WINTER 2024 EDITION 19 MANAGING LIFE WITH VARROA Industry 18 MARK SALTER VISITS QUEENSLAND Rubus 53 FUNGICIDE UPDATE Strawberries 81 GETTING NITROGEN RIGHT Blueberries 102

AUSTRALIAN BERRY JOURNAL

EDITOR

Jane Richter

TERES Communication 0431 700 258 jane@teres.com.au

CONTRIBUTORS

Jane Richter Rachel Mackenzie Anthony Poiner

Simon Dornauf Andrew Bell

Richard McGruddy Brett Fifield

Gaius Leong

ADVERTISING

For

Dr

Jutta

Dr

Apollo Gomez

DESIGN

Sama Creative | samacreative.com.au

Blueberry Growers Field Day, Tasmania .............................................................................. 94 Blueberry Research Open Day, Wollongbar Agricultural Institute, NSW 98 Developing nitrogen fertiliser guidelines for blueberry: Research update ....................... 102 Dam Water Quality Workshop: How to manage algae, aquatic weed & iron issues 104 BLUEBERRIES Varroa destructor Transition to Management: What happens now? 18 SIMODIS® insecticide: Emergency Use Permit for Chilli thrip in berries ............................. 21 Reporting Chemical ‘Non-Performances’ or ‘Adverse Experiences’ 24 IDO & Communications Project Update: Year 1 Achievements ......................................... 26 BerryQuest International 2025: Opportunities to Sponsor & Exhibit................................. 28 Berry Basket Marketing: Burst One ...................................................................................... 33 MT21000: Enhancing Health Professional Engagement ..................................................... 38 Export Update: Market Profile – Hong Kong 40 Certified soil biodegradable mulches ................................................................................... 43 INDUSTRY Profile: Blue Hills Berries & Cherries, Victoria ....................................................................... 47 Profile: Henry Scott, Costa Group ..........................................................................................51 Rubus IDO Mark Salter visits Queensland 53 RUBUS Webinar Report: What yield pattern are you aiming for? ................................................. 61 Yields of strawberry plants vary more with the season than with the cultivar 73 Management of fruit rot diseases & fungicide resistance: 2024 update ............................81 Planting at the right time after fumigation saves money 87 STRAWBERRIES WINTER 2024 EDITION 19 AUSTRALIAN BERRY JOURNAL Wherever you see this logo, the initiative is part of the Hort Innovation Blueberry, Strawberry and Raspberry and Blackberry Fund. Like this publication itself, it has been funded by Hort Innovation using the Blueberry, Strawberry and Raspberry and Blackberry R&D levy and funds from the Australian Government. Some projects also involve funding from additional sources. DISCLAIMER: Whilst every care has been taken in the preparation of this journal, the information contained is necessarily of a general nature and should not be relied upon as a substitute for specific advice. The advice and opinions in the articles published in Australian Berry Journal are essentially those of contributors and do not necessarily reflect the views of Berries Australia or the Editor. The advice is at the reader’s own risk, and no responsibility is accepted for the accuracy of the material presented. Inclusion of an advertisement in this publication does not necessarily imply endorsement of the product, company or service by Berries Australia or the Editor. Horticulture Innovation Australia Limited (Hort Innovation) makes no representations and expressly disclaims all warranties (to the extent permitted by law) about the accuracy, completeness, or currency of information in Australian Berry Journal. Reliance on any information provided by Hort Innovation is entirely at your own risk. Hort Innovation is not responsible for, and will not be liable for, any loss, damage, claim, expense, cost (including legal costs) or other liability arising in any way, including from any Hort Innovation or other person’s negligence or otherwise from your use or non-use of Australian Berry Journal or from reliance on information contained in the material or that Hort Innovation provides to you by any other means. Copyright © Horticulture Innovation Australia Limited 2024 Copyright subsists in Australian Berry Journal. Horticulture Innovation Australia Limited (Hort Innovation) owns the copyright, other than as permitted under the Copyright ACT 1968 (Cth). Australian Berry Journal (in part or as a whole) cannot be reproduced, published, communicated or adapted without the prior written consent of Hort Innovation. Any request or enquiry to use the Australian Berry Journal should be addressed to: Communications Manager, Hort Innovation, Level 7 | 141 Walker Street, North Sydney 2060, Australia | E: communications@horticulture.com.au | P: 02 8295 2300

all Advertising & Partnership

0491 751 123 | admin@berries.net.au

advertising

advertorial material is subject to review

approval prior to publication.

Enquiries

All

and

and

Jen Rowling Dr Angela Atkinson

Mark Salter

Helen Newman Wendy Morris

Parks

Scott Mattner

Melinda Simpson Sophie

Dr

Dylan McFarlane

Wright

Christopher Menzel

Executive Director's Report

Rachel Mackenzie | 0408 796 199 | rachelmackenzie@berries.net.au

It is not often that I get to start an article with not one, but two wins in the advocacy space. The government has walked back its requirement that all PALM workers have to get paid a minimum of 30 hours per week even if they did not work those hours. The new provisions are that PALM workers must get paid for 120 hours averaged over four weeks. This is a huge win for common sense and, I must point out, the result of tireless advocacy from the Australian Fresh Produce Alliance (AFPA). Whilst AFPA members are indeed the big end of town, this is a win for all growers so I would like to take this opportunity to thank Claire McLelland and Cameron Brown on behalf of the berry industry.

The second win relates to the rejection by the Senate of the proposed Biosecurity Protection Levy (BPL). As you may recall this was sprung on industry in the 2023 budget whereby the government announced that they would be collecting a $50 million contribution from primary producers towards the cost of biosecurity. The BPL would have cost the Rubus industry $140,000 per year and the strawberry industry $275,000 per year on top of existing levies, and a new levy of about $280,000 per year was to be applied to the blueberry industry. This levy was additional to any levy funding for biosecurity responses such as Varroa mite.

Berries Australia was part of an informal coalition of industry associations who lobbied hard against the imposition of the BPL. I had the opportunity to present

to a Senate Inquiry relating to the Bill and it was very pleasing that the Greens and Independent Senator David Pocock along with the Coalition indicated to government that they would not support the Bill. To me this is an excellent example of how our democracy should work, with the Senate acting as the check and balance. I would like to thank the Senators for listening to industry and taking the time to make an informed decision.

It is important that I also give Minister Watt and the government credit for the work they are doing in the trade space. We have had several productive meetings with the Department and the Minister’s office in relation to Vietnam market access. The reopening of negotiations with China is enormously significant for the berry industry, particularly blueberries, where our premium offering has the potential to be highly sought after.

As an industry association we are staunchly apolitical in our advocacy, and we support good policy no matter which side of politics it comes from. Further to that, good policy must be evidence-based and so I would like to thank all 85 of the growers who responded to our recent survey on the Core Skills Occupation List. It makes my job so much easier when I can present robust data to government to support our positions. It was clear from the survey responses that many of the occupations under review are still critical for berry production, so I hope that is taken into consideration by government when making the final decision.

We publish our submissions on the website so please check them out if you are interested. It is also important that we hear from you about the issues that are affecting your business so please get in contact with me directly or via your IDO.

2 INDUSTRY BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

Chairman's Report

Anthony Poiner | 0412 010 843 |

Berries Australia recently held our six-monthly face-to-face meetings in Melbourne. As always it was a good opportunity to engage with our fellow growers and the Berries Australia team and re-affirm our priorities which are demand creation, industry development and communication and advocacy.

Demand creation has many facets, but marketing and export are our current areas of focus. A new five-year contract has been signed with Hort Innovation to support export market access for berries. Each of the berry categories is at a different stage of their export journey but this new project will make sure that we are ready to seize every opportunity that comes our way.

The joint berry marketing program is well underway, and you can read more about it on PAGE 33. Whilst this is a pilot program it is giving us an opportunity to see what a berry basket campaign looks like as well as developing marketing collateral which we can all use.

The export and marketing programs are overseen by sub-committees which comprise members from across the category who have expertise or a passion in these areas. The success of these committees has stimulated conversation about how we can best deliver outcomes to all berry growers across a range of topics.

We are actively seeking ways to streamline our current committee structure to deliver better outcomes to our growers. The current model whereby we have three PIB committees supported by the team as well as a Berries Australia board has been fine to a point, but it is increasingly evident that there is a lot of duplication of effort, and it makes sense to cut down on administration so we can focus on delivery.

anthony@smartberries.com.au

We are considering expanding the sub-committee concept so they become the engine room of our activities and may cover issues such as export, marketing, workforce and social license/sustainability which cut across all berries as well as berry-specific topics such as strawberry breeding and access to propagation material. These committees will be formal sub-committees of Berries Australia and can comprise members who are not on the Berries Australia board. This will complement the new research and development consultation process now being delivered by Berries Australia on behalf of Hort Innovation and I welcome Angela Atkinson into the role of our new Research and Development Co-ordinator.

As a committee we are thinking long and hard about how we maximise efficiencies, but at the same time don’t lose the buy-in from you, the growers, and your sense that we are here to represent you. This is where the IDO team become really important as each State has a dedicated IDO, but we also have a range of expertise across the berry categories. The IDOs are your connection to Berries Australia but also provide critical intelligence about what is happening on the ground.

Berry Quest International 2025 is a fantastic opportunity for all growers to share knowledge across the category and learn from a range of informative speakers. Simon Dornauf is doing a stellar job in chairing the event subcommittee and the program is really coming together. Please put it in your calendar and I look forward to seeing you in Hobart next February.

If you are an industry stakeholder or supply chain participant and you would like to be a part of BerryQuest International 2025 we have a wide range of sponsorship and exhibitor options available. Please SEE PAGE 28.

3 INDUSTRY

President's Report

Andrew Bell | 0422 234 124 | andrew@mountainblue.com.au

Why we keep pushing for export!

You may wonder why the ABGA committee remains committed to chasing down export markets. We only have to look across the vineyard to the table grape industry to see why! Recent Trademap data shows that the current value of table grape exports from Australia is $605 million, and it has tripled since 2014.

The big game changer for grapes was access to China, with export value increasing from $9 million in 2014 to a whopping $206 million in 2023. For some context, the current value of Australian blueberry exports is $25 million which is a tidy increase from the $1.9 million in 2014. Nevertheless, we have a long way to go, or should I say an enormous opportunity for growth.

Whilst China offers significant potential, the more immediate opportunity may be in Vietnam which could be a game changer for Australian blueberries. Again, looking at the table grape figures, the value of exports to Vietnam in 2014 was $30 million and has increased to $89 million in 2023. Whilst we can’t expect exactly the same sort of response for blueberries straight away, the market intelligence is that Australian fruit is highly prized by the burgeoning middle class and premium fruit can expect premium prices.

Currently the United States dominates the Vietnamese blueberry market from June to September and New Zealand is the only supplier from October through to

April. There are large gaps in supply in the blueberry market there in the Australian peak season from July through to October. New Zealand achieves considerably higher prices in Vietnam than the USA does, although prices do soften in the February peak supply period. We are realistically hopeful that Vietnam could become our largest export market eclipsing Hong Kong which currently sits at $14 million.

We have had excellent engagement with the Australian Department of Agriculture in recent months. Obviously, progression is dependent on the response from our trading partners, but in the case of Australia and Vietnam, as we have accorded each other special trading partner status the signs are positive.

Along with the rest of the committee, I firmly believe that focusing on gaining market access is the single biggest way we can improve the bottom line for Australian berry growers. Even if you are not considering export yourself, just taking the pressure off the Australian supply chain during peak supply periods will give us all more negotiating power in the domestic market.

The ABGA continues to have access to the services of the highly competent Jenny Van de Meeberg through the Berries Australia export project. We have just signed a new five-year contract which I firmly believe positions us for export success. The project ‘Multi-industry berry trade development and market access project (2024-2029) (MT23004) is a strategic levy investment under the Hort Innovation Blueberry, Strawberry, and Raspberry and Blackberry Funds.

If you would like to know more, please access our Export Hub on the Berries Australia website at bit.ly/BA-Export and make sure that you sign up there to join the Export Group so you receive all of the communications from the Export Project.

