SPRING 2023 EDITION 16 NEW IDO PROJECT UNDER WAY Industry 18 OZGROUP WASTE BUSTERS Blueberries 63 LATEST NEWS ON RED LEAF Strawberries 104 TAMING INVASIVE BLACKBERRY Rubus 111 AUSTRALIAN BERRY JOURNAL

SUPPORT US & BECOME AN INDUSTRY PARTNER Support the largest horticultural group in Australia by becoming an Australian Berry Industry Partner with Berries Australia! To discuss your options in more detail, please contact Jen Rowling at Berries Australia on 0448 322 389 or email jenrowling@berries.net.au FIND OUT MORE AT: www.haygrove.com FIND OUT MORE AT: www.syngenta.com.au SILVER PARTNERS FIND OUT MORE AT: www.agnova.com.au FIND OUT MORE AT: www.fmccrop.com.au BRONZE PARTNERS

EDITOR

Jane Richter TERES Communication 0431 700 258 jane@teres.com.au

CONTRIBUTORS

Jane Richter

Rachel Mackenzie

Anthony Poiner

Simon Dornauf

Andrew Bell

Richard McGruddy

Dr Angela Atkinson

Mark Salter

Helen Newman

Aileen Reid

Jen Rowling

Wendy Morris

Gaius Leong

Eliza Wilding

Sophie Parks

John Hay

Emily Remnant

Joel Mackay

Jessica Carter

Steve Burdette

Craig Shephard

Dr Robin Adair

Dr Rae Kwong

Dr Dylan McFarlane

Dr Scott Mattner

Geoff Kelly

Brendan Rodoni

Fiona Constable

Michelle Paynter

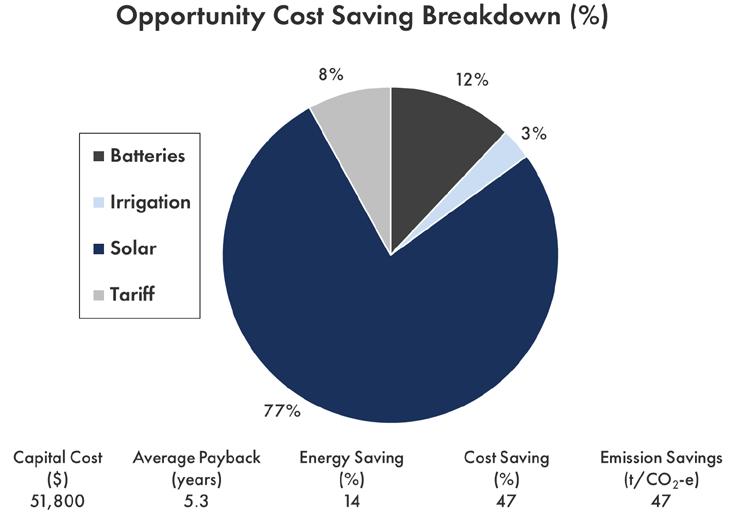

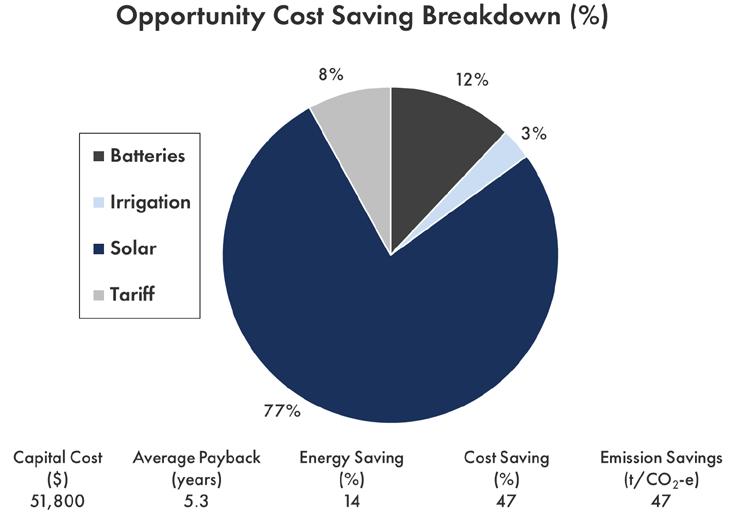

Joanna Gillespie

Ky Mathews

ADVERTISING

For all Advertising & Partnership Enquiries

Kylie Thompson 0 491 751 123 | admin@berries.net.au

All advertising and advertorial material is subject to review and approval prior to publication.

DESIGN

Sama Creative | samacreative.com.au

DISCLAIMER: Whilst every care has been taken in the preparation of this journal, the information contained is necessarily of a general nature and should not be relied upon as a substitute for specific advice. The advice and opinions in the articles published in Australian Berry Journal are essentially those of contributors and do not necessarily reflect the views of Berries Australia or the Editor. The advice is at the reader’s own risk, and no responsibility is accepted for the accuracy of the material presented. Inclusion of an advertisement in this publication does not necessarily imply endorsement of the product, company or service by Berries Australia or the Editor. Horticulture Innovation Australia Limited (Hort Innovation) makes no representations and expressly disclaims all warranties (to the extent permitted by law) about the accuracy, completeness, or currency of information in Australian Berry Journal. Reliance on any information provided by Hort Innovation is entirely at your own risk. Hort Innovation is not responsible for, and will not be liable for, any loss, damage, claim, expense, cost (including legal costs) or other liability arising in any way, including from any Hort Innovation or other person’s negligence or otherwise from your use or non-use of Australian Berry Journal or from reliance on information contained in the material or that Hort Innovation provides to you by any other means. Copyright © Horticulture Innovation Australia Limited 2023 Copyright subsists in Australian Berry Journal. Horticulture Innovation Australia Limited (Hort Innovation) owns the copyright, other than as permitted under the Copyright ACT 1968 (Cth). Australian Berry Journal (in part or as a whole) cannot be reproduced, published, communicated or adapted without the prior written consent of Hort Innovation. Any request or enquiry to use the Australian Berry Journal should be addressed to: Communications Manager, Hort Innovation, Level 7 | 141 Walker Street, North Sydney 2060, Australia | E: communications@horticulture.com.au | P: 02 8295 2300

Tackling Food Waste: Oz Group Co-op’s Third Grade Fruit Management .............................................................. 63 Rewarding pollinators with sweet-talking blueberry flowers 68 Peter McPherson steps down from the International Blueberry Organization 71 Marketing Update 73 BLUEBERRIES BerryQuest International 2025 is heading back to Hobart ......................................................................................... 15 Total Vent Tunnels — A Game Changer: Open Day at Hillwood Berries 16 NEW: MT22010 Industry development and communications project underway 18 Fruit Growers Tasmania Annual Conference 2023 21 Berries Maximum Residue Limit (MRL) App now available 25 Future of the PALM scheme in doubt due to rushed consultations .............................................................................. 28 Early Needs & Recovery Project: Energy Audits Delivered 34 National map of Protected Cropping Systems now live 37 The Mini Farm Project .................................................................................................................................................... 40 Chlorine dosing to manage bacterial iron in a bore (English & Vietnamese) 44 IPM Notes: Chilli Thrips 48 Developing safer, selective insecticides to preserve honey bee health...................................................................... 55 Profile: Parvinder Lalli, NSW 58 Berries Australia team showcases berries at the Queensland EKKA ......................................................................... 60 INDUSTRY Profile: Tasmanian Raspberry Canes, Carolyn & Simon Curtis 109 How do we achieve effective biological control of invasive European Blackberry? 111 RUBUS UV-Transmitting plastics reduce powdery mildew in strawberry tunnel production 77 PH19000 Autonomous pollination using miniature drones 83 BS22000 Australian Strawberry Breeding Program Field Day ................................................................................. 85 The relationship between yield and strawberry runner characteristics 90 To plant or not to plant: Managing the risk of fumigant phytotoxicity ....................................................................... 94 Healthy runners, more high-quality fruit 98 Red Leaf Disorder: knowledge through Field Surveys in South East Queensland 104 STRAWBERRIES SPRING 2023 EDITION 16 AUSTRALIAN BERRY JOURNAL Wherever you see this logo, the initiative is part of the Hort Innovation Blueberry, Strawberry and Raspberry and Blackberry Fund. Like this publication itself, it has been funded by Hort Innovation using the Blueberry, Strawberry and Raspberry and Blackberry R&D levy and funds from the Australian Government. Some projects also involve funding from additional sources.

Executive Director's Report

Rachel Mackenzie | 0408 796 199 | rachelmackenzie@berries.net.au

Rachel Mackenzie | 0408 796 199 | rachelmackenzie@berries.net.au

Welcome to the Spring 2023 edition of the Australian Berry Journal. This is the first journal funded through the new Communications and Industry Development Officer (IDO) project and following the old saying that ‘if it ain’t broke, don’t fix it’, you probably won’t notice any changes from previous editions.

