BY DAVID BERNSTEIN

BY DAVID BERNSTEIN

An oft-repeated story continues to make its rounds among our peers. According to the story, whenever a laundry customer is asked which laundry in their area is the best laundry, the customer will always answer, “The one we just left.”

While the story is allegorical, the point is still well-taken. Too often we and our customers take each other for granted and only realize each other’s value after a separation has occurred.

For those who own and/or run industrial laundries, this is a tragic and costly mistake.

In our highly competitive industry, customer retention is paramount. Acquiring new customers is an expensive and resource-intensive process with estimates suggesting it can cost 5-25 times more than retaining existing customers.

On the flip side, according to Bain & Company research, a mere 5% increase in customer retention can result in a 25% or higher increase in profits (up to a staggering 45%-plus increase for industrial laundries).

Therefore, building strong, enduring relationships with your customers should be a top priority for any successful laundry operation. It all starts with ensuring that your team understands the value of loyal customers and what your customers consider valuable.

What follows is a high-level overview of this topic to help you on the road to customer retention and loyalty.

THE VALUE OF LOYAL CUSTOMERS

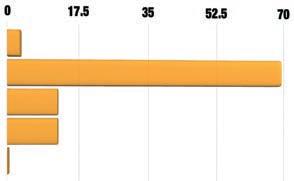

The outsized gain recognized in Bain’s research is driven by the key metrics of Customer Acquisition Cost and Customer Lifetime Value (CLV).

Customer service and customer success teams must understand these numbers and their impact. If they grasp the significant investment made to land each new account and the potential long-term revenue streams that can be unlocked through retention, they will be motivated to make customer satisfaction a top priority.

As the graph on page 6 illustrates, the lifetime value and profitability of a loyal laundry customer grow exponentially over time.

While it initially appears that the costs of customer acquisition create a loss, as

Building long-term customer loyalty

The key to success in the industrial laundry industry after a deal has been closed

the relationship matures, revenue streams expand through new products, services and cost savings.

Loyal customers generate referrals (cold calls result in about 2% closed sales as compared to 55-80% for referrals), reduce operating costs through process efficiencies, and present greater upselling and cross-selling opportunities.

UNDERSTANDING CUSTOMER VALUE PERCEPTIONS

To cultivate enduring bonds, your teams must recognize that value is defined solely by the customer’s perceptions and needs— not your assumptions or subjective opinions.

A common pitfall is focusing too narrowly on the features or advantages of your services and products because that is not what motivates customers to make buying decisions.

Simply stated: customers buy benefits. Think of benefits as outcomes or the “what’s in it for me” for your customers.

The benefits that motivate customers to decide whether to buy from or stay with your company can be broken down into the 5 Ps of Profit (how can I make or save money?): Prestige (is it more highly regarded [think Lexus vs. Toyota]?), Pleasure (will this make me happier?), Pain Relief (does this solve a problem I have?) and Preservation (will it save my job, my business, a life?).

Understand why each of your customers bought and which benefits appealed to them (sometimes it is only one benefit, but it could be as many as all five).

Make sure you understand which specific benefits resonated most for each customer, and then continue to not only reaffirm your ability to reliably deliver on those

Cintas Board of Directors approves 4-for-1 stock split

CINCINNATI — Cintas Corp. reports that its Board of Directors approved a four-for-one split of its common stock. Shareholders of record, as of Sept. 4, will receive three additional shares for each share held, which will be distributed after market close on Sept. 11.

Cintas’s shares are expected to begin trading on a post-split basis at the market open on Sept. 12. The company’s most recent stock split was in 2000.

“At Cintas, we call our employees ‘partners’ in recognition of the value that each individual contributes to our success as a company,” says Todd Schneider, president and CEO.

“Our founder, Dick Farmer, also believed in the importance of each employee-partner having ownership in the company to share collectively in that success. Cintas shares are trading near record highs as a result of our steadfast focus on serving our customers.

“We believe that the time is right to split the stock and increase its accessibility to our employee-partners and investors so that they can continue to share in the future growth of Cintas.”

The company expects that the stock split will increase the number of shares of Cintas’s outstanding common stock from approximately 101 million shares to approximately 404 million shares.

June 2024 • Volume 50, Number 06 www.americanlaundrynews.com

The

Newspaper of Record for Laundry & Linen Management

(Photo: © donscarpo/Depositphotos)

See Loyalty on Page 6 LATE NEWS 1974 - 2024

Most operators indicate laundry business strong

CHICAGO — From time to time, it’s good for industries and businesses to take stock of the state of operations and revenue … and why it is the way it is.

These numbers, trends and details can help guide the way to future success.

In the industrial and institutional laundry industry, many operators indicate that the overall industry and individual businesses are strong and growing.

That’s what the most recent American Laundry News Your Views survey indicates.

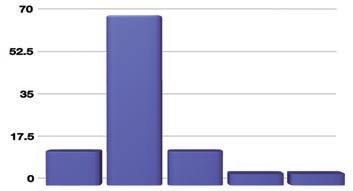

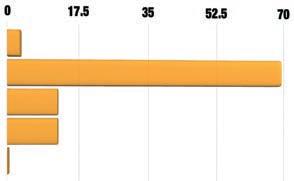

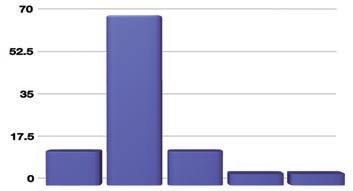

When asked to describe, in general, the state of industrial laundry business, 65.2% of respondents indicate it’s “somewhat strong” while 13% say it’s “very strong.”

Only 13% indicate it’s “neither weak nor strong,” and “somewhat weak” and “very weak” were both selected by 4.3% of respondents.

Answers were varied for the reason survey takers chose their answers, such as:

• Sales are up. Telephone calls/inquiries are up.

• Employees returning to the work sites.

• We are seeing an increase in demand for reusable products particularly in Level 2 and OR products. Focus on environmental and sustainability initiatives is driving the increase.

• Industrial laundries are still regarded as an essential service to hospitals and hotels in our markets. There is a demand/push for better service for COG and rental services. That means quality, delivery schedules and fill rates are priorities for hospitals and hotels. If laundries can deliver on all three, that would be the perfect world.

• I manage an on-premises healthcare laundry and track the daily census of the hospital. The census year over year is up around 5% and climbing. We think these are patients who put off basic procedures due to COVID.

• Certain sectors of industrial laundry remain strong regardless of economic factors. Others are currently strong, but the slightest hint of an economic downturn could have a dramatic impact.

• Acquisition and growth among the nationals are keeping prices artificially low, greatly affecting the independents’ ability to

keep up with inflation and soaring labor prices

• While revenues are up, mandates and a poor labor climate are preventing net growth.

• Because there is no substantial breakthrough in laundry industry except mechanical automation worldwide.