4 INDUSTRY BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

President's Report

Richard McGruddy | 0408

763 804 |

As mentioned by my fellow Chairs, the berry committees all recently met in Melbourne and it was good to convene with my fellow Rubus growers at the RABA meeting. The meetings were definitely an opportunity to reflect on how best we can support the members and there is a strong sense that is time to take the next step towards greater integration with the other berry categories.

Berries Australia recently sent out a survey relating to skilled occupations for visa holders and took the opportunity to understand the demographics of the industry. We had about a 30% response rate which is quite high for this sort of survey and does at least show industry trends. Of the 85 respondents, only 4 grow just Rubus with a further 12 growing Rubus and strawberries, seven growing blueberries and Rubus and eleven growing all three berry types. To put that another way, only 12% of Rubus growers who responded just grow Rubus.

Historically, Victoria was the stronghold of Australian Rubus production but in this survey only 17% were from Victoria whereas 44% of respondents were from Tasmania, followed by 38% in Queensland and 35% from NSW. Interestingly three of the four growers who just grow Rubus were based in Victoria. So, what does this all mean? Without wanting to overstate the statistical validity of the survey, it really does highlight that a stand-alone Rubus industry association is less relevant than it has been in the past and this is reflected in our dwindling membership numbers despite ever increasing production. Many of our members are part of Berries Australia through their ABGA membership or

richard@berryq.com.au

membership of a state based strawberry association, so expecting them to purchase another membership is a hard sell.

Berries Australia is exploring options to streamline the committees, but we are very conscious that we don’t want you to feel that you no longer have a voice. The fact that we have a full time Rubus IDO does ensure that you get value from the joint berry activities and investments.I am also pleased that the new berry consultation mechanism which provides advice to Hort Innovation on research and development opportunities has a stand alone Rubus prioritisation committee and great representation from Rubus growers. As always, the door is open if you would like to have more involvement in any of these processes.

I also want to take this opportunity to farewell Mark Salter - our well respected Rubus IDO - who is sailing off into retirement. He has really established the importance of the role and we will miss him. I am however very happy to welcome our new Rubus IDO Ella Roper. Ella has most recently been working with Costa in Tasmania and has a deep knowledge of Rubus production. I hope you make her welcome when you cross paths with her once she joins the team in late June.

Finally, I do have to draw your attention to the article on PAGE 18 regarding Varroa mite. It is pretty depressing that we have to pay for a battle that we didn’t win but that is the nature of biosecurity. We also need to remember that without the advocacy from Berries Australia and other PIB’s our bill would have been three times higher.

I wish you all a productive few months and I hope you are gearing up for BerryQuest International 2025 in Hobart next February.

5 INDUSTRY

Chairman's Report

Simon Dornauf | 0408 681 206 | simon@hillwoodberries.com.au

Strawberries Australia and Berries Australia recently held face-to-face meetings in Melbourne. Over two days, various important topics were discussed, and I hope this column will bring our readers up to speed on some of the key points.

A major focus was the southern season, where the committee addressed thwe increasing challenges growers face due to rising labour and input costs, contrasted with the relatively stagnant prices received for fruit sold. As growers, it is frustrating to see the supply chain able to increase their margins to match inflation while the prices we receive remain static. We understand the supply and demand environment, but at some point, there must be adjustments to ensure the continued supply of berries to Australian families. Otherwise, growers may be forced to exit the industry.

I'm pleased to announce that BerryQuest is scheduled for 24 – 27 February 2025 and will be hosted in Hobart, Tasmania. As the chairman of the organising committee, I have seen firsthand the tireless work put in by Jen Rowling and her team to make this the most impressive event yet. Tickets will be on sale from 1 July 2024 with early bird deals available and I encourage you all to get in early to secure those discounts.

The program is being developed as I write this and more information will be released in the coming months, but the event will definitely be comprised of two days of farm tours to the northern and southern growing regions, plus two full conference days finishing with a Gala Dinner evening that will also introduce the first Australian Berry Industry Awards. I challenge all growers to attend to gather and learn for the benefit of our entire industry.

Jen and the team have also released a broad range of ways in which industry stakeholder businesses can support the conference and I would urge anyone interested to secure their sponsorship or exhibitor package quickly.

Scan this QR code or visit the BQI25 Conference Website at bit.ly/BQI25Website for all the latest information and to secure Sponsorship or Exhibitor Packages

Another significant topic was the future of the three berry Peak Industry Bodies (PIBs). There is a growing consensus among committee members that consolidating the three PIBs into a larger Berries Australia Board, consisting of three members from each PIB, could be more productive and efficient. The intention is not to disband the current PIBs entirely but to place them in a holding pattern.

Our ultimate aim is to ensure that we, as a berry collective, continue to align on our agri-political concerns and work together for the greater good of our industry. There will be times when berry-specific topics require input from experienced individuals, and sub-committees with a targeted approach can be more effective than relying solely on the main committee. I want to stress that this consolidation is still in the conceptual stage and far from decided. However, with dwindling participation rates within all PIBs, change is necessary to ensure a vibrant future.

As we move into the winter season, I wish all strawberry growers a successful and profitable growing season. Hopefully, your efforts will yield abundant and highquality berries, and the challenges you face will be met with innovative solutions and strong support from our strawberry consumers. Here's to a season of growth, resilience, and profitability for all.

6 INDUSTRY BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

Brett Fifield, Hort Innovation, Chief Executive Officer

Brett Fifield, Hort Innovation, Chief Executive Officer

We’re almost halfway through 2024 and Hort Innovation has been hard at work delivering impactful investments for berry growers. One of the key priorities in Hort Innovation’s Strategy 2024-2026 is to lead world-class innovation to ensure Australian horticulture is globally competitive. Here are just two new initiatives underway to support Australian berry growers:

Embarking on a refreshed non-levy investment approach: Unveiled in June, Hort Innovation’s Frontiers will team up with local and global innovators, to invest in seizing big opportunities and developing solutions to horticulture’s major challenges. Over the next 10 years we’re aiming to inject $500 million in research and development (R&D) to drive transformation in Australian horticulture.

Five new investment themes steer our approach to Frontiers’ R&D co-investment (non-levy funded), helping identify and solve challenges along the value chain to ensure a profitable and sustainable Australian horticulture sector:

Disruptive technologies | Healthy living Adaptation and resilience | Capability building Market growth and security

And we’re simplifying our investment pathways. Moving from 12 to four.

Australian-grown Innovation: Nurtures grassroots ingenuity, empowering growers to take their ideas from concept to reality through a competitive Expression of Interest process.

Innovation Partnerships: Delivered through our existing procurement approaches, this stream beckons strategic collaborations, inviting stakeholders from all corners of the sector to join forces in advancing industry innovation.

Hort Innovation Venture Fund: Channels resources into high-growth early-stage startups, propelling innovative products and services from inception to market readiness.

Incubate and Accelerate: Serves as a launchpad for startup enterprises seeking to scale within the horticulture domain. Through rigorous selection and support mechanisms, budding entrepreneurs,

researchers, and students will be equipped to thrive in the competitive landscape.

This refreshed approach enables Hort Innovation’s Frontiers to address industry critical needs, do business more flexibly, support ideas that sprout in the paddock to come to fruition, and deliver outcomes for growers without the need for levy-investment.

Unleash grassroots ingenuity, talk with Hort Innovations’ Head of Investment, Growth & Commercial, Jesse Reader on 0413 777 501 or visit the Hort Innovation website for more information.

AI-powered weather forecasting accuracy to help berry growers: Berry growers could soon have tailored local weather forecasts directly at their fingertips through a new ground-breaking program that leverages the cutting-edge capabilities of artificial intelligence and machine learning combined with traditional weather forecasting techniques.

Aimed at significantly enhancing the precision, quality and usability of weather-related information, the $1.3 million initiative led by Jane's Weather is tailored to meet the specific needs of individual growers, considering their farming block, unique terrain and operational requirements.

This innovative project seeks to provide local weather predictions, empowering growers with the ability to make more informed decisions regarding frost management, spraying, irrigation, and pest and disease control, among other critical agricultural activities.

Machine learning and artificial intelligence are the missing ingredient in solving the problem of what the weather will do next and will give growers the power of being even more accurate, more often.

As always, I encourage you to get involved with Hort Innovation as your rural research and development corporation dedicated to delivering you value. A great first point of call is our Industry Service & Delivery Manager for berries, Adrian Englefield, who is always willing to have a chat. You can get in touch with him on 0427 143 709 or adrian.englefield@horticulture.com.au

7 INDUSTRY

Victoria & South Australia

Dr Angela Atkinson, Berry Industry Development Officer 0408 416 538 | ido@vicstrawberry.com.au

At the time of writing this we are having beautiful autumn weather here in the Yarra Valley; cold nights and mornings, with clear sunny days, perfect for preparation for next season. As the season winds up everyone will be looking forward to a well-earned break. As strawberry growers prepare for next season, the article in this edition of the journal about plant back timing after soil fumigation is very relevant (SEE PAGE 87), with Scott and Dylan from VSICA Research fine-tuning their in-field tests for fumigant levels.

This has become increasingly important with the widespread adoption of totally impermeable films (TIF) in strawberry production in Victoria meaning that fumigants potentially remain in the soil longer which can impact runners or plugs planted too soon.

In early April, the Australian Strawberry Breeding Program held a farm walk at the Wandin Research Farm after the Program Reference Group meeting for the project, so growers could have a look at potential new plants coming out of the program, and provide feedback.

Victorian Strawberry Industry Development Committee

Victorian Strawberry Industry Development Committee

8 INDUSTRY BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

Wandin Research Farm. Photo credit: Angela Atkinson

Before the meeting and farm walk, I had the opportunity to show Adrian Englefield, Hort Innovation’s Berry Industry Services and Delivery Manager (ISDM), some aspects of strawberry production in Victoria.

We visited the Victorian Strawberry Industry Certification Authority (VSICA), so Adrian could see how the nucleus and mother stock are grown and maintained and learn about the processes involved in the production of certified strawberry planting material in Victoria.

In Toolangi we also visited Perry’s Certified Strawberry Runner Growers to see how strawberry plug plants are produced. Finally, we visited Australian Strawberry Distributors in Coldstream to see strawberry tabletop production in their Cravo greenhouse system. Thanks to Corina Horstra (VSICA), Shane Perry (Perry Runners) and Joe Ripepi (ASD) for giving up their time to show us around.

We have a series of grower events planned for the offseason, and leading into next season. The first event was a field day held at Spirli Strawberries in Wandin North on 9 May, with the team from Polybee in Singapore who have been conducting on-farm trials there.

Polybee have been working with tomatoes and strawberries to develop Autonomous Pollination using small drones, as well as developing a yield forecasting App.

For more information about Polybee, you can download the article from the Spring 2023 edition of this journal at our online Resource Library. Visit berries.net.au/resource-library and type ‘polybee’ into the search box

Foundation screen house, VSICA

Photo credit: Angela Atkinson

Plug plants at Perry’s Certified Strawberry Runner Growers. Photo credit: Angela Atkinson

Foundation screen house, VSICA

Photo credit: Angela Atkinson

Plug plants at Perry’s Certified Strawberry Runner Growers. Photo credit: Angela Atkinson

9

Currently the yield forecasting is done using video captured on a smart phone, but ultimately they intend to use drones to capture the information. There are lots of possibilities going forward for using the images captured, including looking for areas in crops under stress or disease pressure.

They were able to demonstrate the drones used in pollination in the strawberry tunnels after their presentation which was really interesting. In addition to the photos here, we have recordings of the drone and their presentation which will be available on the Resource Library at the Berries Australia website

Finally, this will be my last regional update as IDO for Victoria and South Australia, as I will be starting in a new role as R&D and Biosecurity Manager with Berries Australia from 1 July.

I will still be working with growers, researchers and other industry stakeholders in the new role, just in a different capacity.

I have enjoyed my time in the IDO role immensely, and will continue to work with the industry to support R&D and biosecurity nationally.

