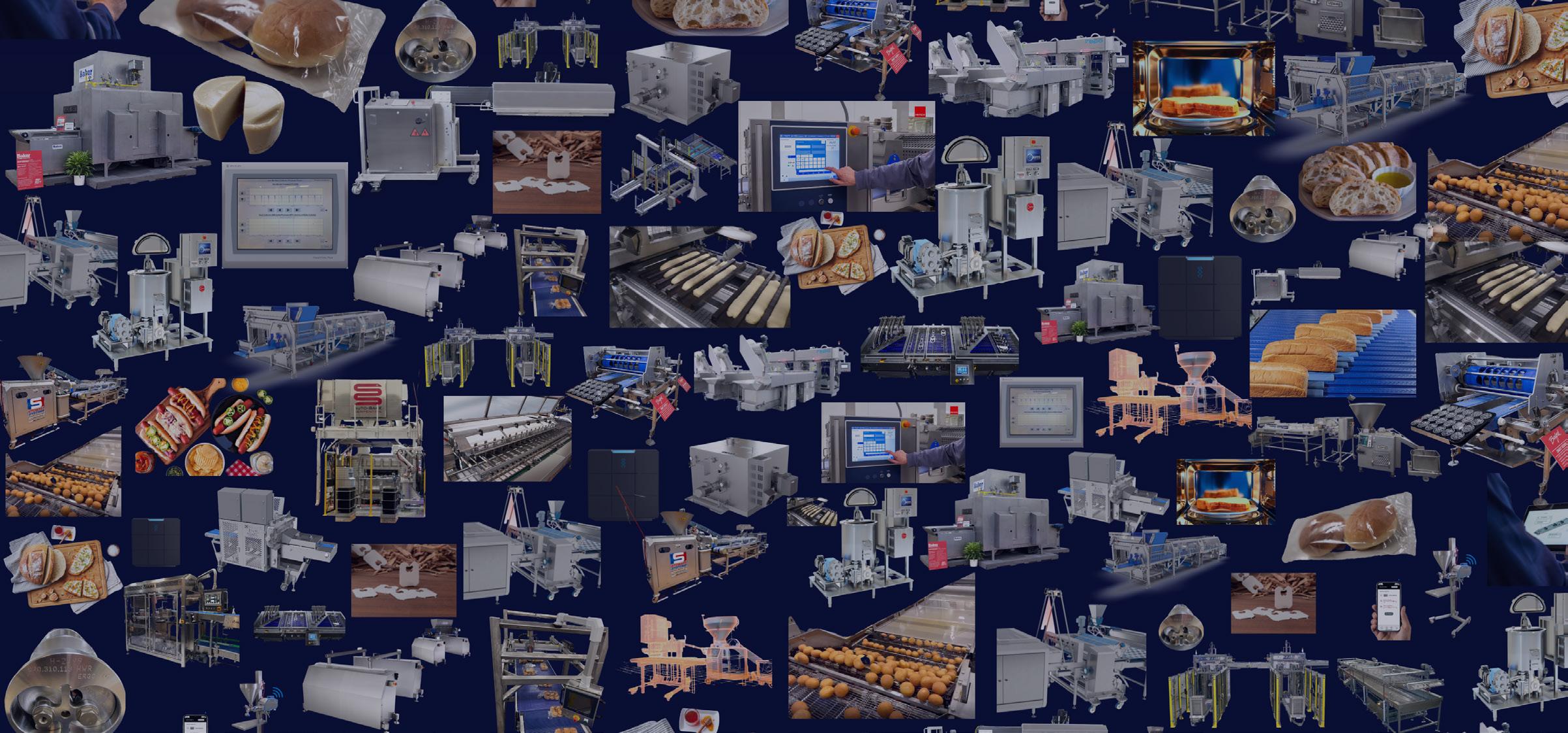

One where advanced analytics and automated production systems combine to elevate technological achievement and change the way your plant operates. A new era where productivity is maximized, downtime is minimized, food safety is prioritized – and possibility is reborn.

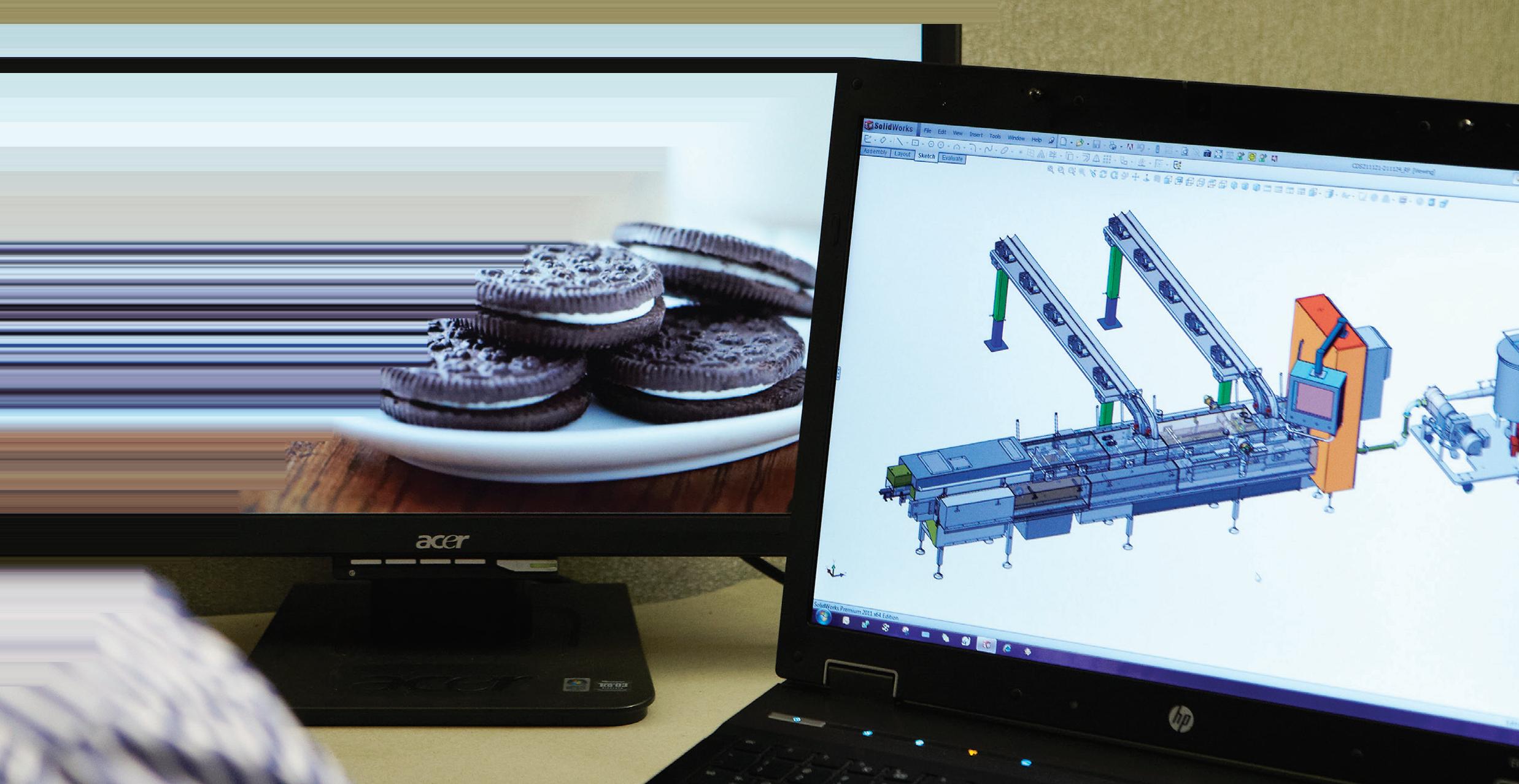

Rexfab is at the forefront of this revolution. We partner with bakeries and food manufacturers to automate downstream processes, implement advanced analytics and install more efficient conveying solutions. We’re ready to serve your needs now and help you reimagine your company’s potential.

Our experience helps you select the perfect equipment to meet your specific needs.

Our skill createsa creates a custom stom solution,builttodelive solution, built to deliver unbeatable bea performanceand performance and longevity. gevit perfo mance

Our service delivers accessible, responsive support ble, respons anytime you need it. ytime youneed ee t

Peerless: World-class food equipment and service. Driving innovation, sanitation, quality and longevity.

Our customized solutions drive your innovative food creations.

Peerless Food Equipment

500 S. Vandemark Road, Sidney, OH 45365-0769 USA (937) 492-4158, (877) 795-7377 | peerlessfood.com

Active Integrated Motion™ (AIM™) technology transforms frozen pizza handling by enabling automation in washdown environments.

Intralox® AIM solutions include sorting, switching, and merging equipment that deliver maximized, reliable throughput and gentle product handling to your pizza packaging lines.

Paul Lattan

President - Principal | 816.585.5030 | paul@avantfoodmedia.com

Steve Berne

Vice President - Principal | 816.605.5037 | steve@avantfoodmedia.com

Joanie Spencer

Director of Content - Partner | 913.777.8874 | joanie@avantfoodmedia.com

Paul Lattan

Publisher

| 816.585.5030 | paul@avantfoodmedia.com

Steve Berne Director of Media | 816.605.5037 | steve@avantfoodmedia.com

Joanie Spencer

Editor-in-Chief | 913.777.8874 | joanie@avantfoodmedia.com

Jordan Winter Creative Director jordan@avantfoodmedia.com

Olivia Huels Multimedia Specialist olivia@avantfoodmedia.com

Annie Hollon

Managing Editor annie@avantfoodmedia.com

Evan Bail

Associate Editor evan@avantfoodmedia.com

Maggie Glisan | Bella Foote

Contributors info@commercialbaking.com

Commercial Baking is published by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Commercial Baking considers its sources reliable and verifies as much data as possible, although reporting inaccuracies can occur. Consequently, readers using this information do so at their own risk. Commercial Baking is distributed with the understanding that the publisher is not liable for errors and omissions. Although persons and companies mentioned herein are believed to be reputable, neither Avant Food Media nor any of its employees accept any responsibility whatsoever for their activities. Commercial Baking magazine is printed in the USA and all rights are reserved. No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher. All contributed content and advertiser supplied information will be treated as unconditionally assigned for publication, copyright purposes and use in any publication or digital product and are subject to Commercial Baking ’s right to edit.

