MIP, Encompass Group terminate long-term distribution agreement

MONTREAL — Tor Lund, CEO of MIP Inc., a provider of reusable healthcare textiles, reports that the long-term distribution agreement between the company and Encompass Group LLC will come to an end Aug. 31.

“After many years of distribution partnership with Encompass, we are excited to work directly with laundries, acute care and senior living systems across the U.S.,” he says.

“Working directly with MIP will provide our partners (or customers) with many advantages: direct access to MIP experts, fast response times and the opportunity to work with the MIP team to find the right solutions for their needs.”

Tor says MIP is rapidly expanding its team in the United States and will bring on board more industry experts that “share our passion for excellent customer care and who role model our values on a daily basis.”

“We thank Encompass for their support and advocacy of the MIP brand for the last 19 years,” he adds. ALN

BY MATT POE, EDITOR

BY MATT POE, EDITOR

C C — or l dcock vice president of sales and marketing for laundry e uipment manufacturer B C Technologies installation and operation manuals form the critical bridge necessary to install operate and maintain a new machine eeping the manuals safe handy and available allow the laundry personnel to uickly access information that is re uired to do their obs most efficiently by providing guidelines for most efficient operational techni ues as well as helping to solve issues and explain any error messages in much greater detail than can be found on a typical display he says

uipment manuals can provide laundry and linen services with vital information on their machines along with helpful ways e uipment can be used more effectively if the laundry makes use of the manuals

TOP REASONS/METHODS FOR USAGE OF MANUALS

uipment manuals are useful for a variety

of reasons according to ary a arre vice president product support Pellerin Milnor Corp including programming and parts information simple troubleshooting instructions on how to read schematics and important safety information

Washer-extractor usage

BY MATT POE, EDITOR

BY MATT POE, EDITOR

C C — very piece of e uipment is important in a laundry operation’s plant owever if the goods aren’t washed all the drying and finishing available won’t make customers happy with the uality of their linens key machine in many operations is the washer-extractor properly used machine removes soil from goods along with extracting water to get a head start on the drying process saving money and energy ow can an operator be sure that his or her team is properly and effectively using the laundry’s washer-extractors

What follows are five tips offered by laundry and linen service operators with plants of varying types and si es to help ensure proper washerextractor usage

Panel of Experts

In

Five tips to help operators use washer-extractors most effectively

S T C T — ick Taft looked forward to uly 1

That’s the day he expected a two-phased e uipment installation pro ect to be completed at Textile Care Services

Taft is C and owner of the commercial laundry operation on Salt ake City’s south side can’t wait to turn on the new e uipment he says t sets us up with our healthcare customers in Utah for the next 10 or 20 years

While new e uipment is exciting for any laundry the completion of this pro ect installing avatec aundry Technology e uipment comes after several months of lifechanging events that impacted the business

UNPRECENTED EVENTS

Before Taft could get his pro ect underway a magnitude- earthuake rattled the Salt ake City area on March 1 The epicenter was located about 1 miles west of the facility but did not cause any damage to his building

Before that he was already dealing with the start of the coronavirus C D-1 pandemic

The situation began on March when Utah’s governor declared a state of emergency and reached an unprecedented level three weeks later when the Stay-at- ome order was issued on March 2

The state has since moved to a phased reopening-health guidance plan

NEW EQUIPMENT

s Utah moved into a phased

system to manage the C D-1 situation Textile Care Services was finally able to start a twophased installation process of its

new e uipment

The company says it had 0 years of reliable service from its previous T C tunnel system and decided to continue using the manufacturer Phase one at Textile Care Services involved the removal of a 0-year-old T C P 1 press The 0-bar unit was still operating and replaced with an upgraded and new 1 2-pound energy-efficient SP D P 2 0-bar hydraulic extraction press

This was necessary before phase two and installation of the new tunnel system could begin Phase two has proceeded smoothly to this point says im Slatcher avatec’s regional sales manager for the Western U S The old tunnel system was still producing at a high level and was sold to another laundry operator who will be installing it at his facility later this year n addition to the SP D P 2 press and new T 0 1 -compartment bottom transfer tunnel Taft ordered other new e uipment that is expected to make his facility even more effi-

cient

The tunnel will be connected to six T C TT 2 2-pound capacity natural gas dryers a press discharge conveyor and discharge conveyor system and a two-tiered shuttle system

The TT dryers are e uipped with infrared technology that determines when the linen is dry thereby reducing dryer times and energy consumption ll of it will be controlled by the os aundry management system which is a platform and technology-independent software program that provides operators with uick real-time information allowing them to make ad ustments to daily production data in a matter of seconds or minutes instead of hourly

The company says reductions in electrical gas and water usage costs are expected from the decreased energy re uirements

We looked at e uipment from other manufacturers but we’ve had a great 0-year run and avatec has always taken good care of us Taft shares They are a very good company with good people

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Mathew Pawlak

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

David Barbe • David Carter

Janice Ayers Davis • Nick Fertig

Deana Griffin • Steve Kallenbach Edward McCauley

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions 630-739-0900 x100 www.americanlaundrynews.com

MEMBERSHIPS

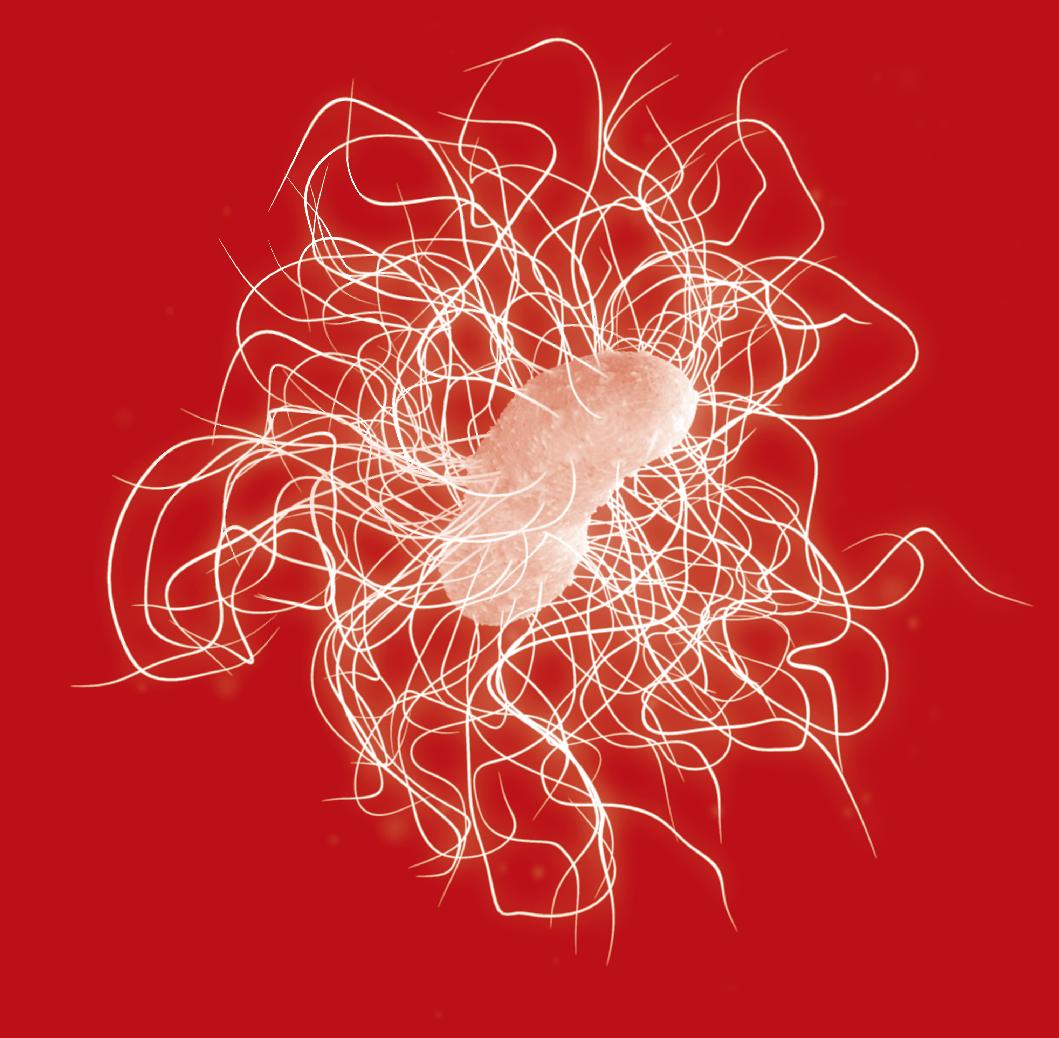

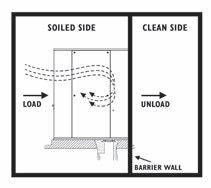

Built to combat infection.