• Industrial laundry is suffering from a dramatic lack of innovation in their garment products, and this is doubled down by

Editor

E-Mail:

Digital

Advisory

National

E-Mail:

2 June 2024 | American Laundry News www.americanlaundrynews.com

01 Building Long-Term Customer Loyalty The key to success in the industrial laundry industry a er a deal has been closed 04 Hiring Entry-Level Laundry Workers from Diverse Backgrounds Columnist at large Richard Engler examines attracting crossover employees with a special focus on upli ing individuals from low-income brackets 04 Wildman Employees Provide 605 Service Hours 170+ team members participate in inaugural Day of Service in Indiana, Michigan 08 Technological, Processing Advancements in Finishing Equipment Examining how laundry operators can best utilize hardware/so ware advancements for customer-satisfying results 12 First steps: O ering Value-Added Products, Services In this issue, the Panel of Experts o er insights into laundry operations providing add-ons for their customers 14 Bates Troy: Small Company with Long History, Big Heart From dry cleaning to healthcare laundry, Binghamton, New York, operation has been a positive force in business and the community 17 Career Track 19 Classified Advertising 20 Source Directory 23 Trade Ticker 23 Calendar of Events INSIDE: See Survey on Page 15 Way up in revenue Somewhat up in revenue It’s the same Somewhat down in revenue Way down in revenue 4.3% 69.6% 13.0% 13.0% 0.0% How would you describe, generally, the state of industrial laundry business right now? How does your 2024 laundry business revenue to date compare with the same period in 2023? Very strongSomewhat strong Neither weak or strong Somewhat weak Very weak 13.0% 65.2% 13.0% 4.3% 4.3% 0624ALN Your Views Charts.indd 2 5/ /24 10:51 AM MEMBERSHIPS American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $50.00; 2 years $100.00. Single copies: U.S. $10.00. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices. POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 50, number 6. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. © Copyright AMERICAN TRADE MAGAZINES LLC, 2024. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

Charles Thompson Editorial Director Bruce Beggs Phone: 312-361-1683

bbeggs@ ATMags.com

Publisher

E-Mail:

Matt Poe

866-942-5694

Phone:

mpoe@ ATMags.com

Media Director Nathan Frerichs Phone: 312-361-1681

nfrerichs@ ATMags.com

E-Mail:

Board

Barbe • Nick Fertig Deana Griffin • Cecil Lee Edward McCauley Jim Slatcher

Manager Mathew Pawlak

David

Production

Sales Manager Linda Lee Phone: 218-310-6838 312-361-1682

Linda@ ATMags.com

Phone: 312-361-1700

ALN@Omeda.com 1974 - 2024

Main

www.americanlaundrynews.com Subscriptions 847-504-8175

Getting bar mops cleaner, faster, using less water than any other tunnel washer in the industry.

For more than a decade, PulseFlow® Technology has proven to deliver cleaner goods for all soil levels, including heavy-soiled food and beverage linen. And we’ve done it using less water to clean the goods than any other tunnel washer in the industry. Milnor CBW® machines require as little as 0.3 gallons per pound for light soil linen and 0.7 gallons for heavy-soil – both processed without the use of a separate water reclamation system. Milnor batch washers in service around the world have saved billions of gallons of fresh water. Discover more about Milnor’s sustainable laundry solutions at milnor.com.

We Raised the Bar for Bar Mops. *PulseFlow

and CBW are Pellerin Milnor’s registered trademarks.

Actual linen photos from a food and beverage plant that uses PulseFlow® Technology. More production, less

consumption.

Customer retention

From The Editor’s Desk

I don’t have to tell you how much effort goes into convincing a person or business to become a customer.

Many of you have probably spent hours with potential clients highlighting your services, quality and pricing.

As much work goes into securing a new client, the next phase of hard work takes place: keeping them as a client. All of the efforts of sales and marketing are wasted if your processing and customer service don’t meet or exceed expectations.

This issue of American Laundry News has several articles related to customer retention.

Obviously, the cover story, written by industry consultant David Bernstein, takes a high-level look

at how laundry and linen services can avoid taking customers for granted, keeping new and current customers happy and willing to stay with your service year after year.

On page 12, the Panel of Experts offers advice on offering value-added products and services to better serve and satisfy customers.

Or maybe your laundry needs upgraded equipment to enhance your quality. If you need help in the finishing department, turn to page 8 to find out what technological advancements have been made in ironers and folders.

We’re here to inform and hopefully help everybody keep it clean.

Wildman employees provide 605 service hours

170+ team members participate in inaugural Day of Service in Indiana,

WARSAW, Ind. — Wildman Business Group, which provides uniform rental, mats, cleaning services and more, reports that more than 170 team members at its various locations participated in an inaugural Day of Service on Feb. 23.

Giving back and changing lives is a major part of Wildman’s culture, the company says. This vision is cast by third-generation CEO Josh Wildman and adopted at all levels within the organization.

The team members provided 605 service hours, partnering with organizations in Warsaw, Fort Wayne, South Bend, Indianapolis, and Griffith, Indiana, and Holland, Michigan.

The community partners Wildman team members served include:

• Animal Welfare League

• Baker Youth Club of Warsaw

• Boys & Girls Club

• Community Harvest

• Community Kitchen

• Food Bank of Northern Indiana

• Food Club

Michigan

• Habitat for Humanity of Kosciusko County

• Hope PKGS

• IKUS Enrichment

• Kids Food Basket

• Kosciusko Senior Services

• Magical Meadows

• Mission 25 of Columbia City

• Nestling Diapers

• Phil’s Friends of Crown Pointe

• Resale Store

• Shepherd Community Center

See Wildman on Page 15

Hiring entry-level laundry workers from diverse backgrounds

In the heart of the service industry, laundry workers are the unsung heroes who ensure the smooth operation of businesses, big and small.

For employers, hiring entry-level laundry workers presents an opportunity to not only fill essential roles but also to make a positive impact on the community by providing second-chance employment opportunities.

This column delves into strategies for attracting crossover employees from other entry-level jobs, with a special focus on uplifting individuals from low-income brackets.

UNDERSTANDING SECOND-CHANCE EMPLOYMENT

Second-chance employment refers to the practice of hiring individuals who have faced significant barriers to employment. This includes those with non-traditional backgrounds, such as former incarceration, minimal work history or previous financial hardship. By focusing on this demographic, employers can offer a lifeline to those seeking to rebuild their lives and contribute meaningfully to society.

CRAFTING AN INCLUSIVE JOB POSTING

The first step in attracting a diverse pool of candidates is to create a job posting that speaks directly to those seeking a fresh start. Use language that emphasizes qualities like resilience, a strong work ethic and a desire to learn.

For example: “Are you ready for a new beginning? We value your dedication and willingness to grow. Join our team as an entrylevel laundry worker and start a rewarding career path.”

OUTREACH TO COMMUNITY ORGANIZATIONS

Partner with local nonprofits, community centers and social service agencies that work with individuals from low-income backgrounds.

These organizations can help identify potential candidates who are eager for a second chance and can thrive in a supportive work environment.

FLEXIBLE HIRING PRACTICES

Adopt flexible hiring criteria that focus on potential rather than past experiences. Consider soft skills, life experiences and the willingness to learn as valuable assets.

Be open to non-traditional resumes and provide opportunities for candidates to showcase their abilities through practical assessments.

COMPREHENSIVE TRAINING PROGRAMS

Invest in robust training programs that equip new hires with the skills they need to succeed. This includes not only laundry-specific training but also soft skills development, such as communication, teamwork and problem-solving.

Supportive training environments can boost confidence and foster a sense of belonging.

MENTORSHIP AND SUPPORT SYSTEMS

Create mentorship programs that pair new employees with experienced staff members. This support system can help new hires navigate the workplace, learn best practices, and integrate into the team.

Regular check-ins and access to resources can aid in their professional development.

CAREER ADVANCEMENT OPPORTUNITIES

AmericanCoinOp.com:

• P&G Recalls 8.2M Bags of Laundry Detergent Packets

• Laundrylux Distribution Opens New Fulfillment Center

Show a clear path for career advancement within the company. Entry-level workers should know that their hard work and dedication can lead to higher positions and increased responsibilities. This not only motivates employees but also helps retain top talent.

See Column on Page 15

4 June 2024 | American Laundry News www.americanlaundrynews.com

Top Stories Appearing on americanlaundrynews.com for the 30 Days Ending May 15. NEWS • Standard Textile Launches TakeBack Recycling Program • UniFirst Completes Rooftop Solar Panel Projects WE • JENSEN USA Launches Fleet of Regional Service Vans • UniFirst Holds Ribbon Cutting for New Michigan Facility WE • TRSA Advocates for Reusable PPE, PFAS Funding COLUMNISTS/FEATURES • Examining Cost Controls in Laundry & Linen Services • Cost Control in Motion for Laundry/ Linen Delivery • Panel of Experts: Cultivating Trust in Laundry Teams

Backup Plan?

