESS offers a fast delivery service for membranes and spare parts for all com-

14 AUGUST 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued from Page 12 Clean

(Photo: Messe Frankfurt) See CLEAN on Page 16

(Photo: Nathan Frerichs)

mon laundry machines.

Drainage membranes for water extraction presses are the core product of MAXI-PRESS. The high-tech membranes provide the highest degree of moisture removal with low wear during laundry operation, effectively helping to save resources and costs, according to the company. The drier the laundry, the less energy has to be invested in the drying process.

MAXI-PRESS develops, manufactures and sells vendor-neutral drainage membranes. It says its EASYFIX water extraction membranes are very popular among customers. EASYFIX membranes feature an inseparable built-in fixing ring, so there is no need of use of the additional fixing rings which make the installation more complicated. This gives the installer a huge reduction in installation time.

MAXI-PRESS says some of its customers even report time savings of up to 80% when installing the membrane. Additionally, customers report obtaining more savings since there is no longer any need to replace the old and worn out fixing rings, which are very costly to replace.

The company adds that customers particularly appreciate the high-quality material and the long service life of EASYFIX membranes. For example, the press cycles of an EASYFIX membrane significantly exceeds the pressing cycles of conventional membranes from other manufacturers.

MAXI-PRESS produces the membranes from specially developed rubber compounds that meet the highest demands. The effective EASYFIX membranes are available for presses JENSEN SEP 36-90 MD/HD, Lavatec LP 571583, Kannegiesser PP10 and PP13, Girbau SPR 50 presses, and also for Passat presses EP 841-9XX.

Since 2006 MAXI-PRESS says it has manufactured and sold water extraction membranes and other spare and wear parts for batch washers, water extraction presses, dryers, flatwork ironers, etc.

Particularly worth mentioning, says the company, is the large selection of ironer supplies, such as cylinder coverings, ironer textiles, ironer tapes, ironer waxes and much more, which complete its product range.

Lavatec Laundry Technology

New Orleans has a reputation for celebration, and that’s exactly what Lavatec did after a successful run at Clean 2019. In addition to the highly anticipated launch of the new LP583 LAVASPEED extraction press, Lavatec found new homes for almost all of the equipment it displayed at the show.

“It was a very good show. We

had a sizeable amount of people in our booth and it generated a substantial amount of new leads for us,” says Keith Ware, vice president of sales.

“We expected good results with the new extraction press and the type of equipment we were offering in the booth. LAVASPEED attracted a lot of interest, and people who understand the technological advancements of today’s machines spent the majority of their time asking questions about it. They were intrigued with the reduced moisture level and how it helps reduce drying times.”

Ware was referring to the faster extraction times made possible with LAVASPEED’s energy efficient hydraulics program. Separate high- and low-pressure systems, combined with an inverter controlled, high-pressure pump, allows the machine to reach maximum pressure quicker and improve moisture extraction.

Helping drive plant efficiency is Lavatec’s osLaundry software package. The newest version of the state-of-the-art software control program was a discussion point at the show. Available with LAVASPEED and other Lavatec equipment, it provides operators with information in real time, giving them the power to make more informed decisions faster so they can save time and money, according to the company.

LAVASPEED can also be custom built to match with any LAVATRAC tunnel system. In this case, the LP583 and a 12-compartment LT100 tunnel washer on the Clean Show floor were sold to Division Laundry & Cleaners of San Antonio, Texas.

Lavatec featured a pair of dryers at Clean Show. Huebsch Services, a uniform rental and floor mat company in Eau Claire, Wis., took home a front-loading FL633 gas unit. Corporate uniform and apparel provider Cintas purchased the TT756 gas dryer.

The TT series of dryers features a line burner system that covers the entire drum and infrared sensors that improve drying times by up to 15%. Lavatec says the end benefits result in higher throughput, linen that is not over-dried, and energy cost savings via reduced gas consumption.

Colmac Industries

Colmac Industries Inc. celebrated its 60th anniversary by debuting a new tunnel finisher at the Clean Show. This machine improves finish quality and increases standard features all while maintaining a competitive cost, according to the company.

Featuring Colmac’s proven patented steam air mixing technology and innovative internal construction, the company says this machine delivers even and consistent steam and airflow throughout.

Other features include modularity, expandability, 81-inch process height, operator productivity monitoring, PLC service

diagnostics, stainless-steel internal construction and a revolutionary bi-directional design allowing for incorporation into most plant layouts.

Additionally, Colmacmanufactured standard and carrier pendant chain, 180° conveyor drive and ability to create custom conveyor layouts accompany the new tunnel.

