Late News

In memoriam:

David Cotter, TCATA

TAMPA, Fla. — The Textile Care Allied Trades Association (TCATA) announced that David Cotter, the association’s CEO, died suddenly Aug. 9. He was 64.

Leslie Schaeffer, TCATA president, will continue to maintain current operations and services to association members.

Office Manager Luci Ward is available by e-mail—luci@ tcata.org—or by calling the TCATA office at 813-3480075.

The international association represents manufacturers and distributors of drycleaning and laundry equipment and supplies. Cotter became its CEO in 1993.

“We appreciate your support during these difficult times,” TCATA says. ALN

Linen employee celebrates 65th anniversary

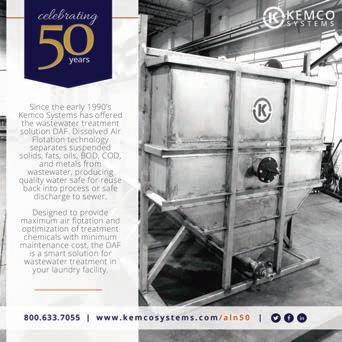

SANTA BARBARA, Calif. — Since he was hired in 1954, David Taggart has been a proud employee of Mission Linen Supply, a provider of products and services to hospitality, healthcare and industrial businesses.

Taggart was hired by the company’s founder, George Page, in April 1954 at the age of 17. To thank him for his 65 years of loyal dedication, Mission says it hosted a celebration in his honor at its headquarters here.

Taggart began his Mission career working as an extractor in the production department. Over the years, the company says he has been involved in a wide variety of projects and roles, including vendor selection, quality control, inventory management, manufacturing, cut and sew operations, warehouse design, site selection, and transportation.

He currently serves as warehouse manager in the purchasing department, assisted by his longtime sidekick George Hernandez.

“It’s an honor and a joy to be part of the Mission team,” says Taggart. “I look forward to coming to work every day, and I am tremendously grateful for all the wonderful people I have met over the years, as well as to Mr. Page for giving me the opportunity to join such a terrific company.”

The lunch celebration consisted of Taggert’s favorite Chinese food, along with a decorated cake inspired by his meticulous care of the company’s 1923 Ford Model T that can be seen year after year in local parades and car shows, and a slideshow showcasing his many

adventures and accomplishments.

Attendees included Taggart’s granddaughter Roxanne, as well as Mission’s owner Linda Page, members of Mission’s leadership team and board, and several retired friends Taggart worked alongside during their time at the company.

“It’s hard to believe David has been with the company over 65 years now,” says Linda Page. “This tells you that my dad knew he was hiring a hardworking, kind, honest and faithful man that has become a friend to all. David is one of a kind and a very special man.

I’m proud to be considered his friend.” ALN

Is your laundry labor law compliant?

Marchetti says there’s a lot happening on the labor front, and the risk of not caring about these issues is great.

During an educational session at the Clean Show in June titled Labor Law Compliance: Current Issues and Trends,

Marchetti and Haylor, Freyer & Coon colleagues Tom Flynn, vice president and director of group benefits, and Mike Halter, vice president and director of loss

BY MATT POE, EDITOR

NEW ORLEANS — Vic Marchetti, senior vice president of Haylor, Freyer & Coon, a firm that provides insurance and risk management solutions based in Syracuse, N.Y., says there are trends and issues that can potentially cost employers a lot of money when it comes to labor.

“They’re expensive issues, and they’re problems that we all face day-to-day, like employee turnover, compliance violations, HIPAA violations, workers’ compensation, OSHA penalties, EEOC violations, legal costs, attorney fees, employee morale,” he points out. “What happens in an organization when there is a claim and it starts affecting your customers, it just hurts general morale in the organization as a whole.”

Labor Savings with Automation

Seth Willer of Girbau Industrial shares how to get the most out of staff with automation.

SEPTEMBER 2019

David Taggart has been with Mission Linen Supply since 1954

www.americanlaundrynews.com INSIDE [4]

The Newspaper of Record for Laundry & Linen Management

[8] Volume 45, Number 9 [12]

licensed by Ingram Publishing)

(Image

See COMPLIANCE on Page 6

Experts talk current issues, trends employers face with workforces

David Taggart, who has been with Mission Linen Supply for 65 years, poses with the company’s 1923 Ford Model T, which he maintains (Photo: Mission Linen Supply)

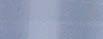

Distributors Directory 2019

Columnist at Large In this issue, Eric Frederick talks effective manager/employee communication.

Cotter

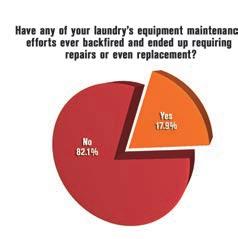

Your Views Survey:

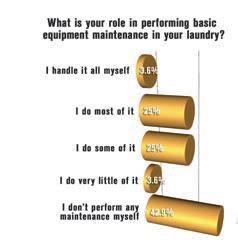

Majority of laundry managers involved with basic maintenance

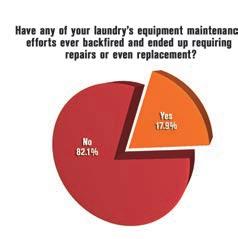

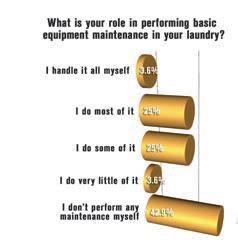

CHICAGO — When it comes to handling the most basic equipment maintenance, the majority of laundry/linen service operators are involved at some level in the process. The rest rely on experienced technicians.

That’s the result of a recent American Laundry News Your Views survey.

When asked about their role in performing basic equipment maintenance in the laundry, the majority of respondents indicate that they do some portion of the facility’s basic maintenance, with “I do most of it” and “I do some of it” each receiving 25% of the responses. Less than 4% indicate “I do very little of it.”

Only 3.6% of respondents indicate “I handle it all myself.” That’s in comparison to the nearly 43% who say “I don’t perform any maintenance myself.”

One survey taker had a particularly strong view on being involved with equipment maintenance: “If you cannot fix your own equipment, you might as well close the doors.”

“Even in that rare time when everything is working, it’s important to be listening to your plant, doing the walk around and always watching,” shares another.

Others have a different view: “Most repairs get contracted out.”

When it comes to being able to handle the basics, most laundry managers who took the survey seem to have the necessary skills. When asked if a repair they did ever backfired, 82% indicate that hasn’t happened.

Of the 18% who have had a maintenance effort go awry, it seems that the repairs were more involved than anticipated.

“Deeper underlying root cause issues were unseen,” shares a survey taker.

“After repairing a broken chain on a CBW, the timing wasn’t reassessed, which started off a whole series of unfortunate events leading to additional repairs and time spent with downed equipment,” writes another.

It doesn’t seem that equipment complexity is an issue, with almost 54% of respondents indicating that performing basic maintenance on equipment today is no different than in the past. In fact, more than 23% say it’s easier, while another 23% indicate it’s more difficult to perform maintenance on equipment today than in the past.

That being said, respondents indicate that finding skilled workers for maintenance is a challenge today.

When asked, “Have you had challenges finding skilled labor to handle maintenance in your facility?,” more than 70% of survey takers say yes, while just under 30% indicate they haven’t had a problem.

“It’s difficult to get timely repair/maintenance due to the shortage of trained techs,” a respondent writes.

Another puts it more bluntly: “Crisis situation to find capable personnel.”

“Using a PM program helps,” shares a survey taker.

In fact, 75% of respondents indicate that no matter who handles maintenance, they have formal schedules for completing these tasks, compared to 25% that don’t have a schedule.

When service technicians do have to handle maintenance tasks in a laundry plant, more than 60% of respondents say the technicians do either a good or great job. Nearly 29% indicate the technicians do an average job, and only 7.1% say the experience is “poor—there are always problems when someone comes out.”

Only 3.6% say they’ve never called a repair person.

“Too often our staff doesn’t have the confidence or skills to perform every task,” a respondent writes.

That’s where service schools offered by equipment manufacturers and distributors can help. Most operators (53.7%) says these schools are very valuable to themselves and staff, while 32.1% indicate they are somewhat valuable.

Only 10.7% are neutral when it comes to how valuable service schools are, and a scant 3.6% don’t consider them valuable at all.

“We need to find ways to get basic maintenance done by the operators,” shares a respondent.

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online each quarter. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and identify industry trends.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Roger Napiwocki

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

David Barbe • Jim Buik

Tony Jackson • Tom Marks

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0900 x100 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies: U.S. $9.00; Foreign $18.00.

Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661.

Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 45, number 9. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2019. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

2 SEPTEMBER 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com INSIDE: September 2019 • Vol. 45 | No. 9 [8] Maytag Celebrates with 60th Annual Meeting In June, more than 200 people from 18 countries attended the 60th meeting/awards recognition [10] Realities of Bringing Laundry Back In-house Author says bringing laundry back in-house starts with the right distributor providing the right equipment [23] Texcare Asia and China Laundry Expo Set First edition of merged trade fair to take place Sept. 25-27 at the Shanghai New International Expo Centre [25] Trade Ticker [26] Classified Advertising [27] Source Directory [30] Calendar of Events

ALN

Milnor has a better solution through dilution.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®, CBW® and RecircONE® are Pellerin Milnor’s registered trademarks.