• Does Your Independent Laundry Have a

Strong OUR SISTER WEBSITES From AmericanDrycleaner.com: • Father, Son Expand Idaho Tide Cleaners Franchise • Ohio Martinizing Cleaners Franchise Changes Ownership From

• Most Operators Indicate Laundry Business

COLUMNIST AT LARGE Richard Engler

MATT POE

(WE) = WEB EXCLUSIVE

(Photo: Wildman Business Group)

WHITE TABLE LINENBLACK TABLE LINEN

Route Ready Bar Mops

Route Ready bar mops are optically white and packed in bags of 25 so you never have to prewash or recount them prior to use. Typically, laundries save at least 70¢ per dozen by freeing washroom and finishing floor operators from a whole wash cycle, you gain production time to focus on other laundry room bottlenecks.

•32oz 16” x 19” Bar Mops

•Folded 25/poly, soft bale pack

•Bright white, durable, woven labels

•Private Label Upon Request

MOQs apply. Call (215) 461-3720 or visit monarchbrands.com Check Live Inventory 24/7/366

Lower Prices on

New

Foodservice Essentials

BISTRO

$8.25 dozen 18”

22”, Spun Poly, 25 Dozen/Case REVERSE BISTRO NAPKINS 18” x 22”, Spun Poly, 25 Dozen/Case $9.25 dozen COLOR NAPKINS 20” x 20”, Spun Poly, 25 Dozen/Case $6.50 dozen

20” x 20”, Spun Poly, 25 Dozen/Case $5.50 dozen STARTING AT $22.33 dozen STARTING AT $25.75 dozen

Matches white spun poly napkins: 42” X 42”, 52” x52”, 62” x 62”, 85” x 85”, 52” x 114” Matches black spun poly napkins: 42” X 42”, 52” x52”, 62” x 62”, 85” x 85”, 52” x 114” $3.35 dozen

NAPKINS

x

BLACK & WHITE NAPKINS

Loyalty

Continued from Page 1

promises but also remind your customers that you have continued to fulfill promises and meet or exceed their expectations.

MASTERING THE CUSTOMER ONBOARDING PROCESS

The first step in delivering upon those promises is to effectively transition new customers from the sales cycle into an engaged service partnership, and that is where a well-designed customer onboarding regimen comes in.

Onboarding is the sequence of interactions that guides your customers from their initial commitment (i.e., the ink on your contract) through to full adoption of your products and services and, eventually, realization of the value (and benefits) you promised in the initial sales process.

Technically, the sales process is the precursor to onboarding, but it should be considered an integral part of your holistic customer retention strategy since this is the point at which your team sets a prospect’s expectations and begins to understand what each customer finds valuable.

Following the close, your sales team will typically hand off to your customer service and/or customer success team to begin to fulfill the expectations set during the sales process. Making a strong, seamless handoff from sales to service is vital.

The salesperson who built initial trust should remain involved early on, while customer service and success assume operational ownership (hint: leverage customer relationship management, CRM, systems to ensure seamless knowledge transfer).

Each stage of the onboarding process builds upon the previous one, deepening the customer’s relationship with your brand over time. Some typical steps include initial contact and introduction of the customer service team, kick-off, training, full adoption and retention.

This final stage will be ongoing and should be considered relationship management, during which time your customer service/success teams will have most of the contact with the customer, but the initial salesperson should also have regular follow-up meetings to remind customers of fulfilled promises, collect proofs or testimonials, and gather referrals.

PROMOTING POSITIVE ONGOING EXPERIENCES

While reliable service delivery is table stakes and a positive onboarding experi-

ence is similarly expected, true customer loyalty stems from consistently delivering on promises, reinforcing the customer/ supplier relationship, tailoring products and services to match each client’s unique definition of value, and delivering new and innovative offerings to match.

Toward that end, forward-thinking businesses invest in the people, resources and training to ensure that customer-facing teams engage in customer experience management practices like:

•Proactively sharing insights, suggestions and new offerings.

•Promptly responding to inquiries.

•Recognizing and accommodating unique needs.

•Gathering voice-of-customer intelligence.

•Managing feedback loops for continuous refinement.

Building bonds that transcend transactions to become true partnerships is the key to cultivating raving fans who drive referrals and renewals.

REDUCING CUSTOMER CHURN

Whereas strong businesses desire high numbers in their assessment of Customer Lifetime Value, they also seek to ensure low numbers in their calculations of Customer Churn Rate. Churn, or the loss of customers to competitors, is the Achilles

heel of customer retention. Combating churn requires a multipronged strategy:

1. Focus on Your Vital Few Implementing incentives or service upgrades across your entire customer base can quickly become unsustainable. Rather, the Pareto Principle dictates that 80% or more of your profits come from 20% or fewer of your customers, so it behooves you to concentrate your resources on cultivating even deeper relationships with your most profitable and loyal “vital few” clients first.

2. Analyze Churn Data

Churn patterns offer invaluable insights for prevention. Examine when and why customers defect, pinpointing high-risk milestones in the customer journey. Proactively reaching out during these periods could potentially re-engage at-risk accounts.

3. Demonstrate Commitment

Don’t wait for customers to raise issues—proactively initiate dialogue to underscore your investment in their success. Update them on service enhancements, solicit candid feedback and express appreciation for their partnership.

LEVERAGING CONTRACT EXTENSIONS

The end of a contract term is a perilous churn phase when competitors aggressively target your customers. A powerful antidote is leveraging contract extensions earlier in the relationship’s lifecycle.

Rather than waiting for costly renewals fraught with negotiation friction and potential legal hurdles, laundries can capitalize on positive service interactions to seamlessly extend existing agreements.

Any time there’s a change or improvement in products, services, pricing or accommodations for a customer’s needs, it presents an opportunity to extend the contract as a gesture of goodwill.

Customers are naturally inclined to maintain relationships delivering ongoing value.

Establishing a policy of routinely extending contracts through service enhancements sends a reassuring message: “We’re committed to your satisfaction, not just during contract periods.”

It transforms contract duration from an adversarial negotiation into a collaborative

partnership benefiting everyone, including your retention rate.

THE MATH OF RETENTION

The financial dividends of customer retention are unambiguous. HubSpot data shows that 55% of high-growth companies consider retention programs “very important,” compared to only 29% of stagnant/ declining businesses.

Loyalty pays compounding returns as existing customers spend 67% more on average than new acquisitions, according to business.com. While prospecting is enticing, the greatest revenue opportunities lie in maximizing customer lifetime value through retention.

In industrial laundry, providing the customer with the quality and consistency they expect are prerequisites—but cannot alone sustain competitiveness. What elevates the leaders is their capability to cultivate resilient loyalty by continually reinforcing value alignment and exceptional experiences.

Differentiation through world-class execution of customer onboarding, relationship management, churn prevention and contract extension are the hallmarks of an industry stalwart positioned to thrive amid perpetual evolution.

Unwavering devotion to understanding and delivering on your clients’ unique needs is the most sustainable path to profitability. With the right combination of the strategies and tactics outlined here, a new narrative can take hold. Instead of longing for “the one we just left,” customers can happily proclaim the best laundry is “the one we’ve continued to partner with for years.”

This long-term perspective is the most sustainable path to profitability for industrial laundries striving to thrive amid perpetual industry evolution.

David Bernstein is the president of Propeller Solutions Group, a laundry industry consulting and training firm providing a variety of industrial engineering services including plant design and process improvement, as well as coaching, training, and mentorship in the areas of sales, customer service, leadership, and strategic planning.

6 June 2024 | American Laundry News www.americanlaundrynews.com

(Graphic: Propeller Solutions Group)

(Image licensed by Ingram Image)

Notice Anything?

InkGo® Is Now Odor Free!

InkGo has been reformulated to remove its odor… and to improve its performance.

InkGo is still the environmentally friendly,* safe way to remove ink stains from all types of fabric. It’s still great at removing autoclave tape and adhesives. And since it’s odor-free, InkGo is more pleasant to work with. Does odor really matter? As more drycleaners position themselves as good environmental stewards, keeping chemical odors in the plant to a minimum can help them differentiate from their competition. And odor-free is a real plus if you’re working on ink for an extended period of time.