The company also highlighted its AccuCounter® Soil Counting system, which sorts, manages inventory, interfaces seamlessly with route accounting software and monitors operator performance.

Colmac says the unit has touchscreen operation, a built-in barcode scanner (optional RFID reader available), an ergonomic worktable, and more.

LG Electronics

At Clean ’19, LG Electronics showcased the company’s complete offering of commercial onpremises laundry product.

Spotlighted machines included the new 35-pound-capacity Titan C Commercial Washer; the Giant C 22.5-pound capacity washer and complementing dryer; and the LG Styler TrueSteam Clothing Care System.

“LG commercial laundry products are designed for use in a variety of on-premises laundry applications, including beauty salons, spas, restaurants, gyms and healthcare clinics,” says Gustavo Gutierrez, LG USA national sales manager. “Our products offer ease of installation, superior efficiency, quiet operation and flexible programmability—simplifying laundry processing.”

The 35-pound capacity Titan C and 22.5-pound capacity Giant C Washers offer inverter Direct Drive systems for superior durability, an optimized washing system that automatically detects over-sudsing, and a twin spray water-delivery system that ensures a quality wash without machine stall-outs. They are configurable to meet the needs of nearly any onpremises laundry application and can stand alone or be stacked with matching dryers.

Offering a simple-to-use control with a large digital display, the washers allow for intuitive programming of a variety of functions, including water temperatures, fill levels, cycle times, spin speed and automatic chemical injection. The washers offer a variety of program offerings.

JENSEN

The JENSEN-GROUP continues to focus on smart digital solutions for heavy-duty laundries. Its booth at this year’s Clean Show in New Orleans reflected its twotier sales strategy with high-tech products from its American and European factories as well as single machines exported from China under the ALPHA by JENSEN brand.

The JENSEN booth also fea-

tured new, innovative solutions from its partners Inwatec and Gotli Labs, as well as a brand-new washroom and a brand-new finishing experience.

The brand-new JENSEN UniQ tunnel washer with integrated ExQ press is based on proven concepts from many years of development and has been revolutionized with many innovations, such as the innovative JENSEN Operating System (JOS), according to the company.

The transfer times are 10% faster than in any other tunnel washer thanks to the open drum design, and the FlexWash and FlexRinse Technology guarantee full batch integrity in the entire machine. The new UVClean system prevents bacterial growth in double drum sections automatically and without any chemical supply. The new JENSEN Operating System (JOS) guarantees a higher usability thanks to the new HMI with a unified look and feel through all JENSEN-technologies.

JOS is the new, state-of-theart control with aligned software and hardware architecture and ready for Industry 4.0. The new ErgoVision video monitoring of the loading and unloading process ensures a higher operational safety.

At the Clean Show, JENSEN presented a completely new finishing line consisting of a new feeder, a new ironer, and a new folder.

The new simplified KliQ feeder, designed for both the healthcare and the hospitality sectors, offers a high and uniform finishing quality. A transfer beam with a mechanical holding bar replaces the vacuum section. In the receiving position, the holding bar is open while the linen is held between the transfer beam and a fixation tube. During the transfer, the holding bar is closed. Based on the clamp design of the successful Logic 2000 feeder, the new spreading clamp is a masterpiece of operator convenience.

The new EXFG ironer has 6% increased capacity and 10% lower gas consumption, as it combines the benefits of a fixed chest with the benefits of a flexible chest. The energy savings are achieved with a new triple-pass boiler design and optional PID regulation. Thanks to the increased oil volume and larger flow channels in the chest, the capacity is much higher than in conventional ironers. The higher

temperature of the newly designed gap piece with direct heating increases the quality of the leading edge and reduces the risk of creating a jam when the leading edge passes it.

The new Katana folder is a compact solution with four inline stackers. Laundries can install up to five stackers underneath the folder to sort all existing sizes of large pieces. All crossfold stations are equipped with reversing conveyors and knife, ensuring optimum control of the folding position and a great finish of light and heavy material. The multiblade technology in both lateral and crossfold section replaces the airblow, which means that laundries can save 50% on compressed air consumption. As an extra bonus, the working environment is much quieter.

The company’s new valueengineered brand premiered in the United States, showing a tunnel washer ALPHA TW5 and a towel folder ALPHA T5. ALPHA by JENSEN machines are standalone equipment, offered in standard configurations with limited options and customizations.