Commercial Baking , ISSN 2767-5319, is published quarterly in Feb, Apr, Aug, and Oct, with special issues in Jun, Jul and Dec, in print and digital formats by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108.

Application to Mail at Periodicals Postage Pending at Kansas City, MO, and additional mailing offices. POSTMASTER: Send address changes to Commercial Baking, c/o Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108.

Circulation is tightly controlled, with print issues sent only to hand-verified industry decision makers and influencers. To apply for a free subscription, please visit www.commercialbaking.com/subscription

For advertising inquiries please call 816.605.5037 or 816.585.5030.

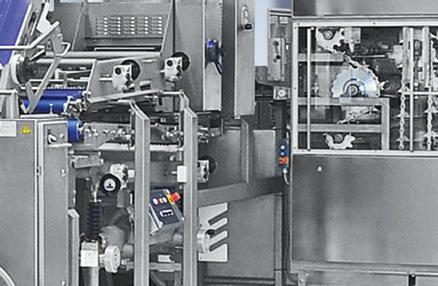

Benchmark recently completed a custom system in which a variety of bakery products are positioned, inspected, and timed into the flights of a horizontal wrapper for both twin-pack and individual packaging. An inspection conveyor was engineered and built to accept and subsequently inspect the product for width, rejecting via air blast into a customer-supplied container before being transferred to an InFlight FT loader. Learn more about our custom designed and built applications at www.benchmarkautomation.net/applications/.

Benchmark provides automated food distribution and loading solutions.

Kleenline provides sanitary conveyors for increased line efficiency and superior performance.

Southern provides a complete line of horizontal form-fill-seal pouch packaging solutions.

To find a solution for your baked goods production lines, call 706-208-0814 or visit www.benchmarkautomation.net/industry/baked-goods-packaging-infeedloaders-wrappers/.

Mel-O-Cream Donuts International: Changing

In its 90th year, this Springfield, IL-based bakery looks to the future under new family leadership.

It’s time the industry experiences the benefits of green energy for a more sustainable bakery operation. Using patent-pending hydrogen-fueled burners, the direct-fired Multibake ® VITA Tunnel Oven delivers consistent product quality and higher throughput with 99.9% fewer CO2 emissions. Independent baking zones offer precise temperature control across a wide variety of baked goods. This breakthrough innovation by AMF Den Boer comes equipped with digital tools to control, manage, and optimize the baking process while reducing your bakery’s environmental impact.

•

• Reduce your carbon footprint with up to 99.9% fewer CO2 emissions

•

•

• Increase cost savings with minimal energy consumption, reliable parts, and preventative maintenance contracts

• maintenance contracts

• Modular and pre-assembled design for efficient installation and primed for future growth

• AMF’s patent-pending hydrogen-fueled burners are also available as a combination hydrogen-natural gas burner solution, additionally patent-pending

• •

• Partner with AMF for consultation and support of your hydrogen production, certification, and installation

• Available as a retrofit solution for existing AMF Den Boer Tunnel Ovens

As we close out the year with our Innovations Annual, I can’t help but notice there’s a theme of family threaded throughout. Whether it’s family-owned companies, families of brands or even lessons learned from childhood, there’s clearly something familial about the baking industry, and it’s shining through in these pages.

Have you heard the phrase “fight like family”? If you know the core Commercial Baking team, you know what I mean. All jokes aside, it describes a culture so tight-knit that, no matter the conflict, the bond is never broken.

If you ask me, it’s that feeling of family that makes the baking industry so relational … not just transactional. There will always be conflict and competition. I mentioned relationships in a previous issue; the ones that are rooted in mutual respect will yield the greatest innovation.

That’s what it means to be family. It’s helped us weather these storms, and it will carry us through whatever the future holds.

Before bidding farewell to a year that brought us 12 full months of in-person events and looking ahead to the unknown that awaits in 2023, take a moment to enjoy our showcase of innovation. I hope you find insight and inspiration, not only from the bounty of supplier solutions but also from the stories of progress told through the eyes of our industry. I wish you a peaceful holiday season and look forward to seeing you again next year!

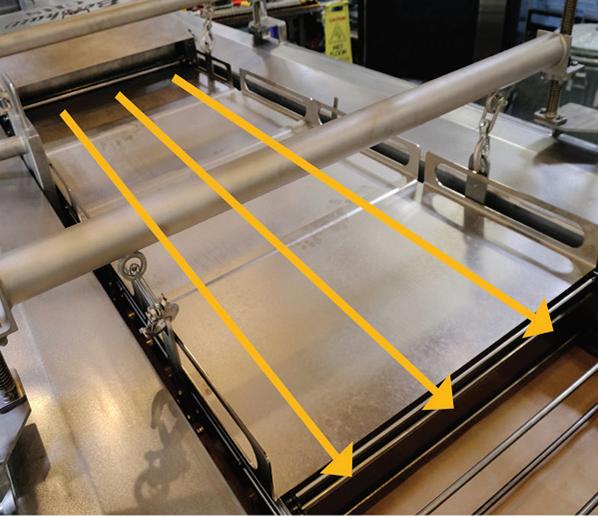

and take control of your release agent us

and take control of your release agent usage with Synova applicators

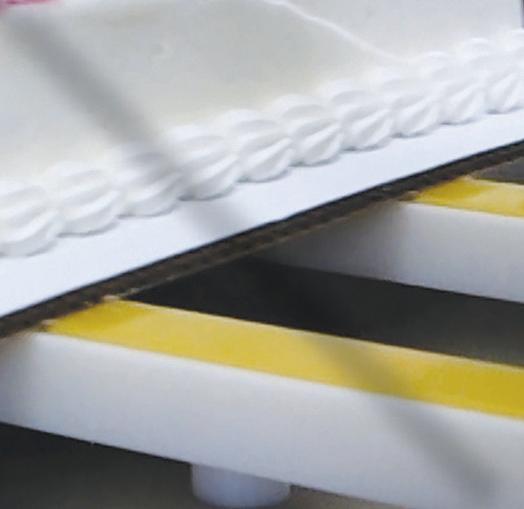

Synova’s innovative AccuTech Pan Oiler and AccuTech Pan Greaser providerecipe-driven control of the nozzle position, amount, pattern, and rate of application; integrated temperature and level control systems to ensure the release agent is always available and at the right temperature; a mist hood and catch pan to collect any overspray; and easy access for maintenance and sanitation needs.

The Synova AccuTech Pan Oiler provides an accurate spray pattern and amount through electronically actuated controls.

The Synova AccuTech Pan Greaser uses a two-step filland-spray process to apply release agents eliminating atomizing of grease and reducing overspray.

Partnering with the Bundy team means that, together, we are developing a plan to make your bakery as successful as possible. We stand behind our products and are committed to the success of every project and every bakery, every day.

For additional information or to request a quote, call +1.614.300.1081 or email info@synovaoil.com.

Commercial Baking checks in on the activity for categories covered in the second half of 2022.

Perimeter Cookies

Dollar Share

ICED | FROSTED: 14.98%

SPECIALTY: 7.9%

ASSORTED | MULTIPACK: 6.72%

COOKIE TRAY | KIT: 5.52%

In the center store, traditional cookies have the lion’s share of sales. And while cookie trays/kits have a sliver of the pie in the perimeter, their share is almost nonexistent in the center store.

Source: IRI OmniMarket Integrated Fresh

Latest 52 Weeks Ending Oct. 9, 2022

TRADITIONAL COOKIES: 63.94%

HOLIDAY | SEASONAL: 0.82%

ALL OTHER: 0.15%

Traditional cookies dominate the perimeter with nearly 64% of sales. However, they are not seeing the bulk of the growth. That distinction goes to perimeter cookie trays/kits with a 47% increase in dollar sales over a year ago.

Source: IRI OmniMarket Integrated Fresh Latest 52 Weeks Ending Oct. 9, 2022

Center-Store Cookies Dollar Share

TRADITIONAL COOKIES: 84.55%

ICED | FROSTED: 13.99%

ASSORTED | MULTIPACK: 1.00%

SPECIALTY: 0.41%

COOKIE TRAYS | KITS: 0.04%

HOLIDAY | SEASONAL: 0.02%

Growth for center-store cookies is significantly stronger than the first half of the year, with 23.1% growth vs. a year ago, as opposed to the 7.1% increase at the 52 weeks ending May 15, 2022. However, in that same time period, centerstore assorted/multipack cookies’ 151.8% growth eclipsed the 52 weeks ending Oct. 9, 2022.

FLATBREAD: 10.19% ALL OTHER: 4.27%

Source: IRI OmniMarket Integrated Fresh Latest 52 Weeks Ending Oct. 9, 2022

While snack cake items bar/finger and cupcakes maintained steady growth from the previous reporting period, roll snack cakes saw a slight bump in growth since the Q4 report (the 52 weeks ending Sept. 4, 2022), and nut swirls went from 5.9% growth to 8.0%.

Source: IRI OmniMarket Integrated Fresh Latest 52 Weeks Ending Oct. 9, 2022

BY JOANIE SPENCER

BY JOANIE SPENCER

It’s a household name around this town. People will stand in line to get donuts by the dozen from any of the five Mel-OCream Secret Recipe Donuts shops. And supermarket shoppers throughout the Midwest may not realize it, but they, too, enjoy the quality of Springfield, IL-based Mel-O-Cream Donuts International.

The signature yellow sign lights retail locations throughout Springfield, while the original commercial facility has produced its secret recipe for wholesale customers for nine decades.

In 1932, Kelly Grant Sr. bought the original donut shop for a rumored $500 and with no baking experience. He learned the trade while all six of his kids worked in the bakery through their teen years. Mel-OCream began as a retail shop, but after supply chain shortages during World War II, the retail business fell sharply postwar, and the model shifted to wholesale routes for grocery stores and restaurants.