The new Milnor MWB series washer-extractors are built to help decontaminate. Available in loading capacities of 60-200 lb. (26-90 kg), these hospital-grade machines are built with an aseptic pass-through barrier system that reduces the risk of cross contamination by separating soiled linen from clean linen. Automatic safety interlocks on two sets of doors maintain complete separation. Intuitive MilTouchTM controls offer unprecedented insight into your wash, utilizing full color graphic display and resistive touchscreen technology. Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

Going back to basics

E very now and then it pays to go back to basics to review basic skills and processes and evaluate how you’re doing in your profession

That’s true of the laundry and linen services industry and with current world events it’s a good time for operators to go back and make sure the simple important tasks are getting done—and done well

So ’m calling this the American Laundry News Back to Basics issue ust look at page 1 and you’ll see what mean

The first article of the issue looks at e uipment manuals ou’re probably saying to yourself ep pretty basic but are you taking advantage of everything manufacturers include in those manuals

Then there’s the other page 1

The Editor’s Desk MATT POEarticle on washer-extractor usage gain basic stuff but the laundry operators who shared tips for the piece ust might have provided a golden nugget that improves how you use that piece of e uipment

Maybe it’s time to check the finishing side of your business

n page 1 Mike and from C C shares how hotel guests are going to be even pickier about perceived uality in the C D-1 era Wrinkled sheets will be a no-go Maybe you need an e uipment flexibility programming performance checklist for new machines irbau ndustrial’s Seth Willer has you covered on page 1

Besides going back to basics also think this is a time to celebrate success in the industry such as the recent successful e uipment install that took place at Textile Care Services in Salt ake City on page 2—or the expansion at oly City inen on page

So let’s get back to basics celebrate when we can and keep it clean everybody ALN

Processing surgical gowns in a laundry (Part 1)

The ob of a laundry is to take a soiled contaminated reusable item and return it to a hygienically clean state The laundry process is not designed to sterili e the item being washed but rather to significantly reduce the contamination level to an acceptable safe level

wonderful study was conducted many years ago by the Department of eterans ffairs and it determined that the No 1 factor in reducing the level of bacteria or virus on a piece of soiled textile product is the simple act of dilution very time you fill a washer with water agitate it for at least a minute and then drain you remove more than 0 of all the bacteria or viruses on the textile product Most conventional washers will have a minimum of seven fills and drains n processing reusable barrier gowns have always sorted them together separate from any item containing cotton This allows for a uni ue wash formula designed ust for this type of product and also prohibits lint from showing up on the end product

Because of their lightweight nature found it necessary to under-load a washer-extractor by 2 of rated capacity Mechanical action is always an important factor in obtaining clean textile products and under-loading is re uired to ensure proper mechanical action in the wash load

C UMB S C — oly City inen a commercial laundry service company reports it plans to expand operations in Charleston County The company’s 12 million investment will create 2 new obs

The company had planned to open a new 000-s uare-foot facility in North Charleston on Memorial Day The new facility which broke ground in September was originally a million expansion designed to handle more than 20 million pounds a year and add 0 full-time obs

The opening which was reported by American Laundry News in

ebruary was delayed by the coronavirus C D-1 pandemic owever instead of losing business owner nn Son says interest in the operation allowed her to increase the expansion

Since your article was published and C D-1 we have had a tremendous amount of interest from the medical sector which also increased the proposed ob creation numbers she says There was an increase in materials but also it includes additional e uipment that we added and a rail system ounded in 201 in Mount Pleasant oly City inen provides

a uality eco-friendly commercial laundry service throughout the Charleston area

This expansion will allow oly City inen to further its mission in providing a hygienically clean product and uality commercial laundry service in an eco-friendly manner Son says

The second facility will be located at 12 emount oad in North Charleston oly City inen says the increase in capacity will allow it to meet growing demand in the medical and hospitality industries

Son says the expansion is expected to be online in ugust ALN

The next uestion is how prevent stains and remove soils that are inherently found in the surgical suite like blood fat oil and medicine Blood is the easiest item to remove from the textile product as long as you follow this guideline The initial rinse must be under 120 nything over that temperature will cause the blood to set and make a stain

Blood becomes more soluble the closer it gets to 120 degrees My mother always told me to use cold water to rinse out a spot of blood on a shirt but warm water works better and faster s a precaution to avoid any residual blood from setting in future wash steps recommend adding a little alkali to the first rinse Blood will not set in the presence of alkali

The hardest stain to remove from a microfilament highthread-count gown or a tri-layer laminate is oil These fabrics love oil My recommendation to handle this problem is to use a solvated detergent in the first rinse and to run that rinse for at least five minutes nce the temperature goes above 120 degrees the solvent will become ineffective

Traditional laundry procedures would call for large amounts of alkali to be used to remove the oil Barrier fabrics will be damaged by high concentrations of alkali therefore they should be avoided recommend washing barrier fabric in conventional washers only The use of a hydraulic extractor on the end of a tunnel is not good for the fabric and this type of fabric does not make a good cake which will not transfer well from on the press to the dryers

The most important reason is that proper wash formulations for this type of product is difficult to maintain in a tunnel based on the natural water reuse system built into the e uipment t is key for the processor of reusable barrier fabric to reali e that the fabric does not absorb any chemicals and that every surfactant that you use in the wash process must be completely removed to ensure proper barrier performance n washing these textile products using less is very desirable Therefore the wash formula needs to contain a number of rinses and at least one intermediate extract Proper rinsing is the key to good barrier performance

’ll finish this next issue with more thoughts on chemistry extraction drying and inspection ALN

Eric Frederick served 44 years in laundry management before retiring and remains active in the industry as a laundry operations consultant. You can contact him by e-mail at elfrederick@cox.net, or by phone at 540-520-6288.

I recently received this uestion from a military reader

“Do you have any guidelines/specifications for processing and sterilizing reusable surgeon gowns?”

manager of technical support for Dexter aundry They are used to walk operators through installation, manual programming, preventive maintenance, troubleshooting, larger service procedures and parts identification

Tony Schult service director for annegiesser T C adds n our experience, the main purpose is for operators to utilize the manual information to safely and efficiently maximize uptime and minimize downtime of e uipment

Adcock believes one of the most valuable portions in an equipment manual is the routine maintenance chapter, which describes preventative maintenance steps to be performed on a daily, weekly, monthly, quarterly, semi-annual and annual basis.

nsuring that these steps are completed in time will add years of life to the machines, as well as significantly reduce any unplanned downtime in the laundry, again adding to the efficiency of the laundry’s operation he says

Another valuable segment Jeanne George, inside sales manager for Rennco, sees included in manuals is a parts listing with exploded views that offer listing of parts on the machine in the event a replacement part is needed

The NS N US Service Team agrees, saying equipment manuals are valuable for referencing electrical schematics and spare parts.

t is almost impossible to troubleshoot issues without the wiring diagram the team says When a customer calls in for phone support, and that is the first question asked, our helpdesk will ask customers Do you have the electrical schematics ’

This is to ensure both parties are on the same page and our helpdesk can explain machine function— that what should be happening compared to what is actually happening

We find that our customers utilize their machine manuals when they are unclear of a process or procedure necessary to complete a specific non-routine task says Douglas Konke, professional service director at Miele nc r they need to understand what steps they should take to correct an unknown operating issue.