Now that’s worth noticing!

*InkGo is Biodegradable and is California Prop-65 and California VOC Compliant.

learn more, visit ALWilson.com or call 800-526-1188

To

A. L. WILSON CHEMICAL CO. Become a STAIN WIZARD at ALWilson.com

Technological, processing advancements in finishing equipment

Examining how laundry operators can best utilize advancements for customer-satisfying results

BY MATT POE, EDITOR

BY MATT POE, EDITOR

Factors such as quality, efficiency, safety and labor issues have pushed technological advances in industrial laundry technology in recent years. These upgrades and advancements have been researched, tested and implemented by manufacturers of equipment throughout laundry processing facilities.

That includes the final phase of the operation: finishing.

American Laundry News reached out to operators and finishing equipment manufacturers to learn about recent advancements and the benefits they provide in the processing of goods.

What are some of the most recent upgrades in finishing equipment?

EDWARD MCCAULEY, president and CEO of United Hospital Services and a member of the American Laundry News editorial advisory board: The biggest advancement in my mind is the ability to add a QC (quality control) camera. These cameras can pull out stains, mends and other things such as tape and even misfolded goods.

ED KIREJCZYK, president of Sealion America Company: Our finishing systems’ automatic spreader/feeder has bionic spreading robot arms that are driven by servo motors to keep linens in the specified feeding position making difficult items (such as fitted sheets) easier to process.

The serpentine ironing method of the high-speed serpentine flatwork ironer finishes both sides of linen for the highest quality results.

Finally, the intelligent control system on the high-speed flatwork folder selects the corresponding folding program according to differ-

ent types of linen to complete the folding.

PATRICK GITTARD, marketing manager for JENSEN USA Inc.: Express Pro is a groundbreaking product, the first cornerless feeder that offers true leading-edge quality on all linen categories of largepiece linen, even table linen.

Like the other feeders in JENSEN’s Express range, cornerless feeding doubles the capacity per operator hour, and it comes with either two or three feeding stations. Now, thanks to the integration of a mechanical transfer beam, it is possible to achieve this elevated production capacity on heavier and larger linen, without sacrificing efficiency or quality.

The Kalor is the latest innovation in JENSEN ironing technology, combining the best of fixed and flexible chests, incorporating what is referred to as a semi-flexible chest design. As the design is very similar to a standard flexible chest, it offers the same excellent evaporation performance.

However, the Kalor utilizes a thicker inner chest plate, which makes it more optimal for processing linen with EKG buttons. Furthermore, the addition of a large diameter heated gap piece further improves the evaporation capacity, effectively adding additional ironing capacity with minimal additional floor space.

AL ADCOCK, vice president of sales and marketing for B&C Technologies: With labor so difficult to find and retain, one of the best investments for ironing is a built-in feeding system. If you are thinking about adding an ironer or replacing your current ironing system, labor reduction can be incorporated which can reduce the overall operational cost of the equipment

8 June 2024 | American Laundry News www.americanlaundrynews.com

A finishing system can include a spreader/feeder, ironer and folder. (Photo: Sea-lion America Company) See Finishing on Page 10

Cornerless feeding increases the capacity per operator hour. (Photo: JENSEN USA Inc.)

Finishing

over its lifetime.

PAULO ROCHA, head of service U.S., regional service director NAM Region, Miele Professional: Impeccable fabric finishing is a hallmark of excellence in the dynamic world of textile care. Manufacturers industry-wide are responding with upgrades to meet the evolving needs of operators.

Flatwork ironers are needed in a variety of applications and environments, from hotels and hospitals to commercial laundries. Offering different-sized ironers provides higher throughput and more efficient work processes.

Commercial flatwork ironers should be able to handle a wide range of fabric types, from delicate to heavy-duty materials. This versatility helps businesses improve the output of finished products.

Operator safety is a top priority, and ironers should be designed with safety features to help prevent any potential accidents or injuries. Ergonomic design ensures that operators can work comfortably, minimizing strain.

CAROL TYLER, director of marketing for Chicago Dryer Company: Automation in the finishing department is becoming more desirable.

For instance, automated towel feeding into small-piece folders using both AI (artificial intelligence) and vision technology is beginning to find its way into laundries.

How do these upgrades work within the normal finishing process?

MCCAULEY: The QC cameras fit on the feed table of the folder/cross folder. The sheet comes up the feed table and is photographed. The photograph is compared to a setting that you input into the camera and is either accepted as a good sheet or rejected.

KIREJCZYK: The material conveying system on the high-speed serpentine flatwork ironer uses wide-width spindle belts to avoid the difficult-to-solve swimming phenomenon of wide-width canvases dur-

ing processing.

The high-speed flatwork folder’s fourth and fifth folds adopt forward and reverse control, whereby fold quality is not affected by the thickness and material of the linen.

GITTARD: Due to the high capacity of the Express Pro, it typically is equipped with a highcapacity ironer. It is also possible to connect to cornerless remote feeding solutions.

Kalor operates like a standard ironer.

ROCHA: Most of these upgrades should seamlessly integrate into the normal finishing process by optimizing key aspects of operation. By enhancing efficiency, reducing energy consumption and improving overall performance, they facilitate a smoother workflow and elevate the quality of finished products.

While some upgrades may require investment in new machinery—particularly for operators using older, outdated models—the long-term benefits in terms of productivity and cost savings justify the transition and cost.

Ultimately, these advancements are engineered to ensure consistent, superior results for commercial laundry operators.

TYLER: An automated towel feeder automatically accepts the towels from a delivery system and picks, shakes, orients and feeds the towels into a small-piece folder.

The system has to evaluate the towel and make decisions if the piece is to be accepted or rejected and if accepted, determine where to pick up the towel to initiate the feeding process.

How do these benefit laundry operators?

MCCAULEY: The good thing about QC cameras is they look at the sheet in dry condition as opposed to manually

looking at the sheets up front by the feeders when the sheets are damp.

So many stains only show up after the sheets are dry like some medicinal and oil-based stains. If you have two or more quality levels of sheets, the cameras are also perfect for this because you can have an almost infinite number of formulas to get to the quality level that you are seeking.

KIREJCZYK: Fitted with dual stackers, the intelligent control on the high-speed flatwork folder can automatically sort different linen sizes.

GITTARD: Before, laundry operators had to choose between speed and quality. Now, even when feeding table linen or king-size sheets, with Express Pro, it is possible to double the capacity per operator, meaning major manpower savings.

The Kalor offers added evaporation capacity resulting in faster possible ironing speeds, and for healthcare laundries that process linen with EKG buttons, there is an additional peace of mind from the thicker inner chest plate.

ADCOCK: Without a built-in feeder, you’ll need to hand-feed the machine, which usually requires two operators for good results, or purchase a stand-alone feeder. More operators mean more labor costs while a separate feeding system will have the added cost of another machine, plus the floor space required to install it.

A built-in feeder, which doesn’t add to the overall footprint of the machine, is the simplest and most costeffective solution as built-in feeders are lower in price than you’ll pay in salary for an employee and thus offer a quick return on investment (well less than one year).

ROCHA: These upgrades offer laundry operators a multitude of benefits.

The higher throughput and streamlined workflow enable businesses to meet increased demand without compromis-

ing quality. That translates to improved operational efficiency and stronger customer satisfaction.

The ability of these enhanced commercial flatwork ironers to handle different fabric types ensures that operators can confidently process everything from delicate textiles to heavy-duty fabrics with one machine without compromising on performance or garment integrity. Laundry businesses can, in turn, expand their service offerings to meet the needs of a wider array of clients, improving competitive market position and revenue potential. Safety mechanisms such as automatic shut-off and protective guards help to keep operators safe, providing peace of mind and maintaining a secure and positive working environment.

TYLER: Automation, by definition, is the use of technology to perform tasks with reduced human assistance.