His oldest son, Kelly Grant Jr., joined the family business, and although his father offered to give him half the company and sell him the other half, his work was cut out for him. Grant Sr. was a self-taught baker, and he expected his son to learn the same way.

“He was supposed to teach me how to make donuts, and it became very clear he wasn’t interested in that,” Grant Jr. recalled. “But if you don’t like work, you don’t want to be in the donut business.”

For 65 years, Grant Jr. owned and operated Mel-O-Cream with partner Dave Waltrip as donuts maintained a stronghold in the market, gaining momentum in the franchising trend of the ‘60s and, as the retail business waned, taking center stage during the dawn of in-store bakeries in the ’80s.

“When the in-store bakeries started around Springfield, there really wasn’t anyone supplying a high-quality product,” Grant Jr. said. “We went in with our retailquality products, and from the first place we went, they bought into it right away.”

In 2019, Grant Jr. sold the company to Eric Larson, Mel-O-Cream’s head of sales. But Grant Jr. didn’t just sell the company … he also inadvertently ensured Mel-OCream would live on as a family business.

Today, Mel-O-Cream Donuts International is led by Eric Larson as president and CEO and his sons, Chad Larson and Chris Larson, as VP/COO and VP/ secretary, respectively.

The Larson family may be the new owners, but they’re no strangers to the company. One might even say baking is in their blood.

Long before the sale, Chad had joined Mel-O-Cream in 2004 as manager of quality and R&D. Shortly after came Eric, who had touched nearly every facet of baking including managing an in-store bakery, owning a donut shop and a full-service retail bakery, and selling bakery equipment and ingredients.

“Eric had a background of selling quality product, and he was good at it,” Grant Jr. recalled. “He was the only sales manager we ever had who would get behind the wheel and drive hundreds of miles to make a deal happen … and he was happy to be doing it.”

Meanwhile, Chad’s background revolved around sanitation and quality, including HACCP, having worked closely with Waltrip on achieving HACCP certification and AIB superior audit ratings. They also worked together on R&D, ideating new product development.

“Too often companies answer a question for today without thinking about tomorrow, but we want to make sure we’re thinking about what happens down the road and how we can grow the business.”Chad Larson | VP and COO | Mel-O-Cream Donuts International — Left (From left) Chris Larson, Chad Larson, Kelly Grant Jr. and Eric Larson.

“Mel-O-Cream had become an institution in Springfield, and we did not want to sell it to anyone who wouldn’t maintain that reputation,” Grant Jr. said, reminiscing on dozens of offers, none of which would guarantee support of the retail stores still operating in town. “I was ready to sell, but I wanted it to maintain the traditions.”

With Eric’s bakery sales experience and relationships with Mel-O-Cream customers, Chad’s expertise in bakery operations and quality, and Chris’ engineering background, the Larson family was a perfect fit. And when Chad’s daughter Samantha, his wife Christie and Chris’ son Alex came on board in operations, admin and maintenance, respectively, the Larsons formed a veritable Mel-O-Cream dream team.

“They brought a combination of skills and backgrounds that made them perfect to take over and make sure it performs,” Grant Jr. said. “It was also very clear they would honor Mel-O-Cream’s traditions.”

Today, Mel-O-Cream is a frozen dough and finished-frozen operation serving primarily in-store bakeries, a model Grant Jr. built when he bought the first walk-in freezer.

When the Larsons took over on Dec. 2, 2019, they couldn’t predict the challenges that were waiting just a quarter away. Despite the COVID-19 chaos that ensued, the team got to work ensuring that Mel-O-Cream could stay on track for growth through internal efficiencies and investment in technology upgrades and process optimization.

“When you buy a business and COVID hits, you burn the original plan and think about how to retool everything,” Chad said.

In its 72,000-sq.-ft. facility, Mel-O-Cream makes a variety of products for its in-store bakery product portfolio including Kelly’s Creations branded products — named after Grant Jr. — which are also sold in in-store bakeries. Meanwhile, the five retail shops still operate independently through a licensing agreement.

Currently, the plan is to focus on organic growth in the name of recovery and rebirth, then look at how to expand beyond the portfolio and the capital investments it will take to get there.

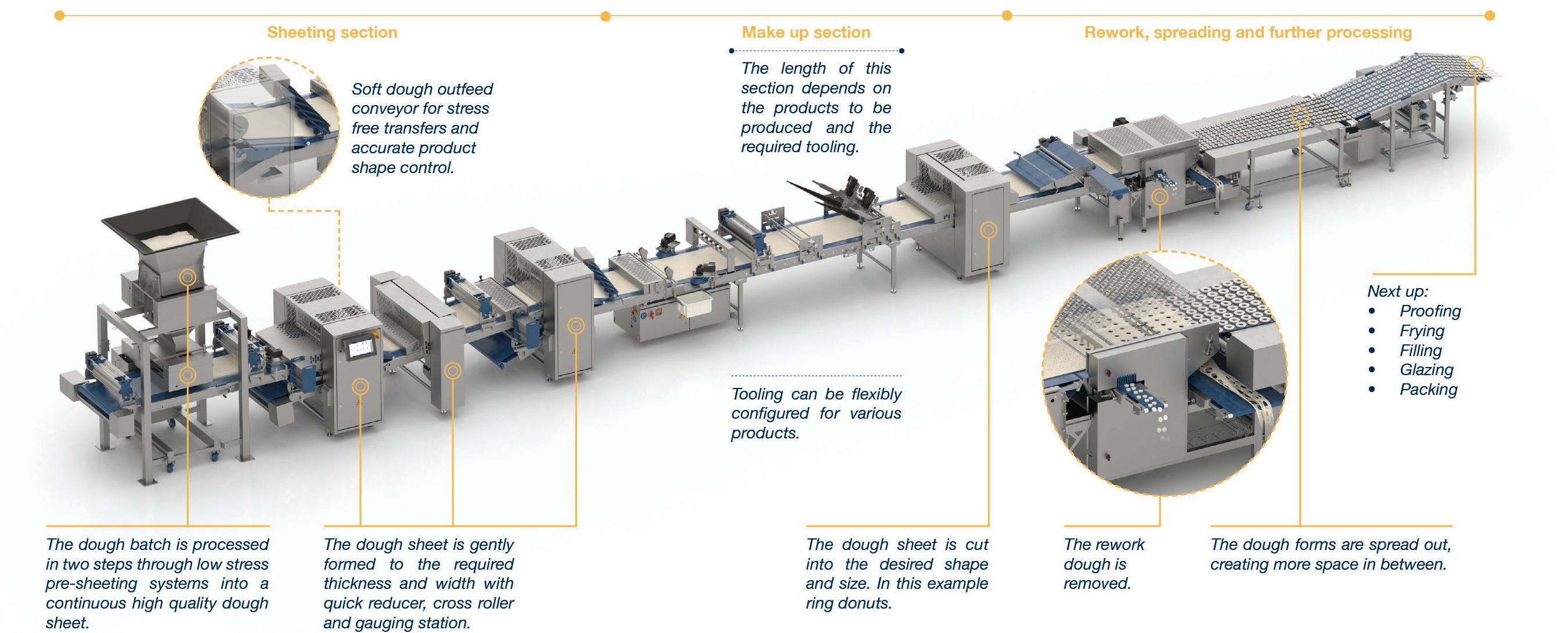

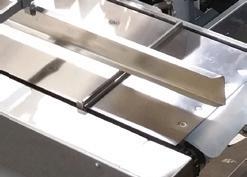

The bakery currently operates two Moline production lines that make pre-fried frozen and frozen dough products in yeast-raised and cake formats. Prior to the sale, a 32-ft. Moline fryer was added to the sheeting and makeup system for the finished-frozen products. Mel-O-Cream also kept the old 28-ft. Moline fryer because new iterations of the traditional old-fashioned donut could soon necessitate investment in building a third line, including another freezer, around that fryer.

“We’re looking at the future saying, ‘How do we build this into the process?’” Chad said. “We have this new product that we really love and want to get out there, so that could be our avenue to do it.”

For its current pre-fried products, proper filtration has been a focus of the existing line. It’s key for an operation that runs three shifts five days a week.

“We have a continuous filtration process,” Chad said. “It gives us the ability to run around the clock without having problems with the oil degrading to the point that it changes the product profile.”

When a bakery is in the business of selling a traditional product that doesn’t stray far from the norm, manufacturing becomes the point of differentiation.

“I believe that’s what makes our product better in terms of eating quality, shelf life and things like that, that our customers are looking for,” Chad said. “We can provide it without having to make a fancy product or add a lot of cost.”

In Chad’s eyes, donuts are a commodity. A bold statement to be sure, but a fair assessment when looking at the pricing structure and competition in the marketplace.

For a new leadership team at a 90-yearold company, there’s no better place to shop for innovation than the International Baking Industry Exposition (IBIE), held Sept. 18-21 in Las Vegas.

The leadership at Mel-O-Cream Donuts International — Eric Larson, president and CEO; Chad Larson, VP and COO; and Chris Larson, VP and secretary — perused the aisles of the Western Hemisphere’s largest bakery show to seek the latest innovations that can help propel its operation into the future.

Overall labor shortages in the American workforce due in part to the pandemic have hit both commercial and in-store bakeries. It leaves baking companies trying to help their workforce-strapped customers overcome those shortages while simultaneously figuring out how to operate efficiently with staff deficiencies of their own.

“We wanted to look at what equipment’s out there that can streamline our process and make employees’ — and our customers’ — jobs easier and make the product better,” Chris said.

One of Mel-O-Cream’s biggest sellers is a filled Bizmark, currently a laborintensive, semi-manual, process of “punching” the dough.

“At IBIE, we found several companies who offer that solution and were reasonably priced, considering the automation that’s involved,” Chad said. “The labor market has tightened, and this is a skilled position, where the people who do it are not easily replaceable.”

“A lot of companies make really great donuts, and we’ve got to be smart about how we run this business,” Chad said. “We’ve got to stay on trend and keep costs down to remain competitive for the long term.”