We always recommend that customers go through the manual to make sure they understand the extensive capabilities of a Miele machine and to ensure they can get the most operational efficiency and flexibility out of their systems

Rick Gaston, technical support department manager for Miura merica Co offers straightforward advice for when customers should use their manuals When installing the boiler system, when first starting up the boiler system, when configuring auxiliary equipment to

the boiler system, when there is a problem. Following the correct procedures have seen in plants that operator staff use manuals in all different ways, from helping to fill out an online preventative maintenance program to propping a door open and everything in between shares Bob Fesmire, president of llis Corp

OVERLOOKED USES

f a manual is used as a doorstop, as Fesmire shared, then the laundry operation is overlooking everything the manual has to offer.

owever many operations aren’t that extreme, but they are often missing out on the full value of the manual and the machine.

ike buying a new car very rarely does anyone read the owner’s manual cover to cover do but ’m an exception says Dave McAllister, director of services and project management for Girbau ndustrial We often ust reference these manuals when we have a feature we don’t understand or want to shut off a function like the auto door lock or have to navigate a roadside emergency like changing a flat tire.

The same applies to laundry equipment servicers and operators, as they most often reference manuals when there is a problem with the e uipment This reactive use’ often results in longer equipment downtime while the proper information is being located and distilled.

nstallation operation and maintenance manuals don’t have to be a reference we just use for emergencies. A better way to manage this documented knowledge is to be proactive. Designate some time for technicians or operators to review and refresh their knowledge They will find key information that can help maintain a safe and smoothly running operation

Most operators do not refer to the manual often enough before troubleshooting problems adds Ware Manuals should also be used in staff training, operating parameters and production performance We often ask customers who seek our support, did they review the manual and follow the

troubleshooting steps we provided

e points out that many operators of older e uipment often don’t have access to manuals because they are locked up in the general manager’s or engineer’s office

Some operators do not reali e that by not following certain procedures or buying specific parts, this can invalidate your warranty Ware points out During the warranty period, some operators have installed improper or nonfactory parts This will often invalidate your warranty and can lead to much more expensive repairs in the future

wning e uipment for several years and expecting that equipment to perform means that regular maintenance is necessary shares Cooper

The e uipment manuals lay out in detail exactly what procedures are required and how often to do them to make sure your washers and dryers are performing at their peak efficiency. Failure to do this not only develops into costly service, but in a loss of much-needed production through that machine

Another overlooked benefit of equipment manuals, according to McAllister, is that safety warnings can be copied, laminated and posted for employees to review when hired and then as a regular part of ongoing safety training. Machine specifications and maintenance procedures can be used in the same manner.

t sounds odd that you would want a copy of the machine specifications, but you will most likely be asked several questions regarding installation, utilities or operation when you contact a manufacturer for support he shares nd they will reference back to the machine specifications if they believe there is an issue with the machine’s connections or installation that are causing the performance issue or failure ne thing operators could do is write the model and serial number to that specific piece of equipment in the manual, as this always helps when calling the manufacturer for help shares Dan arnsworth vice president of sales for Leonard

Automatics.

ulie Socha technical documentation and digital services manager at lliance aundry Systems adds that laundries can use the manual to provide references for employees on errors.

or instance simple errors can be uickly addressed by reading the programming manual to avoid downtime of the e uipment she says.

Carol Tyler director of marketing for Chicago Dryer Co says that along with troubleshooting and repair the company’s manuals also cover installation, operating guidelines, preventive maintenance and operating principles.

We try to provide as much useful information as possible to help keep the machine operating at its highest efficiency she says etting to know the machines ahead of time, taking care of them using the preventive maintenance schedule and learning proper technique can go a long way toward keeping production high and downtime low, as well as extending life of the machine ne benefit d ire c yk president of Sea-lion merica Company sees operators missing out in terms of using equipment manuals is understanding the theory of use in the intended design of the equipment.

Miele offers high- uality engineering, but operators may realize poor results if they don’t gain a basic understanding of the machine and its operations before using it adds onke n fact when a customer or client goes through the manual and/or is given user training on a Miele product, we see as much as a 40% reduction in calls for to our service center technicians in the first year of operation

The team at Systems US also says that overall knowledge of a machine’s capabilities is often overlooked or forgotten about This is sometimes due to the fact the machine may have been needed for a specific purpose, and its flexibility is under-utilized.

When there is a problem many operators choose to call a specialist or call the company to talk through the problem, when they might be

able to troubleshoot with the manual shares aston es maybe also ust general maintenance ur manual provides details about water samples blowdowns etc

PHYSICAL MANUALS

There are many ways e uipment manuals can be used to the benefit of a laundry operation, and that means if an operation has a physical copy of the manual, then it has to be accessible to staff.

eeping the manual handy and available is of utmost importance dcock says Placing all manuals in a binder which is stored near the machines, perhaps in the laundry manager’s office is best practice

eplacement manuals are easily found on the manufacturer’s website, but one may need to contact the company with the machine’s serial number to ensure that you have the correct version for your particular piece of e uipment

Tyler recommends keeping manuals someplace conveniently located near the machines for easy reference.

n enclosed shelf to protect them helps too she says ften they are held in an engineering office f this is the case visibility is key to keeping them accessible

According to Konke, the key to storage is that it is clean and free of moisture or excessive temperatures.

Some operators might find a plastic file folder secured to a nearby surface does the ob he says That said some operators may store all machine and equipment manuals in a central file system or with their maintenance departments if they exist

The NS N US Service Teams also recommends laminating important pages, such as safety the programmable logic controller P C input list a list of inputs and outputs by module, and maybe belt specification for quick reference.

Tab important sections of electrical drawings (emergency stop, inputs outputs P C rack and parts list suggests the team

We have found that printed manuals seem to never be by the equipment, so we have been putting the manual documents on a USB drive that can be stored in the electrical cabinet for easy access from any computer says eorge We are also in the process of putting some details in the M human-machine interface so it’s very easy to access

Fesmire recommends having two copies of each manual, one in an engineering office and one in a manager’s office

We also recommend keeping a digital copy of the manuals he says This makes searches of the manual faster when looking up keywords, also the digital copy can be reprinted as necessary.

ELECTRONIC OPTIONS

Fesmire mentioned digital equipment manuals, and George brought up files on a USB drive n

KEEP THEM SAFE

THE RIGHT CLEAN MATTERS

Now more than ever, laundries must continue to ensure the health of their staff and customers through precise laundering. Whether you have an existing or new washer, Girbau Industrial has the adaptability to meet all recognized laundering standards. Available in capacities up to 255-pounds, Girbau Industrial washers deliver complete control over chemical dosing, water levels, number of baths & rinses, extract speeds and rotation action. All washers are ozone & UV disinfectant compatible and through auxiliary electric heat kits can be adapted to hit and hold up to 192˚F water without upgrading your hot water system.

Tools f the Trade

Innovative solution to ensure laundry disinfection released

fection as it ensures compliance with the parameters necessary for proper textile sanitization and, in addition, allows data to be stored and sent to owners.

Girbau NA says that through Sapphire, the DMP shows, in real-time, the evolution of machine wash cycles with details of temperature, water levels and cycle phases. It allows the owner to quickly configure cycle conditions—including those for disinfection compliance—and verify that all cycles have met the disinfection parameters previously stipulated by the customer.

Girbau North America reports it recently developed and released the COVID-19 Disinfection Monitoring Package (DMP), a module that works in concert with Sapphire laundry management software to monitor and verify disinfection of washed textiles.

The company says DMP was innovated by Girbau Global Laundry Solutions to address the immediate need for disinfection and hygiene within laundries across the globe. Available on all Girbau NA on-premises and industrial washer-extractors, the company says DMP comes as a result of its targeted effort to help counter the COVID-19 pandemic and stop the spread of infection.