Demonstration of drone for autonomous pollination

Photo credit: Clarissa Cincotta

Drone in action

10 BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

Photo credit: Angela Atkinson

Climate and crop

Western Australia

Helen Newman, Industry Development Officer, Agricultural Produce Commission

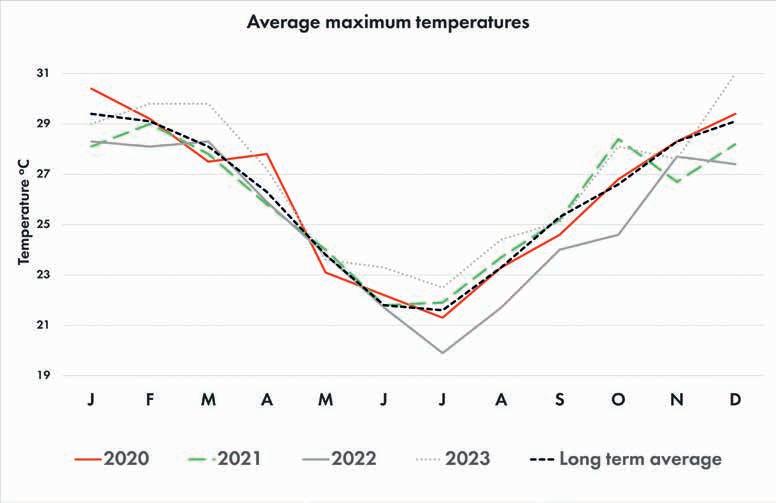

Scorching summer temperatures reported in the last update continued into February which was exceptionally warm with mean maximum temperatures 2–4°C above average across growing regions. An unprecedented high number of extremely hot days with maximum temperatures of at least 40°C were also recorded. Pearce RAAF base to the north of Perth reached a record-breaking 46.1°C on 19 February. A fourth severe-intensity heatwave for the summer was recorded on 17-21 February. Warmer than normal temperatures continued into autumn with maximum temperatures 1–2°C above average in March and 1–4°C above average in April. The impacts of the very hot summer, warm autumn, and a notable absence of soil moisture are evident throughout the southwest landscape with the death of many well-established native trees and understory plants. Water storages in some regions are also under pressure. Warmer than average temperatures are expected to continue for the next three months and below average rainfall is expected in May.

The hot dry conditions have provided the perfect environment for the Chilli thrip to thrive. Early-season blueberry crops have been the most affected, with warm weather and high population numbers persisting into the flowering stage.

Strawberry growers have had a good start to their planting season with the very hot temperatures dropping away just in time for new season plantings. The continued warm weather is helping plants to get well established before soil temperatures are expected to drop off in late May/June.

Industry news

Food safety standards: Implementation of the new Primary Production and Processing Standards for leafy vegetables, melons, and berries is underway in WA.

If you haven’t already, please complete the WA Health Department survey so that you can be connected with your Local Government Authority who will be implementing the standard in your area: https://datalibrary-rc.health.wa.gov.au/ surveys/?s=EMFW8RCAY8P9HW9J

Emergency Use Permit for Chilli thrip: The APVMA issued a permit for the use of Simodis® Plinazolin technology Insecticide (isocycloseram) for Chilli thrip suppression in Blueberries, Rubus, and second-year Strawberries in early April. SEE PAGE 21

Fungicide-resistant botrytis: Associate Professor Fran Lopez-Ruiz from The Fungicide Resistance Group at Curtin University has been testing berry samples at the retail level in WA and has uncovered alarming levels of fungicide resistant botrytis. If you think you are having issues with fungicide resistance in your berries let me know and I’ll collect a sample for lab testing.

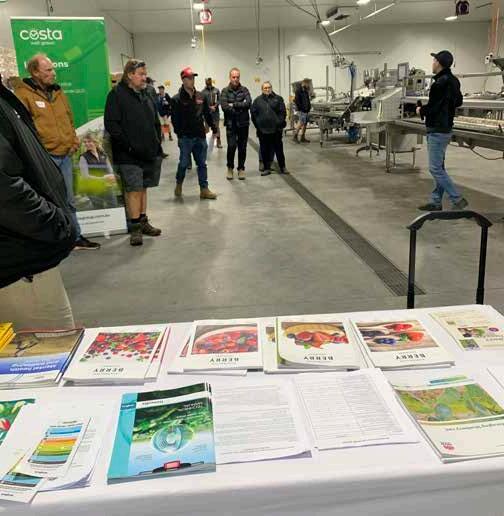

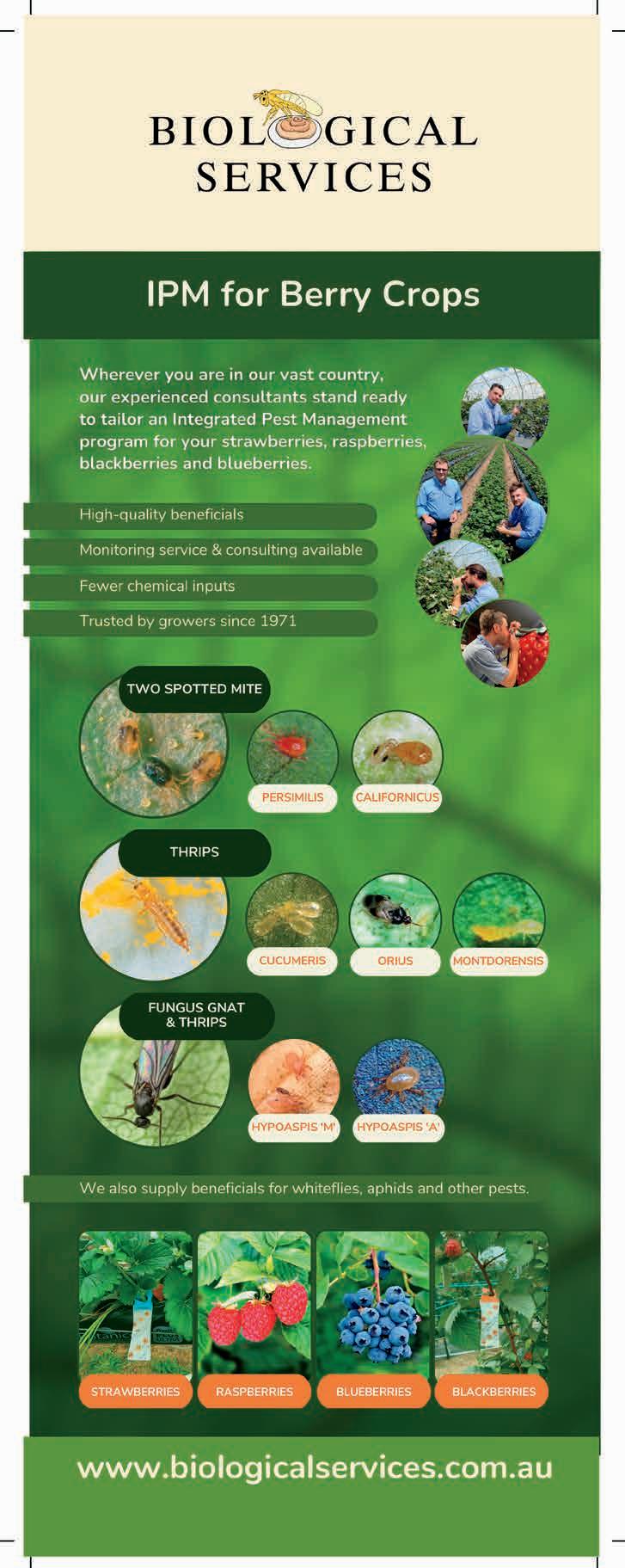

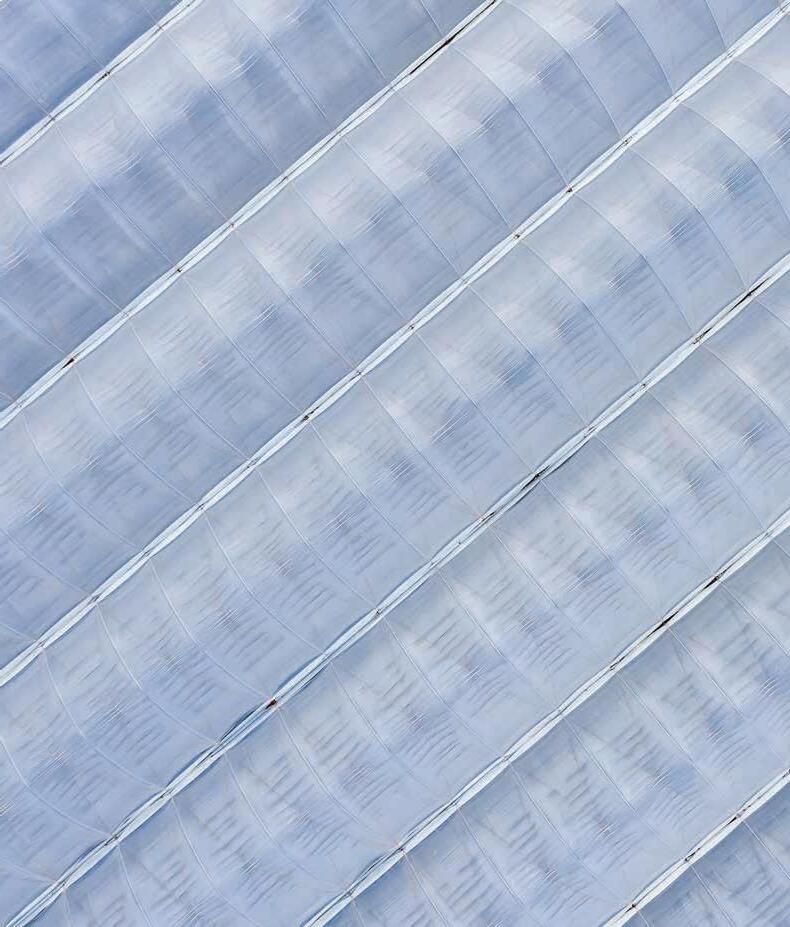

Blueberry Pest and Disease Event: A BIG thank you to Costa in Neergabby for hosting the first WA Blueberry Field Day on 30 April. The weather for the first part of the day was terrible (cold wind, lightning, and then rain), but when the sun came out after lunch, we enjoyed a walk in the field and more discussion around pest and Chilli thrip management. Stuart Doyle from AgVista shared his extensive knowledge of blueberry pest and disease management and highlighted some key international pests on the horizon. Brendon Fewster, Director of the Bee Industry Council of WA, spoke about how to care for bees used for blueberry pollination and the potential impact Varroa mites will have if they reach WA. The 40-strong crowd also participated in a Chilli thrip discussion with input from participating growers, Stuart Doyle, Biological services, DPIRD Entomologists, and chemical suppliers. Before we ventured back outside, Luca Zanini took us on a tour of the Costa packing shed from the forced-air-cooler through the end of the packing line.

11 INDUSTRY

Attendees enjoyed a tour of the Costa packing shed

Photo credit: Katrina Hill, Vegetables WA

Brendon Fewster, Director of the Bee Industry Council of WA spoke to the group. Photo credit: Helen Newman

Attendees at the Blueberry Field Day on 30 April braved the weather to learn from industry expert Stuart Doyle.

Attendees enjoyed a tour of the Costa packing shed

Photo credit: Katrina Hill, Vegetables WA

Brendon Fewster, Director of the Bee Industry Council of WA spoke to the group. Photo credit: Helen Newman

Attendees at the Blueberry Field Day on 30 April braved the weather to learn from industry expert Stuart Doyle.

12 BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

Photo credit: Helen Newman

Chilli thrip management ideas

Potential chemical, biological, and cultural options for managing Chilli thrips were discussed at the Blueberry event on 30 April. Those that were of most interest are listed here.

Some additional chemistries that could be tested:

• Cyantraniliprole (Benevia ®) Group 28

• Broflanilide (Cimegra ®) Group 30

• Dimpropyridaz (Efficon ®) Group 36

• Clitoria Ternatea Extract (Sero-X ®)

A rotation of softer chemistries that can be used with biological controls is ideal but knockdowns for emergencies can sometimes be useful. Sero-X ® is particularly interesting because it is a non-toxic, bee-friendly, plant extract botanical pesticide.