What has changed is the new project has been contracted for five years and was developed collaboratively between Berries Australia and Hort Innovation. This enables us to give better job security to our hard-working IDOs, and spend more time delivering to berry growers and less time reporting and contracting. We actively welcome feedback and suggestions from growers so don’t hesitate to call your local IDO or any of the Berries Australia team. Whilst on a family holiday in Europe in July I was able to pop over to Poland to attend the International Blueberry Organisation (IBO) Summit. The focus was obviously on blueberries but there were a lot of learnings across the whole berry category. I was very impressed by the Polish berry industry who are incredibly cohesive and have worked hard to build social license by promoting the industry as a whole, not just the fruit. This is something I think we can do better across berries and the whole of horticulture.

The Berries Australia team was able to put learning into practice at the Brisbane Royal Exhibition (the Ekka) where we were able to host a ‘berry day’ at the Queensland Fruit and Vegetable Growers’ (QFVG) Stand in the Agricultural Hall. The team handed out nearly 2000 mini-trays of the most delicious berries and chatted to about as many members of the general public. The horticulture industry has been conspicuously absent from the Ekka in recent

years and credit must go to the QFVG team for enabling us to showcase our wonderful industry. You can see more on PAGE 60.

Interestingly, the IBO Summit also highlighted that workforce challenges are not unique to Australia and labour cost and supply continues to be one of the biggest issues facing the berry sector globally. Disappointingly, the new PALM guidelines for the Pacific Worker Scheme are even more unwieldy than the previous versions and we seem to be moving further away from a sustainable workforce.

Many growers have raised concerns that the new requirements are too inflexible for many businesses and they are returning to backpackers even though they are a less reliable workforce. Concerns have been raised that the 88-day requirement for a second year visa may be removed but at this stage there have been unofficial assurances from government that this will not be the case. As these issues are not unique to berries, we are working with our industry colleagues such as the NFF Horticulture Council, the Australian Fresh Produce Alliance and the Approved Employers of Australia to address these issues. We are also intending to form a workforce sub-committee across the berry category to ensure that we have a consistent message.

I am very hopeful that by the time the next edition of the Journal swings around, we will have instigated our berry basket marketing campaign. This campaign will build on the successful blueberry marketing campaign to market across the whole berry category. The benefit of berry basket marketing was also mentioned at the IBO summit and, as it seems like we are heading toward a bumper season across all berry types, the timing is perfect. There are still some bridges to cross in terms of getting this model up but it would seem a logical way forward for the sector.

2 INDUSTRY BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

Chairman's Report

Anthony Poiner | 0412 010 843 | anthony@smartberries.com.au

Welcome to the Spring edition of the Australian Berry Journal. In the Eastern parts of Australia spring has well and truly sprung after a warm winter, whereas the West coast has been experiencing cool, damp conditions. The huge geographic and climatic diversity in Australia is certainly a benefit in an era where consumers expect year-round supply, but it also means we have a diversity of pest and disease issues across the country.

Access to modern crop protection products to deal with the full range of pests and diseases impacting berry producers is fundamental to the ongoing success of the industry. The chemical regulatory system has a very low risk appetite (as it should) so some traditional chemicals are being phased out long before any negative consequences can be realised. This is frustrating on one level, but ultimately protecting the consumer and the environment has to be the number one priority.

Ensuring that growers have a range of options to deal with pest and diseases over the next decades is a key priority for the Berries Australia committee. To that end, Rachel and the team are working with Hort Innovation to undertake a review of the current pest and disease issues facing growers across the nation as well as identifying potential future threats. This process is facilitated through the Strategic Agrichemical Review Process (SARP) with Hort Innovation and is updated every few years. An analysis will then be undertaken as to what chemistry is currently available, what has the potential to be withdrawn in the near future and what other options might be coming through the pipeline.

We are undertaking this process at a whole of berries level as we are aware that there is a degree of mismatch between the berry categories.

It is much better to be ahead of the curve in terms of chemical access as alternative options, particularly for export, can take a long time to develop and implement. Whilst recent developments in Europe seem to be more driven by politics than science, they do foreshadow a scenario where many of the products we rely on may no longer be available. By global standards Australia is a very small market for the chemical companies and, as such, if actives are banned overseas, there may be no commercial value in producing them for the Australian market alone. On a more optimistic note, new softer chemistry is continuously being developed overseas and we need to push to ensure those chemicals become available here. I should also note that integrated pest and disease management approaches (IPDM) and new varietals are also important tools in our toolbox.

The SARP workshop is only the first step in this process, but it is an important one to ensure we are all pulling the same direction. We have invited leading agronomists and technical experts in this area to attend but it is open to any of our members as well. Please contact your local IDO if you would like an invite.

Based on the information provided at the recent Berries Australia meeting we are expecting a bumper crop across the category with Queensland strawberries being predicted to peak in September potentially crossing over with the blueberry season. We are also aware that there are significant plantings of Rubus coming on. Whilst at the time of writing it is not over the line, we are hopeful that for the first time ever we may be able to launch a “berry basket” marketing campaign to lift sales across the category. Stay tuned!

3 INDUSTRY

President's Report

Andrew Bell | 0422 234 124 | andrew@mountainblue.com.au

As we head into our peak blueberry growing season, I do hope you received the letter from me outlining the change to the voluntary blueberry levy from 7 cents to 3 cents per kg. The change took place on 1 August 2023 and will be in place for the next two financial years.

The Australian Blueberry Growers' Association (ABGA) committee recognises the past few years have been tough and as such we wanted to put more money back into your pockets whilst still being able to fund industry priorities. The committee has elected to maintain a voluntary rather than compulsory levy to ensure levy payers have full control over how their funds are spent, which means we can continue to manipulate the levy rate according to the needs of the industry. Obviously, the issue with a voluntary levy is that some growers don’t pay, whilst continuing to reap the benefits of the levy investment.

I am still really disappointed that there are major growers who read this journal (funded by the levy), access minor use permits (funded by the levy), engage with the IDO (funded by the levy) or benefit from having a professional body to actively advocate in times of crisis such as Varroa mite, and continue to not to pay the levy consistently or at all.

The ABGA has again committed to an industry-wide marketing program in light of what looks like a bumper season. In exciting news, it looks like the funds will be supplemented by Rubus and possibly strawberry levy funds to enable a ‘berry basket’ campaign. The berry basket approach has been proven overseas to lift sales across the category and we are hopeful it will do the same here. Again, this can only happen if growers pay the levy!

In terms of research and development, we are working with Hort Innovation to develop a project to understand the causes of blueberry root wrapping and associated crown disorders. Symptoms are normally visible several months (or years) after planting and it translates into abnormal growth of tissue. This growth may resemble the crown gall symptoms although no pathogen has been associated with this disorder; other times the problem translates into a non-standard growth pattern (e.g. root wrapping, tissue proliferation, crown restriction & stem occlusion).

The range of crown and root disorders affecting blueberry plants is growing in incidence and severity globally. To date, the Australian industry has not been as affected as some international locations and propagators, but there is a growing concern that these crown and root disorders are increasing in the domestic industry. This is the kind of proactive research we can fund if we have a functioning levy.

Having observed the other berry categories jump through hoops to get their priorities funded, I really believe that the voluntary levy approach remains the best model, but this model can only work if all growers play their part.

All of the ABGA committee members are volunteers, and we are very open to new committee members. If you genuinely believe the levy and the ABGA delivers nothing to you then we would welcome your contribution at the committee level to ensure you get the best value from the levy. I am always very happy to take calls from ABGA members on how we can best serve the interests of the industry.

4 INDUSTRY BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

President's Report

Richard McGruddy | 0408 763 804 | richard@berryq.com.au

It feels like we have been talking about the raspberry and blackberry levy amendment for years, but it is finally here. From 1 October 2023 your levy payment will decrease from 12c/kg to 4c/kg. The timing is quite good as we are heading into one of our biggest seasons ever and hopefully the levy reduction will give some financial relief to growers.

The warm winter weather in the Eastern states means there is a likelihood of higher yields over an extended period with the season looking to be about a fortnight ahead of where it was in 2022. Whilst the yields will be up the timing looks to be more favourable in terms of coinciding with Christmas.

With increasing yields, we need to look at increasing consumption. As part of the winding down of the Rubus marketing fund we are currently in negotiations with Hort Innovation about combining the remaining Rubus marketing funds with the blueberry marketing funds and potentially some strawberry royalty funds to deliver a “berry basket’ campaign. Research from overseas suggests that a berry basket approach lifts sales across the whole category and we are excited to trial this approach over the next year or so.

A recent consumer demand report commissioned by Hort Innovation looked into the future potential of certain markets across the horticulture category. The report was based on extensive consumer interviews and interestingly uncovered some opportunities, particularly for blackberries, in some Asian countries.

We will be examining the data in depth, but it certainly shows that an increased focus on export is warranted for the Rubus category. This report is available from the Hort Innovation website at www.horticulture.com.au/ growers/help-your-business-grow/research-reportspublications-fact-sheets-and-more/st21007

In other positive news, we have been told that all but one grower in the Varroa red zone in the Coffs Harbour region had a successful pollination event. Considering that at one point it was looking like there would be no pollination services in the red zone at all this is a great outcome and a great relief to the growers in the region. Again, we would like to thank the NSW DPI for their efforts in working with industry to enable this to happen as well as the bee keeping industry, Rachel Mackenzie from Berries Australia and Tyler Scofield from Driscoll's.