Sapphire greatly facilitates the management of a laundry, reporting irregularities and reducing costs and downtime. It also plays a crucial role in disin-

It also makes it possible to remotely manage all the parameters of the wash cycle, including temperature, water level and cycle phases, or to carry out detailed monitoring with the recording of the entire cycle history.

Moreover, the company says DMP provides the option of creating custom disinfection criteria based on the time and temperature for each program on each machine—adapting to the specific needs of each laundry.

In doing so, it displays a summary of the disinfection rules and conditions created by the user.

Laundry managers can then run a report to see if any program or machine does not comply with the established parameters set for disinfection. In the event that the washing cycle has not fulfilled a disinfection condition, the user is alerted with a notification.

www.cgilaundry.com 800-256-1073

safe, secure

Ecolab reports that its dvaCare Disinfectant has received the first approval given by the U.S. Environmental Protection Agency (EPA) for a laundry disinfectant and oxidizer emerging viral pathogen claim as effective against SARS-CoV-2, the virus that causes COVID-19.

dvaCare Disinfectant is an P -registered laundry disinfectant— registration number 1 -1 —and the concentrated formulation is permitted for use in commercial and industrial laundry operations.

The current U.S. EPA-approved master label for AdvaCare Disinfectant now contains use directions for emerging viral pathogens, such as SARS-CoV-2, and Clostridium difficile (newly named Clostridioides difficile) at an attainable daily use level for all textiles laundered in a commercial laundry.

The disinfectant is listed on the P ’s ST N website www.epa. gov/pesticide-registration/list-n-disinfectants-use-against-sars-cov2-covid-19) for products that can be used against SARS-CoV-2. www.ecolab.com 800-553-8683

Flexible drainage hose system launched

Crushproof Tubing, a manufacturer of high-grade rubber products used in the military, aftermarket automotive, and breathing markets, reports it has launched its Flex Flow flexible drainage hose products.

Plastics rotomolder Meese reports the availability of its newest innovation, the Cargo Closet. The company says it is uniquely designed to haul and store just about anything easily, safely and securely. A heavy duty, multifunctional, material-handling product, it can be easily maneuvered due to the hand truck wheels and molded-in grips. Its built-in garment bar allows for convenient and easy hanging of any item.

Meese adds that the flip-top, lockable lid means the user can be assured the items are always safe and secure. The ergonomically designed deep opening of the lid (like the 72 ERGO) makes loading and unloading easier, minimizing the potential for injuries and workers’ compensation claims. www.meese-inc.com 800-829-4535

Flex Flow drainage hoses are made from a solid EPDM rubber that is durable, delivers outstanding performance and is unaffected by UV light, ozone, detergents, bleaches and high temperatures.

The company says Flex Flow drainage hoses are able to do what P C can’t—flex to fit in tight and confined areas and install in less than 45 seconds.

Crushproof Tubing says that overall installation time and cost will drop dramatically when compared to hard PVC pipe. Flex Flow can wrap around poles, make tight turns and conform to odd angles.

The company says that Flex Flow hoses eliminate all the extra steps to install as many as a dozen machines in the same amount of time it takes to install one PVC unit.

www.crushproof.com 419-293-2111

Gurtler Industries says that laundries can now choose to saniti e or disinfect with its alidox or alidox Plus products The company says that with Validox sanitizer, laundries can reduce the bacteria present by 99.9%. With Validox Plus disinfectant, laundries can reduce the bacteria present by 99.9999%. Validox is registered with the U.S. Environmental Protection Agency (EPA) for use in commercial,

institutional and industrial laundry operations for sanitization, says Gurtler. It is registered as a laundry sanitizer and a bleach brightener that is gentle on fabrics.

Validox Plus is registered with the EPA for use in commercial and institutional/industrial operations as a disinfectant, according to the company. At lower use levels, Validox Plus is also registered as a laundry sanitizer.

The Gurtler Rx Program that now includes Validox and Validox Plus continues a long track record of delivering compliance with TRSA and other microbial laboratory measures of certified hygienically clean textile results, the company says.

www.gurtler.com 800-638-7300

Manufacturers: Have you introduced a new product? Revamped your system? Released a new catalog? E-mail your product news, along with a high-resolution image, to mpoe@atmags.com and we’ll consider publishing your news free in Tools of the Trade.

Laundry disinfectant, oxidizer receives EPA approval for claim as effective against COVID-19 virus

New cargo closet said to make hauling items easy,EPA-registered laundry sanitizer, disinfectant introduced

Manuals

today’s technologically advancing world the trend is for manufacturers to offer some type of electronic and or online manual

With today’s available technology and the cost of the asset e uipment the operator is investing in manuals training and troubleshooting need to move into the next generation says esmire t is harder and harder to find and engage young engineers in our industry We must meet them where they are which is in general a real engagement of technology

Ms original e uipment manufacturers need to meet the new generation coming into our industry and also help owner operators protect their sophisticated assets

With the influx of big data and the nternet of Things oT Sealion has migrated to digital documentation for a ma ority of their e uipment particularly e uipment that is networked into integrated systems shares ire c yk This has also resulted into remote access for a variety of uses including monitoring programming and troubleshooting

The team at NS N US says manuals are shifting to either online or on a disc that is supplied with each machine

This allows for the end-user to keep digital copies on PCs or mobile devices for safekeeping the team says f they chose to have printed copies they are able to print as many copies as they desire The digital versions on mobile devices allows for the engineering team to be in front of the e uipment and view the manuals on their tablets or cell phone

Ware says that many machines also have manuals stored in their operating systems and can also show trends of faults including downtime so the engineer knows what the symptoms are before they look at solving the problem or example we had a location that kept trying to fix the press and speed up its program to get more throughput he shares fter our team reviewed the results of the fault log it showed that the press worked fine But it was the lack of dryers on the system that were making the press wait to proceed so the problem was not with the press

a arre notes that print manuals are static meaning that updates made after the manuals are produced won’t have the new information

Static manuals are also generally light on troubleshooting information he says Therefore Milnor has created an online Technical nowledge Base which we recommend be used as a starting point for any information needed by an operator or technician

ur digital database allows us to expand beyond the machine manuals by providing corresponding articles and video tutorials on a wide variety of topics We have found that most of our users prefer pictures and videos compared to the written text nline manuals are also available and we offer those to our dealers for distribution to our endusers These assist with finding data by electronically searching the document We also distribute them as re uested when helping end-users directly

Schult points out that operators can utili e the digital manual infor-

mation by inserting pages or links into their maintenance software CMMS system

Most PM systems now are cloud-based and can be easily accessed by mobile devices he says ou can place labels on your e uipment that can be scanned and instantly show operators the PM steps troubleshooting procedures safety info parts lists how-to videos etc s more companies take their manuals into the digital world some re uire a login password to access it for customers only says Ware Make sure your team has knowledge of the method in which

to log in t is also recommended that operators keep a folder to links for the information that is accessible to anyone who will be using the product onke adds

The team at Systems US notes that manuals can be electronically sent via PD or similar format for storage best suited to the laundry’s needs ur manuals are not yet fully online but we do provide interactive PD s with each hardcopy that ships with the machine says Tyler aving these PD s in a digital library or accessible on devices can be especially useful for the engi-

neers and maintenance personnel digital library is helpful in large facilities where physical storage could become too difficult to manage aving the library on mobile devices or tablets allows the entire collection to travel with the user and can be less cumbersome than the physical binder especially when performing maintenance or repair procedures

digital version makes searching for content a much easier process agrees Socha n addition paper copies can become lost ruined or take up desk space

The Braun Medicare Top Side Loader Washer/Extractor

Braun

If

Braun Medicare TSL Washer/Extractors are available with dry load capacities of 200, 400, 600 and 800 pounds. Unlike others this machine can be sling loaded and features an automated door.

