15 minute read

CARBON CAPTURE AND STORAGE

Sequestration:

A BLUEPRINT FOR SUCCESS

While a few ethanol producers have taken advantage of the 45Q tax credit, the policy precludes full industry participation. A blueprint lays out recommendations from lessons learned.

By Lisa Gibson

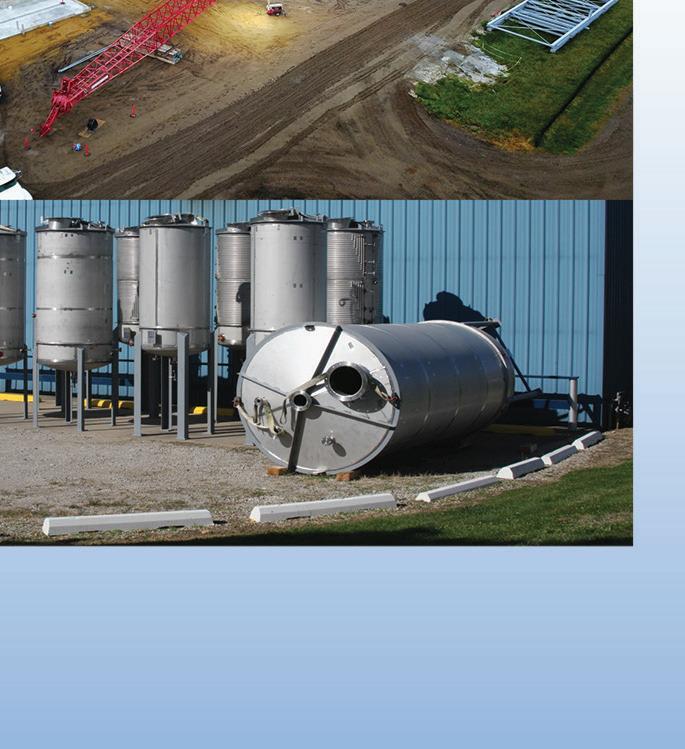

With a stratigraphic well already completed, and ongoing modeling to determine volumes of carbon dioxide to be injected, Blue Flint in Underwood, North Dakota, is on its way to producing a zero-carbon fuel.

The goal is prompted in large part by the 45Q tax credit, says Jeff Zueger, CEO of Midwest AgEnergy, Blue Flint’s parent company.

“45Q is a big driver,” Zueger says. “It unlocked the potential for these types of projects. The changes in 45Q have been a significant enabler to advancing these projects to make sure there’s enough economic opportunity there to support the risk that goes along with it.” 45Q provides a tax credit incentive for qualifying carbon emitters to capture and store carbon dioxide. Changes in 2018 extended the credit for two years and lowered the qualifying threshold for emitters from 500,000 metric tons of carbon dioxide to 100,000, opening the opportunity to more of the ethanol industry.

CARBON COUNTS: Midwest AgEnergy’s Blue Flint in Underwood, North Dakota, is leading the company’s progress toward zero emissions in ethanol production. With a stratigraphic test well already drilled, the project is on its way to storing 185,000 metric tons of carbon dioxide from Blue Flint.

PHOTO: MIDWEST AGENERGY

SPEAKERS CELEBRATE: Midwest AgEnergy’s Vision Carbon Zero project has received praise from state and local officials. From the well commencement event, left to right: North Dakota Attorney General Wayne Stenehjem, North Dakota Lt. Gov. Brent Sanford; Sen. John Hoeven (R, N.D.); Jeff Zueger, Midwest AgEnergy CEO; Jason Bohrer, Lignite Energy Council president; North Dakota Agriculture Commissioner Doug Goehring; and Adam Dunlop, Midwest AgEnergy director of regulatory and strategic planning.

PHOTO: MIDWEST AGENERGY

“45Q is absolutely part of our business model,” Zueger says.

The tax credit is part of many carbon-capturing business models across the country where applicable, beyond ethanol. It’s the focus of the Carbon Capture Coalition’s newest policy blueprint and has prompted companion legislation in both the U.S. House of Representatives and Senate. Those bills introduce a series of necessary updates to 45Q in its current form, several emphasized in Carbon Capture Coalition’s blueprint.