We are aware that access to minor use permits is an ongoing issue, and you will be pleased to know that we are addressing it at a Berries Australia level. Please raise any pest and disease issues you are seeing on the ground with your local IDO so we can ensure they are being picked up in our discussions. You will also find an updated copy of the Minor Use Permit booklet covering the existing permits with this edition of the Journal. Finally, I am aware that the last 12 months have been tough for many growers with reduced prices and significantly increased input costs. We understand that the changes to the PALM scheme have made it more costly and bureaucratic than in the past and we will continue to work through Berries Australia to push for a more pragmatic approach from government.

5 INDUSTRY

Chairman's Report

Simon Dornauf | 0408 681 206 | simon@hillwoodberries.com.au

The recent winter season has seen above average temperatures which reflects the shift from a La Niña to an El Niño weather pattern. This transition typically leads to an earlier peak in winter production, however, delays in Queensland plantings means supply will likely peak in September, aligning the strawberry supply peak closer to the height of the blueberry season. Despite our aspiration to have a well distributed berry category to optimise consumer demand, the interplay of natural factors and external forces can complicate these efforts.

In our commitment to focus on variables within our control, we are exploring the concept of a marketing program that encompasses the entire berry category. Currently the blueberry industry funds its own marketing program which is run by Berries Australia. Encouragingly, the Rubus industry is also set to participate in this initiative. International research consistently indicates that the ‘berry basket’ approach boosts sales across the entire category, reducing the risk of different berry types eroding each other's market share. To this end, Strawberries Australia has endorsed the berry basket campaign, for the first time potentially leveraging royalty funds overseen by Hort Innovation. While consultations with Hort Innovation are yet to occur due to the fund's management, we are optimistic this concept can become a reality.

The success of the Australian strawberry industry hinges upon access to high-quality runners. Nonetheless, growers continue to confront obstacles in securing varietals and timely runner supply. While acknowledging the gravity of this issue for the industry, Strawberries Australia recognises its complicated nature. The economics of runner cultivation are intricate, demonstrated by Sweets Runners shifting away from bare-root production.

It is important that all of us as an industry work together and remain open minded to new concepts ensuring a sustainable runner industry for the future. One option is to facilitate the entry of more plug-plant propagators into the sector, although this must be executed without compromising biosecurity and product quality. Adopting a constructive and sustainable approach, Strawberries Australia aspires to engage with all segments of the supply chain to navigate this challenge.

Over the last decade, the berry industry has strongly supported the government’s Pacific worker schemes. We have forged invaluable relationships with our Pacific Island workers who have become the backbone of many of our businesses. Essential to the scheme's continued viability is its practicality and cost-effectiveness for growers. We take pride in supporting many workers to establish homes and provide education for their children back home. In a win for common sense, the government has amended its deed regarding the minimum wage vs award pay issue. Frustratingly there are still many issues that need to be addressed in the new deed and guidelines and growers would ask for far more consultation regarding these matters. Read more on PAGE 28.

The current administration has made no effort to get on the ground and talk to growers and workers who have been successfully operating the program for many years. They need to see how the program works in reality, rather than punishing good growers and workers for the misdeeds of a small number of employers. I extend an open invitation to Minister Burke and any of his team to visit my farm, tour our worker accommodation, get to know some of our workers and see the conditions they work under.

6 INDUSTRY BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

CEO Report

Brett Fifield, Hort Innovation, Chief Executive Officer

Australian horticulture has had an impressive run over the past decade. The annual production value of the industry increased by $6.4 billion between 2012 and 2022 to $15.9 billion, and Aussie growers are producing 850,000 tonnes more than they were a decade ago. Our growers are adding more than $700 million to the value of horticulture each year on average – not a bad result.

At Hort Innovation, we have released new research that shows the industry will reach a production value of $21.8 billion by 2030 – around $2 billion higher than previously expected. This growth is based on a number of assumptions and trends and our modelling is based on a moderate growth scenario.

Our Contribution of Australian horticulture industry report also shows strong growth in Australia’s key horticulture regions. The Coffs Harbour/Grafton region’s production value will grow to $522 million by 2030, an increase of 18 per cent compared to 2020/21. The report also showed for this region, berries account for 81 per cent of total horticulture (including processing). You can view the full report at bit.ly/MT21010

On paper, things look pretty good even with moderate growth – a higher growth scenario puts the industry at $25.6 billion. As any farmer will tell you though, you keep an eye on what is around the corner and invest in the good years to prepare for what is ahead.

Like the berry growers who invest in Hort Innovation through levies, as a rural research and development corporation (RDC), we need to look to the future and stay ahead of the game. We need to ensure our priorities are growers’ priorities. To do just that, we have launched the Hort Innovation Strategy 2024-2026, which will take our company through the next three years. This plan was developed in consultation with both growers and peak industry bodies. You can review the strategy online at bit.ly/Strat-24-26

We are preparing for the challenges ahead by enhancing and safeguarding the supply of Aussie produce, accelerating local and global demand for these products, and maximising and diversifying the investments we make in our research and development (R&D) work and marketing campaigns.

We know that growers want us to take bigger swings on our investments. You want us to focus on big-picture programs of work rather than tactical, individual research projects.

Just this month, Hort Innovation announced the largest and most ambitious trade initiative in Australian horticulture industry. The breakthrough $136 million program, the Fresh and Secure Trade Alliance (FASTA) will see key Aussie industry stakeholders and authorities joining forces to help protect and grow Australia’s horticultural exports.

Last year Hort Innovation invested $160 million in levy funds and this investment is important because of the return it generates for the horticulture industry. Aussie growers entrust Hort Innovation with their levy funds to make investments for the future.

When you think of the entire economic impact of Australian horticulture — production value of $15.9 billion, $12.96 billion in additional economic impact, and being one of the largest employers in the country — there is a lot at stake in getting your levy investment right to meet the challenges ahead of us.

That is why Hort Innovation is working with Berries Australia to ‘reset and refresh’ the whole-of-berries advisory mechanism including appointing refreshed ideation and project advisory panels across the blueberry, Rubus and strawberry industries. The advisory mechanism will be led by industry through Berries Australia and will support grower ideas and create industry impact where most needed. Please keep an eye out for updates through Berries Australia and Hort Innovation.

7 INDUSTRY

Victoria & South Australia

Dr Angela Atkinson, Berry Industry Development Officer 0408 416 538 | ido@vicstrawberry.com.au

After a cold and still fairly wet winter in the southern states, hopefully everyone is looking forward to spring and the season ahead.

The predicted El Niño weather pattern that we may be moving into later this year will likely bring a hotter and drier season, probably more like those we were used to before the last three or so cooler and wetter summers. The possibility of hotter drier weather means those growing in the ground may see increased levels of stress related issues, such as charcoal rot.

A best management guide for charcoal rot, based on years of working with growers to find solutions, is being produced by VSICA Research and funded through the Victorian Strawberry levy, and will be available later this year. Management of charcoal rot and other pest and disease issues, as well as other topics of concern for growers for the coming season, will be the focus of a field day in September, before the season really kicks off.

VSICA research (again funded by the VSIDC levy) has also worked with Victorian strawberry growers to develop technology to measure the levels of fumigant in soils, prior to planting, which has become an important issue with the adoption of totally impermeable films (TIF). To learn more about this research SEE PAGE 94 in this edition.

Recently growers in Victoria hosted a number of researchers working in strawberries, to demonstrate the production systems and challenges in the region. One of these, a team from Singaporean company Polybee, working on using miniature drones to aid pollination in protected cropping systems visited a Victorian farm to see how berries are grown under tunnels here. Polybee has worked with greenhouse strawberry growers in other countries and have run trials at Western Sydney University and also in glasshouse tomato production in South Australia as part of a Hort Frontiers pollination project. For more information about this project SEE PAGE 83 in this edition of the journal.

At the end of July, I attended the National Fruit Fly Council Symposium in Adelaide, which had a focus on how growers will manage fruit flies, particularly in regard to both domestic and international market access, in a chemically limited future. Instead of the usual technical presentations the symposium was a series of panel discussions and round table working groups, to capture input from growers, industry, supply chain participants and other stakeholders, including government and researchers. It was interesting to hear how markets are changing internationally, where the carbon footprint of food production is becoming as important as phytosanitary concerns and MRLs, with the most extreme example given being a supermarket chain in Europe choosing not to stock fresh produce delivered by airfreight.

The ‘toolbox’ for managing pests such as fruit flies was an important topic of discussion, and going forward it needs to become less reliant on chemical options, as more and more chemistry becomes unavailable. Focus needs to shift to other ways of ensuring clean fruit, such as maintaining areas of low pest prevalence by area wide management (AWM), leveraging off traceability systems already in place, using systems approach options and new technologies such as SIT (Sterile Insect Technology) and irradiation as an end point treatment. Many of these options are not yet accepted by importing jurisdictions, and work needs to be done to educate markets both here and overseas.

There is also a need for a stable mechanism for funding initiatives such as SIT and AWM, that doesn’t put the responsibility back on producers. While the problems of the world were not solved, it was a good opportunity for governments in particular to get some targeted and specific feedback from industry and start a productive discussion.