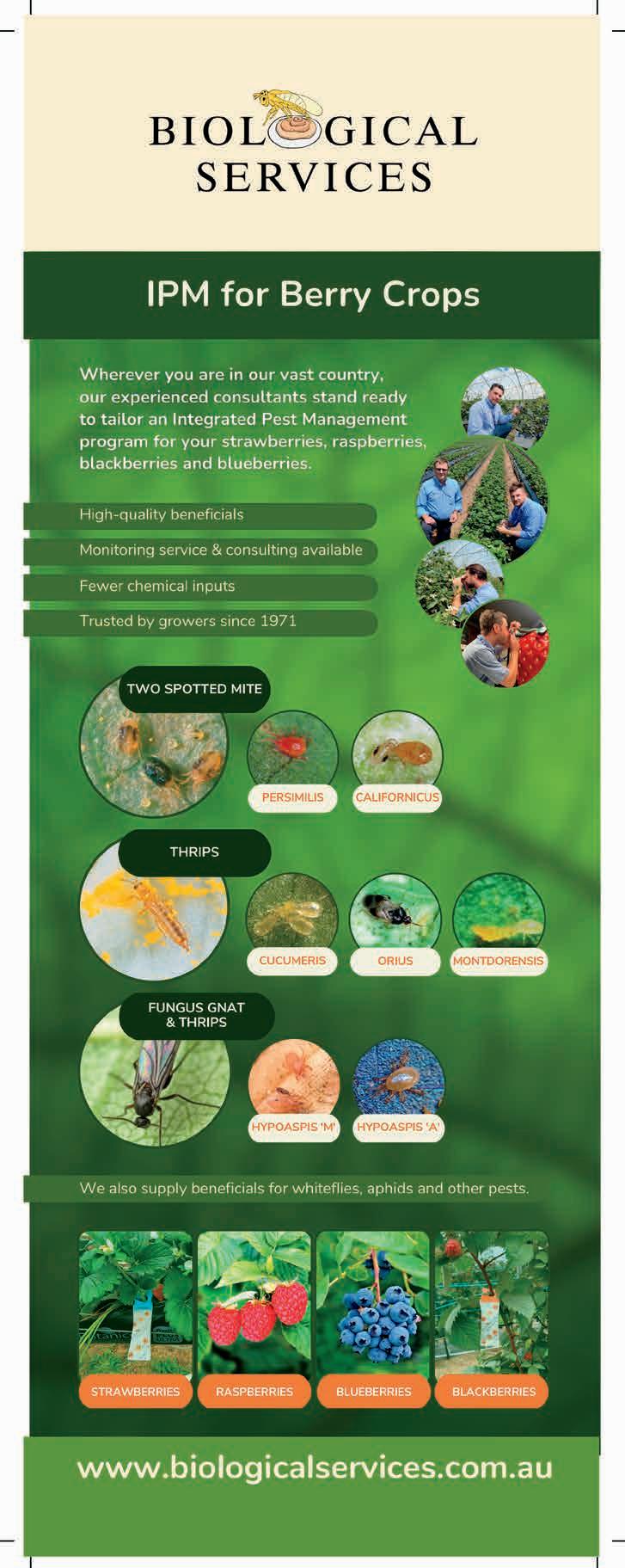

Some biological controls that could be tested:

• Predatory nematode Steinernema feltiae: this nematode feeds on pupae and larvae mainly in the soil/substrate

• Predatory thrip Franklinothrips vespiformis: this thrip potentially feeds on all life stages. Biological Services are currently running trials with this predatory thrip

• Banker plants to support the establishment and retention of beneficial insects: e.g. Sweet alyssum

Other potential management options:

• Entomopathogenic Fungi (soil and foliar applications). Spores germinate and hyphae penetrate the thrip's body cavity where they proliferate and destroy the tissues

• Overhead watering to knock thrips off the foliage onto the ground where they are vulnerable

• Reflective mulch under the plants to deter thrips from entering the crop

• Barriers over the pot or ground to stop the thrip pupae from dropping into substrate/soil and prevent any existing pupae from emerging

• Coloured netting (such as red netting) to deter thrips from entering the crop

An understanding of Chilli thrip population dynamics in WA blueberry crops is also still required. Entomologists at DPIRD now have some capacity to assist in this area and planning is underway for glasshouse trials next spring.

The appearance of bronzing on new flush may be the first indication of the chilli thrip's presence in blueberries

Photo credit: Cezar Moraes, Biological Services

Early signs of chilli thrip damage in blackberry are browning and dehydration of the leaf margins

Photo credit: Elliot Howse, DPIRD

Heavy feeding by chilli thrips in strawberry causes reddening and darkening of leaf veins and petioles

For a more information about Chilli thrip, visit our RESOURCE LIBRARY online at berries.net.au/resource-library and type 'chilli' in the Search box 13

Photo credit: Cezar Moraes, Biological Services

Tasmania

Mark Salter, Berry Industry Development Officer 0400 100 593 | berryido@fruitgrowerstas.org.au

Tasmania’s berry season is now at its tail end and from all reports it’s been a good season as far as production is concerned.

I recently had the pleasure of visiting Queensland berry growers in Caboolture and Stanthorpe as part of a visit organised by Queensland IDO Wendy Morris. As we visited local strawberry growers it was clear planting has been delayed again this year by above average rainfall. It was great to see how the early season Rubus production was progressing in both regions with some growers only weeks away from harvest. SEE PAGE 53

Until recently, blueberry growers have been reluctant to travel to other farms because of the blueberry rust issue. This was particularly evident during the years when the Tasmanian blueberry industry was trying to contain and eradicate the disease, following a government regulated containment plan which restricted movement between farms. Unfortunately, blueberry rust eradication was unsuccessful, and the plan was deregulated in 2022. Following the decision to lift blueberry rust restrictions, growers have become more relaxed about visiting other farms and indicated they would like to get together for on-farm workshops and field days.

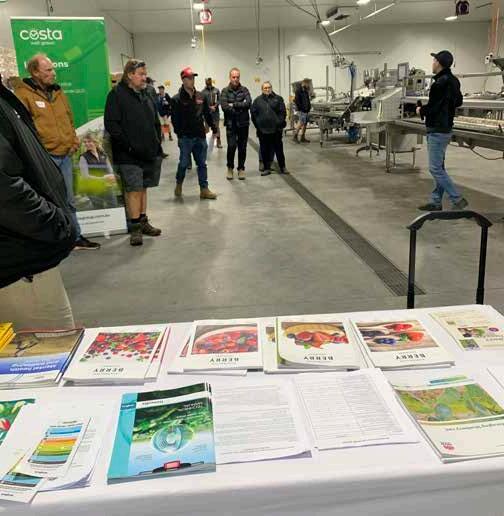

Taking this feedback on board, Fruit Growers Tasmania and Berries Australia recently held a Blueberry Growers Field Day at Griggs Bros, Castle Forbes Bay in the state’s south. More than 30 growers and industry people attended the day which included presentations from Stuart Doyle from AgVista on pest and disease issues. NSW IDO and blueberry specialist Gaius Leong travelled down to give an informative presentation on nutrition for blueberries. Kara Berry from the Tasmanian Institute of Agriculture gave growers an update on the blueberry rust project her team is conducting, including results on the various defoliation treatments. The morning session concluded with Kate Dickenson from Fruit Growers Tasmania giving an interesting and informative presentation on trade and export opportunities for blueberries.

Following lunch, those attending had a chance to view the blueberry rust defoliation trials Kara and her team are conducting at Griggs Bros. SEE PAGE 94

The next day Gaius and I took the opportunity to visit berry farms in the south and southeast. Visiting Piñata Farms at Orielton, we looked at their strawberry and raspberry production and had a chance to view their packing line in action, with many thanks to Jan Booysen for showing us around the site. From there it was a trip south to visit Tru Blu Berries at Lymington where we met with Damian Clark and Sharon Keetch who manage 13ha of blueberries. Damian explained they are growing northern highbush public varieties, all grown in the ground under bird net. While there, Gaius took the opportunity to share his knowledge on nutrition and pruning techniques with Damian. On our way back to Hobart we dropped in to visit Stuart Griggs from Griggs Bros who was keen to get some advice on pruning techniques to help control vigour in some of his plants, and after further discussion Gaius was able to help with some pointers on various pruning techniques.

As this will be my last report before retiring, I would like to take the opportunity to thank berry growers both in Tasmania and the mainland for your support. I have enjoyed the Industry Development role and particularly enjoyed wcommunicating and working with growers; at the end of the day you are the reason we are here.

I would also like to thank Rachel Mackenzie, the Berry IDO team and staff for your support and encouragement. I would also like to thank Peter Cornish and the team at Fruit Growers Tasmania; it has been a pleasure to work with you.

Thank you again and all the best for the future.

14 INDUSTRY BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

Queensland

Wendy Morris, Berry Industry Development Officer 0484 272 963 | qldberryido@berries.net.au

With autumn finally upon us, many of us are reflecting on the weather forecast and wondering what lies ahead. One thing is for certain; it is keeping growers on their toes as they continually adapt to changing weather conditions.

The end of the Stanthorpe strawberry season was hot, with fruit size being affected. Despite the smaller size, the fruit still ate well. Raspberry growers in various locations were also battling the heat, with plants protesting the number of hot, humid days.

On the coast, our Sunshine Coast and Bundaberg strawberry growers have commenced planting. Field preparation was hurried for many growers who battled to find a break in the weather to put down plastic. For a number of growers, one field was being planted while another was still being prepped.

Variety substitutions continue to be part of the challenges growers face, as well as the usual gamut of pests and diseases. Fall armyworm is looking to become increasingly problematic, with the distribution and concentration appearing to be on the increase.

In 2023, we saw several occasions where retailers rejected low quality fruit. This fruit subsequently made it’s way to the market floor, where it negatively impacted prices for all growers. From there, very lowquality fruit often ends up in ‘bottom rung’ fruit and veg stores, where it is bought by unsuspecting consumers.

We know that a consumer who has a bad experience with a fruit or vegetable will typically wait around six weeks before buying it again. As such, poor quality strawberries have a disastrous impact not only on growers who receive low pricing, but on consumer confidence.

This winter season, I’m working closely with DAF and the Queensland Strawberry Growers Association to provide timely information throughout the growing

season on what pests and diseases we are noticing or anticipating. This information is not designed to replace thorough agronomic advice, but to act alongside it, and to assist those who are either inexperienced growers or who do not have the funds to pay for personalised agronomy advice. We find it is often the latter group who is most vulnerable to pest and disease problems.

Another important topic for growers is water quality, particularly in the Pumicestone Passage area. Regular testing of the water at Six Mile Creek and Coochin Creek continues and it is a timely reminder to all to ensure that good spray and run-off management practices are always adhered to.

To ensure our growers do not find themselves facing the same social license issues as the Northern NSW blueberry growers, the Queensland Strawberry Growers Association have been in contact with a number of growers whose properties abound Six Mile and Coochin Creeks to ensure they are comfortable with their measures of control for nitrate and sediment run off. It has been great that the QSGA and our growers are so proactive on this front.

If you are a grower who operates in the Six Mile or Coochin Creeks and have any concerns at all please feel free to contact me at any time. I can connect you with any existing resources as well as assist with identifying any potential grants or funding available to help you to make improvements on your farm to better manage water quality.

On the topic of water, The Department of Natural Resources, Mines and Energy has engaged a consultancy to investigate water security in the SEQ region. During farm visits growers in this region will be asked about the source of your water, and any concerns you may have. Gathering this information is crucial if our industry is to survive and expand.

It hasn’t all been serious business over the past three months. I have attended a number of interesting and informative events, including the AllClass Kubota

15 INDUSTRY

Open Day, 3rd Smart Agricultural Symposium at Griffith University and the Clean Coastal Catchments (CCC) in March Field Day down in NSW (SEE PAGE 98) where I expanded my knowledge about ways to better manage irrigation run off.