The use of a system like this will reduce labor exposure in this area of the laundry therefore allowing the reallocation of valuable labor assets to other important tasks.

How can operators best make use of these upgrades?

MCCAULEY: QC cameras are so sensitive that you could literally reject 100% of your items or nothing at all, so the set-up process is the key. We like to set the cameras to give us about a 6% reject rate.

We can also tell the camera not to look at anything that is within 8 inches of the borders because stains or mends in this area are not as critical to the overall quality of the sheet.

These cameras can provide a quality level unmatched by your competitors.

ADCOCK: The type of washer-extractor plays an important role in the productivity of the ironer. Soft-mount washer-extractors with extraction forces of 300-400 G-force will provide the optimum moisture retention to allow the ironer to run at high speeds while providing quality results. Hard-mount machines with extract speeds of 200 G-force will require you to slow the ironer significantly or force you to condition the goods in the dryer prior to ironing. Double handling the goods in this way reduces the overall efficiency and

10

Ergonomic design ensures that operators can work comfortably, minimizing strain. (Photo: Miele Professional)

June 2024 | American Laundry News www.americanlaundrynews.com

Continued from Page 8

The addition of a large diameter heated gap piece improves on evaporation capacity. (Photo: JENSEN USA Inc.)

productivity of your facility. Be wary of high-speed hard mounts that claim to extract at 400 G-force. While the machines may occasionally reach these extract speeds, the problem lies with an extract speed that completely depends on the amount of imbalance in the wash cylinder prior to extraction. The problem with a varying extract is uncertainty in moisture retention, causing unpredictable results.

If the goods extract at 400 G-force, the ironer needs to run at a fast speed. Conversely, a 100 G-force extract will require much slower speeds. All of this will add up to confusion among the operators of the ironer since there is no good way to tell what the moisture retention is and at what speed to run the ironer for best results.

Speaking of the wash process, wash chemistry is of critical importance as incorrect pH levels, the use of softener, and inadequate rinsing will all show up and create problems in the ironing process. It is important to work with a chemical company representative who is familiar with setting up wash processes for ironing.

ROCHA: Operators should engage in thorough training sessions to fully understand the equipment’s capabilities. By familiarizing themselves with the upgraded features, operators can harness the full potential of the equipment to enhance their laundry operations.

Additionally, adherence to regularly scheduled maintenance and calibration procedures is crucial to ensure consistent performance and prolong the lifespan of the equipment.

Miele Professional stands by our commitment to customer support, offering assistance through our trained network of service technicians to address questions or issues that may arise.

TYLER: Operators need to educate themselves on the technology and take advantage of training on the use and care of newer technology. With that, they will be able to gain the most from such a system.

Have operators requested other changes/upgrades? If so, what?

David Netusil, sales support manager for JENSEN USA Inc.: Yes, a two-lane cornerless spreader/feeder and multi-lane small-piece automatic feeding. Both are difficult to accomplish but not out of the realm of possibilities.

TYLER: Anywhere that is both possible and practical, operators are requesting further automation. It will be necessary to run as close to peak efficiency as possible. Automation can offer repeatability and reliability that can be hard to achieve manually.

In addition, the expansion of RFID technology to better manage linen and reject linen that either does or does not meet the required standards will likely be more widely used.

Are there any upgrades that will be coming soon? If so, what?

NETUSIL: JENSEN-GROUP is always innovating, so, the answer is yes. There are new designs in research and design and product development that will be unveiled in the coming days, but unfortunately, we can-

not offer any details at this time. Stay tuned.

TYLER: There will be further upgrades along these lines that will expand upon automatically processing towels. That will include washcloths.

Plus, the ability to reject items from an automated system that were not properly sorted out in the soil sort area of the laundry.

Please share any other information you consider important for operators to know.

NETUSIL: The U.S. market

is quickly catching up with the European market in terms of operator efficiency, ergonomics, and resource consumption, changing the laundry landscape for the better.

ADCOCK: Make sure to perform all scheduled maintenance on your ironer. This is the best way to protect your investment throughout its life. Allowing critical maintenance steps to go by the wayside is the surest way to heartache as an ironer has many moving parts that must all work in concert

together to perform the task at hand.

Planning for and performing maintenance is of the utmost importance if you expect to utilize your ironer to its fullest potential.

TYLER: Our industry is changing and evolving. Operators will want to embrace it, learn it and utilize it in the most efficient fashion possible. But, it has to make sense for that particular operation. With the installation of the right system, the benefits can be realized.

11 American Laundry News | June 2024 www.americanlaundrynews.com

Performance Efficiency Safety Made in the USA | ISO 9001:2015 Certified | gabraun.com New Technology Backed by Science! Dependable, Repeatable Quality Every Time. A Superb Flatwork Finish! ALN_Jr Page.indd 1 5/6/24 4:1 M

PANEL of EXPERTS

First steps: Offering value-added products, services

S“My operation is looking into providing value-added products and services for our customers. What would be a good starting point for these?”

Uniforms/Workwear

Manufacturing

Duane Houvener

ADI-American Dawn Inc., Los Angeles, Calif

tarting with customer feedback and market research is an excellent first step.

Engage with and involve your customers to understand their needs, pain points and expectations. What are they looking for that they’re not currently getting from your operation or your competitors? Perform customer surveys, and interviews, to gather this information.

Once you have a clear understanding of your customer’s needs, you can start brainstorming ideas for value-added products and services that address those needs. Consider how you can enhance your existing offerings or introduce new ones that provide additional benefits to your customers.

You should also analyze your competitors to see what value-added products and services they are offering and how you can differentiate yourself. Look for gaps in the market or areas where you can innovate to provide unique value to your customers. Ultimately, the key is to focus on creating products and services that solve real problems for your customers and provide them with added VALUE.

This approach will help ensure that your value-added offerings resonate with your target audience and drive customer satisfaction and probably more importantly, their loyalty.

AEquipment/Supply

Distribution

Ross Sanders

Looking at a starting point, you must first look at what could be something that would be truly beneficial for your accounts.

What can save them money? What can save on labor costs for them? What would make their job easier? What extra service can you offer that helps to put you above your competition?

A good example of what Streamline Solutions offers is our plastic bag recycling program. I think this is a good example to use because on our end, we can offer what we feel is a great add-on service for our many laundry customers but many of the same benefits are transferable to their customers as well.

program, which the laundry promoted as an add-on service. In many cases, the hospital’s laundry competition did not have a program like recycling which may have even helped the laundry to pick up the linen business initially because you never know what helps someone at an account make a move your way business-wise.

With an add-on service like this, it is a true win/win/win for every party involved. The vendor wins, the laundry wins and the laundry customer wins.

Streamline Solutions, Orlando, Fla. Healthcare Laundry

s a vendor to the laundry industry, it might be hard to say exactly what could work best for the laundries as there are a lot of factors that have to be looked at to see what is feasible, time- and cost-wise.

However, once that is worked out by the laundry, then it is a concept that certainly should be looked at.

As I have mentioned before in many of my comments in the Panel of Experts pieces, as a company, we feel it is always important to see how you can help your customers.

Any extra feature on a product or service that the laundry can offer can only be beneficial to their customers, which, in turn, would no doubt help in possibly securing business and even a longer-term relationship with those same customers.

For example, the environmental positives of the plastic recycling program are huge as it helps to lower the amount of plastic that would go to the landfill. Every medical facility has some sort of green initiative program in place no matter how large that facility may be in size. So, the laundries who use our program have the advantage of offering to help the healthcare facilities reach their green initiative goals because of the program that we have with them.

The laundry can promote our recycling program to their respective accounts as an add-on service and there is not one hospital who would not want to be involved with that. Especially at no cost to them.

We have seen some hospitals promote to their local community that they are helping the environment because of our

I do honestly think that this is a very good example of how a laundry can use certain opportunities (services or products) to see how they can add on to what they normally offer to help themselves and their customers to reach their respective goals.