Learn more and see it in action visit gabraun.com Made in the USA | ISO 9001 Certified

The leading ergonomic split-pocket design since 1965!

Harmful Bacteria and Pathogens have met their match.

Manuals

Digital versions are always available and create less waste

My recommendation is to save a tree and forget the paper manual says Cooper aving a tablet or laptop not only allows you to view the manuals but also to view a whole range of service videos and troubleshooting support

THE KEY: TRAINING

While the use of an e uipment manual may seem fairly straightforward employees will be better able to take advantage of the informa-

tion with training. While technical in nature our chapters are often written in a narrative style with the intent to make the information accessible says Tyler The goal is to educate users at all levels from maintenance engineer to machine operator to understand and respect the machine so that both it and they can get the ob done safely and effectively or facilities with multiple generations of machines it is important to identify and use the correct manual for each piece of e uipment to ensure safe machine operations and maintenance

Schult points out that some manuals are extremely lengthy and overwhelming and some manufacturers

provide uick reference guides for fre uently used information

But if you don’t have them and you have time it’s a good training and learning exercise for your maintenance team to create the uick reference guides he suggests t annegiesser T C we provide online training sessions and webinars in which we train using the e uipment manuals to familiari e your maintenance team on how to utili e them

ach customer facility will have different types and hours of use onke points out Miele recommends that they read through the information and have a clear understanding of how they want to utili e the e uipment and align the right use and care needed to opti-

mi e results and longevity e also recommends making notes and highlighting what affects the operation specifically nd always proactively ask uestions of the manufacturer about the operation rather than waiting until there is an issue onke adds

ead it when you get it and place tabs where there is important information aston says Many operators do not read the manual and then ust call someone when there is a problem Many times the manual will have a troubleshoot chart or some important maintenance procedures that are easy to follow and do and will save you time and money in the long run esmire agrees that maintenance

personnel should have familiari ed themselves with the manual and the training material before having to operate and repair a machine nsure all maintenance personnel know where to find the manuals either the paper version or digital version he stresses

Next time an employee asks you something specific about the e uipment they use take the time to share the manufacturer’s published information suggests Mc llister Manufacturers stress that they are here to help operators use their machines properly and efficiently

When in a pinch have your manual handy but please call the manufacturer for help says arnsworth That is what we are here for ALN

NO. 1—GET LOADS RIGHT

That was the first tip out of the mouth of Tommy Cocanougher from Cintas Corp.

et your loads right stresses the director-operations engineering for the Western U.S./Western Canada in Tulsa klahoma Underloading and overloading both wind up not only costing you money but time rewash and uality results

Properly loading washer-extractors was the main thrust of every laundry manager operator contacted for this article

Don’t stuff the machine too full says nn Son owner of oly City inen in Charleston South Carolina t’s hard to get good agitation and definitely harder to get everything out including the

laundry when it’s done felia lman a plant manager of Puget Sound aundry Services in ent Washington says her operation follows the C M Program training manual when it comes to loading washer-extractors including filling the machine with 0- 0 dry linen and verifying extraction efficiency ver-loading and under-loading will impact the extraction she says ollowing these tips have given us not only greater production efficiencies but have also helped with utilities aving a good extraction in the wash means less drying time len Woods corporate production manager for Prudential verall Supply in rvine California says that it’s important to ensure load weights are correct before goods enter the washerextractor

When managing a wash alley one of the most often overlooked processes is inaccurate sling

weights he says The chemical providers construct the wash formulas with a small variance of the target wash weight nconsistent sling weights will then contribute to inaccurate wash weights

Woods says washing to the correct target weight is important because underloading or overloading machines changes the mechanical action of the e uipment

Changing mechanical action then re uires one of the other variables of the washroom pie to compensate for this he says verloading a machine will ultimately lead to the soil on the merchandise not being properly removed

Under-loading a machine loses potential washer capacity and subse uently the merchandise will receive too much mechanical action potentially damaging the merchandise Pro-tip audit your sling weights often Cocanougher adds Work with your manufacturer and wash chemistry suppliers to determine

Clean 2021 booth sales open

T NT — The 2021 Clean Show presented by Texcare is accepting booth space contracts from all 201 exhibitors for the show here une 10-1 Space is assigned on a first-come firstserved basis Sales will open to all other companies interested in exhibiting this fall

ll exhibitor information can be found on the Clean Show’s website the-cleanshow us messefrankfurt com us en html With the online xhibitor Prospectus interested exhibitors can view the floorplan select sponsorship opportunities for additional exposure explore rules and regulations and download the contract

ttendee registration for Clean 2021 is scheduled to open in November

Clean 201 attracted more than 11 000 total industry professionals and 2 exhibiting companies The event was a huge success garnering rave reviews and making it to No on Trade Show News Network’s list of The Top 2 0 Tradeshows in the U.S.

The 2021 tlanta event marks a transition as it will be the first Clean Show fully produced by Messe rankfurt The ermany-based trade fair organi er purchased Clean in 201 from the five associations that sponsored the show for decades and retained longtime show

manager iddle ssociates to manage Clean 201 ate last year Messe rankfurt announced via e-mail that it planned to update the overall look and feel of Clean for 2021 but that no significant changes were planned at the time.

The Clean Show is organi ed in collaboration with five industry-leading associations ssociation for inen Management M Coin aundry ssociation C Dry-cleaning aundry nstitute D Textile Care llied Trades ssociation TC T and T S the association for linen uniform and facility services ALN

the best way to maximi e load si es and minimi e issues

f you find you are running a large number of half loads or have smaller loads then get an appropriately si ed supplemental pony washer

NO. 2—STAY ON TOP OF MAINTENANCE

Second on the list is to keep washer-extractors in the best working condition

The maintenance and reliability tasks indicated by the manufacturer are key to keeping your machine producing as it was intended to produce shares Cocanougher.

e stresses the importance of completing recommended PMs preventative maintenance and recommends dealing with any issues discovered with the e uipment without delay

Without your washer-extractor running as the manufacturer intended you’re bound to see a negative impact on operations costs safety uality and productivity Cocanougher points out

NO. 3—MAKE EMPLOYEES EXPERTS

While PMs are important e ually important is knowing that a washer-extractor is functioning properly at all times nly the employees running the machine can know minute-to-minute if everything is right with a washer-extractor

Train your operators to be experts in the knowledge of how the machine should run look sound and produce says Cocanougher ive them ownership of keeping the machine clean and turning loads uickly They will be your first alarm source when something is going awry.

So the better they are at knowing what to expect the better you’ll be at the end of the day with all e uipment running as expected

NO. 4—USE PROPER FORMULAS aundry and linen services

need to use the correct wash formulas to process goods This formula is guided by a pie chart giving e ual weight to time temperature mechanical action and chemical

s Woods mentioned earlier when one part of the washroom pie is altered the other three factors need to be ad usted for proper washer-extractor usage perators need to check their formulas to ensure that proper e uipment usage and processing of goods is achieved

et with your chemical provider and make sure you are using the proper formulas says lman a

See if you can ad ust or decrease your rinses in between cycles so you can save on water Son adds UN has been helped me develop special programs

NO. 5—ENSURE MANEUVERABILITY

inally while it may not seem as important as loads maintenance and formulas it’s important to use washer-extractors in a way that makes it as easy as possible for employees to maneuver the goods n in ured employee expert or one struggling with sheets and towels and so on isn’t helping the work get done on time and in a uality manner

s Son mentioned earlier washer-extractors loaded too full make it difficult to get the laundry out of the machine when the cycle is complete

Use net bags for small items that may get lost ’ she adds dd an extra small load program for half loads

When pulling out towels grab the ones from the top first ravity will help with loosening them up making it easier to unload

Properly using washer-extractors is all about balance and maintenance By reviewing loading PMs training formulas and maneuverability operators can help assure their e uipment is being properly used—to the benefit of everyone involved

Study shows hospitals can exceed FDA guidelines for cleaning, disinfecting beds, mattresses