Back home in not-so-sunny Queensland, Tasmanian IDO Mark Salter and I met with raspberry growers. As part of Mark’s tour, we held grower dinners in Caboolture and Stanthorpe for all berry growers, and it was fabulous to have so many attendees. These were great opportunities to connect with industry experts as well as fellow growers. SEE PAGE 53

One of our guests at the Caboolture dinner was Amy Nash from Queensland Agriculture Workforce Network (QAWN). QAWN is a regional network of industry-based agricultural workforce officers, directly supporting producers and operators across the supply chain. Officers can provide a broad range of advice and guidance to assist with addressing recruitment and skilling issues. This is a free service available to any agribusiness with operations in Queensland, regardless of commodity or organisation membership. Through extensive links with employment and training providers across the state, a QAWN representative can support any agribusiness trying to understand or access strategies to both identify and meet future workforce or training needs.

QAWN officers can support you with advice about:

• Workforce planning

• Sourcing labour and skilled workers

• Recruitment induction

• Requirements

• Funded training opportunities

There are seven QAWN officers positioned across Queensland, hosted by industry or economic bodies. Your regional officer can be identified and contacted at www.business.qld.gov.au/industries/farms-fishingforestry/agriculture/business/workforce/qawn

QAWN is funded by the Department of Agriculture and Fisheries

Further events were held in Bundaberg (22 May) and planned for Nambour (July). If you have not attended a Berries Australia event before, we strongly encourage you to come along. If you don’t know any other berry growers, let me know beforehand as I’m happy to introduce you.

News of our events and other important industry information is frequently shared through our monthly e-newsletter, and now on our Facebook and LinkedIn pages so why not follow us to get our updates

FACEBOOK-SQUARE www.facebook.com/berriesaus linkedin-in www.linkedin.com/company/berries-australia

1 3 2

(1) Irrigation Shed at CCC Field Day (2) (L-R) Wendy Morris, Angelo Pinna & Mark Salter at Angelo’s Wamuran Farm (3) AllClass Kubota Open Day. Photo credit: Wendy Morris

16 BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

New South Wales

Gaius Leong, Berry Industry Development Officer

0484 055 748 | gaius.leong@dpi.nsw.gov.au

Thoughts of a drier winter accompanied by lower disease pressure have all but vanished. At the time of writing (early May), there have been frequent rainy days and the forecast is for rainy weather with overcast days for this week along the mid north coast of NSW. A continued lack of pollinating days and increased disease pressure is expected with the current and forecast weather. This again emphasises the benefits derived from protected cropping, in particular reduced disease pressure and increased shelf life without the need to compromise on the harvest schedule.

Talking about production systems, I am thankful for the opportunity to visit beautiful Tasmania recently and to catch up with the wonderful growers and Fruit Growers Tasmania team. Whilst in Tasmania I presented on blueberry soil nutrition at the Field Day held on 18 April (SEE PAGE 94), Mark Salter (TAS IDO) showed me around the berry farms, and it struck me how different the soil production systems are between southern Tasmania and mid north coast New South Wales. The biggest difference is in the soil organic matter (SOM) content and the nutrition that the organic fraction provided to the crop.

Looking at some of the soil analyses, it is common for soils in Tasmania’s blueberry production systems to have organic matter contents of 8-10 % compared to the NSW mid north coast region’s 2-4%. The application of mulch under fertigation system in Tasmania compared to the use of weed mat (NSW) plays an important role in increasing the organic matter content of soils overtime. This higher organic matter level allows blueberry growers not only to reduce their fertiliser inputs but also ensures better soil structure which assists with a healthier root system.

In addition to blueberry systems, we visited Piñata Farms and tasted their incredible raspberries and tabletop strawberries. The highlights include the fantastic flavour profile of both their berry categories and innovative V-trellis system for raspberry production.

The potential to create organic production systems and reduce reliance on conventional chemistry allows a more holistic approach to producing berries. This is evidently possible in Tasmania with the cooler climate (lower pest/disease/weed pressure) and deciduous, compact phenological stages. Comparatively, the climate along NSW’s mid-north coast increases the potential range of diseases, weeds, and pests. This accompanied by multiple phenological stages across the production cycle makes it extremely difficult to achieve economic viability without chemical interventions. As such, ensuring resistance management strategies are used is an important part of ensuring the current available chemistry stays viable for longer.

For example, with Botrytis management, most growers can attest to the efficacy when using certain chemistry compared to others which are available. The most common strategy is to rotate chemical groups so that the pathogen or pest is not repeatedly treated with the same mode of action. All registered pesticides have a symbol on the label which identifies the action group to which it belongs. This assists growers in choosing a different mode of action when seeking to rotate chemicals in a program.

For strawberry growers, you can see more about fungicide resistance management in Apollo Gomez’s article on PAGE 81.

Research into resistance screening of old and new chemical formulations, along with having access to efficacious chemistries must not be overlooked even as we push towards more effective biological controls.

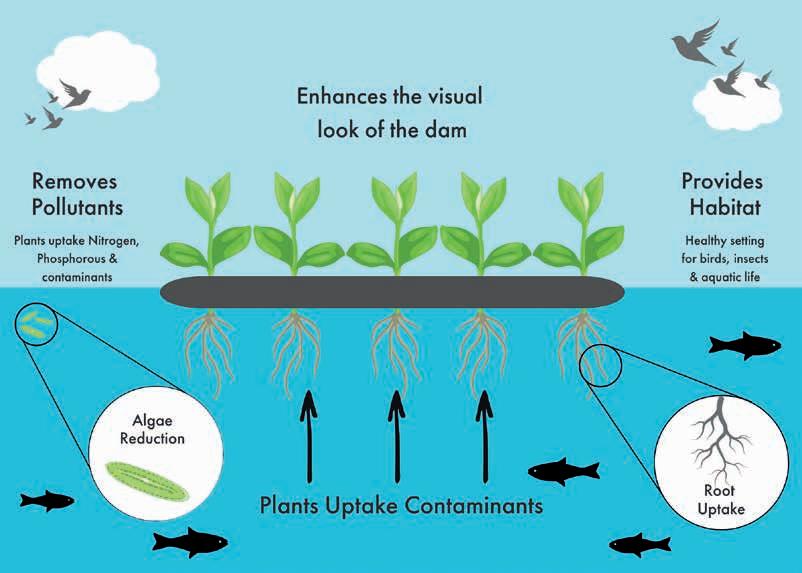

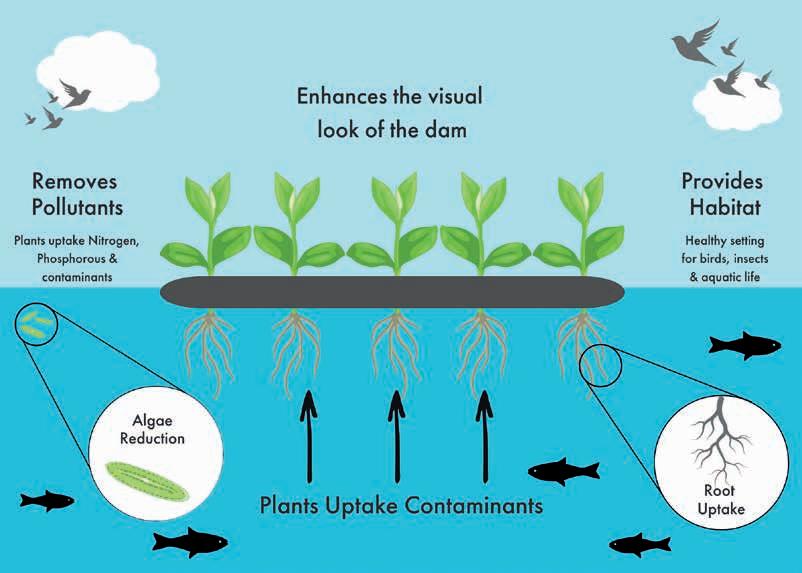

In addition to the trip to Tasmania, we have been busy with a range of projects and workshops. Notably, a dam (source for irrigation) water quality workshop held in Woolgoolga (SEE PAGE 104). We will look at creating a similar workshop for growers in the southern growing region around Macksville.

17 INDUSTRY

Varroa destructor –Transition to Management: what happens now?

Angela Atkinson, Berry Industry Development Officer, Victoria & SA

• Varroa mite (Varroa destructor), the most serious pest of European honey bees, was detected for the first time in Australia at the Port of Newcastle (NSW) in June 2022

• An emergency response was initiated according to the Emergency Plant Pest Response Deed (EPPRD) supported by the Commonwealth, state and territory governments, and agricultural industries potentially affected by this pest

• Both the strawberry and Rubus industries were involved in this response, as signatories to the EPPRD

• The Response was led by the NSW Department of Primary Industries, and was the largest agricultural biosecurity response in Australia to date

• In September 2023 the National Management Group (NMG) agreed it was no longer feasible to eradicate Varroa mite and a plan to assist industry and the community to transition to management (T2M) was developed

• The T2M plan was approved in February 2024

The aim of the T2M plan is to provide an orderly transition from the response program which focused on eradication, to management of the pest while minimising the ongoing effects of Varroa mite naturalisation on the European honey bee industry and pollinationreliant industries.

The plan focuses on maintaining business continuity for the honey bee industry and the horticulture industries that rely on honey bee pollination.

It aims to slow the spread of Varroa mite to allow beekeepers, pollination-dependent industries and the community sufficient time to prepare for the inevitable spread of Varroa mite.

The T2M plan will be delivered over 24 months to allow for recruitment of personnel, with the majority of activities delivered during the first 12 months.

There are four objectives within the plan:

• Completion of activities under the response plan

• Building industry resilience

• Slowing the spread of Varroa mite

• Future-ready industries

18 INDUSTRY BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

Completion of the activities planned under Response Plan Version 3

All activities associated with eradication were completed by March 2024, including tracing and surveillance for infested premises, opt-in hive euthanasia for beekeepers who were in previous eradication zones, and wild European honey bee surveillance and baiting.

The NSW DPI compliance team are continuing to investigate complaints and progress prosecutions relating to offences under the Eradication phase of the response.

Building industry resilience

It was agreed by all industries involved that the most effective way to prepare for the impact of Varroa mites is to train beekeepers and provide them with the skills they need to manage Varroa mite and maintain healthy hives.

Over 70% of the budget is allocated to delivery of training and extension services to achieve this. Under the T2M plan, tailored resources are being developed to provide accessible, current and consistent information and training programs for best practice beekeeping in the Australian context.

Training will include nationally delivered online and face-to-face training for beekeepers, by state-based trainers who have completed a ‘Train the Trainer’ program delivered by Tocal College, NSW DPI technical specialists and Bee Biosecurity Officers.

The Australian Honey Bee Industry Biosecurity Code of Practice and the Bee Biosecurity Manual will also be updated as part of the T2M plan. The Code of Practice provides a framework for beekeepers to use best practice biosecurity measures to achieve pest and disease prevention and control.

Varroa Development Officers (VDOs) will be engaged in each state to work with commercial and recreational beekeepers to promote best management practice guidelines and resolve problems. The VDOs will also establish, coordinate and maintain a voluntary Varroa mite monitoring program, in collaboration with volunteer beekeepers and beekeeping clubs.

For pollination-dependent industries, a National Pollination Industry Coordinator (PIC) will work with industries to identify their concerns, knowledge gaps and future needs related to managing pollination.

19

An adult female Varroa mite feeds on a developing bee. Photo credit: Scott Bauer, USDA Agricultural Research Service, Bugwood.org

The PIC will coordinate the development of resources specific to the needs of pollination-dependent industries and will work with existing IDO networks to support delivery of resources to growers. The PIC will act as a key point of contact for IDOs to clarify information or raise concerns about industry needs. The VDOs may also work with plant industries, where a beekeeping perspective is required for engagement with growers. While diagnostic capability and capacity within NSW have been well established through the emergency response, more work is required to bolster this on a national scale to support ongoing surveillance and management needs. The T2M plan will share knowledge and expertise to enable interstate diagnostic laboratories to detect Varroa mite and associated exotic viruses quickly.

Slowing the spread of Varroa mite

After the decision that Varroa mite was no longer technically feasible to eradicate, NSW introduced biosecurity zones aimed at preventing the movement of heavily infested colonies throughout NSW. These zones will be kept in place for no longer than 12 months. Varroa mite will remain a notifiable pest in NSW.

Other states are considering options for consistent movement conditions for bees, queens, hives and other associated material across borders, that are practical, least restrictive to trade, technically justified and address the risks to support business continuity and pollination security.