Directory assistance

Welcome to the annual American Laundry News Distributors Directory issue.

It’s likely that as a laundry operator, you’ve purchased equipment or other products through a distributor.

This year, the directory starts on page 12 to offer you a look at other options for laundry-related goods/services distributors. The listing offers names and contact information for businesses that distribute laundry equipment, parts/service, chemicals, textiles, and other products/supplies.

Information on the distributors is listed alphabetically by city and state to help you find a distributor near your laundry operation. Say you’re in Florida. You’d find the section of the Distributors Directory for Florida (which happens to be on page 14). Under the

The Editor’s Desk

MATT POE

state heading, you’ll find a list of industry distributors operating in the state.

Each business listing features the distributor’s name, the types of equipment/products it provides and contact information. From there, you can contact the distributors to find out exactly the

brands and products and services they offer, along with their coverage areas.

However, as they say on TV, that’s not all!

This edition of American Laundry News also looks at labor issues. You probably noticed the story on page 1 about labor law compliance. This report from a Clean Show educational session looks at a few trends and issues employers need to be aware of to avoid getting “tagged” (i.e., cited and fined) when it comes to federal, state and local agencies.

But what about cutting labor costs? On page 8, Seth Willer from Girbau Industrial shares how automation can help make staff more efficient.

There’s also news and more in this edition. Plenty to help keep it clean, everybody! ALN

Letter to the Editor

Writer suggests more precise microfiber terms

The June issue of American Laundry News featured an article by Nancy Jenkins, “Demystifying Microfiber” (page 14). In it, Jenkins touched on key points relating to reusable microfiber products, and discussed key facts about oft-misunderstood microfiber products.

Jenkins provided the standard industry definition of microfiber—a fiber measuring 1.0 denier or less (but greater than .3 denier). She also refutes the claim that some disposable microfiber suppliers are making that implicates the laundering of reusable textiles in contributing micro-fragments to water systems. This is a critical point and reflects growing concern about how many in the industry are leveraging the term “microfiber.”

Unfortunately, in many cases manufacturers of disposable microfiber products are misleading customers, implying that they are contributing to the problem by using durable, reusable microfiber flat

mops and wipers and should change to disposable “microfiber” products—especially in the healthcare market.

Such misinformation could result in tens of millions of disposable microfiber products languishing in landfills for generations to come.

In reality, high-quality, reusable microfiber products are extensively tested for use in many industries, including pharmaceutical clean room manufacturing. The Helmke Drum test, in particular, measures the exact number of particles given off by a material to determine its level of particulate shedding. This is especially important in applications such as pharmaceuticals and healthcare, as you cannot have particle contamination in a facility making products that are injected into the human blood stream.

Understanding communication needs

ave you ever wondered what your employees think of management? Do you think they are impressed by your educational certificates and degrees, or do they think you lack common sense and the ability to properly lead your operation?

Top management puts a very high importance on a college degree, but line employees feel that common sense and learning the business from the bottom up is more important.

If you are going to be a leader in your operation, you must command the respect of your employees and be able to effectively direct them to get the job done. What impresses top management will not help you with your line employees.

If you want to understand your employees’ needs, then you must be prepared to talk to them about their needs in an environment that is comfortable for them. Do not call them into your office and ask them questions; under those circumstances, they will not tell you what you need to know.

The best way to learn about a job in your laundry is to do it for a day. The best way to get to know what an employee or group of employees think is to work with them for at least a day, but a week is better.

Always tell them the truth when you are talking to them. When you have to quote the company line, tell them the company has told you to tell them this or that.

Many rumors float through a laundry every day. Some are work related, some are simply gossip. The employees deserve to know the truth about work-related rumors, and this information needs to come directly from you. If you have taken the time to get to know your employees and they trust you to tell the truth, many problems can be avoided.

In my current part-time job, the drivers believe that the company requirement for a college degree in order to be a manager is ridiculous. What does a college degree teach a person about moving cars in the summer heat from point A to point B? Where in their college education did they learn how to clean and detail a car? And most of the mangers are clueless as to how to relate to or motivate a part-time staff composed mainly of retired workers.

Many of my fellow drivers were managers in their regular careers but now enjoy working 20 hours a week and earning some extra money. The fellowship with the other drivers and the ability to get out of the house and do something different is what is most important to them.

During my 44 years in the laundry industry, I always believed that the ability of the staff to work together to achieve a common goal made the work satisfying. The laundry had a weekly rhythm to it, and an experienced employee knew where we needed to be on any given day. They knew if we were ahead or behind and they often looked to management for confirmation.

OUR SISTER WEBSITES

Perhaps they were testing management. If we were behind and the production manager or the director said we were exactly where we needed to be, then they quickly decided we were not smart enough to understand the laundry business.

When management made their job harder to do while telling them the change was to increase production, they just shook their heads. They would tell themselves there was no sense trying to help them run the laundry, they are too stupid to understand the basics of production. A laundry expert is someone who does

•

4 SEPTEMBER 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

From

COLUMNIST AT LARGE Eric L. Frederick, RLLD

H

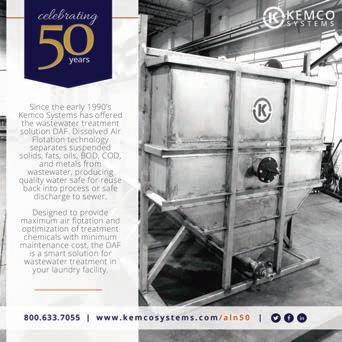

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending August 15 (WE) = WEB EXCLUSIVE NEWS • HandCraft Services Acquires Facility from Crothall Healthcare • Pellerin Milnor Corp. Presents Dealer Network Honors • ImageFIRST Acquires Two of Its Franchisees • Dempsey Uniform & Linen Acquires W.H. Linen & Supply • Kemco Systems Hires Vergo as CFO COLUMNISTS/FEATURES • Effective Commercial Laundry Marketing • Linen Storage, Transport—Keepin’ It Clean

Q&A: Industry Consolidation Impact

Eric Fredrick: It Pays to be ‘Semper Gumby’ (Always Flexible)

Employees of ‘All Abilities’ Make Laundry Successful

AmericanDrycleaner.com:

Starting Out in Dry Cleaning

Bamberg Brothers Own Platinum Dry Cleaners

AmericanCoinOp.com:

Akron Dry Cleaner Debuts First Vended Laundry

•

•

•

From

•

•

From

•

Laundrylux Acquires Texas Coin and Commercial Laundry

See FREDERICK on Page 22

See

“I F Y O U A RE G O ING T O BE A LEA DER IN Y OUR O PER A TI O N, Y O U MUST CO MM A ND T H E RESPECT O F Y O UR EMP LOYEES AND BE ABL E T O EFFECTIVE LY DIRECT T H EM T O GET T HE JO B D O NE.”

LETTER on Page 22

americandawn.com | imagine@americandawn.com HACCP IS ABOUT FOOD SAFETY In food processing plants, HACCP plans are about ensuring that critical control points are contaminant free. American Dawn offers a full line of HACCP Garments, as well as the knowledge and training to support your team. Give us a call to learn more about how we can open the door to this growing marketplace. CALL US: 800 821 2221 LET’S KEEP OUR FOOD SAFE

control, covered a few of these issues, along with presenting some solutions for mitigating them.

HUMAN RESOURCES

Flynn opened by talking about human resources (HR) compliance issues and solutions, the importance of creating policies with training and documentation that keep a business in compliance with federal, state and local labor law.

He says it starts with measuring a company’s policies when it comes to areas such as health and safety, discrimination, and healthcare.

“First of all, you have to know what you have as far as issues inside your company,” he says. “If you think about it, a lot of HR issues are managed by people who are either double-heading or someone who’s a mid-level manager. They always need some type of resource They may think that they’re actually doing everything fine.

“You can’t think you’re fine. You have to know it.”

Flynn say companies have to have a process, and it starts with auditing, conducting a gap analysis that shows where a company is lacking in terms of policies and training. He shares that, in many cases, a broker or outsourced HR consultant or even a payroll provider might have tools available, adding that it’s important to make sure that the partners a company does have can offer support in those areas.

“There are still fines for being noncompliant, and those are things you have to understand,” he says. “It’s going to be based on the size of your company, the number of employees you have, the states that you’re in, etc. Those are types of things that anyone can use some type of resources to support their decision-making on.”

As an example, he points out that a number of states have mandatory sexual harassment training, and some companies have been slow to react.

“In some of those states, that applies to every company in the state,” he says. “It doesn’t matter how many employees you have, if you have sales people that come and work in the office for a couple of days a year for a conference or just a training session, they have to be trained.”

In all these instances, Flynn says companies need to have a policy in place so they know what has to be done, know the timelines around when it has to be delivered, and have it all documented.

Tools and resources to help with a company’s HR compliance come in many forms.

“You have some people who like doing it themselves,” says Flynn. “They want to have some tools that they can go out and self-serve and bring down those checklists, maybe some training modules. Maybe it’s something to do with the developing a handbook. Those are all available.

“Or you can have someone totally outsourced do it all for you, or, again, you can have someone that uses the tools that are available in sort of self-serve environment.”

He shares that businesses have more than one option for training staff.