Laundering removable bed barriers shown more effective at reducing hospital-acquired infections, keeping patients safe

C NC NN T — peerreviewed study recently published in Sage ournals’ Infectious Disease Research and Treatment publication found that cleaning and disinfecting mattresses by using removable launderable bed barriers is more effective at eliminating bacteria that cause C diff M S and coli than manual processes using chemical disinfectants

Trinity uardion maker of the Soteria Bed Barrier—a removable and launderable bed barrier— sponsored the study

The company says the findings indicate a new much-needed industry best practice for hospitals to adopt to keep patients safe— especially in today’s C D-1 reality as more patients begin to re-enter hospitals and resume elective procedures

Most hospitals currently conduct a manual one-step process of cleaning hospital beds and mattresses despite being off-label use of the disinfectant and the manufacturer’s multi-step instructions for cleaning and disinfection according to Trinity uardion

The company adds that studies have also shown that mattresses which are difficult to disinfect contribute to the high rates of hospital-ac uired infections s in the United States

These concerns prompted C an independent nonprofit organi ation improving the safety uality and cost-effectiveness of care across all healthcare settings to cite mattress contamination as one of its top health ha ards in both 201 and 201

We evaluated the effectiveness of the commercial laundry process under extreme test conditions using high concentrations of soilage blood and urine says dmond ooker MD DrP an epidemiologist and practicing physician who co-authored the study aundering the removable bed barriers eliminated every ma or organism that contributes to s—when the fabric was tested both at the beginning and end of life of the barrier

The findings are both significant and timely as hospitals grapple with growing concerns about patient safety and how to prevent the spread of C D-1 and other diseases The time is now to take action and protect patients with this evidenced-based approach to cleaning and disinfecting

The commercial laundry process detailed in the study provides detergent bleach agitation and repeatability These elements allow bacteria and spores to be physically separated from the bar-

rier surface The chlorine works to kill residual organisms Multiple rinse cycles allow the microorganisms to be removed from the washing machine

The current state of cleaning and disinfecting beds and mat-

tresses is dangerous because it can leave residual bacteria that can be transmitted from patient to patient says rdis oven MD Professor of Medicine at the University of entucky and an infectious disease consultant

to the entucky Department for Public ealth owever laundering removable bed barriers provides an alternative t eliminates issues with insufficient removal of pathogens from the patient surface

Unlike the commonly used manual process it exceeded D guidance on this type of device ospital administrators must translate this new knowledge into action to protect the patients and families they serve ALN

PANEL OF EXPERTS

Employee motivation—and celebration

when downtime was factored in, was huge.

There are a couple downsides to the bonus system that I feel I should mention.

Piece work is a tedious job whether it is performed in a laundry or on an assembly line of an automotive factory. Keeping workers engaged in these jobs is a challenge for all industries.

Fortunately, since this is an issue that faces so many industries, there are many resources available that can help you decide the best method to implement in your plant.

It all starts with tracking and giving feedback to your employees. If an employee does not know what is expected from them, they cannot maintain any type of motivation to improve. Trying to tap into an employee’s internal pride is the basis for production improvement. Some employees need very little motivation, while others require more effort.

Once you have established your expectations and tracking methods, then there are several methods that you can use to keep employees engaged in the job, following are a couple that we have used over the years:

1. Bonus for reaching numbers. There is no doubt that giving bonuses for achieving high production numbers is very effective.

On the surface, this seems to be the easiest form of increasing production and rewarding employees who get their numbers. It does require a solid tracking method and strict rules on how the bonus is paid.

Piece numbers are easy to get, it is the tracking of any machine downtime, either from equipment breakdowns or lack of product, that can tie up a supervisor’s time and can lead to unethical bonus pay outs.

There are quite of few solid tracking systems out there that can help you monitor this. We put our electronic system in because of the unethical numbers we would get when we made all calculations by hand. The bonus paid for employee that threw 5,000 sheets in 7.5 hours versus the bonus they received for throwing 5,000 sheets in 6.5 hours,

Ergonomics. When an employee figures out that they get their best numbers when they are throwing blankets from their right side, they get to where they don’t want to either rotate out of that job or throw blankets from the left side. This will eventually cause a repetitive motion accident and then both the employee and the company lose in the long run.

Overtime rules. When you are paying a piece bonus, then you really need to pay a higher amount for the piece bonus that was earned when the employee was working in an overtime state. This naturally can become a tracking nightmare. NOTE: I am not a labor lawyer, but if you are considering this methodology, I would certainly reach out to one.

2. Real-time electronic coaching. This is my preferred method. Each employee has an individual counter that tells them whether they are reaching their standards or not.

I prefer the system to give the feedback via the color of their lights—red if they are below standard, yellow if they are close to being too slow, and green if they are at the correct pace. Most systems allow for you to have a separate standard for each employee. A new employee cannot produce as fast as experienced employee.

We try to analy e an employee’s numbers each week and change the target count accordingly. If an employee is always in the red or always in the green, then the target number should be adjusted. Keep the target number to where they are constantly working to stay in the green or out of the red, this will help keep them engaged.

many good examples in plants of people being celebrated for their work.

I can say that for us at Ellis and Ludell, we do our best to rotate jobs and cross train as much as possible. This way our people kept active in learning multiple tasks. This is good for our people and for the company in that no one person only does one task.

To that end, we created what we call a Skillset Matrix. This rates people 0-4 on every task in our plants, with 0 being no experience and 4 being they have skills to teach others.

Some people push to learn more; some we ask to learn more. t depends on the person’s motivation.

The different levels also mean more pay, so if they wish to get paid more, they need to learn more. It helps us in taking away personal bias that can naturally occur.

We can all do a better job of public recognition, but when done properly and in the right intervals, it is a great tool for employees and, frankly, the right thing to do as well.

business licenses, association membership certificates, accreditations, sponsored sports teams and photos of the business going back to when laundry was delivered by horse drawn carriages.

Among these was one of those motivational Successories posters this one showing a small stand of trees standing apart from a larger forest. The sun shone between and among the trunks of the small stand of trees, each casting a long shadow on the grassy meadow in the foreground.

Beneath the photo was the word collaborate in all caps and a slogan that stuck with me t said to stand apart from the competition, you must first stand together as a team sn’t that the truth

Don’t get me wrong there is no management challenge that can be solved through the use of posters or signs alone, particularly the challenge of employee recognition and motivation. If that were the case, parody web sites like despair.com would not be selling spoofs of these ubiquitous motivational posters.

That said, there is wisdom in the thought expressed by that poster in the laundry company waiting room, especially in troubled times during which people need to feel welcome, appreciated and part of a greater effort.

food to teams to reward and to help keep them motivated.

Many of you are already familiar with how a simple pizza party, barbecue or morning doughnuts can help put a spring in your employees’ steps Take these efforts further by, for instance, cooking up and serving those burgers and dogs yourself, surprising the team with popsicles or a sundae bar on a hot day or serving up hot cocoa don’t forget the marshmallows) in to-go cups as your team heads home on a wintry afternoon.

Many companies give their team members cards or send them emails to recognize birthdays and work anniversaries. Too often, however, these conventional means of recognition can seem impersonal and insincere, especially if the employee gets the same card or e-mail yearafter-year.

Instead, consider making the celebration more personal by matching the card or e-mail (or birthday cake to each team member’s interests, hobbies, families, upcoming vacations, etc.

But David can hear you saying what if don’t know about each of my team member’s interests or hobbies That is an excellent question, and I am glad you asked.

Several years ago, I had the pleasure of touring the headquarters of Zappos.com near Las Vegas. While you might think that their business is about shoes, any Zappos employee will tell you that their business is about people, culture, and service, and that if you want to build great customer service, and deliver happiness to both consumers and team members, you need to know your people.