That’s one benefit of being a flexible operation; Mel-O-Cream can try out new varieties for their customers without disrupting the flow of consistency, quality and category management.

“Our team is really in tune with what our customers need,” Chad said. “We speak their language, and, to me, that’s what’s going to be the key to long-term success. They’re less likely to drop us because something trends higher than our product. We can have a conversation to see what we have in our wheelhouse to help them where they need it.”

That said, it’s important to watch consumer trends across the board, specifically in areas such as foodservice, where menu trends are a healthy predictor of what’s coming to the in-store bakery.

Looking ahead, Mel-O-Cream is now focused on cinching up the operation to modernize its manufacturing and further its ability to innovate for customers. With his experience working in several commercial bakeries that make a variety of products, Chad has a keen eye for the innovation the bakery needs to continue its growth trajectory.

“Getting ourselves to the next level means spending time focusing on our internal operation and core organic growth,” he said. “We have a lot of different customers with different needs that we will be able to service in the future. Innovation in our world revolves around the operational aspect and how we make our core items.”

Innovation in refrigeration will be one area of focus. That’s in terms of not only production efficiency but also energy consumption. In what could be considered a global energy crisis, identifying the correct refrigeration solution is critical with several refrigerants no longer viable options.

It needs a strong fiscal strategy as well. For an exclusively frozen operation, this is arguably the most expensive area of the bakery.

That becomes a major factor at Mel-OCream when not only is one of the biggest drivers in the consumer price index energy costs but also when Springfield is facing one of the highest kilowattsper-hour rates in the country. Lowering energy costs by 10% through refrigeration upgrades can make a significant impact on the overall operation.

“We have to start with looking at how we drive costs down so customers don’t bear that in the long term,” Chad said. “Especially as we regionally sell outside of the Springfield area.”

As the company considers refrigeration in its capital investment strategies, the

team will also identify what growth opportunities will likely come with it.

“When you’re retooling a process, you get the chance to think about the bigger, more long-term picture,” Chad said. “Too often companies answer a question for today without thinking about tomorrow, but we want to make sure we’re thinking about what happens down the road and how we can grow the business.”

With a background in large-scale automation outside of baking, Chris’ perspective on efficiency is a key factor in making the right investments.

“Our processes are laid out from how the equipment runs to the products running through them,” Chris said. “It’s a donut, so there are only so many ways it can be made. A lot of my time is spent going through the operation and processes and finding spots where we can improve and get more out of our lines.”

As the Larson family leads Mel-OCream toward its centennial, Chris sees opportunities to invest capital in technology that can do more with a

www.axisautomation.com info@axisautomation.com

T: 262.367.4444 F: 262.367.5555

Faced with labor shortages and the difficulty of lifting mixing bowls overhead to dump products, this bakery turned to AXIS for the Hopper Buddy Transfer Pump. Capable of handling a wide range of batters – including those with inclusions – the Hopper Buddy has made it easier and safer to get their products from mixing bowls or dough troughs to their process equipment.

limited workforce, make life easier for existing labor and make strides toward waste reduction.

No matter if the bakery business is a family affair, relationships are vital to gaining best practices and new tricks for efficiency. Chad has created connections with leaders from other donut producers like Donut Peddler, Baker Boy and Clyde’s Donuts, as well as networking through associations like BEMA.

“It’s helpful to have ‘friendly partners’ and even ‘friendly competitors’ in business,” Chad said.

Tapping into a variety of resources will surely broaden the scope of innovation for these young owners of a storied operation.

While the building sits on 19 acres that provide plenty of room for expansion or even a whole new building to mirror the current one, the Larsons aren’t getting ahead of themselves.

“We have to look at how we can make things smarter,” Chris said. “There are only so many things you can improve upon, and it all comes down to time, money and energy. Working smarter, not harder, has always been a priority. Looking at what’s smart and what’s the right way to do things will be how we get the best results.” CB

For Springfield, IL-based Mel-O-Cream Donuts International, 2022 marks 90 years in business. The company has evolved from a small donut shop to a regional supplier of frozen products for in-store bakeries throughout the Midwest. To Springfield natives, it’s a name synonymous with the town itself; to customers, it’s synonymous with quality.

Below is a list of supplier innovations that can be found on the floor of this 72,000-sq.-ft. bakery.

ABI dough handling

Ashworth conveyors

Banner Engineering sensors

Belshaw test fryer

Cambridge Air Solutions air filtration

Columbia Okuma robotic palletizing

Diosna mixers

Dorner conveyors

Gemini dough handling

Hytrol conveyors

IJ White cooling tower

Innovative Refrigeration Systems blast freezer

Moline sheeting, makeup and frying

Safeline metal detection

San Cassiano continuous batch mixing system

Topos Mondial mixers

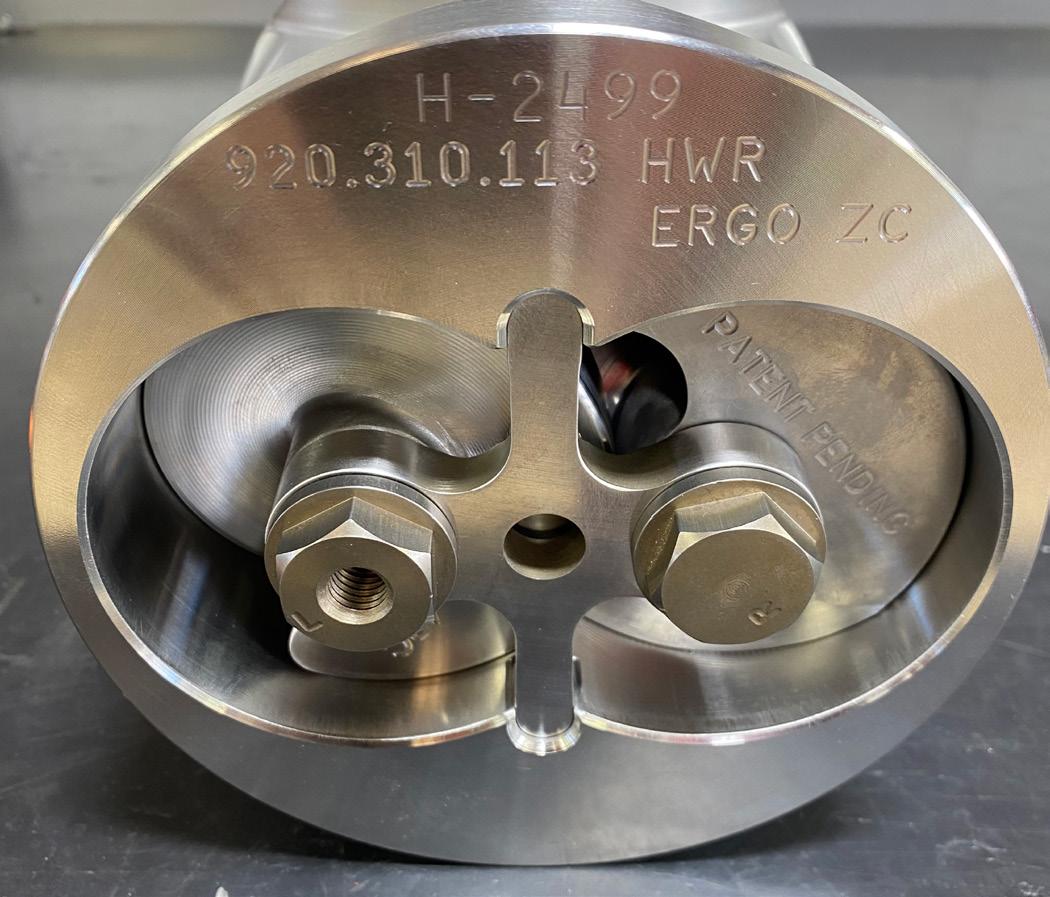

The CRS system combines three techniques Cascade, Roll and Submerge (or a combination of the three) to alleviate damage and inconsistencies caused by automated frying of fragile products.

Improves operational efficiency reduces damaged and/or partially fried products.

Scalable for both large and small fryers, the CRS system is field installable on existing machines. Patent pending.

Latest

• Clarity Process Management • IO-Link Remote I/O and Devices • PlantPAx/FactoryTalk

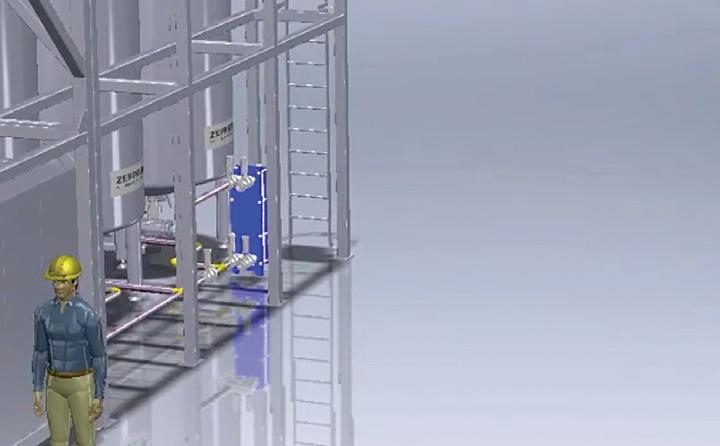

Experience the Linxis North American Technology Center. Contact us today to get started. FOLLOW US

The technology center is utilized for the testing and demonstration of the latest in ingredient automation and leading-edge process control technology. Experience first-hand how ingredient automation, dough technology and process management can benefit your needs. shickesteve.com/technologycenter

For Milwaukee Pretzel Co.’s Matt and Katie Wessel, delivering an authentic German experience requires balance in all things.

BY JOANIE SPENCER

BY JOANIE SPENCER

As husband and wife and co-owners of Milwaukee-based Milwaukee Pretzel Co., Matt and Katie Wessel — president and COO, and CEO, respectively — under stand the value of a strong partnership. It’s their foundation for taking big leaps of faith, which is also something this duo knows a thing or two about.