I’d just like to wish everyone the best for the start of the season, hopefully it will be a good one, and remind you to get in touch by phone or email if there is anything I can help you with.

Victorian Strawberry Industry Development Committee

8 INDUSTRY BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

Mark Salter, Berry Industry Development Officer 0400 100 593 |

After a challenging year Tasmanian berry growers are in the process of preparing for the new season. Strawberry planting is complete, preparations for the next Rubus crop are well underway and blueberry growers are in the final stages of pruning their bushes.

Indications so far are pointing to an early season, with most Tasmanian growing regions experiencing slightly above average winter temperatures which may have an impact on chill hour accumulation for some varieties. The very windy weather in late July has also played havoc in certain areas, with some growers reporting damage to tunnels and other infrastructure.

Fruit Growers Tasmania held its annual conference from 15-16 June at the Launceston Country Club. The event was well attended with over 220 registrations over the two days. Sessions included Pest and Disease Management, Crop Management, Labour Management and Agritourism. The conference wrapped up with a Gala dinner on the Thursday night, and during the evening several awards were presented. Kate Sutherland from Burlington Berries received this year’s Award for Excellence, and Tamara Clark from Murrakei Farm received the Outstanding Young Berry Grower Award. Congratulations to both award recipients. You can read more about the conference on PAGE 21.

A series of workshops were recently delivered by Donna Mogg, Grower Engagement Officer with Fair Farms. The workshops covered a range of information relating to the changes to the Fair Work Act that have come into place in 2022 and 2023. They also looked at how growers can get the most out of flexible hours of work under the Horticulture Award, wage increases from 1 July 2023 and the Fair Farms program.

Around 30 growers and industry members attended a workshop to hear the current situation with Bass Strait freight movements focusing on the changes in infrastructure, freight capacity, and cost. Growers heard from speakers including representatives from TT-Line, SRT Logistics, StraitLink (previously known as Toll Shipping)

and Tasmanian Freight Equalisation Scheme (TFES) expert Lee Panton who outlined the structure of the TFES scheme.

Lastly, I recently attended the Protected Cropping Australia (PCA) Conference in Brisbane from 18-19 July with many of the Berries Australia team. The theme for this year’s conference was “Growing Our Future”. Sessions included Sustainability and Waste, Vertical Farming, IPDM and Biosecurity as well as New Opportunities in Protected Cropping.

The new opportunities session offered some interesting insights and opportunities for protected cropping including medicinal cannabis cultivation. Another highlight of the conference was listening to a group of PhD students give presentations on their R&D projects. The six students were given 3 minutes to deliver an outline of their project with prizes awarded to the best speaker. It is inspiring to see the next generation of researchers starting their careers.

The technical sessions wrapped up on Wednesday followed by a Gala Dinner that evening. The following day growers took the opportunity to participate on the various field trips. The conference was well attended and provided an opportunity for me to spend time with some of the newer Berries Australia team members in person. The new 5-year ‘Facilitating the development of the Australian berry industries (MT22010)’ project is a strategic levy investment under the Hort Innovation Blueberry, Strawberry and Raspberry and Blackberry funds and I’m delighted to say this is now formally underway. I look forward to visiting and meet with growers to identify R&D gaps and provide technical support across the life of this project. At this stage, planned events in the coming months include a Pre-Season Berry Field Day in late September/early October, as well as a Crop Sprayer information webinar later in October.

As always, details of these events will be shared widely through The Burst, this journal and our Fruit Growers Tasmania communication channels.

berryido@fruitgrowerstas.org.au 9 INDUSTRY BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

Tasmania

Queensland

July has been such a busy month, and I can’t thank the growers, industry stakeholders and Berries Australia team enough for my warm welcome into the Industry Development Officer role.

For those of you who do not know me, I’ve spent the past three years as the Berries Australia Membership and Administration Officer, whilst also working at Passionfruit Australia as their Industry Services Manager, and in the family greenkeeping business which has now been wound up. It’s been fabulous to take a more hands-on role and start meeting growers.

In the labour arena, the recent changes to the PALM Deed of Agreement have caused a significant amount of angst in the industry. Brendon Hoyle from Ashbern Farms shared grower concerns over the lack of clarity and excessive burdens placed on growers. Ashbern Farms have utilised PALM workers for a number of years, noting that they have had a pretty fantastic experience up to this point. “It’s great to be able to train staff and have them return for successive seasons,” explained Brendon echoing the sentiment shared by many employers in Horticulture. He also estimates that a trained, experienced worker is twice as productive as an untrained worker.

With the increasingly heavy burden being placed on employers under the scheme, Brendon admitted they may need to revisit using backpacker labour, an option that would disadvantage Pacific workers who come to Australia to earn much-needed money to improve the lives of their families back home as well as remove the ‘returning-skilled-worker’ benefit.

Many growers I’ve spoken to feel the same. Despite the efforts of Steve Burdette and the Approved Employers’ of Australia, the government seems resistant to understanding the needs of industry and the overall positive experience workers have in Australia, instead focusing on the small number of rogue employers. You can find out more about the recent changes to the PALM scheme on PAGE 28.

On a more positive note, while the start of the winter strawberry season was late this year, the quality has been excellent. Variety-wise, there is a lot on the market with old favourites selling well alongside new varieties. Growing-wise, the flavour, shape and ripening habits of some varieties have differed markedly from farm to farm. I’m currently identifying topics for future journal articles and field days, and drawing growers together to discuss the best growing methods – particularly for newer varieties – has made its way to the list. If this is a topic you feel would be of interest to your farm business please get in touch.

As part of the recent Protected Cropping Association conference held in Brisbane, I attended a full day of plenary sessions and a Berry Farm Tour. The tour sites included the Steritech facility at Narangba, Basset Barks potting mix and mulch production facility in the Glass House Mountains, plus berry farms Pinata and Queensland Berries near Wamuran. Rubus production was well underway at both Pinata and Queensland Berries, with fruit being of excellent quality.

The month was rounded off with a field day at Maroochy Research Station. Full details are in the separate article, however special thanks to all growers who allowed their photos to be taken for promotional purposes. It was great to see a number of young growers in attendance.

I’m starting to get out and about with a day at the Ekka in mid-August helping to promote our winter strawberries and educate consumers about the berry industry. In late August, I will be visiting the Stanthorpe region and visiting growers with Narissa Corfe from the Granite Belt Growers Association and in late September, I will be in the Bundaberg/Wide Bay region to attend the Hillwood Berries Open Day to meet with growers and tour the new Haygrove tunnel systems installed at the farm. You can find out more about this Open Day on PAGE 16. In the interim, I look forward to further immersing myself in the wonderful world of Berries. Please don’t hesitate to give me a call if I can assist in any way.

Wendy Morris, Berry Industry Development Officer 0484 272 963 | qldberryido@berries.net.au 10 INDUSTRY BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

New South Wales

Gaius Leong, Berry Industry Development Officer

0484 055 748 | gaius.leong@dpi.nsw.gov.au

0484 055 748 | gaius.leong@dpi.nsw.gov.au

It is great to be back in the berry industry and I’m enjoying the ability to indulge in unreserved berry foraging while visiting farms. The short time I have spent away from the industry has provided new focus and perspective for me.

In this role, I look forward to rekindling working relationships with those I have met along the way and forging new relations with those I have yet to meet. I feel a reinvigorated need to help to improve the industry and ensure the increased sustainability of the industry for years to come.

The past two seasons have been nothing short of catastrophic for berry production in NSW. There have been heavy rain periods which brought severe floods, quality issues and a host of pest and disease challenges.

In addition, a shortage of labour from the impact of Covid-19 has created ripples that were felt throughout the whole industry. Growers directly affected by flooding and producing in open field systems copped the brunt with many businesses still in recovery. Throw in the Varroa mite issue and we really have had the perfect storm.

Spring is in the air, bringing with it a new harvest season that has been comparatively uneventful. Growers are getting used to seeing foliage and berries on their plants again in winter.

As the industry prepares for a bumper crop over a compact time period, the importance of production forecasting, arranging sufficient labour and adequate pollination cannot be overemphasised in ensuring the industry bounces back to its previous heights. Maintaining consistently high quality standards and ensuring consumer satisfaction has also never been more important.

However, as we embark on this road to recovery and expansion, we must keep in mind the detrimental situation we found ourselves in at the end of the previous El-Niño cycle.

With the last few years of exceptionally wet weather, water scarcity, dry dams and raging bushfires seem like a distant memory, but drought resilience is definitely an area for your attention now.

Improving crop water use efficiency and reducing fertiliser run-off are aspects which we know we should focus on as an industry. It provides positive stewardship of our waterways and increases cost-effectiveness for the grower. The ongoing Clean Coastal Catchments (CCC) project provides research input that assists industry in achieving these goals, by increasing fertiliser use efficiency and improving production cost ratios.

Clearer weather and more production moving to protected cropping has reduced Blueberry rust incidence this season, but if left unchecked and poorly managed this disease can grow to become a significant problem.