Adding products and services is always a good idea as part of a comprehensive growth strategy. It potentially makes an individual customer more profitable, and it makes the service you provide even more valuable to that customer. However, it is not easy to do.

The first issue (generally speaking) is that most of the individuals in the indus-

try servicing the clients are not sales professionals. They often balk at anything beyond simply delivering or servicing the customers.

The way around this roadblock is by figuring out how to make it easier for them to present ideas, easier for them to present additional products and services to decision-makers. That will be addressed below.

The second concern is first ensuring that the customer is happy. Unhappy customers will not even think about doing more business with your company if they are not pleased with the current program. When advising teams on this, the focus is always on the second concern first. Evaluate your current satisfaction levels. If the customer is not happy, look to fix that first.

Once you are confident they are pleased with what is currently going on, now we can tackle the first issue. To do this depends on the overall level of the service team and their sales aptitude.

For example, if it will be way too big a lift for delivery folks to present new products and services to decision-makers, consider training a service leader or sales professional to do this for you.

Another approach is to utilize an account executive position whose sole purpose is to grow existing customers. If the delivery team has the potential to grow existing customers, then there are a number of things to do.

First and foremost, make it easy for them. Develop marketing materials that lay out the features and benefits of the value-added items so that the team can easily explain and gain the attention of your clients.

Secondly, train and develop the team to ensure they (and you) have confidence they can clearly present the idea.

Finally, take time to role play and train them on how to address the common objections they will hear in the field. Make it simple, make it fun and make it rewarding for them.

Your internal growth will be taken to new heights if you can effectively do this.

MServices

y suggestion to add value and differentiate yourselves from your competitors is to find solutions that meet the most common complaints from the customer. One thing I often hear is my entire delivery wasn’t on time—they shorted me 200 blankets and now I have to wait for a

12 June 2024 | American Laundry News www.americanlaundrynews.com

Jay

Juffre

ImageFIRST,

King of Prussia, Pa. Consulting

Stephanie Gregg Vizient, Little Elm, Texas

(Image licensed by Ingram Image)

second delivery later today.

I have a key performance indicator (KPI) saying they can’t have more than three shorts per month, but there is no way to verify the data.

There is technology available that will automatically send alerts to the hospital or member when an item is being shorted and alert them when the remaining product will be delivered.

Data allows monthly reports to be submitted, validating the KPI and allowing operations to plan for the event.

Lace House Linen, Petaluma, Calif.

As we all know, our industry is highly competitive, and the quality of our offerings and our ability to cater precisely to our client’s needs are crucial for our success.

If you are considering introducing new products or services, it is essential to conduct careful planning and thorough research first. By doing so, you will not only ensure prudence but also attract and retain customers.

To begin with, it’s crucial to understand the specific requirements and preferences of your current and potential clients. You can conduct surveys, talk to colleagues, visit other plants, go to trade shows, and engage in one-on-one conversations with clients, owners, and operators to find out what is working and what areas need improvement.

Once you have a solid grasp of your client’s requirements, it’s crucial to delve into market research to identify potential gaps and opportunities. By analyzing industry trends, examining competitor offerings, and evaluating consumer preferences, you can effectively pinpoint areas where new

products can fill a void or provide a superior alternative.

This approach will enable you to differentiate yourself from your competitors and confidently position yourself to succeed.

It’s also essential to conduct a thorough cost-benefit analysis to determine the viability of new products. Even if your strategy is to add new products like hand sanitizers, paper products, latex gloves, first aid kits or logo mats just to “get your foot in the door” and eventually focus on selling/renting core products like uniforms, tablecloths, or sheets and towels, you need to strike a balance between affordability for clients and profitability for your business.

Offering competitive pricing without compromising on quality will enhance the attractiveness of your products.

One big advantage of “get your foot in the door” products is that most companies often offer help with marketing, promotion and client education. You should always take advantage of these offerings and use them to your benefit.

In conclusion, introducing new products to industrial laundry clients requires meticulous due diligence at every step of the way.

By understanding client needs, conducting thorough research, developing high-quality offerings, providing ongoing support, and striking a balance between affordability and profitability, you will be able to attract and, most importantly, retain more customers.

ATextile/Uniform Rental

W. Kirby Wagg

Performance Matters, Sarasota, Fla.

s the textile rental industry continues to evolve, providing value-added products and services has become a pivotal strategy

for enhancing customer satisfaction and staying competitive in the market. Today, customers are not just looking for quality uniforms and linen solutions but also seek convenience and efficiency in managing their facilities. Offering a range of supplementary products and services can significantly augment your operation and meet the diverse needs of your clientele. When considering value-added offerings, it’s essential to start with products and services that complement your core business while addressing common pain points and enhancing the overall customer experience.

Here are some key areas to explore as a starting point:

1.Hygiene Solutions: In today’s world, maintaining hygiene standards is paramount. Expand your offerings to include essential hygiene products such as air fresheners, hand soaps, paper towels and toilet paper. These items are not only essential for maintaining cleanliness but also contribute to a healthier and more pleasant environment for your customers’ employees and visitors.

2.Safety and Compliance: Enhance workplace safety by providing first-aid cabinets stocked with essential medical supplies. This value-added service not only demonstrates your commitment to the well-being of your customers’ employees but also helps them meet regulatory requirements and maintain a safe working environment.

3.Ergonomic Solutions: Anti-fatigue mats are invaluable in environments where employees stand for extended periods, such as industrial facilities and commercial kitchens. Offering anti-fatigue mats as part of your service package can improve comfort, reduce fatigue-related injuries and enhance productivity for your customers.

4.Consultative Approach: Beyond products, differentiate your business by offering expert advice and per-

sonalized solutions tailored to each customer’s unique needs. Train your sales reps, service reps and route reps to act as consultants who can assess facility requirements, recommend appropriate products and services, and provide ongoing support to ensure customer satisfaction.

5.Customization and Branding: Consider offering customized solutions and branding options to help your customers promote their brand and create a cohesive workplace environment. Whether it’s custom logo mats, branded dispensers or personalized hygiene products, adding a touch of customization can add value and strengthen customer loyalty.

6.Technology Integration: Explore opportunities to leverage technology to streamline operations and enhance customer experience. This could include implementing RFID (radiofrequency identification) tracking systems for inventory management, providing online ordering portals for convenience, or offering data analytics to help customers optimize their usage and reduce costs.

By diversifying your offerings to include value-added products and services, you can position your textile rental operation as a one-stop solution provider that addresses the comprehensive needs of your customers. Emphasize the benefits of convenience, efficiency and enhanced workplace satisfaction to highlight the value proposition of your expanded service portfolio.

In conclusion, the journey toward providing value-added products and services begins with understanding your customer’s needs and tailoring your offerings to meet those needs effectively.

By focusing on hygiene solutions, safety, ergonomics, consultative approach, customization and technology integration, you can elevate your textile rental business to new heights of success while delivering exceptional value to your customers.

13

American Laundry News | June 2024 www.americanlaundrynews.com

Commercial Laundry

Rodrigo Patron

ALN_Tab_Hthird.indd 1 2/2/24 10:52 AM

Bates Troy: Small company with long history, big heart

From dry cleaning to healthcare laundry, Binghamton, New York, operation has been a positive force in business and the community

BY MATT POE, EDITOR

BINGHAMTON, N.Y. — Bates Troy Healthcare Linen in Binghamton, New York, has a long history.

The company dates to the late 1800s when two laundries started: Bates Steam Laundry and Troy Laundry.

In the early 1900s, the two operations joined to form Bates Troy.

Enter the Kradjian family.

The Kradjians have owned and operated the laundry since the 1940s, but the family’s history with the operation began, dramatically, in 1915.

“My grandfather Kenneth and his brother Arthur Kradjian emigrated to America, as young teenagers, escaping the Armenian Genocide of 1915 perpetrated by the Ottoman Empire,” says Brian Kradjian, president of Bates Troy.

“They settled in Binghamton, New York, via Ellis Island for the promise of work in the Endicott Johnson Shoe factory where they worked extremely hard and long hours like many immigrants of their time.”