Being in manufacturing of large capital equipment, we have some tasks that are repetitive, but nothing compared to feeding napkins into an ironer all day. I see

Several months ago, I found myself in a client’s waiting room waiting for their previous appointment to end so that we could start our planned meeting. Adorning the walls were items ’ve become accustomed to seeing in waiting rooms around the world, including framed

And while every single team member (you included) is motivated by the money in their paycheck, there are other ways to help motivate, inspire and reward team members to help ensure their personal success and the success of the entire enterprise.

It has been said that an army marches on its stomach, and this holds true for laundry workers, too. It is one of the reasons why there are so many examples of providing

That’s why managers at appos are encouraged to spend 20% of their time with their team: to get to know them. Taking the time to get to know team members builds trust and team unity (remember the trees in the poster where both leaders and team members can learn from, grow with, and fight for each other.

According to Marcela Gutierrez, manager of Zappos insights and new hire training f you take the time to get to know your employees, I mean really get to know them, you will be able to become a mentor.

The difference between a mentor and a manager is that you will know how to coach them and help them achieve not only professional but personal goals. They will also

“Since the overwhelming majority of laundry tasks are repetitive in nature, how do you motivate employees and celebrate successes?”Commercial Laundry David Griggs Superior Linen Service, Muskogee, Okla. Consulting Services David Bernstein Propeller Solutions Group, Park City, Utah Equipment Manufacturing Bob Fesmire Ellis Corp., Itasca, Ill. (Image licensed by Ingram Image)

work harder for you because they will trust you 100 There’s nothing better than to have someone you can trust and come to for anything

Speaking of mentoring one way to motivate and encourage employees is by encouraging them to learn new and important life and work skills ne way of doing this is by having team members with certain skills mentor and teach those among the team who need those skills xamples include teaching nglish sign language or computer and nternet skills

nother way to encourage personal and professional development is by recogni ing employees who show particular potential or motivation by offering to pay for outside training and classes that will make them more valuable to your business in the future and offer the potential for career advancement

Many of our industry’s most respected senior managers have stories to tell about how some manager or supervisor in their past saw potential even when their obs involved sweeping floors sorting soil or driving a route truck and how that recognition and encouragement led them to be the leaders they are today.

nother way of recogni ing motivating and encouraging employees is by giving them a voice ne familiar way of doing this is by putting team members from throughout the plant on a safety committee

nother way is to form focus groups from among each of your various departments Bring in lunch or better yet take them out to lunch and take the time to ask considerate uestions of the group to find out how things are going what they think could be improved and what ideas they have about making their obs easier and your business more profitable Nobody knows more about the ob than those who do it every hour of every day so spend these times with your employees Use the appos 0 20 rule and spend 0 of each lunch listening to your team ou will be surprised what you will learn the confidence they will gain and the improvements your business will achieve Do you have employees who volunteer their time in the community or fundraise for important causes Celebrate them at work and better yet oin in the effort along with other managers and staff members to help make an even greater impact on your local community

Unlike contrived and oft-hated team building sessions shared experiences at events like these can become among some of your team’s most treasured moments magine the genuine camaraderie you’ll create when you walk run or cycle alongside your team members to raise funds and awareness for an important cause the incredible feelings you’ll generate when you and your team help build or repair a home for someone in need etc

We live in the age of the nternet and social media so be sure that you celebrate your team members publicly for each birthday anniversary and personal or professional achievement

ike the aforementioned cards be sure that your posts to Twitter acebook and inked n are personali ed to each employee you’re celebrating and be sure to tag each employee so that their families and friends can share in the celebration as well.

ast but certainly not least take the time to show your genuine gratitude to your employees and team

members t is ama ing how much can be gained from a simple thank you and how much those two words can make someone’s day veryone likes to know when they’re going a good ob and when they are appreciated by supervisors and managers Take time out of every day to show your team members how much you appreciate the work they’re doing

Some of you may recall my answers to ebruary’s Panel of xperts uestion about employee retention many of which apply to this month’s prompt as well so encourage you to go back and

read my thoughts about company culture benefits and amenities and employee engagement apps closed that column by mentioning Underutili ed uman esources as one of the eight wastes of ean Six Sigma Making your employees feel welcome seen heard and genuinely appreciated can all go a long way to ensuring their long-term success nd yours t will likely not surprise you to know that as walked out of the meeting with my client the last thing saw before walking outside was a poster on the exit door with an image of a road bordered on

each side by a row of pink-blossomed cherry trees

Beneath the trees was the word gratitude again in all caps followed by the words Take time out every day to be thankful for the people in our lives that drive us toward the path of success and for those that have helped us get to where we are today ave an attitude of gratitude

Spend part of each day encouraging collaboration by showing your gratitude and can almost guarantee that your business will blossom and stand head and shoulders above the competition ALN

The new Little GiantsHandle the load.

Now more than ever laundry is mission critical. For small businesses, it’s the uniforms that represent the brand, the towels and linens that comfort the customers and the tablecloths and napkins that set the tables. Every day fabrics and textiles need efficient and superior hygienic cleaning – reputations depend on it. The all new Miele Little Giants washers and dryers provide superior disinfection and fabric care in a high-efficiency, compact system.

• M Touch Flex user interface (no buttons or dials)

• Heat pump dryer technology rated Energy Star Most Efficient

• 19-gallon drum size (18 lb. capacity)

• 49-minute Cotton 140° F program (with HW connection)

• 25-minute Express wash cycle

• 50+ washing programs; 5 customizable

• 35 drying programs; 5 customizable

• High temperature disinfection (up to 200°F) To learn more about the new Little Giants or about becoming a Miele dealer partner, visit mieleusa.com/pro/littlegiants.

PRODUCT SHOWCASE

Large-Capacity Dryers

COMPILED BY MATT POE, EDITORTOLON

TOLON says the TTD60 (132 pounds) and TTD110 (242 two) are its two large-capacity machines available for onpremises laundries.

The company says the dryers distinguish themselves because of their attractive, modern design and unique, spacesaving slidingdoor system. Because of this feature, in combination with the exhaust to the top, space needed in a laundry to install the dryers has been reduced to a minimum and allow for adjacent placement.

All TTD dryer models, available in electric, gas or steam heating, are standard equipped with a stainless-steel and reversing basket, TOLON says. The inverter drive offers the possibility to adjust the speed according to the dryness level, which makes them more efficient and reduces the total cycle time.

Saving dryer time can also be achieved with the company’s heat recirculation option, as part of the heated air is brought back into the drum for faster drying. These features lead toward reduced monthly utility bills, according to the company.

The direct air flap on steam models allows for fast cooldown, and TOLON says it can offer a high-pressure steam coil up to 12 bar for heavy-duty applications.

The status light gives a good visual overview in the laundry of the status of the drying cycle, the company says. All panels, including the filter door with window, are hinged to allow for easy maintenance and service.

www.tolon.com 850-980-1554

CONSOLIDATED LAUNDRY MACHINERY

Consolidated Laundry Machinery (CLM) says its dryers are built to last for many years of productive and

efficient operation.

The company says it took the best attributes from its highperforming, long-lasting dryers and updated them with features that further enhance productivity, efficiency and ease of use. CLM provides six industrial sizes with several heating options.

The company says its unique door-to-basket design protects products. The rotating door turns with the load and eliminates the need for a seal between the drying basket and the faceplate, so there are no pinch points in this crucial area.

CLM says its Micro-Command III PLC now includes three heatcycle termination methods to help reduce dry times and save fuel. It is simple to use and contains operator-friendly screens that assist with proper program development and serviceability.

The CLM dryer control is capable of handling stand-alone and automated applications, communicating with third-party data management systems, and integrating into nonCLM automated systems.

Further, CLM says its compact and powerful heating system provides superior fuel modulation for additional gas savings along with reduced emissions.

www.clmco.com 323-232-2417

UNIMAC

UniMac says its 200-pound capacity tumble dryer, equipped with the UniLinc control, delivers a balance of large capacity, speed and efficiency to help mediumand high-volume laundries manage their loads.

Efficiency is driven by an enclosed heat system that uses radiant heat from the stove top to preheat intake air

before it enters the combustion chamber, the company says.