The Wessels’ passion for bringing authentic Bavarian pretzels to the American market is no secret. A simple Google search or a few clicks on the company website quickly reveals the brand story: The couple discovered their love for this traditional German fare after spending a year in Munich.

But what the product means to Matt and Katie is something much deeper. The pretzel they sell is a manifestation of their values as business owners, manufacturers, community members and even as a family. It’s all tied together … in a pretzel knot, if you will.

“There’s a German word, gemütlichkeit,” Katie said. “It’s not translatable into English, but it means that feeling you get when you’re surrounded by the people you love and doing something you love. That feeling was instrumental in the development of our business. For us, the experience is not just about having a pretzel; it’s about recreating what it feels like to have a pretzel in a beer garden under the chestnut trees on a beautiful day.”

Despite the high Germanic population in Milwaukee, soft pretzels were not a big part of the landscape. So, Matt and Katie felt compelled to create a pretzel that played an unmistakable role in a truly German experience. But they also felt a calling to create one that played an unmistakable role in that truly German experience.

Katie Wessel | CEO | Milwaukee Pretzel Co.“It’s important to us as business owners to develop a brand that aligns with these warm memories that were such a big part of our life,” Matt added. “It comes from our own experiences, but we can use that to help people create their own memories when they’re eating our product.”

Bringing Bavarian pretzels to the US market was a decision that was a perfect balance between business and personal.

“Our mission was not just to sell pretzels; it was also to bring the gemütlichkeit experience to people through them,” Matt said. “Yes, we saw a business opportunity, but we also saw a way to bring something we had fallen in love with to people in our community and beyond.”

It’s what sparked the momentum for the company’s rapid growth that’s occurred just inside of a decade.

“When you’re staying up late or getting up early to put the work in, sometimes that’s what pushes you the most to succeed,” Katie said. “Passion has pushed us to grow, and it’s continued that momentum for us.”

As the company matures, the workforce is growing along with it. On one hand, Matt chalks it up to luck; then again, discovering talent — and retaining it — requires a commitment that mirrors the Wessels’ love for their product.

“As you grow, you need help,” Matt said. “And hiring people who not only can do the work but also go beyond their job descriptions and quickly grow into new roles, identify opportunities, and live and breathe the brand and mission as much as we do — that’s so critical.”

“We realized very quickly how important it is to let go of some of that control … you can’t have good processes or good manufacturing without trusting your people.”

Commitment also means being able to let go. For a young manufacturer — especially those whose career paths didn’t start with manufacturing as the finish line — it’s a lesson that can only come from experience.

“We realized very quickly how import ant it is to let go of some of that control,” Katie said. “You cannot grow without doing that; you can’t have good processes or good manufacturing without trusting your people.”

Building a network of not only leadership but also mentors and trusted advisors was also key to their success. And much of that has come from Katie, who also happens to be the company’s creator. Initially running Milwaukee Pretzel on her own, Katie built a solid coalition of experts who helped her develop the process and make incremental business and manufacturing improvements.

Trust is often born out of faith, and that has been a foundation for the Wessels’ investments. It started with the first piece of automation for the pretzels’ caustic bath, the first area of production to be impacted by the growth. Although “sticker shock” is one of the first pains a business owner must get used to, the Wessels also believe in investing for the future and designing an operation that can be grown into.

That’s also reflected in the most recent investment for a new production line in the current facility.

“We had to trust that we could do it,” Matt said. “It’s risk, but it’s a mitigated risk because you know deep down it’s going to pay off.”

The Wessels’ business acumen and community involvement has propelled each of them into the Milwaukee spot

light, as both Matt and Katie have been named to the Milwaukee Business Journal ’s 40 under 40, each in sepa rate years. Currently, Katie engages in thought leadership in the Milwaukee business community through speaking engagements and panels.

“There are so many incredible things happening around us every day, and we are learning a lot from this community,” Katie said. “There are business leaders out there often doing things very quietly, and the Business Journal brings their leadership to light. And that allows me to learn from them every day.”

As bakery owners and business lead ers, the Wessels face a challenge that has haunted bakers for generations: balance.

Our MULTITWIST is a true all rounder when it comes to the fully automated production of U T TWIS s l o nd r w e om s t l y u m te r d twisted products It is the only machine on the market which can twist more than just pretzels into all shapes and sizes. The MULTITWIST also twists bread sticks, rings, flat into all and sizes The MULTITWIST also twists bread sticks, flat breads and labor-intensive products such as single strand plaits and knots with ease. Find out more at www.fritsch-group.com

FRITSCH is part of the MULTIVAC group

Burnout in this industry is real, and for Matt and Katie, it comes down to a numbers game. The natural inclination is to give 100% of oneself in every aspect. While that’s mathematically impossible, the key is to prioritize what areas to go all-in and lean on resources where possible for the rest.

That might mean scaling back community involvement or business networking one month or perhaps sending a proxy to a meeting in favor of attending an important family event. Those strategic decisions often bring clarity for when the business takes the front seat.

Matt and Katie — two self-professed “Type A” personalities — see themselves as a yin and yang.

“We love our pretzels and everything we’re doing, but it all comes down to our family and each other,” Katie said. “If that’s not strong, then nothing else can be.”

That prioritization is the foundation for how the Wessels have managed Milwaukee Pretzels’ growth. From building the team to investing in automation to expanding sales into 17 states, each step was made with intention to strengthen the “family” in this family business.

“Growing more rapidly than we did would have been at the expense of those other things we prioritize,” Matt said. “The sole goal was never about ‘more, more, more’ pretzels. This company is a part of our life. But it’s not our entire life.”

That’s not to say they aren’t prepared to keep growing the brand. In fact, the ultimate goal is for Milwaukee Pret zel to have a presence throughout the entire US. Even so, the Wessels’ priori ties remain the same, right down to their

partnership with the March of Dimes Milwaukee chapter, specifically through the Randol Thomas Wessel Memorial Fund, established in honor of the family’s first born, who passed away in 2013.

“In growing this business, I’ve learned the importance of focus in areas we want to support,” Katie said. “The March of Dimes is important to us, and it’s something we put a lot of time and energy into. We don’t want to do anything less than 100% … we could be working with several organizations, but we wouldn’t really feel like we were contributing something meaningful.”

Ultimately, it comes back to that untrans latable, but unmistakable, gemütlichkeit For Matt and Katie Wessel, sharing this Bavarian delicacy brings as much joy as the art of creating it. CB

“Our mission was not just to sell pretzels; it was to bring that gemütlichkeit experience to people through them.”

Matt Wessel | president and COO | Milwaukee Pretzel Co.

There’s a reason why so many baked goods made our list of the 20 most influential made-with-honey food and beverage products ever formulated. Honey is truly an all-natural sweetener that consumers crave in their breads, cereals, snacks and food bars.

We assembled a team of industry experts to name 20 food and beverage products formulated with honey that have changed consumer perceptions, influenced categories and driven revenue growth. Find inspiration in your next new product development by recognizing some of the most influential products ever developed.

Some people were shaped into the lead ers they are today through the course of their respective academic and profes sional careers. Tina Lambert was born one. The VP of the Marketing Center of Excellence for Lenexa, KS-based Hostess Brands hit her stride as a leader early on from the very first role she held as the oldest of seven children.

Raised as an “Army brat,” Lambert is no stranger to change. She attended eight different schools between preschool and high school and spent much of her childhood traveling across the US and abroad before her father retired in Ohio. As a result, Lambert remained near her family for college. She earned her bachelor’s in marketing and international business from the University of Cincinnati Carl H. Lidner College of Business.

Her past experiences, Lambert shared, are what shaped who she is as an executive.

“I’m a very creative solutions-minded person, and I’m not someone who becomes attached to the way things are now because I spent my whole life know ing that everything was always in flux,” she said. “I’m actually not afraid of change; I crave change, and that led to a lot of the choices I’ve made with my career.”

Lambert’s path to Hostess Brands was one filled with innovation. Among the pivotal points of her career, two stand out to her as major lessons in ingenuity: a college internship with toy c onglomerate Hasbro and the launch of a new snack brand under Procter & Gamble (P&G).

With her work at Hasbro’s Kenner Toys division, which included contributing to the company’s acquisition for the license of Pokémon, Lambert gained a deep appreciation for understanding the consumer.

The next came from her time at P&G on the team behind launching Torengos, a Pringles-like triangular tortilla chip stack stored in a prism-shaped can. Despite pre-launch consumer feedback praising the flavor and the company’s investment in two full production lines, marketing and capital, it ultimately failed within a year.

“Ironically, I think the failure of P&G’s Torengos brand launch is what led to focusing the rest of my career on innovation because it happened early enough that I had nothing to lose, but so much to learn,” Lambert reflected. “Seeing how such a strong idea could fail so fast — and understanding the whys behind it — was mind-opening.”

Over the years, Lambert learned that, similar to life, innovation failures both “teach you more and stick with you longer.” She would carry these lessons into future roles at companies including Kellogg’s, Kraft Foods and Tyson Foods.

It was at Tyson where Lambert first connected with Andy Callahan, current president and CEO of Hostess Brands. Through their work together in the retail and foodservice businesses at the company, Lambert was inspired by the

“magical” balance of inspirational and pragmatic leadership upheld in his work.

It was this connection with Callahan that brought Lambert to lead the Marketing Center of Excellence two years ago. With the role built specifically for her, she oversees a centralized marketing support team that covers an array of matters including innovation, advertis ing, e-commerce, shopper marketing, consumer insights, public relations, external communications and, most recently, packaging.

Though change has led Lambert to companies across the spectrum of CPGs, one concept ties them all together: innovation. The term has been a constant throughout the roles she’s held in her career. Over time, Lambert’s definition of innovation has evolved from a product-focused point of view to one that is more organizational.

Tina | Marketing Center of Excellence | Hostess Brands“As a senior leader, when you’re running a team of experts, it’s all about giving them the tools they need to succeed, clearing obstacles out of their path and then getting out of their way.”