“Instead of spending a lot of money to have one person come in one day year to do sexual harassment training for your entire staff, maybe have a training solution that goes beyond that. Maybe an online

solution might be better. That way people can do it on their own pace, and that’s documented.”

Flynn points out that labor law is constantly changing and that “even a seasoned HR professional needs to have a heads up or a reminder.” There are services and partners that will send changes to a business proactively.

“Really, what the whole goal here is, you have to be consistent,” shares Flynn. “Consistency is sort of a rule, and ignorance is not an excuse. Those are two things you hear from attorneys.”

He reiterates that a consistent compliance policy is always going to start with the audits, knowing where the gaps are, and then doing the work to fill those gaps and creating policies.

“Having some type of policy in place for all these areas and, better yet, knowing where you should have policies in place, are sort of just the table stakes for being compliant,” he adds.

OSHA

The agency a business is most likely to come into contact with in terms of labor law compliance is the Occupational Safety and Health Administration (OSHA), so Halter shared a few thoughts on inspections, penalties, requirements and how to interact with OSHA.

First, he went over the numerous violations and penalties OSHA can “tag” a business with.

To start, there are “other than serious” violations, shares Halter. Basically, these are things that OSHA doesn’t think is going to significantly hurt, harm or kill someone. He says that when these types of violations are cited, sometimes there are no fines associated—but the department can levy a fine of up to $7,000.

The next level is a “serious” violation. That’s a violation that could cause significant harm, cause the loss of a body part or even get someone killed.

“In the past, the maximum citation or fine amount for those was $7,000,” Halter shares. “Today that’s been increased to $13,260, and we’ll see those numbers increase every year because there’s a 2.5% inflationary increase.”

Then there are “willful” and “repeat” violations.

“So, if you’ve been cited for something before and OSHA comes back and they cite you again, all the sudden your fine structure can go up tenfold,” he says “The max used to be $70,000, now it’s $132,000.”

Halter points out that this type of violation must be addressed at every facility a business has, not just the one cited.

“If OSHA comes into one of your facilities and they see that someone’s entering into a confined space, and they cite you for a confined space violation and you fix it, you’re all good at that facility,” he says.

“But then they go to another one of your facilities and they cite you for a similar confined space violation, that could be considered a repeat or willful violation because you should have known better, because you’ve already been tagged for that one at another facility.”

The next level of violation is failure to abate. Halter says when OSHA gives a citation, the business gets an abatement date, a certain time period to fix the problem. The fine for failure to fix the problem by the abatement date used to be $7,000. Today, it’s $13,000.

“Now, if you can’t fix it by that abatement date, you have an opportunity to ask for an extension,” he points out.

OSHA, like every employer, has limited resources, with roughly 2,100 inspectors, which averages out to about 42 per state. So, how does OSHA decide to inspect? Halter says the agency has a “hierarchy” of how it picks and chooses which companies to inspect.

The first level of the hierarchy is “imminent danger.” As an example, he says if an inspector was driving past a facility and saw an employee working in an unsafe manner, that would likely trigger a visit right then.

Next is if a fatality or hospitalization occurs.

“If you have a fatality, you have to call OSHA, you have to call them within eight hours and let them know that you had a fatality,” Halter says, “or if you had a hospitalization where the employee got admitted to the hospital.”

The next inspection trigger he shares is worker complaints. Being resource constrained, OSHA will take the time to determine if the complaint is valid, or just “sour apples,” before sending an inspector.

Then there are referrals. Halter says many organizations, such as the police or a hospital, are obligated to contact OSHA if an incident occurs, like an injury.

Next is a national or special emphasis program, such as targeting employers who use highly hazardous materials.

Site-specific targeting takes place when OSHA examines a company’s OSHA 300 log report and sees that the DART (days away, restricted or transferred) rate is above the national average, or well below the average, according to Halter.

Finally, there are program inspections.

“This is, it’s just your turn,” he says. “They do a number of inspections, and they said well we’re going to be in this area, and we’re going to come visit you.”

Halter then posed a question: Do you have to let OSHA in? The answer is no, but he cautions that the agency will get a warrant and be back.

“When would you want to say no?” he says. “Generally, I’d say let them in, but if you don’t have the right people there, if you think your place is a disaster and you

need some time to clean it up, maybe say no, but generally, unless you have a really good reason to not let them in, you want to. You want to look like you want to play ball.”

Halter goes on to say that OSHA can’t find a violation during an inspection and then say it’s really dangerous and shut a business down immediately. However, the agency can make it financially onerous, so the company will be compelled to fix the issue. He does points out, however, that businesses can contest citations and fines.

“When OSHA shows up, be really considerate to them,” he says. “Treat them the way you want to be treated. They can stay for up to six months if they want. They have the right to do that.”

INSURANCE IMPACT

Marchetti wrapped up the session sharing how labor law can impact a company’s overall insurance program.

“Costs are on the upswing,” he says. “It’s more risk-specific and industry-specific. What’s going on is the underwriters are going through a more disciplined underwriting process. Underwriters are researching accounts pretty comprehensibly before they start the process.”

He says many factors are impacting insurance costs, ranging from catastrophic events to cyber incidents, from property considerations to fleet issues.

“Take the time to look at your information, what is out there, and take the time to do the gap analysis and identify your risk hazards,” suggests Marchetti. “Work to mitigate risk exposures before anything happens.

“Make sure you’re taking the time to make sure you’re in compliance, the sexual harassment training, wages, etc. Make sure your folks are educated.

“If you do all of these things and you bring it all together and take advantage of what’s out there, you should have a positive impact on lowering your overall total cost of risk. That’s ideally what you want to accomplish to put your business in a better position to help you grow.”

6 SEPTEMBER 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ALN

Continued from Page 1

Compliance

(Image licensed by Ingram Publishing)

Cultivate your existing ironer’s production and quality by adding a Girbau Industrial spreader/feeder to your current ironing system. Our series of feeders improve product quality, enhance labor efficiencies and increase production in laundries. Keep pace and grow your laundry with Girbau Industrial. Nurture your growth – one piece at a time – with an investment sure to reap healthy dividends.

Discover how Girbau Industrial works seamlessly with your existing equipment. Call 800-256-1073. We have equipment in inventory and ready for installation.

INDUSTRIAL girbauindustrial.com INNOVATIVE LAUNDRY SOLUTIONS CULTIVATING YOUR IRONING LINE THROUGH SEAMLESS EQUIPMENT INTEGRATION Equipment Sizing | Laundry Design & Workflow | Installation & Commissioning | Training & Follow-up Care INCREASE PRODUCTION IMPROVE QUALITY PROMOTE GROWTH ENHANCE LABOR EFFICIENCIES

Getting the most out of staff, automatically

most out of your staff as you move into automation.

INTEGRATE MULTIPLE FUNCTIONS IN A SINGLE MACHINE

BY SETH WILLER

OSHKOSH, Wis. — All industrial, commercial and onpremises laundries offer different services, utilize different pieces of equipment, strive toward unique quality goals and operate at varying levels of efficiency. Justifying new equipment and automation isn’t always easy.

When it comes to taking the leap into automation, investing in one piece of equipment can significantly impact quality, production, per-pound laundry processing and labor costs.

If you’re at a crossroads and considering automation, remember that you aren’t alone in determining whether it makes sense. Contact your equipment distributor to help you assess—in hard numbers—if and when the time is right.

In this column, I’ll provide some insight into how to get the

When a laundry gets above 180 washing pounds per hour, a more automated system makes sense. When you go to a machine that automatically irons, folds and stacks flat goods, laundries eliminate almost all hands-on folding and stacking.

With a higher-production all-in-one machine, operators feed sheets. The primary folding, secondary folding and stacking are all automatically performed for boosted quality and labor production.

Some all-in-one machines have options for spreader/feeders. The benefit of adding the spreader/ feeder is twofold. It improves quality and increases labor efficiencies. A single operator uses spreading clamps for automatic feeding into the ironer/folder/ stacker. The automatic spreader/ feeder ensures a straight feed, which contributes to a higher quality finished product.

Labor benefits to installing an all-in-one machine: One opera-

tor can process 229 pounds per operator hour (1.8 pounds per sheet at 85% efficiency), which equates to 2.5 sheets per minute and 150 sheets per hour. The allin-one machine eliminates hand feeding, folding and stacking.

MOVE FROM A HEATEDROLL TO A HEATED-CHEST IRONING SYSTEM

A heated-roll ironer features an open-air combustion system. Thus, some of its heat escapes and makes it less efficient than a heated-chest ironer. Heated-roll ironers are 70-75% efficient.

Conversely, a heated-chest ironer offers a sealed combustion system that can use selfcontained thermal fluid as a heat source. The closed-loop system transfers more heat through the chest to the damp linen and puts more heat energy to the task of evaporating and ironing. A chest ironer has a faster recovery time to keep at consistent programmed temperatures.

A heated-chest system with a self-contained thermal fluid system is between 93 and 95% efficient. Because heat stays in the chest ironer, textiles run through more quickly allowing operators

to process more linen volume per operator hour.

Labor benefits to installing a heated-chest ironing system: Three operators can process 306 pounds per operator hour (1.8 pounds per sheet at 85% efficiency), which equates to 10 sheets per minute and 600 sheets per hour. Hand folding is eliminated when the ironing systems includes an integrated folder.