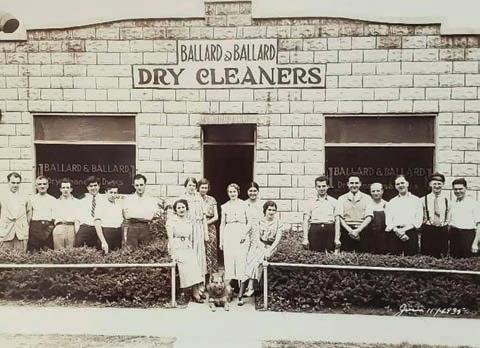

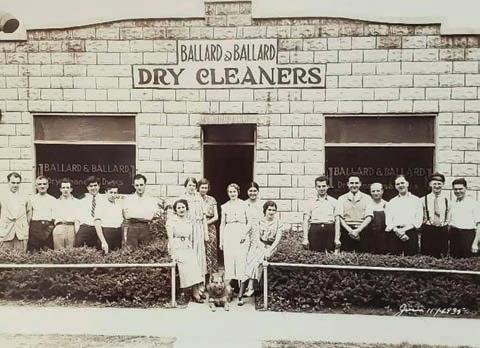

The brothers, along with another relative, were eventually able to pool their money to purchase a small dry cleaner, Ballard & Ballard Dry Cleaning.

They experienced some success and purchased other competitors, eventually buying Bates Troy in the early 1940s.

“At our peak, we had over 15 retail drycleaning stores,” shares Brian. “Bates Troy was a mixed plant doing dry cleaning and laundry.

“On the laundry side, we did house-tohouse routes and diapers, later adding uniforms, food and beverage, hospitality, mats, and a small amount of healthcare.”

From World War II to the late 1980s, the area was very stable and prospered. The Binghamton area was the birthplace of IBM, which flourished and was flush with engineering jobs and ingenuity.

“I joined the business in 1993 after college,” Brian says. “In the mid-1990s, my father, Ara Kradjian, had the vision to specialize in healthcare, and it was exciting for

us to envision retooling and repurposing our old, tired plant. We had a lot of inefficient conventional washers, high maintenance, breakdowns, overtime, etc., so we knew we had to be a low-cost producer.

“We invested in our first Lavatec 110 Continuous Batch Tunnel Washing (CBTW) System to pursue healthcare and be dependable which is demanded. We had a second $4.5 million expansion in 2008 where we had building additions and brought in our second larger CBTW System.”

Today, Bates Troy Healthcare Linen is a third-generation, locally-owned and -operated family business that’s thriving.

As a Hygienically Clean accredited laundry, it specializes in acute, non-acute and long-term care environments with a market radius of 120 miles from Binghamton.

HEALTHCARE FOCUS

Greater Binghamton was a stable manufacturing and defense-based area with a population of 250,000 until the late 1980s

when the downsizing of IBM, GE, Link Simulation and others started, which resulted in job and population flight both locally and statewide.

“We saw our retail dry-cleaning business go from 15-plus stores down to five stores, along with our margins,” Brian shares. “As a mixed plant, our productivity and efficiencies were low. The dry-cleaning industry was changing along with our area.

“Healthcare was an area that was specialized, growing, would never be offshored/ outsourced, and prior to COVID was often thought to be recession-proof, although be it an entirely different, high-volume lowmargin model.”

He says that healthcare linen—acute (hospitals), non-acute (outpatient clinics) and long-term care (nursing homes)—represents 97% of the company’s business.

The retail dry cleaning and laundry segment has two drop-off store locations with on-site alterations. They also offer wash and fold service, fire and water restoration, and

hotel dry cleaning.

While the dry-cleaning business is less than it used to be, the operation has won the Reader’s Choice Awards for Best Dry Cleaner in the area for 15 years.

The healthcare linen operation runs two shifts on sort and wash along with 1.5 shifts of finishing Monday through Friday and a third of a day on Saturdays.

“We have about 160 employees overall with a truly diverse, multicultural workforce,” Brian says.

Bates Troy processes around 20 million pounds of soiled linen per year with more than 17.25 million pounds clean delivered per year. The processing happens in a wellequipped, 50,000-square-foot plant.

Bates Troy Healthcare Linen Services was certified by the Healthcare Laundry Accreditation Council (HLAC) laundry from 2007-2022, one the first of 25 laundries to do so, Brian says.

The operation has been TRSA Hygienically Clean accredited for the past two years.

“We measure productivity in all departments and strive for continual improvement,” Brian shares. “As they say, ‘You can’t manage what you don’t measure.’ We continually invest in our people, plant and equipment.”

Bates Troy leases its delivery fleet, and Brian says the company has a 6-year age limit on the trucks it uses to ensure dependability.

“Bates Troy is always trying to upgrade SKUs where we can and offer high-quality linen within the Upstate New York market,” Brian says.

SERVICE-MINDED AND NIMBLE

Brian shares that Bates Troy is a smaller laundry relative to others, and it has a small, nimble management team of 12 that can implement changes/solutions quickly for its customers.

“Our team is strong, very competent and has a lot of combined linen experience,” he says.

See Bates Troy on Page 16

14

Kenneth and Arthur Kradjian’s first laundry operation purchase (with another relative) was Ballard & Ballard Dry Cleaning. (Photos: Bates Troy)

June 2024 | American Laundry News www.americanlaundrynews.com

Bates Troy Healthcare Linen service operates in a 50,000-square-foot plant in Binghamton, New York.

Bates Troy delivers more than 17.25 million pounds of clean goods per year.

Survey

Continued from Page 2

poor service and capability to serve to today’s standards.

• Industry is flatlining with no new markets being developed and few new ideas being trialed.

• Labor and utility costs are still rising while clients are looking for lower pricing.

• We keep signing up business. The pricing is staying relatively flat.

• It’s California.

When comparing business revenue up to mid-2024 compared to the same time last year, 69.6% of respondents indicate they are “somewhat up in revenue.”

Both “it’s the same” and “somewhat down in revenue” were chosen by 13%. Only 4.3% indicate revenue is “way up,” and no one says they are “way down in revenue.”

Reasons for those laundries who say sales have improved include:

• Customer base increased (47.4%).

• Competition decreased (21.1%).

• Costs/expenses decreased (15.8%).

• Offered additional services or extra-profit centers (21.1%).

• Boosted marketing efforts (26.3%).

• Increased prices (52.6%).

• Other (stronger hiring indicated) (10.5%).

For industrial laundries that didn’t see improved sales, reasons ranged from “competition” to “very steady market.”

When asked, “What’s the best thing that’s happened to your business so far in 2024?” Answers include:

• Laundry upgrades of various units to increase profits and reduce operating costs.

• Competition has been making bad decisions on equipment distribution.

• Increased volume.

• Able to hire strong hourly unskilled

labor. This particular group of the labor market is strong right now.

• Census growth and improved materials management on core linen items.

• Move to new facility.

The generally positive atmosphere indicated by survey takers looks to carry on through the rest of the year with 61.9% indicating, “I’m confident my business will keep improving.”

Just over 38% expect their business to remain the same, and no one expresses concern about declines.

Reasons for these attitudes include:

• Stable markets.

• The word is getting out in our new markets about our experience stemming over 85 years in the industrial-commercial laundry industry.

• No new ideas, fresh demand or new opportunities emerging.

• Many companies are concerned about the future economy and will consumer purchases still stay strong.

• We are well-positioned for future growth. Emphasis on reusable products is stronger than ever.

One respondent shares this bit of encouragement, “Hold true on your best practices, maintaining the highest level of service and quality, and deliver on your promises.”

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online each quarter. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and identify industry trends.

Wildman

Continued from Page 4

Wildman thanks its community partners for the opportunity to serve and all its customers for their understanding while the team was out of the office to give back.

The company says its four-day workweek for service and production allows opportunities like this to happen.