“Congress has opted to prioritize carbon capture because of its many benefits,” says Brad Crabtree, director of the Carbon Capture Coalition. “It’s worth spending tax dollars to incentivize these technologies.”

Vision Carbon Zero

CarbonZero, the storage project at Blue Flint, is the tip of the spear as far as Midwest AgEnergy’s zero-carbon goals, Zueger says. Blue Flint will explore even more carbon-reducing strategies, in addition to potential measures at Midwest AgEnergy’s Dakota Spirit in Spiritwood, North Dakota.

Blue Flint’s project began with coordination with the North Dakota Industrial Commission and the Dakota Resource Council, Zueger says. The team conducted 2D and 3D seismic modeling of the area to determine geologic locations capable of longterm, safe carbon storage. With the drilling of the stratigraphic test well came core samples, well logs and other data, now turned over to the Energy & Environmental Research Center at the University of North Dakota in Grand Forks, for further modeling and demonstration of the chosen reservoir’s capacity.

“We found, in fact, multiple reservoirs, so the data was positive,” Zueger says. “Everything points to the fact that we will be able to effectively inject and store CO2.”

Seismic testing was done in a 9-square-mile radius, Zueger says. “We let the data inform us as to where to put that test well. And it said to go a little farther west than we had planned. So that’s where we put the stratigraphic test well.

“We followed the data.”

Blue Flint plans to inject about 185,000 metric tons of CO2 per year, Zueger says. EERC’s modeling will determine the parameters, including whether the well can hold increased volumes from Dakota Spirit, by providing a better understanding of how the reservoir will respond under different injection profiles.

“In any case, we plan to move forward with the Blue Flint plant, getting the reservoir completed and requirements for a Class VI permit,” Zueger says.

He says the state has indicated it can process a Class VI permit in about seven months. “We’d continue to develop all additional components of the design and final engineering around compression, pipeline and so on and, upon getting the permit, advance the project with a goal of injecting CO2 late in 2022.”

The test well is the largest investment in the project thus far, and is designed to serve as the injection well also, Zueger says. The main investment in the entire project is around the compression, dehydration and other equipment that prepares the carbon dioxide for injection in a supercritical manner, he adds.

Blue Flint has been evaluating carbon capture for about 12 years, Zueger says. It thoroughly analyzed options for enhanced fracking, enhanced oil recovery, industrial use of carbon dioxide and more. “We determined that our best path forward is capture and storage of CO2 with a Class VI well.”

Blue Flint is uniquely positioned to become a zerocarbon fuel producer, as it is a combined heat-and-power plant that gets its thermal energy from the nearby Coal Creek Station. “That CHP design has afforded us a lowcarbon pathway into low-carbon markets,” Zueger says, hesitating to report the plant’s current carbon intensity score, as factors in that measurement vary widely among states. It can be misleading, he cautions.

“Most energy coming in from Coal Creek is waste energy, so we’ve started off with a pretty good low-carbon score with a pretty minimal impact to the environment and when we further add the carbon sequestration project, we’re starting to approach those zero carbonintensity levels because we don’t have a boiler onsite.”

Coal Creek is scheduled to shut down in summer of 2022, but Zueger says if the station isn’t purchased and able to continue operating, Blue Flint is prepared to repower using technologies that deliver a low-carbon fuel.

In the meantime, Blue Flint’s project is moving forward and able to take advantage of 45Q, with some innovative partnerships. Privately owned by 22 individual investors, Blue Flint’s ownership structure precludes it from qualifying for 45Q, so a partnership is in development that would allow monetization of the credit, Zueger says.

“That partner will work through the execution and ongoing operations and will be able to take advantage of the tax credit,” he says, declining to identify the partner.

Still, Zueger emphasizes the importance of simpler parameters for taking advantage of 45Q. “I think it’s important to continue to provide a cleaner path toward being able to monetize the 45Q benefit. We’re contemplating a partner because of the tax structure we have. It’s a significant part of the project economics.”