ADDING AN AUTOMATED FEEDER ONTO YOUR IRONING LINE

A feeder offers one to four feeding stations with mechanical clips to spread, center and feed large-sized items, such as sheets. The advantage to an automated feeder—over hand feeding—is quality and production.

The automated feeder feeds items more quickly than operators can by hand. It also has options, such as vacuum suction and spreading brushes and belts, to ensure consistent quality on every sheet.

These are important features because

they automatically straighten the sheets when fed into the ironer. This eliminates the possibility of operators feeding sheets into the ironer so they sit crookedly rather than centered. Finally, in terms of productivity, the automated feeder can feed sheets as quickly as the chest ironer/folder can process them.

Labor benefits to installing an automated feeder onto your ironing line: Four operators can process 321 pounds per operator hour (1.8 pounds per sheet at 85% efficiency), which equates to 14 sheets per minute and 840 sheets per hour. Hand folding and hand feeding are eliminated when adding a spreader/feeder to your ironing system. ALN

Seth Willer is an expert in onpremises, commercial and industrial laundry design, equipment, workflow and productivity.

As Girbau Industrial (GI) national sales manager, he works closely with laundry facilities to develop highly efficient and productive laundries for an array of industries, including hospitality, vacation rental and healthcare.

Maytag Commercial Laundry celebrates with 60th Annual Meeting

BENTON HARBOR, Mich. —

In 1959, Maytag® Commercial Laundry hosted an Annual Meeting at its Iowa headquarters. That inaugural event was created to share news about the brand, educate on products and discuss plans for the coming year. Attendees also celebrated and honored distributor performances and accomplishments of the past year.

The tradition continues. In June, more than 200 people from 18 countries attended the 60th Maytag® Commercial Laundry Annual Meeting and Awards Recognition at the Roosevelt Hotel in New Orleans.

The fast-paced, one-day event took attendees through several topics, including an up-close look at the new Maytag® MultiLoad Washer, product insights and industry trends; the Whirlpool® Commercial Portal; and an overview of Maytag® Commercial Laundry marketing support and programs.

“It’s exciting to witness a tradition as rich and storied as the Maytag® Annual Meeting,” says Randy Karn, Whirlpool Global Service Manager, Whirlpool Corp. Commercial Laundry, who has attended 33 of the meetings.

“It’s an event that has evolved over the years based on loca-

tions, trends in the industry, and customers’ needs, but the ideals on which it was founded have remained steadfast. That is to celebrate our successes, communicate with our customers and honor the brand’s achievements.”

“The Annual Meeting adds value to our relationship,” says Malcolm Caldwell, vice president of sales and marketing at distributor Harco Co. Ltd.

“We look at the Annual Meeting as a comprehensive overview allowing us to learn about the year’s brand goals and objectives, examine products, share experiences with our peers,

and perhaps most importantly, gain insights that help us capture sales and grow our business.”

The learning and exchanging of industry knowledge have always been a key meeting component.

“Whether structured as workshops, product demos or peer discussions, the goal is to form a foundation of success for Maytag® Commercial Laundry distributors, route operators and team members,” says Chad Lange, sales director of commercial laundry for Whirlpool Corp.

Richard and Susan LaMaina with Equipment Marketers,

based in Cherry Hill, N.J., say they look forward to the Annual Meeting for the camaraderie, the product knowledge and learning from other distributors. The LaMainas attended their first Annual Meeting in 1978.

“We appreciate the opportunity each year to learn firsthand about the brand’s strategic plans for products and enhancements being made to product lineups,” says Richard LaMaina. “The event provides a chance for hands-on experiences, product demonstrations and key service topics, all of which help us to run our business more efficiently and successfully.”

During this year’s 60th Fred Maytag Awards Dinner, Maytag recognized the hard work that went into the past year. Outstanding distributors recognized included:

• Excellence Appliance Technologies, Quezon City, Manila, Philippines, winner of the Fred Maytag Award.

• CLA Malaysia, based in Kuala Lumpur, received the Maytag® Commercial Laundry Vended Excellence Award.

• Hercules Corporation of Hicksville, N.Y., was recognized as the Quality Partner of the Year.

• Harco Co. Ltd. of Mississauga,

Ontario, Canada, was given the Marketing Excellence Award.

• SEBCO Laundry Systems™ of Raritan, N.J., was presented with the Red Carpet Service® Award, which recognizes excellent service and dependability.

• PT Triton Internasional, of Jakarta, Indonesia, was named the International Distributor of the Year.

• CSC ServiceWorks, headquartered in Plainview, N.Y., was presented with the MultiHousing Excellence Award.

• Aqualys of Paris, France, was the Maytag® Commercial Laundry Outstanding First Year Performer.

• Richard Jay, with locations throughout Australia, received the International Multi-Housing Excellence Award.

“The accomplishments we have achieved thus far as a brand have been attainable thanks to the tremendous dedication and support of our (distributor) customers,” says Lange.

“Collaboration is vital. We are not only proud of the successes we have achieved together with our reputable distributors over the past 60 years, but even more excited to witness what the future holds.”

8 SEPTEMBER 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ALN

Willer

How automation improves labor efficiencies in laundries

Fred Maytag leads the first Maytag ® Commercial Laundry Distributor Meeting at Maytag headquarters in Newton, Iowa, in 1959. (Photo: Maytag ® Commercial Laundry)

When dealing with laundry stains, your reputation rides on getting the outstanding results The Laundry Two deliver. RiteGo® laundry spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to Laundry TarGo® to remove any tough oil based stains that remain behind.

Use The Laundry Two with confidence on shirts, wedding gowns... anything you're washing or wetcleaning.

Both Laundry TarGo and RiteGo are chlorinated-solvent free, biodegradable, noncombustible and California 2013 VOC and Prop-65 compliant.

Use them to deliver stain-free laundry and wetcleaning. You'll build your reputation for quality - which is what keeps customers coming back.

FROM COLLARS AND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... FROM COLLARS AND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

a STAIN WIZARD at ALWilson.com

Become

Realities of bringing laundry service back in-house

BY MARK E. MOORE

VERSAILLES, Ky. — You’ve probably heard the following before.

Don’t swim right after you eat. Chameleons change color to match their surroundings. Wear a hat when it’s cold outside since 90% of your body heat escapes through your head. Coffee comes from beans.

But none of those “facts” are, in fact, true.

Waiting 30 minutes after eating before swimming does nothing more than help you avoid a minor cramp. It’s true chameleons do change colors, but it’s actually due to physiological and emotional changes. According to the British Medical Journal, just 7% of your body heat escapes through your head. And coffee actually comes from the pit inside the coffee fruit, so coffee seed is more accurate.

Here’s another falsehood that too many people believe: It’s cheaper for hotels, nursing homes, hospitals and other facilities to outsource laundry, rather than do it themselves.

In fact, it’s not only much less expensive to do laundry in-house than it is to send it out, but it also ensures better quality and avoids transportation delays. With the efficiencies of the new machines on the market, you can save 30% or more off your laundry costs. That’s because you’re not paying for another company’s profit.

SAVINGS THROUGH MANAGEMENT

While the actual savings will depend on what you’re sending out—sheets and towels are less expensive to launder than specialty linen, for instance—today’s equipment has the ability to monitor every function of the spectrum of doing laundry inhouse. In fact, managing your machines will help you save money.

With the management tools and system monitoring available from today’s high-performance machines, you can get daily or weekly reports that measure usage, productivity, performance and more. Those reports show you how you can improve your usage and, thus, decrease your costs.

For example, the typical cost for doing in-house laundry is 20 to 24 cents a pound, including utilities, labor and other associated costs. But I have a nursing

home facility that is running 14 cents a pound since its supervisor is effectively monitoring both of its shifts and managing the machines’ usage. While most businesses will use their laundry machines about 50% of the available time, that nursing home is running in the mid- to high-70% range.

LAUNDRY THAT DOESN’T NEED A RIDE

The second advantage of doing laundry in-house is that you don’t have to worry about transportation delays, whether caused by a traffic accident on the interstate or a storm that shuts down the entire state or region. It’s huge not having to worry if your delivery truck will make it every day.

Third, doing laundry in-house allows you to control quality. If you do laundry in-house, you have control over who inspects it, but when you send laundry out-of-house, someone else has control over that inspection.

By doing laundry in-house, you also get to decide when to scrap your towels, sheets and other linens. It gives you complete control over your laundry and the appearance of what is seen in your rooms or on your beds.

You also need to consider if out-of-house laundries are in compliance with state regulations that ensure things are sanitized and cleaned properly. If you’re sending it to an outside laundry, you don’t know if there are problems with cross contamination or other issues.

The state of Kentucky, for instance, requires the water used in washing machines to be 140 F, but some other states require 160 F. The states routinely come in and inspect laundries once or twice a year, and if your hot water is not reaching your set point, they will give you a week to fix the problem. If it’s not fixed within that week, they’ll shut your laundry down.

LINEN MIX UPS

Lastly, it’s not unheard of for big laundries to mix up your linen with someone else’s. And if you’re a five-star resort and get sent back two-star hotel linen, that could be a big problem.

For those deciding to do laundry in-house, it’s important to keep quality and cost in mind when deciding which equipment to purchase or lease. Cheaper

equipment may work for the moment, but what happens when your company’s needs change?