Beekeepers in NSW will be audited to ensure they comply with monitoring and reporting requirements, and conditions of beekeeper registration. Compliance activities in Vic, SA and Qld will focus on interstate movement of risk material to ensure compliance with permitted movement. Activities may change if Varroa is detected in other states.

The VDOs will engage with beekeepers on a voluntary basis to help them undertake surveillance activities in their apiaries, to facilitate the collection of surveillance data from managed commercial and recreational hives. This data will support decisions around intra- and interstate regulation aimed at slowing the spread, and help to measure the success of the T2M program.

Future-ready industries

As part of the T2M plan, a survey similar to COLOSS will be initiated, to help understand the effects of Varroa mite and how it is being managed. COLOSS is a global initiative which conducts standardised colony loss surveys in 30 countries to better understand the risk factors of colony loss. This would be initiated for Australia as part of the T2M plan, with support beyond the plan being provided through alternative funding mechanisms.

A system will also be introduced to collate and analyse monitoring and surveillance data nationwide, in order to map the spread of Varroa mite over the next 3 to 5 years. Consistent data reporting is important, as the beekeeping industry is mobile, with hives moving across state borders to provide pollination services.

Upskilling of queen bee breeders will also help to futureproof the industry, to enable breeders to use advanced techniques for the selection of Varroa mite-resistant queens and improve breeding for Varroa mite tolerance.

Finally, the T2M plan will include a review of current research supporting greater pollination efficiency in a post-Varroa mite Australia, and provide recommendations for further work to support future ready industries.

The establishment of Varroa mite in Australia will radically change the way European honey bees are managed, and potentially the access to pollination for industries that rely on honey bees. The activities in the T2M plan have been developed to provide the knowledge and tools needed to minimise the impact of this pest to beekeepers, pollination-dependent industries and the community, and enable management of Varroa mite in the long term.

More Information

The Australian Honey Bee Industry Council (AHBIC), in collaboration with AgriFutures Honey Bee & Pollination program, is hosting a series of podcasts and interviews on Varroa mite which can be accessed at https://honeybee.org.au/varroa/ podcasts-webinars

For more information about the transition to management go to bit.ly/VM-NSW or honeybee.org.au

20 BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

SIMODIS® insecticide: Emergency Use Permit for Chilli thrip in berries

Helen Newman, Berry Industry Development Officer, Agricultural Produce Commission, WA

Thrips are notorious for developing insecticide resistance so any control strategy must use a combination of methods including cultural and biological controls and a rotation of different chemistries.

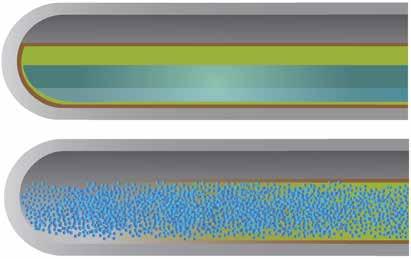

SIMODIS® is classified as a Group 30 insecticide (active ingredient Isocycloseram). It is the first Group 30 insecticide to be permitted on berries and adds to the rotation of chemistries that can be used during the vegetative stage of the crop cycle.

This chemical is not permitted for use during flowering and fruiting

SIMODIS® is a foliar applied contact insecticide, with no translaminar (systemic) movement in the plant. The active ingredient is absorbed by insect pests either through contact or by ingestion while feeding. Within 13 hours of contact or ingestion, insect pests stop moving.

SIMODIS® suppresses Chilli thrips with the first application. The second application 7 to 10 days later controls the thrip.

To help manage resistance to this new chemistry, a maximum of two applications per season are permitted.

SIMODIS® is toxic to bees and beneficial arthropods. It cannot be used on flowering berry crops and any nearby managed hives must be moved away from sprayed areas and provided with a safe source of nectar and pollen. Bees and predators used in IPM programs can be released into the crop 28 days after the final application of SIMODIS®

Mode of Action

SIMODIS® insecticide works on the insect’s nervous system to block an important mechanism for controlling nerve to muscle communication. The target site in the nervous system is in the GABA (gamma-aminobutyric acid) receptor. These receptors control how electrical signals pass from one nerve cell to another. When the active ingredient in SIMODIS® insecticide stops the receptors from working, the nervous system goes into overload, resulting in muscular cramps and paralysis of the insect pest. Treated insects and mites are no longer able to move or feed properly, and eventually die from starvation. This novel mode of action has been classified as Group 30 as outlined in the Insecticide Resistance Action Committee guidelines.

INDUSTRY 21

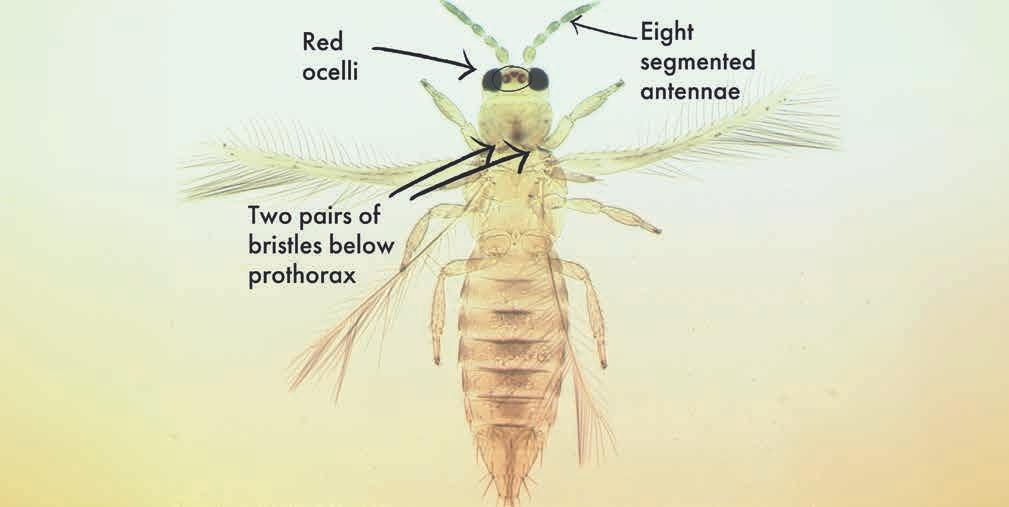

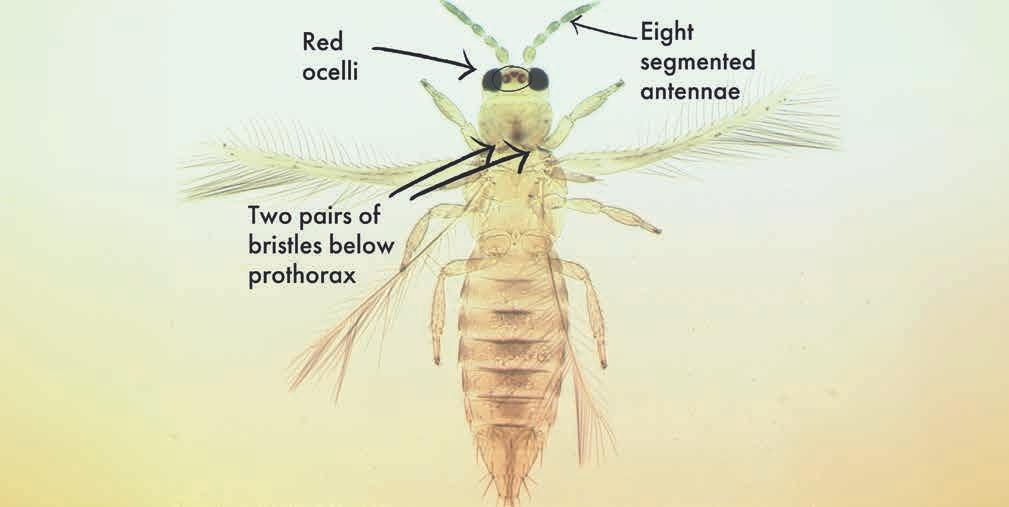

Figure 1. Chilli thrips are pale yellow in colour. They are very small (0.5-1.2mm long) and hard to distinguish from other thrips species without a microscope. Key distinguishing features are shown here.

How Simodis can be used under the Emergency Use Permit

SIMODIS® is registered for use in a variety of vegetable crops where it demonstrates excellent crop safety and helps growers manage resistance in a range of Lepidoptera species, mites, and thrips. Below is a guide to how the chemical can be used on berry crops under Emergency Use Permit PER94616.

Rubus: Only use after pruning/planting when Chilli thrips are present and new growth is developing throughout summer and before flowering. Apply 300mL/ha with a non-ionic surfactant using a vertical sprayer. Ensure thorough coverage of the crop using 500-1000 L/ha.

Blueberries: Only use in evergreen production, apply when Chilli thrips are present after pruning when new growth is developing throughout summer and before flowering. Apply 300mL/ha with a non-ionic surfactant using a vertical sprayer. Ensure thorough coverage of the crop using 600 L/ha.

Strawberries: Only use on second-year plants when Chilli thrips are present in the weeks before they are cut back for second-year production. Apply 300mL/ha with a non-ionic surfactant using a boomspray. Ensure thorough coverage of the crop using 1000 L/ha.

Other considerations

SIMODIS® must not be applied if heavy rains or storms that might cause runoff are forecast within 3 days. Overhead irrigation that wets foliage to the point of runoff must also be avoided for at least 3 days after application.

Spray drift restraints including mandatory downwind buffers between the sprayed crop and natural aquatic areas are also required:

• For second-year strawberry crops, a minimum buffer of 350m between the sprayed and natural aquatic areas is required. Boom sprayers must be set no more than 0.5m above the crop and spray droplets must be no smaller than the ‘COARSE’ spray droplet size category.

• For blueberry and Rubus crops, spray must not be directed above the target canopy and the outside of the sprayer must be turned off when turning at the end of rows and when spraying the outer row on each side of the application site. Where dilute water rates are used, a minimum buffer of 75m between the sprayed and natural aquatic areas is required.

22 BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

Notes on the formulation

SIMODIS® is a liquid formulation, known as a dispersible concentrate (DC), similar to emulsifiable concentrates (EC). When added to water it completely mixes to give a uniform dispersion. It can be added directly to the spray tank, however, to ensure good compatibility with other tank-mix partners, the following tank-mix order is recommended: This tank mix information and chart, produced with information provided by Syngenta, is not intended to replace product labels. Always check product labels and manufacturer’s tank mix recommendations. If unsure of compatibility, perform a jar test. The physical and chemical properties of various manufacturer’s formulations may differ.

Download the 'Tank Mixing Chemicals' Factsheet from the website RESOURCE LIBRARY by visiting berries.net.au/resource-library and typing 'tank mixing chemicals' in the Search box.

More Information

If you would like to use SIMODIS® on your crop, speak to your local supplier for a detailed overview of the stewardship requirements associated with its use, and always follow the directions of the APVMA permit. Permit on APVMA website: https://permits.apvma.gov.au/PER94616.PDF

Syngenta Simodis web page: https://www.syngenta.com.au/simodis

IPM Notes: Chilli Thrips (Spring 2023 issue of the Australian Berry Journal): Find this article online at our website RESOURCE LIBRARY by visiting berries.net.au/resource-library and typing 'chilli thrip' in the Search box.

23

Reporting Chemical ‘Non-Performances’ or ‘Adverse Experiences’

Jane Richter, Communications Manager, Berries Australia

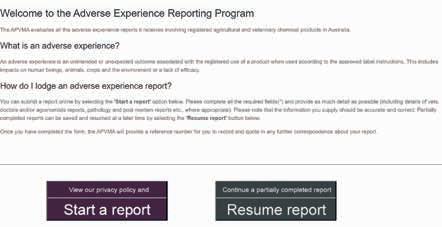

The Adverse Experience Reporting Program (AERP) is a post-registration program that assesses reports of adverse experiences associated with the use of a registered chemical product (or those on minor use permit). Reports of adverse experiences are closely monitored by the Australian Pesticides and Veterinary Medicines Authority (APVMA) and it is vital to record, assess and classify adverse experiences to detect uncommon events not evident during the initial registration process of a product.