Blueprint Priorities

Simpler parameters and cleaner pathways in 45Q are priorities for the Carbon Capture Coalition, as well. Its first policy blueprint was released in 2019, a collaborative effort among its 80-some member organizations. The plan is to continue releasing a blueprint every two years, Crabtree says. It’s a large undertaking, yes, but the issues are evolving quickly, he says. “It’s necessary every two years.”

Crabtree emphasizes the importance of an agreedupon policy want list from a large number of organizations and industries. The most difficult part, he says, isn’t technical details; it’s reaching consensus on the overall policy priorities among the entire coalition. “Given the size of the group, it’s remarkable we’re able to come up with something like this,” he says. The first iteration was the most difficult, building it from the ground up, and subsequent blueprints will build on that foundation, with new and fun damental changes to policy. The following are the main 45Q priorities in this year’s blueprint, released in February.

First: A direct payment option.

“At the top of our list is providing a direct payment option for 45Q,” Crabtree says.

Direct payments, as recommended by the Carbon Capture Coalition, would reduce tax investment risk for 45Q projects, but also streamline overall how technology incentives are deployed, Crabtree says. “Long-term, it’s what we really need to do to for these tax incentives to have their maximum impact in the marketplace, but it does also provide a very near-term jobs and economic development benefit as we try to recover from this Covid pandemic.”

The blueprint proposes a structure wherein the developer—the owner of the carbon capture equipment—would claim the 45Q tax credit in the form of an estimated payment on their tax return. That way, if they have tax liabilities, the 45Q direct payment reduces the taxes they have to pay. If they don’t have tax liability, or not enough of it, they get cash back after they file their returns. Either way, a developer can put revenue into their pro forma to finance their project.

“That means they’re not limited to tax equity investment,” Crabtree says. “They can go to a whole other

FOLLOW THE DATA: Midwest AgEnergy used extensive data and modeling to locate its injection well site at Blue Flint, ending up farther west than developers expected would be optimal.

PHOTO: MIDWEST AGENERGY range of potential investors, so it both broadens the pool of capital available, and also reduces the cost of the capital investment that they do receive.”

It addresses one of the largest hiccups to 45Q monetization in the ethanol industry. Carbon capture and storage is relatively new and not all technologies have been widely used on a commercial scale. They’re proven, but not largely implemented. Wind and solar power, on the other hand, have gigawatts of installations in place, so investment companies are more comfortable with those technologies.

“We’re in much more of a learning curve with these technologies and so the problem is that tax equity investors are requiring really large haircuts for investing in projects,” Crabtree says. As much as 50% of the value of the tax credit is lost to tax and equity transactions, and not used on development of the project, he cites. “So, dollar for dollar, we’re losing a lot of value to third parties.”

Zueger emphatically agrees, saying a direct payment would be important for Midwest AgEnergy’s second capture and storage project.

“It’s much more than a Covid response,” Crabtree says of

the direct payment proposal. “It’s actually a transformative way to improve and streamline how we incentivize technology deployment to reduce emissions and support economic development and job creation.”

Second: Further 45Q extension.

The two-year extension in the FY 2021 Omnibus Appropriations Bill at the end of last year was a victory, Crabtree says. The extension pushes the start of construction date to Dec. 31, 2025.

“We’ve lost essentially three years to the development of guidance and the final rule for 45Q,” Crabtree says. “When it was passed, it was authorized for 6 years.

“This gets us back to five years for projects to develop and begin construction. That’s critical.”

For perspective, wind tax credits were enacted in Congress in 1992, solar in 2005. “I think by anyone’s definition, the deployment and commercialization of wind and solar in the marketplace has been a very significant success story,” Crabtree says. “The longevity of these tax credits has been a major component of that.

“We need that same long-term investment horizon for 45Q, and then the carbon utilization and direct air capture.”

John Fuher, vice president of government affairs at Growth Energy, agrees. “I think the biggest thing when you look at 45Q, you have to have a longer runway. You have to extend it. You have to find a way to allow more time for people to take advantage of it. In the ethanol sector, there’s a lot of interest.”

Two bills have been introduced that include extensions: In the House, the Accelerating Carbon Capture and Extending Secure Storage through 45Q (ACCESS 45Q) Act would extend 45Q for 10 years; and the 45Q Carbon Capture Utilization and Storage (CCUS) Tax Credit Amendments Act of 2020 in the Senate would extend it for five.