If you have equipment that is flexible and programmable, you can adapt your cycles to your current needs, as well as to your future needs. So, if a hotel changes to a sheer, delicate duvet cover, their machines need to be able to adjust cycles appropriately so it doesn’t damage the linens.

The equipment and the controls will also help you maintain the quality of your laundry. For instance, dry something in a dryer that only has a timer control, and most people will set the timer too long. The towels and the sheets get overdried and feel brittle.

But if you dry those same items in a machine that measures the moisture level of the linens, it will shut off when it measures a preset moisture level. That will help extend the life of your goods and ensure you put out a better product for your customers to use.

ACTIONS TO BRING LAUNDRY BACK IN

Choosing the right equipment starts with choosing the right distributor to work with. Find a company that has a sales force that will come visit you, look at your needs, figure out what will work in your application, and ask the right questions to help guide you to the proper equipment.

A lot of companies will quote

you the cheapest price. But they often don’t offer support or service, and if they do, it may take weeks to get a response.

And while a cheaper machine may save you money upfront, higher performance equipment tends to process a load of laundry 7 to 8 cents per pound cheaper than lower-cost machines. That’s because the throughput is greater and they extract faster, which means it takes less time for your laundry to dry. That, in turn, cuts down on your labor costs, estimated to be two-thirds of the cost of doing laundry.

How long does it take to recover the cost of new equipment?

The answer to that depends on your output. Here’s a quick story about the efficiencies of scale.

A chain of six nursing homes in a 20-mile radius was averaging 20 to 24 cents per pound at their facilities, except for one. That nursing home was averaging 40 cents a pound. The time between unloading, reloading and restarting the machine was about 10 minutes for five of the nursing homes. But the sixth nursing home took a full hour or more.

Once it became apparent why—they didn’t have enough linen and they were waiting for the dirty linen to come down so they could wash it and

send it back up on the floors—we suggested they buy $10,000 in additional linens.

Within 60 days, that nursing home was in the 24 cents a pound range. By saving about 15 cents a pound on average, they saved $75,000 for the year, which would easily pay for new laundry equipment.

When you compare a new, cheaper machine running at 27 to 28 cents a pound to a new, more expensive model running 20 cents a pound, it still makes financial sense to go with the higher performance version. The difference of 7 to 8 cents a pound will pay for the high-performance machine in a year’s time.

Leasing is a good option for companies that don’t want to pay for high-performance equipment up front. The leasing option allows a facility to put in new equipment without paying anything out of pocket. In fact, the money you save with the new, higher performance models will provide you monthly savings that will pay for the lease. ALN

Moore

Mark E. Moore is president of REM Co., which for 52 years has been serving the commercial laundry industry in Kentucky and Tennessee. He can be reached at mmoore@remlaundry.com or by calling 859-873-8812.

10 SEPTEMBER 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Author says bringing laundry back in-house starts with the right distributor providing the right equipment

(Image licensed by Ingram Publishing)

ALABAMA

Wholesale Commercial E P O

Laundry Equipment Co. SE 2950 Highway 77 Southside, AL 35907

B 256-312-4761 or 866-544-7228

O www.alaundryman.com

r Russ Arbuckle l thelaundryman1@gmail.com

ALASKA

Automated Laundry E C P

Systems & Supply 360 E. 100th Ave.. Anchorage, AK 99515

B 907-561-1752 or 800-478-1752

O www.autolaundrysystems.com

r Kevin Lewellyn l sales@autolaundrysystems.com

ARIZONA

Pierce Machinery E P.O. Box 2110 Chandler, AZ 85244

B 602-625-1902 or 602-538-5081

O www.piercemachinery.com

r Rod Pierce l rod@piercemachinery.com

Sunshine Sales E P O 6064 N. 57th Ave. Glendale, AZ 85301 B 623-937-0125 or 800-789-6412

O www.sunshinesalesaz.com

r Bob Ropp l bobropp@sunshinesalesaz.net

Astro Distributing E P O & Leasing 4329 E. Magnolia St. Phoenix, AZ 85034

B 602-267-7072 or 800-362-7876

O www.astrodistributing.com l admin@astrodistributing.com

C-PEC E P 3120 W. Weldon Ave. Phoenix, AZ 85017

B 602-248-0808 or 877-835-5866

O www.cpec-laundry.com r Dave Svancara l sales@cpec-laundry.com

Laundry & Cleaners E P Equipment Co. 320 S. 25th St. Phoenix, AZ 85034

B 602-244-0800

O www.laundryandcleaners.com r Tim Eckenrode l teckenrode@laundryandcleaners.com

Laundry & Cleaners C O Supply Inc. 402 S. 50th St. Phoenix, AZ 85034 B 602-244-0770 or 800-258-9664 O www.lcsupplyaz.com r Dave Eckenrode l deckenrode@lcsupplyaz.com

Wardlaw Equipment E P Consultants Phoenix, AZ 85013

B 520-791-2804 or 877-927-3529 O www.wardlawequipment consultants.com r Kevin Wardlaw l wardequip@aol.com

C-PEC E P 3202 S. Richey Ave. Tucson, AZ 85713

B 520-790-7377 or 877-835-5867 O www.cpec-laundry.com r Greg Svancara l greg@cpec-laundry.com

ARKANSAS

FabriClean Supply C O of Arkansas

6600 Allied Way Little Rock, AR 72209

B 501-565-5288 or 800-482-1283 O www.fabricleansupply.com l info@fabricleansupply.com

Justin Laundry Systems E P 5310 Baseline Rd. Little Rock, AR 72209 B 501-551-8600 or 888-403-9600 O www.justinlaundry.com r Phil Gray l pgray@justinlaundry.com

Central Laundry E P O Equipment P.O. Box 324 Ward, AR 72176 B 501-843-3194 or 800-467-3194 O www.centrallaundryequipment.com r Jeff Craig l jeff@centrallaundryequipment.com

CALIFORNIA

Washex Machinery E P of California 101 E. Santa Anita Ave. Burbank, CA 91502 B 818-840-8900 or 800-397-8811 O www.washexcalifornia.com r Mark Sanders l washexcasales@aol.com

Western State Design E P 17000 Marquardt Ave. Cerritos, CA 90703 B 800-633-7153, ext. 301 O www.westernstatedesign.com l sales@westernstatedesign.com

Consolidated E P 3804 Main St., Ste. 1 Chula Vista, CA 91911 B 866-632-2298 O www.cicus.com l sales@cicus.com

Super Laundry Los Angeles E P 14426 Bonelli St. City of Industry, CA 91746 B 844-272-9675 O www.superlaundry.com r Stephanie Osta l sosta@cscserviceworks.com

California Textiles T P.O. Box 77306 Corona, CA 92877 B 951-272-1200 O www.catextiles.com r Lenore Law l catex1@att.net

WASH E P 100 N. Pacific Coast Hwy., 12th Floor El Segundo, CA 90245 B 800-421-6897 O www.wash.com

Golden State E P Laundry Systems 26203 Production Ave., Ste. 11 Hayward, CA 94545 B 510-782-6707 or 800-465-8300 O www.gsls4laundry.com l info@gsls4laundry.com

Innovative Laundry Systems E P 1316 W. Winton Ave. Hayward, CA 94545 B 510-259-1494 or 877-777-3727 O www.innovativelaundry.com r Cheri Guffey l cguffey@innovativelaundry.com

Western State Design E P O 2331 Tripaldi Way Hayward, CA 94545 B 510-786-9271 or 800-633-7153 O www.westernstatedesign.com l info@westernstatedesign.com

Automated Laundry E P O Systems 3626 S. San Pedro St. Los Angeles, CA 90011 B 818-556-6432 or 800-423-8045 O www.automated-laundry.com r Oncho Kerian l info@automated-laundry.com

United Fabricare Supply C O P.O. Box 01796 Los Angeles, CA 90001 B 310-537-2096 or 800-540-9727 O www.unitedfabricaresupply.com l unitedfabricare@aol.com

Golden State E P Laundry Systems

1729 Coolidge Ave. National City, CA 91950 B 619-477-8364 or 800-465-8300 O www.gsls4laundry.com l info@gsls4laundry.com

Taylor Houseman E P O 162 Harbor Ct. Pittsburg, CA 94565 B 925-432-0323 or 800-464-6866 O www.taylorhousemanlaundry.com l sales@taylorhouseman.com

Golden State E P Laundry Systems

1984 E. Gladwick St. Rancho Dominguez, CA 90220 B 310-223-2240 or 800-465-8300

O www.gsls4laundry.com l info@gsls4laundry.com

Continental Girbau West E P 9830 Alburtis Ave.