Flood recovery funding has enabled the DPI’s entomology team to conduct scouting on farms. We have noticed girdling moth larvae damage to the crown region in some production areas. This pest has not been prevalent in the recent wet seasons, but will flourish in the forecast drier weather so stay vigilant. The updated Plant Protection Guide in 2024 will include more information on this pest and Blueberry Rust management.

In addition, we have a new Rubus IPM project being led by the University of Tasmania which will be conducting research into the pests and diseases of critical importance to the Rubus industry.

In the coming weeks, I will be asking growers, farm managers and agronomists to participate in a short survey which will be essential in bringing an industry perspective to the research. A workshop will then be organised for industry and researchers to interact over potential pest and disease IPM strategies.

I look forward to working with one and all –please don’t hesitate to get in touch.

11

Western Australia

Helen Newman & Aileen Reid, Industry Development Team, Agricultural Produce Commission

Climate and crop

Autumn finished with well below average rainfall recorded throughout growing areas. With more sun around, daytime temperatures were slightly warmer than average and night-time temperatures were cooler in May. Cooler than average daytime and night-time temperatures were recorded in June along with record breaking daily and monthly rainfall in parts. Most areas received above average rainfall in June and there were more rainy days and longer periods without sun than normal.

July was drier and warmer than average in most growing areas, but also had more cloudy and rainy days than normal. An increased incidence of frosty mornings (compared to last year) was also reported from some areas in late June and parts of July.

Harvest of new season strawberries in the Perth region started in early August for most growers, five to six weeks later than normal for the bulk of producers. Delays in planting and cooler soil temperatures resulted in slower root development and delayed flushes.

Planting of new season strawberry runners in the southern growing region finished in late July-early August, about six weeks later than usual.

Blueberry and Rubus crops are generally following their normal schedule in northern and southern growing regions despite some setbacks caused by Chilli thrip.

Industry news

DPIRD hosted a cross industry workshop in late July to discuss Chilli thrip and identify what is needed to improve understanding and management of the pest. The berry industry was well represented in the workshop.

DPIRD Entomologist Elliot Howse gave an overview of the biology of the thrip, its distribution and the damage it causes.

Cezar Moraes from Biological Services gave a detailed overview of how to monitor for Chilli thrip and what the symptoms look like on the different crops, the different chemicals and insect predators they have been using to control the thrip, and the potential of using coloured lures to attract the thrip away from the crop.

Top research priorities identified by participants were focused on understanding the life cycle of the pest including where it overwinters and how it behaves in different hosts, testing chemical efficacy and resistance, and identifying and developing additional biological controls/predators. You can read more about Chilli thrip on PAGE 48.

No new detections of Qfly have been made in the Bayswater Qfly response (early August). Should no more Qfly be found, DPRID anticipates being able to claim ‘area freedom’ by early to mid-October.

In preparation for future incursions, the feasibility of irradiation is being reviewed and DPIRD is in the early stages of developing an on-farm systems approach to support the movement of fruit from an Export Assurance Zone (the 15km zone around the Qfly detection) without the requirement for an end-point treatment. The systems approach will need to be accepted by the other states and Federal Government to come into effect.

Strawberry growers took a trip south of Perth in June to visit two nurseries using innovative production systems. The first visit was to Touchwood Nursery where owner Ben Archibald discussed the function, management, longevity and return on investment from his Cravo retractable roof production system. The full automation of the system, low maintenance inputs and the ability to have the roof fully open when it’s sunny was very attractive. The structure has also withstood some very significant storm events without any damage.

12 INDUSTRY BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

Figure 2. Ben Funnekotter showing growers his plug production system at The Seedling Factory.

Photo credit: Helen Newman

Figure 1. Ben Archibald of Touchwood Nursery explaining how he uses his Cravo retractable roof production system.

Figure 2. Ben Funnekotter showing growers his plug production system at The Seedling Factory.

Photo credit: Helen Newman

Figure 1. Ben Archibald of Touchwood Nursery explaining how he uses his Cravo retractable roof production system.

13

Photo credit: Helen Newman

While on site, Ben showed us a water treatment system he built that enables him to remove ferrous iron from the bore water without the need for large aeration tanks. The system uses in-line venturi air injection to precipitate the iron from the water before it is cleaned by a series of sand filters.

The second visit was to The Seedling Factory where the Australian Strawberry Breeding Program (ASBP) varieties are now being propagated as plug plants and trials are under way on new F1 Hybrid seedling strawberries from Holland.

Ben Funnekotter, his business partner Barry Winterbourn, and staff members involved in managing the strawberry seed and plug production took us on a full tour of the nursery. Alek Moreno, the WA rep for Lefroy Valley seeds gave an overview of the genetics they have access to for strawberries.

While on site, Ben showed us a water treatment system he built to deal with the iron bacteria (iron sludge) he has in his bore water, and you can see the details of this on PAGE 44 of this journal.

14

BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

Figure 3. F1 Hybrid seedlings from Holland might be a game changer for WA strawberry producers if they are successful in the field. Photo credit: Helen Newman

BerryQuest International 2025

BQI25 IS HEADING TO TASMANIA

Following the hugely successful BerryQuest International conference held on the Gold Coast in July 2022, plans are underway for the next event planned for 2025 which will be held in Hobart.

You can expect a stunning line up of speakers both from Australia and overseas, as well as a full schedule of farm tours in and around Hobart.

BQI25 is delighted to confirm our conference venue as the Wrest Point Hotel & Casino at Sandy Point just south of Hobart CBD.

The complex is in the final stages of a $64m redevelopment which delivers first class facilities including three styles of accommodation, excellent dining options and a newly renovated casino space with gaming floor.

SAVE THE DATE — FEBRUARY 2025

Total Vent — A Game Changer!

Haygrove

Horticulture is at the forefront of today’s volatile world, directly affected by both global inflation and the increasingly unpredictable climate. The economics of horticulture are changing. Labour costs are rising rapidly, and labour availability is decreasing. Investment in technology is needed to replace manual labour and those investments need to be maximised. The expense of compromising crop yield, quality and timing through not venting polytunnels is becoming less justifiable.

Berries Australia Silver Partner Haygrove's versatile product range has been specifically engineered with tomorrow in mind. With a focus on strength, ease of management and a superior agronomic environment to allow growers to reduce labour requirements, extend cropping seasons and optimise yield and quality, Haygrove have developed their Advantage series polytunnels which offer a range of mechanised venting solutions that are practical on a field-scale.

The latest addition to Haygrove’s Advantage range is Total Vent, a patent-pending polytunnel design that mechanically rolls the polythene to the apex of the tunnel. Simply put it offers the ultimate in venting flexibility. An early adopter of Total Vent with 15 hectares already in production, Marcus Dornauf from Hillwood Berries described it as ‘A game changer’.

The fully retractable Total Vent combats a range of challenges, including some that are widely accepted as a downside to protected cropping. Management of the climate through frequent, timely and complete venting gives the agility to manipulate the growing conditions to maximum effect achieving improved plant health and peak yield potential in both hot, dry and hot, humid environments.

By managing Vapour Pressure Deficit or VPD (relationship between temperature and humidity) through precision

venting and use of Haygrove’s retractable shade net, the fruit quality has the potential to be maintained throughout the variations and spikes of the season, mitigating the risks to the crop but without accumulating labour or spray costs.

Mechanised venting means tunnel vent height is no longer determined by human working height. Vents positioned above the crop are more effective providing direct escape for hot air rising vertically. The larger Total Vent structure increases air volume to buffer climate fluctuations creating a more consistent growing environment.

Total Vent has a standard specification of 10-metre-wide bay width and support leg height of 3 metres. The wider bay width has agronomic, construction and economic advantages. Less leg rows means a reduction in leg row crop which is the most susceptible to quality issues. Less legs and hoops reduce construction time and cost.

With rain becoming less predictable, the benefits of mechanised venting go beyond improving yield and quality, and season extension. The combination of roller vents fitted with Haygrove’s rainwater gutters maximises the rainwater collection and mitigates the risk of irrigation failure through drought. By closing the vents during rainfall, the water catchment area increases to be the entire covered area.

16 INDUSTRY BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

OPEN DAY

Haygrove & Hillwood Berries

Open Day

Haygrove are delighted to be hosting an Open Day at Hillwood Berries, featuring the launch of Total Vent polytunnels.

The Open Day will be at 10am on Wednesday 20 September 2023 at Hillwood Berries near Bundaberg, by kind invitation of the Dornauf family.

After a long-standing relationship with Haygrove, Hillwood Berries have an impressive 15 hectares of Total Vent and 4 hectares of EZvent on their Bundaberg site growing tabletop strawberries, blackberries, raspberries and blueberries. And a Fixed Top Vent tunnel will be constructed for demonstration.

It will be a unique opportunity to see Haygrove’s Advantage range products in commercial use during the growing season. The day will showcase Total Vent tunnels, for the ultimate in venting flexibility; EZvent tunnels, for mechanised venting on a field scale; and the Fixed Top Vent tunnels, for continual air exchange.