Crabtree and Fuher agree that any 45Q extensions would likely be rolled into a larger package surrounding climate, economic relief, etc. “We do increasingly feel like the provisions we’re recommending are an essential component of a broader policy,” Crabtree says.

Third: Elimination of thresholds.

In a normal year, most ethanol plants would qualify for the current 100,000-metric ton-threshold, but could risk not qualifying in a year like 2020, when plants reduced production and even went offline.

“We think these thresholds do not serve any public policy purpose,” Crabtree says. “They simply deter innovation. If we’re interested in fostering innovation and reducing carbon emissions as much as we can, then why do we have these thresholds?”

PLANT UPTIME IS IMPORTANT TO YOU, SO IT IS IMPORTANT TO US. Our full service team of experts have 20 years of ethanol plant maintenance reliability and uptime history. 24/7 support and ready access to a full inventory and all Fluid Quip equipment parts, ensures that you maintain your plant’s uptime status.

• OEM Parts Warehouse • $1 million+ on-hand inventory • Fully stocked trucks • Overnight/hot shot shipping

PARTS

EQUIPMENT SERVICE

• Factory Trained & Certified • MSC™ Systems • SGT™ Grind Systems • FBP™ Fiber By-Pass Systems • MZSA™ Screens • Paddle Screens • Grind Mills • • Centrifuges Centrifuges

FluidQuipMechanical.com | 920-350-5823 | follow us on on Fluid Quip Mechanical is a division of Fluid Quip Technologies i .

John Fuher Growth Energy

Fourth: Infrastructure develop-

ment. Some ethanol-producing states, including Iowa, don’t have geologic saline formations to hold carbon dioxide, or pipelines to transport it. “If these incentives are going to work in a significant way, there needs to be support in a pipeline infrastructure that will connect ethanol plants together and transport CO2 to where it can be geologically stored,” Crabtree says.

Green Plains Inc. announced in February that a partnership with Summit Carbon Solutions will allow construction of a pipeline to bring carbon from three of its Iowa plants to geologic storage sites in North Dakota. The setup will sequester more than 10 million metric tons of carbon dioxide annually, making it the world's largest carbon capture and sequestration project, according to Green Plains.

Shortly after Green Plains’ announcement, Glacial Lakes Energy said it, too, would join the Summit Carbon Solutions project, contributing more than 1.6 million tons of carbon dioxide from its four ethanol plants in South Dakota.

The Storing CO2 And Lowering Emissions (SCALE) Act, introduced in the House, would offer low-interest federal loans to finance similar projects. “The goal is to create interconnected CO2 pipelines to make it easier and more economical to transport CO2 to where it’s needed,” Fuher says.

SCALE also would create large-scale saline geologic storage hubs and provide the U.S. EPA with increased funding to permit Class VI wells.

“Given where the bulk of the ethanol production is in the U.S., the infrastructure part of this is really key to the future of carbon management in the ethanol industry,” Crabtree says.

The Future

“That’s the future—lower-carbon fuels,” Fuher says. “You’re seeing it already. You see a lot of plants making decisions strictly around the carbon intensity.”

But the challenges to 45Q are “unacceptable,” Crabtree says. The blueprint’s goal is to resolve those challenges, and Crabtree says it’s the most widely used and read policy document he’s ever helped produce.

“We’re really speaking to Congress more and more with one voice, which is always helpful,” Crabtree says.

Zueger says even more changes could be made to carbon capture incentives, including removing sales tax from captured and sold carbon. A bill in the North Dakota legislature seeks to accomplish that.

Clearly, ethanol plants represent a prime opportunity to capture carbon and reduce emissions in the U.S., and an evolving 45Q could make a significant difference in the number of plants equipped to take advantage of it.

“It’s pretty easy to capture carbon off a fermentation stack,” Fuher says. “It’s all carbon. If you can capture that and find a way to use it or sequester it, that lowers your CI and gives your fuel more value in this long-term march toward low-carbon liquid fuels.”

Author: Lisa Gibson Editor, Ethanol Producer Magazine 701.738.4920 lgibson@bbiinternational.com