Santa Fe Springs, CA 90670

B 562-205-0140 or 866-950-2449 O www.cg-west.com l info@cg-west.com

TheLaundryList.com E P O 4525 Sherman Oaks Ave. Sherman Oaks, CA 91403 B 818-789-8045 O www.thelaundrylist.com r Brian Cohen l sales@thelaundrylist.com

PWS–The Laundry Co. E P O 12020 Garfield Ave. South Gate, CA 90280

B 323-490-1900 or 800-800-4797 O www.pwslaundry.com l web-inquiry@pwslaundry.com

ACE Commercial E P O Laundry Equipment

14404 Hoover St.. Westminster, CA 92683

B 714-897-4342 or 877-630-7278 O www.acelaundry.com l sales@acelaundry.com

COLORADO

Cowell Sales Co. E P 2220 Downing St. Denver, CO 80205

B 303-861-8826 or 800-861-8826 l cowellsales@aol.com

Katzson Brothers E C T P O 960 Vallejo St. Denver, CO 80204

B 303-893-3535 or 800-332-2417 O www.katzson.com r Richard H. Right l sales@katzson.com

Martin-Ray E P O

Laundry Systems

2050 W. 9th Ave. Denver, CO 80204

B 720-359-8000 or 800-279-6622 O www.martinray.com r Bill Mann l bill@martinray.com

Commercial Laundry E C P O Systems of the Rockies

P.O. Box 974

Johnstown, CO 80534

B 970-587-2727 or 800-270-8539 O www.clsrockies.com r Brenda Maetzold l brenda@clsrockies.com

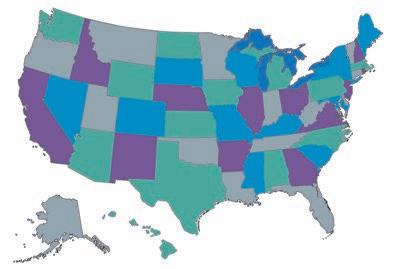

12 SEPTEMBER 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com KEY B Phone O Website r Contact l E-Mail e Equipment C Chemicals T Textiles P Parts & Service o Other Products or Supplies WA 21 OR 19 CA 12 NV 18 UT 20 WY — MT 16 ND SD 20 NE 18 KS 16 AK 12 VT 20 DE — NH 18 MA 16 RI 20 CT 14 NJ 18 MD 16 HI 14 PUERTO RICO 21 MN 16 IA 16 MO 16 AR 12 LA 16 MS 16 AL 12 GA 14 FL 14 TN 20 SC 20 NC 18 KY 16 IL 14 WI 21 MI 16 IN 14 OH 18 WV 21 VA 20 PA 19 NY 18 ME — AZ 12 NM 18 TX 20 OK 19 CO 12 ID 14 2019 Distributors Directory These distributors and suppliers responded to American Laundry News’ invitation to be listed. They provide laundry equipment, textiles, chemicals, parts and service, and/or other products or supplies, and are listed alphabetically by city and state. Contact distributors to determine their coverage area—local, regional or national. The map below indicates on which page a given state’s listings begin. No distributor information was received from states that have no listings. The Distributors Directory runs through page 21.

At your facility, your production is strategic. It’s scheduled. It happens on every shift, every day. And you don’t like surprises. It’s why we bring you purposeful engineering in powerful machines built to help your facility perform at its peak — because we don’t like surprises, either. Maximize your productivity with the help of Maytag® Commercial Laundry by your side.

PRODUCTIVITY DOESN’T

BY ACCIDENT. *This promotion is valid for applications received by Eastern Funding between July 1 and December 31, 2019, and funded by February 15, 2020. Visit maytagcommerciallaundry.com for complete promotional details. ®/™ © 2019 Maytag. All rights reserved. 0% — First 6 Months 5.99% — 30 Months 5.99% — 60 Months * * 36-MONTH FINANCING 60-MONTH FINANCING OR

GO WITH THE NAME YOU KNOW Visit us at MaytagCommercial.com

HAPPEN

Clean Designs E P

2800 S. Oak St. Lakewood, CO 80227

B 303-969-8288 or 800-444-4580

O www.cleandesigns.com

r Tim Stoklosa l tim@cleandesigns.com

CONNECTICUT

Lavatec Laundry Technology E P

49 Lancaster Dr. Beacon Falls, CT 06403

B 203-632-8777

O www.lavatec.com

r Mark Thrasher l m.thrasher@lavatec.com

Cromwell Textile T 44 Windy Knoll Dr. Berlin, CT 06037

B 860-828-3946

O www.cromtex.com

r Dave Gagnon l sales@cromtex.com

Super Laundry E P O Connecticut

266 Prestige Park Rd. East Hartford, CT 06108

B 800-678-9247

O www.superlaundry.com r Stephanie Osta l sosta@cscserviceworks.com

Connecticut Laundry E P O Equipment Co.

P.O. Box 399 Fairfield, CT 06824 B 203-763-9163

r Steven Olmanni l ctlaundryequip@aol.com

MAXI-PRESS P O

80 Turnpike Dr., Ste. 4 Middlebury, CT 06762 B 844-447-5559

O www.maxi-press.us

r Reiner Schmelcher l r.schmelcher@maxi-press.us

Lubbert Supply Co. P O 89 Eastern Steel Rd. Milford, CT 06460 B 855-922-1705

O www.lubbertsupply.com r Eric Lubbert l sales@lubbertsupply.com

FLORIDA

Commercial Laundry E P Equipment 2054 Sprint Blvd. Apopka, FL 32703 B 407-886-1722 or 800-226-9449

O www.commerciallaundry.net

Baring Industries Inc. E P 3249 S.W. 42nd St. Fort Lauderdale, FL 33312 B 954-327-6759 or 800-736-5464, ext. 759

O www.baring.com

r Sean Melody l s.melody@baring.com

Commercial & Coin E P

Laundry Equipment Co. 1626 Tradewinds Dr. Gulf Breeze, FL 32563

B 850-932-8348 or 800-366-4168

O www.clecco.com

r Craig Dakauskas l sales@clecco.com

Allen Wholesale Supply P O 3948 3rd St. S. Jacksonville, FL 32250 B 904-353-7341 or 800-874-0548

O www.steamsuppliers.com l sales@steamsuppliers.com

Automated E P O

Laundry Systems 2849 Dawn Rd. Jacksonville, FL 32207

B 904-733-5500 or 800-518-9274

O www.alstoday.com l hello@alstoday.com

FabriClean Supply C O of Florida 11705 Industry Dr. Jacksonville, FL 32218

B 904-696-7685 or 800-553-9040 O www.fabricleansupply.com l info@fabricleansupply.com

Laundry Pro of Florida E P O

3920 Holden Rd. Lakeland, FL 33811

B 863-701-7714 or 800-232-5736

O www.laundryproofflorida.com r Ron Jansen or Joel Edris l jedris@laundryproofflorida.com

Florida Laundry Systems E P

5149 Northeast 12th Ave. Lauderdale, FL 33334

B 954-928-0950

O www.fllaundry.com r Ira Gottlieb l fllaundry@fllaundry.com

Industrial Equipment C O & Supplies

2055 N.W. 7th Ave.

Miami, Florida 33127

B 305-324-0410 or 800-969-4766 O www.getdrycleansupplies.com l info@getdrycleansupplies.com

Steiner-Atlantic Corp. E P O 290 N.E. 68th St. Miami, FL 33138

B 305-754-4551 or 800-333-8883 O www.steineratlantic.com r Ralph Tuccillo l sales@steineratlantic.com

Worldwide Laundry E P 3325 N.W. 97th Ave. Miami, FL 33172 B 305-418-4030 or 877-953-9433 O www.worldwidelaundry.com l sales@worldwidelaundry.com

Friedman & Co. T Ocala, FL 30340 B 352-401-0251 r Lee Friedman l lee.friedman@gmail.com

Streamline Solutions O P.O. Box 560775 Orlando, FL 32856 B 866-244-7700 O www.soiledlinenbags.com r Ross Sanders l rsanders@streamlinesolutionsusa.com

B&C Technologies E P O 17740 Ashley Dr., Ste. 109 Panama City Beach, FL 32413 B 850-249-2222 O www.bandctech.com r Al Adcock l sales@bandctech.com

JENSEN USA E P 99 Aberdeen Loop Panama City, FL 32405 B 850-271-5959 O www.jensen-group.com l norbert.gittard@jensen-group.com

Mesmen Inc. E P 4100 N. Powerline Rd., Ste. Y2 Pompano Beach, FL 33073 B 954-973-2714 or 800-637-6365 O www.mesmen.com

r David Hancock l mesmen@earthlink.net

PSP Industrial E P Laundry Equipment 2700 Gateway Dr. Pompano Beach, FL 33069 B 305-517-1421 or 800-517-1432

O www.pspindustrial.com l info@pspindustrial.com

AMKO America/ E P JB Industries 8011 Monetary Dr., Ste. B-5

Riviera Beach, FL 33404 B 561-863-9099 O www.jbilaundryfolder.com r Jurgen Bischoff l amkoamerica@gmail.com or JBI.Incorporated@gmail.com

FRONTEC P

1330 Main St. Floor 2 Sarasota, FL 34236 B 941-726-0808 O www.frontec.us l sales@frontec.us

PODAB E P O

1330 Main St. Floor 2 Sarasota, FL 34236 B 941-479-0763 O www.podab.us l info@podab.us

Hicks Laundry Equipment E P 4475 28th St. N. St. Petersburg, FL 33714 B 727-522-0644 or 800-574-8738 O www.hickslaundry.com l parts@hickslaundry.com

FabriClean Supply C O of Florida

5030 N.W. 109th Ave., Ste. E&F Sunrise, FL 33351 B 954-306-3342 O www.fabricleansupply.com l info@fabricleansupply.com

Commercial Laundries E of West Florida

5313 Johns Rd., Ste. 210 Tampa, FL 33634 B 813-886-1477 or 800-876-1477 O www.commerciallaundriesflorida.com r Mike Albanese l mike@clwf.net