REGISTER TODAY

To register for the Open Day on Wednesday 20 September or for more information please contact:

Mark Woodhead mark.woodhead@haygrove.co.uk

New Industry development and communications project underway

Jen Rowling, Project Manager, Berries Australia

A five-year continuation of the Industry Development and Communications project, delivered by Berries Australia in collaboration with regional delivery partners, has been contracted by Hort Innovation and is now underway.

The new project ‘Facilitating the development of the Australian Berry Industries (MT22010)’ has been funded by Hort Innovation using the Blueberry, Strawberry, and Raspberry and Blackberry research and development levy and contributions from the Australian Government. This new project follows on from the previous 3-year project (MT18020) and aims to further hone in on the specific needs of the industry going forward.

The overarching objective of the project for the Australian Berry industry is to enhance the adoption of innovation and technology through the communication of research and development (R&D) information and the facilitation of capacity building.

The project focuses on communicating best practice to berry growers and assisting with the improvement of knowledge and skills required to adopt the R&D outcomes of projects funded through the grower levy and the Australian Government.

The ‘whole of berries’ approach, which was pioneered by Berries Australia in 2019, helps to improve efficiencies and allow for a coordinated approach for communication of the many cross-berry R&D projects as well as a platform for commodity specific project extension.

The project is delivered as a nationally coordinated, locally implemented program. All berry growers in Australia will continue to have access to a local Industry Development Officer (IDO), with specialist skills and knowledge to support the range of extension

and communication needs of the different industries within berries. Each IDO is supported by a statebased organisation (regional delivery partner) for additional support and to ensure regional relevance and effective program delivery. This is underpinned by a highly regarded communications program including the quarterly Australian Berry Journal, The Burst e-Newsletter and the Berries Australia website which will be extended significantly under the new project.

A Project Reference Group (PRG), consisting of a berry grower from each of the major berry growing regions and commodities, other key industry stakeholders and Hort Innovation will also meet on a half yearly basis to provide direction for the project and important input into extension activities and workplans.

Industry consultation

A survey was distributed to growers and industry stakeholders in January 2023 to identify any gaps in information delivery and variances in priorities and knowledge transfer preferences across commodities, regions and industry segments.

The survey was part of an extension strategy and co-design process with Hort Innovation for the development of this new project (MT22010), providing valuable information about how the previous project was received by industry and potential gaps in information delivery which will become the focus going forward.

18 BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16 INDUSTRY

The breakdown of the commodities, regions and segmentation for the purpose of the survey:

Commodities

Blueberry

Strawberry

Raspberry and Blackberry

Combination of berries

Regions

Queensland

New South Wales

Victoria

South Australia

Tasmania

Western Australia

Segmentation

Business type:

• Operate as part of a marketing group

• Operate as an independent family business

• Have an agritourism component

• Grow certified organic berries

Production method:

• Substrate production

• In-ground production

• Combination of substrate and in-ground

The four key areas of priority identified across all commodities, regions and segmentation are:

The results of this survey combined with feedback gained through direct consultation with growers highlighted the value of the current communication and extension methods. This includes a mix of written products (Australian Berry Journal, fact sheets, website and e-news), online workshops and in-person learning events (workshops, field days, conferences). One-on-one communication with growers and industry stakeholders was not included in the industry survey, but will continue to be an integral part of the day to day activities of the IDOs.

Berries Australia also facilitated a project co-design workshop with industry stakeholders in January 2023 to review the findings of the survey and industry consultation.

The workshop confirmed the need for a mix of activities to deliver outcomes in the priority areas identified for the next five years.

The extension strategy process determined a number of priority areas for increased awareness and practice change, but also highlighted regional differences in needs and priorities, as well as differences across diverse business models. The project will take these differences into account when planning activities and opportunities for learning in each region, while ensuring a consistent approach to extension, and capitalising on the extensive range of expertise within the team.

1 2 3 4

Irrigation & Nutrient

Management

Pest & Disease Management

Business & Labour Management

19

New Technologies & Robotics

The Project Team

Project Team

Position & Expertise

Industry Development Officer – NSW (Blueberries/Pollination/Chemical/Next Gen)

Gaius Leong NSW Dept of Primary Industries (NSW DPI)

Wollongbar, NSW

Industry Development Officer – VIC & SA (Strawberries/Biosecurity/Pest & Disease)

Industry Development Officer – QLD (Strawberries)

Industry Development Officer – TAS (Rubus)

Industry Development Officer – WA (Strawberries)

Angela Atkinson Vic Strawberry Industry Development Committee (VSIDC) Wandin, VIC

Wendy Morris Berries Australia Brisbane, QLD

Mark Salter Fruit Growers Tasmania Inc (FGT) Hobart, TAS

Helen Newman Aileen Reid (part time)

Agricultural Produce Commission (APC) Perth, WA

Communications Manager Jane Richter Teres Communication Sunshine Coast, QLD

Management & Project Support

Location

Name Regional Delivery Partner

Position Name Organisation Location Project Leader Rachel Mackenzie Berries Australia Brisbane, QLD Project Manager Jennifer Rowling Berries Australia Brisbane, QLD

Coordinator Kylie Thompson Berries Australia Forster, NSW

Project

20 BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

Fruit Growers Tasmania Annual Conference 2023

Mark Salter, Berry Industry Development Officer, Fruit Growers Tasmania

Fruit Growers Tasmania recently held their annual conference on 15–16 June in Launceston at the Country Club Tasmania. Focusing on growing sustainability and business profitability, the conference delved into the different elements which help businesses to achieve this.

The Hon. Jo Palmer Tasmanian Minister for Primary Industries and Water opened the conference on Thursday morning. Many great presentations followed over the next two days on subjects including pollination, biosecurity, labour management, markets and supply chains, production costs and efficiencies, and Agritourism.

Several interesting presentations for berry growers included Kara Barry, an Associate Professor with the Tasmanian Institute of Agriculture (TIA), with an update on the blueberry defoliation trials her team is carrying out. The trials, across various locations in Tasmania, are being conducted to help control Blueberry rust by promoting early leaf fall in semi-evergreen and evergreen varieties of blueberries. Early indications are promising with at least one of the trials proving positive.

Dr Jon Finch, a research fellow at TIA, then spoke on developing effective pheromone-based methods for managing mirids and vegetable bugs. His presentation centred around providing recommendations for raspberry and blackberry growers on how pheromones and traps fit within an integrated pest management approach. The project is well on the way to identifying various pheromones and ultimately looking at being able to synthesise and produce pheromones for a commercial mirid and vegetable bug trap.

Dr Raylea Rowbottom, an entomologist and researcher with seedPurity, spoke on the commercial efficacy of fly pollinators. Her research shows how flies can prove to be effective pollinators, which may have commercial benefit for producers where honeybees are not available.

Later, Jon Finch hosted a session on pollination in berries, in which he discussed the various alternative pollinators that may have commercial possibilities.

Narelle Jones, Senior Biosecurity Officer (Industry Collaboration) at Biosecurity Tasmania, spoke on biosecurity responses for bee pollinators including small hive beetle and Varroa mite. She also outlined to growers the process that Biosecurity Tasmania takes when there is an exotic pest incursion. Narelle coordinates relationships and communications with industry and other internal and external stakeholders to ensure they have up-to-date and accurate information on current biosecurity developments.

Jake Gaudion, a consultant with RMCG, spoke on improving resource use efficiency in substrate performance, reducing waste and improving production efficiency within Tasmania’s berry sectors. His presentation centred around progress on a research and development project on coir reuse led by Fruit Growers Tasmania. The project involves research agency RMCG along with four commercial growers. The project is researching the reuse of coir in strawberry production systems and has identified two wood fibre products which have the potential to be used either as a stand-alone substrate alternative or mixed with coir to extend its life. Early results from trials carried out are looking promising.

You can find out more about this project in articles published in the Autumn 2020, Winter 2022 and Autumn 2023 editions of this journal which are available online at bit.ly/BA-ABJ

INDUSTRY 21

1 4 2 3 22 BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

1 & 2. Delegates attending the presentations made at the conference. 3. Conference attendees networking over drinks in the Trade Show area. 4. Award winner, Kate Sutherland from Burlington Berries with the Hon. Jo Palmer Minister for Primary Industries and Water. Photo credit: FGT

With the rising cost of labour, talks focusing on labour management and supplementation were well received across all sectors. Feedback from berry attendees highlighted the following talks:

• Ross Wilson’s talks on business decision-making and how to make effective data-driven decisions at harvest, which resonated with growers across all fruit-growing sectors. A grower in his own right, Ross is also a founding member of Agfirst in New Zealand who brings with him over 20 years of horticultural experience and regularly leads field days to ensure the latest technical advances and tree management techniques make it into the hands of growers.

• Simon Drum also spoke in the labour management session and outlined his experience incorporating LEAN manufacturing principles into fruit production. The example he used was how the production line of a large vegetable processor, through the LEAN production system, was able to reduce labour inputs and turn their inefficient production system into an efficient and profitable process.

• Eva Thilderkvist, a software engineer and Tasmanian Site Manager with Dogtooth Robotics at Burlington Berries in Cressy, maintains and supports the ongoing training of Dogtooth’s sixteen robots operating at the site. Eva spoke on the progress of the robotic strawberry harvesting trials which have been going on for over five years. She outlined the five-step process the robots take to harvest each berry. Each season’s harvest data from the robots in Cressy is collated along with 70 other sites globally using the same technology to improve the harvest efficiency of all the robots.