The idea for a Day of Service came about as a way to honor Wildman’s founder Rex

Column

Continued from Page 4

FAIR COMPENSATION AND BENEFITS

Offer competitive wages and benefits that reflect the value of the work being done. This includes health insurance, paid time off and other perks that contribute to the well-being of employees.

Fair compensation is crucial for attracting and retaining workers, especially those from low-income brackets.

FOSTERING A CULTURE OF INCLUSION

Build a workplace culture that celebrates diversity and inclusion. Encourage open communication, provide diversity training and create a safe space for employees to share their experiences and perspectives. A positive work environment can lead to higher job satisfaction and loyalty.

LEGAL COMPLIANCE AND ETHICAL CONSIDERATIONS

Ensure that all hiring practices comply with labor laws and anti-discrimination policies.

Wildman. The company shares that Rex was an “all-in” type of man. He had no reservations when it came to life, business or serving others whether as a pilot in World War II, in his local church, as a city councilman, or as an entrepreneur and philanthropist.

“This was the mindset on which Wildman was founded, so honoring Rex Wildman in this way more than seven decades later felt right,” the company says.

“Wildman encourages you to have a ‘No REXervations’ mindset when it comes to serving others. If you are an employer, we invite you to host your own day of service.”

Ethical hiring practices not only protect the business legally but also demonstrate a commitment to fair and equitable treatment of all employees.

CONCLUSION

Hiring entry-level laundry workers with an emphasis on second-chance employment and crossover from other entry-level jobs is a powerful way to enrich your workforce and give back to the community.

By implementing inclusive hiring practices, providing comprehensive training, and fostering a supportive work environment, employers can empower individuals from low-income brackets to achieve their full potential. In doing so, businesses can create a loyal, diverse, and skilled team that drives success for everyone involved.

This column serves as a guide for employers looking to make a meaningful difference through their hiring practices. By embracing the principles of secondchance employment, companies can transform lives and strengthen their teams from the ground up.

Richard Engler is operations manager for Evergreen Cooperative Laundry in Cleveland.

15 American Laundry News | June 2024 www.americanlaundrynews.com

Bates Troy

“In any service business composed of people and machines which are both subject to failure, there can always be a hiccup, but it is the responsiveness to problems or issues which is always important. We do not have a large corporate bureaucratic structure.

“We treat our employees well and have a healthy dynamic between management and production.”

Brian adds that a Bates Troy customer can always reach just about anyone in the company, from sales and service to management and ownership.

“Bates Troy has cultivated many longterm partnerships with our customers beyond just vendor/client dynamics,” he says. “We offer high-quality linen, great service, at a good value.

“We visit our customers frequently. We try to demonstrate true value-added service as opposed to treating linen merely as a commodity, which is always the challenge for our industry.”

BIG HEART

Besides close partnering with its customers, Bates Troy partners with many community organizations.

“Bates Troy invests in our local community supporting many nonprofits, charitable organizations, community events, etc.,” Brian says.

The company is a corporate partner of New York Industries for the Disabled (NYSID), participating in the Preferred Source Program and creating meaningful employment for individuals with disabilities.

Bates Troy also partners locally with Achieve for job training and the Association for Vison Rehab and Employment (AVRE) where their disabled individuals process (folds) some of its work offsite.

The company has participated in the WBNG Annual Coats for Kids Drive for more than 20 years. Every year, Bates Troy launders and dry cleans 1,300-1,500 coats

free for children whose families cannot afford and need winter coats.

“This year it amounted to over $25,000 in donated dry cleaning and laundry services,” Brian says.

In 2007 and 2011, Greater Binghamton was devastated by 500-year floods. Bates Troy supplied linens at no cost for displaced residents taking emergency shelter at Binghamton University Event Center, and Brian says, “It was our duty.”

Finally, a team of 50 people from Bates Troy participated in the American Heart Association of the Southern Tier Annual Heart Walk at the end of April.

“We are a small company with a big heart,” says Brian.

FOCUS ON SUCCESS

Like many healthcare laundry operations, COVID-19 was a challenge for Bates Troy with volume loss initially on the hospital customer side and then, later, on the nursing home side.

“Many nursing homes in New York State still have not fully recovered in census and staffing,” points out Brian.

“The pandemic forced a lot of businesses to adapt, get better or perish. We also pivoted to PPE (personal protective equipment) processing and invested in Kannegiesser

equipment to process it.”

Then came hyperinflation, which impacted all laundries, customers, businesses and consumers alike.

Although these pressures have largely decreased (rate of inflation) many cost inputs for laundries (labor, electricity, natural gas, plastics, chemistry, insurance) are still higher than where they were a few years back, he says.

“Last, but not least, New York State has had an aggressive minimum wage phase-in from 2013-2024 where wages increased from $7.25 an hour to $15 an hour,” shares Brian.

“With more increases in the next two years, which all laundries face, this will result in increased costs of services and the push for automation.”

One “push” that Brian says Bates Troy is proud of is its green and sustainability efforts.

“We have saved millions of gallons per year since 2008 when we installed our more efficient CBTW,” he says. “We have saved significant electricity and carbon footprint since 2011 when we installed our own $1.5 million microgrid.

“We have successfully worked with the New York State Energy Research and Development Authority (NYSERDA).”

Brian shares that Bates Troy also takes

a lot of satisfaction when it converts an inefficient on-premises laundry (OPL) to outsource its linen, resulting in cost savings to the customer, higher quality linen, fewer skin incidents (removing detergency and better pH), improved service, costly equipment replacement cost avoidance, repurposing the OPL space and the intangible aspect of it no longer worrying about processing their linen (rising wages, benefits, labor scarcity, etc.).

“We perform an analysis of their OPL covering all cost centers, which most OPLs rarely fully quantify,” he says.

“It is also gratifying to help lower a customer’s linen loss by examining their loss points and seeing a motivated customer work with us to reduce their loss.

“Not all healthcare organizations have the bandwidth to make such reductions or the ability to impact nursing.”

From time to time, Brian says, Bates Troy helps non-customers when they have breakdowns or emergencies.

“As my father, Ara, always said, ‘Even though our address is Laurel Ave., we can never rest on our Laurels’ continues to ring true,” he shares. “We are blessed to have good people and a supporting wife and family.

“We are focused on continual improvement, safety and measured growth.”

16 June 2024 | American Laundry News www.americanlaundrynews.com

-Laundry Wrappers ▪ Parts ▪ Wrap Wrap! Seal! Protect! Minimize Contamination and Loss Simplify Content Identification Enhance Appearance and Delivery Presentation Fully wrapped and sealed bundles... Keep Finished Laundry Clean and Protected Davis Wrapper Exclusives: Burn Guard, Height Adjust, Thermostat Guard, Easy Loading, Great Service! NEED PARTS? Davis, Felrap, HeatSeal in Stock! www.americanlaundrynews.com FOLLOW US on Facebook & X Share Our Content Tell Us What’s on Your Mind @AmericanLaundryNews facebook/americanlaundrynews 2024 ALN Facebook-Twitter_JR 3rd Page.indd 1 2/6/24 10:4 AM

Continued

Page 14

from

Bates Troy leases its delivery vehicles, limiting them to 6 years of age to ensure dependability.

Brian Kradjian (left) and his father, Ara, accept a Central New York Service Excellence Award.

George Courey promotes Victor to VP of sales

LAVAL, Quebec — George Courey Inc., a provider of hospitality and healthcare linens, reports it has promoted Matthew Victor to the position of vice president of sales.

“Matthew’s unwavering dedication, strategic vision and unparalleled leadership have been instrumental in propelling our sales team to new heights,” says Jeff Courey, president and CEO of George Courey Inc.

“His active involvement in industry associations, combined with his knack for building lasting relationships, has not only boosted our company’s position in the market but has also made him a

Track Career

favorite among clients and peers alike.”

Victor joined George Courey Inc. in 2015 as the national sales director. The company says that he has played a pivotal role in shaping sales strategies and fostering a culture of excellence within the sales team.