FabriClean Supply C O of Florida 6401 Badger Dr. Tampa, FL 33610 B 813-623-3553 or 800-282-2924 O www.fabricleansupply.com l info@fabricleansupply.com

Commercial Laundry E P O Equipment Co. 1114 53rd Ct. S. West Palm Beach, FL 33407 B 561-848-0054 or 800-638-1869 O www.commerciallaundryequip.com r Holly Ortman l hortman@clecusa.com

GEORGIA

Atlantic Coast Textiles T 3132 Oakcliff Industrial St. Atlanta, GA 30340 B 770-458-0772 or 800-533-0228 O www.actextiles.com l sales@actextiles.com

ZEP C 3330 Cumberland Blvd., Ste. 700 Atlanta, GA 30339 B 877-428-9937 O www.zep.com l zephelp.commercial@zep.com

FabriClean Supply C O of Atlanta 1200 2nd Ave. N. Birmingham, GA 35203 B 205-251-7272 or 800-626-8428 O www.fabricleansupply.com l info@fabricleansupply.com

FabriClean Supply C O of Atlanta 5330 Dividend Dr. Decatur, GA 30035 B 770-981-2800 or 800-688-3032 O www.fabricleansupply.com l info@fabricleansupply.com

Southern Automatic E P O Machinery Co. 133 N. 85 Pkwy. Fayetteville, GA 30214

B 770-892-0098 or 800-969-7627 O www.southernautomatic.com l sales@southernautomatic.com

Arent Machinery Co. E P O 352 Worthington Circle Fort Valley, GA 31030 B 503-657-3000 or 800-547-2527 O www.arentmachinery.com r Jay-Dee Arent l jaydee.arent@arentmachinery.com

Southeastern Laundry E P Equipment 1105 Shana Ct. Marietta, GA 30066 B 770-928-0080 or 800-522-9274 O www.selaundry.com r Joe Cole l joe@selaundry.com

Tingue E P O 309 Dividend Dr. Peachtree City, GA 30269 B 800-829-3864 O www.tingue.com l questions@tingue.com

TLC Tri-State E P 1560 Old Clyatteville Rd. Valdosta, GA 31601 B 877-755-3440 O www.tlctristate.com r Keith Quarles l keith.quarles@tlctristate.com

HAWAII

Associate Chemical E C P O & Supplies 810 Gulick Ave. Honolulu, HI 96819 B 808-841-2423

r Clinton C.C. Lee l ccclee@aol.com

Happy Valley Service E P 2696 Kilihau St. Honolulu, HI 96819 B 808-833-0800 O www.happyvalleyservice.com r Victor Flocco l victor@happyvalleyservice.com

Sadd Supplies P O 1359 Colburn St. Honolulu, HI 96817 B 808-841-3818

r Michael C. Sadd l saddsupplies@yahoo.com

WLSN Pacific E T C P O 73-5580 Maiau St., Bay 7 or G Kailua Kona, HI 96740 B 808-896-6454 O www.wlsnpac.com r Francis Wilson l wlsn.info@gmail.com

Happy Valley Service E P 42 Kaniela St. Wailuku, HI 96793 B 808-244-4677 O www.happyvalleyservice.com r Victor Flocco l victor@happyvalleyservice.com

IDAHO

Thompsons Inc. E P O 1707 Broadway Ave. Boise, ID 83705 B 208-344-5179 or 800-881-5179

O www.thompsonsinc.com

r Scott K. Thompson l scott@thompsonsinc.com

ILLINOIS

Laundry Concepts E P 302 S. Stewart Ave. Addison, IL 60101 B 800-845-3903 O www.laundryconcepts.com l info@laundryconcepts.com

D&M Equipment Co. E P O 4822 W. Fullerton Ave. Chicago, IL 60639 B 773-889-5500 or 800-451-2676

O www.dandmequipment.com r Joe Frankian l info@dandmequipment.com

Midwest Laundries E P 2910 W. 36th St. Chicago, IL 60632 B 773-538-7892

O www.midwestlaundries.com l sales@midwestlaundries.com

Washburn Machinery E P 175 Gaylord St. Elk Grove Village, IL 60007

B 847-364-9274 or 800-245-8425

O www.washburnmachinery.com r Jeff Fox l info@washburnmachinery.com

Haiges Machinery E P 11314 E. Main St. Huntley, IL 60142

B 847-669-3300 or 800-542-2828

O www.haigesmachinery.com l info@haigesmachinery.com

Equipment International E P 8778 Ferris Ave. Morton Grove, IL 60053

B 847-679-2211 or 800-364-0657 O www.equipment-international.com l sales@equipment-international.com

Soap Center/ E C P Hales Equipment

1607 Fulton Ave. Rockford, IL 61103

B 815-965-8767

O www.soapcenter.biz r Ben Hales l ben@soapcenter.biz

American Hotel O Register Co.

100 S. Milwaukee Ave. Vernon Hills, IL 60061

B 800-323-5686

O www.americanhotel.com l orderdpt@americanhotel.com

INDIANA

Stanco Industries E 2626 Jefferds Ave. Fort Wayne, IN 46803 B 260-420-2600 or 800-932-3769 O www.stancoind.com r Michael Stanley l stanco2626@aol.com

Cornerstone Equipment E & Rigging 2535 Burton Ave. Indianapolis, IN 46208 B 317-910-5738 or 877-773-1850

O www.cornerstonemachinery.com r Eric Trudo l eric@cornerstonemachinery.com

Haiges Machinery E P 5754 W. 85th St. Indianapolis, IN 46278 B 317-876-8900 or 800-382-4253 O www.haigesmachinery.com l info@haigesmachinery.com

J.P. Equipment E P 4024 Millersville Rd. Indianapolis, IN 46205 B 317-546-7158 or 800-925-3236

O www.ineedjpequipment.com r Patrick Bowers l pbowers@ineedjpequipment.com

Super Laundry Indiana P 2450 N. Shadeland Ave. Indianapolis, IN 46219

B 317-783-6175 or 800-622-4480 O www.superlaundry.com r Stephanie Osta l sosta@cscserviceworks.com

O’Dell Equipment E P 133 Harrison Ave.

14 SEPTEMBER 2019 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com 2019 Distributors Directory

Financing as low as 4.99% for up to 36 months.* CONTACT AN ADC™ DISTRIBUTOR TO LEARN MORE OR VISIT ADCLAUNDRY.COM Trust Your Linens With ADC™. Machines designed to help streamline your laundry facility’s throughput. ®/™ ©2019 ADC. All rights reserved. *This promotion is valid July 1, 2019 – September 30, 2019, and rate may vary depending upon individual credit profile. This promotion is valid for applications received by September 30, 2019, and funded by November 15, 2019.

Jeffersonville, IN 47130

B 812-283-0355 or 800-333-0355

O www.odellequipment.com r Craig O’Dell l craig@odellequipment.com

Meese O

1745 Cragmont St. Madison Heights, IN 47250

B 800-829-4535

O www.meese-inc.com r Dan Rodriguez l drodriguez@meese-inc.com

Ultra Clean Sales E P 2300 W. Wildwood Trail Warsaw, IN 46580 B 574-267-3166

r Wade Frauhiger l ultracleanwarsaw@gmail.com

IOWA

Ross Chemical E C P O Systems

P.O. Box 523 Altoona, IA 50009

B 515-244-1788 or 800-870-2702

O www.rosschemicalsystems.com r Mike Ross l mike.rosschemicalsystems@ outlook.com

Century Laundry E

775 Kacena Rd. Hiawatha, IA 52233

B 319-364-1592 or 800-791-9321

O www.centurylaundry.com r Rod Malcolm l rmalcolm@centurylaundry.com

KANSAS

FabriClean Supply C O of Kansas

14400 W. 97th Terr. Lenexa, KS 66215

B 913-492-1743 or 800-832-0096

O www.fabricleansupply.com l info@fabricleansupply.com

Midwest Commercial E P O

Laundry Equipment

616 E. North St. Salina, KS 67402 B 785-827-9017

O www.mcle-inc.com r Doug Hoeffner l doug@mcle-inc.com

FabriClean Supply C O of Kansas

1040 E. MacArthur Wichita, KS 67216 B 316-529-8555 or 888-432-0433

O www.fabricleansupply.com l info@fabricleansupply.com

KENTUCKY

O’Dell Equipment E P

P.O. Box 3366 Louisville, KY 40201 B 502-584-6100 or 800-333-0355

O www.odellequipment.com l sales@odellequipment.com

REM Co. E P O

P.O. Box 455 Versailles, KY 40383 B 800-292-5070

O www.remlaundry.com r Mark Moore l mmoore@remlaundry.com

LOUISIANA

Commercial & Coin E P O

Laundry Equipment Co. 2965 Nicholson Lake Baton Rouge, LA 70810 B 225-819-7752 or 800-366-4168

O www.clecco.com

r Craig Dakauskas l sales@clecco.com

FabriClean Supply C O of Houston 8666 Kiowa Baton Rouge, LA 70815

B 225-237-3045 or 800-738-7380 O www.fabricleansupply.com l info@fabricleansupply.com