The Agritourism session also proved to be very popular, with two examples of successful agritourism businesses on show. This was the first time Agritourism had been included in the session and proved popular with businesses of all sizes. The invited speakers presenting as part of the session included:

• Allison Clark, who spoke on the information and support available to producers looking to start their own journey into Agritourism, and the wider efforts being made by producers and government to grow Agritourism across the state.

• Kate Bradley, who shared her experiences building a successful business, starting off 32 years ago after moving from Victoria to Tasmania and purchasing a block of land on the east coast. Kate is the owner and

manager of Kate's Berry Farm, an English-style farm growing strawberries, raspberries and blueberries, which has become an icon for Tasmanian locals, interstate and international visitors and is well known for showcasing the quality of Tasmania’s cool climate products. Kate puts her success down to listening and engaging with her customers and providing a unique experience on her farm. You can read more about Kate’s operations in the Spring 2022 edition of this journal which is available online at bit.ly/BA-ABJ

Rebecca Duffy also spoke on her experience of building a well-known premium Tasmanian wine brand, Holm Oak. She has more than 20 years of winemaking experience in Tasmania, mainland Australia and California. Based in Rowella, Rebecca manages the creation of complex and unique cool climate wines, as well as interacting with buyers and consumers within the site’s cellar door outlet and sensory garden experience.

The conference also included two panel sessions where growers, suppliers, researchers and other stakeholders could ask questions of growers and industry representatives. These provided an opportunity for the audience to hear back from growers about some of the pressures and challenges facing the sector, and to find out how Tasmanian businesses and industry were addressing these. It was also an opportunity for audience members to recognise and focus on the many positives the industry has, and some of the reasons why people in the sector continue to choose to be fruit growers.

The conference wrapped up with a Gala dinner on Friday evening. During the event, several awards were presented including to Kate Sutherland from Burlington Berries who received this year’s award for Excellence. Tamara Clark from Murrakei Farms received the ‘Outstanding Young Berry Grower’ award. Congratulations to both award recipients.

Fruit Growers Tasmania would like to thank the many attendees, sponsors and exhibitors for supporting this year’s conference. With special thanks to ServeAg, Steritech and Hort Innovation for their support in making this year’s conference one of the most successful so far.

23

spray dry application fertigation consumables inventory management www.abcsoftware.co.nz +64 6 845 0068 hello@abcsoftware.co.nz FREE 45-DAY NO-OBLIGATION TRIAL Take your spray diary online Information automation made easy One digital diary for all agrichemical applications Auto-calculation of rates, nutrients, withholding periods Chemical and stock inventory management Compliance-ready reproducible reports Mobile-friendly for use on any device with a data connection Enter information once, use it everywhere Data security with cloud storage Integration with ABCgrower labour management software Simple efficient record keeping Scan to learn more

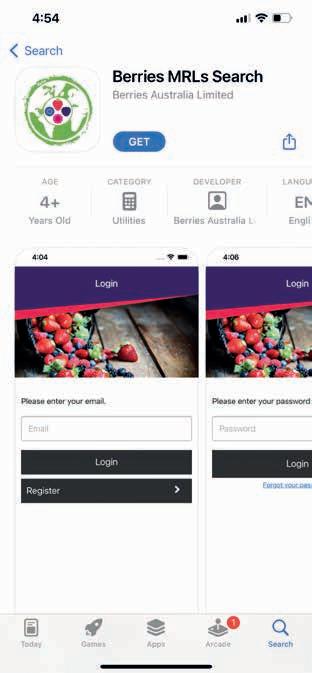

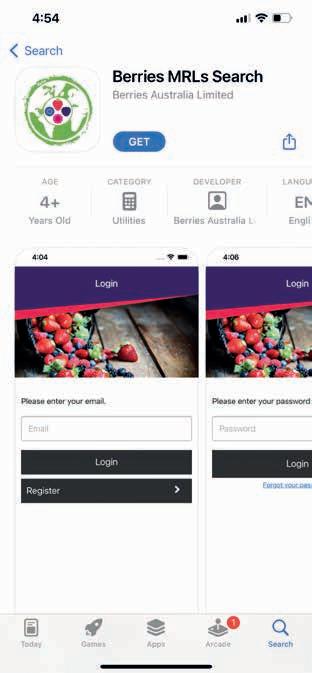

Berries Maximum Residue Limit (MRL) App now available

Jen Rowling, Projects Manager, Berries Australia

The Berries Australia MRL App provides information on maximum residue limits (MRLs) and withholding periods (WHPs) for both domestic and export markets. The easy-to-use interface provides users with access to real-time pre- and post-harvest chemical application data based on domestic and export market, target pest or disease and/or active constituents. And with its offline capability, the app can be used anywhere and anytime.

The MRLs app has been developed in partnership with the Australian Wine Research Institute (AWRI) and the Australian Table Grape Association (ATGA) with funding support from the Department of Agriculture, Fisheries and Forestry (DAFF) to help industry members comply with MRLs in export markets. Changes in MRL and WHP recommendations will be updated as new information becomes available to ensure that the data provided is kept up to date.

What are MRLs and WHPs and why are they important?

A Maximum Residue Limit (MRL) is the maximum level of pesticide residue that can legally remain on a food product.

The Australian Pesticides and Veterinary Medicine Authority (APVMA) sets MRLs for agvet chemicals in agricultural produce, particularly products entering the food chain. These MRLs are set at levels that are not likely to be exceeded if the chemicals are used in accordance with the approved label directions (including the withholding period).

The role of MRLs is to ensure food safety and to protect consumers from exposure to harmful pesticide residues. At the time MRLs are set, the APVMA undertakes a dietary exposure evaluation to ensure the levels do not pose an undue hazard to human health.

The withholding period (WHP) is the minimum period that must elapse between the last administration or application of a pesticide and the harvesting of the fruit for human consumption. The objective of a WHP is to provide users with the information they need to ensure that residues in their treated produce will not exceed the MRL. WHPs are mandatory for domestic sale and are on the label of every registered product.

Compliance with MRL levels is mandatory for all growers to avoid legal consequences and maintain market access. Ensuring that a product is safe and free from harmful residues is also vital to safeguard the reputation of the industry and improve consumer trust. Breaches of MRL levels can seriously jeopardise trade and existing market access.

Why do we need an App for MRLs in export markets?

MRLs in export markets may differ from Australia.

If the MRL in an export market is higher than the Australian MRL, then exporters do not need to change their practices to be compliant with that market’s regulations. If the MRL is lower than the Australian MRL, then exporters must modify how they manage their production in blocks destined for export. In some circumstances, the MRL may be so low that it is not possible to use particular chemicals and growers need to be mindful of this in advance of committing fruit to export markets.

Berries Australia has developed the MRL app to help growers check if an export market MRL is higher or lower than Australia. The MRL app compiles information published by a wide range of countries and is the best available data at a point in time. Exporters are

A new mobile phone app designed to help growers manage chemical application and facilitate trade has been released by Berries Australia.

25 INDUSTRY

encouraged to speak to their importer for confirmation as they should be able to clarify any particulars relating to a specific product. Breaching another country’s MRL levels represents a serious export non-compliance. If detected upon arrival, the consequence may be the rejection of the consignment (at the exporters cost) or possibly broader, commodity-wide ramifications such as closure of market access.

Important points to consider

The WHP recommendations are determined by the export market maximum residue limit (MRL) and are based on the residue results of trials conducted in Australia and overseas.

As these results may not reflect the residue levels in all growing conditions and varieties, it is advised that berry growers test their produce for agrochemical residues to confirm that export market MRL levels are being met.

• WHPs may vary if chemicals are applied in a protected cropping environment.

• The growth-stage can be variable across a plot or block. When assessing for the purpose of applying agrochemicals, base the assessment on the most advanced crops in the plot or block to minimise the possibility of residues at harvest.

• When spraying, ensure that the amount of chemical applied never exceeds the rate specified on the manufacturer's label (unless otherwise specified).

• Always read the label on the chemical container. The products mentioned in the App might not necessarily be registered for use in your state.

• Keep detailed records of agrochemical applications and when spray equipment is calibrated.

• Should residue testing results not conform with the information provided in the App, contact Berries Australia.

The Berries MRL app is restricted for download in Australian app stores and users must have a login account to use the app.

User accounts are only available to berry industry members. After installing the app on a device, select Register > and follow the prompts. Once your access has been approved, you will receive a confirmation email with a temporary password. Open the app & enter your registered email address then follow the prompts to set up your secure password.

We encourage all growers to download the App for use, whether supplying domestically or for export.

Not only can it help to protect the integrity of your own business, but compliance will help our industry to grow into international markets whilst ensuring the safety of our produce and building the trust of consumers.