Lambert

VP,

“As I think about innovation in an organizational context, there are four ingredients I always talk about: having the right people in place, the right strategy in place, the right processes in place and then the right financial support,” she said, noting that Hostess Brands continues to invest in all four.

This investment includes positioning experts to support the company’s growth through advertising and R&D in addi tion to innovation. These strategies are centered around the five fastest grow ing snacking occasions that offer a $50 billion market opportunity. Addition ally, agility in process — including fewer meetings and paperwork — has paid off.

In addition to the organization behind innovation, Lambert also noted key components: Plan as far ahead as you can, and to be agile when the plan goes sideways.

A case study in this strategy is Hostess Bouncers, an early project she initiated after joining the Hostess Brands team. When the bite-sized snack cakes entered the market, the team had to pivot when the launch was pushed back due to delays driven by COVID-19, labor and equipment delays.

Starting a new role at any company comes with its own set of challenges, but stepping into a newly formed position

at a company that has brands that are 100 years old requires finesse and a steadfast leadership style cemented from years of practice.

Lambert has both in spades.

Remaining resilient in the face of reduced consumer confidence, a looming reces sion, supply chain disruption and more, Lambert celebrates that, through it all, Hostess supports what she and her team believe will drive long term growth.

“My three favorite things to do are build teams, create new strategies and tackle tough challenges,” she said. “I’m an innovator at heart, and if you give me

something meaty and challenging, that’s when I get really excited. And this role has allowed me to showcase those three things, for sure.”

Of the three, Lambert prides herself most on the team she’s built. The experts who have joined her team over the past three years — all new to Hostess Brands — are transforming the company’s brands, Hostess and Voortman, through innovative and agile marketing.

“Our advertising is 100% digital at Hostess Brands, so we’re able to read the results every few weeks and actually make adjustments to our advertising program to maximize the ROI,” she explained. “You can’t do that with a traditional TV kind of plan. But the fact that we’re 100% digital really gives us that flexibility and efficiency.”

It all comes back to that first title Lambert ever held, long before she led teams at major CPG companies: big sister. Lambert isn’t surprised that throughout her career people have described her leadership as “sisterly.”

“As a senior leader, when you’re running a team of experts, it’s all about giving them the tools they need to succeed, clear ing obstacles out of their path and then getting out of their way,” she explained. “And as a big sister, it’s kind of the same thing. I’ll give you the support and help that you need, and then you’re going to run from there and be successful.”

Throughout her history of working in innovation, Lambert seems to inevitably return to one guiding mantra: The Ford Model-T wouldn’t sell today.

“I say that because what worked in the past can’t guide our future,” she said. “You have to look at three things: innovation,

Tina Lambert | VP, Marketing Center of Excellence | Hostess Brandsthe advertising tactics you’re using and the advertising messages you’re deliver ing. They all have to be constantly evolving to meet changing consumers’ needs.”

With the wisdom of an older sister, Lambert’s learned that innovation will more likely fail if the benefit to consumers is weak. Whether it’s diffi cult to communicate and market or it faces challenges from competitors or distribution, innovation’s biggest enemy is often the idea itself. As she continues her work at Hostess Brands, Lambert will use her experiences, lessons and commitment to the consumer to maintain her track record of success.

“I’m an innovator at heart because my whole life I’ve been two things: an idea person and someone who prides themselves on understanding people,” Lambert said. “I think that’s where it’s helped me learn from my failures and succeed in a lot of other places.” CB

“I’m actually not afraid of change; I crave change, and that led to a lot of the choices I’ve made with my career.”

How automation is changing who is best fit for the job.

BY MAGGIE GLISANWith continued automation in bakery, manufacturers have the opportunity to diversify their production teams.

Innovation and the adoption of smart technology in today’s bakery equipment is changing not only how the work gets done but also who can do it. The industry has been gradually embracing robotics and automation to streamline key aspects of production in recent years, but the COVID-19 pandemic only accelerated that trend. As manu facturers contend with ongoing supply chain challenges and labor shortages, investing in system automation is no longer a novelty; it’s a necessity.

This shift is having a considerable effect on who is working on the production floor. The days of relying on physically strong — often male — workers to lug around heavy bags or lift cast iron

have become a thing of the past. And although automation and robotics aren’t eliminating the need for manual labor altogether, it is easing the industry’s reli ance on physically demanding positions. As such, automation could provide greater opportunity for manufacturers to tap into a more diverse pool of candi dates, such as women or people with otherwise physical limitations, for jobs on the production line.

Diversity, equity and inclusion (DEI) programs, policies and practices are top of mind industry wide. According to an April 2022 American Bakers Associ ation (ABA) study, 65% of companies in the baking industry have DEI programs in place. Additionally, 44% provide DEI

training to employees and 26% plans to implement diversity education programs.

Pursuing DEI initiatives isn’t just bene ficial to improving workplace culture; it also attracts a more engaged work force and improves customer loyalty. Data from the Manufacturing Institute cited “becoming an employer of choice” and “reflecting the community in which they operate” as the top two reasons companies develop diversity initiatives.

At a time when the industry faces alarm ing workforce shortages (a study by the Manufacturing Institute and Deloitte indicates the shortage could result in 2.1 million unfilled jobs by 2030), DEI initiatives should remain at the forefront

of manufacturers’ strategic plans for recruitment and retention.

One tool that’s becoming more common is robotics. But it comes with a miscon ception that its primary purpose is to eliminate jobs.

“When we first started talking about automation, people were scared,” said Nathan Norris, director of DEI for North brook, IL-based Highland Baking Co. “They thought automation was coming to replace them.” He said the tran sition required some education and communication of the advantages, but that ultimately workers were recep tive to the new technology, especially when they saw how it benefited them.

Automation has also been a win-win for DEI at Highland, Norris said, and with the easing of physical barriers to

Nathan Norris | director of DEI | Highland Baking Co.entry, there’s greater opportunity to tap individuals from a broader range of backgrounds and experiences to work on the lines.

Take palletizing robots, for example.

“They’ve been a game changer,” Norris said. “Prior to that, people had to stack manually, and some of the boxes could get pretty heavy. When you have people at different heights, weights and body types, it could be really difficult for some people to do the work. Now, it doesn’t matter the size or shape of the individual; the robot takes that out of the equation.”

Eric Riggle, president of Rademaker USA, said recent innovations have taken the weight out of much of their equipment, allowing for people with a broader range of physical ability, size and strength to do the job.

“Now, it doesn’t matter the size or shape of the individual; the robot takes that out of the equation.”Rather than rely on traditionally manual labor, automation relieves that need and broadens the scope of who can work in manufacturing. © Dusko on Adobe Stock

Bread

LeMatic is an expert at bun production, but now we can also handle your bread production! Introducing the new DB5 Bread Bagger and Bread Slicer. Our 50 years of proven technology for buns, now begins for bread.

LeMatic is an expert at bun but now we can also handle your bread Introducing the new DB5 Bread Bagger and Bread Slicer. Our 50 years of proven technology for buns, now begins for bread.

“In some cases, lighter-weight equip ment can be managed and handled by one person instead of two burly operators,” Riggle said. ”So, a wider vari ety of personnel can use and operate it.”

Recent innovations to human- machine interfaces (HMIs) are also helping broaden the scope of who can operate certain equipment. Those that feature bilingual, trilingual or even pictorial controls can help manufacturers elimi nate language barriers and recruit work ers from different ethnic populations.

“We’re constantly working toward greater universality with operating inter faces so even if there is a language barrier, a worker can still do the job,” said Riggle, who is also trying to put to bed the notion that automation kills jobs.

“Robotics doesn’t mean we don’t need people; it means we need different people,” he said. “The things you want to automate tend to be the things you don’t want to be doing anyway. These jobs don’t lead to satisfying careers. You need to get rid of repetitive tasks.”

Instead, automation should be seen as a chance for more training and education to elevate the skills of the existing workforce and recruit new workers who might not have considered manufacturing previously.

“There should be a reeducation of the workforce to meet the needs of the automated bakery,” Riggle said. “Just because you don’t need people who are bending and pinching 50,000 croissants an hour doesn’t mean there still isn’t a need for people to maintain, operate, and run that automation that produces those 50,000 croissants an hour. And those people are lacking in the workforce.”

Jorge Izquierdo, VP of market develop ment for the PMMI, the Association for Packaging and Processing Technolo gies, said automation can lead to greater ownership and responsibility among workers, which is key for retention.

“Automation is making manufacturing less and less about physical things and more about critical thinking and decision making,” he said. “Critical think ing is one thing that every CPG [brand] is looking for.”

Similarly, Norris said automation is increasing the need for more techni cal skill among workers, which could open the door for greater diversity in the workplace.

“These jobs require people to use their brain a little bit,” he explained. “It’s not just waiting on bread to come down the line and picking it up and setting it in a case. You need a little more knowledge and skill.”

With that comes greater opportunity for training and education ... along with an increase in hourly wage, which can be a big incentive for workers who might not have otherwise considered a career in food manufacturing.

This comes at a critical time when interest in manufacturing jobs is still in decline.

“One of the biggest long-term issues our industry is confronting is the percep tion problem, said Carolyn Lee, pres ident of The Manufacturing Institute, while speaking at Made in Connecticut: 2022 Manufacturing Summit. “Many Americans — usually parents — cling to the belief that the manufacturing industry is not a place where people can find satisfying, well-paying, life long careers … Our industry needs to overcome this perception and grow the supply of young workers.”

On the other hand, there is no such thing as a silver bullet.

Craig Souser, president and CEO of JLS Automation, said there are some significant systemic challenges facing manufacturers who want to diversify their workforce. He fears automation could accelerate workforce inequities — at least in the short term.

“I think the opportunity gap has been made worse in the short term because of automation, but I don’t think it has to stay that way,” Souser said.

According to “Diversity and the Age of Automation,” a recent study by Faethm, the adoption of AI and robotic technology accelerates across industries, disparities are likely to increase further.

“This is particularly true for Black and Hispanic employees, for women, and women of color in our focus industries, as they tend to occupy roles with repeatable, repetitive and lower-skilled tasks, which are prone to replacement by technology,” the study noted.