The company says efficiency gets even better with UniMac’s OPtidry system, which eliminates costly over-drying by drying to a set moisture level and stopping. Many operations unknowingly suffer the effects of over-drying, which are inefficient in both utilities and labor.

When UniMac’s 200-pound tumble dryer is equipped with the UniLinc control and paired with the cutting-edge TotalVue laundry management system, the company says laundry managers can leverage vast amounts of data to more effectively manage all laundry resources. The end results are improved processes, better quality and the pinnacle of drying efficiency, according to UniMac. www.unimac.com 800-587-5458

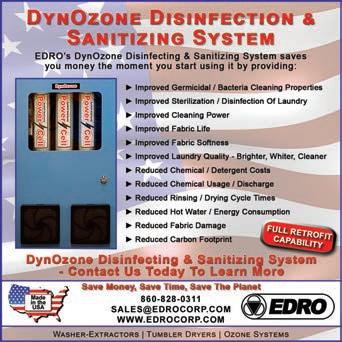

EDRO CORP.

EDRO Corp. says its C110, 110-pound (50 kg) capacity tumbler dryer is a powerful, fast-drying machine with high-quality and robust components that ensure a long and useful machine life.

The dryer is available in gas and steam versions and is designed to meet the needs of virtually every on-premises and commercial laundry facility.

The company says that the C110’s market-leading features include:

ï A superior spider-and-basket assembly construction comprising tough tubular steel supports with a machined shaft and extruded basket perforations for a smoother surface and stronger basket. This smooth surface is comparable to a washer basket more than a typical dryer basket.

ï An industrial-strength, compact drive and gearbox that offers an efficient transmission of power. There are no large pulleys or multiple belts and requires less maintenance.

ï An exceptionally high CFM

airflow that delivers outstanding drying results.

ï DMP Microprocessor Control featuring five preset programs with time and temperature display, ON/ OFF reversing, anti-wrinkle tumble, end of cycle buzzer, and extra contacts.

Standard features on the C110 include fully insulated front, side and rear panels; a large door opening for easy loading; and fewer moving parts. The dryer is easy to clean thanks to the selfcleaning lint screen.

www.edrocorp.com 860-828-0311

JENSEN USA

JENSEN says it offers a full spectrum of dryers ranging from the JTD series with capacities of 45 to 250 pounds, to the DTX series in 450- and 800-pound capacities, the DT series batch system dryers in 130 to 520-pound capacities, the new ALPHA D5 series batch system dryer in 120- and 240-pound capacities, and the WR series batch system dryers in 120 to 240-pound capacities.

The company says its experience is quite vast with more than 5,000 dryers built. JENSEN dryers can have features such as directdrive technology, frequency-controlled basket speed, a modulating gas valve on the burner system, mirror image design, a high basket volume, extremely well insulated and sealed basket housing, and built-in lint collection, all depending upon the series.

JENSEN says that the combination of heat generation, air conduction, basket geometry and insulation results in an optimal heat distribution in the basket and the best possible air flow through the linen, while maintaining low

radiant heat and noise levels.

The company adds that all its dryers are maintenance friendly. www.jensen-group.com 850-248-5264

G.A. BRAUN

G.A. Braun says its PT (Pass Thru) Series Dryers are available in natural gas and optional steamheated machines in processing capacities of 300-400, 500-600, and 700-800 pounds, clean dry weight.

They are installed as standalone machines or in open pocket washer-extractor systems and batch tunnel washer systems.

Braun’s PT Dryers are also available with an optional roll-up door for low-ceiling clearance installations and patent-pending chute load configurations. In this system, a shuttle transfer of goods is eliminated allowing for great flexibility with respect to washroom layouts.

The company says standard features include, but are not limited to:

ï 42-inch direct ignition modulating line burner, ensuing uniform distribution throughout the basket.

ï Automated Blowdown Internal Lint Collection System—No need for regular manual cleaning between loads.

ï Dual panel control box separates high voltage from low voltage components—excep-

Nasty wrinkles don’t say ‘quality’

BY MIKE HANDUST N — aundry has always been about uality t has to be

inen replacement costs are not a cheap expenditure whether you are a large luxury resort 1 0-room limited-service hotel or long-term care facility inens need to be treated to the best wash formulas not over-dried and generally handled well s we come out of the C D1 crisis uality will be paramount aundry managers will be tasked to ensure all processes are being followed—items sorted according to stain level like type and chemicals in ected properly and at the correct dosage

Now more than ever how linens look and feel will be udged by guests and residents as a reflection of how clean they are t makes sense as we are all concerned about preventing the spread of the virus that the little things will mean so much more in a postC D-1 world

So what about those nasty wrinkles f you’re a guest at a hotel and pull down the covers to see wrinkles in the bed linens and pillowcases what will your first thoughts be Did they change the linens after the last guest Were they properly laundered Details matter and wrinkles make a poor first impression t may be time to consider a better finish

FINISH STRONG

Most hospitality properties in urope are operating with an

ironer as part of their laundry operation The message is that overall look has much to do with the guest’s perception of uality Details matter and may become more important than ever n the past finishers might have been considered e uipment reserved for luxury properties

The reasons included cost but also space Most laundry rooms were designed to use the smallest footprint possible—basically an architect’s afterthought roners were also one of those pieces that were perceived as being maintenance heavy Today however technology has made finishers easier than ever to use and with a variety of manufacturers out there they are also more affordable than ever Many can also be operated by one employee

INITIAL CONSIDERATIONS

s with all pieces of laundry e uipment it’s important to work with an experienced distributor who understands not only your laundry’s needs but has extensive experience with ironers t’s easy to end up over your head with a finisher that doesn’t match your needs staffing level or maintenance expectations f your property is okay with a single fold down the middle of the sheet an 0- or even 0-inch finished width can work in a fairly small space or higher-end facilities finishing widths will need to be larger which will necessitate more space in the laundry needing to be dedicated to the unit

So as you begin considering an ironer start by aligning on creases and what your property standards are single fold on king and ueen sheets is pretty standard which makes smaller finishers an option for most properties

Priorities to consider are your laundry space available price and ease of use ou’ll also want to look at electrical and gas connections in the laundry gas is often preferred for finishers ou’ll also want to game plan the exhaust venting shorter runs are preferred

OPERATIONS AND MAINTENANCE

ne of the biggest tips can offer and it’s based on the biggest mistake ’ve seen made with ironers is feed linens into the finisher correctly Too often items are fed on one side which will create unevenness in the roll Staff should be trained to feed linens left to right

Work with your e uipment distributor to identify the optimum residual moisture for linens Typically the range will be between to 10 Properties utili ing high-thread-count 100 cotton linens will be on the low end of the range while cotton poly blends will re uire higher residual moisture

The obvious benefit of utili ing an ironer is that often linens can go directly from the washer-extractor if it is utili ing high -forces of 00 or more to the finisher or with minimal conditioning in the tumble dryer This speeds processing times and reduces utility con-

sumption

n the maintenance side the most important focus is ensuring ribbons are waxed regularly and the unit is kept clean Belts and ribbons will eventually need replacement but most facility maintenance technicians can manage that task without having to call for service bviously you’ll want to ensure the exhaust vent is kept clear and that the ironer is turned off when not in use

To get maximum life out of the finisher managers want to make sure they are si ing properly for their location Under-si ing or not planning for future growth and linen upgrades can uickly render the unit a pricey paperweight Make sure your staff is properly trained on its operation and finished uality standards

FINAL THOUGHTS

s hospitality properties reopen and long-term care and nursing homes place increased pressure on hygiene cleaning linens will undoubtedly become a focal point ll laundry operations will be taking a fresh look at processes formula and overall training of staff This is an obvious starting point The natural extension will be a review of e uipment and technology available to streamline the process reach a higher level of hygiene and verify that level of clean is reached with each cycle owever clean is more than ust smell and how linens feel ur first