26 BERRY AUSTRALIAN JOURNAL SPRING 2023 EDITION 16

The Berries Australia MRL App is now available to download for FREE Searching by Active Constituent provides a summary with each country, the MRL level expressed in mg/kg and the Withholding Period You can also search within Markets by Target Pest or Disease For each crop, you can search the MRL by Active Constituent or by Export Market The MRL app contains information about Blueberries, Rubus and Strawberries Download Berries Australia MRL App on Apple and Android devices here: If you need any assistance to access the App, please contact Jen Rowling: jenrowling@berries.net.au | 0448 322 389

Berries

Agriculture

Market”

27

Acknowledgements The

MRL App was designed and developed by the AWRI, Berries Australia and ATGA, with funding via the

Victoria “Food to

and Federal Government “Projects Assisting Small Exporters” schemes.

Future of the PALM scheme in doubt due to rushed consultations

Steve Burdette, Executive Officer, Approved Employers of Australia

After working with industry for years to support the development of the Pacific Australia Labour Mobility (PALM) scheme, the Australian Government gives industry and other stakeholders just 10 days to consider the most significant changes to the scheme in a decade. The future of the scheme is at risk with a series of unworkable and ill-considered requirements being introduced.

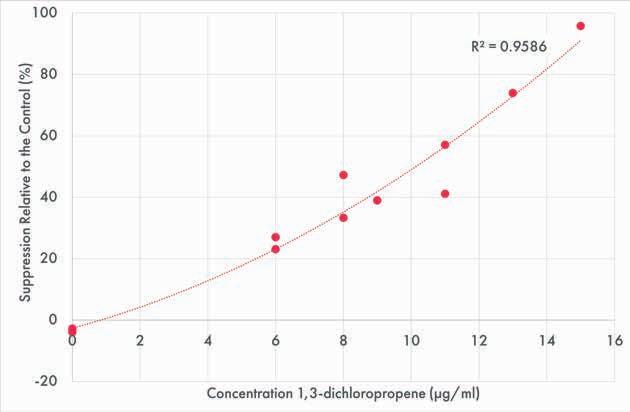

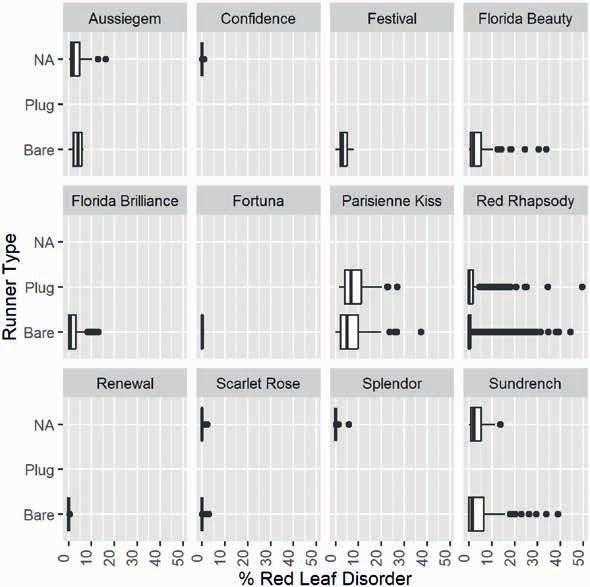

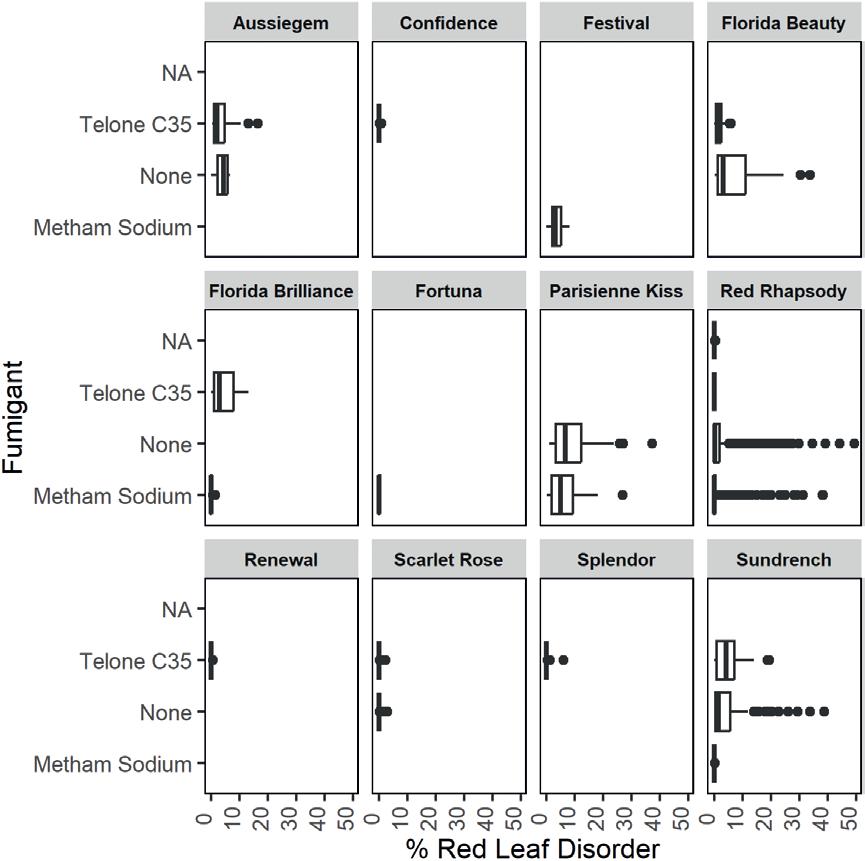

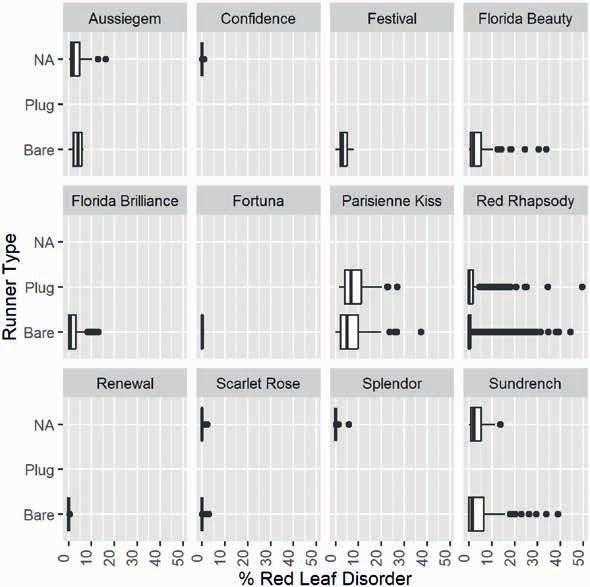

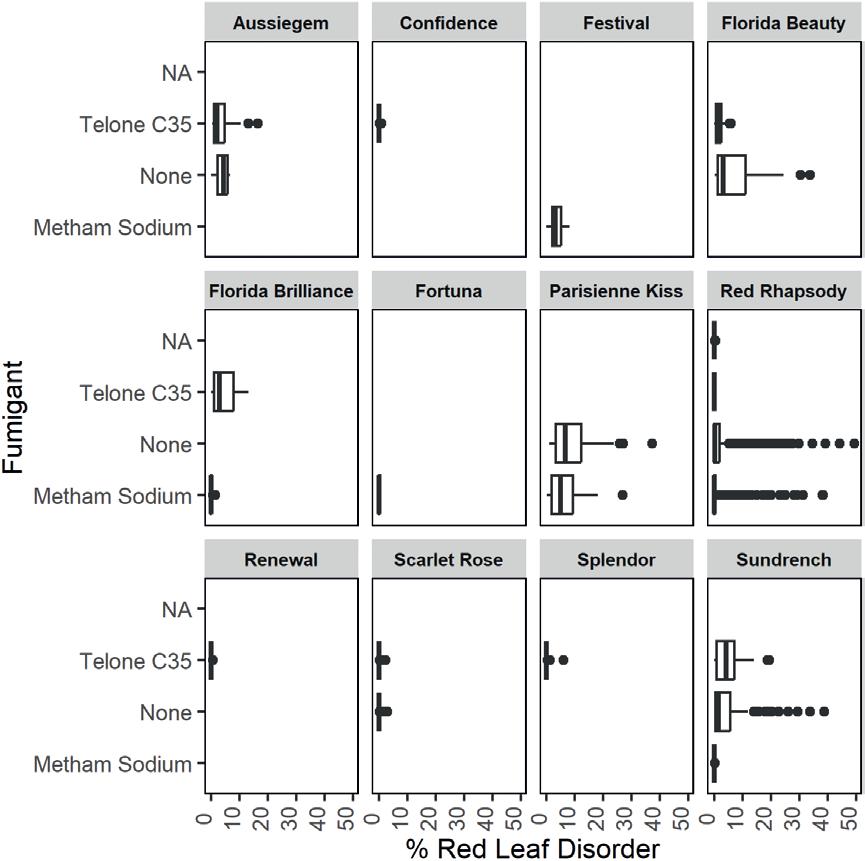

The PALM scheme is one of Australia’s most significant international development and foreign policy success stories in the last decade. Through COVID when Pacific countries were struggling with no tourism and Australia had a workforce shortage due to closed borders, the PALM scheme expanded rapidly.