Inwatec’s automated soil-side sorting system minimizes the need for human interaction to quality control and surveillance, and consists of an X-ray machine and a learning system. The robot picks up the individual laundry pieces from conveyor belts and transports them to RFID chip readers to identify and register each garment. Directly after that, an X-ray scanner automatically detects unwanted hidden objects in the pockets and automatically rejects these garments.

With X-ray technology, harmful foreign sharps such as needles, scissors, scalpels, etc. can no longer remain undetected in the pockets. Only approved laundry articles are forwarded further to be sorted accordingly by the system.

G.A. Braun

Equipment manufacturer G.A. Braun took advantage of Clean in New Orleans to announce the availability of a new tunnel washer press, an expanded offering of side-by-side dryers and a new spreader/feeder.

The company says its new SmoothFlow® Batch Tunnel

16 AUGUST 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued from Page 14 Clean See CLEAN on Page 18

(Photo: Nathan Frerichs)

BECAUSE THERE’S NOTHING UNIFORM ABOUT FLEET REQUIREMENTS.

With Freightliner Custom Chassis, it’s all about delivering greater profits through increased productivity and proven fuel economy. Our commercial chassis feature heavy-duty components that are designed to surpass automotive-class vans for maximum uptime and unbeatable driver safety. FCCC chassis also provide the ultimate flexibility for box configurations to meet your needs. Most importantly, as an FCCC owner, you have access to 24/7 factory support and the largest nationwide service network.

FUEL EFFICIENCY

No matter which power you choose, you can count on the MT to lead the way in fuel efficiency that translates into enhanced profitability.

SAFETY

From heavy-duty braking to maneuverability, ergonomics and curbside access – driver safety is our top priority.

QUALITY

As part of the Daimler family, FCCC chassis are developed with legendary resources for design, engineering and manufacturing processes.

UPTIME

With 24/7 factory support and the largest nationwide service network, issues are quickly resolved to keep you on the road.

FUEL OPTIONS Choose from gas or diesel to best meet the needs of your delivery fleet.

REAL COST OF OWNERSHIP™ 1-800-545-8831 | freightlinerchassis.com For ordering details, contact your local dealer. Specifications are subject to change without notice. Freightliner Custom Chassis Corporation is registered to ISO 9001:2008 and ISO 14001:2004. Copyright ©2016 Daimler Trucks North America LLC. All rights reserved. Freightliner Custom Chassis Corporation is a subsidiary of Daimler Trucks North America LLC, a Daimler company.

Washer Press has been engineered with the focus on performance, reliability and safety.

Some of the new features include a waterless membrane, which reduces the impact of punctures and cuts; a white membrane with molded clamp ring that significantly reduces downtime for unplanned membrane change out; a floating press head in a nonlinear fashion for even membrane wear; inverter drive electric belt; and up to 50 Bar adjustable.

Other key features include improved water collection tanks, enhanced door and guarding design, a split-panel control box, and newly designed hydraulics.

Braun also announced the expanded offering of its Side-BySide Dryers. SBS tunnel system dryers are available in natural gas or steam, in a non-chute or a patent-pending chute loading system, in 300-pound and now 500-pound processing capacities.

Finally, Braun says its new Precision Series® Spreader/Feeder serves a wide variety of flatwork laundry processing needs, including hospitality, healthcare, commercial linen providers and general industrial laundries.

Unique to the new spreader/ feeder is a single motor servo spread drive technology coupled with new spread detection and speed synchronized spread belts.

The short list of a few innovative design changes includes new feed and spread clamps, lower feed carriage heights, lane marking belts on the small-piece table, ball bearing carriers for all transport motions and optional large format station counters.

B&C Technologies

B&C Technologies reports it had a great show, premiering its WashTools™ Android programming app that streamlines and simplifies the process of programming its FM7 control (standard on all B&C washers).

Washtools is an application used to program B&C Technologies’ FM7 washing machine controls.

It allows operators to easily create and edit programs using a simple programming format and a wizard creation mode. Programs are automatically scaled for any machine size and easily sent to machines via Bluetooth.

Representatives say the app was well received, and many people downloaded and began using it.

Utilimaster

Spartan Fleet Vehicles and Services, a business unit of Spartan Motors Inc., which specializes in commercial, retail and specialty service vehicle and upfit design, manufacturing and assembling under its Utilimaster® brand, showcased the latest technology

and capabilities of walk-in vans for linen and laundry service providers at Clean.

Utilitmaster industry-first solutions were on display at the booth and featured improved driver ergonomics and safety provisions, including an innovative curbside liftgate to make entry and egress with heavy laundry carts in tow safer and easier for drivers.