For successful DEI in the bakery, it’s important to see automation as a resource, not the solution. For example, Souser said diversifying the manufacturing workforce in an increasingly automated industry needs

to start with improving diversity within higher education.

Women and ethnic minorities remain underrepresented in STEM fields. Based on 2019 data from the US Census Bureau, women make up just 15% of workers in engineering, and accord ing to a 2019 study from Pew Research Center, Black workers make up only 9% of those in STEM-related fields.

Speaking to racial diversity specifi cally, underrepresentation can in large part be attributed to the lack of diver sity in higher education in general. By contrast, the underrepresentation of women in engineering is specifically tied to the field of study, not to the overall number of females seeking post secondary degrees.

“Automation is making manufacturing less and less about physical things and more about critical thinking and decision making.”

Jorge Izquierdo | VP of market development | PMMI

When it comes to diversifying the work force in an increasingly automated industry, it’s important for companies to strategize within the context of these broader issues. For JLS, that means investing in scholarships specifically for people of color and recruiting from historically Black and women’s colleges and universities.

“We need to think about how we can create opportunities for all groups with higher paying jobs that become great careers,” Souser said.

Progress won’t happen overnight, and the return on an investment in education now won’t be realized until several years down the line. But all those small steps do matter and will add up over time to narrow the opportunity gap.

“At the end of the day, we need more technicians and engineers, so the demand is going up,” Souser continued. “We need more of the population to embrace that, and if we could pull folks from areas that haven’t been tapped, there is a huge opportunity.”

Both BEMA and ABA are working to help members address DEI and identify best practices. This is just one way companies can ensure they are making strides toward change.

As technology advances in robotics and automation across manufacturing industries, bakeries should keep DEI top of mind.

The radical shifts in the labor market will undoubtedly continue to impact day-to-

day operations, and companies need to consider the intersection of all these moving parts to remain competitive.

“The more diverse you are as an organization, the smarter you are and the better decisions you make,” Souser said. “I’m embracing [DEI] because it’s going to make the company better. It’s going to make the industry better.” CB

In the past year, BEMA and ABA have developed individual task forces and working groups to identify the baking industry’s DEI challenges and the best practices to solve them. Highland Baking Co., Rademaker and JLS Automation are all active participants in groups for both associations.

Flexibility, advanced industrial performance and product quality. The M-TA oven has everything covered to give you that competitive edge. It can produce an almost infinite variety of bakery and pastry products in a market that is constantly growing and evolving.

Contact us at info@mecatherm.fr

As the baking industry becomes a breeding ground for M&A activity, a transformation is happening at break neck speed.

From Mexico City-based Grupo Bimbo’s acquisition of UK-based St. Pierre Groupe and the addition of Dianne’s Fine Desserts into the Dessert Holdings portfolio to growth by acquisition from the likes of Crown Bakeries and Quebec City-based Bakery Humanity, the business of baking is driving change … in a big way.

Two years ago, most baking companies were either struggling to stay afloat or scrambling to keep product on store shelves. As the world settles into what’s unofficially considered a postCOVID-19 reality where disruption is the status quo, bakeries are pushing the envelope on innovation.

According to a report from Barnes Dennig — a Cincinnati-based tax firm with expertise in the manufacturing, transportation/logistics and wholesale/ distribution fields — manufacturing has seen an uptick in M&A activity in the past

year. That’s due to a few factors, accord ing to the firm, starting with the return of production back to pre-pandemic levels.

Other factors include tax and regula tory issues, availability of funds, shifts in strategic growth plans and, of course, the impact of COVID-19 on businesses and their owners.

It’s not just happening in the bakeries. M&A has been prevalent on the supplier side, as well. During the International Baking Industry Exposition (IBIE), held Sept. 18-21 in Las Vegas, three of the show’s largest exhibitors shared best practices on incorporating multiple brands into one IBIE booth experience. In this Innovations Annual, those compa nies sat down with Commercial Baking to identify some of the most important implications for innovation when working with multiple brands under one umbrella.

Developing complex organizations that encompass several brands — each with its own technology solutions, leadership and customer base — requires targeted focus for each brand that is born out of identifying specific operational needs.

AMF Bakery Systems, part of the Markel Food Group, recently restruc tured its family of brands organized as nine individual business units based on their product technology, all under the AMF banner.

Each brand was developed to bring its own identity and equity to the market place and to ensure strategic and operational focus. However, they each leverage common sales and customer care organizations around the world and work together to provide integrated solutions to customers.

“While we continue to invest in the brands, there’s also a company sitting behind each one,” said Jason Ward, AMF Bakery Systems president. “Each brand is its own business unit with a focused product line.”

Each one has its own dedicated lead ership team that focuses on best-inclass product development that can then create integrated solutions for complete production lines for soft bread and bun, artisan bread, flatbread, cake, pie, croissant or pastry.

This is what AMF calls the “battle for ‘and.’” Success is twofold: On one hand, each unit has a tightly focused product development strategy that must deliver success at the unit and sub-system

level; on the other, it’s a group effort to bring innovation in full bakery systems solutions from mixing to post-packaging automation.

“There has to be intense collaboration across the brands in order to provide a seamless, complete system solution,” Ward said. “That collaboration across our brands, sales and customer care organi zations, coupled with extreme focus at the product line level, is what makes us different, and we must deliver both to be successful.”

While each unit has its own strategy for meeting specific customer needs, AMF has a high overall standard for its digital transformation strategy. In pursuit of next-level bakery intelligence, the company is leveraging technology like artificial intelligence to develop fully autonomous bakery equipment by 2030.

Collaboration isn’t an all-or-nothing proposition; it depends on customers’ needs and how machines work together for specific product types or in different areas of the line.

“Sometimes, it’s OK to be different, and there are good reasons for those differ ences,” Ward said. “In those cases, we wouldn’t necessarily need to have every technology the same across the entire AMF product line.”

There are many reasons why one-stop shopping can streamline the process of outfitting a bakery, but that’s not always the goal. AMF brands offer a variety of technology including extrusion-based makeup, volumetric makeup, sheeting, laminating and depositing, as well as proofing and baking technology and packaging at the end of the line.

At the front of the line, AMF mixing tech nology has typically focused on batch varieties. Recently, though, the AMF Fusion unit partnered with Reading Bakery Systems (RBS), another Markel company specializing in continuous mixing through its Exact Mixing plat form. The result is an unprecedented take on cross-pollinated innovation as Jim Warren, VP of Exact Mixing at RBS, and Terry Bartsch, executive product manager – dough systems for AMF Fusion, work closely to identify and drive new solutions for both platforms.

“We have to empower the businesses and the brands to be the very best at what they do, to respond to customers and drive continuous improvement,” Ward said. “When you have a complex organization that encompasses different brands or businesses, you must make it easy for customers to get the help they need. That’s the case whether it’s a project that includes one or two product groups or the entire bakery.”

“There has to be intense collaboration across the brands in order to provide a seamless, complete system solution.”Jason Ward | president | AMF Bakery Systems

Linxis Group, which includes six brands for ingredient handling, mixing and portioning technology, has built its network through acquiring brands that have established strength in the market. This allows each brand in the group to leverage its own expertise while also tapping into a deep knowledge base from other areas of the bakery.

“We take a strategy of a combined, cohesive team of experts, each specific to their field,” said Jason Stricker, VP of sales and marketing for Shick Esteve, a Linxis Group brand since 2017. “They’re already strong brands in their own right, but when they come into the fold, they can leverage the expertise of all the Linxis Group companies.”

For Shick Esteve, joining Linxis Group gave the team more resources for new opportunities and product development.

“Being part of Linxis Group gives us multiple opportunities to address customers’ needs, not only for automated ingredient handling but also mixing and other technology,” said Blake Day, president and CEO of Shick Esteve. “It allows us to provide solutions that we know will support our customers and make their products better.”

Linxis has taken a specific approach to building the brand portfolio. Currently offering solutions that include ingredient automation, mixing, depositing, cutting and more, the company prioritizes best-in-class manufacturing and a likeminded customer approach.

“To be a member of the Linxis Group, you have to deliver on that brand prom ise and provide expert support and innovative design,” Stricker said.

For this company, it’s about strength of the brand and the expertise it provides, no matter what stage of the process. The strategy focuses on expertise in specific fields while leveraging the innovation that comes from being part of a cohesive group.

Although the brands function autono mously, they also share best practices in areas such as sales, engineering, R&D and project management.

“When we developed our IoT platform Clarity data management, we had discussions with the whole group to build the best platform,” Stricker said. “Each of our IoT solutions is tailored to the function and needs of customers who invest in our equipment and systems, but under the hood, we’ve developed a unified platform.”

This level of interaction is vital, especially for a parent company with manufacturing facilities around the world. Manufactur ing standards and regulations can vary

from country to country, so the brands must all be well versed in Linxis Group standards as well as regulations in areas like food safety and hygienic design.

To put innovation into action, Linxis Group brands can come together in the Linxis North American Technol ogy Center (LNATC), located in Shick Esteve’s Kansas City, MO headquarters.

Oftentimes customers will contact Linxis brands such as Shick Esteve for help with solving a particular challenge. Because the brands interact so frequently in the technology center, these challenges are often the impetus for brainstorming future innovation.

“We are fortunate to have invested in the Linxis North American Technology Center,” Day said. “It’s helpful for custom ers to see how the equipment all works together and how the brands integrate. That’s how we collaborate from a project standpoint; There’s constant teamwork among all Linxis Group brands.”

“It’s helpful for customers to see how the equipment all works together and how all the brands integrate. That’s how we collaborate from a project standpoint.”

Blake Day | president and CEO | Shick Esteve

Middleby Bakery, a division of Middleby, developed its brand acquisition exper tise from the company’s innovation in the foodservice sector. Whether for fast food, QSR or white tablecloth, Middleby developed a platform that provided a full suite of solutions in one kitchen.

“We developed a similar strategy with a focus on incorporating best-in-class brands for our total food processing line solutions,” said Mark Salman, president of Middleby Bakery.