Problems reported with chemical products may result in further regulatory action in accordance with the legislation, for instance, through compliance action or chemical review. If the issue reported is related to control of use, or is otherwise outside the jurisdiction of the APVMA, the information may be referred to the appropriate authority.

What is a ‘non-performance’?

A 'non-performance' or adverse experience is an unintended or unexpected effect on plants, plant products, animals, human beings or the environment, including injury, sensitivity reactions or lack of efficacy associated with the use of an agricultural chemical product(s) when used according to label (or permit) directions.

Why is it important to report nonperformances or adverse experiences with registered chemicals?

Before any agricultural chemical product can be legally supplied, sold, or used in Australia it must be registered by the APVMA. The process to register a chemical for use in Australia is a comprehensive one, with the application being supported by information that allows the APVMA to determine whether they are satisfied that the product meets the applicable ‘statutory criteria’; namely, safety, trade, efficacy and labelling criteria.

For a new agricultural or veterinary (agvet) chemical product that contains a new active constituent, the APVMA must approve the active constituent before it will register the product. Once approved, the active constituent may then be used in new agvet chemical products that are presented for registration.

The process to test the efficacy and safety of a new active constituent – particularly where that active ingredient will be applied to food crops – is a significant one and requires the applicant to provide scientific data to support the application. Despite this rigour, it is impossible for every chemical to be tested fully on every crop in every growing region and so from timeto-time adverse experiences will occur.

As an authorised and trained user of agvet chemicals, it is your responsibility to notice, record and report anything unexpected when using a registered chemical as directed on the label or minor use permit.

24 INDUSTRY BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

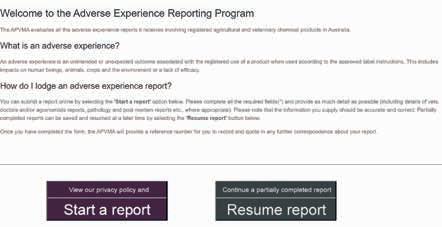

How do I report a non-performance or adverse experience?

If you believe you have had a non-performance or an adverse experience following use of a registered chemical or under a minor use permit, please submit a report via the new online reporting process at bit.ly/APVMA-AE.

This replaces the paper document that previously would have been completed and returned via email.

Once you open the portal, you can submit a report by selecting the 'Start a report' option.

Complete all the required fields (*) and provide as much detail as possible (including details of agronomists reports, test reports etc., where appropriate).

Please note that the information you supply should be accurate and correct.

Partially completed reports can also be saved and resumed at a later time by selecting the 'Resume report' button.

Once you have completed the form, the APVMA will provide a reference number for you to record and quote in any further correspondence about your report.

Further details about the APVMA’s Adverse Experience Reporting Program for Agricultural Chemicals may be found at: http://apvma.gov.au/node/311 or https://portal.apvma.gov.au

IDO & Communications Project Update: Year 1 Achievements

Jen Rowling, Project Manager, Berries Australia

They say time flies when you’re having fun…well our Industry Development and Communications project team must be having lots of fun because the first year of the new project has absolutely flown by!

The new project – Facilitating the development of the Australian Berry Industry (MT22010) - which kicked off in July 2023 is in full swing and the team got together recently in Melbourne to review the first year of the project and put plans in place for year 2.

This project has been funded by Hort Innovation, using the Blueberry, Strawberry, Raspberry and Blackberry research and development levies and contributions from the Australian Government.

Industry Development

A key aspect of the new project is the flexibility around delivery of information-sharing activities, which allows the Industry Development Officers (IDOs) to coordinate events and resources to suit the grower demographics in each of their regions. There are noticeable differences in how growers like to receive information from state to state and also by commodity and business type, and the flexibility of the project provides the IDOs with the ability to effectively reach a broader cross-section of growers. To date, a range of in-person and online activities have been delivered and have been well attended by growers and industry associates.

The team will continue to focus on the key priority areas that were highlighted from a survey carried out early last year, but again, the project provides the flexibility to address important issues as they arise. The four key areas of priority are:

• Irrigation & nutrient management

• Pest & disease management

• Business & labour management

• New technologies & robotics

Each of the IDOs has a berry specialty and this matrix approach means the team has expertise across the berry categories and can work together to ensure that growers also have access to relevant technical knowledge and experience.

In April, Gaius Leong (blueberry specialist) travelled to Tasmania to visit blueberry growers and participate in a field day coordinated by Mark Salter, presenting on nutrition for blueberries. Attendees also heard from other industry experts covering pest and disease management, blueberry rust and blueberry export for Tasmania and the event attracted over 30 growers and industry associates.

As our Rubus specialist, Mark also travelled to Queensland in April to meet with Rubus growers in both the South East Queensland and Stanthorpe growing regions. The tour was coordinated by Queensland IDO Wendy Morris and gave Rubus growers in the state an opportunity to tap into Mark’s knowledge and experience on Rubus production.

Our Victorian IDO, Angela Atkinson, is the team’s biosecurity specialist and as such has been heavily involved in the national Varroa mite response. Her representation of the berry industry at the countless meetings held since the incursion has helped to ensure that the industry is considered in the response, and provides our team with a thorough understanding of how and why the response has progressed as it has, which can then be communicated with growers and industry.

In WA, Helen Newman has developed a range of translated resources such as fact sheets and articles for the Australian Berry Journal and delivered events with translation for the local Vietnamese strawberry growing community. This has significantly expanded the scope of growers in the state receiving important news and information through the project.

The project team have also worked together on nationally coordinated activities such as a webinar held in February on strawberry nursery plug plant quality and establishment with international expert Klaas Plas as guest speaker. This important topic for the strawberry industry attracted over 150 growers, propagators and industry associates and is a perfect example of how the team were able to respond to a particular issue based on grower feedback. The webinar was recorded and is available to view from our website Resource Library.

With BerryQuest International on the near horizon, a significant part of the IDO workplans for the coming

26 INDUSTRY BERRY AUSTRALIAN JOURNAL WINTER 2024 EDITION 19

year will be focussed on development of the program and farm tours. The end goal is a highly informative, relevant and inspiring suite of speakers and topics for the biannual conference of the Australian Berry Industry taking place in February 2025 in Tasmania. The first year of the project has seen the IDO team work exceptionally well together but there are changes ahead, with Mark (Tas) heading into retirement and Angela Atkinson (Vic) moving into the newly created role of R&D Manager with Berries Australia. Whilst we will miss having them as part of the IDO team, we look forward to welcoming two new IDOs into the fold. Stay tuned for further developments!

Communications

Our Communications Manager, Jane Richter, has continued to compile and produce both print and digital resources for the industry. The first year of the project has delivered:

4 editions of the Australian Berry Journal (Spring 23, Summer 23, Autumn 24 and this edition Winter 24) with a printed copy of each edition distributed to over 850 recipients

12 editions of The Burst e-Newsletter, with 1,775 subscribers and an above average open rate compared to industry average (Agriculture and Food Services)

9 additional news alerts delivered via email to e-News subscribers containing time-sensitive information

A significant increase in the amount of information shared on our social media channels. This is an additional method being utilised to reach growers and stakeholders

The Project Team

with timely messaging and can be quantified with the following stats for the period 1 Jan to 30 Apr 2024:

@berriesaus

948

berries-australia

1,613 page followers with +727 this year 60 posts | 37,560 impressions

2,903 link clicks | 8.4% Engagement Rate

(Note: A 2% LinkedIn engagement rate is

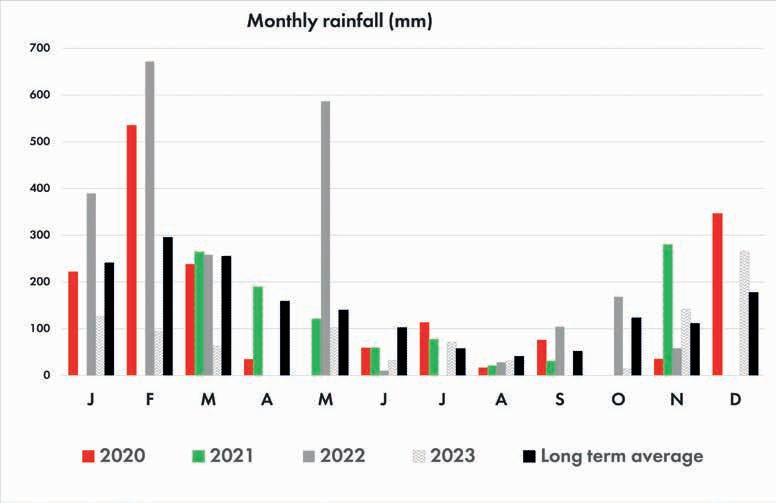

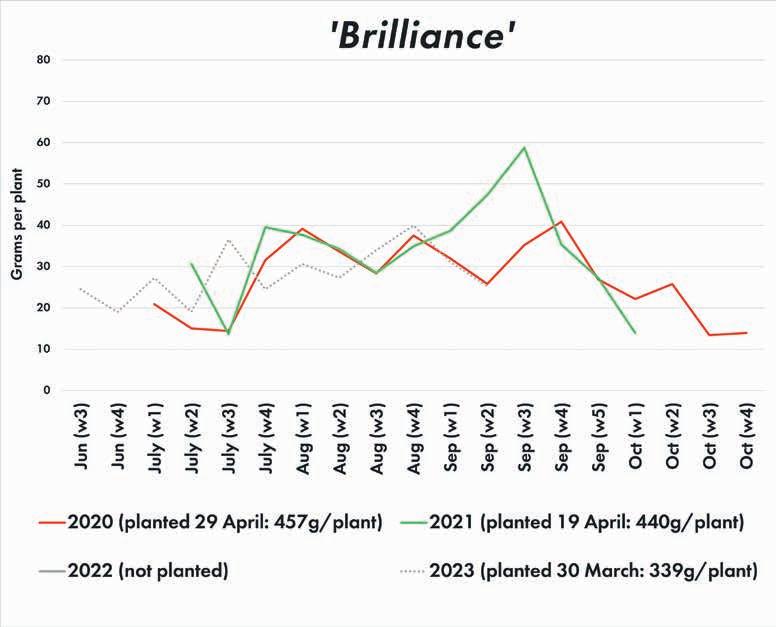

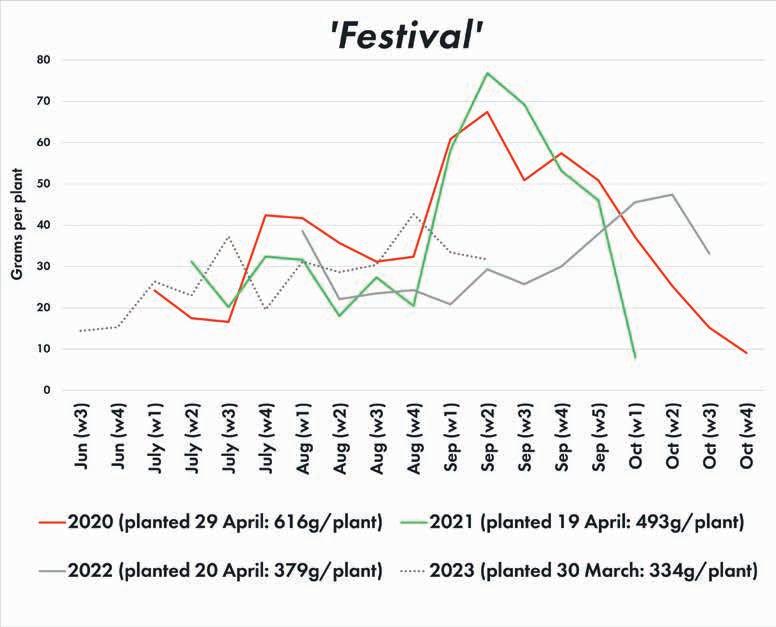

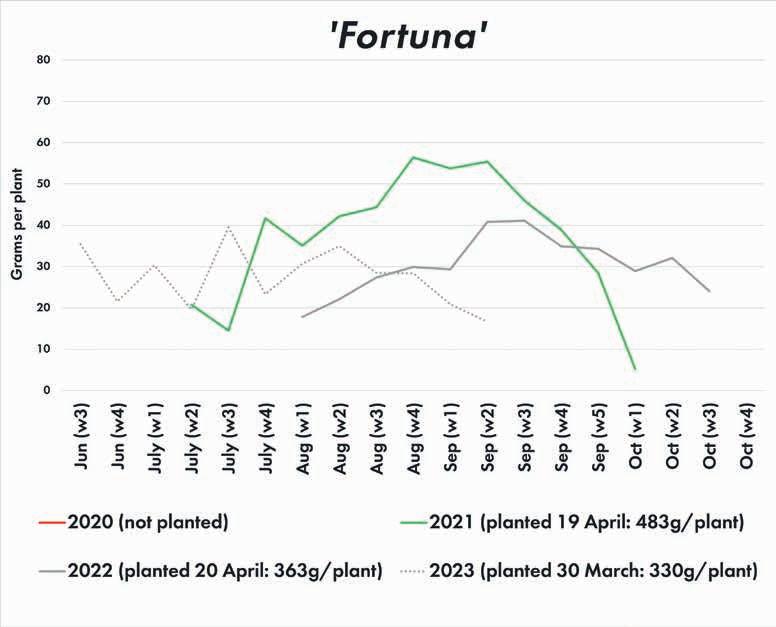

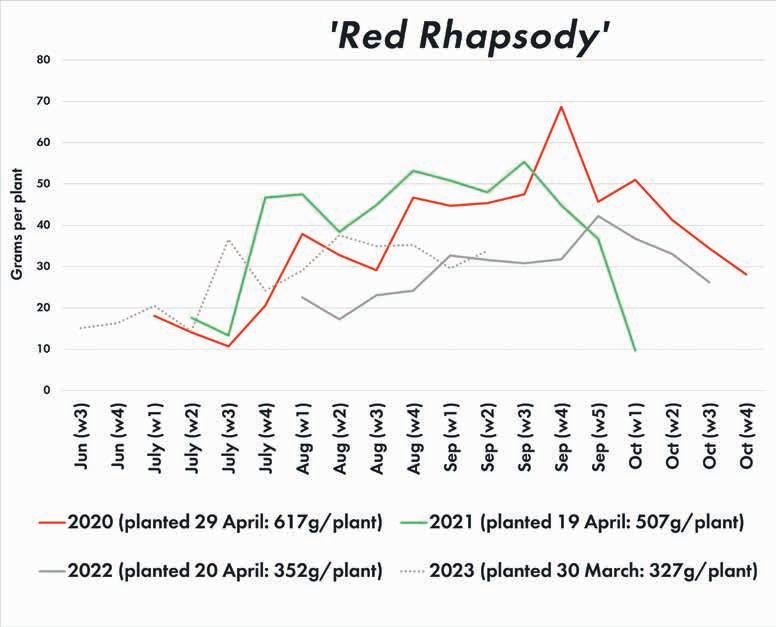

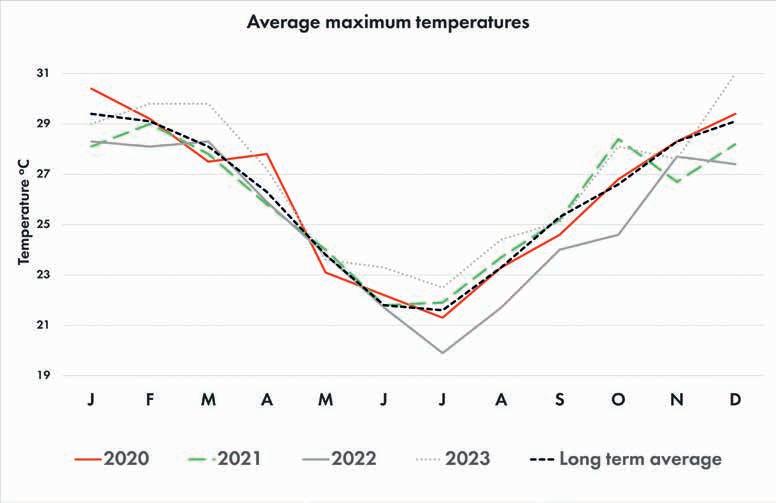

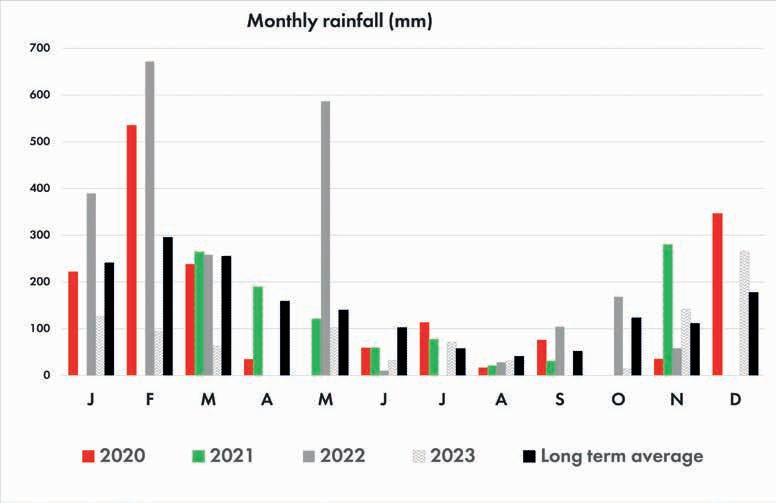

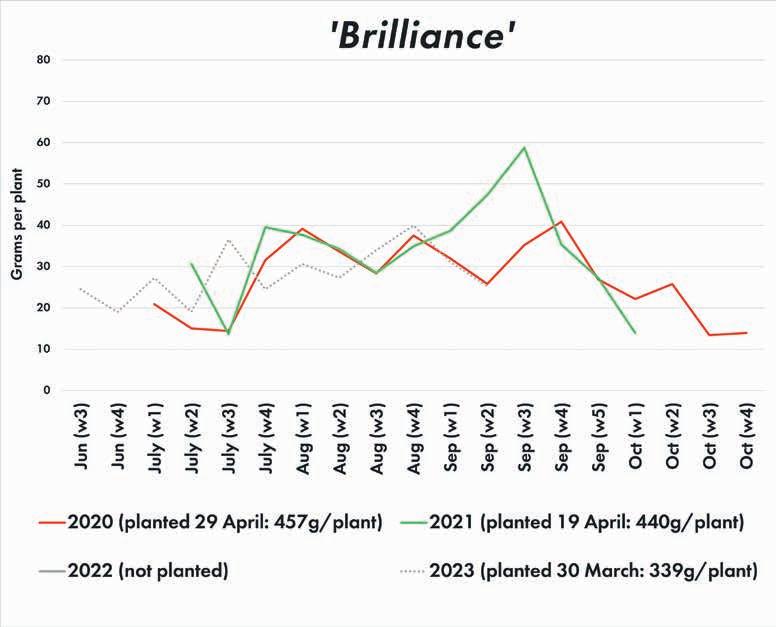

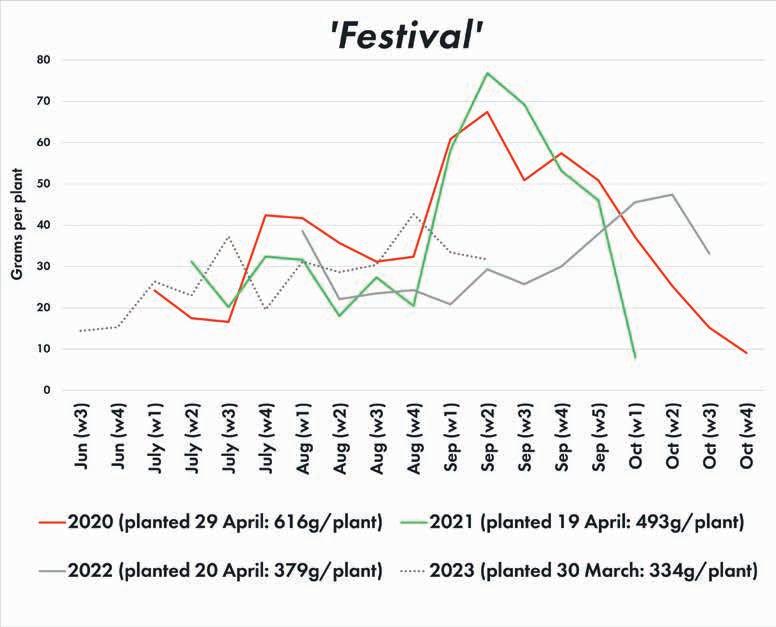

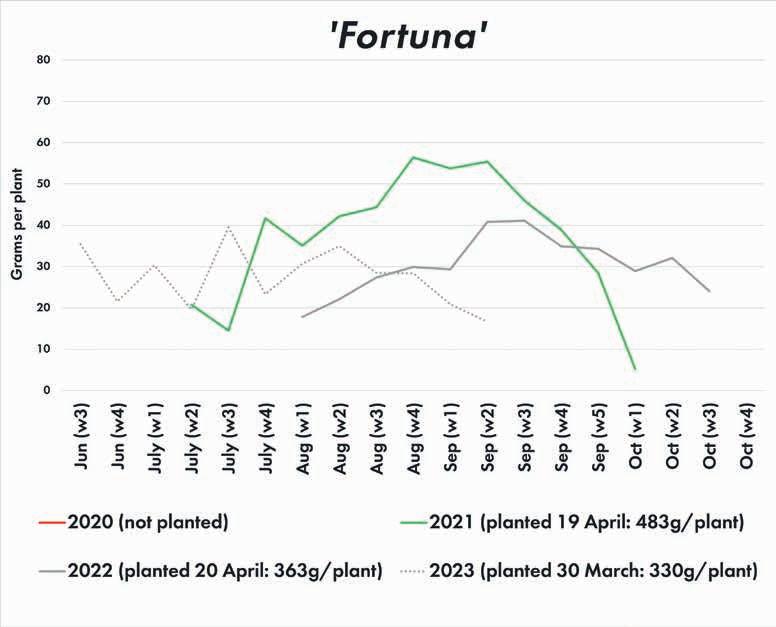

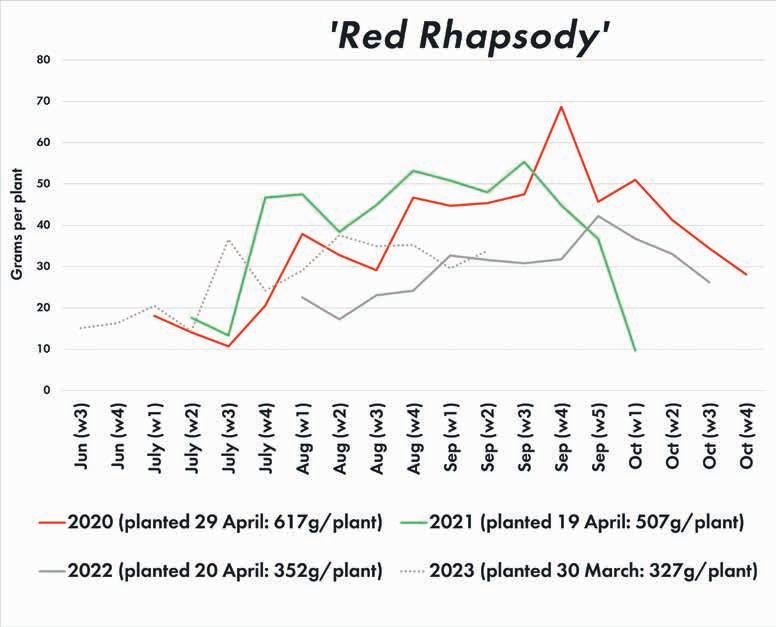

Jane has also worked tirelessly on the development of the new Resource Library which is housed within the Berries Australia website. The library now contains almost 600 documents and resources including factsheets, posters, case studies, research reports, videos and links to resources hosted on other websites. All journal articles since the very first edition of the Australian Berry Journal (2019) are now included in the Library in downloadable PDF format, providing our industry with access to a plethora of information and resources. You can filter by Category, Author or simply type a search term into the ‘Search’ box. This Resource Library will continue to be expanded on an ongoing basis.