Jim Welsh Inc. E P 1020 LaCrete Ln. Baton Rouge, LA 70810 B 225-766-8905 or 800-348-8905

O www.jimwelshlaundryeqpt.com l welshinc@bellsouth.net

Ideal Chemical C O

3848 Industrial Cir. Bossier City, LA 71112 B 318-746-4358 or 800-231-6776 O www.idealchemical.com r Sam Block Jr. l sblock@idealchem.com

Ideal Chemical C O 5800 Jefferson Hwy., Ste. B Harahan, LA 70123 B 504-733-3531 or 800-233-6776 O www.idealchemical.com r Sam Block Jr. l sblock@idealchem.com

Pellerin Laundry E P

Machinery Sales Co. 731 Jackson St. Kenner, LA 70062 B 504-467-9593 O www.pellerinlaundry.com l sales@pellerinlaundry.com

Pierce Commercial E P O

Laundry Distributors 22258 Marshall Rd. Mandeville, LA 70471 B 800-254-9274 O www.piercecommercial.com

MARYLAND

Laundry Equipment Services E P 13015 Salem Ave. Hagerstown, MD 21740 B 800-866-6905 O www.leslaundry.com l info@leslaundry.com

Laundry Equipment P Repair Service 3241 Lucky Dr. Street, MD 21154 B 410-452-5260 r Charlie Fitzpatrick l lersco@gmail.com

Hynes & Waller E P

16000 Trade Zone Ave., Bldg. 403 & 404 Upper Marlboro, MD 20774 B 301-249-9421 or 800-776-9424 O www.hynesandwaller.com l sales@hynesandwaller.com

MASSACHUSETTS

National Conveyor E P O

& Machine 16 Scenna Rd. Beverly, MA 01915

B 978-927-1281

O www.ncm1.com

r Bob Baker l ncmtextile@aol.com

ERC Wiping Products O 19 Bennett St. Lynn, MA 01905

B 781-593-4000 or 800-225-9473

O www.ercwipe.com

r Valerie Sweeney l erc@ercwipe.com

M&R Machinery Corp. E P 505 Lynn St. Malden, MA 02148

B 781-324-3395

r Robert Carozza l mrmachinerycorp@aol.com

Garment Machinery Co. P

220-20 Reservoir St. Needham, MA 02494 B 781-559-4077 or 800-238-6930 O www.garmentmachinery.com l joriel@garmentmachinery.com

Aristo Craft Supply O

8 Industrial Park Rd. W. Oxford, MA 01540 B 508-987-6444 or 800-875-0479 O www.aristocraftsupply.com l info@aristocraftsupply.com

Super Laundry E P O

New England

61 Holton St. Woburn, MA 01801 B 888-622-4729 O www.superlaundry.com r Stephanie Osta l sosta@cscserviceworks.com

WET-TECH,

Darling’s Sales E P & Service Co. 10007 Baltimore St. N.E. Minneapolis, MN 55449 B 763-786-1803 O www.darlingsales.com r Ralph or Brad Darling l bdar@darlingsales.com or rdar@darlingsales.com

E. Weinberg Supply Co. E C P 7434 W. 27th St. Minneapolis, MN 55426 B 952-920-0888 or 800-279-0888 O www.weinbergsupply.com l david@weinbergsupply.com

O www.jetzservice.com l jetzkc@jetzservice.com

Laundry Solutions Co. E C P O 3509 N. Kimball Dr. Kansas City, MO 64161

B 913-384-5200 or 800-383-9274

O www.laundrysolutionscompany.com r Richard Gaar l rgaar@laundrysolutionscompany.com

Loomis Bros. E P O Equipment Co.

6110 Deramus Ave., Ste. B Kansas City, MO 64120

B 816-452-4115 or 800-783-6665

E P O

The Ozone People 1102 Pleasant St. Worcester, MA 01602-1232 B 610-368-8035 O www.wet-tech.com r Carl Gustafson

MICHIGAN

Allied Eagle Supply Co. E O 1801 Howard St. Detroit, MI 48216 B 313-230-0770 or 800-211-6244 O www.alliedeagle.com l info@alliedeagle.com

Curtis Equipment Co. E P 1410 W. Main (P.O. Box 209) Lowell, MI 49331 B 616-897-9810 O www.curtisequipmentco.com r John Curtis l john@curtisequipmentco.com

A&B Equipment Co. E P 635 Wellington St. Saginaw, MI 48604 B 989-753-4764 or 800-369-4764 O www.ab-equipment.com r Scott Clark l sales@ab-equipment.com

E&N Equipment Co. E P 6492 Malvern Dr. Troy, MI 48098 B 248-866-5500 O www.enequipment.com r Steve Casalou l steve@enequipment.com

Eagle Star Equipment E C P O 2329 Alger Dr. Troy, MI 48083 B 248-457-1140 or 800-482-3400 O www.eaglestarequipment.com l info@eaglestarequipment.com

Universal Laundry E P Machinery 38700 Webb Dr. Westland, MI 48185 B 734-727-0478 or 800-825-7787 O www.univlaundry.com r Mark Hubbard l mhubbard@univlaundry.com

MINNESOTA

The Minnesota E T C P O Chemical Co. 3750 Dunlap St. N. Arden Hills, MN 55112 B 651-646-7521 or 800-328-5689 O www.minnesotachemical.com r Michael F. Baker (ext. 205) l mike.baker@minnesotachemical.com

PROS Parts P 1630 91st Ave. N.E., Ste. 107 Blaine, MN 55449 B 800-359-0628 O www.prosparts.com r Barry Victor l barryv@prosparts.com

Kannegiesser ETECH E P 2090 Elm St., S.E. Minneapolis, MN 55414 B 612-722-1366 or 800-344-0403 O www.kannegiesser-etech.com l sales@kannegiesser-etech.com

Bobco Systems E P O 12713 320th Ave. Princeton, MN 55371 B 763-389-3625 O www.bobcosystems.com l tia@bobcosystems.com

BDS Laundry Systems E P 2430 Enterprise Dr. St. Paul, MN 55120 B 651-688-8000 or 800-688-0020 O www.bdslaundry.com r Karen Ganter l sales@bdslaundry.com

MISSISSIPPI

Dongieux E P P.O. Box 9386 Jackson, MS 39286-9386 B 601-366-2636 or 800-844-3664 O www.dongieuxs.com r John R. Schemmel l dongieuxs@bellsouth.net

Ideal Chemical C O 106 Ware St. Jackson, MS 39208 B 601-932-4920 or 800-824-0356 O www.idealchemical.com r Sam Block Jr. l sblock@idealchem.com

Laundry South E P O System & Repair 2215 Hwy. 80 East Pearl, MS 39208 B 601-420-9414 O www.laundrysouth.com r Robert Harris l robert@laundrysouth.com

MISSOURI

Commercial Coils E P 213 Chesterfield Industrial Blvd. Chesterfield, MO 63005 B 636-532-1523 or 800-532-2645 O www.comcoil.com r Rob Andersen l rob@comcoil.com

Loomis Bros. E P O Equipment Co. 409 Biltmore Dr. Fenton, MO 63026 B 636-343-8888 or 800-783-6665 O www.loomisbros.com r Matt Lamons l sales@loomisbros.com

S.Q.S. Laundry E P O Equipment 410 Silver Maple View Fenton, MO 63026 B 314-941-3120 or 888-443-7180 O www.sqslaundry.com l dllsqs@sbcglobal.net

JETZ Service Co. E P O 3737 N.E. Great Midwest Dr. Kansas City, MO 64161 B 816-454-9274 or 800-530-5726

O www.loomisbros.com r Drew Hoselton l sales@loomisbros.com

Sav-A-Day E P

Laundry Machinery

55 Millwell Ct. Maryland Heights, MO 63043

B 314-291-1910 or 800-489-9274 O www.sav-a-day.com l sales@sav-a-day.com

RJ Kool Co. E C P 234 W. 12th Ave. North Kansas City, MO 64116

B 816-474-9274 or 800-345-4551

O www.rjkool.com r William Kimmel l bkimmel@rjkool.com

Phoenix Textile Corp. T 21 Commerce Dr. O’Fallon, MO 63366

B 314-291-2151 or 800-325-1440 O www.phoenixtextile.com l dzumwalt@phoenixtextile.com

Centraz Industries C 4051 Bingham Ave. St. Louis, MO 63116

B 314-752-7627 or 800-695-7627

O www.centraz.com r Dennis Miller l centrazind@centraz.com

Komro Supply Co. C O 2600 S. 2nd St. St. Louis, MO 63118

B 314-772-4360 or 800-264-6535 O www.komrosupplycompany.com r Gary Thuro l gary@komrosupply.com

John Morris Equipment E P & Supply Co. 2023 S. Glenstone Springfield, MO 65804

B 417-881-1215 or 800-725-5055

O www.johnmorrisequipment.com r Vi Longwell l vi@johnmorrisequipment.com

Laundry Solutions Co. E C P 4629 W. Calhoun Springfield, MO 65802

B 417-862-8464

O www.laundrysolutionscompany.com r Nick Luzecky l nluzecky@laundry solutionscompany.com

Performance Laundry E P O Equipment

4323 W. Chestnut Expressway Springfield, MO 65802

B 417-771-7711

O www.performance-laundry.com