If there is one rule of thumb for supplier consolidation, it’s that one company can’t — or, at least, shouldn’t — try to do everything. The power of the parent is in the strength of its brands. Middleby Bakery is a portfolio of 14 brands providing integrated production lines for bread/buns, cakes/muffins, cookies/crackers and pizza/pastry.

“We bring in the company that really fits in terms of innovation, management team or the market they focus on,” Salman said. “We look at different syner gies when we seek an acquisition.”

A lifelong entrepreneur and former baker, Salman has seen the trials and tribulations that come with starting a business and running both large and small companies. In the current climate, between the pandemic, supply chain woes, inflation and a potential reces sion, smaller suppliers are more often collaborating with larger companies, if not through acquisition, then at least in strategic partnership.

Although Middleby Bakery’s flagship brands are headquartered in Plano, TX — home to Middleby’s Bakery Innovation Center and the Middleby Innovation Kitchen for the foodservice portfolio, this is a global company with great

diversity among all brands. That can come in handy for innovation.

“With companies in the US and compa nies in Europe, we encompass many different cultures,” Salman said. “And we are able to use that diversity within our group to find new ways of looking at and solving problems.”

Each year at budget time, all Middleby brands do more than crunch the numbers. They collaborate and find incremental, yet impactful, changes that can be made among the brands.

“We call it ‘transformational innovation,’” Salman said. “We sit together with lead ers and engineers for all the brands and look at each other’s initiatives to identify the best practices. We’ll have people from around the world with expertise in biscuits and crackers or bread and buns, and we just talk about innovation.”

The cross-pollination of ideas becomes particularly impactful when suppliers from different sectors exchange best practices.

“We have this diversity of people, functions and product applications,” Salman said. “We have people from protein, bakery and foodservice, and we can uncover different ways to tackle a variety of problems.”

It’s easy to assume that conglomerate suppliers simply strive to be a “one size fits all” solution, but that’s not necessarily the case. In fact, one of Middleby’s core values is entrepreneurship.

“We are very entrepreneurial,” Salman said. “We strive to do what’s right, what’s fair and what’s proper. Integrity is import ant, and we work to focus on small changes that make a great impact.” CB

| president | Middleby“With companies in the US and companies in Europe, we encompass many different cultures, and we are able to use that diversity within our group to find new ways of looking at and solving problems.”

Mark Salman

Bakery

loaded with a 110v blower motor for wicketed inflation Great for clustered or very firm products can

Simple spring loaded design with a 110v blower motor for wicketed bag inflation. Great for clustered or very firm products. Average operator can operate bag between 10 and 25 bags/min.

Air operated retractable tuckers designed for a more positive bag hold. This works great for really soft or hard to hand bag products. Uses compressed air. Average speeds run between 10 and 25 bags/min.

This is a hand-loaded automatic bagging system. Operators load flights with product as they pass by. Allowing for the bagging of most items with ease at average speeds of 30 to 55 bags/min.

Fully automated line that groups, slices, stacks, and bags most types of buns/rolls at average speeds of 35 to 55 bags/min. High Speed option allows for speeds up to 66 bags/min. Not all products run at the same speeds.

It’s all about connectivity

ionSuite™ is packed with innovative features to complement Doran checkweighers and indicators It’s a seamless weighing solution that provides pinpoint control of the production process to lower costs, achieve plant wide efficiencies and ensure employee accountability

Doran. Powering Performance.

Precise formulation. Real-time data. Actionable reports.

ionSuite software applications are web based, accessible from any browser, mobile compatible and can integrate with ERP/MRP systems

Ingredient suppliers are innovating amid supply chain disruption.

BY BELLA FOOTESupply chain, a topic of conversation typically confined to those working within manufacturing industries, has now become a hot-button topic for many. Its disruption has impacted every day consumer activities, with 79% of people noticing product shortages according to Momentive, an experience management company formerly known as SurveyMonkey. Within the baking industry, the American Bakers Associ ation (ABA) noted nearly every bakery operation has seen price increases. The consumer economy has always

been at the mercy of the supply chain, but it’s one that has often worked tirelessly and quietly in the background … until now.

Although a spotlight has been shone on the consumer-related fallout, it’s import ant to understand what’s happening on the ingredient supply side. What does the environment look like for ingredient suppliers, and how are they navigating shortages and disruptions?

This torrent of supply chain disruption has been the perfect storm.

Dave Hufford, SVP of procurement and quality assurance and regulatory compliance at AB Mauri, a global supplier of yeast and other bakery ingredient products, described the conditions at hand.

“We have been dealing with a series of never-ending challenges since February 2020,” Hufford said. “That includes multiple global impacts associated with the pandemic, weather events, container shortages, extended lead times on most items, the impact of the conflict in

Russia and Ukraine, avian flu, and heavy inflation, just to name a few.”

Storms, droughts and fires — all ampli fied by climate change — have dealt blows to the raw ingredient supply. According to the UN Food and Agri culture Organization, the month of January alone saw a 4.2% surge in vegetable oil prices due to South Amer ican droughts and Malaysian typhoons. Additionally, the war in Ukraine has had reverberating effects with the country being the top supplier of sesame seeds and an important grower of crops such as wheat, corn, soy and barley.

What’s more, the baking industry, like many others, suffers from serious work force challenges, with more than 12,000 jobs available on ABA’s career website.

Raw material shortages — and their rising cost — have been the biggest focus for Corbion, which supplies emulsifiers, functional enzyme blends, vitamins and minerals.

“For our baking business, we buy between 1,000 and 1,500 different raw materials,” said Abby Ceule, senior director of ingredient solutions at Corbion. “It’s been almost exactly a year since we started to see the raw material delays and shortage start to creep up on us. It’s been a rolling trend; starches right now are a hot topic for our business. We’ve seen different issues with gluten, emul sifiers and different food assets at various times.”

The ingredients and commodities that were commonplace five years ago are now beginning to dry up.

“I’ve been absolutely floored by the sheer number of things that are extremely tight,” said Nesha Zalesny, a partner at IMR International, an indus trial market research and consulting company in food hydrocolloids. “Even things as ubiquitous as xanthan gum, you cannot get it in the United States. That is really shocking.”

Even if ingredients can be acquired, delayed shipments propose an issue.

“We typically can source most ingredi ents, but lead times are much longer and more difficult,” said Edward Mlotek, VP of sales and marketing for global ingredi ent supplier Repco Bakery Solutions.

In addition to price increases and lead times, bakeries in need of ingredients may overorder to account for inventory loss and potentially delayed material.

“Overordering, like hoarding toilet paper during the pandemic, creates a feedback loop that stretches an already dwindling supply,” said Ben Reusser, Innovative Center manager for Cain Food Industries. “That will cause our suppliers to cap new business or not even be able to add any at all.”

As outside factors become increas ingly more difficult to predict and regu late, ingredient suppliers rely heavily on internal regulation and management.

Keto-friendly full ingredient mixes for breads, buns, crusts, bagels, and more. Stand out to consumers with a premium loaf of flavorful keto friendly bread. This easy to use blend gives a high quality product without a chalky aftertaste and gummy texture. Sesame, MultiGrain, White and Sour varieties available to fit perfectly into your bakery and into a low carb diet.

Who needs carbs when you’ve got bread this good.

BROLITE PRODUCTS, INC (630) 830-0340 | TOLL FREE (888) 276-5483 | FAX (630) 830-0356

1335 SCHIFERL ROAD, BARTLETT, IL 60103 | 1900 S PARK AVE, STREAMWOOD, IL 60107

This takes the form of consistent and open communication.

“We manage our customer expectations with great care,” Reusser explained. “We let them know what we can get from our suppliers along with lead times and current pricing.”

Therefore, trust between bakers and their suppliers has become more critical than ever.

“Our customers trust us to keep them informed about sourcing challenges,” Mlotek said. “Our intervention and management of this issue is some thing we are proud of. When we run into a hiccup or we have an issue with sourcing an ingredient, we immediately communicate with our customers, keep ing them updated on where we’re at and how the sourcing is going.”

Strong communication is also neces sary to ensure the supply chain remains

fluid and that suppliers can pivot quickly when it comes to creative R&D. Ingredient shortages and delays have forced many suppliers to expand their network, sourcing the same product from various places.

“We started to ask, ’Who else can we get this from?’” Ceule said. “We’ve had to expand our own network of suppliers into our business.”

Network expansion is becoming more common throughout the supply chain. KPMG — a global organization of independent professional services firms — identified overreliance on a limited number of suppliers as a key trend impacting the current situation.

“As we emerge from the COVID-19 slowdown, many businesses recog nize the need to better equip their supply chains by identifying alternative trading partnerships,” KPMG reported. “They are actively seeking a broader

Even in the face of extreme conditions, baking industry ingredient suppliers have managed to not only ease the supply chain burden for their consumers but also create new — and better — formulations.Photo courtesy of AB Mauri

list of suppliers, alternative markets/ customers, as well as different transport and logistics providers.”

Then again, sometimes certain ingredi ents are simply not available.

“Like everyone in this industry, we too experience some of the pains of the supply crisis with certain ingredients that our customers ask us to blend,” Mlotek said. ”So, we have worked with bakers to substitute ingredients or formulate a difficult ingredient out of a product.”

Ingredient supplier R&D teams have worked tirelessly to test and develop new ideations of certain recipes for their customers.

“For instance, gluten reduction is nothing new, so we have ascorbic acid, enzyme blends and other classic conditioners that have been used previously to great effect in reducing the overall gluten needed in a formula,” Reusser explained. “Emulsifiers have been an issue as well due to lack of oils. We also have enzyme blends that are also used to reduce or eliminate these ingredients.”

Ingredient suppliers often have an R&D team with baking expertise, so they can understand exactly what they are dealing with.

“We utilize our in-house bakery lab for experimenting with replacement ingredi ents and enzymes to offer replacements and unique solutions,” Mlotek said.

Suppliers often provide an ingredient substitute that doesn’t impact the nutri tional claims or ingredient statements, especially when it comes to allergens.